Exploring Lithium-Ion Battery Degradation: A Concise Review of Critical Factors, Impacts, Data-Driven Degradation Estimation Techniques, and Sustainable Directions for Energy Storage Systems

Abstract

:1. Introduction

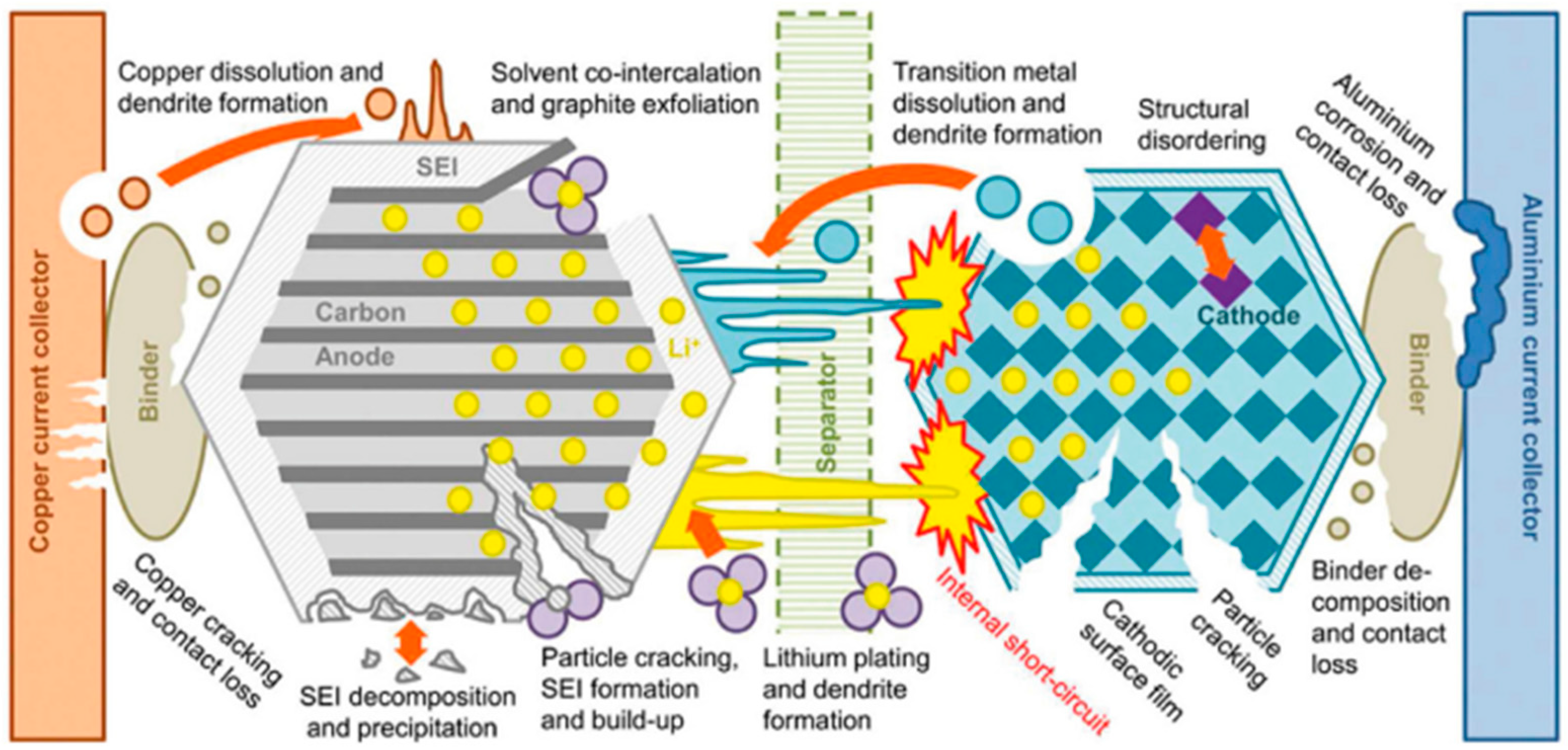

2. Battery Degradation Mechanism

2.1. Degradation in Anode

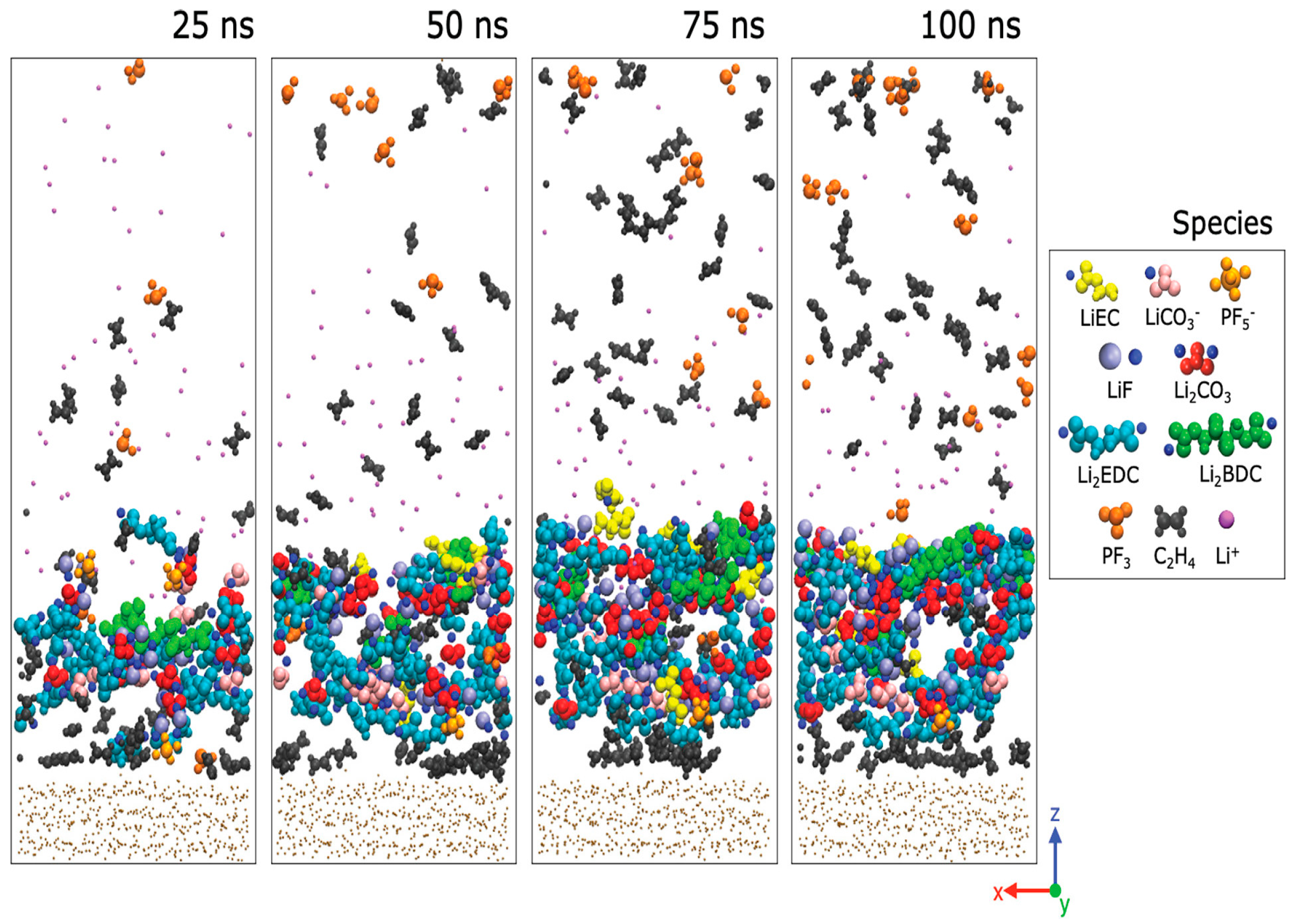

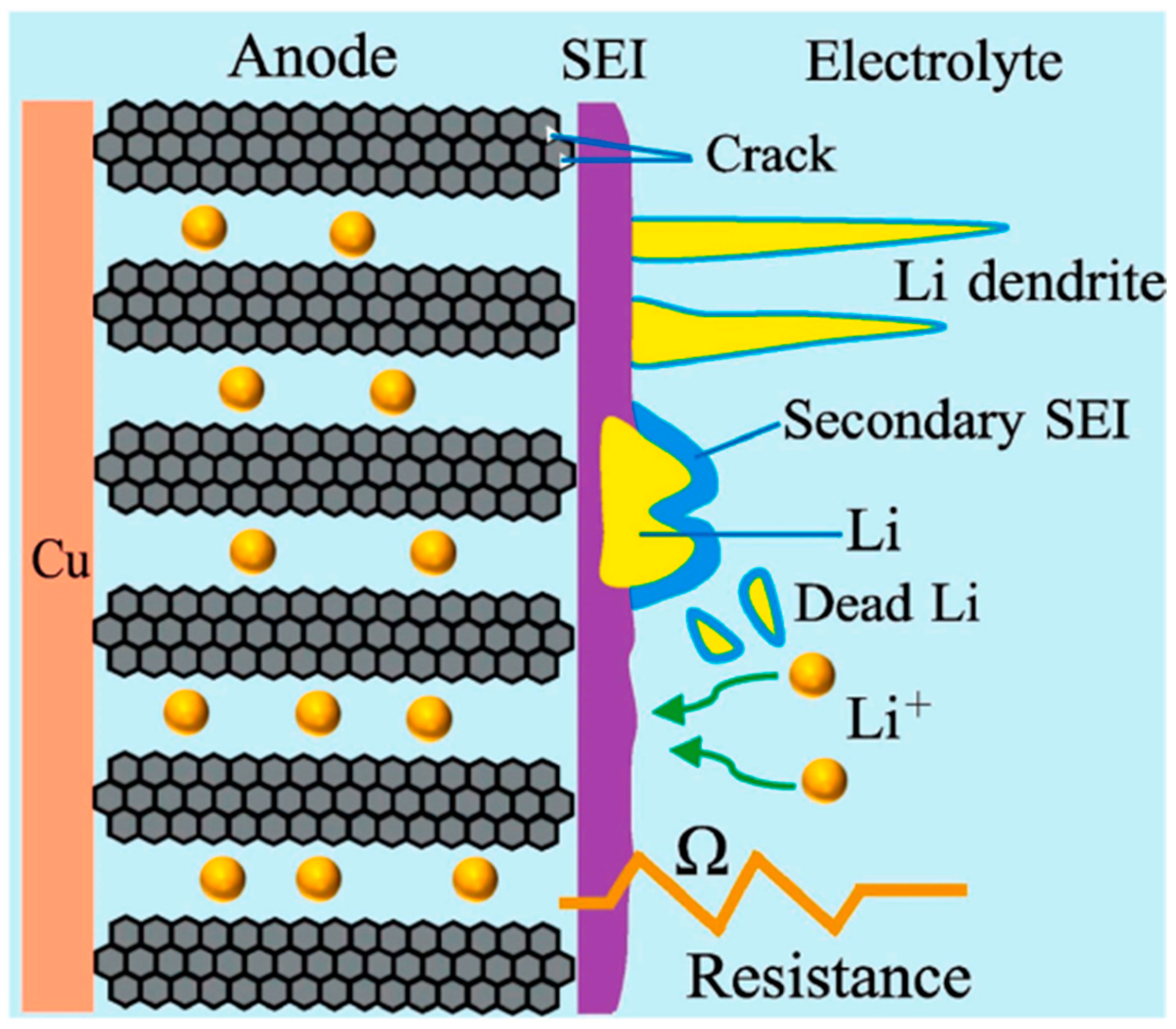

2.1.1. Degradation in the Layer of Solid Electrolyte Interphase

2.1.2. Lithium Plating

2.1.3. Stress

2.2. Degradation in Cathode

2.2.1. Film on Cathode Surface Layer

2.2.2. Stress

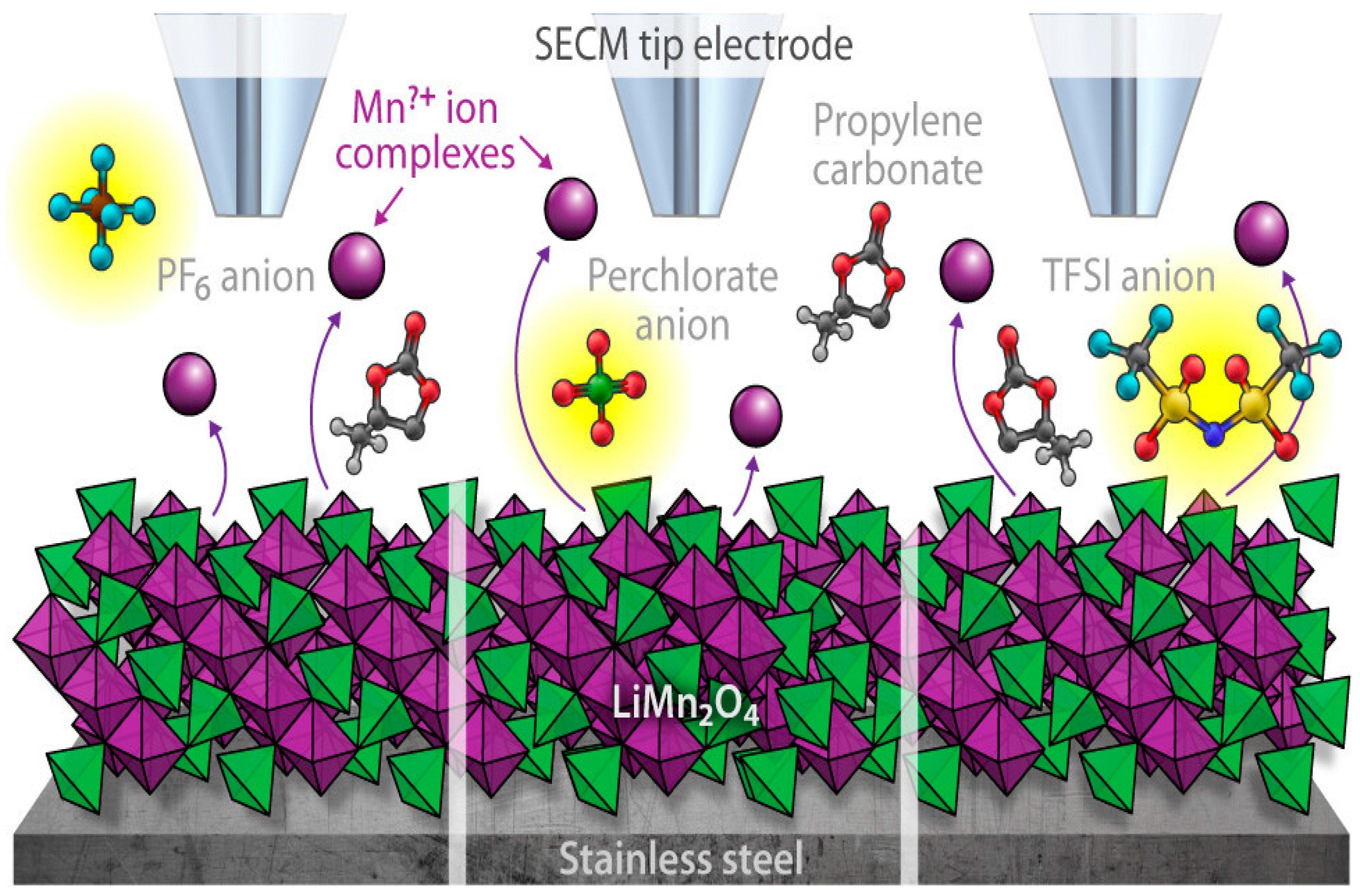

2.2.3. Dissolution of Transition Metals

3. Key Degradation Factor

3.1. Cycling Degradation

3.2. Electrolyte Breakdown

3.3. Temperature

3.3.1. High Temperature

3.3.2. Low Temperature

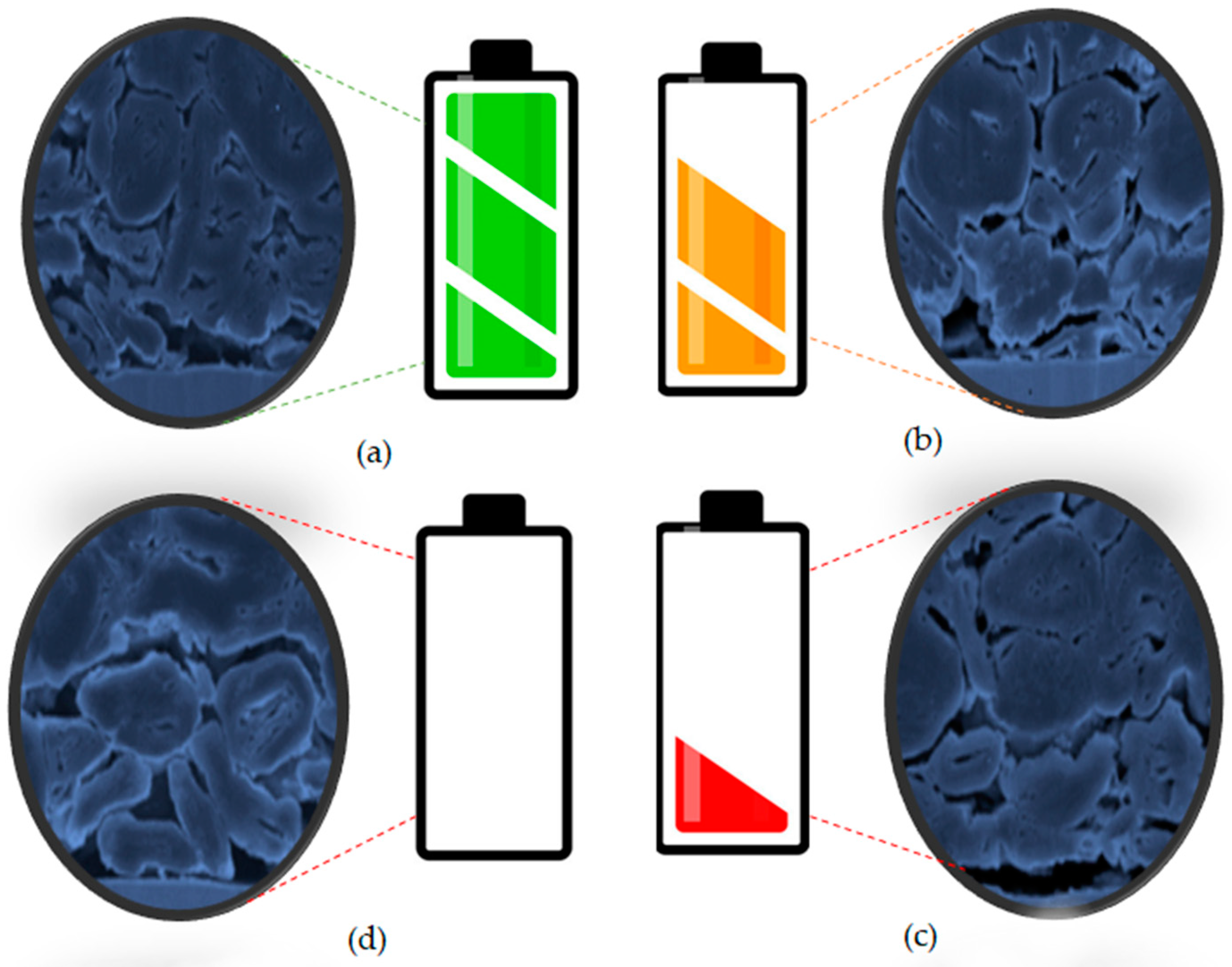

3.4. Calendar Aging

3.5. State of Charge

3.6. Depth of Discharge

4. Key Effect of Battery Degradation on EVs and Energy Storage Systems

4.1. Capacity Fade

4.2. Reduction in Energy Density

4.3. Increase in Internal Resistance

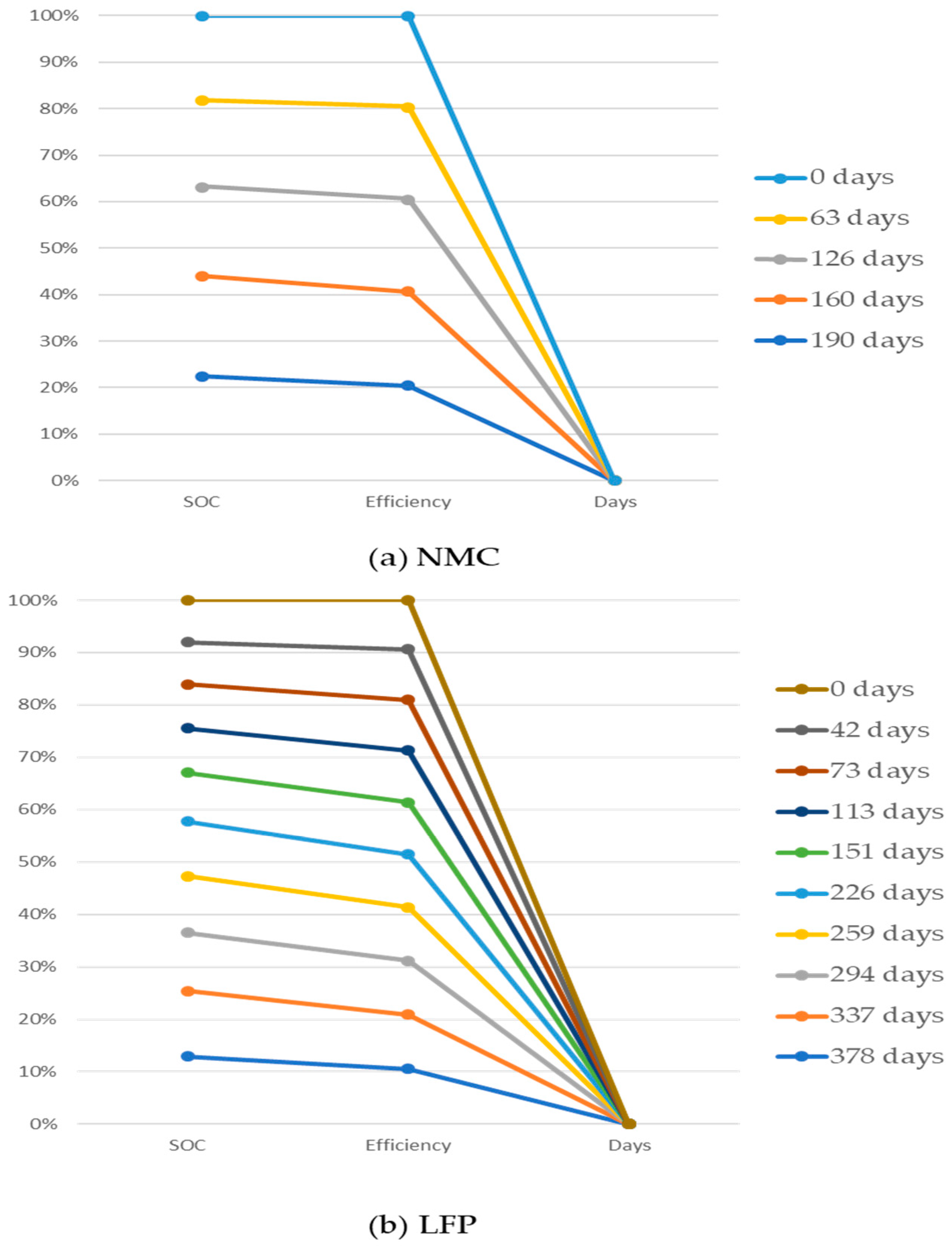

4.4. Reduction in Overall Efficiency

5. Data-Driven Approaches for Estimation of Battery Degradation

5.1. Support Vector Machines (SVM)

5.2. Relevance Vector Machines (RVM)

5.3. Gaussian Process Regression (GPR)

5.4. Deep Learning

5.4.1. Artificial Neural Network (ANN)

5.4.2. Long Short-Term Memory Neural Network

5.4.3. Gated Recurrent Unit Neural Network

5.4.4. Convolution Neural Network

6. Conclusions and Future Directions

- ▪

- Electrolyte breakdown and the formation of SEI are key factors contributing to battery degradation. Research into novel electrode materials, electrolytes, and coatings can potentially result in batteries with enhanced durability, stability, and resistance to degradation mechanisms such as electrode dissolution, electrolyte decomposition, and SEI formation. Integration of advanced nanomaterials, solid-state electrolytes, and multifunctional coatings has the potential to improve battery performance and longevity.

- ▪

- The detrimental effects of heat stress and overheating in EV batteries can be mitigated through enhanced thermal management systems, which incorporate active cooling, thermal insulation, and temperature regulation. Longer battery life spans and optimal operating temperatures can be attained by integrating advanced cooling technologies such as liquid immersion cooling, thermoelectric cooling, and phase change materials.

- ▪

- Energy consumption in EV batteries can be maximized, and degradation effects reduced by implementing dynamic load-balancing strategies, adaptive energy management algorithms, and intelligent charging profiles. BMS can decrease losses caused by deterioration and enhance overall battery performance by adjusting charging parameters in response to environmental conditions and battery status.

- ▪

- The integration of AI and ML algorithms holds great potential for predictive modeling and optimization of battery degradation under diverse operating conditions. Leveraging data-driven approaches can enable proactive maintenance strategies, predictive failure analysis, and adaptive control algorithms, thereby enhancing the efficiency and reliability of the battery systems.

- ▪

- Real-time monitoring of battery degradation and health can be facilitated by implementing advanced diagnostic techniques such as electrochemical impedance spectroscopy (EIS), voltammetry, and impedance spectroscopy. Lithium-ion battery systems can benefit from proactive maintenance and management enabled by the integration of sensor technologies and data analytics platforms.

Author Contributions

Funding

Conflicts of Interest

References

- Huang, W.C.; Zhang, Q.; You, F. Impacts of battery energy storage technologies and renewable integration on the energy transition in the New York State. Adv. Appl. Energy 2022, 9, 100126. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Mamun, A.A.; Ansari, S.; Miah, M.S.; Hasan, K.; Meraj, S.T.; Abdolrasol, M.G.M.; Rahman, T.; Maruf, M.H.; Sarker, M.R.; et al. Battery Management, Key Technologies, Methods, Issues, and Future Trends of Electric Vehicles: A Pathway toward Achieving Sustainable Development Goals. Batteries 2022, 8, 119. [Google Scholar] [CrossRef]

- Huang, P.; Zeng, G.; He, Y.; Liu, S.; Li, E.; Bai, Z. Damage evolution mechanism and early warning using long short-term memory networks for battery slight overcharge cycles. Renew. Energy 2023, 127, 119171. [Google Scholar] [CrossRef]

- Habib, A.K.M.A.; Hasan, M.K.; Issa, G.F.; Singh, D.; Islam, S.; Ghazal, T.M. Lithium-Ion Battery Management System for Electric Vehicles: Constraints, Challenges, and Recommendations. Batteries 2023, 9, 152. [Google Scholar] [CrossRef]

- Edge, J.S.; O’Kane, S.; Prosser, R.; Kirkaldy, N.D.; Patel, A.N.; Hales, A.; Ghosh, A.; Ai, W.; Chen, J.; Yang, J.; et al. Lithium ion battery degradation: What you need to know. Phys. Chem. Chem. Phys. 2021, 23, 8200–8221. [Google Scholar] [CrossRef]

- Spitthoff, L.; Wahl, M.S.; Lamb, J.J.; Shearing, P.R.; Vie, P.J.S.; Burheim, O.S. On the Relations between Lithium-Ion Battery Reaction Entropy, Surface Temperatures and Degradation. Batteries 2023, 9, 249. [Google Scholar] [CrossRef]

- Sarkar, J.; Bhattacharyya, S. Application of graphene and graphene-based materials in clean energy-related devices Minghui. Arch. Thermodyn. 2012, 33, 23–40. [Google Scholar] [CrossRef]

- Birkl, C.R.; Roberts, M.R.; McTurk, E.; Bruce, P.G.; Howey, D.A. Degradation diagnostics for lithium ion cells. J. Power Sources 2017, 341, 373–386. [Google Scholar] [CrossRef]

- Perez, A.; Moreno, R.; Moreira, R.; Orchard, M.E.; Strbac, G. Effect of Battery Degradation—Policy invest by imperial. IEEE 2018, 1–11. [Google Scholar]

- Amini, M.; Nazari, M.H.; Hosseinian, S.H. Predictive energy management strategy for battery energy storage considering battery degradation cost. IET Renew. Power Gener. 2023, 17, 1119–1138. [Google Scholar] [CrossRef]

- Timilsina, L.; Badr, P.R.; Hoang, P.H.; Ozkan, G.; Papari, B.; Edrington, C.S. Battery Degradation in Electric and Hybrid Electric Vehicles: A Survey Study. IEEE Access 2023, 11, 42431–42462. [Google Scholar] [CrossRef]

- Cui, J.; Tan, Q.; Liu, L.; Li, J. Environmental Benefit Assessment of Second-Life Use of Electric Vehicle Lithium-Ion Batteries in Multiple Scenarios Considering Performance Degradation and Economic Value. Environ. Sci. Technol. 2023, 57, 8559–8567. [Google Scholar] [CrossRef] [PubMed]

- Pasini, G.; Lutzemberger, G.; Ferrari, L. Renewable Electricity for Decarbonisation of Road Transport: Batteries or E-Fuels? Batteries 2023, 9, 135. [Google Scholar] [CrossRef]

- Xu, R.; Wang, Y.; Chen, Z. Data-Driven Battery Aging Mechanism Analysis and Degradation Pathway Prediction. Batteries 2023, 9, 129. [Google Scholar] [CrossRef]

- Chen, Y.; Miao, Q.; Zheng, B.; Wu, S.; Pecht, M. Quantitative analysis of lithium-ion battery capacity prediction via adaptive bathtub-shaped function. Energies 2013, 6, 3082–3096. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Miah, M.S.; Jamal, T.; Rahman, T.; Ansari, S.; Rahman, M.S.; Ashique, R.H.; Shihavuddin, A.S.M.; Shakib, M.N. Artificial Intelligence Approaches for Advanced Battery Management System in Electric Vehicle Applications: A Statistical Analysis towards Future Research Opportunities. Vehicles 2023, 6, 22–70. [Google Scholar] [CrossRef]

- Xiong, R.; Pan, Y.; Shen, W.; Li, H.; Sun, F. Lithium-ion battery aging mechanisms and diagnosis method for automotive applications: Recent advances and perspectives. Renew. Sustain. Energy Rev. 2020, 131, 110048. [Google Scholar] [CrossRef]

- Liu, J.; Zhou, L.; Zhang, Y.; Wang, J.; Wang, Z. Aging behavior and mechanisms of lithium-ion battery under multi-aging path. J. Clean. Prod. 2023, 423, 138678. [Google Scholar] [CrossRef]

- Liu, D.; Song, Y.; Li, L.; Liao, H.; Peng, Y.; Guo, J.; Li, Y.; Pedersen, K.; Stroe, D.; Sarkar, J.; et al. Lithium-Ion Battery Operation, Degradation, and Aging Mechanism in Electric Vehicles: An Overview. Energies 2021, 14, 5220. [Google Scholar] [CrossRef]

- Wankmüller, F.; Thimmapuram, P.R.; Gallagher, K.G.; Botterud, A. Impact of battery degradation on energy arbitrage revenue of grid-level energy storage. J. Energy Storage 2017, 10, 56–66. [Google Scholar] [CrossRef]

- Ou, S. Estimate long-term impact on battery degradation by considering electric vehicle real-world end-use factors. J. Power Sources 2023, 573, 233133. [Google Scholar] [CrossRef]

- Kaliaperumal, M.; Dharanendrakumar, M.S.; Prasanna, S.; Abhishek, K.V.; Chidambaram, R.K.; Adams, S.; Zaghib, K.; Reddy, M.V. Cause and mitigation of lithium-ion battery failure—A review. Materials 2021, 14, 5676. [Google Scholar] [CrossRef] [PubMed]

- Afzal, A.; Bhutto, J.K.; Alrobaian, A.; Kaladgi, A.R.; Khan, S.A. Modelling and computational experiment to obtain optimized neural network for battery thermal management data. Energies 2021, 14, 7370. [Google Scholar] [CrossRef]

- Sun, J.; Ye, L.; Zhao, X.; Zhang, P.; Yang, J. Electronic Modulation and Structural Engineering of Carbon-Based Anodes for Low-Temperature Lithium-Ion Batteries: A Review. Molecules 2023, 28, 2108. [Google Scholar] [CrossRef]

- Keil, P.; Schuster, S.F.; Wilhelm, J.; Travi, J.; Hauser, A.; Karl, R.C.; Jossen, A. Calendar Aging of Lithium-Ion Batteries. J. Electrochem. Soc. 2016, 163, A1872–A1880. [Google Scholar] [CrossRef]

- Ohzuku, T.; Iwakoshi, Y.; Sawai, K. Formation of Lithium-Graphite Intercalation Compounds in Nonaqueous Electrolytes and Their Application as a Negative Electrode for a Lithium Ion (Shuttlecock) Cell. J. Electrochem. Soc. 1993, 140, 2490–2498. [Google Scholar] [CrossRef]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Sources 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Atalay, S.; Sheikh, M.; Mariani, A.; Merla, Y.; Bower, E.; Widanage, W.D. Theory of battery ageing in a lithium-ion battery: Capacity fade, nonlinear ageing and lifetime prediction. J. Power Sources 2020, 478, 229026. [Google Scholar] [CrossRef]

- Carnovale, A.; Li, X. A modeling and experimental study of capacity fade for lithium-ion batteries. Energy AI 2020, 2, 100032. [Google Scholar] [CrossRef]

- Pantenburg, I.; Cronau, M.; Boll, T.; Duncker, A.; Roling, B. Challenging Prevalent Solid Electrolyte Interphase (SEI) Models: An Atom Probe Tomography Study on a Commercial Graphite Electrode. ACS Nano 2023, 17, 21531–21538. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, Y.; Tang, A. Capacity Degradation and Aging Mechanisms Evolution of Lithium-Ion Batteries under Different Operation Conditions. Energies 2023, 16, 4232. [Google Scholar] [CrossRef]

- Maheshwari, A. Modelling, Aging and Optimal Operation of Lithium-Ion Batteries; Eindhoven University of Technology: Eindhoven, The Netherlands, 2018; ISBN 9789038646077. [Google Scholar]

- Agubra, V.A.; Fergus, J.W. The formation and stability of the solid electrolyte interface on the graphite anode. J. Power Sources 2014, 268, 153–162. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, D.; Schaltz, E.; Stroe, D.I.; Gismero, A.; Yang, B. Lithium-ion battery calendar aging mechanism analysis and impedance-based State-of-Health estimation method. J. Energy Storage 2023, 64, 107029. [Google Scholar] [CrossRef]

- Deckenbach, D.; Schneider, J.J. A Long-Overlooked Pitfall in Rechargeable Zinc–Air Batteries: Proper Electrode Balancing. Adv. Mater. Interfaces 2023, 10, 2202494. [Google Scholar] [CrossRef]

- Cheng, L.; Wan, Y.; Zhou, Y.; Gao, D.W. Operational Reliability Modeling and Assessment of Battery Energy Storage Based on Lithium-ion Battery Lifetime Degradation. J. Mod. Power Syst. Clean Energy 2022, 10, 1738–1749. [Google Scholar] [CrossRef]

- Köbbing, L.; Latz, A.; Horstmann, B. Growth of the solid-electrolyte interphase: Electron diffusion versus solvent diffusion. J. Power Sources 2023, 561, 232651. [Google Scholar] [CrossRef]

- Alzate-Vargas, L.; Blau, S.M.; Spotte-Smith, E.W.C.; Allu, S.; Persson, K.A.; Fattebert, J.L. Insight into SEI Growth in Li-Ion Batteries using Molecular Dynamics and Accelerated Chemical Reactions. J. Phys. Chem. C 2021, 125, 18588–18596. [Google Scholar] [CrossRef]

- Kamyab, N.; Weidner, J.W.; White, R.E. Mixed Mode Growth Model for the Solid Electrolyte Interface (SEI). J. Electrochem. Soc. 2019, 166, A334–A341. [Google Scholar] [CrossRef]

- Ploehn, H.J.; Ramadass, P.; White, R.E. Solvent Diffusion Model for Aging of Lithium-Ion Battery Cells. J. Electrochem. Soc. 2004, 151, A456. [Google Scholar] [CrossRef]

- Smith, A.J.; Fang, Y.; Mikheenkova, A.; Ekström, H.; Svens, P.; Ahmed, I.; Lacey, M.J.; Lindbergh, G.; Furó, I.; Lindström, R.W. Localized lithium plating under mild cycling conditions in high-energy lithium-ion batteries. J. Power Sources 2023, 573, 233118. [Google Scholar] [CrossRef]

- Campbell, I.D.; Marzook, M.; Marinescu, M.; Offer, G.J. How Observable Is Lithium Plating? Differential Voltage Analysis to Identify and Quantify Lithium Plating Following Fast Charging of Cold Lithium-Ion Batteries. J. Electrochem. Soc. 2019, 166, A725–A739. [Google Scholar] [CrossRef]

- Ando, K.; Matsuda, T.; Miwa, T.; Kawai, M.; Imamura, D. Degradation mechanism of all-solid-state lithium-ion batteries with argyrodite Li7−xPS6−xClx sulfide through high-temperature cycling test. Batter. Energy 2023, 2, 20220052. [Google Scholar] [CrossRef]

- Waldmann, T.; Hogg, B.I.; Wohlfahrt-Mehrens, M. Li plating as unwanted side reaction in commercial Li-ion cells—A review. J. Power Sources 2018, 384, 107–124. [Google Scholar] [CrossRef]

- Juarez-Robles, D.; Vyas, A.A.; Fear, C.; Jeevarajan, J.A.; Mukherjee, P.P. Overcharge and Aging Analytics of Li-ion Cells. J. Electrochem. Soc. 2020, 167, 090547. [Google Scholar] [CrossRef]

- Che, Y.; Zheng, Y.; Forest, F.E.; Sui, X.; Hu, X.; Teodorescu, R. Predictive health assessment for lithium-ion batteries with probabilistic degradation prediction and accelerating aging detection. Reliab. Eng. Syst. Saf. 2024, 241, 109603. [Google Scholar] [CrossRef]

- Janakiraman, U.; Garrick, T.R.; Fortier, M.E. Review—Lithium Plating Detection Methods in Li-Ion Batteries. J. Electrochem. Soc. 2020, 167, 160552. [Google Scholar] [CrossRef]

- Ren, Y.; Widanage, D.; Marco, J. A Plating-Free Charging Scheme for Battery Module Based on Anode Potential Estimation to Prevent Lithium Plating. Batteries 2023, 9, 294. [Google Scholar] [CrossRef]

- Koleti, U.R.; Rajan, A.; Tan, C.; Moharana, S.; Dinh, T.Q.; Marco, J. A study on the influence of lithium plating on battery degradation. Energies 2020, 13, 3458. [Google Scholar] [CrossRef]

- Diallo, M.S.; Shi, T.; Zhang, Y.; Peng, X.; Shozib, I.; Wang, Y.; Miara, L.J.; Scott, M.C.; Tu, Q.H.; Ceder, G. Effect of solid-electrolyte pellet density on failure of solid-state batteries. Nat. Commun. 2024, 15, 858. [Google Scholar] [CrossRef]

- Gu, J.; Chen, X.; He, Z.; Liang, Z.; Lin, Y.; Shi, J.; Yang, Y. Decoding Internal Stress-Induced Micro-Short Circuit Events in Sulfide-Based All-Solid-State Li-Metal Batteries via Operando Pressure Measurements. Adv. Energy Mater. 2023, 13, 2302643. [Google Scholar] [CrossRef]

- Agubra, V.; Fergus, J. Lithium ion battery anode aging mechanisms. Materials 2013, 6, 1310–1325. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Whitacre, J.F. Inhomogeneous aging of cathode materials in commercial 18650 lithium ion battery cells. J. Energy Storage 2021, 35, 102244. [Google Scholar] [CrossRef]

- Zhao, X.; Yin, Y.; Hu, Y.; Choe, S.Y. Electrochemical-thermal modeling of lithium plating/stripping of Li(Ni0.6Mn0.2Co0.2)O2/Carbon lithium-ion batteries at subzero ambient temperatures. J. Power Sources 2019, 418, 61–73. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, X.; Han, G.; Dai, H.; Zhu, J.; Wang, X.; Tang, X.; Ye, J. Lithium plating on the anode for lithium-ion batteries during long-term low temperature cycling. J. Power Sources 2021, 484, 229312. [Google Scholar] [CrossRef]

- Saxena, S.; Roman, D.; Robu, V.; Flynn, D.; Pecht, M. Battery stress factor ranking for accelerated degradation test planning using machine learning. Energies 2021, 14, 723. [Google Scholar] [CrossRef]

- Liu, G.; Wan, W.; Nie, Q.; Zhang, C.; Chen, X.; Lin, W.; Wei, X.; Huang, Y.; Li, J.; Wang, C. Controllable Long-term Lithium Replenishment for Enhancing Energy Density and Cycle Life of Lithium-ion Batteries. Energy Environ. Sci. 2024, 17, 1163–1174. [Google Scholar] [CrossRef]

- Wang, L.; Yin, S.; Zhang, C.; Huan, Y.; Xu, J. Mechanical characterization and modeling for anodes and cathodes in lithium-ion batteries. J. Power Sources 2018, 392, 265–273. [Google Scholar] [CrossRef]

- Fathiannasab, H.; Zhu, L.; Chen, Z. Chemo-mechanical modeling of stress evolution in all-solid-state lithium-ion batteries using synchrotron transmission X-ray microscopy tomography. J. Power Sources 2021, 483, 229028. [Google Scholar] [CrossRef]

- Kemeny, M.; Ondrejka, P.; Mikolasek, M. Comprehensive Degradation Analysis of NCA Li-Ion Batteries via Methods of Electrochemical Characterisation for Various Stress-Inducing Scenarios. Batteries 2023, 9, 33. [Google Scholar] [CrossRef]

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005. [Google Scholar] [CrossRef]

- Xu, J. Critical Review on cathode–electrolyte Interphase Toward High-Voltage Cathodes for Li-Ion Batteries. Nano-Micro Lett. 2022, 14, 166. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Ikuhara, Y.H.; Fisher, C.A.J.; Huang, R.; Kuwabara, A.; Moriwake, H.; Kohama, K.; Ikuhara, Y. Oxygen loss and surface degradation during electrochemical cycling of lithium-ion battery cathode material LiMn2O4. J. Mater. Chem. A 2019, 7, 8845–8854. [Google Scholar] [CrossRef]

- Arabolla Rodríguez, R.; González Montiel, M.; Della Santina Mohallem, N.; Mosqueda Laffita, Y.; Andrey Montoro, L.; Avila Santos, M.; León Ramírez, H.; Pérez-Cappe, E.L. The role of defects on the Jahn-teller effect and electrochemical charge storage in nanometric LiMn2O4 material. Solid State Ion. 2021, 369, 115707. [Google Scholar] [CrossRef]

- Kim, S.; Huang, H.Y.S. Mechanical stresses at the cathode-electrolyte interface in lithium-ion batteries. J. Mater. Res. 2016, 31, 3506–3512. [Google Scholar] [CrossRef]

- Gao, X.; He, P.; Ren, J.; Xu, J. Modeling of contact stress among compound particles in high energy lithium-ion battery. Energy Storage Mater. 2019, 18, 23–33. [Google Scholar] [CrossRef]

- Son, S.B.; Zhang, Z.; Gim, J.; Johnson, C.S.; Tsai, Y.; Kalensky, M.; Lopykinski, S.; Kahvecioglu, O.; Yang, Z.; Montoya, A.T.; et al. Transition Metal Dissolution in Lithium-Ion Cells: A Piece of the Puzzle. J. Phys. Chem. C 2023, 127, 1767–1775. [Google Scholar] [CrossRef]

- Frankenberger, M.; Trunk, M.; Seidlmayer, S.; Dinter, A.; Dittloff, J.; Werner, L.; Gernhäuser, R.; Revay, Z.; Märkisch, B.; Gilles, R.; et al. SEI growth impacts of lamination, formation and cycling in lithium ion batteries. Batteries 2020, 6, 21. [Google Scholar] [CrossRef]

- Shinagawa, C.; Ushiyama, H.; Yamashita, K. Multiscale Simulations for Lithium-Ion Batteries: SEI Film Growth and Capacity Fading. J. Electrochem. Soc. 2017, 164, A3018–A3024. [Google Scholar] [CrossRef]

- Roy, P.K.; Shahjalal, M.; Shams, T.; Fly, A.; Stoyanov, S.; Ahsan, M.; Haider, J. A Critical Review on Battery Aging and State Estimation Technologies of Lithium-Ion Batteries: Prospects and Issues. Electronics 2023, 12, 4105. [Google Scholar] [CrossRef]

- Wang, L.F.; Geng, M.M.; Ding, X.N.; Fang, C.; Zhang, Y.; Shi, S.S.; Zheng, Y.; Yang, K.; Zhan, C.; Wang, X.D. Research progress of the electrochemical impedance technique applied to the high-capacity lithium-ion battery. Int. J. Miner. Metall. Mater. 2021, 28, 538–552. [Google Scholar] [CrossRef]

- Hunter, J.C. Preparation of a new crystal form of manganese dioxide: λ-MnO2. J. Solid State Chem. 1994, 48, 173–174. [Google Scholar] [CrossRef]

- Li, W. Review—An Unpredictable Hazard in Lithium-ion Batteries from Transition Metal Ions: Dissolution from Cathodes, Deposition on Anodes and Elimination Strategies. J. Electrochem. Soc. 2020, 167, 090514. [Google Scholar] [CrossRef]

- Vermeer, W.; Chandra Mouli, G.R.; Bauer, P. A Comprehensive Review on the Characteristics and Modeling of Lithium-Ion Battery Aging. IEEE Trans. Transp. Electrif. 2022, 8, 2205–2232. [Google Scholar] [CrossRef]

- Mikheenkova, A.; Gustafsson, O.; Misiewicz, C.; Brant, W.R.; Hahlin, M.; Lacey, M.J. Resolving high potential structural deterioration in Ni-rich layered cathode materials for lithium-ion batteries operando. J. Energy Storage 2023, 57, 106211. [Google Scholar] [CrossRef]

- Love, C.T.; Korovina, A.; Patridge, C.J.; Swider-Lyons, K.E.; Twigg, M.E.; Ramaker, D.E. Review of LiFePO 4 Phase Transition Mechanisms and New Observations from X-ray Absorption Spectroscopy. J. Electrochem. Soc. 2013, 160, A3153–A3161. [Google Scholar] [CrossRef]

- Zhan, C.; Wu, T.; Lu, J.; Amine, K. Dissolution, migration, and deposition of transition metal ions in Li-ion batteries exemplified by Mn-based cathodes-A critical review. Energy Environ. Sci. 2018, 11, 243–257. [Google Scholar] [CrossRef]

- Vu, T.T.; Cheon, H.J.; Shin, S.Y.; Jeong, G.; Wi, E.; Chang, M. Hybrid electrolytes for solid-state lithium batteries: Challenges, progress, and prospects. Energy Storage Mater. 2023, 61, 102876. [Google Scholar] [CrossRef]

- Liao, X.; Huang, Q.; Mai, S.; Wang, X.; Xu, M.; Xing, L.; Liao, Y.; Li, W. Understanding self-discharge mechanism of layered nickel cobalt manganese oxide at high potential. J. Power Sources 2015, 286, 551–556. [Google Scholar] [CrossRef]

- Wandt, J.; Freiberg, A.; Thomas, R.; Gorlin, Y.; Siebel, A.; Jung, R.; Gasteiger, H.A.; Tromp, M. Transition metal dissolution and deposition in Li-ion batteries investigated by operando X-ray absorption spectroscopy. J. Mater. Chem. A 2016, 4, 18300–18305. [Google Scholar] [CrossRef]

- Rynearson, L.; Antolini, C.; Jayawardana, C.; Yeddala, M.; Hayes, D.; Lucht, B.L. Speciation of Transition Metal Dissolution in Electrolyte from Common Cathode Materials. Angew. Chem. 2024, 136, e202317109. [Google Scholar] [CrossRef]

- Huang, D.; Engtrakul, C.; Nanayakkara, S.; Mulder, D.W.; Han, S.D.; Zhou, M.; Luo, H.; Tenent, R.C. Understanding Degradation at the Lithium-Ion Battery Cathode/Electrolyte Interface: Connecting Transition-Metal Dissolution Mechanisms to Electrolyte Composition. ACS Appl. Mater. Interfaces 2021, 13, 11930–11939. [Google Scholar] [CrossRef]

- Krupp, A.; Beckmann, R.; Diekmann, T.; Ferg, E.; Schuldt, F.; Agert, C. Calendar aging model for lithium-ion batteries considering the influence of cell characterization. J. Energy Storage 2022, 45, 103506. [Google Scholar] [CrossRef]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef]

- Hou, J.; Qu, S.; Yang, M.; Zhang, J. Materials and electrode engineering of high capacity anodes in lithium ion batteries. J. Power Sources 2020, 450, 227697. [Google Scholar] [CrossRef]

- Lucu, M.; Martinez-Laserna, E.; Gandiaga, I.; Liu, K.; Camblong, H.; Widanage, W.D.; Marco, J. Data-driven nonparametric Li-ion battery ageing model aiming at learning from real operation data—Part B: Cycling operation. J. Energy Storage 2020, 30, 101410. [Google Scholar] [CrossRef]

- Serhan, M.; Sprowls, M.; Jackemeyer, D.; Long, M.; Perez, I.D.; Maret, W.; Tao, N.; Forzani, E. Total iron measurement in human serum with a smartphone. In Proceedings of the AIChE Annual Meeting Conference Proceedings, San Francisco, CA, USA, 15–20 November 2019; pp. 1–3. [Google Scholar]

- Lee, Y.K. Effect of transition metal ions on solid electrolyte interphase layer on the graphite electrode in lithium ion battery. J. Power Sources 2021, 484, 229270. [Google Scholar] [CrossRef]

- Xu, B.; Oudalov, A.; Ulbig, A.; Andersson, G.; Kirschen, D.S. Modeling of lithiumion battery degradation for cell life assessment. IEEE Trans. Smart Grid 2018, 9, 1131–1140. [Google Scholar] [CrossRef]

- Lee, C.H.; Wu, Z.Y.; Hsu, S.H.; Jiang, J.A. Cycle Life Study of Li-Ion Batteries with an Aging-Level-Based Charging Method. IEEE Trans. Energy Convers. 2020, 35, 1475–1484. [Google Scholar] [CrossRef]

- Campion, C.L.; Li, W.; Lucht, B.L. Thermal Decomposition of LiPF6-Based Electrolytes for Lithium-Ion Batteries. J. Electrochem. Soc. 2005, 152, A2327. [Google Scholar] [CrossRef]

- Xu, J.; Deshpande, R.D.; Pan, J.; Cheng, Y.-T.; Battaglia, V.S. Electrode Side Reactions, Capacity Loss and Mechanical Degradation in Lithium-Ion Batteries. J. Electrochem. Soc. 2015, 162, A2026–A2035. [Google Scholar] [CrossRef]

- Pinson, M.B.; Bazant, M.Z. Theory of SEI Formation in Rechargeable Batteries: Capacity Fade, Accelerated Aging and Lifetime Prediction. ECS Meet. Abstr. 2013, MA2013-01, 405. [Google Scholar] [CrossRef]

- Alsagri, A.S. An innovative design of solar-assisted carnot battery for multigeneration of power, cooling, and process heating: Techno-economic analysis and optimization. Renew. Energy 2023, 210, 375–385. [Google Scholar] [CrossRef]

- Alsagri, A.S.; Rahbari, H.R.; Wang, L.; Arabkoohsar, A. Thermo-economic optimization of an innovative integration of thermal energy storage and supercritical CO2 cycle using artificial intelligence techniques. Process Saf. Environ. Prot. 2024, 186, 1373–1386. [Google Scholar] [CrossRef]

- Alsagri, A.S.; Arabkoohsar, A.; Khosravi, M.; Alrobaian, A.A. Efficient and cost-effective district heating system with decentralized heat storage units, and triple-pipes. Energy 2019, 188, 116035. [Google Scholar] [CrossRef]

- Wood, S.M.; Fang, C.; Dufek, E.J.; Nagpure, S.C.; Sazhin, S.V.; Liaw, B.; Meng, Y.S. Predicting Calendar Aging in Lithium Metal Secondary Batteries: The Impacts of Solid Electrolyte Interphase Composition and Stability. Adv. Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Dose, W.M.; Temprano, I.; Allen, J.P.; Björklund, E.; O’Keefe, C.A.; Li, W.; Mehdi, B.L.; Weatherup, R.S.; De Volder, M.F.L.; Grey, C.P. Electrolyte Reactivity at the Charged Ni-Rich Cathode Interface and Degradation in Li-Ion Batteries. ACS Appl. Mater. Interfaces 2022, 14, 13206–13222. [Google Scholar] [CrossRef]

- Fermín-Cueto, P.; McTurk, E.; Allerhand, M.; Medina-Lopez, E.; Anjos, M.F.; Sylvester, J.; dos Reis, G. Identification and machine learning prediction of knee-point and knee-onset in capacity degradation curves of lithium-ion cells. Energy AI 2020, 1. [Google Scholar] [CrossRef]

- Aris, A.M.; Shabani, B. An Experimental Study of a Lithium Ion Cell Operation at Low Temperature Conditions. Energy Procedia 2017, 110, 128–135. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, W.; Li, H.; Zhang, M. Review on state of charge estimation methods for Li-ion batteries. Trans. Electr. Electron. Mater. 2017, 18, 136–140. [Google Scholar] [CrossRef]

- Li, Q.; Jiao, S.; Luo, L.; Ding, M.S.; Zheng, J.; Cartmell, S.S.; Wang, C.M.; Xu, K.; Zhang, J.G.; Xu, W. Wide-Temperature Electrolytes for Lithium-Ion Batteries. ACS Appl. Mater. Interfaces 2017, 9, 18826–18835. [Google Scholar] [CrossRef]

- Gao, F.; Tang, Z. Kinetic behavior of LiFePO4/C cathode material for lithium-ion batteries. Electrochim. Acta 2008, 53, 5071–5075. [Google Scholar] [CrossRef]

- Almeida, C.S. Analysis of the co-dispersion structure of health-related indicators, the center of the subject’s sense of health, and the elderly people living at home. Rev. Bras. Linguística Apl. 2016, 5, 1689–1699. [Google Scholar]

- Kalaga, K.; Rodrigues, M.T.F.; Trask, S.E.; Shkrob, I.A.; Abraham, D.P. Calendar-life versus cycle-life aging of lithium-ion cells with silicon-graphite composite electrodes. Electrochim. Acta 2018, 280, 221–228. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, H.; Yu, L.; Fan, W.Z.; Huang, D. Lithium difluorophosphate as an additive to improve the low temperature performance of LiNi0.5Co0.2Mn0.3O2/graphite cells. Electrochim. Acta 2016, 221, 107–114. [Google Scholar] [CrossRef]

- Ren, D.; Smith, K.; Guo, D.; Han, X.; Feng, X.; Lu, L.; Ouyang, M.; Li, J. Investigation of Lithium Plating-Stripping Process in Li-Ion Batteries at Low Temperature Using an Electrochemical Model. J. Electrochem. Soc. 2018, 165, A2167–A2178. [Google Scholar] [CrossRef]

- Tang, X.; Wang, Y.; Zou, C.; Yao, K.; Xia, Y.; Gao, F. A novel framework for Lithium-ion battery modeling considering uncertainties of temperature and aging. Energy Convers. Manag. 2019, 180, 162–170. [Google Scholar] [CrossRef]

- Hahn, S.L.; Storch, M.; Swaminathan, R.; Obry, B.; Bandlow, J.; Birke, K.P. Quantitative validation of calendar aging models for lithium-ion batteries. J. Power Sources 2018, 400, 402–414. [Google Scholar] [CrossRef]

- Röder, P.; Stiaszny, B.; Ziegler, J.C.; Baba, N.; Lagaly, P.; Wiemhöfer, H.D. The impact of calendar aging on the thermal stability of a LiMn2O4-Li(Ni1/3Mn1/3Co1/3)O2/graphite lithium-ion cell. J. Power Sources 2014, 268, 315–325. [Google Scholar] [CrossRef]

- Wright, R.B.; Motloch, C.G.; Belt, J.R.; Christophersen, J.P.; Ho, C.D.; Richardson, R.A.; Bloom, I.; Jones, S.A.; Battaglia, V.S.; Henriksen, G.L.; et al. Calendar- and cycle-life studies of advanced technology development program generation 1 lithium-ion batteries. J. Power Sources 2002, 110, 445–470. [Google Scholar] [CrossRef]

- Thomas, E.V.; Bloom, I.; Christophersen, J.P.; Battaglia, V.S. Statistical methodology for predicting the life of lithium-ion cells via accelerated degradation testing. J. Power Sources 2008, 184, 312–317. [Google Scholar] [CrossRef]

- Liu, K.; Ashwin, T.R.; Hu, X.; Lucu, M.; Widanage, W.D. An evaluation study of different modelling techniques for calendar ageing prediction of lithium-ion batteries. Renew. Sustain. Energy Rev. 2020, 131, 110017. [Google Scholar] [CrossRef]

- Gismero, A.; Stroe, D.I.; Schaltz, E. Calendar Aging Lifetime Model for NMC-based Lithium-ion Batteries Based on EIS Measurements. In Proceedings of the 2019 Fourteenth International Conference on Ecological Vehicles and Renewable Energies, Monte-Carlo, Monaco, 8–10 May 2019. [Google Scholar] [CrossRef]

- Ning, G.; Haran, B.; Popov, B.N. Capacity fade study of lithium-ion batteries cycled at high discharge rates. J. Power Sources 2003, 117, 160–169. [Google Scholar] [CrossRef]

- Cordoba-Arenas, A.; Onori, S.; Guezennec, Y.; Rizzoni, G. Capacity and power fade cycle-life model for plug-in hybrid electric vehicle lithium-ion battery cells containing blended spinel and layered-oxide positive electrodes. J. Power Sources 2015, 278, 473–483. [Google Scholar] [CrossRef]

- Lam, L.; Bauer, P. Practical capacity fading model for Li-ion battery cells in electric vehicles. IEEE Trans. Power Electron. 2013, 28, 5910–5918. [Google Scholar] [CrossRef]

- Sun, T.; Xu, B.; Cui, Y.; Feng, X.; Han, X.; Zheng, Y. A sequential capacity estimation for the lithium-ion batteries combining incremental capacity curve and discrete Arrhenius fading model. J. Power Sources 2021, 484, 229248. [Google Scholar] [CrossRef]

- Kim, J.H.; Woo, S.C.; Park, M.S.; Kim, K.J.; Yim, T.; Kim, J.S.; Kim, Y.J. Capacity fading mechanism of LiFePO4-based lithium secondary batteries for stationary energy storage. J. Power Sources 2013, 229, 190–197. [Google Scholar] [CrossRef]

- Li, J.; Gee, A.M.; Zhang, M.; Yuan, W. Analysis of battery lifetime extension in a SMES-battery hybrid energy storage system using a novel battery lifetime model. Energy 2015, 86, 175–185. [Google Scholar] [CrossRef]

- Suri, G.; Onori, S. A control-oriented cycle-life model for hybrid electric vehicle lithium-ion batteries. Energy 2016, 96, 644–653. [Google Scholar] [CrossRef]

- Bui, T.M.N.; Sheikh, M.; Dinh, T.Q.; Gupta, A.; Widanalage, D.W.; Marco, J. A Study of Reduced Battery Degradation through State-of-Charge Pre-Conditioning for Vehicle-to-Grid Operations. IEEE Access 2021, 9, 155871–155896. [Google Scholar] [CrossRef]

- Guena, T.; Leblanc, P. How depth of discharge affects the cycle life of lithium-metal-polymer batteries. In Proceedings of the INTELEC 06-Twenty-Eighth International Telecommunications Energy Conference, Providence, RI, USA, 10–14 September 2006. [Google Scholar] [CrossRef]

- Redondo-Iglesias, E.; Venet, P.; Pelissier, S. Efficiency Degradation Model of Lithium-Ion Batteries for Electric Vehicles. IEEE Trans. Ind. Appl. 2019, 55, 1932–1940. [Google Scholar] [CrossRef]

- Madani, S.S.; Schaltz, E.; Kær, S.K. Effect of current rate and prior cycling on the coulombic efficiency of a lithium-ion battery. Batteries 2019, 5, 57. [Google Scholar] [CrossRef]

- Chiang, Y.H.; Sean, W.Y.; Ke, J.C. Online estimation of internal resistance and open-circuit voltage of lithium-ion batteries in electric vehicles. J. Power Sources 2011, 196, 3921–3932. [Google Scholar] [CrossRef]

- Lin, N.; Jia, Z.; Wang, Z.; Zhao, H.; Ai, G.; Song, X.; Bai, Y.; Battaglia, V.; Sun, C.; Qiao, J.; et al. Understanding the crack formation of graphite particles in cycled commercial lithium-ion batteries by focused ion beam—Scanning electron microscopy. J. Power Sources 2017, 365, 235–239. [Google Scholar] [CrossRef]

- Chen, X.; Shen, W.; Vo, T.T.; Cao, Z.; Kapoor, A. An overview of lithium-ion batteries for electric vehicles. In Proceedings of the 2012 10th International Power & Energy Conference (IPEC), Ho Chi Minh City, Vietnam, 12–14 December 2012; pp. 230–235. [Google Scholar] [CrossRef]

- Fanoro, M.; Božanić, M.; Sinha, S. A Review of the Impact of Battery Degradation on Energy Management Systems with a Special Emphasis on Electric Vehicles. Energies 2022, 15, 5889. [Google Scholar] [CrossRef]

- Yang, F.; Xie, Y.; Deng, Y.; Yuan, C. Impacts of battery degradation on state-level energy consumption and GHG emissions from electric vehicle operation in the United States. Procedia CIRP 2019, 80, 530–535. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Hall, J.C.; Lin, T.; Brown, G.; Biensan, P.; Bonhomme, F. Decay processes and life predictions for lithium ion satellite cells. In Proceedings of the Collection Technology Paper, 4th International Energy Conversion Engineering Conference and Exhibit (IECEC), San Diego, CA, USA, 26–29 June 2006; Volume 1, pp. 632–642. [Google Scholar] [CrossRef]

- Marongiu, A.; Roscher, M.; Sauer, D.U. Influence of the vehicle-to-grid strategy on the aging behavior of lithium battery electric vehicles. Appl. Energy 2015, 137, 899–912. [Google Scholar] [CrossRef]

- Ziv, B.; Borgel, V.; Aurbach, D.; Kim, J.-H.; Xiao, X.; Powell, B.R. Investigation of the Reasons for Capacity Fading in Li-Ion Battery Cells. J. Electrochem. Soc. 2014, 161, A1672–A1680. [Google Scholar] [CrossRef]

- Lawder, M.T.; Northrop, P.W.C.; Subramanian, V.R. Model-Based SEI Layer Growth and Capacity Fade Analysis for EV and PHEV Batteries and Drive Cycles. J. Electrochem. Soc. 2014, 161, A2099–A2108. [Google Scholar] [CrossRef]

- Sun, T.; Jiang, S.; Li, X.; Cui, Y.; Lai, X.; Wang, X.; Ma, Y.; Zheng, Y. A Novel Capacity Estimation Approach for Lithium-Ion Batteries Combining Three-Parameter Capacity Fade Model with Constant Current Charging Curves. IEEE Trans. Energy Convers. 2021, 36, 2574–2584. [Google Scholar] [CrossRef]

- Myung, S.T.; Hitoshi, Y.; Sun, Y.K. Electrochemical behavior and passivation of current collectors in lithium-ion batteries. J. Mater. Chem. 2011, 21, 9891–9911. [Google Scholar] [CrossRef]

- Fares, R.L.; Webber, M.E. What are the tradeoffs between battery energy storage cycle life and calendar life in the energy arbitrage application? J. Energy Storage 2018, 16, 37–45. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Noelle, D.J.; Wang, M.; Le, A.V.; Shi, Y.; Qiao, Y. Internal resistance and polarization dynamics of lithium-ion batteries upon internal shorting. Appl. Energy 2018, 212, 796–808. [Google Scholar] [CrossRef]

- Canals Casals, L.; Schiffer Gonzalez, A.M.; Garcia, B.; Llorca, J. PHEV Battery Aging Study Using Voltage Recovery and Internal Resistance from Onboard Data. IEEE Trans. Veh. Technol. 2016, 65, 4209–4216. [Google Scholar] [CrossRef]

- Tröltzsch, U.; Kanoun, O.; Tränkler, H.R. Characterizing aging effects of lithium ion batteries by impedance spectroscopy. Electrochim. Acta 2006, 51, 1664–1672. [Google Scholar] [CrossRef]

- Yang, F.; Wang, D.; Zhao, Y.; Tsui, K.L.; Bae, S.J. A study of the relationship between coulombic efficiency and capacity degradation of commercial lithium-ion batteries. Energy 2018, 145, 486–495. [Google Scholar] [CrossRef]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage Support Vector Machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Kassem, M.; Delacourt, C. Postmortem analysis of calendar-aged graphite/LiFePO4 cells. J. Power Sources 2013, 235, 159–171. [Google Scholar] [CrossRef]

- Darma, M.S.D.; Lang, M.; Kleiner, K.; Mereacre, L.; Liebau, V.; Fauth, F.; Bergfeldt, T.; Ehrenberg, H. The influence of cycling temperature and cycling rate on the phase specific degradation of a positive electrode in lithium ion batteries: A post mortem analysis. J. Power Sources 2016, 327, 714–725. [Google Scholar] [CrossRef]

- Palacín, M.R. Understanding ageing in Li-ion batteries: A chemical issue. Chem. Soc. Rev. 2018, 47, 4924–4933. [Google Scholar] [CrossRef] [PubMed]

- Uddin, K.; Perera, S.; Widanage, W.D.; Somerville, L.; Marco, J. Characterising lithium-ion battery degradation through the identification and tracking of electrochemical battery model parameters. Batteries 2016, 2, 13. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1. [Google Scholar] [CrossRef]

- Zhang, X.; Winget, B.; Doeff, M.; Evans, J.W.; Devine, T.M. Corrosion of Aluminum Current Collectors in Lithium-Ion Batteries with Electrolytes Containing LiPF6. J. Electrochem. Soc. 2005, 152, B448. [Google Scholar] [CrossRef]

- Lewerenz, M.; Fuchs, G.; Becker, L.; Sauer, D.U. Irreversible calendar aging and quantification of the reversible capacity loss caused by anode overhang. J. Energy Storage 2018, 18, 149–159. [Google Scholar] [CrossRef]

- Guo, W.; He, M. An optimal relevance vector machine with a modified degradation model for remaining useful lifetime prediction of lithium-ion batteries. Appl. Soft Comput. 2022, 124, 108967. [Google Scholar] [CrossRef]

- Zhao, J.; Zhu, Y.; Zhang, B.; Liu, M.; Wang, J.; Liu, C.; Zhang, Y. Method of Predicting SOH and RUL of Lithium-Ion Battery Based on the Combination of LSTM and GPR. Sustainability 2022, 14, 11865. [Google Scholar] [CrossRef]

- Tagade, P.; Hariharan, K.S.; Ramachandran, S.; Khandelwal, A.; Naha, A.; Kolake, S.M.; Han, S.H. Deep Gaussian process regression for lithium-ion battery health prognosis and degradation mode diagnosis. J. Power Sources 2020, 445, 227281. [Google Scholar] [CrossRef]

- Rauf, H.; Khalid, M.; Arshad, N. Machine learning in state of health and remaining useful life estimation: Theoretical and technological development in battery degradation modelling. Renew. Sustain. Energy Rev. 2022, 156, 111903. [Google Scholar] [CrossRef]

- May, G.; El-Shahat, A. Battery-degradation model based on the ANN regression function for EV applications. In Proceedings of the 2017 IEEE Global Humanitarian Technology Conference (GHTC), San Jose, CA, USA, 19–22 October 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Pang, B.; Chen, L.; Dong, Z. Data-Driven Degradation Modeling and SOH Prediction of Li-Ion Batteries. Batteries 2022, 15, 5580. [Google Scholar] [CrossRef]

- MAlmuhaylan, M.R.; Ghumman, A.R.; Al-Salamah, I.S.; Ahmad, A.; Ghazaw, Y.M.; Haider, H.; Shafiquzzaman, M. Evaluating the impacts of pumping on aquifer depletion in arid regions using MODFLOW, ANFIS and ANN. Water 2020, 12, 2297. [Google Scholar] [CrossRef]

- Kang, L.W.; Zhao, X.; Ma, J. A new neural network model for the state-of-charge estimation in the battery degradation process. Appl. Energy 2014, 121, 20–27. [Google Scholar] [CrossRef]

- Zhao, C.; Li, X. Microgrid Optimal Energy Scheduling Considering Neural Network Based Battery Degradation. IEEE Trans. Power Syst. 2024, 39, 1594–1606. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Garg, A.; Guo, L. Enhancing real-time degradation prediction of lithium-ion battery: A digital twin framework with CNN-LSTM-attention model. Energy 2024, 124, 129681. [Google Scholar] [CrossRef]

- Jafari, S.; Byun, Y.C. A CNN-GRU Approach to the Accurate Prediction of Batteries’ Remaining Useful Life from Charging Profiles. Computers 2023, 12, 219. [Google Scholar] [CrossRef]

- Cui, S.; Joe, I. A Dynamic Spatial-Temporal Attention-Based GRU Model with Healthy Features for State-of-Health Estimation of Lithium-Ion Batteries. IEEE Access 2021, 9, 27374–27388. [Google Scholar] [CrossRef]

- Nan, J.; Deng, B.; Cao, W.; Tan, Z. Prediction for the Remaining Useful Life of Lithium–Ion Battery Based on RVM-GM with Dynamic Size of Moving Window. World Electr. Veh. J. 2022, 13, 25. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, N.; Ji, Y.; Niu, M.; Wang, Y. Lithium-ion batteries remaining useful life prediction based on BLS-RVM. Energy 2021, 234, 121269. [Google Scholar] [CrossRef]

- Li, X.; Zhang, L.; Wang, Z.; Dong, P. Remaining useful life prediction for lithium-ion batteries based on a hybrid model combining the long short-term memory and Elman neural networks. J. Energy Storage 2019, 21, 510–518. [Google Scholar] [CrossRef]

- Cong, X.; Zhang, C.; Jiang, J.; Zhang, W.; Jiang, Y. A Hybrid Method for the Prediction of the Remaining Useful Life of Lithium-Ion Batteries with Accelerated Capacity Degradation. IEEE Trans. Veh. Technol. 2020, 69, 12775–12785. [Google Scholar] [CrossRef]

- Nash, W.; Drummond, T.; Birbilis, N. A review of deep learning in the study of materials degradation. npj Mater. Degrad. 2018, 2, 37. [Google Scholar] [CrossRef]

- Park, K.; Choi, Y.; Choi, W.J.; Ryu, H.Y.; Kim, H. LSTM-Based Battery Remaining Useful Life Prediction with Multi-Channel Charging Profiles. IEEE Access 2020, 8, 20786–20798. [Google Scholar] [CrossRef]

- Chinomona, B.; Chung, C.; Chang, L.K.; Su, W.C.; Tsai, M.C. Long short-term memory approach to estimate battery remaining useful life using partial data. IEEE Access 2020, 8, 165419–165431. [Google Scholar] [CrossRef]

- Li, W.; Sengupta, N.; Dechent, P.; Howey, D.; Annaswamy, A.; Sauer, D.U. One-shot battery degradation trajectory prediction with deep learning. J. Power Sources 2021, 506, 230024. [Google Scholar] [CrossRef]

- Nutakki, T.U.; Alghassab, M.A.; Dutta, A.K.; Abdullaeva, B.S.; Alkhalaf, S.; Alharbi, F.S.; Ghandour, R.; Al Barakeh, Z.; Knani, S. Thermo-environmental multi- investigation and ANN-based optimization of a novel heat integration criteria system integrated with a marine engine generating liquefied hydrogen. Case Stud. Therm. Eng. 2024, 56, 104240. [Google Scholar] [CrossRef]

- Lu, J.; Xiong, R.; Tian, J.; Wang, C.; Hsu, C.W.; Tsou, N.T.; Sun, F.; Li, J. Battery degradation prediction against uncertain future conditions with recurrent neural network enabled deep learning. Energy Storage Mater. 2022, 50, 139–151. [Google Scholar] [CrossRef]

- Ren, L.; Dong, J.; Wang, X.; Meng, Z.; Zhao, L.; Deen, M.J. A Data-Driven Auto-CNN-LSTM Prediction Model for Lithium-Ion Battery Remaining Useful Life. IEEE Trans. Ind. Inform. 2021, 17, 3478–3487. [Google Scholar] [CrossRef]

- Li, Z.; Liu, F.; Yang, W.; Peng, S.; Zhou, J. A Survey of Convolutional Neural Networks: Analysis, Applications, and Prospects. IEEE Trans. Neural Netw. Learn. Syst. 2022, 33, 6999–7019. [Google Scholar] [CrossRef]

- Costa, N.; Sánchez, L.; Anseán, D.; Dubarry, M. Li-ion battery degradation modes diagnosis via Convolutional Neural Networks. J. Energy Storage 2022, 55, 105558. [Google Scholar] [CrossRef]

- Haris, M.; Hasan, M.N.; Qin, S. Degradation Curve Prediction of Lithium-Ion Batteries Based on Knee Point Detection Algorithm and Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2022, 71, 1–10. [Google Scholar] [CrossRef]

| Goal | Key Findings | Research Gap | Reference |

|---|---|---|---|

| Degradation mechanism of lithium-ion batteries | Lithium-ion batteries degraded over time when used. External factors such as temperature can influence the degradation mechanism. | The authors have presented a review about the degradation mechanism; however, the effects of battery degradation are still required for better understanding. | [17] |

| Battery aging at lower temperature. | A high charging rate accelerates the battery aging at a low temperature. The rate of aging of the battery charging at 0.6℃ is higher than the battery charging at 0.8℃ | Although the aging rate at a low temperature has been investigated, what the situation will be at a high temperature has not been explained. | [18] |

| Aging mechanism of lithium-ion batteries for EVS | It is possible to extend the battery life by reducing exposure to the factors that most quickly age batteries. Low temperatures expedite the metallization of lithium on the anode, whereas high temperatures will result in side reactions in the battery. | More study is still needed on the issue of battery deterioration, particularly in relation to the operation of EVs. There is currently relatively little research on battery performance deterioration and the identification of the aging mechanism that follows. | [19] |

| Data-driven battery aging mechanism approach. | Different battery degradation factor such as temperature, charge cut off voltage, charge current, discharge cut off voltage, discharge current have great influence on battery degradation and depend on how the battery degradation varies in different aging phases. | Although the authors presented a model for estimating battery degradation accurately, the impact of battery degradation on EVs and energy storage systems has not been taken into consideration. | [14] |

| Impact of battery degradation on the energy storage system. | Depending on the degradation model and EOL criteria for a C-rate of 1C, the revenue drop resulting from deterioration ranges from 12 to 46%. | The effect of battery degradation on energy storage systems has been carefully investigated; however, the case of EVs still needs to be investigated. | [20] |

| Long-term impact of battery degradation on electric vehicles. | The battery degradation can be delayed by around 0.5% with the help of the battery thermal management system. Higher outside temperatures enhance the use of BEV batteries. Compared to the New England area, the Los Angeles area has 6% higher battery capacity. | Although having a contribution on the impact of battery degradation for EV, this paper ignores the battery degradation mechanism for electric vehicles. | [21] |

| Battery degradation mitigation techniques. | The use of extra protective mechanisms, fire suppression, ventilation, and intrinsic safety as mitigation techniques in LiBs can help them overcome the failure modes. | This paper provides a lot of information about mitigation techniques for battery degradation; however, the issues and challenges regarding this have not been addressed. | [22] |

| DOD | Number of Cycle to Date | Number of Full Discharge to Date | Cumulative Discharge Capacity to Date | Expected Number of Cycle to Reach EOL | Equivalent Number of Full Cycle to Reach EOL |

|---|---|---|---|---|---|

| 50% | 407 | 15 | 11,760 Ah | 1300 | 650 |

| 60% | 351 | 13 | 11,930 Ah | 680 | 400 |

| 70% | 305 | 12 | 11,820 Ah | 680 | 400 |

| 80% | 276 | 10 | 12,380 Ah | 300 | 240 |

| 90% | 110 | 10 | 5600 Ah | 300 | 250 |

| 100% | 60 | 60 | 3030 Ah | 180 | 150 |

| Parameters | Lead-Acid | Ni-Cd | Ni-MH | Lithium-Ion |

|---|---|---|---|---|

| Energy density(W/kg) | 30–50 | 45–80 | 60–120 | 110–160 |

| Power density | 180 | 150 | 250–100 | 1800 |

| Nominal voltage | 2 V | 1.25 V | 1.25 V | 3.6 V |

| Overcharge tolerance | High | Moderate | Low | Very Low |

| Self-discharge | Low | Moderate | High | Very Low |

| Operating temperature | −20–60 °C | −40–60 °C | −20–60 °C | −20–60 °C |

| Cycle life | 200–300 | 1500 | 300–500 | 500–1000 |

| Reference | Battery Type | Factors | Temperature | DOD | SOC | C-Rate | Throughput |

|---|---|---|---|---|---|---|---|

| [117] | LFP | SOC, DOD, C, T | 25–40 °C | 12.5–75% | 30–70% | 1–1.82 | 900 FEC |

| [134] | NMC | SOC, DOD, C, T | −10–50 °C | 10–100% | 20–80% | 1/3–2 | 900–1 K FEC |

| [135] | LMO | SOC, DOD, T | 20 °C | 50–75% | 75–100% | 1 | 4 k–8 k FEC |

| [136] | NCA | T, C | 40–50 °C | 20–65% | 60–85% | 18 | 4 K FEC |

| [118] | LCO | SOC, DOD, T | 0–60 °C | 3–80% | 0–100% | 1/5 | 10 k FEC |

| Degradation Factor | Affected Battery Parts | Effects | Reference |

|---|---|---|---|

| High Temperature | Anode | 1. Decomposition of the blinder causes mechanical instability. 2. Increased SEI layer and reduced accessible surface area as a result of SEI. 3. Decomposition of the electrolyte yielding the cycleable lithium ion and further SEI development. 4. Phase change brought on by material dissolution in an active material. | [28,93,124,153,154] |

| Cathode | 1. Elevation in phase transitions within active materials. 2. Gas evolution and loss of cycleable lithium as a result of electrolyte oxidation. 3. Blinder decomposition. | [144,155] | |

| Low Temperature | Anode | Lithium plating at high SOC during charging. | [43,129,156] |

| Depth of Discharge (DOD) | Both anode and Cathode | 1. Fragmentation brought on by mechanical stress. 2. Because of the value change while cycling, it comes into contact with the LAM particle. | [157,158,159] |

| High SOC | Anode | Lithium plating at high charging rates. | [158,160] |

| Cathode | Current collector corrosion. | ||

| Both Anode and Cathode | 1. Electrolyte decomposition. 2. Formation of blinders. | ||

| Low SOC | Anode | Current collector corrosion. | [161,162] |

| Cathode | Transition metal dissolution. | ||

| Both Anode and Cathode | 1. Electrolyte decomposition 2. Formation of blinders. | ||

| Calendar Aging | Anode | 1. Due to calendar aging, anode material degraded which results in capacity fade. 2. Increase internal resistance. 3. Capacity fade. | [135,163] |

| Cathode | 1. Increase in voltage irreversibility. 2. Degradation of electrolyte compatibility. 3. Changes in the cathode material which results the cracking, phase transition, and formation of surface film. | [152,164] |

| Techniques | Accuracy | Advantages | Disadvantages | Reference |

|---|---|---|---|---|

| ANN | Error 5.9% | In order to support proactive maintenance plans, ANN can effectively anticipate degradation, adapt to a variety of battery types, and capture complicated correlations in battery data. | When it comes to effectively simulating the changing behavior and degradation processes seen in battery systems over time, artificial neural networks fall short in their intrinsic ability to grasp temporal dependencies and long-term trends in time series data. | [173] |

| SVM | Root mean square error is 0.11%. Model accuracy is 99.89%. | SVM is useful for precise estimation of battery deterioration because it is good at handling high-dimensional data, resilient against overfitting, and successful in nonlinear relationships. | The primary drawback of using support vector machines (SVM) to estimate battery deterioration is that it is very dependent on the kernel function selected and requires parameter adjustment, which can lead to a computationally complicated and complex model. | [166] |

| RVM | Relative prediction error 3.3% | Relevance vector machines offer sparse solutions, which maximize computational efficiency and improve model interpretability. This is the fundamental benefit of using RVMs to estimate battery deterioration. | relevance vector machines are less appropriate for big datasets or real-time applications due to their computational complexity and longer training times when compared to simpler models like SVM. This is the fundamental drawback of using RVMs to estimate battery deterioration. | [168] |

| GPR | Mean absolute percentage error 0.4% | The capacity to provide probabilistic forecasts, which provide insights into uncertainty levels and facilitate better-informed decision-making in battery health management, is the primary benefit of gaussian process regression (GPR) for estimating battery deterioration. | Due to its high memory needs and computational complexity, gaussian process regression is not as useful for anticipating battery deterioration in real-time scenarios, especially when dealing with huge datasets. | [171] |

| DL | Median prediction error 1.1% | The capacity of deep learning to automatically identify complicated patterns and correlations from complex battery performance data is its most significant benefit for evaluating battery degradation. This ability to produce precise forecasts and facilitate proactive maintenance plans makes deep learning an invaluable tool. | The primary drawback of deep learning for battery degradation estimation is that it is susceptible to overfitting, especially when there is a dearth of training data. Because deep learning models are complicated, large quantities of data may be needed to generalize properly and prevent them from producing predictions that are unduly particular. | [158] |

| LSTM | Model accuracy is 99.6% | The fundamental benefit of using a long short-term memory network to estimate battery deterioration is that it can accurately forecast degradation levels and remaining usable life by capturing long-term dependencies and temporal patterns in battery performance data. | When trained on sparse data, LSTM models are especially vulnerable to overfitting, which happens when the model learns to recall the training data rather than generalizing to new examples. | [174] |

| GRU | Root mean square error is 2.4% | GRU methods are particularly good at identifying long-term relationships in time series data, which makes it possible for them to study how battery behavior and degradation patterns change over time. | GRU networks are excellent at capturing long-term associations, but they may struggle to recall specifics over very lengthy periods. This may limit their use in modeling complex battery characteristics or extended deterioration patterns. | [177] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, T.; Alharbi, T. Exploring Lithium-Ion Battery Degradation: A Concise Review of Critical Factors, Impacts, Data-Driven Degradation Estimation Techniques, and Sustainable Directions for Energy Storage Systems. Batteries 2024, 10, 220. https://doi.org/10.3390/batteries10070220

Rahman T, Alharbi T. Exploring Lithium-Ion Battery Degradation: A Concise Review of Critical Factors, Impacts, Data-Driven Degradation Estimation Techniques, and Sustainable Directions for Energy Storage Systems. Batteries. 2024; 10(7):220. https://doi.org/10.3390/batteries10070220

Chicago/Turabian StyleRahman, Tuhibur, and Talal Alharbi. 2024. "Exploring Lithium-Ion Battery Degradation: A Concise Review of Critical Factors, Impacts, Data-Driven Degradation Estimation Techniques, and Sustainable Directions for Energy Storage Systems" Batteries 10, no. 7: 220. https://doi.org/10.3390/batteries10070220

APA StyleRahman, T., & Alharbi, T. (2024). Exploring Lithium-Ion Battery Degradation: A Concise Review of Critical Factors, Impacts, Data-Driven Degradation Estimation Techniques, and Sustainable Directions for Energy Storage Systems. Batteries, 10(7), 220. https://doi.org/10.3390/batteries10070220