A Y-Type Air-Cooled Battery Thermal Management System with a Short Airflow Path for Temperature Uniformity

Abstract

:1. Introduction

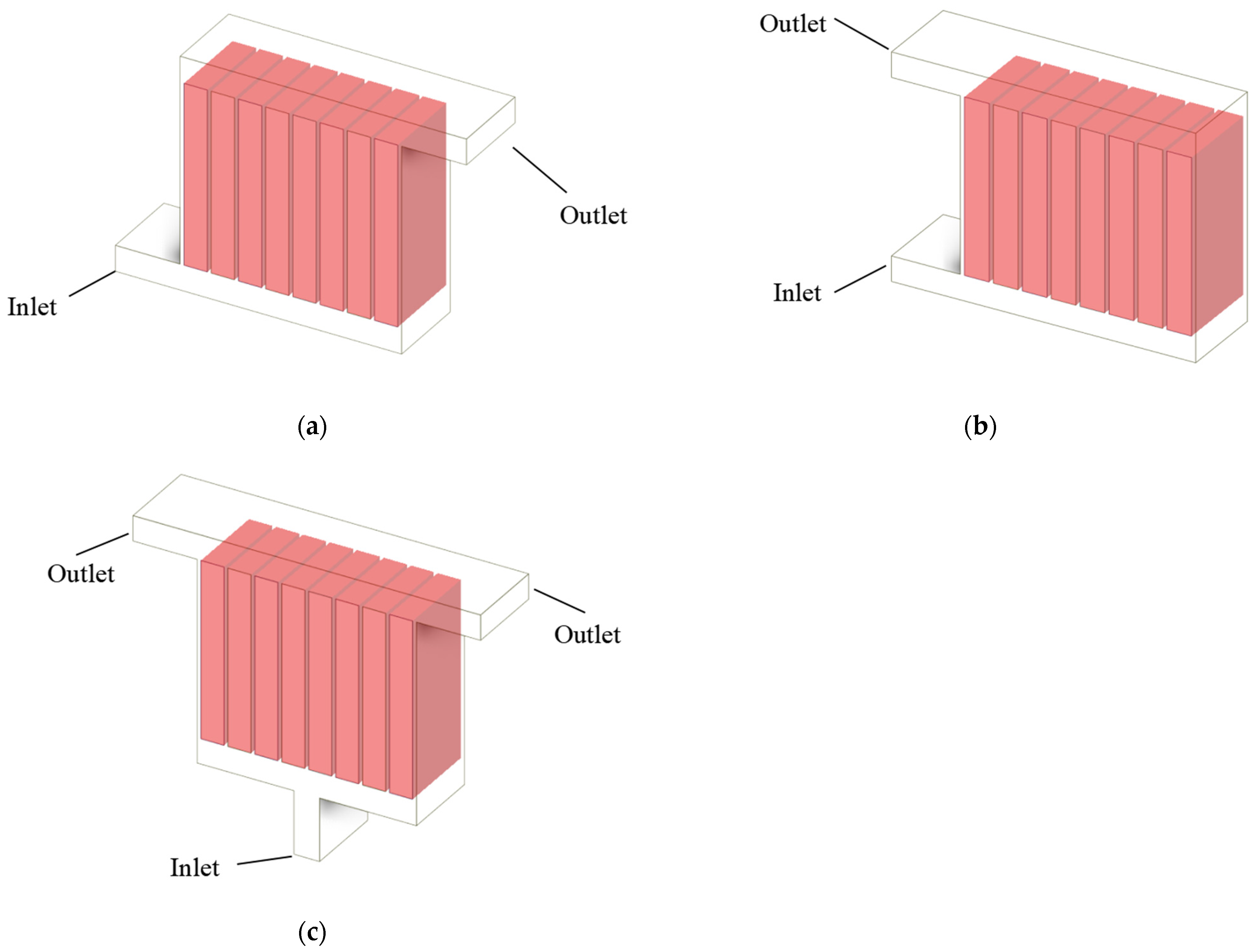

2. Model and Methodology

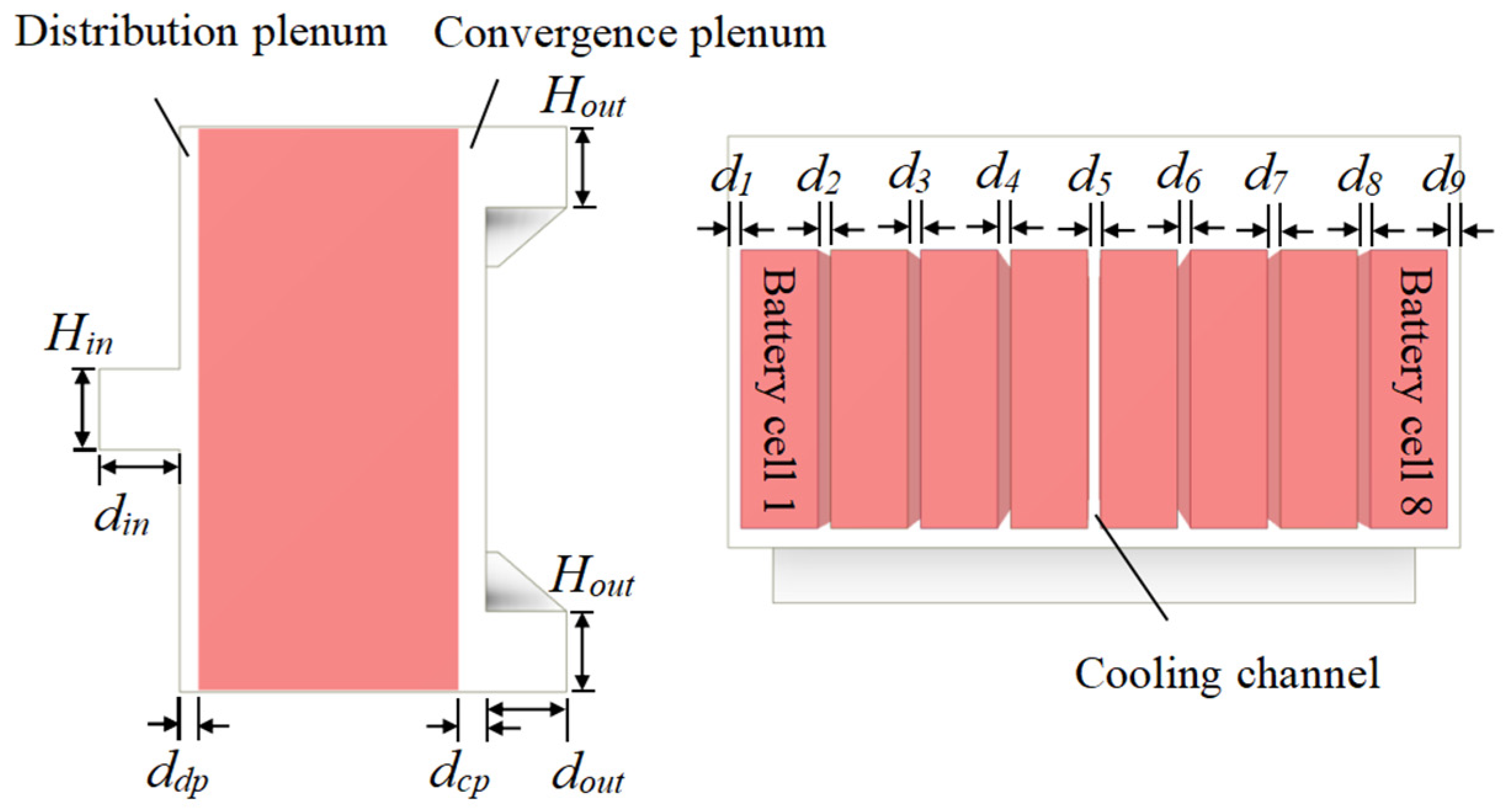

2.1. Model Description

2.2. Numerical Model

2.2.1. Control Equation

2.2.2. Mesh Generation and Evaluation

2.3. Calculation Process

2.3.1. Boundary Conditions

2.3.2. CFD Model Validation

3. Results and Discussion

3.1. Distribution Plenum and Convergence Plenum

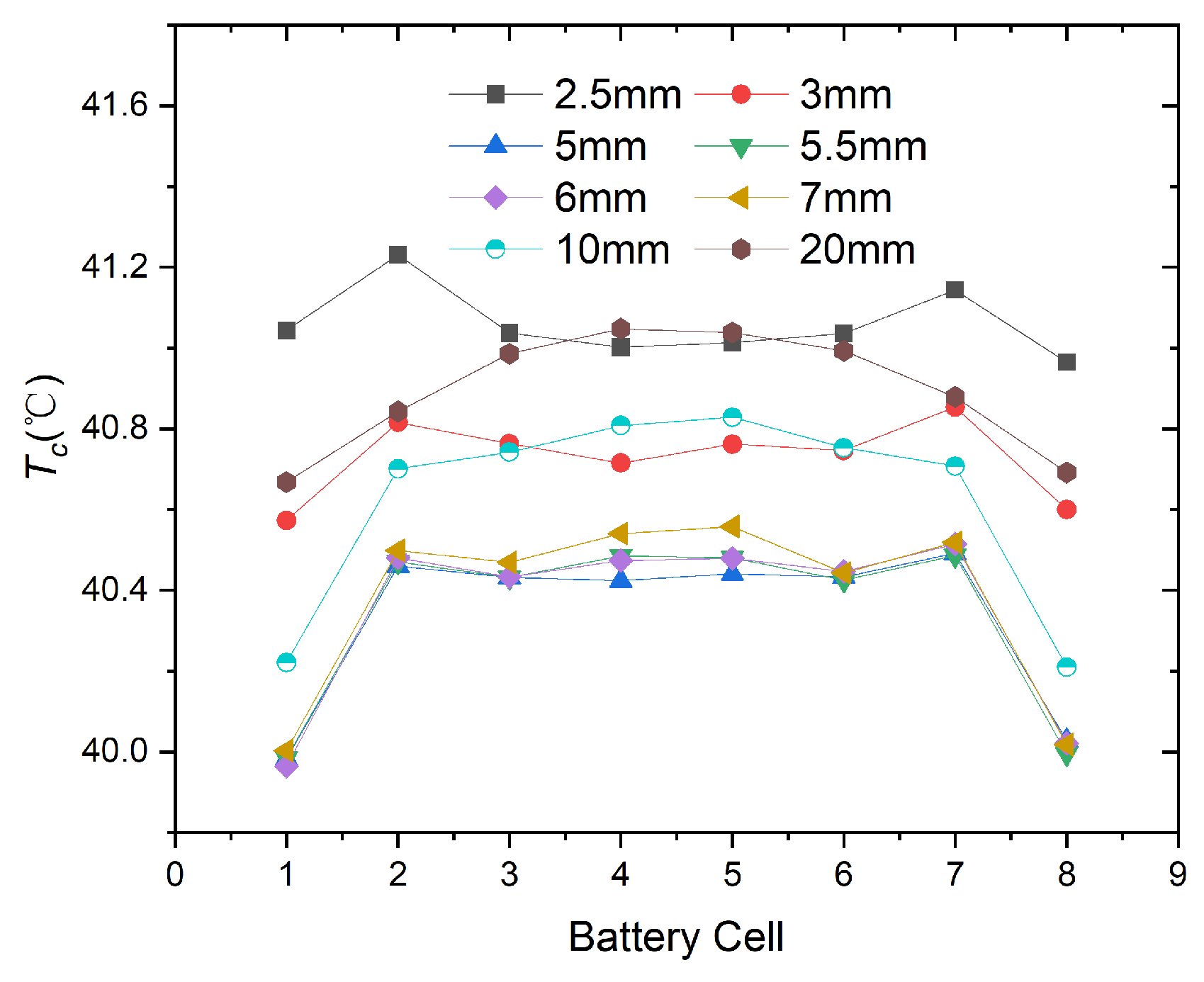

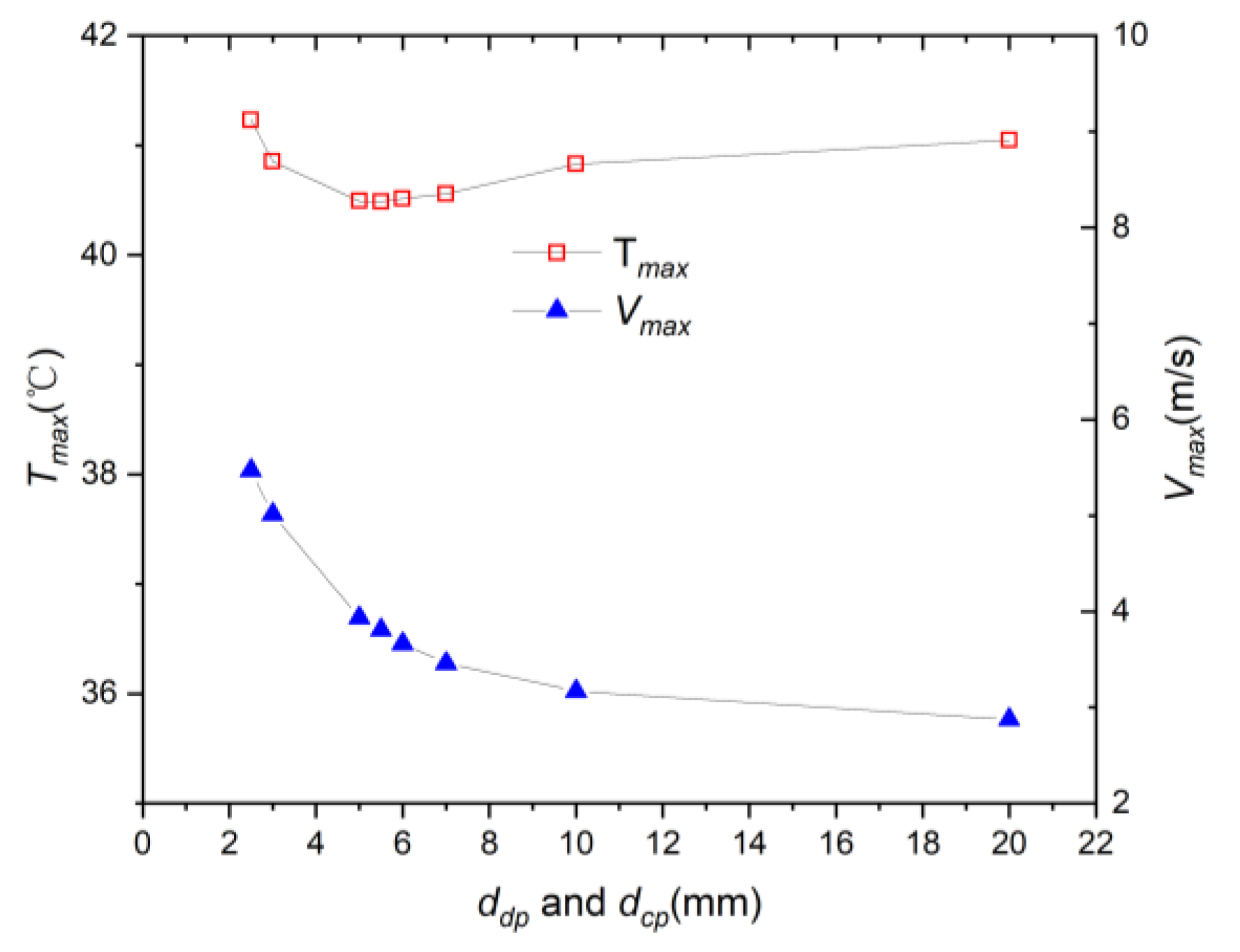

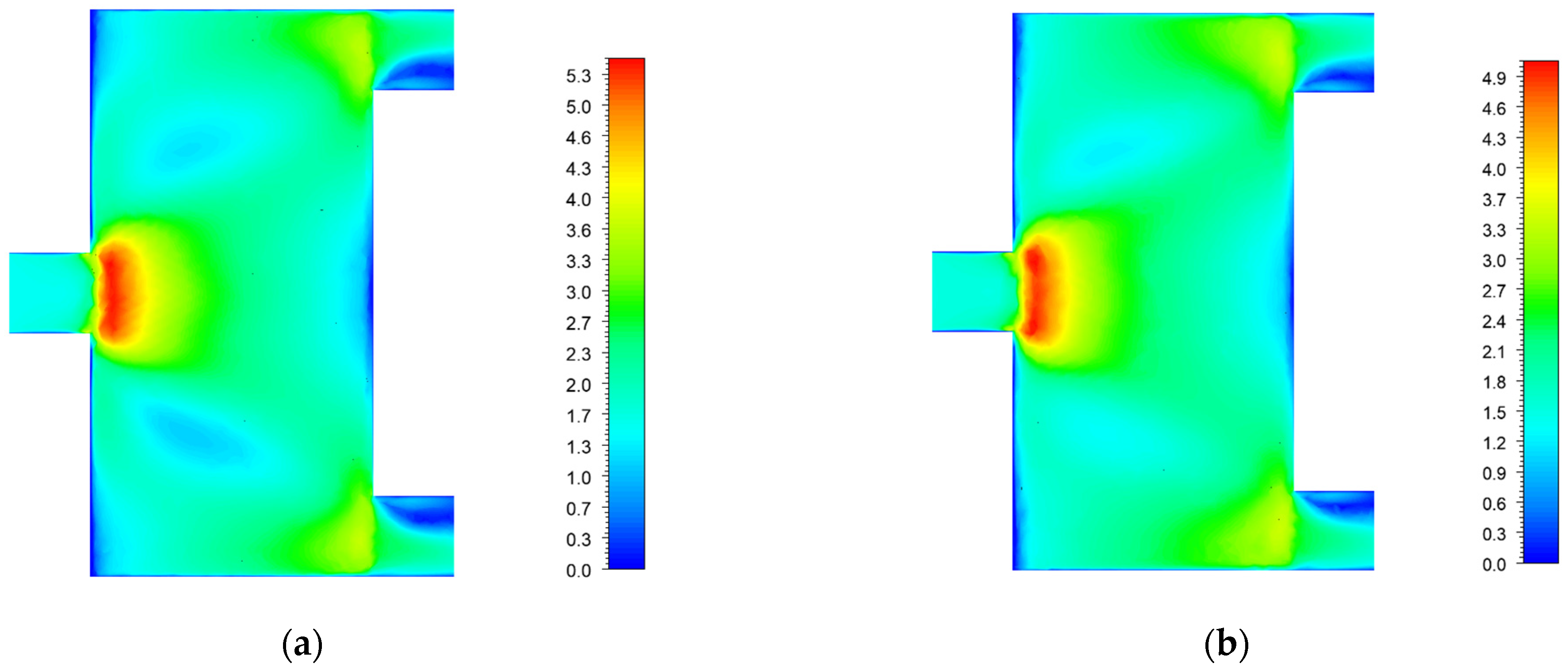

3.1.1. Distribution Plenum and Convergence Plenum with Same Depth

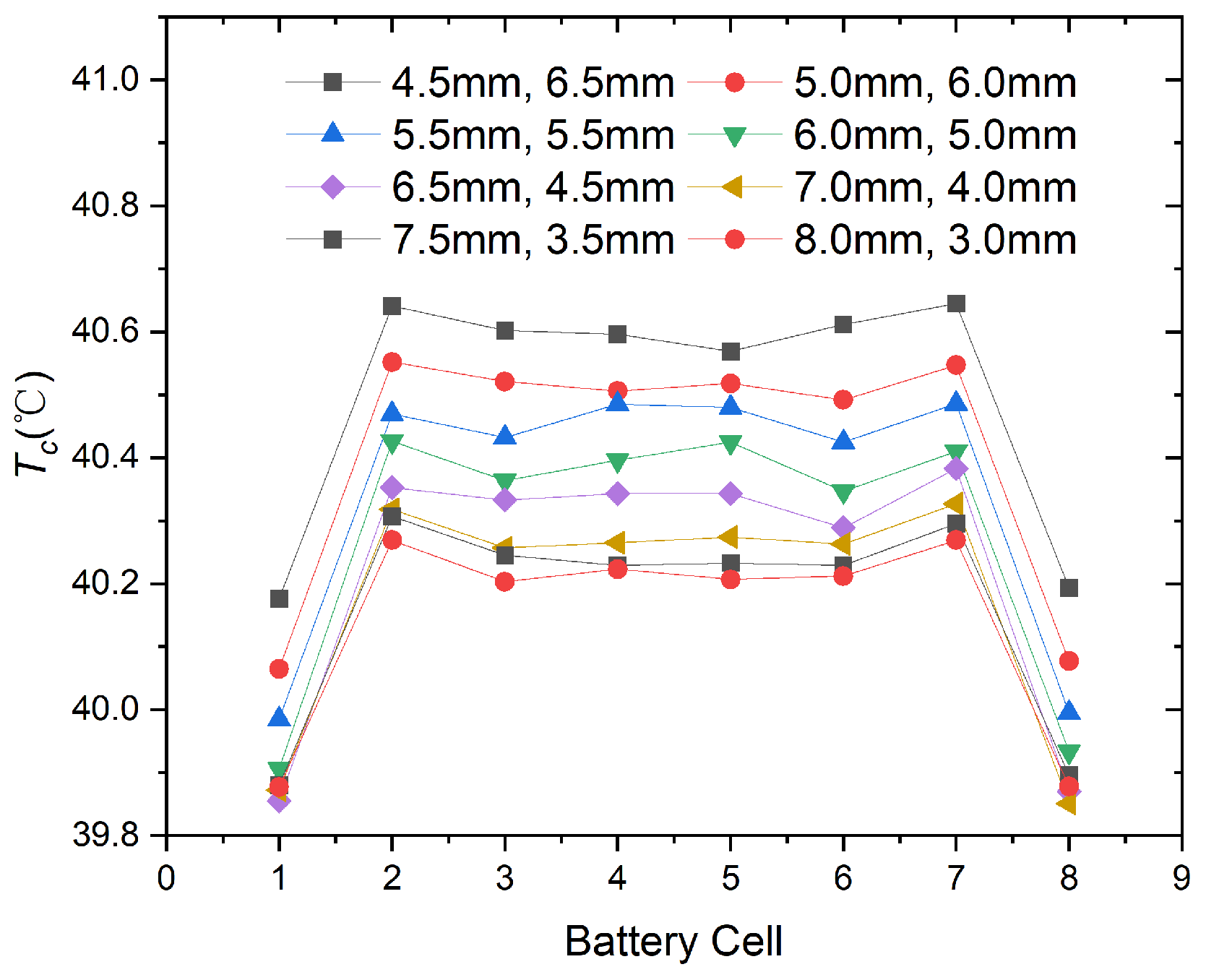

3.1.2. Distribution Plenum and Convergence Plenum with Different Depths

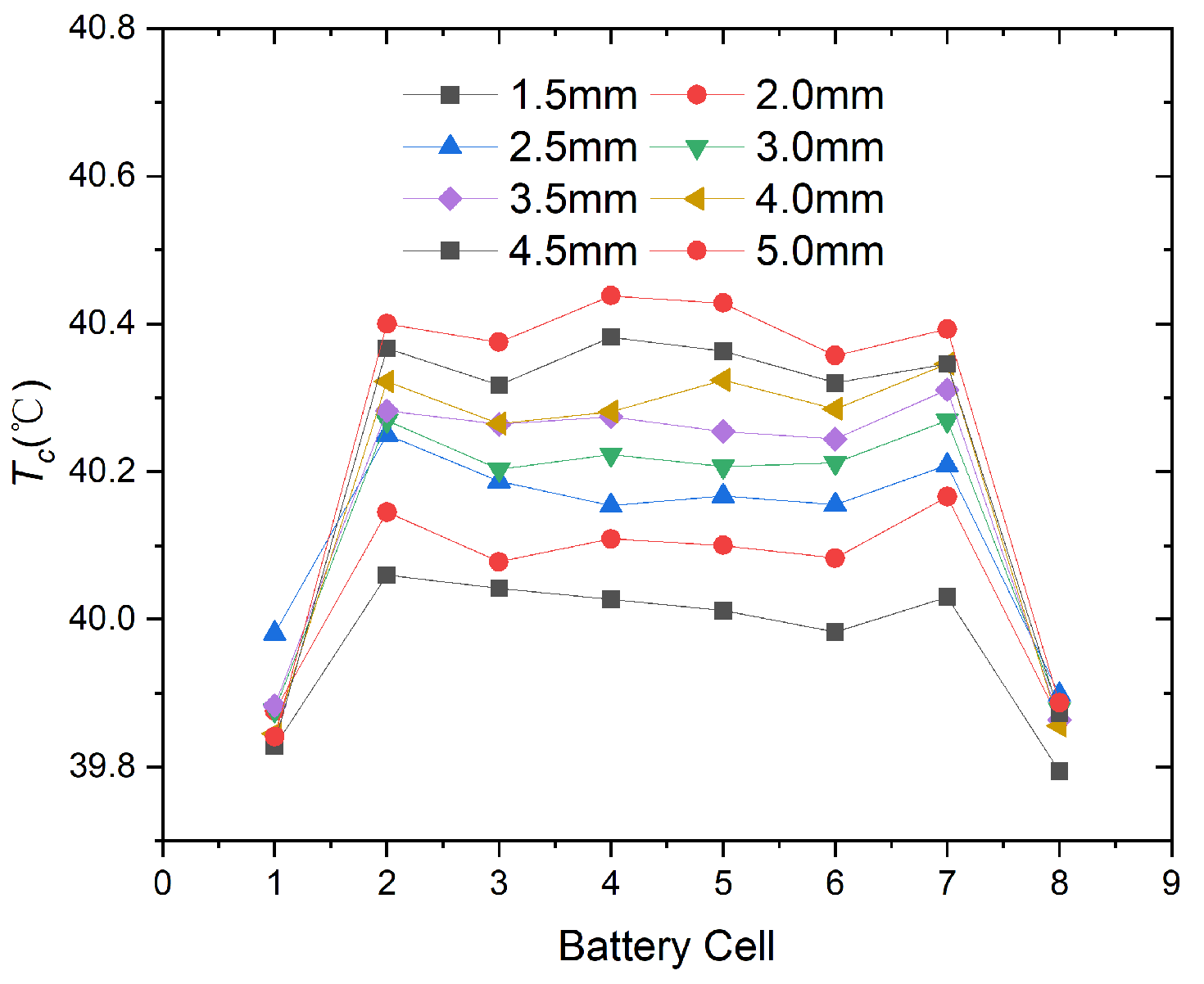

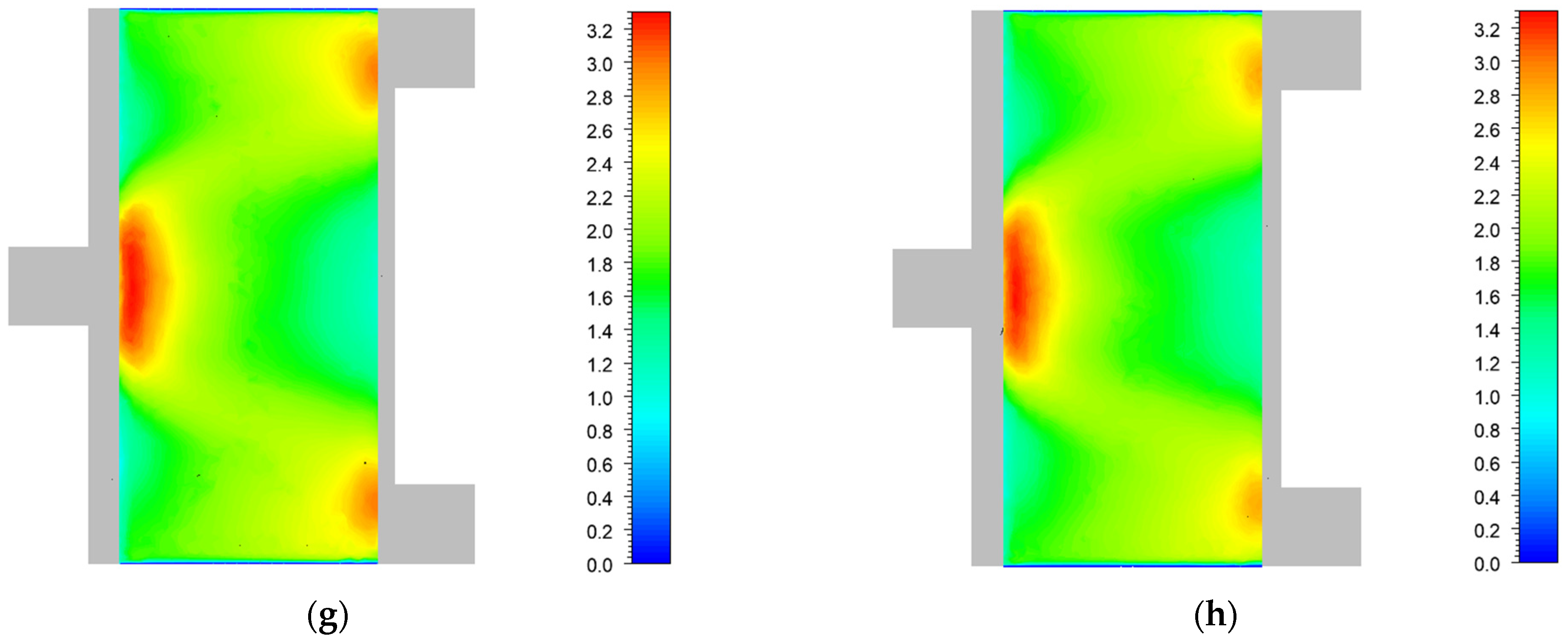

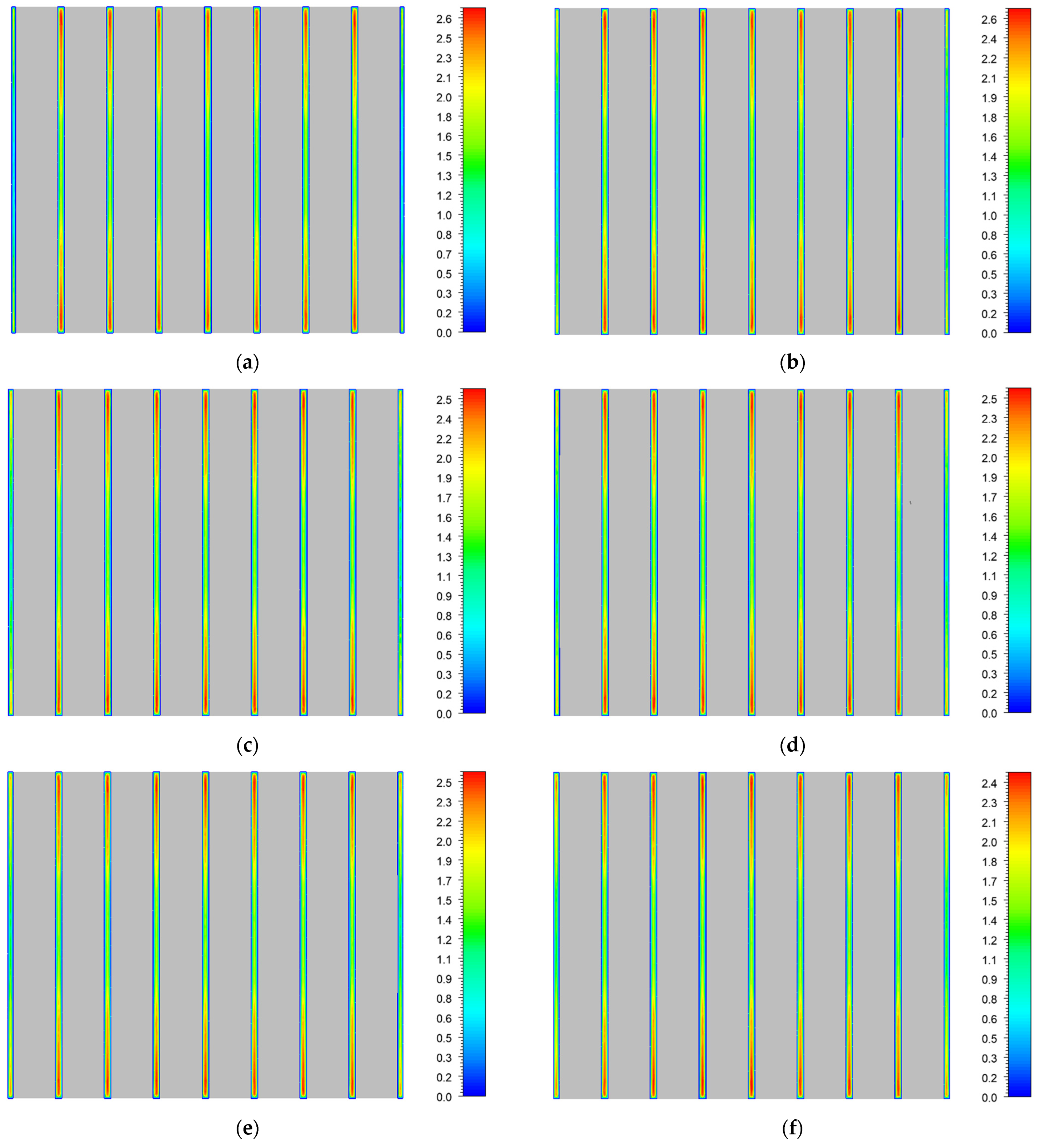

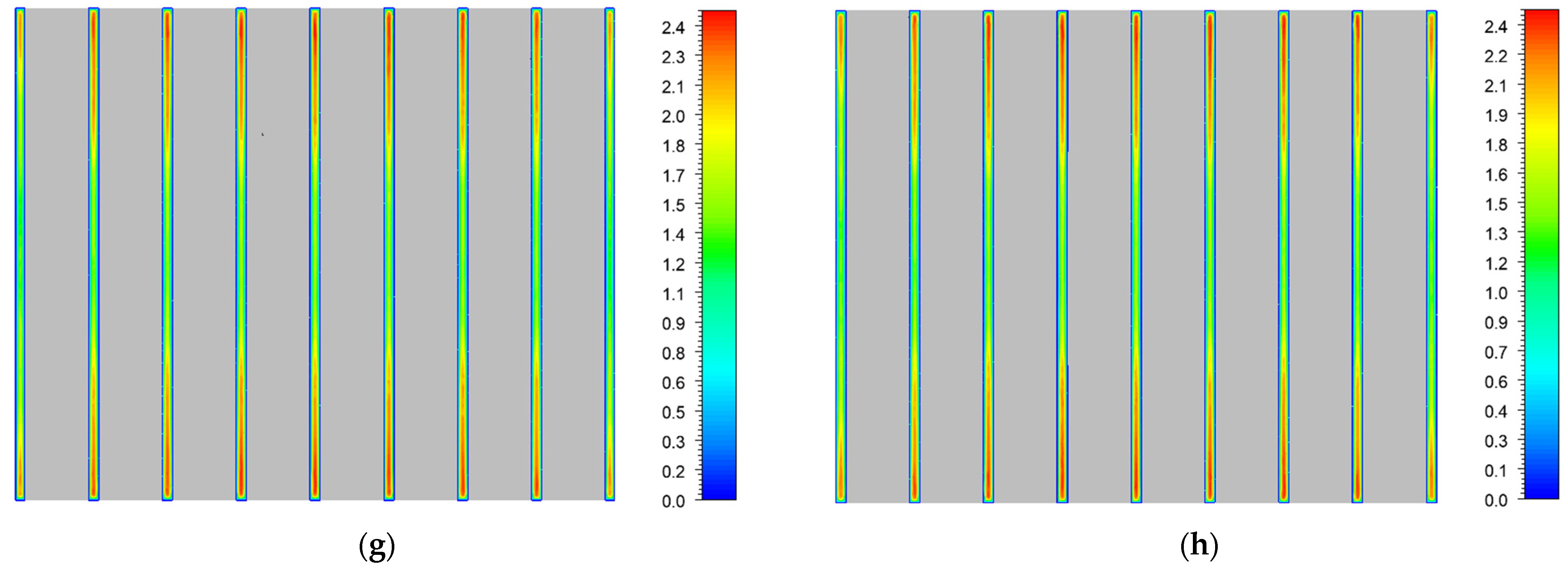

3.2. Influence of Cooling Channel Width on Temperature Uniformity

3.3. Inlet and Outlet

3.4. Energy Consumption and Safety Analysis

3.4.1. Energy Consumption

3.4.2. Safety Analysis

4. Conclusions

- (1)

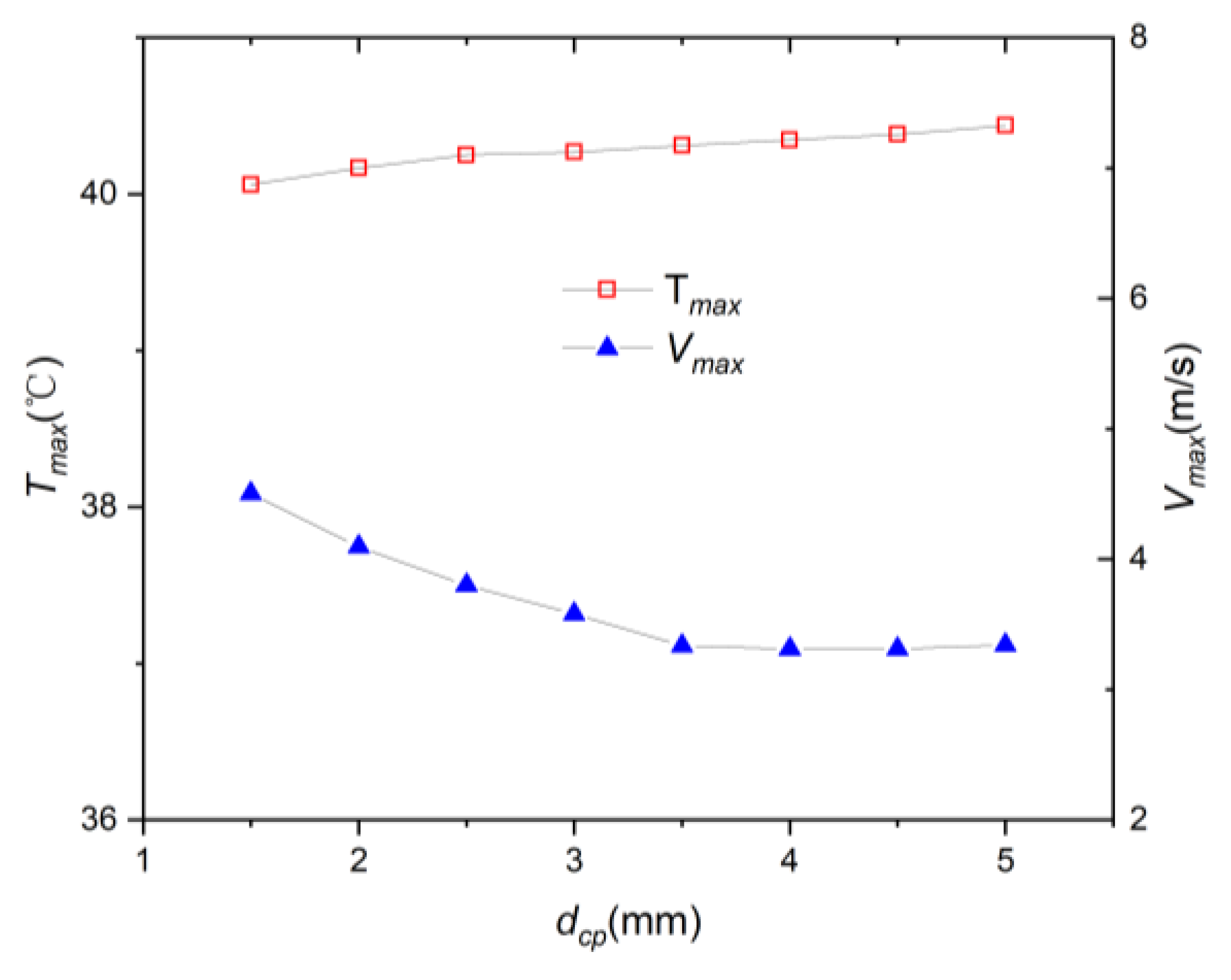

- By adjusting the depths of the distribution plenum and convergence plenum, the airflow velocities passing through the vicinities of the battery cells can be changed, thereby reducing . When remains at 8.0 mm and decreases from 3.5 mm to 1.5 mm, rapidly increases, and the corresponding can be reduced to 40.06 °C.

- (2)

- By changing the width of cooling channels 1 and 9, the flow velocity of these two channels can be adjusted to improve the temperature uniformity of the system. When and decrease from 3.0 mm to 1.7 mm, the value of the middle six batteries gradually decreases, and the value of batteries 1 and 8 first decreases and then increases. When and are 2.2 mm, the heat dissipation performance and temperature uniformity of the system are optimal, with of 39.84 °C and of 0.066 °C. The maximum flow velocity of all cooling channels and the maximum flow velocity of cooling channel 1 can be used separately to analyze and of battery cell 1.

- (3)

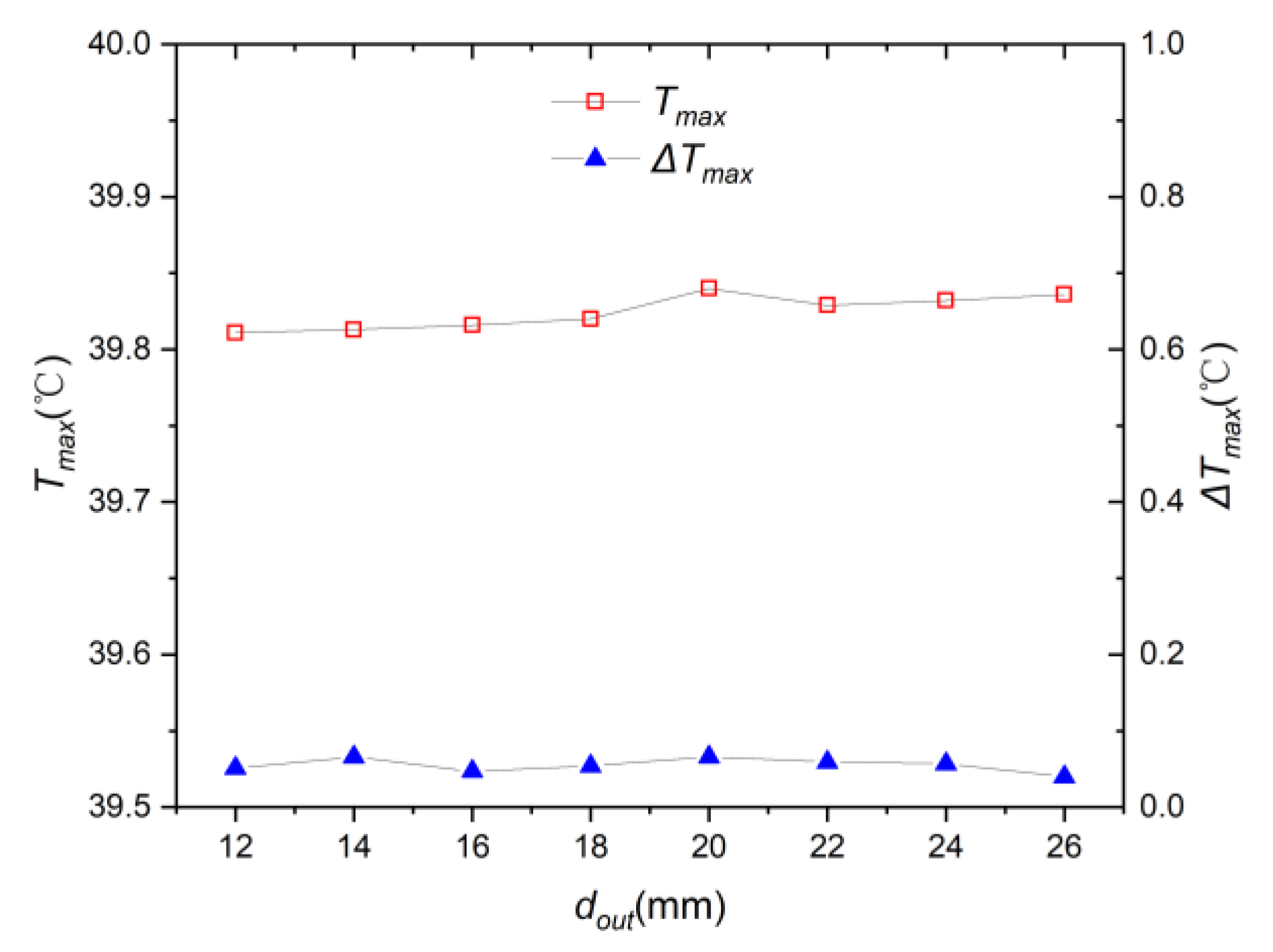

- The inlet and outlet widths have little effect on the heat dissipation performance and temperature uniformity of the system. When increases from 12 mm to 26 mm, the average values of the and are 39.825 °C and 0.055 °C, respectively. The battery cells in the system are still within the optimal operating temperature range of 20–40 °C. is less than 0.1 °C, and the system achieves excellent temperature uniformity.

- (4)

- The cooling performance and energy consumption of the BTMS at each design stage at the end of a 2.5 C discharge rate are summarized. The results indicate that the reduction in energy consumption (pressure drop) is mainly influenced by . The energy consumption of the sample with the best cooling performance is 0.0825 W, which is 0.0124 W (13.1%) lower than that of the T-type model.

- (5)

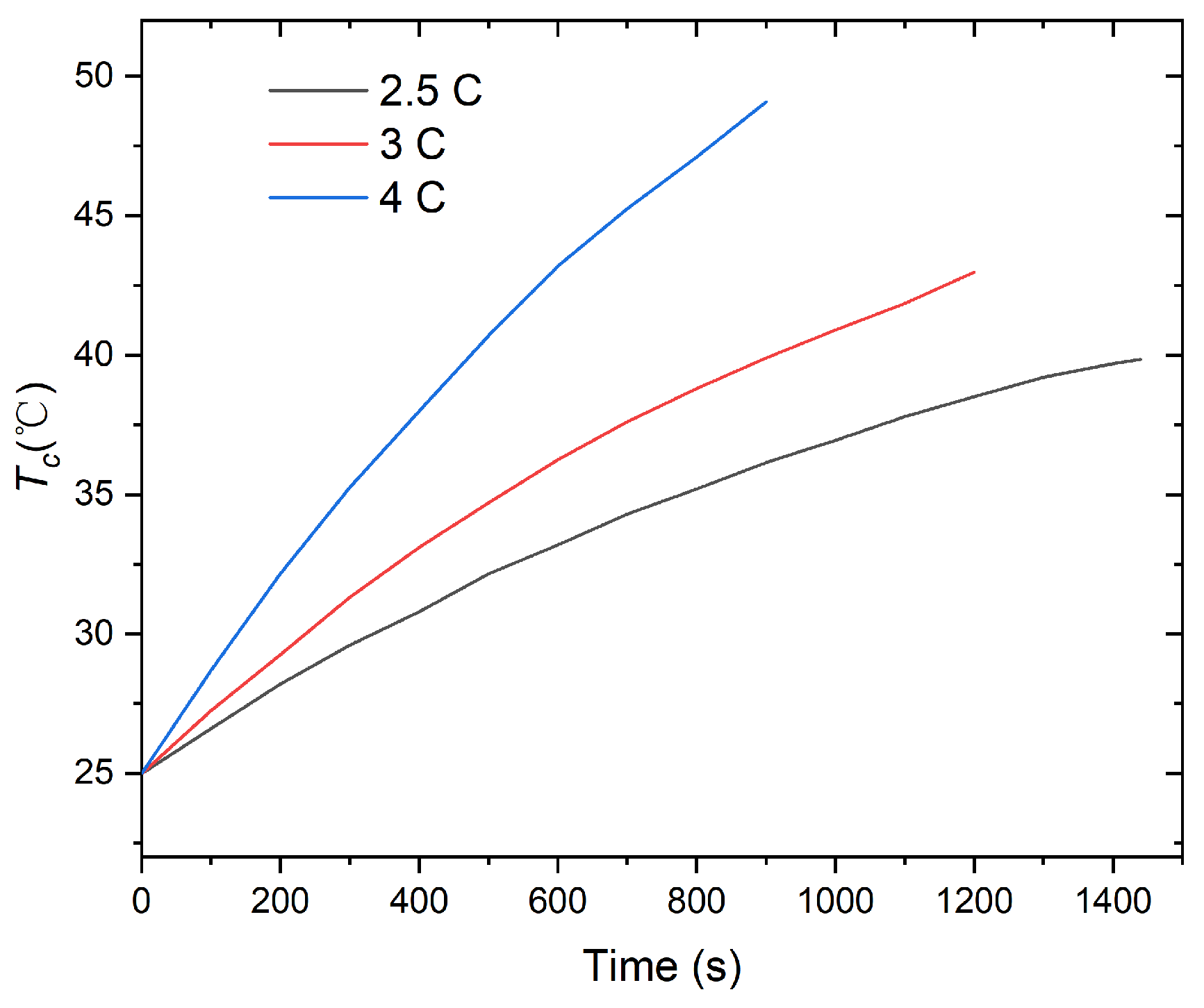

- is very small when the BTMS is exposed to higher ambient temperatures and higher discharge rates, indicating that the BTMS has excellent temperature uniformity. Keeping the discharge rate constant, the relationship between and different ambient temperatures can be obtained.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gibbons, L.; Javed, S. A review of HVAC solution-sets and energy performance of nearly zero-energy multi-story apartment buildings in Nordic climates by statistical analysis of environmental performance certificates and literature review. Energy 2022, 238, 121709. [Google Scholar] [CrossRef]

- Asif, A.; Abdul, R.R.K.; Mohammed, S.A.D.; Rahul, K.; Mit, A.; Goon, P.S. A critical review on renewable battery thermal management system using heat pipes. J. Therm. Anal. Calorim. 2023, 16, 148. [Google Scholar]

- Hajidavalloo, M.R.; Chen, J.; Hu, Q.; Song, Z.; Yin, X.; Li, Z. NMPC-Based integrated thermal management of battery and cabin for electric vehicles in cold weather conditions. IEEE Trans. Intell. Veh. 2023, 8, 4208–4222. [Google Scholar] [CrossRef]

- Kiani, M.; Omiddezyani, S.; Houshfar, E.; Miremadi, S.R.; Ashjaee, M.; Nejad, A.M. Lithium-ion battery thermal management system with Al2O3/AgO/CuO nanofluids and phase change material. Appl. Therm. Eng. 2020, 180, 115840. [Google Scholar] [CrossRef]

- Shen, K.; Yang, L.; Sun, J.; Xu, C.; Wang, H.; Zheng, Y.; Feng, X. Experimental and simulations study of thermal performance of cell-to-pack structure for a lithium-ion battery pack. J. Electrochem. Energy Convers. Storage 2023, 20, 041003. [Google Scholar] [CrossRef]

- Zhao, C.; Cao, W.; Dong, T.; Jiang, F. Thermal behavior study of discharging/charging cylindrical lithium-ion battery module cooled by channeled liquid flow. Int. J. Heat Mass Transf. 2018, 120, 751–762. [Google Scholar] [CrossRef]

- Ravikumar, B.; Mynam, M.; Rai, B. Molecular dynamics investigation of electric field altered behavior of lithium ion battery electrolytes. J. Mol. Liq. 2020, 300, 112252. [Google Scholar] [CrossRef]

- Lu, Z.; Yu, X.; Wei, L.; Qiu, Y.; Zhang, L.; Meng, X.; Jin, L. Parametric study of forced air cooling strategy for lithium-ion battery pack with staggered arrangement. Appl. Therm. Eng. 2018, 136, 28–40. [Google Scholar] [CrossRef]

- Wang, T.; Tseng, K.J.; Zhao, J. Development of efficient air-cooling strategies for lithium-ion battery module based on empirical heat source model. Appl. Therm. Eng. 2015, 90, 521–529. [Google Scholar] [CrossRef]

- Hong, S.; Zhang, X.; Chen, K. Design of flow configuration for parallel air-cooled battery thermal management system with secondary vent. Int. J. Heat Mass Transf. 2018, 116, 1204–1212. [Google Scholar] [CrossRef]

- Yu, K.; Yang, X.; Cheng, Y.; Li, C. Thermal analysis and two-directional air flow thermal management for lithium-ion battery pack. J. Power Sources 2014, 270, 193–200. [Google Scholar] [CrossRef]

- Shahid, S.; Agelin-Chaab, M. Development and analysis of a technique to improve air-cooling and temperature uniformity in a battery pack for cylindrical batteries. Therm. Sci. Eng. Prog. 2018, 5, 351–363. [Google Scholar] [CrossRef]

- Peng, X.; Ma, C.; Garg, A.; Bao, N.; Liao, X. Thermal performance investigation of an aircooled lithium-ion battery pack considering the inconsistency of battery cells. Appl. Therm. Eng. 2019, 153, 596–603. [Google Scholar] [CrossRef]

- Zhang, F.; Yi, M.; Wang, P.; Liu, C. Optimization design for improving thermal performance of T-type air-cooled lithium-ion battery pack. J. Energy Storage 2021, 44, 103464. [Google Scholar] [CrossRef]

- Chen, K.; Song, M.; Wei, W.; Wang, S. Design of the structure of battery pack in parallel air-cooled battery thermal management system for cooling efficiency improvement. Int. J. Heat Mass Transf. 2019, 132, 309–321. [Google Scholar] [CrossRef]

- Zhang, F.; Lin, A.; Wang, P.; Liu, P. Optimization design of a parallel air-cooled battery thermal management system with spoilers. Appl. Therm. Eng. 2021, 182, 116062. [Google Scholar] [CrossRef]

- Weng, J.; Xiao, C.; Yang, X.; Ouyang, D.; Chen, M.; Zhang, G.; Waiming, L.E.; Yuen, K.K.R.; Wang, J. An energy-saving battery thermal management strategy coupling tubular phase-change-material with dynamic liquid cooling under different ambient temperatures. Renew. Energy 2022, 195, 918–930. [Google Scholar] [CrossRef]

| Properties | Unit | Air |

|---|---|---|

| Density | 1.165 | |

| 1005 | ||

| Thermal Conductivity | 0.0267 | |

| Viscosity |

| Properties | Unit | Cell |

|---|---|---|

| Density | 2136.8 | |

| Specific Heat Capacity | J | 1633 |

| Thermal Conductivity | W | |

| Heat Generation Rate | W | 60,439.56 |

| Stage | Factors | Results | |||

|---|---|---|---|---|---|

| 1 | (mm) | (°C) | (°C) | (W) | |

| 2.5 | 41.231 | 0.266 | 0.0942 | ||

| 3.0 | 40.854 | 0.281 | 0.0766 | ||

| 5.0 | 40.492 | 0.51 | 0.0458 | ||

| 5.5 | |||||

| 6.0 | |||||

| 7.0 | |||||

| 10.0 | |||||

| 20.0 | |||||

| 2 | (mm) | (mm) | (°C) | ||

| 4.5 | 6.5 | 40.645 | |||

| 5.0 | 6.0 | 40.552 | |||

| 5.5 | 5.5 | 40.486 | |||

| 6.0 | 5.0 | 40.426 | |||

| 6.5 | 4.5 | 40.383 | |||

| 7.0 | 4.0 | 40.327 | |||

| 7.5 | 3.5 | 40.307 | |||

| 8.0 | 3.0 | 40.269 | |||

| 3 | = 8 mm (mm) | (°C) | (°C) | ||

| 1.5 | 40.06 | 0.266 | |||

| 2.0 | 40.166 | 0.302 | |||

| 2.5 | 40.25 | 0.352 | |||

| 3.0 | 40.269 | 0.392 | |||

| 3.5 | 40.311 | 0.447 | |||

| 4.0 | 40.346 | 0.501 | |||

| 4.5 | 40.382 | 0.549 | |||

| 5.0 | 40.438 | 0.597 | |||

| 4 | = 1.5 mm (mm) | (°C) | (°C) | ||

| 1.7 | 40.08 | 0.533 | |||

| 1.9 | 39.956 | 0.3 | |||

| 2.1 | 39.862 | 0.129 | |||

| 2.2 | 39.84 | 0.066 | |||

| 2.3 | 39.856 | 0.083 | |||

| 2.5 | 39.907 | 0.193 | |||

| 2.7 | 39.967 | 0.225 | |||

| 3.0 | 40.06 | 0.266 | |||

| Ambient Temperature (°C) | Discharge Rate (C) | Results | ||

|---|---|---|---|---|

| (°C) | (°C) | (W) | ||

| 25 | 2.5 | 39.84 | 0.066 | 0.0833 |

| 25 | 3 | 42.967 | 0.067 | 0.0833 |

| 25 | 4 | 49.077 | 0.064 | 0.0833 |

| 30 | 2.5 | 44.84 | 0.066 | 0.0833 |

| 30 | 3 | 47.967 | 0.067 | 0.0833 |

| 30 | 4 | 54.077 | 0.064 | 0.0833 |

| 35 | 2.5 | 49.84 | 0.066 | 0.0833 |

| 35 | 3 | 52.967 | 0.067 | 0.0833 |

| 35 | 4 | 59.077 | 0.064 | 0.0833 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Liu, J.; Li, X. A Y-Type Air-Cooled Battery Thermal Management System with a Short Airflow Path for Temperature Uniformity. Batteries 2024, 10, 302. https://doi.org/10.3390/batteries10090302

Li X, Liu J, Li X. A Y-Type Air-Cooled Battery Thermal Management System with a Short Airflow Path for Temperature Uniformity. Batteries. 2024; 10(9):302. https://doi.org/10.3390/batteries10090302

Chicago/Turabian StyleLi, Xiangyang, Jing Liu, and Xiaomin Li. 2024. "A Y-Type Air-Cooled Battery Thermal Management System with a Short Airflow Path for Temperature Uniformity" Batteries 10, no. 9: 302. https://doi.org/10.3390/batteries10090302

APA StyleLi, X., Liu, J., & Li, X. (2024). A Y-Type Air-Cooled Battery Thermal Management System with a Short Airflow Path for Temperature Uniformity. Batteries, 10(9), 302. https://doi.org/10.3390/batteries10090302