Analysis of the Effect of Motor Waste Heat Recovery on the Temperature and Driving Range of Electric Heavy Truck Batteries

Abstract

1. Introduction

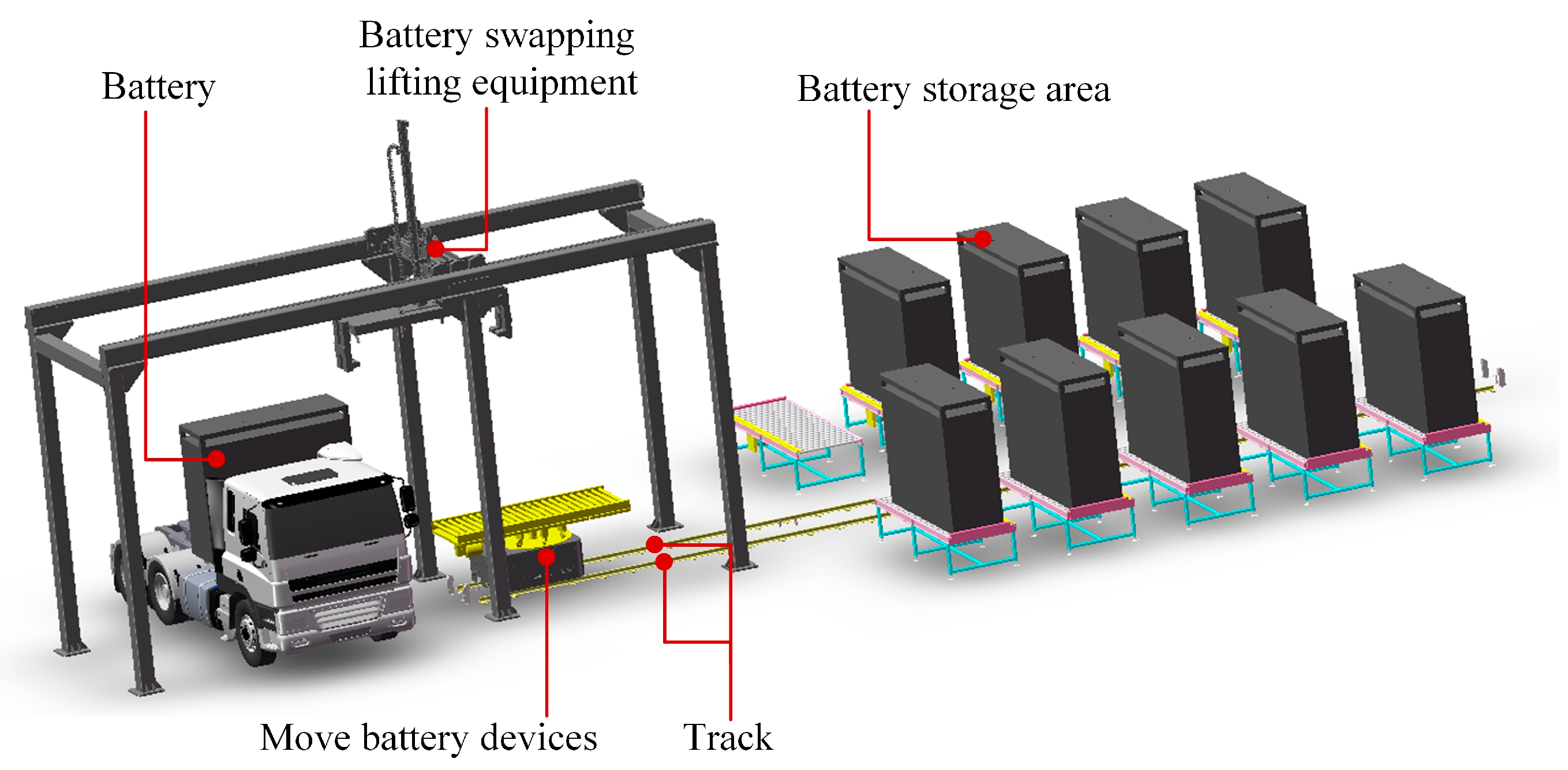

2. Battery Swapping ETBSm Design and Parameters

2.1. Structural Design

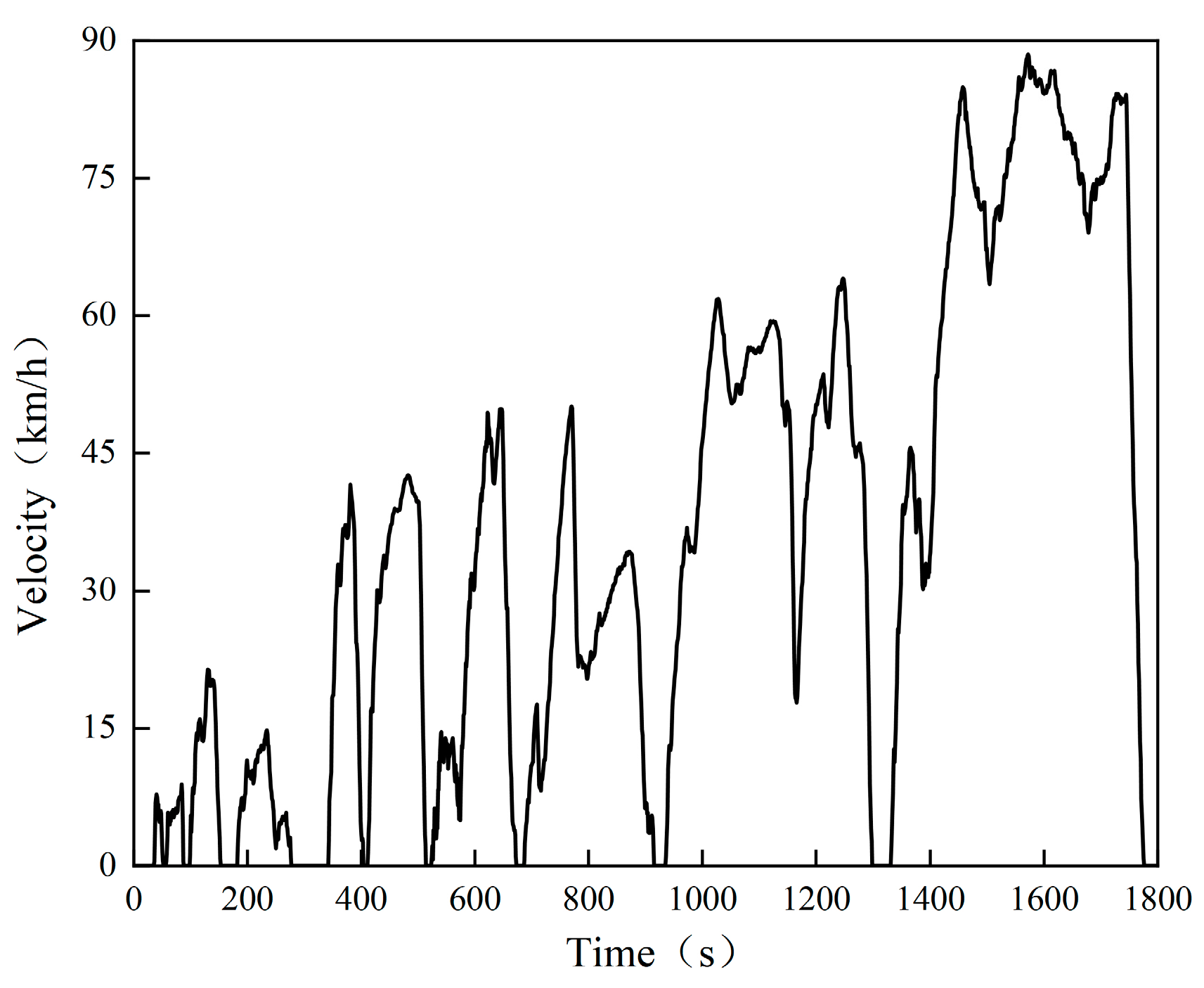

2.2. BSHT Dynamic Parameter

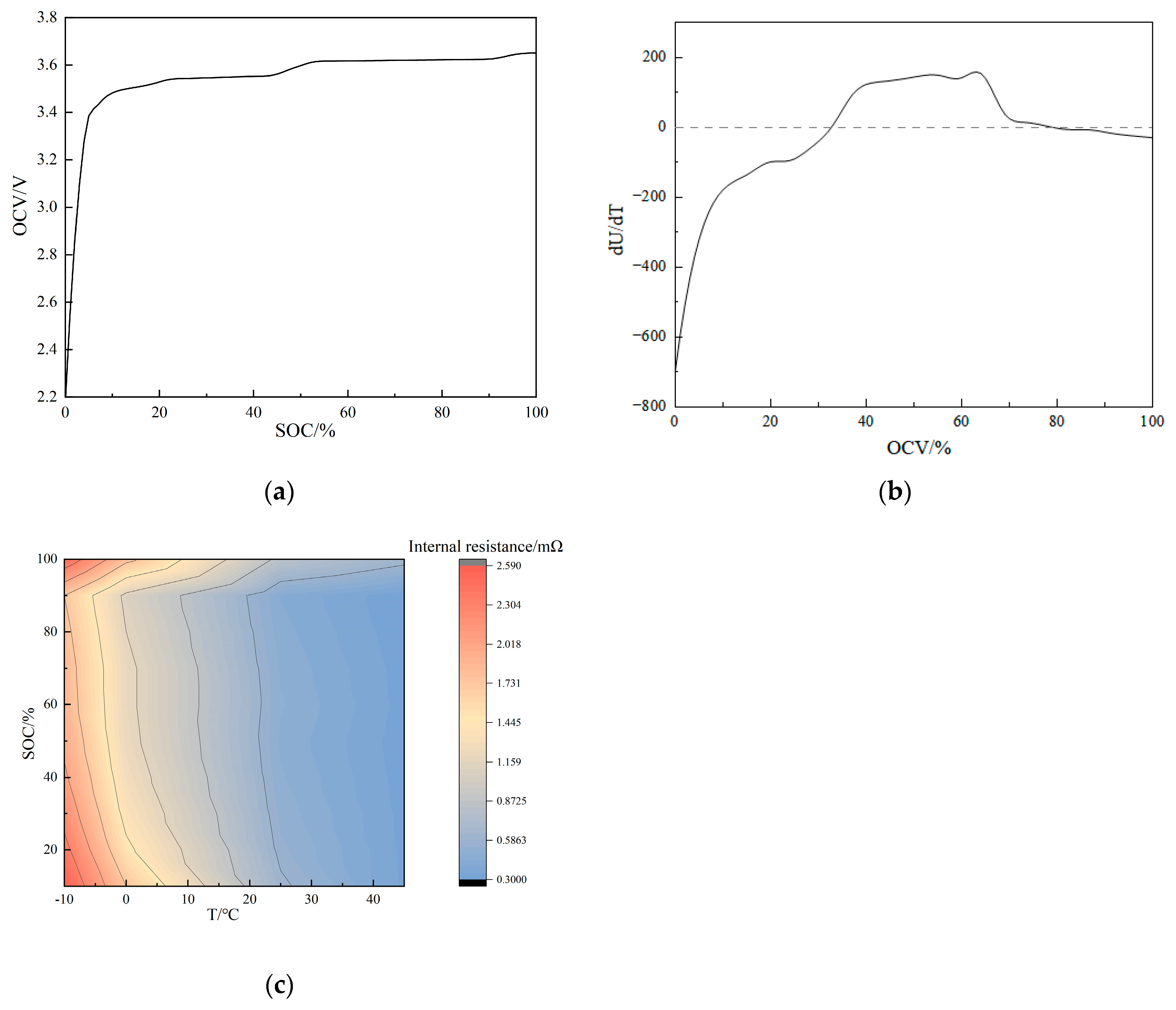

2.3. Testing for Battery

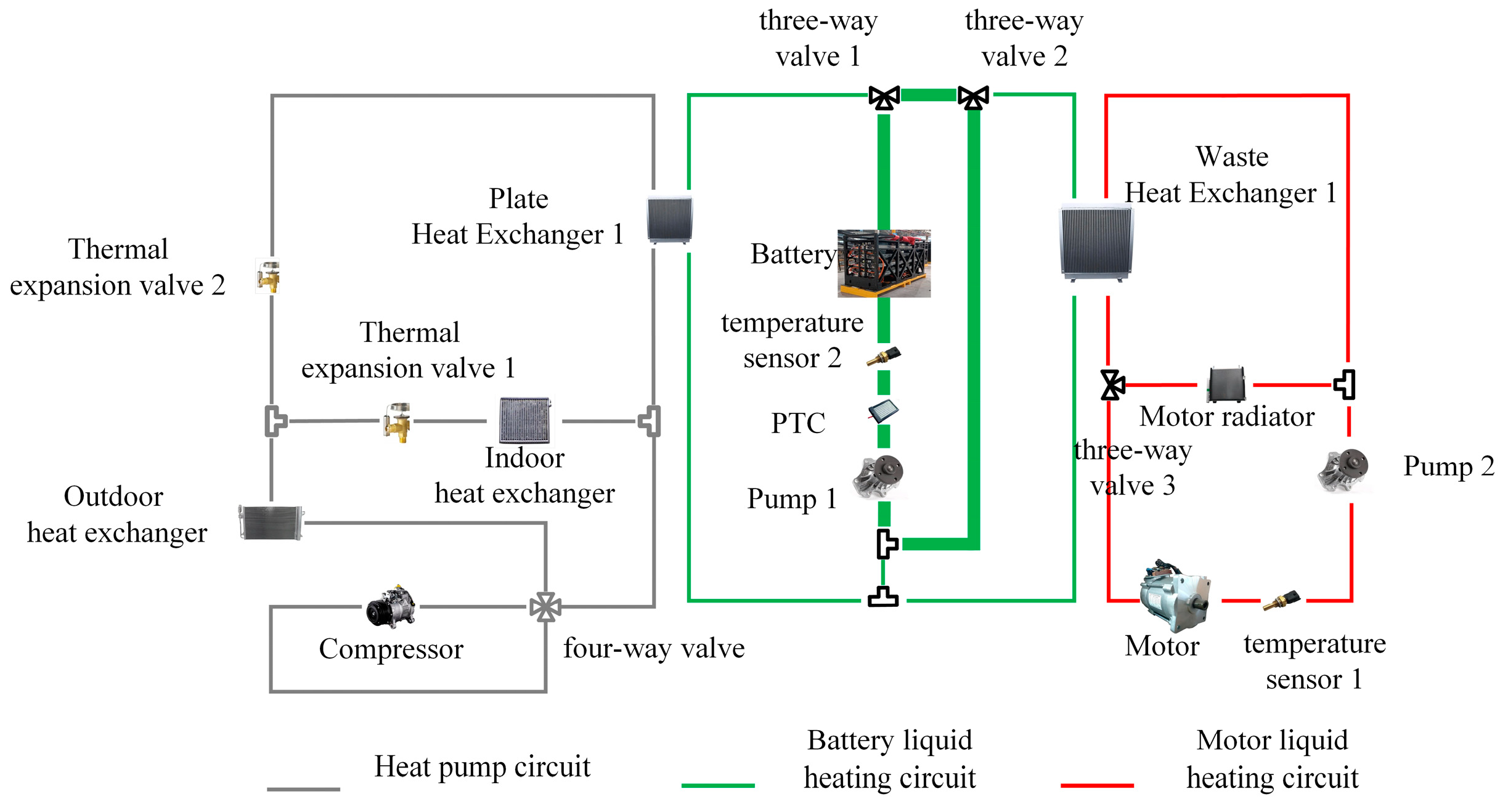

3. Heat Transfer Frameworks and Temperature Control Strategy

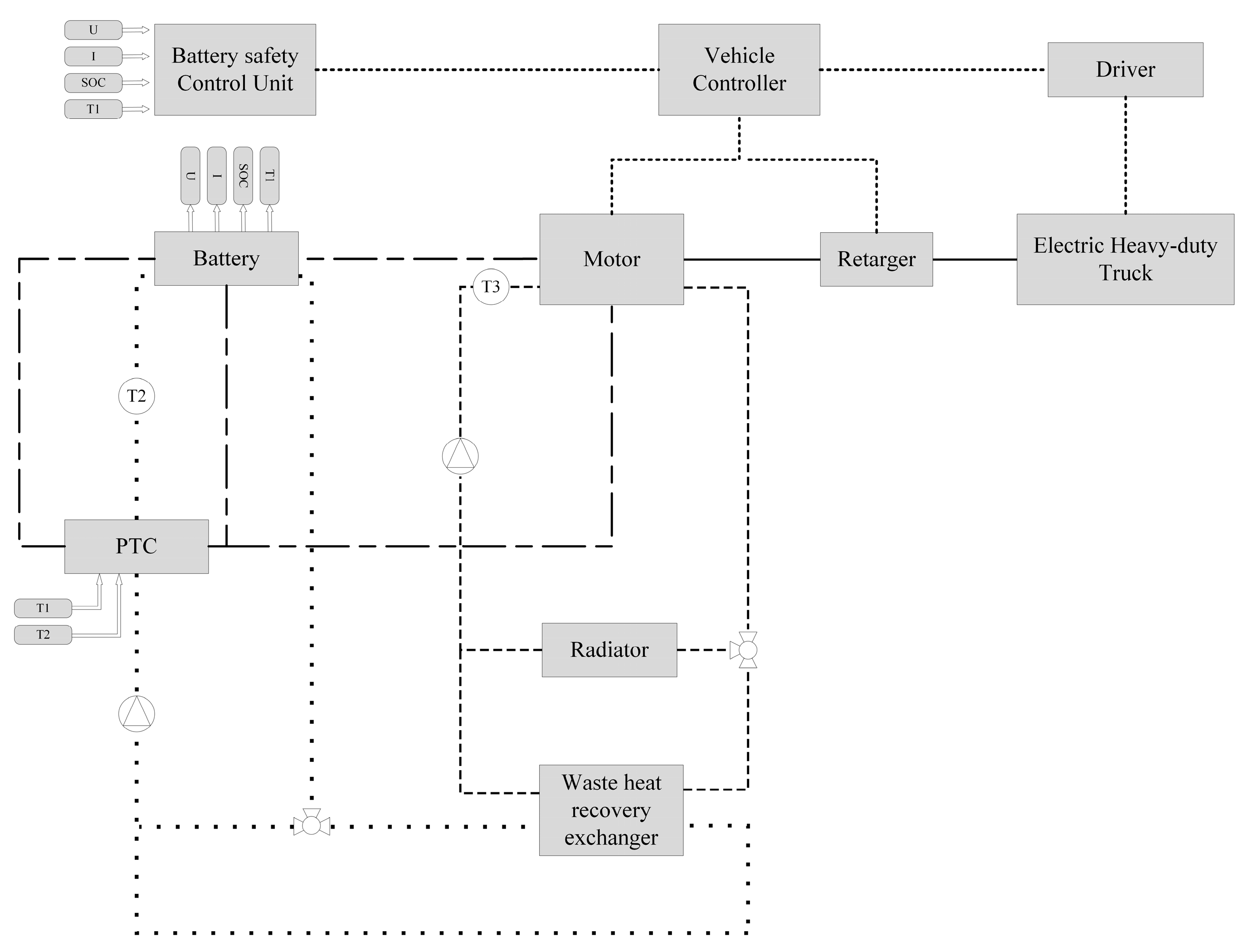

3.1. Integrated TMS Framework

3.2. Operation Mode

3.3. Thermal Management System Control Strategy

4. Modeling and Validation

4.1. Simulation Model

4.1.1. ETBSm Model

4.1.2. Battery Model

4.1.3. Electric Motor Model

4.1.4. TMS Model

4.2. Validation of the Simulation Model

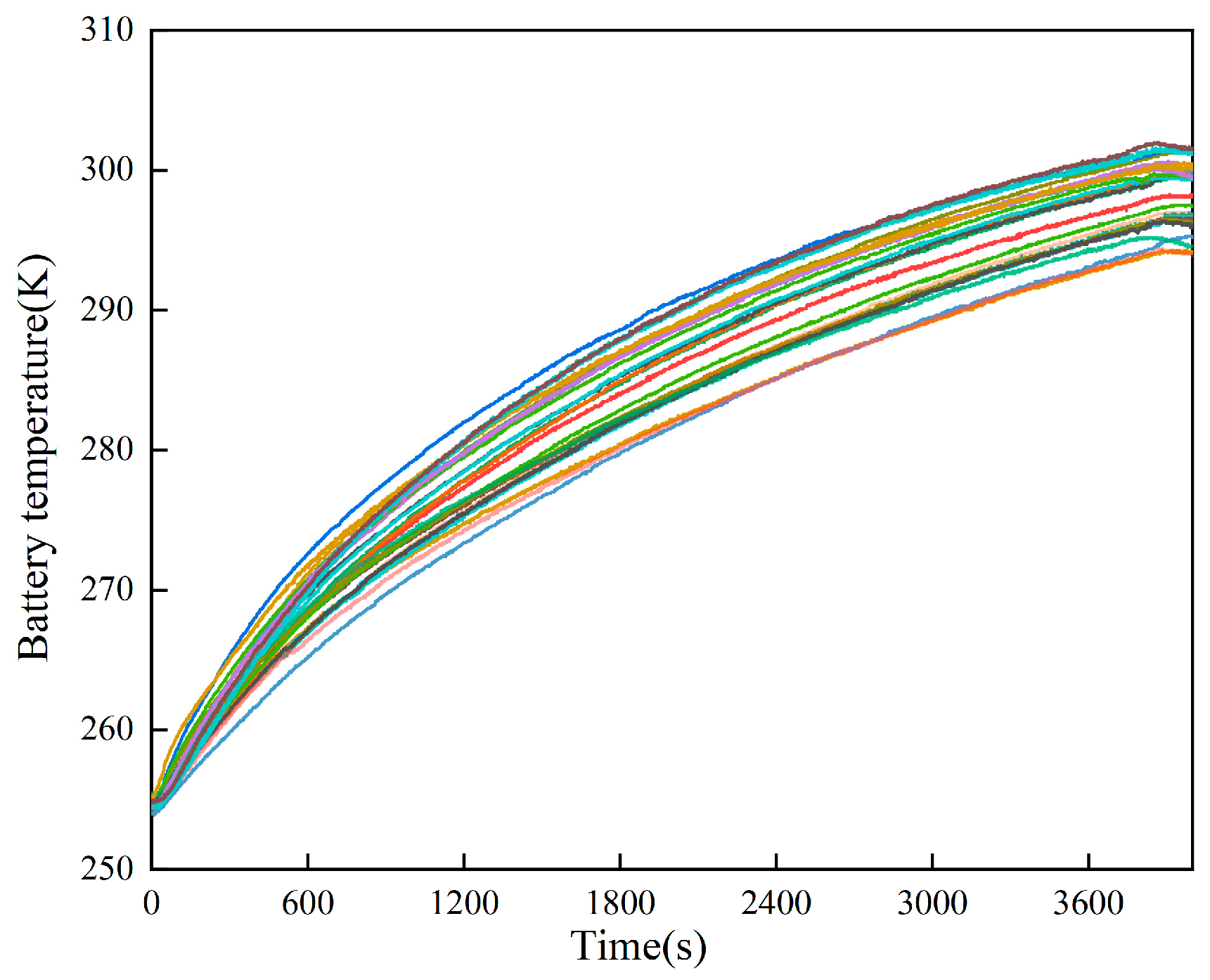

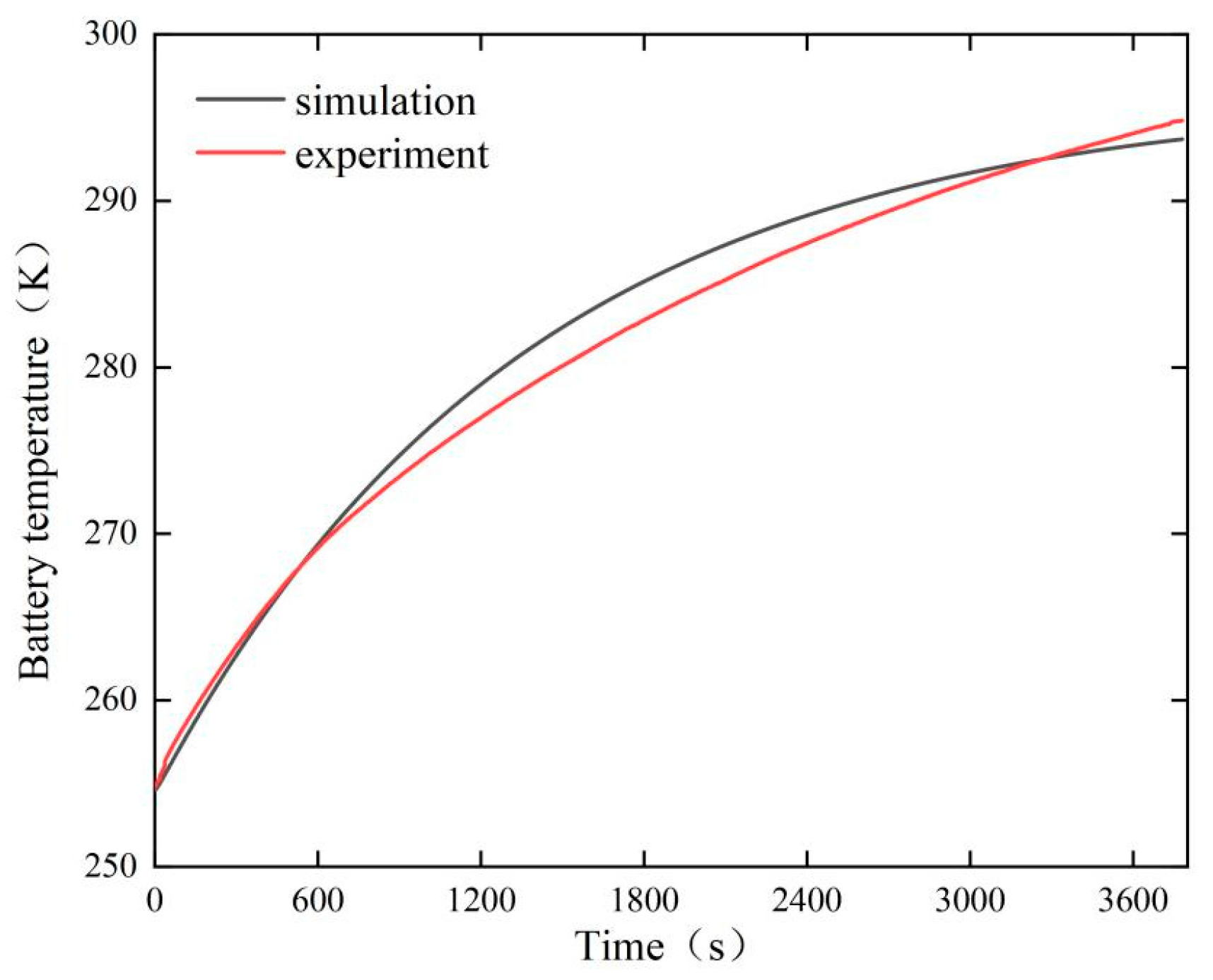

4.2.1. Battery Temperature Rise Rate

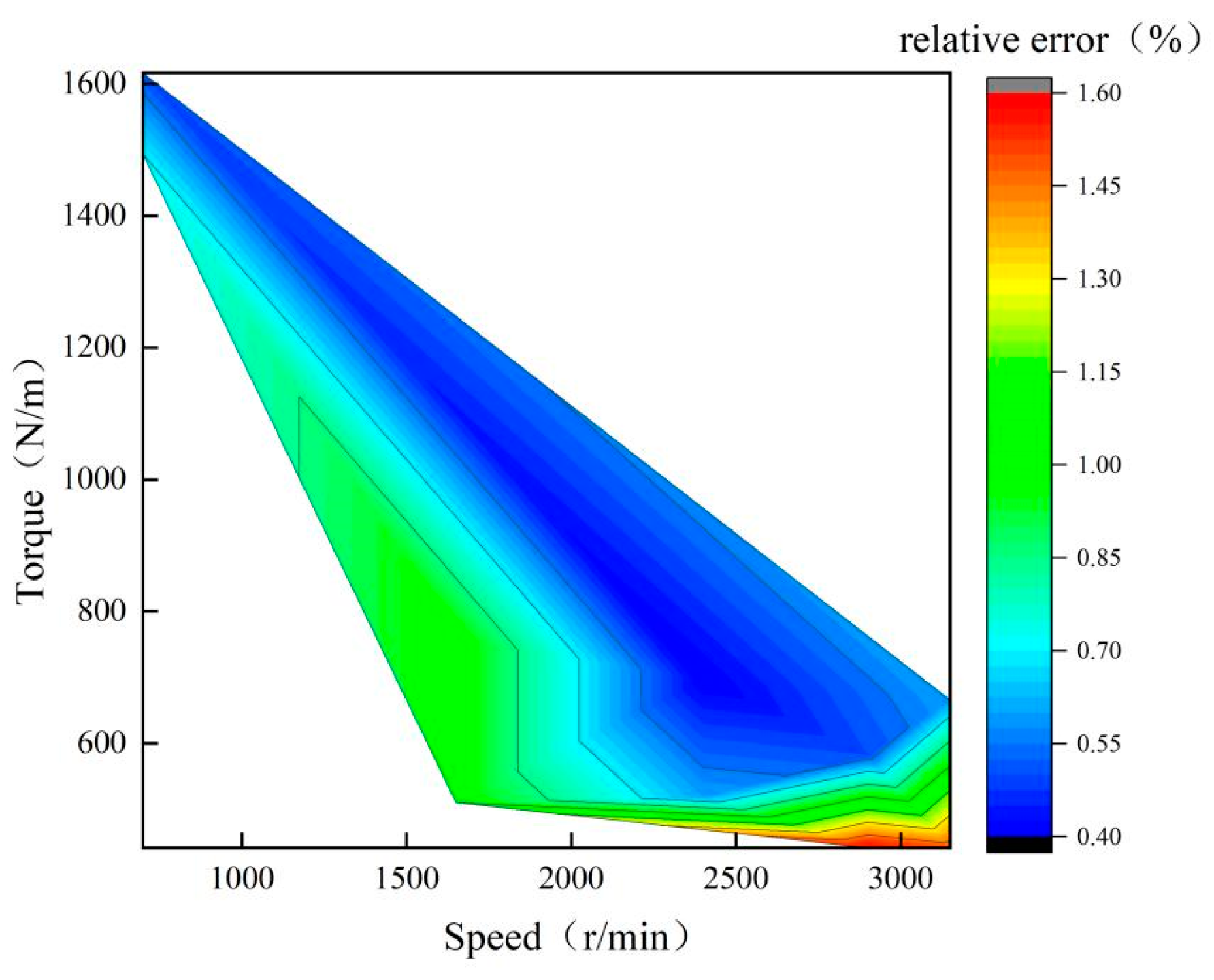

4.2.2. Motor Efficiency

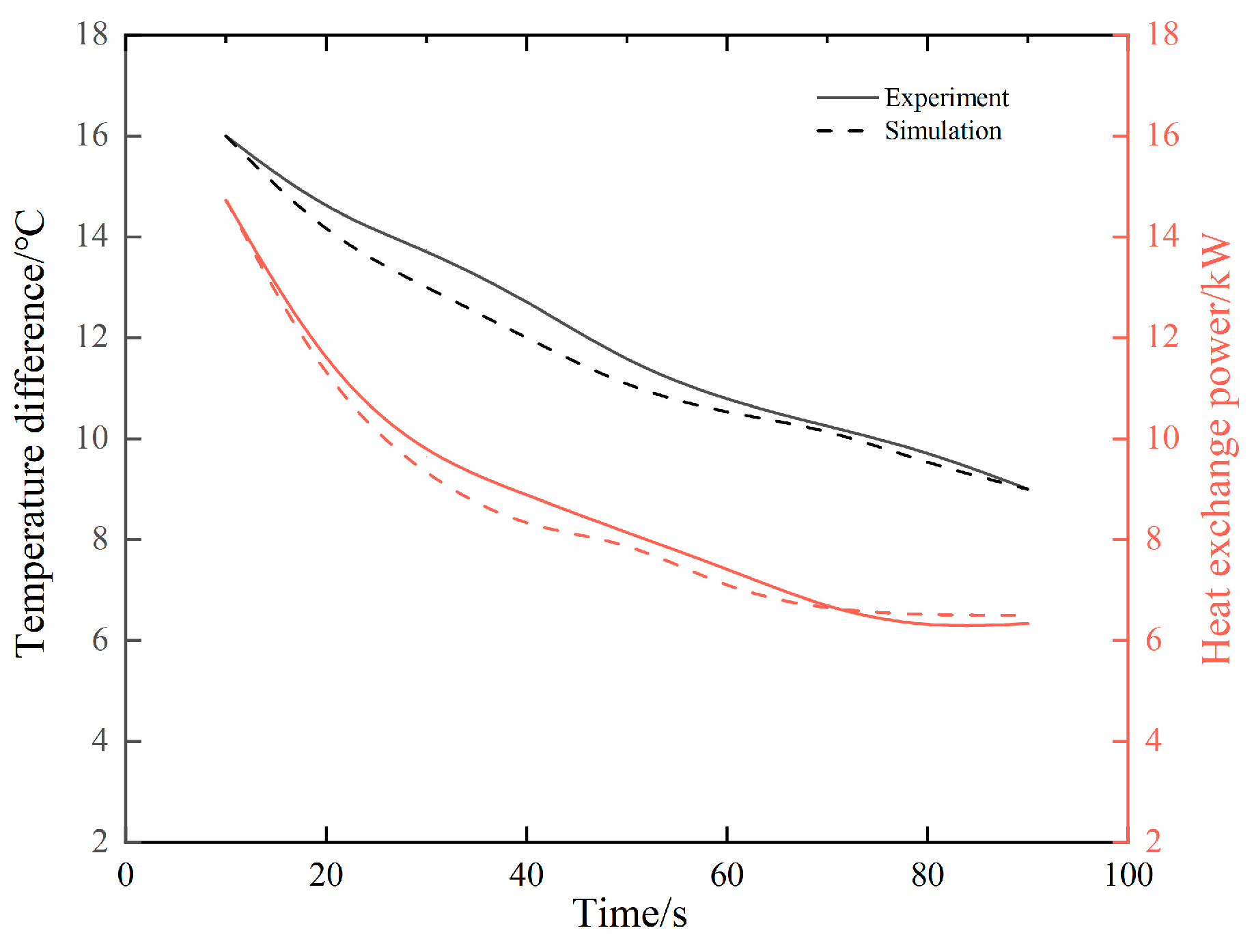

4.2.3. Waste Heat Recovery Exchanger

4.3. Simulation Model Framework

5. Results and Discussions

5.1. TMS Performance for ETBSm

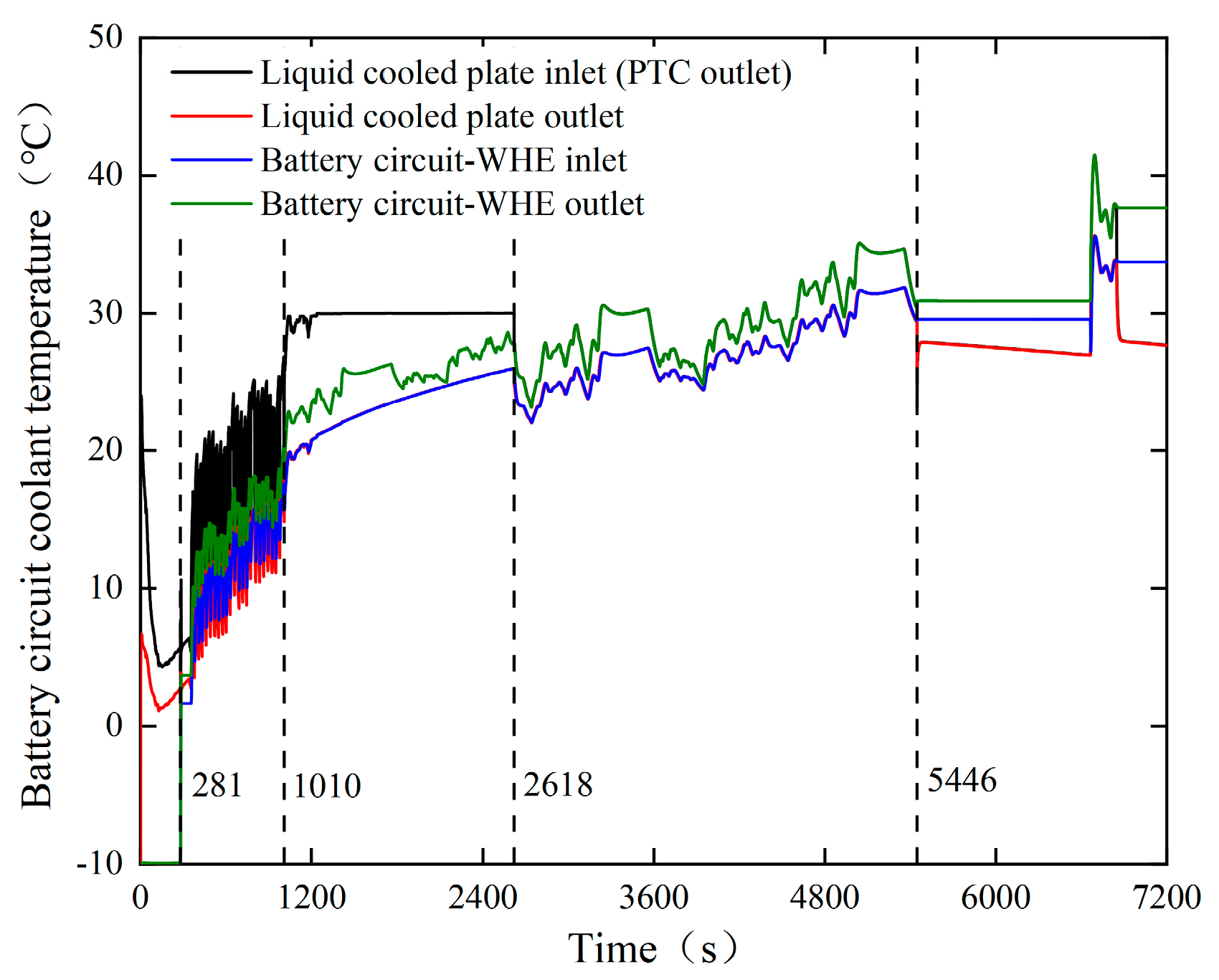

5.1.1. Coolant Temperature

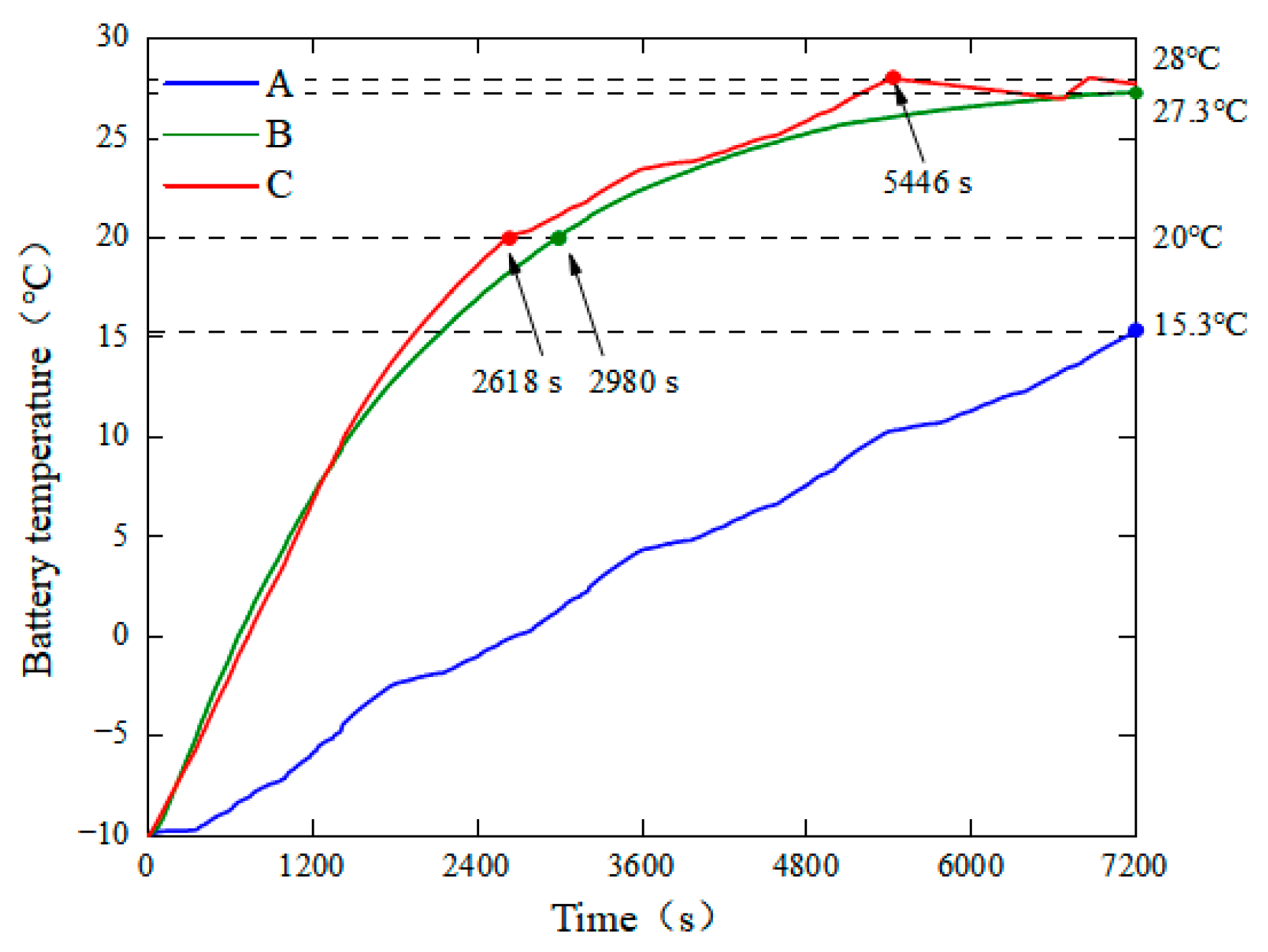

5.1.2. Battery Temperature and Temperature Rise Rate

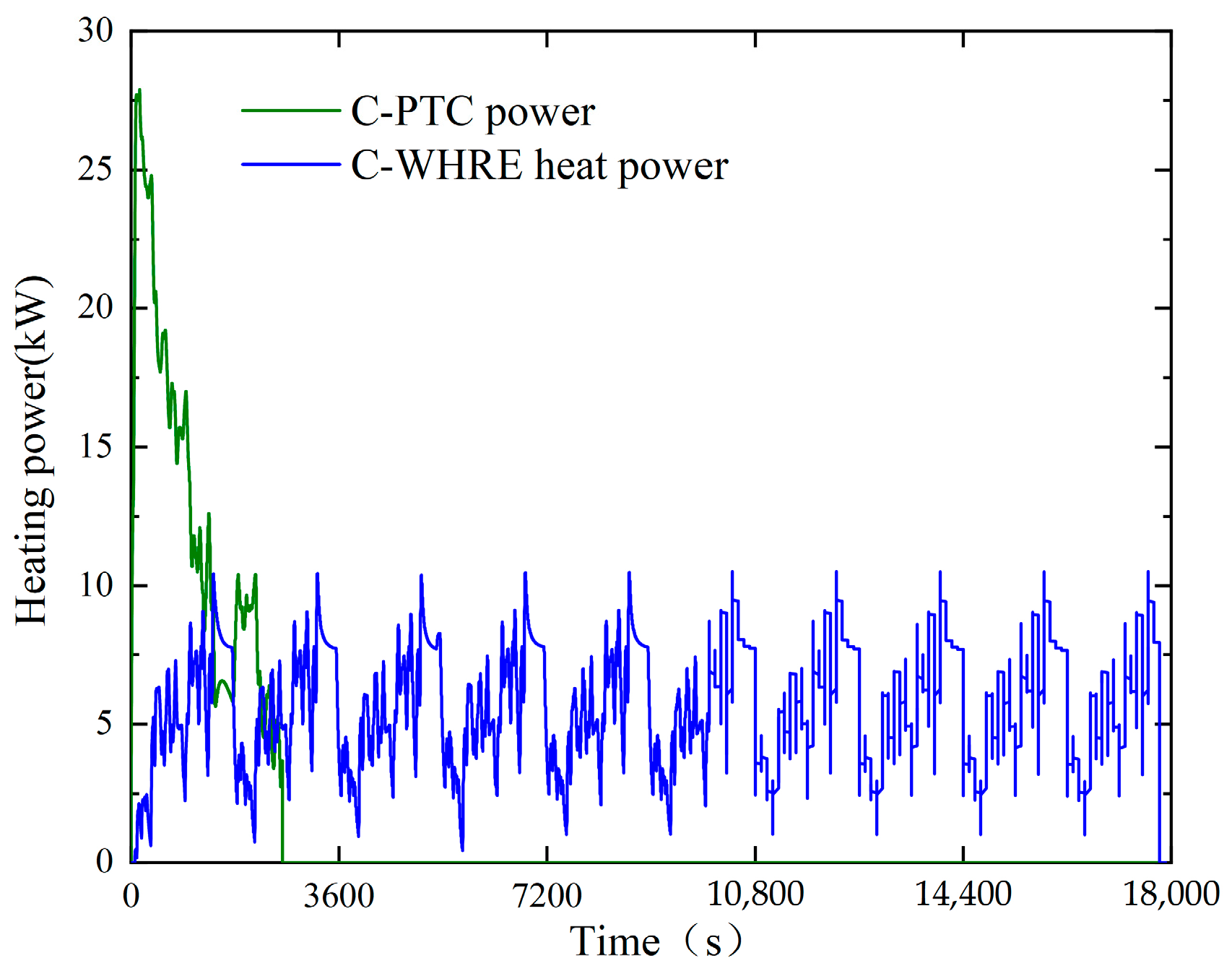

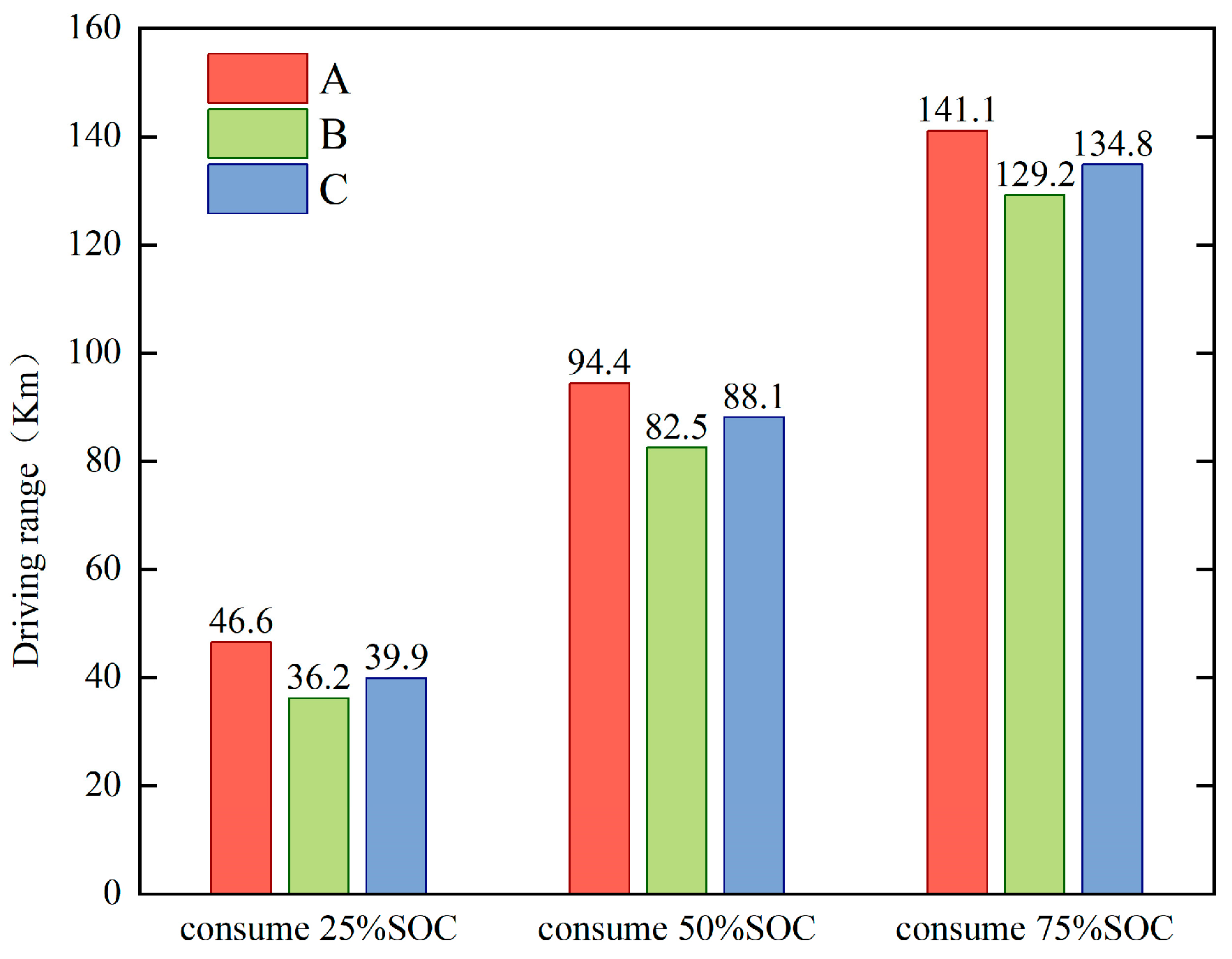

5.1.3. Power Consumption and Driving Range

5.2. Ambient Temperature

5.2.1. Temperature Characteristics

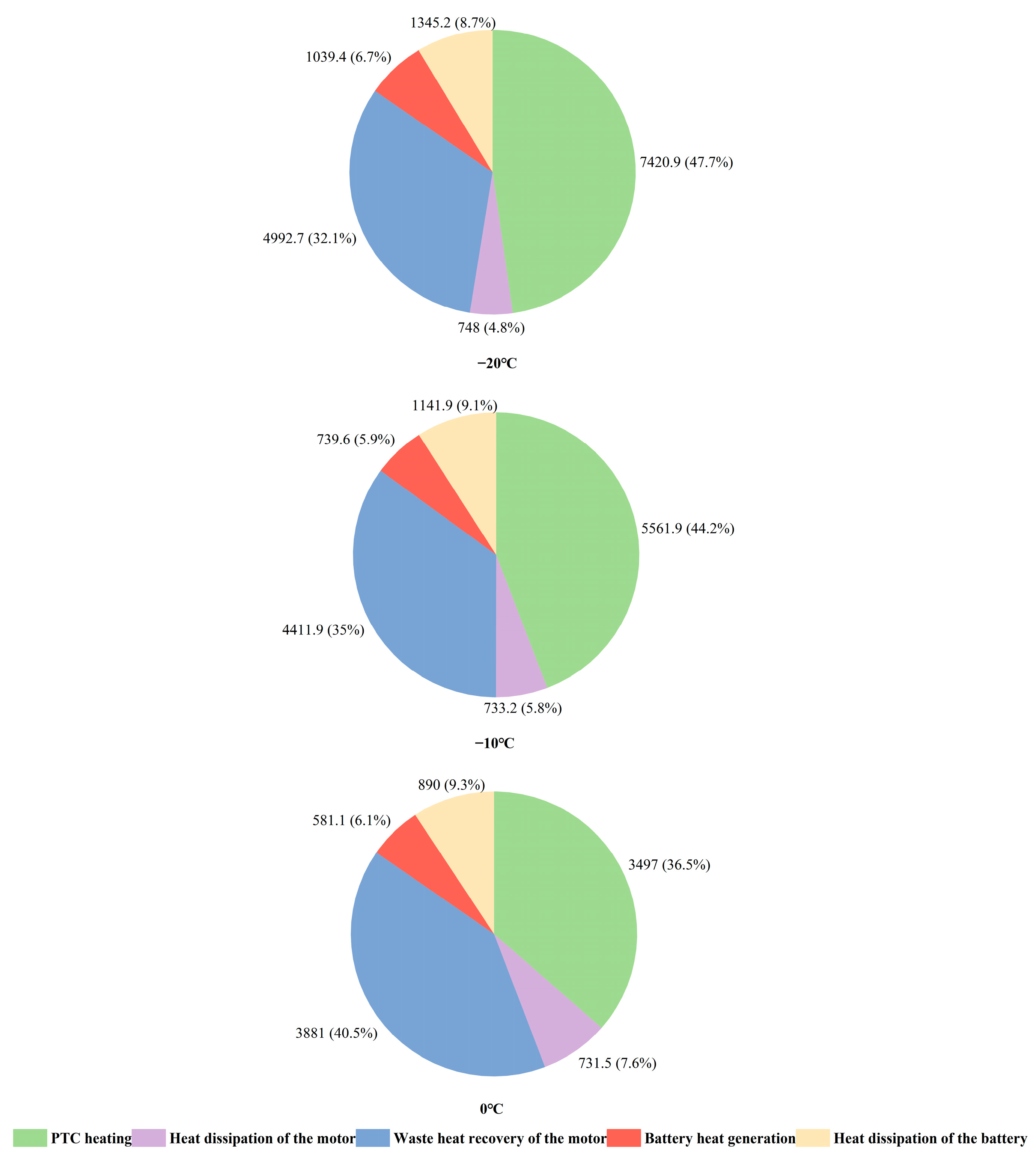

5.2.2. Heat Flow Chart

5.2.3. Driving Range

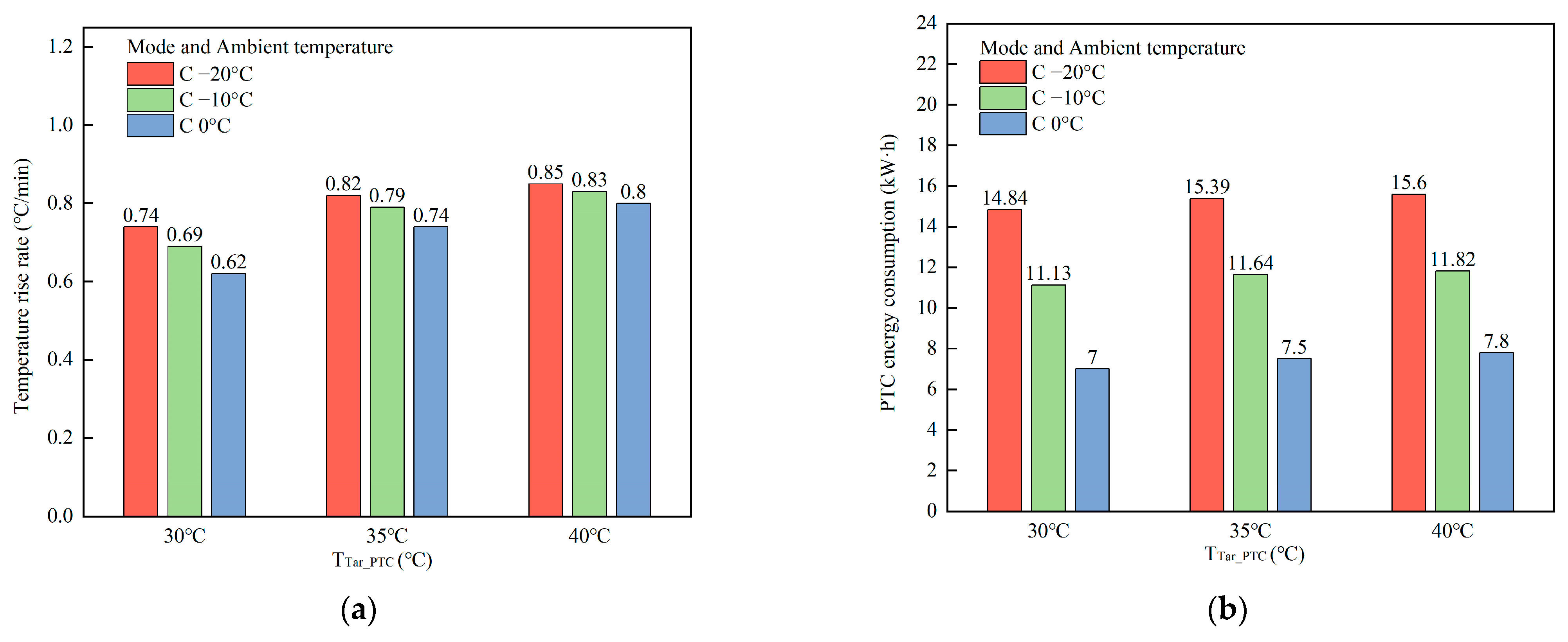

5.3. PTC Heater Target Temperature

5.3.1. Temperature Rise Rate

5.3.2. Power Consumption

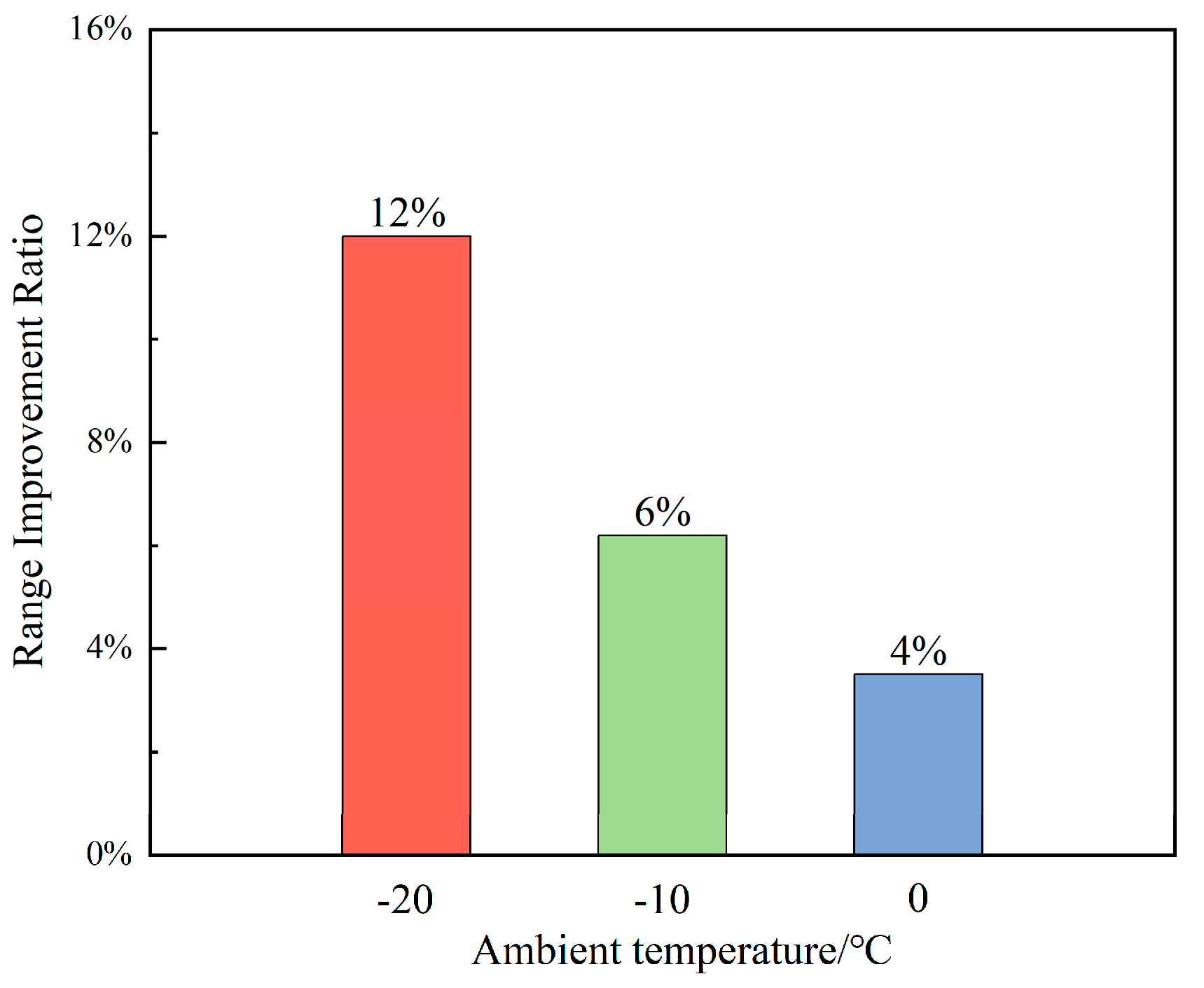

5.4. Route Test

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qiu, K.; Ribberink, H.; Entchev, E. Economic feasibility of electrified highways for heavy-duty electric trucks. Appl. Energy 2022, 326, 119935. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, X.; Liu, Y.; Wu, R.; Shan, X.; Li, S. Contribution of potential clean trucks in carbon peak pathway of road freight based on scenario analysis: A case study of China. J. Clean. Prod. 2022, 379, 134669. [Google Scholar] [CrossRef]

- Khanna, N.; Lu, H.; Fridley, D.; Zhou, N. Near and long-term perspectives on strategies to decarbonize China’s heavy-duty trucks through 2050. Sci. Rep. 2021, 11, 20414. [Google Scholar] [CrossRef] [PubMed]

- Gunawan, T.A.; Monaghan, R.F. Techno-econo-environmental comparisons of zero- and low-emission heavy-duty trucks. Appl. Energy 2022, 308, 118327. [Google Scholar] [CrossRef]

- Li, Y.; Zhu, F.; Li, L.; Ouyang, M. Electrifying heavy-duty truck through battery swapping. Joule 2024, 8, 1556–1561. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, K.; Jow, T. Low-temperature performance of Li-ion cells with a LiBF4-based electrolyte. J. Solid State Electrochem. 2003, 7, 147–151. [Google Scholar] [CrossRef]

- Bhide, S.; Shim, T. Development of improved Li-ion battery model incorporating thermal and rate factor effects. In Proceedings of the 5th IEEE Vehicle Power and Propulsion Conference, VPPC ‘09, Dearborn, MI, USA, 7–10 September 2009; IEEE Computer Society: Washington, DC, USA, 2009; pp. 544–550. [Google Scholar]

- Fan, J.; Tan, S. Studies on Charging Lithium-Ion Cells at Low Temperatures. J. Electrochem. Soc. 2006, 153, A1081–A1092. [Google Scholar] [CrossRef]

- Al-Wreikat, Y.; Serrano, C.; Sodré, J.R. Effects of ambient temperature and trip characteristics on the energy consumption of an electric vehicle. Energy 2022, 238, 122028. [Google Scholar] [CrossRef]

- Zhu, T.; Min, H.; Yu, Y.; Zhao, Z.; Xu, T.; Chen, Y.; Li, X.; Zhang, C. An Optimized Energy Management Strategy for Preheating Vehicle-Mounted Li-ion Batteries at Subzero Temperatures. Energies 2017, 10, 243. [Google Scholar] [CrossRef]

- Jiang, Z.; Qu, Z.; Wang, Q. Experimental and numerical investigation of fast preheating of lithium ion pouch cell via low-power inductive heating in cold climate. Int. J. Heat Mass Transf. 2023, 214, 124381. [Google Scholar] [CrossRef]

- Lei, S.; Xin, S.; Liu, S. Separate and integrated thermal management solutions for electric vehicles: A review. J. Power Sources 2022, 550, 232133. [Google Scholar] [CrossRef]

- Qu, Z.; Jiang, Z.; Wang, Q. Experimental study on pulse self–heating of lithium–ion battery at low temperature. Int. J. Heat Mass Transf. 2019, 135, 696–705. [Google Scholar] [CrossRef]

- Li, J.; Sun, D.; Chai, Z.; Jiang, H.; Sun, C. Sinusoidal alternating current heating strategy and optimization of lithium-ion batteries with a thermo-electric coupled model. Energy 2019, 186, 115798. [Google Scholar] [CrossRef]

- Longchamps, R.S.; Yang, X.-G.; Ge, S.; Liu, T.; Wang, C.-Y. Transforming rate capability through self-heating of energy-dense and next-generation batteries. J. Power Sources 2021, 510, 230416. [Google Scholar] [CrossRef]

- Ruan, H.; Barreras, J.V.; Steinhardt, M.; Jossen, A.; Offer, G.J.; Wu, B. The heating triangle: A quantitative review of self-heating methods for lithium-ion batteries at low temperatures. J. Power Sources 2023, 581, 233484. [Google Scholar] [CrossRef]

- Hu, X.; Zheng, Y.; Howey, D.A.; Perez, H.; Foley, A.; Pecht, M. Battery warm-up methodologies at subzero temperatures for automotive applications: Recent advances and perspectives. Prog. Energy Combust. Sci. 2020, 77, 100806. [Google Scholar] [CrossRef]

- Sun, X.; Xu, X.; Fu, J.; Tang, W.; Yuan, Q. Research on thermal equilibrium performance of liquid-cooled lithium-ion power battery system at low temperature. Therm. Sci. 2020, 24, 4147–4158. [Google Scholar] [CrossRef]

- Zhang, C.; Huang, J.; Sun, W.; Xu, X.; Li, C.; Li, Y. Research on liquid preheating performance for battery thermal management of electric vehicles at low temperature. J. Energy Storage 2022, 55, 105497. [Google Scholar] [CrossRef]

- Min, H.; Zhang, Z.; Sun, W.; Min, Z.; Yu, Y.; Wang, B. A thermal management system control strategy for electric vehicles under low-temperature driving conditions considering battery lifetime. Appl. Therm. Eng. 2020, 181, 115944. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Luo, L.; Fan, Y.; Du, Z. A review on thermal management of lithium-ion batteries for electric vehicles. Energy 2022, 238, 121652. [Google Scholar] [CrossRef]

- Jeffs, J.; Dinh, T.Q.; Widanage, W.D.; McGordon, A.; Picarelli, A. Optimisation of Direct Battery Thermal Management for EVs Operating in Low-Temperature Climates. Energies 2020, 13, 5980. [Google Scholar] [CrossRef]

- Guo, R.; Li, L.; Sun, Z.; Xue, X. An integrated thermal management strategy for cabin and battery heating in range-extended electric vehicles under low-temperature conditions. Appl. Therm. Eng. 2023, 228, 120502. [Google Scholar] [CrossRef]

- Ma, Y.; Ding, H.; Liu, Y.; Gao, J. Battery thermal management of intelligent-connected electric vehicles at low temperature based on NMPC. Energy 2022, 244, 122571. [Google Scholar] [CrossRef]

- He, L.G.; Gu, Z.H.; Zhang, Y.; Jing, H.D.; Li, P.P. Control Strategy Analysis of Vehicle Thermal Management System Based on Motor Heat Utilization. Energy Technol. 2023, 11, 2300495. [Google Scholar] [CrossRef]

- Tian, Z.; Gu, B.; Gao, W.; Zhang, Y. Performance evaluation of an electric vehicle thermal management system with waste heat recovery. Appl. Therm. Eng. 2020, 169, 114976. [Google Scholar] [CrossRef]

- Ding, P.; Gu, X.Y.A.; Wang, Y.; Xi, J.C.; Song, M.Q.; Li, K.Y. Distributed multi-heat-source hybrid heating system based on waste heat recovery for electric vehicles. Appl. Therm. Eng. 2023, 235, 121352. [Google Scholar]

- Shelly, T.J.; Weibel, J.A.; Ziviani, D.; Groll, E.A. Comparative analysis of battery electric vehicle thermal management systems under long-range drive cycles. Appl. Therm. Eng. 2021, 198, 117506. [Google Scholar] [CrossRef]

- Schneider, J.; Teichert, O.; Zähringer, M.; Balke, G.; Lienkamp, M. The novel Megawatt Charging System standard: Impact on battery size and cell requirements for battery-electric long-haul trucks. eTransportation 2023, 17, 100253. [Google Scholar] [CrossRef]

- Babu, A.R.; Andric, J.; Minovski, B.; Sebben, S. System-Level Modeling and Thermal Simulations of Large Battery Packs for Electric Trucks. Energies 2021, 14, 4796. [Google Scholar] [CrossRef]

- Babu, A.R.; Minovski, B.; Sebben, S. Thermal encapsulation of large battery packs for electric vehicles operating in cold climate. Appl. Therm. Eng. 2022, 212, 118548. [Google Scholar] [CrossRef]

- Mohamed, W.; Singh, B.; Mohamed, M.; Aizuwan, A.; Zubair, A. Effects of fuel cell vehicle waste heat temperatures and cruising speeds on the outputs of a thermoelectric generator energy recovery module. Int. J. Hydrogen Energy 2021, 46, 25634–25649. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.; Kim, Y. Heating performance of a coolant-source heat pump using waste heat from stack and electric devices in fuel cell electric vehicles under cold conditions. Energy Convers. Manag. 2022, 252, 115092. [Google Scholar] [CrossRef]

- Hu, D.; Hou, W.; Xiang, C.; Lu, D.; Yang, Q.; Li, J.; Wang, J. Waste heat utilization performance verification of Heat Exchanger Only Thermal Management System for fuel cell vehicle. J. Clean. Prod. 2023, 428, 139479. [Google Scholar] [CrossRef]

- Li, C.; Zhang, H.; Zhang, R.; Lin, Y.; Fang, H. On the characteristics analysis and tab design of an 18650 type cylindrical LiFePO4 battery. Appl. Therm. Eng. 2021, 182, 116144. [Google Scholar] [CrossRef]

- Białoń, T.; Niestrój, R.; Skarka, W.; Korski, W. HPPC Test Methodology Using LFP Battery Cell Identification Tests as an Example. Energies 2023, 16, 6239. [Google Scholar] [CrossRef]

- Bernardi, D.; Pawlikowski, E.; Newman, J. A General Energy Balance for Battery Systems. J. Electrochem. Soc. 1985, 132, 5–12. [Google Scholar] [CrossRef]

| Symbol | Parameters | Values |

|---|---|---|

| m | Mass (kg) | 35,000 |

| f | Rolling resistance coefficient | 0.01 |

| Aerodynamic drag coefficient | 0.7 | |

| A | Windward area (m2) | 7.8 |

| R | Wheel rolling radius (mm) | 542.5 |

| i | Gear ratio | 5.286 |

| n | drive efficiency | 0.98 |

| Cell Characteristics | Value |

|---|---|

| Nominal capacity (Ah) | 228 |

| Nominal voltage (V) | 3.22 |

| Cut-off voltage (V) | 2.5~3.65 |

| Size (mm × mm × mm) | 54 × 174 × 205 |

| Specific heat capacity (J·kg·k) | 961 |

| Thermal conductivity (W·m·k) | 3 |

| Number | 2P192S |

| Heating Mode | A | B | C |

|---|---|---|---|

| PTC | √ | √ | |

| MWHR | √ | √ |

| Time Period | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Time | 0~281 s | 281~1010 s | 1010~2618 s | 2616~5446 s |

| PTC | √ | √ | √ | |

| MWHR | √ or × | √ | √ |

| Consume 25% SOC | Consume 50% SOC | Consume 75% SOC | |

|---|---|---|---|

| −20 °C | 8.51% | 7.89% | 6.55% |

| −10 °C | 10.21% | 6.79% | 4.37% |

| 0 °C | 8.85% | 5.85% | 4.49% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Z.; Li, S.; Wang, Y.; Li, L.; Hua, J.; Lu, L.; Li, Y.; Wang, H.; Shang, X.; Li, R. Analysis of the Effect of Motor Waste Heat Recovery on the Temperature and Driving Range of Electric Heavy Truck Batteries. Batteries 2024, 10, 328. https://doi.org/10.3390/batteries10090328

Song Z, Li S, Wang Y, Li L, Hua J, Lu L, Li Y, Wang H, Shang X, Li R. Analysis of the Effect of Motor Waste Heat Recovery on the Temperature and Driving Range of Electric Heavy Truck Batteries. Batteries. 2024; 10(9):328. https://doi.org/10.3390/batteries10090328

Chicago/Turabian StyleSong, Zenghai, Shuhao Li, Yan Wang, Liguo Li, Jianfeng Hua, Languang Lu, Yalun Li, Hewu Wang, Xuegang Shang, and Ruiping Li. 2024. "Analysis of the Effect of Motor Waste Heat Recovery on the Temperature and Driving Range of Electric Heavy Truck Batteries" Batteries 10, no. 9: 328. https://doi.org/10.3390/batteries10090328

APA StyleSong, Z., Li, S., Wang, Y., Li, L., Hua, J., Lu, L., Li, Y., Wang, H., Shang, X., & Li, R. (2024). Analysis of the Effect of Motor Waste Heat Recovery on the Temperature and Driving Range of Electric Heavy Truck Batteries. Batteries, 10(9), 328. https://doi.org/10.3390/batteries10090328