Comparative Study on Environmental Impact of Electric Vehicle Batteries from a Regional and Energy Perspective

Abstract

:1. Introduction

2. Methodology

2.1. Definition of Objective and Scope

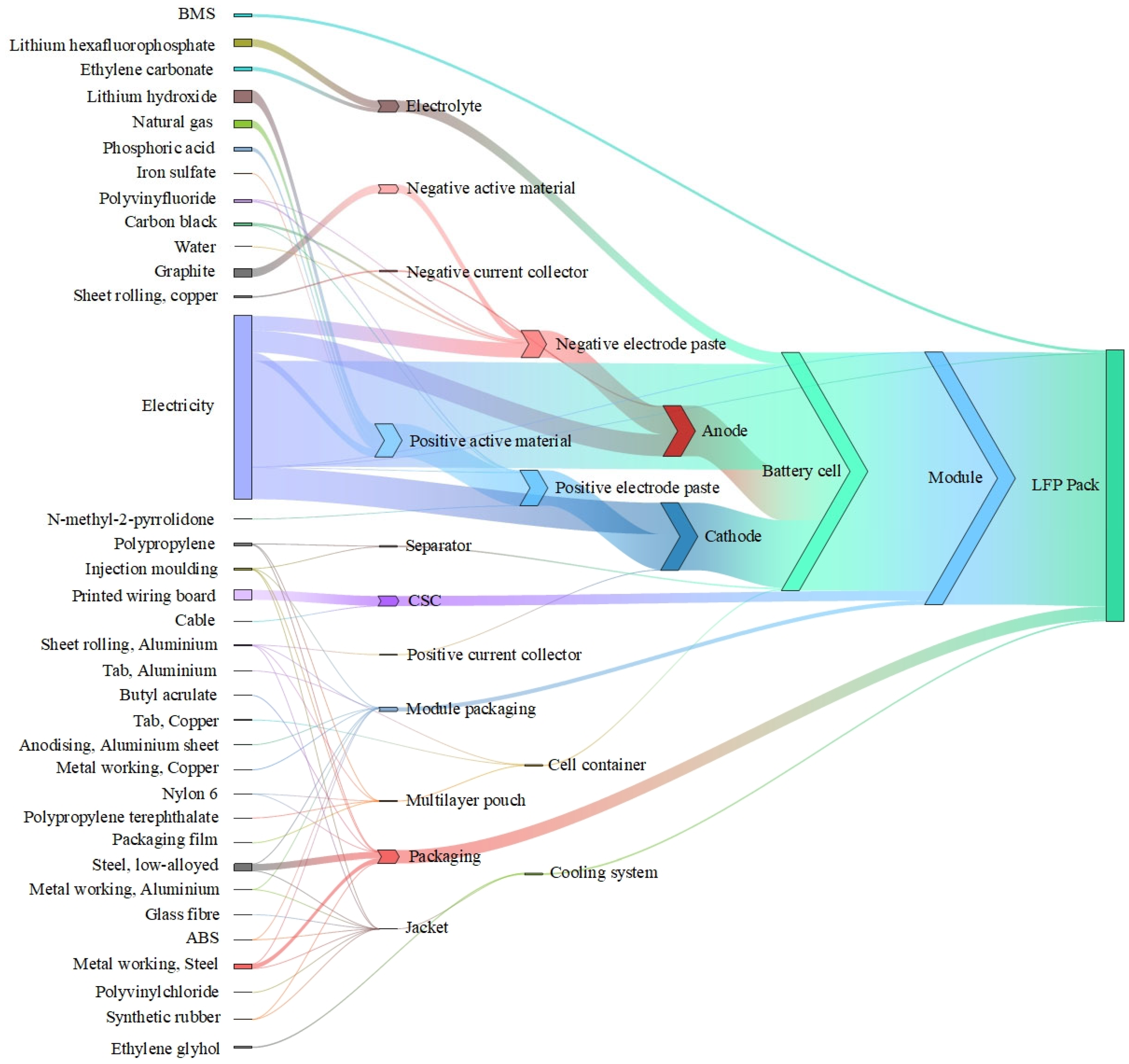

2.2. Life Cycle Inventory Analysis

- (1)

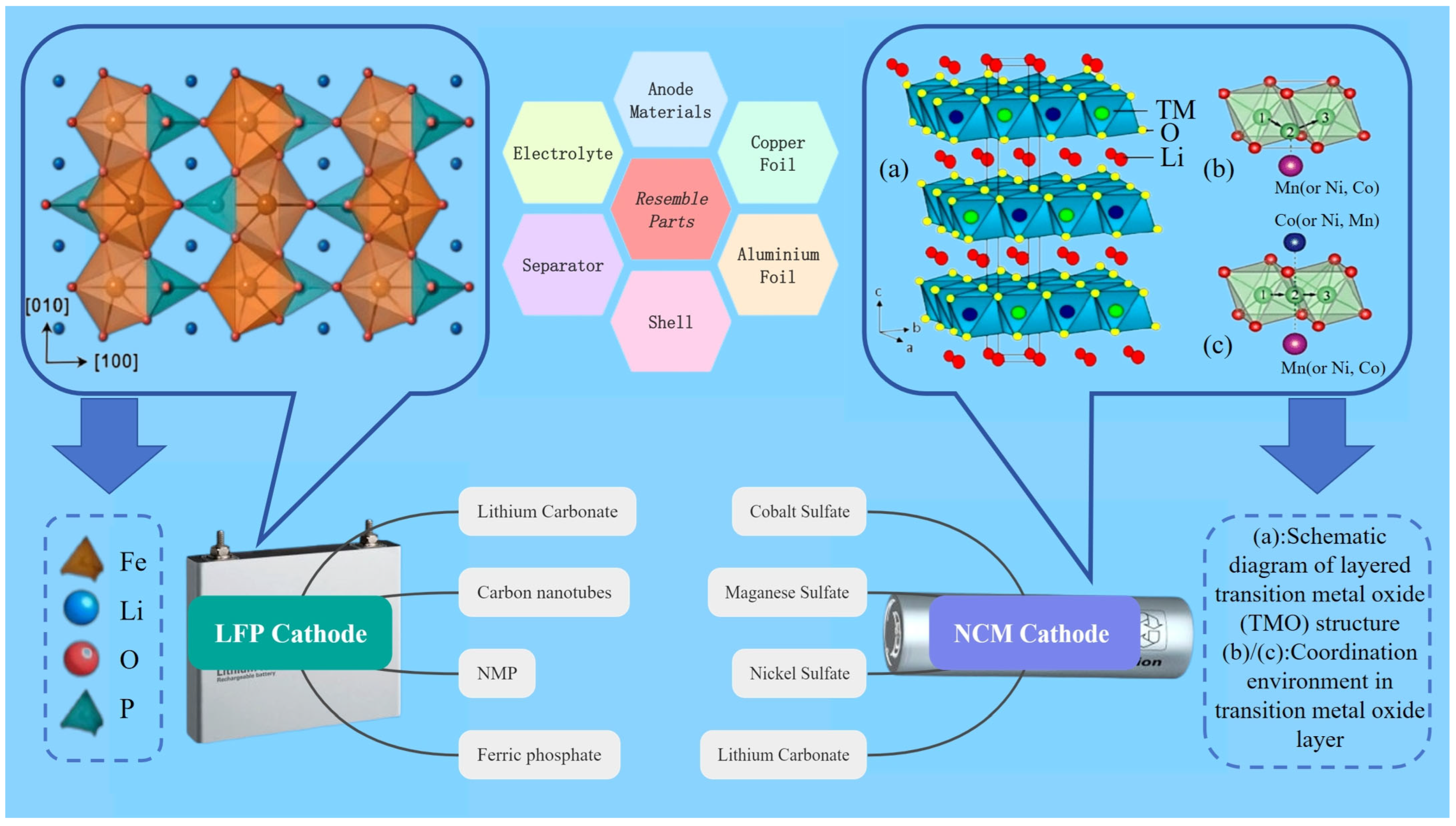

- Raw material acquisition and battery assembly production process: constructing LCA models for LFP and NCM power batteries.

- (2)

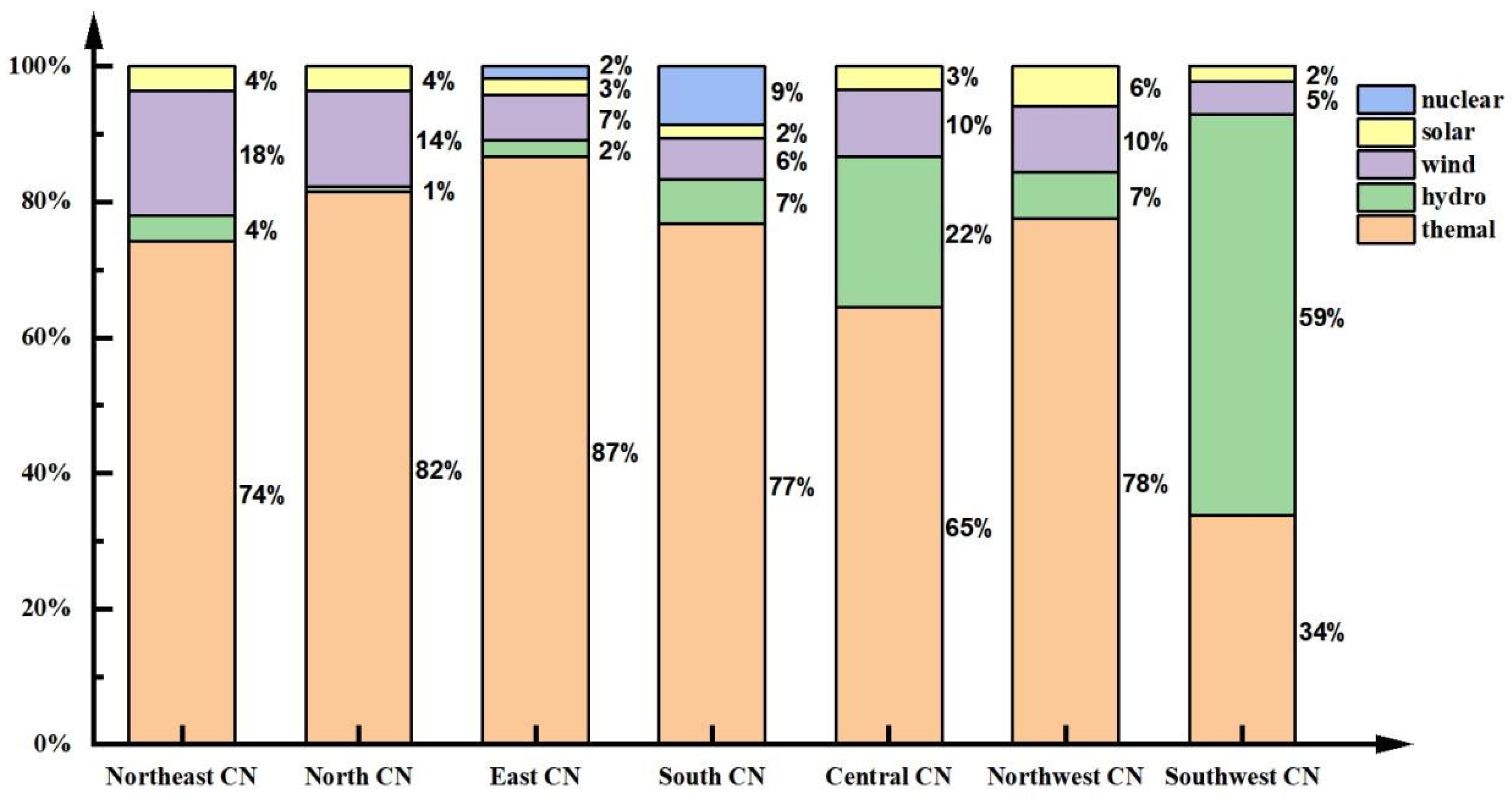

- The production process of power batteries: integration and impact analysis of diverse power generation sources (thermal, hydro, wind, and solar) regarding resource utilization and environmental impacts.

- (3)

- Regional power analysis in China: We substitute the power generation infrastructure of individual regions into the production framework of power batteries and evaluate its implications for resource utilization and environmental impact.

Power Cell Production

2.3. Life Cycle Impact and Sustainability Evaluation

3. Results and Discussion

3.1. Carbon Footprint Results

3.2. Energy Analysis

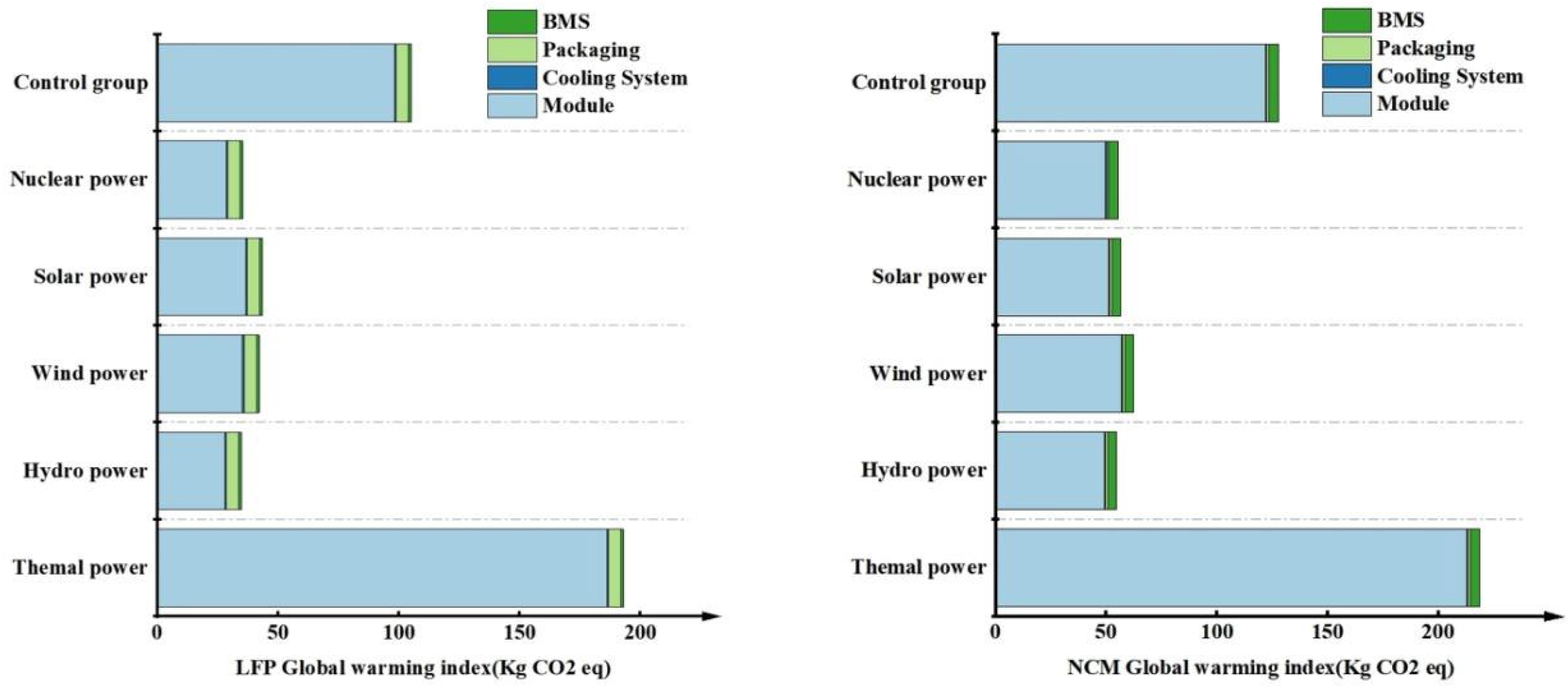

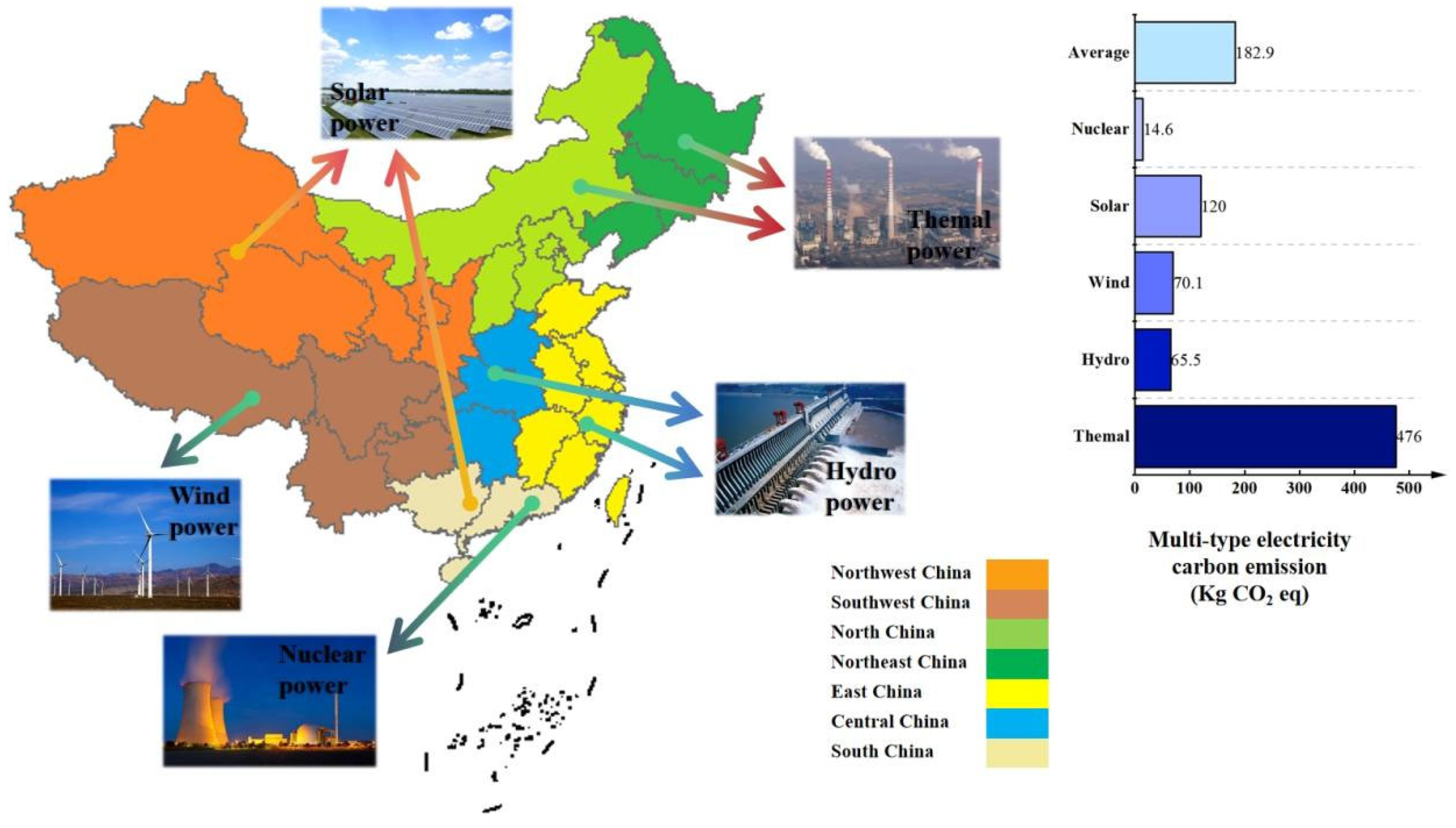

3.2.1. Carbon Emission Analysis

- (1)

- Effect of battery type on global warming potential:

- (2)

- The effect of energy type on global warming potential:

- (3)

- Contribution of each component to global warming potential:

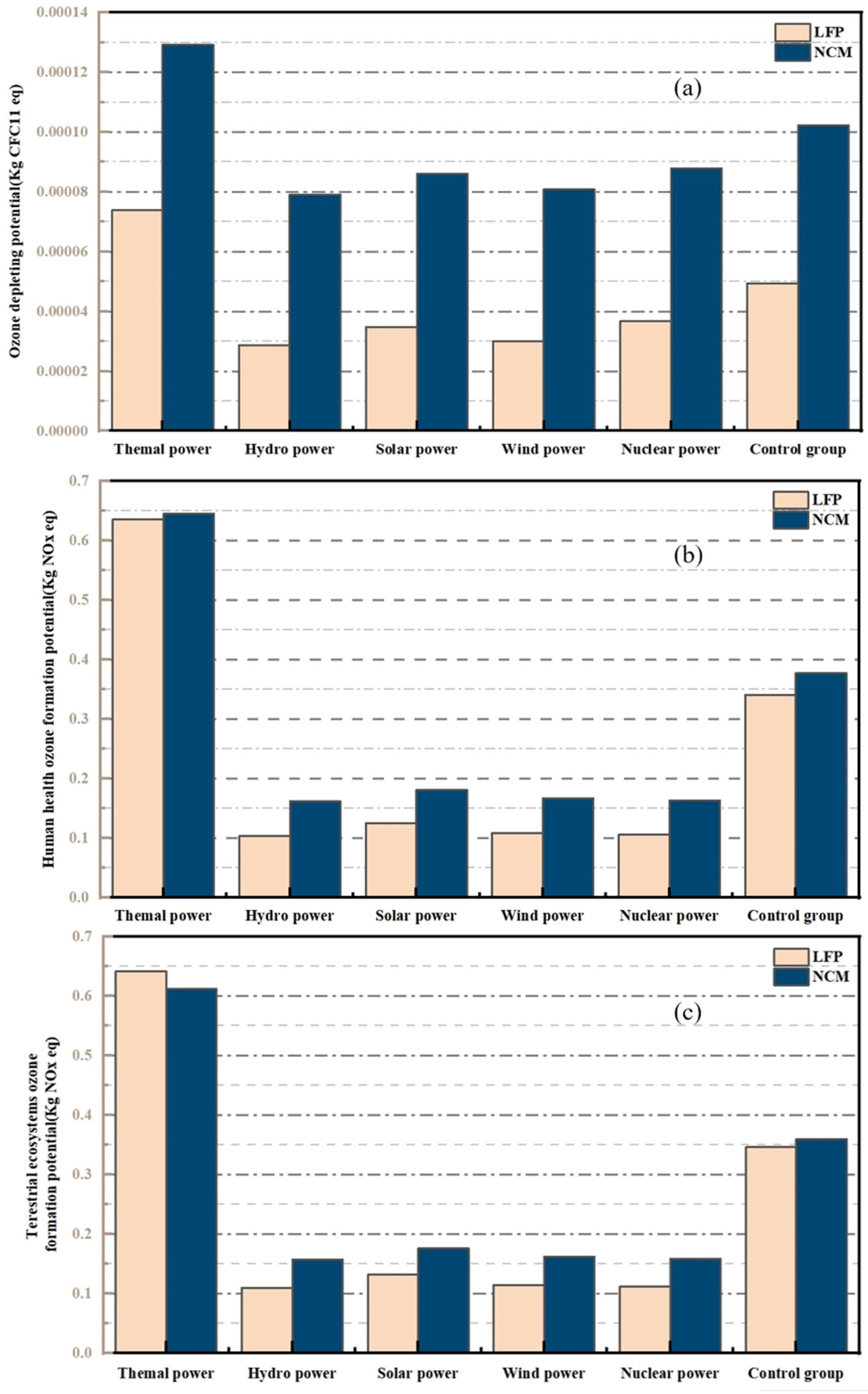

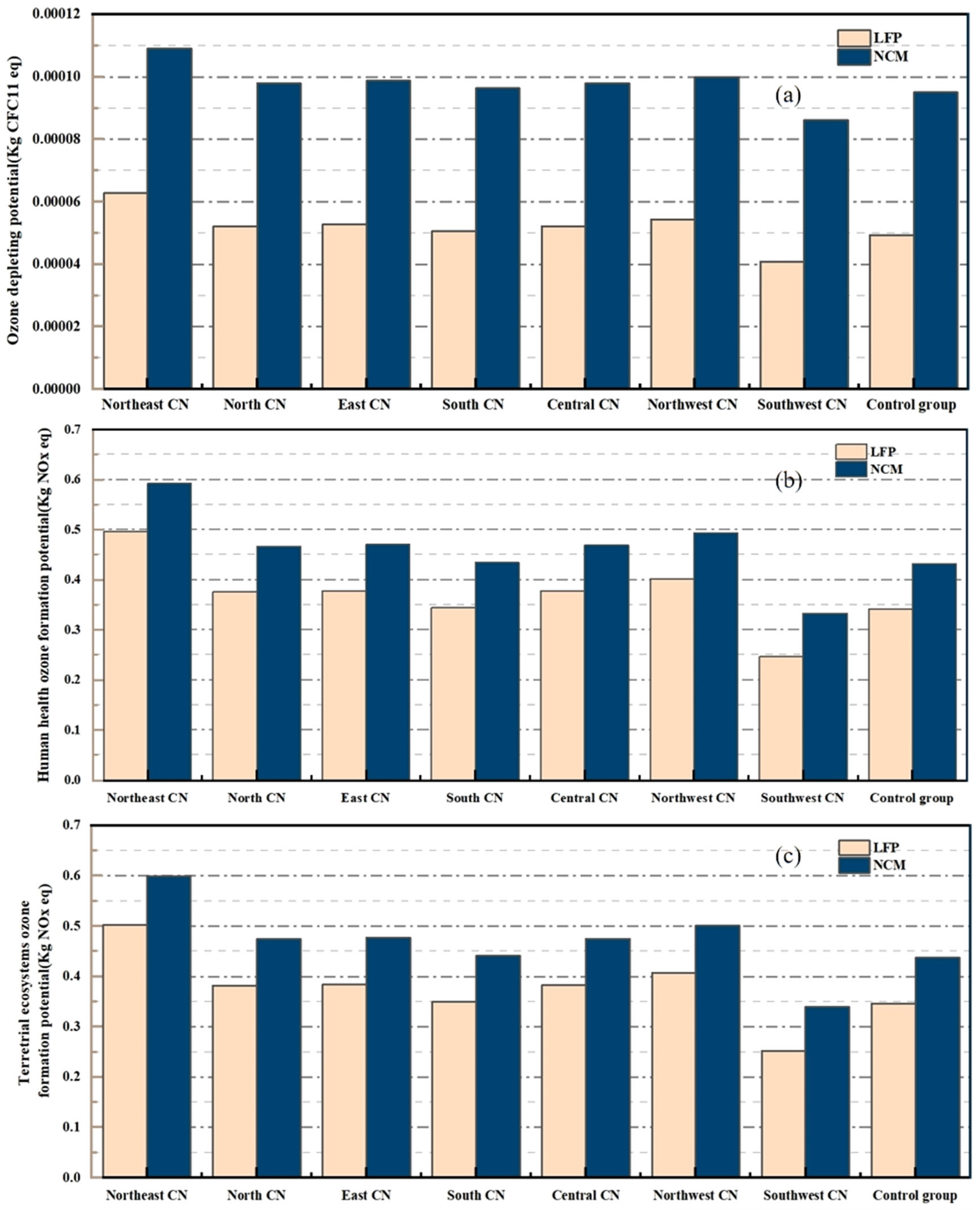

3.2.2. Analysis of Ozone Depletion

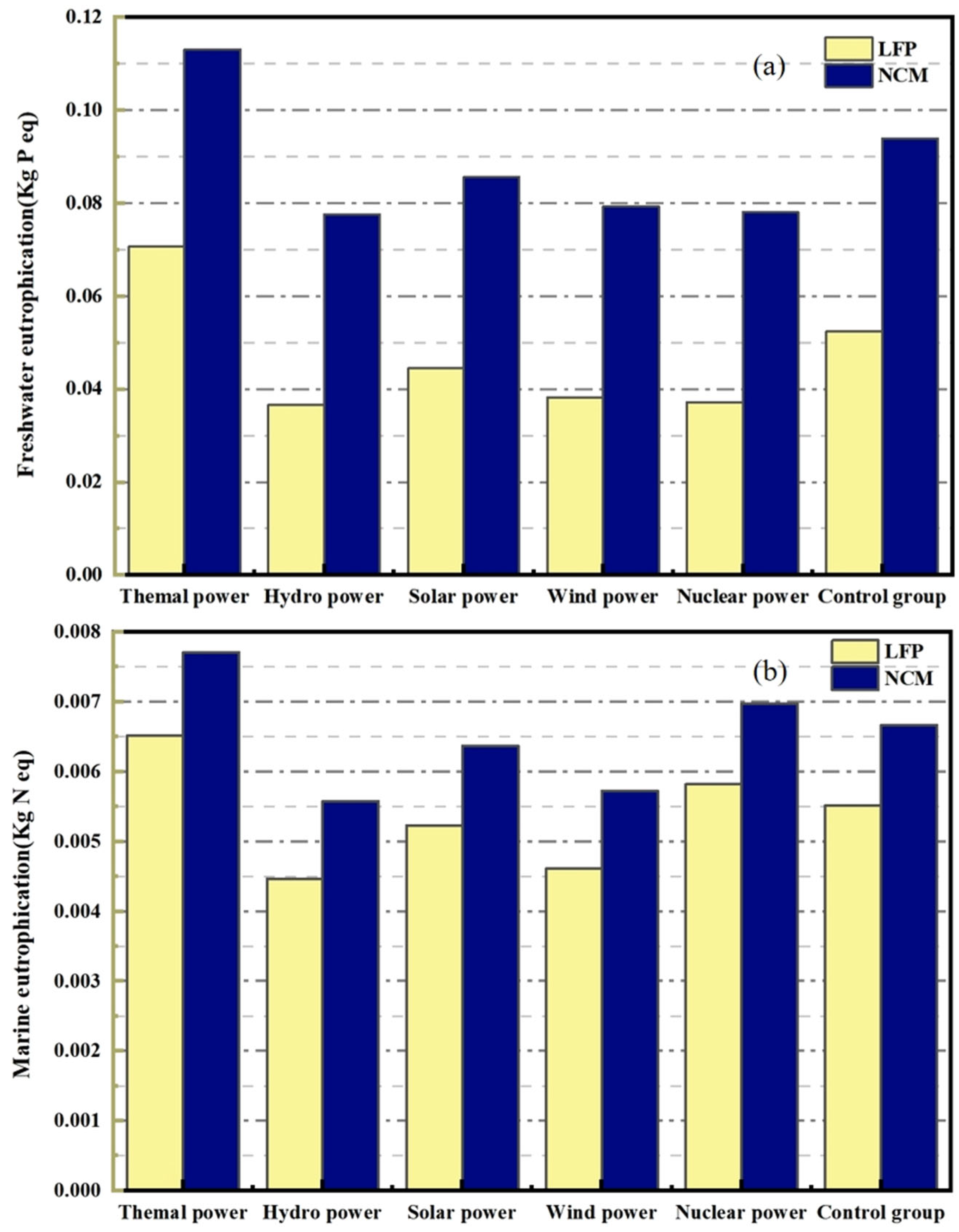

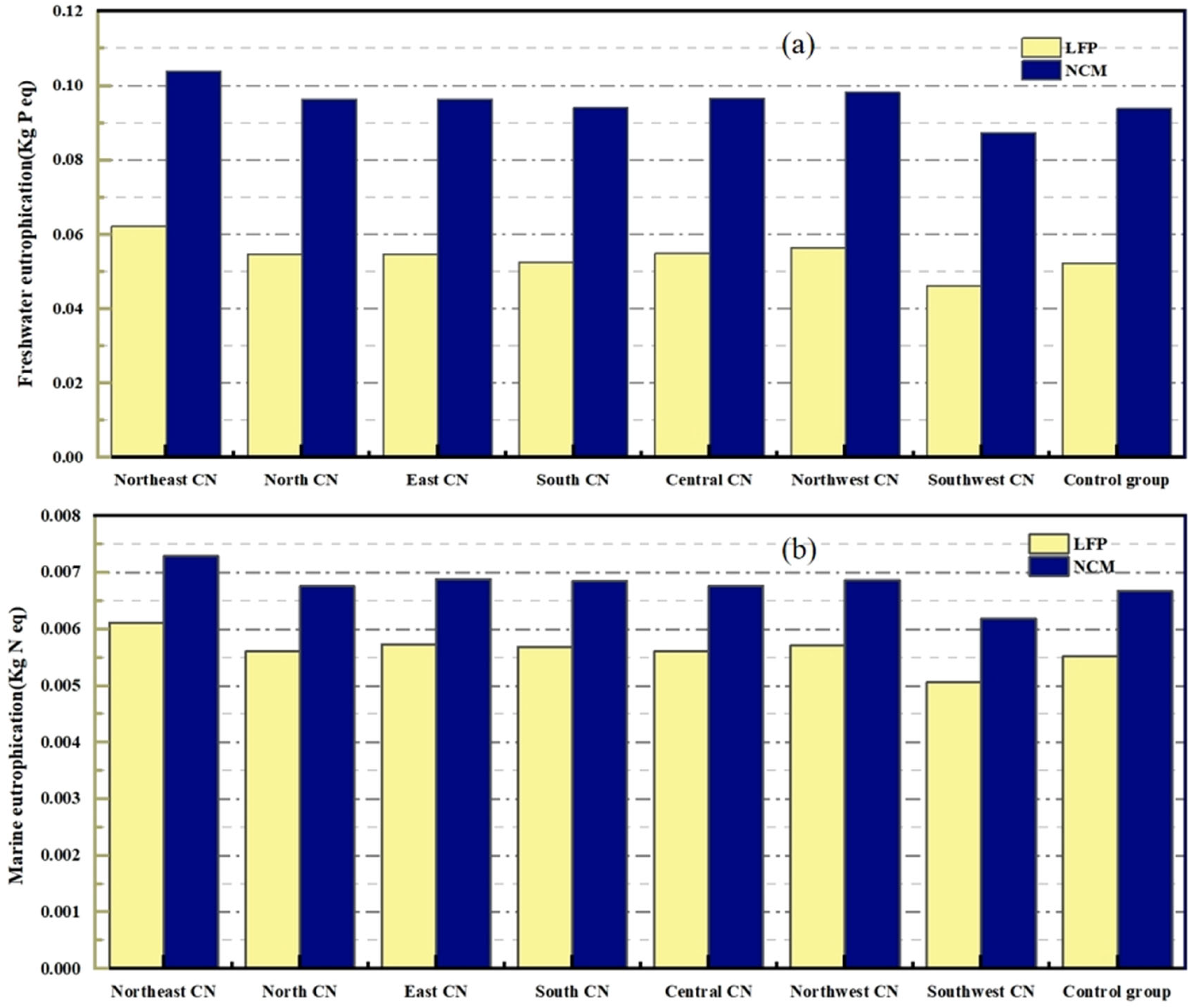

3.2.3. Eutrophication Depletion Analysis

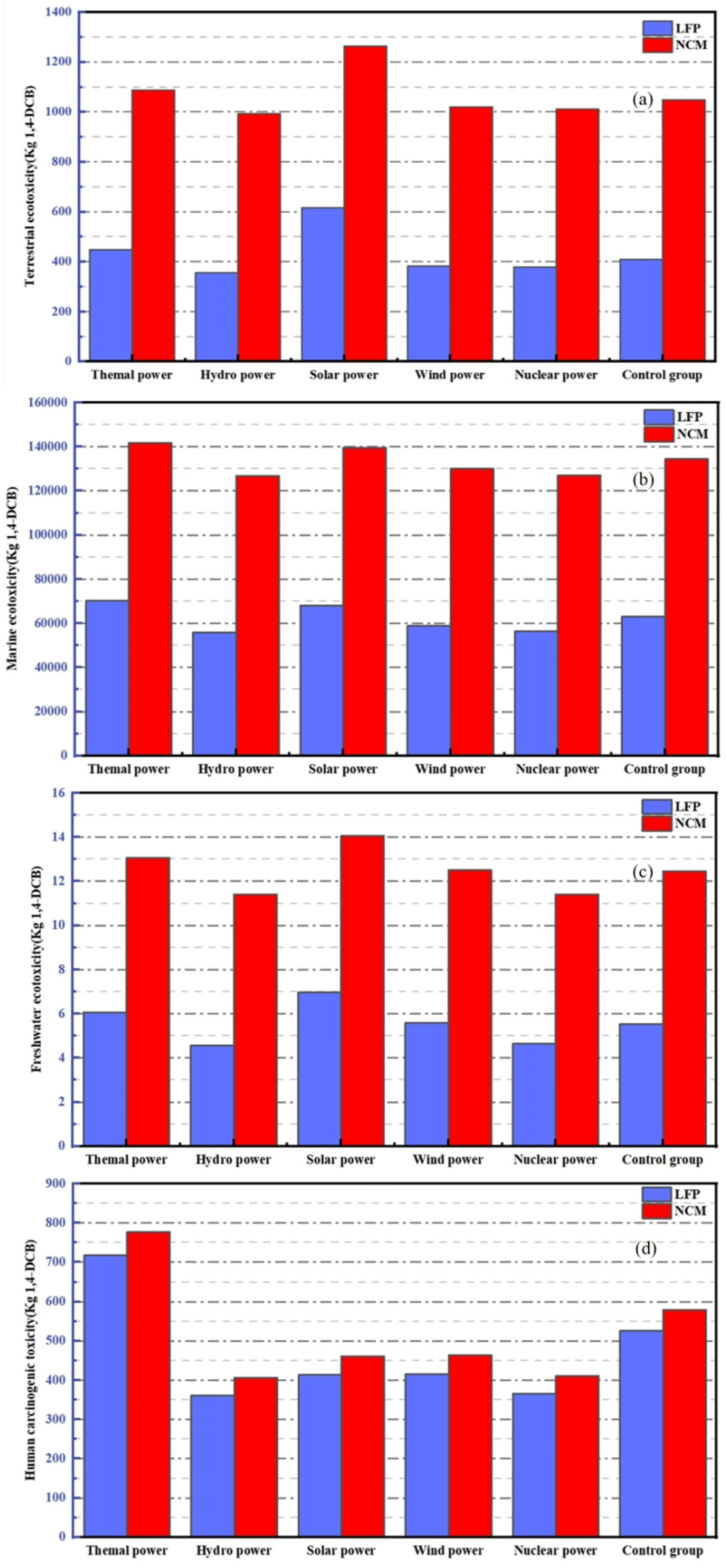

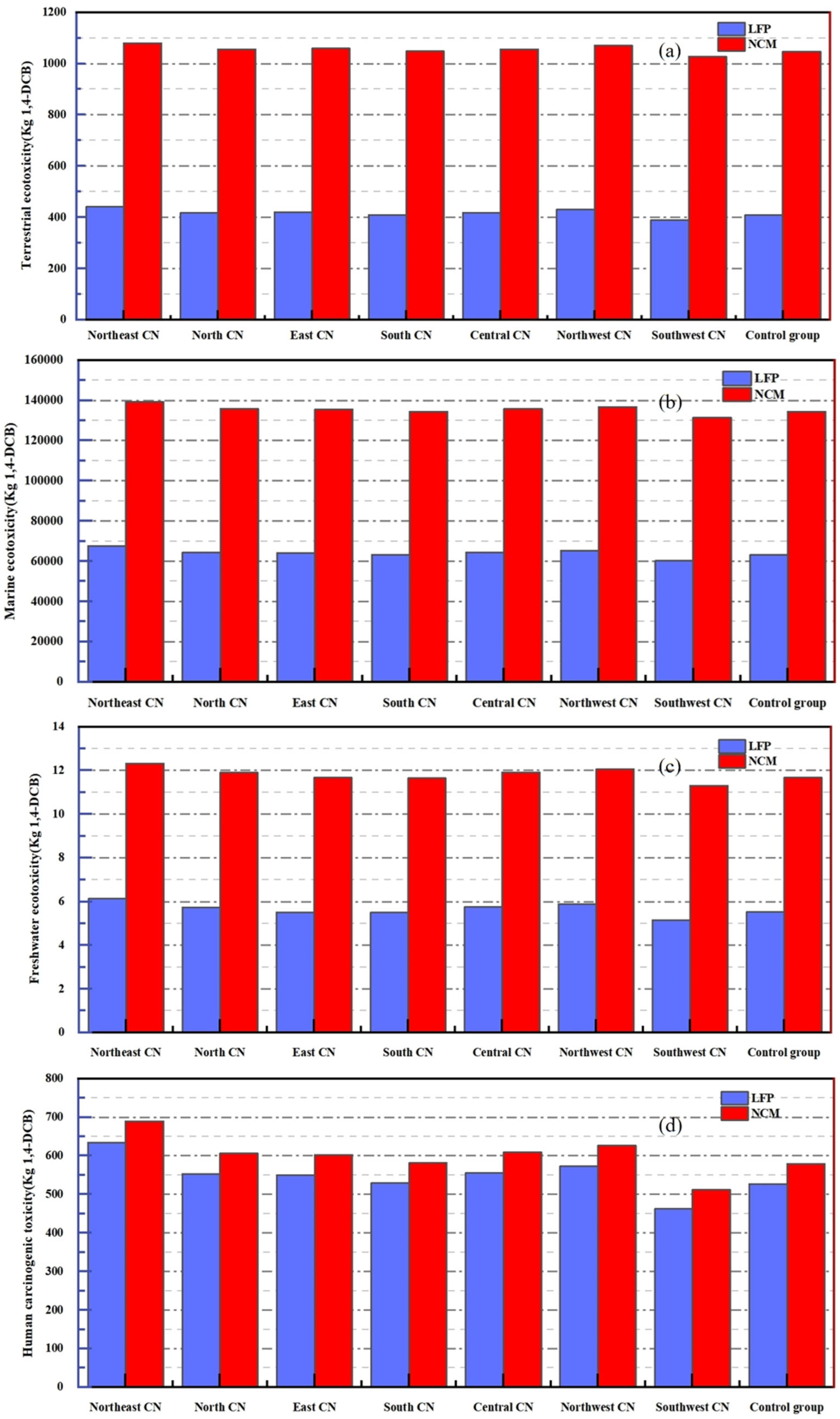

3.2.4. Eco-Toxicity Loss Analysis

3.3. Regional Analyses

3.3.1. Analysis of Carbon Emissions

- (1)

- General trends:

- (2)

- Impact of battery type on regions:

- (3)

- Regional differences:

3.3.2. Ozone Depletion Analysis

3.3.3. Eutrophication Depletion Analysis

3.3.4. Eco-Toxicity Analyses

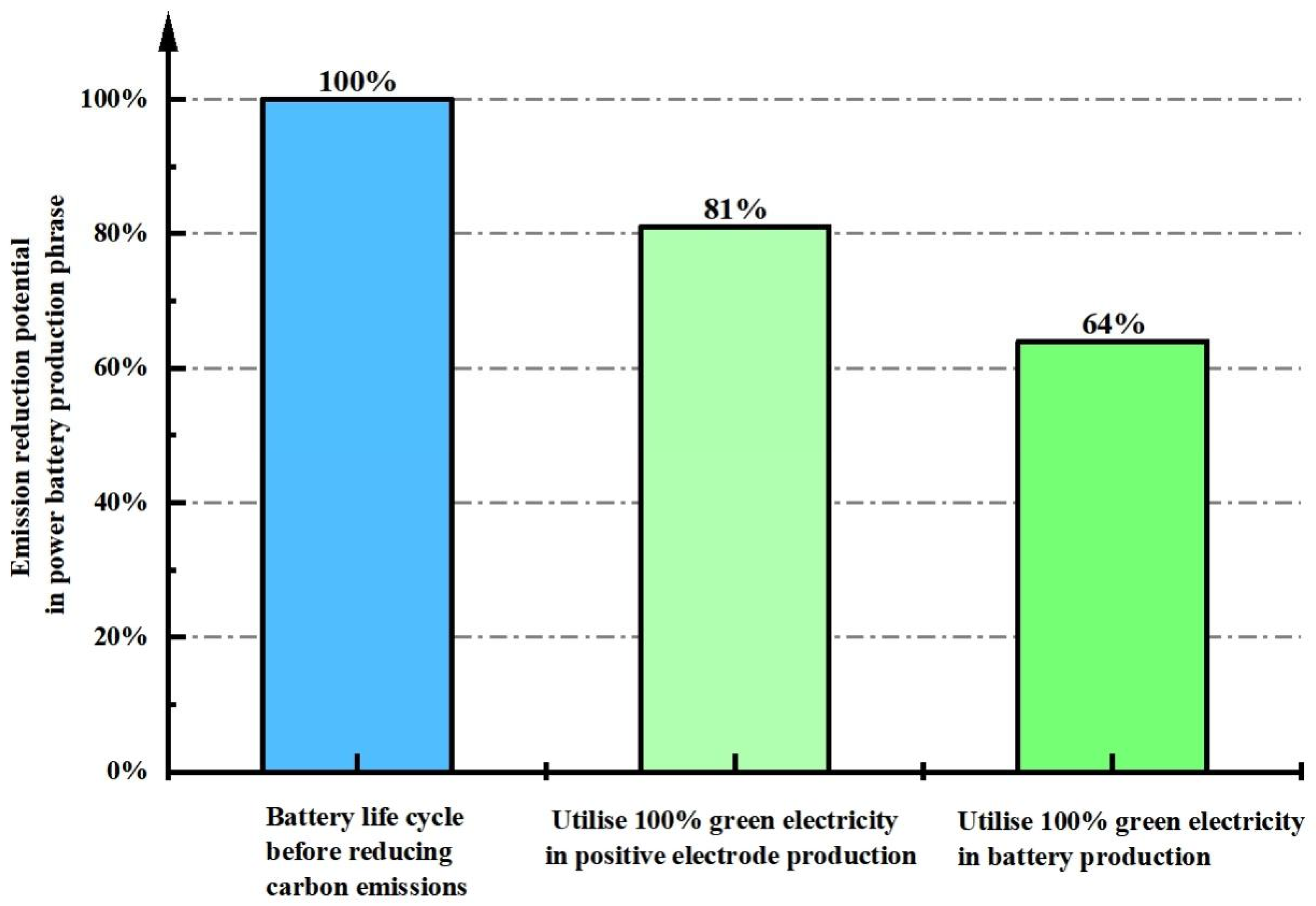

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, X. Thoughts on strategies and paths to achieve carbon peaking and carbon neutrality in China. Front. Energy 2023, 17, 324–331. [Google Scholar] [CrossRef]

- He, B.; Yuan, X.; Qian, S.; Li, B. Carbon Neutrality: A Review. J. Comput. Inf. Sci. Eng. 2023, 23, 060809. [Google Scholar] [CrossRef]

- Liu, M.; Wu, J.; Lang, Z.; Meng, X. Long-term energy-environment-economic programming under carbon neutrality target: A study on China’s regional energy transition pathways and CO2 mitigation strategies. Energy Sources Part B Econ. Plan. Policy 2023, 18, 2229321. [Google Scholar] [CrossRef]

- Liu, X. The impact of China’s high-quality development of energy on carbon neutrality. Energy Rep. 2023, 9, 2665–2675. [Google Scholar] [CrossRef]

- Zhan, J.; Wang, C.; Wang, H.; Zhang, F.; Li, Z. Pathways to achieve carbon emission peak and carbon neutrality by 2060: A case study in the Beijing-Tianjin-Hebei region, China. Renew. Sustain. Energy Rev. 2024, 189, 113955. [Google Scholar] [CrossRef]

- Dai, F.; Kahrl, F.; Gordon, J.A.; Perron, J.; Chen, Z.; Liu, Z.; Yu, Y.; Zhu, B.; Xie, Y.; Yuan, Y.; et al. US-China coordination on carbon neutrality: An analytical framework. Clim. Policy 2023, 23, 929–943. [Google Scholar] [CrossRef]

- Morris, J.; Chen, Y.H.H.; Gurgel, A.; Reilly, J.; Sokolov, A. Net Zero Emissions of Greenhouse Gases by 2050: Achievable and at What Cost? Clim. Chang. Econ. 2023, 14, 2340002. [Google Scholar] [CrossRef]

- Tang, W.; Mai, L.; Li, M. Green innovation and resource efficiency to meet net-zero emission. Resour. Policy 2023, 86, 104231. [Google Scholar] [CrossRef]

- Zickfeld, K.; Macisaac, A.J.; Canadell, J.G.; Fuss, S.; Jackson, R.B.; Jones, C.D.; Lohila, A.; Matthews, H.D.; Peters, G.P.; Rogelj, J.; et al. Net-zero approaches must consider Earth system impacts to achieve climate goals. Nat. Clim. Chang. 2023, 13, 1298–1305. [Google Scholar] [CrossRef]

- Arvidsson, R.; Svanstrom, M.; Sanden, B.A.; Thonemann, N.; Steubing, B.; Cucurachi, S. Terminology for future-oriented life cycle assessment: Review and recommendations. Int. J. Life Cycle Assess. 2024, 29, 607–613. [Google Scholar] [CrossRef]

- Guo, W.; Feng, T.; Li, W.; Hua, L.; Meng, Z.H.; Li, K. Comparative life cycle assessment of sodium-ion and lithium iron phosphate batteries in the context of carbon neutrality. J. Energy Storage 2023, 32, 885–889. [Google Scholar] [CrossRef]

- Peters, J.F. Best practices for life cycle assessment of batteries. Nat. Sustain. 2023, 6, 614–616. [Google Scholar] [CrossRef]

- Bulut, M.; Özcan, E. How to build a state-of-the-art battery energy storage market? Challenges, opportunities, and future directions. J. Energy Storage 2024, 86, 111174. [Google Scholar] [CrossRef]

- Parsons, D. The environmental impact of disposable versus re-chargeable batteries for consumer use. Int. J. Life Cycle Assess. 2007, 12, 197–203. [Google Scholar] [CrossRef]

- Picatoste, A.; Justel, D.; Mendoza, J.M.F. Circularity and life cycle environmental impact assessment of batteries for electric vehicles: Industrial challenges, best practices and research guidelines. Renew. Sustain. Energy Rev. 2022, 169, 112941. [Google Scholar] [CrossRef]

- Simaitis, J.; Allen, S.; Vagg, C. Are future recycling benefits misleading? Prospective life cycle assessment of lithium-ion batteries. J. Ind. Ecol. 2023, 27, 1291–1303. [Google Scholar] [CrossRef]

- Feng, T.; Guo, W.; Li, Q.; Meng, Z.H.; Liang, W.C. Life cycle assessment of lithium nickel cobalt manganese oxide batteries and lithium iron phosphate batteries for electric vehicles in China. J. Energy Storage 2022, 52, 104767. [Google Scholar] [CrossRef]

- Tang, W.; Xu, S.; Zhou, X.; Yang, K.; Wang, Y.; Qin, J.; Wang, H.; Li, X. Meeting China’s electricity demand with renewable energy over Tibetan Plateau. Sci. Bull. 2023, 68, 39–42. [Google Scholar] [CrossRef]

- Xiang, M.-Y.; Wang, S.; Lu, L.-H.; Zhang, N.; Bai, Z.-H. Synergistic Paths of Reduced Pollution and Carbon Emissions Based on Different Power Demands in China. Huan Jing Ke Xue = Huanjing Kexue 2023, 44, 3637–3648, (In Chinese with English Abstract). [Google Scholar] [CrossRef]

- Zhu, G.; Huan, H.; Yu, D.; Guo, X.; Tian, Q. Selective Recovery of Lithium from Spent Lithium-Ion Batteries. Prog. Chem. 2023, 35, 287–301. [Google Scholar] [CrossRef]

- Jin, S.; Mu, D.Y.; Lu, Z.; Li, R.H.; Liu, Z.; Wang, Y.; Tian, S.; Dai, C.S. A comprehensive review on the recycling of spent lithium-ion batteries: Urgent status and technology advances. J. Clean. Prod. 2022, 340, 130535. [Google Scholar] [CrossRef]

- Ma, L.W.; Xi, X.L.; Zhang, Z.Z.; Lyu, Z. Separation and Comprehensive Recovery of Cobalt, Nickel, and Lithium from Spent Power Lithium-Ion Batteries. Minerals 2022, 12, 425. [Google Scholar] [CrossRef]

- de Biasi, L.; Schwarz, B.; Brezesinski, T.; Hartmann, P.; Janek, J.; Ehrenberg, H. Chemical, Structural, and Electronic Aspects of Formation and Degradation Behaviour on Different Length Scales of Ni-Rich NCM and Li-Rich HE-NCM Cathode Materials in Li-Ion Batteries. Adv. Mater. 2019, 31, 1900985. [Google Scholar] [CrossRef] [PubMed]

- Ellis, B.L.; Lee, K.T.; Nazar, L.F. Positive Electrode Materials for Li-Ion and Li-Batteries. Chem. Mater. 2010, 22, 691–714. [Google Scholar] [CrossRef]

- Ellis, B.L.; Nazar, L.F. Reply to Comment on “Positive Electrode Materials for Li-Ion and Li-Batteries”. Chem. Mater. 2012, 24, 2244–2245. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.B.H.; Christiansen, K.; Klüppel, H.J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Klöpffer, W. The critical review of life cycle assessment studies according to ISO 14040 and 14044. Int. J. Life Cycle Assess. 2012, 17, 1087–1093. [Google Scholar] [CrossRef]

- Pryshlakivsky, J.; Searcy, C. Fifteen years of ISO 14040: A review. J. Clean. Prod. 2013, 57, 115–123. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A harmonised life cycle impact assessment method at midpoint and endpoint level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Dekker, E.; Zijp, M.C.; van de Kamp, M.E.; Temme, E.H.M.; van Zelm, R. A taste of the new ReCiPe for life cycle assessment: Consequences of the updated impact assessment method on food product LCAs. Int. J. Life Cycle Assess. 2020, 25, 2315–2324. [Google Scholar] [CrossRef]

| Year | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 | |

| EVs | Product | 7.85 | 34.05 | 51.6 | 79.4 | 127.2 | 124.2 | 136.6 |

| Sale | 7.48 | 33.11 | 60.7 | 77.7 | 125.6 | 120.6 | 136.7 | |

| Market share | 0.3% | 1.35% | 1.81% | 2.69% | 4.47% | 4.68% | 5.40% | |

| Year | 2021 | 2022 | 2023 | 2024 | 2025 | 2030 | 2035 | |

| Product | 354.5 | 705.8 | 958.7 | 1200 | 1400 | 3300 | 4000 | |

| Sale | 352.1 | 688.7 | 949.5 | 1150 | 1360 | 3200 | 3800 | |

| Market share | 13.4% | 25.6% | 31.6% | 45.0% | 50% | 70% | 90% |

| Methods | Numerical Value/(g/(kW-h)) | Average Value/(g/(kW-h)) | |

|---|---|---|---|

| Thermal power | Coal | 838.6, 810.0, 973.4 | 874.0 |

| Gas | 522.4, 420.0, 392.0 | 444.8 | |

| Oil | 710.0 | 710.0 | |

| Hydro power | 3.3, 12.8, 3.5, 25.8, 18.5, 22.2 | 15.1 | |

| Wind power | 28.6, 17.8, 31.4, 2.7 | 20.1 | |

| Solar power | 92.0, 119.4, 28.8, 50.0 | 72.5 | |

| Nuclear power | 13.4, 10, 20, 15 | 14.6 | |

| Parameter Name | Notation | Unit |

|---|---|---|

| Theoretical (gram) capacity | Ctheoretical | mAh/g |

| Actual (gram) capacity | Cactual | mAh/g |

| Faraday’s constant | F | C/mol |

| Molecular weight | M | g/mol |

| Lithium quantity | nLi | mol |

| Li-ion removal coefficient | µLi | Dimensionless,less than one |

| Battery design capacity | Qdesign | mAh |

| Coating layer density | Γcoating | g/m2 |

| Proportion of active substance | Pactive | Dimensionless,less than one |

| Gram capacity of active substance | Cactive | mAh/g |

| Electrode coating area | A | m2 |

| N/P ratio | RN/P | Dimensionless,less than one |

| Gram capacity of negative active substance | Cnegative | mAh/g |

| Density of negative surface | Γnegative | g/m2 |

| Content ratio of negative active substance | Pnegative | Dimensionless,less than one |

| Gram capacity of positive active substance | Cpositive | mAh/g |

| Density of positive surface | Γpositive | g/m2 |

| Content ratio of positive active substance | Ppositive | Dimensionless,less than one |

| Battery mass energy density | Γmass | Wh/kg |

| Battery volumetric energy density | Γvolume | Wh/L |

| Battery capacity | Q | mAh |

| Battery mass | m | kg |

| Battery volume | V | L |

| Battery voltage | U | V |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, R.; Guo, W.; Zhang, C.; Nie, Y.; Li, J. Comparative Study on Environmental Impact of Electric Vehicle Batteries from a Regional and Energy Perspective. Batteries 2025, 11, 23. https://doi.org/10.3390/batteries11010023

Feng R, Guo W, Zhang C, Nie Y, Li J. Comparative Study on Environmental Impact of Electric Vehicle Batteries from a Regional and Energy Perspective. Batteries. 2025; 11(1):23. https://doi.org/10.3390/batteries11010023

Chicago/Turabian StyleFeng, Ruiqi, Wei Guo, Chenjie Zhang, Yuxuan Nie, and Jiajing Li. 2025. "Comparative Study on Environmental Impact of Electric Vehicle Batteries from a Regional and Energy Perspective" Batteries 11, no. 1: 23. https://doi.org/10.3390/batteries11010023

APA StyleFeng, R., Guo, W., Zhang, C., Nie, Y., & Li, J. (2025). Comparative Study on Environmental Impact of Electric Vehicle Batteries from a Regional and Energy Perspective. Batteries, 11(1), 23. https://doi.org/10.3390/batteries11010023