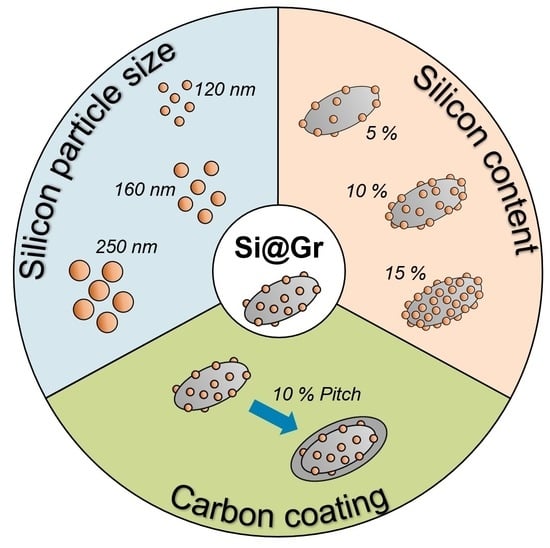

3.1. Material Properties of Si@Gr and Si@Gr/C Composites and Electrodes

In order to understand the electrochemical performance, it is critical to characterize both the electrode structure and the particulate properties of the composites. These include, in particular, the particle size distribution, the chemical composition, the specific surface area and the electrode porosity.

The particle size distribution of the pristine Gr (0 wt.% Si) and Si@Gr composites with three different Si contents of 0, 5, 10 and 15 wt.% is given in

Figure 1a. Pristine Gr exhibits a sharp distribution with a median particle size of x

50,3 = 18.1 µm and no particle fraction <5 µm or >40 µm. In contrast to this, the particle size distribution broadens with increasing Si content and a particle size fraction below 1 µm arises. The increase in particle size is related to the agglomeration of Gr and Si particles with increasing process time. The appearance of particles <1 µm, however, is caused by the instability of the Si@Gr composites and the detachment of Si NPs from the Gr surface. With increasing Si content, this particle size fraction increases significantly, indicating that increasingly more silicon is not firmly attached to the Gr surface.

As it is difficult to evaluate the composite stability during slurry production, especially because the particle size of carbon black is similar to that of the Si NPs, the stability was measured indirectly by applying 30 and 60 s of ultrasonic stress to the samples during particle size measurement. Even though this is not directly comparable to the actual shear stress during dispersing, it can give a first impression of the stability. As expected, the ultrasonic treatment results in an even more pronounced detachment of Si NPs and indicates that the initial aimed structure might not be maintained during electrode production. In

Figure 1b the particle size fraction < 1 µm (free Si NPs) is plotted as a function of the silicon content for three ultrasonic stressing times (0, 30, 60 s). With increasing Si content, the amount of detached, i.e., free, Si NPs increases linearly. However, the values for 5 wt.% Si are smaller than expected and do not fit in the linear trend. This might be related to the possibility that a certain amount of Si can firmly attach to the Gr surface. If more Si NPs are added, these may only be loosely or not attached to the Gr surface. It is noteworthy that an improvement in composite stability after carbon coating was already demonstrated in our previous publication [

24].

Within the fluidized bed process, some of the Si suspension sticks to the walls, filters and sieve plate, so the real Si content of the composites might differ from the theoretically calculated value. Therefore, thermogravimetric analysis (TGA) is used to determine the real silicon content and the results for Si@Gr composites with varying Si content are given in

Figure 1c. During the measurement, the sample is heated under oxygen atmosphere, which leads to the complete decomposition of Gr (0 wt.% Si) above 800 °C. The Si containing Si@Gr composites, however, show a local minimum followed by a mass increase and a plateau at 1100 °C. This mass increase is related to the formation of SiO

2 at higher temperatures. Based on the final values of 10.39, 19.63 and 28.75 wt.% and taking into account the molecular weight ratio of Si and SiO

2, the overall Si content for 5, 10 and 15 wt.% Si can be calculated to 4.85, 9.16 and 13.42 wt.% Si, respectively. All values are slightly lower than the theoretical values. To simplify the following results, only the theoretical values of 5, 10 and 15 wt.% are used.

The results of TGA for the Si@Gr composites with varying Si particle size and Si@Gr/C composites with carbon coating are given in

Figure S2. It can be seen that the variation in particle size has only minor influence on the results. In contrast to this, the existence of a carbon coating for Si@Gr/C composites is clearly evident, as an additional weight loss starting at around 500 °C occurs, which we attribute to the oxidation of the carbon coating. Apart from that, the curve is similar in shape to the others.

The specific surface area (SSA) is an important parameter for anode materials as it is related to the initial capacity loss. Besides that, it is also linked to the capacity loss during cycling, in particular, for Si anodes. Therefore, the SSA of Si@Gr composites as a function of Si content and Si particle size is given in

Figure 2. At a constant Si particle size of 120 nm, the SSA as a function of the Si content shows a linear correlation (

Figure 2a), it changes from 2.89 m

2 g

−1 for pristine Gr to 6.76, 10.06 and 13.10 m

2 g

−1 for 5, 10 and 15 wt.% Si, respectively.

In

Figure 2b, the SSA is plotted against the Si particle size at a constant Si content of 10 wt.%. It can be seen that a decrease in Si particle size results in an exponential increase in the SSA. This behavior counteracts the improved electrochemical performance caused by the decrease in absolute volume expansion with decreasing particle size. A larger SSA may lead to more side reactions as it is linked to the SEI growth, which is continuously taking place in unstructured Si anodes.

As clear trends for the SSA could be observed, it was tried to find a method to describe or even predict the resulting SSA at certain Si contents and Si particle sizes. Therefore, theoretical calculations based on the amount of Si content and Si particle size were conducted. Starting from the total volume of Si particles and the amount of Si particles in the sample, the theoretical SSA for spherical Si particles at certain Si contents and Si particle sizes can be calculated. The results are plotted in blue in

Figure 2a,b. It can be seen that the calculated values always underestimate the measured data, especially at higher Si contents and smaller Si particle sizes. In order to obtain a better correlation, the real shape of the particles needs to be taken into account. As already noticed in previous publications [

28,

38], the ground Si NPs exhibit a platelet shape with larger extent in width than in height. Consequently, a cylindrical shape with a larger diameter than height is used as a basis for the calculation. A diameter to height ratio of 8:1 shows promising results. Within the range of measured data points, the theoretical values are in good agreement with the measured data, particularly for the variation of Si content. However, for the variation of Si particle size an even steeper increase in the measured data is observed. Despite this, the calculated values can still give a good first way to describe the SSA within the measured range. For even smaller Si particles, this model may exhibit too high deviation.

In

Figure 2c, a comparison between the pristine Si@Gr and the carbon coated Si@Gr/C composite particles at a constant Si content of 10 wt.% is given. The positive effect of the pitch derived carbon coating is clearly visible. For composites with 120 nm Si NP size, the SSA is reduced from 10.06 to 3.14 m

2 g

−1, which is close to the value of pure Gr (2.89 m g

−1). As previously determined, a strong dependency of the SSA on the particle size is also apparent here. For a Si particle size of 160 nm, the SSA can be reduced even below the value of pristine Gr (6.43 m

2 g

−1 to 2.24 m

2 g

−1). Therefore, a carbon coating can help to significantly reduce the active surface area and should thus reduce the initial SEI losses.

In addition to the particulate properties, an understanding of the electrode structure can give further insight into the processes during operation. Here, one important factor is the pore size distribution, which is shown in

Figure 3a,b. Two peaks in the pore size distribution can be noted, one from 1–10 µm and one below 1 µm. The peak in the coarser pore size range is related to the active material. With increasing Si content, this peak diminishes and nearly disappears at 15 wt.% Si (

Figure 3a). This behavior is most likely caused by free Si, which has detached and is now filling the pores between the coarser Gr or composite particles. This accumulation of Si within the pores might cause some problems during cycling, as the volume expansion is locally pronounced within this region. The second peak is usually attributed to the pores of carbon black, so no significant change should be observable between pristine Gr and Si@Gr anodes. However, distinct differences between the two materials can be noted. While for Gr a broad peak from 0.1–1 µm is visible, this peak shifts towards smaller pore sizes for Si@Gr composites. The Si NPs are in the same particle size range and are likely the reason for this. As this peak is reproducible for all Si contents, this might relate to the fixed silicon on the surface of the Gr particles. For the variation of Si particle size (

Figure 3b), only a slight shift to coarser pore sizes with increasing Si particle size can be recognized.

However, with carbon coating (Si@Gr/C), the active material peak is enlarged and shifts towards coarser pore sizes. This shift is caused by the fact that the particle size increases after carbon coating [

24]. The enlargement of the peak height means that more pores are present in this pore size range. In contrast to the Si@Gr electrode, in which the pores are filled with free Si NPs and the peak height diminishes, the carbon coating can stabilize the composite structure and inhibit the detachment of Si NPs. The hypothesis that the peak in the smaller pore size region might relate to the fixed Si NPs is further underlined by the fact that it almost diminishes after carbon coating. The smallest peak <0.03 µm is only visible after carbon coating and could be related to an inner porosity of the carbon coating or to measuring artefacts.

Another parameter, which relates to the structural properties and can be detected, is the electrical conductivity of electrodes. The results of such measurements are depicted in

Figure 3c,d. As expected, the highest electrical conductivity can be obtained for Gr, while a decline is evident for the Si containing Si@Gr electrodes (

Figure 3c). This can be explained by the lower intrinsic electrical conductivity of Si. Even though the measured values are lower, an electrical limitation is not expected, because the values are still relatively high in relation to the ionic resistances [

41,

42]. However, during operation the low electrical conductivity of Si can locally lead to inhomogeneous or even incomplete delithiation, causing a loss of active lithium, especially in places with locally more Si. For the variation of particle size, no change was expected. However, a decrease in the electrical conductivity with increasing particle size is evident. The reason behind this phenomenon remains unclear to this point and necessitates further investigation. After carbon coating, an increase in the electrical conductivity can be noted, which is in good accordance with the expectations, because the amorphous carbon coating is highly conductive. In conclusion, the measurement of the electrical conductivity of anodes provides an easy way to detect structural differences.

3.2. Electrochemical Performance

The electrochemical measurements were performed in small test cells (PAT cells from EL-Cell GmbH, Hamburg, Germany) with an electrode diameter of 18 mm against an NMC 622 cathode. For all produced anodes, full cells were built and tested in a symmetrical rate capability test up to 2 C without a constant voltage (CV) step. Subsequently, a symmetrical long-term cycling test at 0.5 C with inserted recovery steps at 0.1 C after 50 cycles was carried out. In order to differentiate whether the electrical performance was related to the anodes or the full cell setup with a limited amount of lithium, some half cells were also built. For this, the Si@Gr and Si@Gr/C composites with a Si content of 10 wt.% and a Si particle size of 120 nm were chosen.

The specific discharge capacity (related to the mass of the active material of the anode) of the half cells (with 10 wt.% Si) as a function of the C-rate is shown in

Figure 4a. The Si@Gr and Si@Gr/C anodes reach initial specific capacities of 612.6 and 674.0 mAh g

−1, respectively, which is close to the theoretical capacity of about 600 mAh g

−1. Furthermore, the cells show high initial coulombic efficiencies (ICEs) of 84.1 and 86.0%, respectively. The higher ICE of the carbon coated material could be caused by the reduction in SSA (

Figure 2c). Besides that, the carbon coated Si@Gr/C composite anodes consistently exhibit higher capacities than the uncoated Si@Gr. This may be related to the lithium storage capacity of the pitch coating, which has been discussed in our previous work [

24]. In the further course, both anodes show good rate capability, reaching 448.4 and 508.9 mAh g

−1 at 1 C, which relates to 73.2 and 75.5% of the initial capacity. At a C-rate of 2 C, values of 266.7 (43.5%) and 334.0 mAh g

−1 (50.0%) are obtained. In the subsequent recovery step again at 0.1 C, the specific capacities obtained (606.6 and 681.2 mAh g

−1) reached their initial values. Consequently, no visible aging took place during the rate capability test. The coulombic efficiency shows some fluctuations in the beginning, which is related to the change in the C-rate. Nevertheless, a strong trend towards 100% is evident within the long-term cycling test. With regard to the capacity, the trend of higher capacities of the carbon coated Si@Gr/C is prolonged during the long-term cycling test (

Figure 4b). However, a slightly unsteady cycling behavior is apparent. This behavior might be related to side reactions of the lithium reference electrode, but the exact reason cannot be distinguished from these data. In contrast to this, Si@Gr shows a linear capacity fading in the beginning and only minor fluctuations in the end. The inserted recovery cycles (0.1 C) at cycle 72 and 123 reveal that at low C-rates most of the capacity can be retained. The relative capacities (normalized to the recovery cycles before the long-term cycling test (cycle 17)) are given in

Figure S3. Even after 123 cycles, Si@Gr and Si@Gr/C show a capacity retention of 86.4 and 92.5%, respectively.

In summary, the anodes exhibit excellent cycling behavior in half cell configuration, as they reach high ICEs of >84%, initial capacities near their theoretical values (>600 mAh g−1), good rate capability (about 43–50% of initial capacity at 2 C) and high capacity retention after long-term cycling (up to 92% after 123 cycles). In addition to that, the positive effects of a carbon coating are clearly visible in the cycling data.

In a next step, full cells are built to test the anodes under more practical conditions. Again, rate capability and long-term cycling tests are performed to investigate the differences for a variation in Si content and Si particle size (

Figure 5). As the limiting factor in full cells is the lithium amount of the cathode, in the following the specific discharge capacities refer to the mass of the cathode active material. Since the same cathode is used in all cells, all arising differences can be attributed solely to the anode (at a constant areal capacity of 3 mAh cm

−2 for all compositions). Voltage curves of all built full cells at different cycles (all at 0.1 C) are shown in

Figure S6. For the variation of Si content, which is shown in

Figure 5a,b, the initial specific discharge capacities for 0, 5, 10 and 15 wt.% Si are 162.0, 158.6, 151.1 and 150.8 mAh g

−1, respectively. This means that with increasing Si content the achievable capacity decreases. This can be explained by the irreversible lithium loss in the first cycle. The ICEs follow the same trend with 85.7, 83.5, 82.9 and 80.4% for 0, 5, 10 and 15 wt.% Si, respectively. Lower ICEs mean higher lithium losses within the first charging step and, thus, less free lithium is available within the following discharge step. A linear trend can be found for both the specific discharge capacity and ICE as a function of the SSA (

Figure 2a and

Figure 5c). Within the first cycle, the build-up of the SEI takes place, which consumes lithium and is related to the surface area of the active material. As previously shown, a higher Si content leads to a linear increase in SSA and the same trend can also be found for the ICE and thus the discharge capacities. Hence, the structural properties of the composite particles can be directly related to the electrochemical performance (

Figure 5c).

Within the next cycles, a similar trend is evident, and anodes with higher Si contents show lower capacities. At C-rates of 1 C and 2 C, almost 75% and 50% of the initial capacities can be retained. This is in good accordance with the previous half cell results of 10 wt.% Si in

Figure 4a. At a C-rate of 2 C, the cells with 5 and 10 wt.% Si exhibit higher specific capacities than pure Gr. This finding is in contrast to the previously obtained results and might be caused by the change in electrode height. When the areal capacity is kept constant, as carried out in this study, the mass loading and thus the electrode height decrease with higher Si content (

Table S1). Therefore, a higher Si content relates to lower electrode thicknesses and shorter diffusion lengths for the Li-ions. This effect might not be dominant at low C-rates but gains in significance at high charging rates. Based on this, the achievable capacity for 15 wt.% should theoretically be even higher at higher C-rates, but this is not the case. Anodes with high Si contents suffer from more pronounced aging, as a larger surface area and larger volume expansion can lead to increased lithium consumption and the pores are blocked by free Si NPs. Therefore, the lithium loss within the previous cycles may have prevented a higher rate capability. In the subsequent recovery step (0.1 C), more distinct differences become visible. While the cells with pure Gr anodes show no capacity loss, the cells with 5, 10 and 15 wt.% Si suffer from 5.5, 5.8 and 10.3% capacity loss, respectively.

In long-term cycling, which corresponds to 123 cycles, distinct differences between Gr and Si@Gr cells can be distinguished (

Figure 5b). Gr cells show nearly no capacity loss, so that even after 123 cycles, 96.7% of the initial capacity is still retained. In contrast to this, the Si@Gr cells suffer from severe capacity loss. For 5, 10 and 15 wt.% Si, capacity retentions of 81.7, 76.8 and 65.6% after 71 cycles and 72.9, 64.4 and 56.4% after 123 cycles are reached (

Figure S4a), respectively. This again shows the obstacle in using higher silicon contents as it leads to increased SEI losses, higher volume expansion and thus structural changes in the electrode. The consequence of this is continuous lithium consumption. Compared to half cells, which have a nearly unlimited lithium reservoir, the amount of lithium in full cells is constricted by the amount of lithium stored in the cathode. Hence, in full cells a loss of active lithium is directly related to an overall capacity loss. This is also the reason for the differences to the half cell results in

Figure 4b.

In order to study the impact of Si particle sizes, three different values are selected. As a critical particle size of 150 nm is often stated in the literature, a similar particle size of 160 nm was used as the standard size. Furthermore, one finer (120 nm) and one coarser fraction (250 nm) were also chosen. Based on literature data, distinct differences with better electrochemical performance for smaller Si particle sizes are expected. The initial discharge capacities follow the opposite trend, as values of 151.8, 154.6 and 156.5 mAh g

−1 are reached for 120, 160 and 250 nm. This might again be related to the larger SSA of composites with smaller Si particles (

Figure 2b). However, this effect cannot be seen by the ICEs as the differences show no clear trend but are also within the standard deviation. In the following, only minor differences between the three particle sizes can be distinguished in the rate capability test (

Figure 6a) and long-term cycling test (

Figure 6b). After 123 cycles, capacity retentions of 64.4, 61.3 and 61.1% are reached (

Figure S4b), respectively. This means that, indeed, a small improvement can be obtained for the smallest particle size, but larger differences were expected. As the capacity retention of 160 and 250 nm is nearly the same, the theory of a worsening in performance with increasing particle size cannot be confirmed for the investigated composite structure. Consequently, the particle size of Si might be not as important for anodes comprising mostly Gr with small amounts of Si. When larger Si particle sizes can be used, the grinding time and thus the energy consumption can be significantly reduced. By using only 250 nm instead of 120 nm, the energy consumption can be reduced by almost a factor of 3 (20,000 kJ kg

−1 vs. 58,000 kJ kg

−1,

Figure S1).

Next, the addition of a carbon coating is investigated, which is also shown in

Figure 6. In comparison to the cells with the uncoated Si@Gr composite anode, the Si@Gr/C cells show only slight advantages in the rate capability test. Within the long-term cycling test, the positive impact of the carbon coating becomes clearer, because the capacity fading of Si@Gr/C is not as pronounced as for Si@Gr. Even though the differences seem to be small, the measured capacity retentions of 69.6 and 68.8% for Si@Gr/C composites with 120 and 160 nm, respectively, are about 8% larger than for Si@Gr. The reason for this small difference is the limited amount of lithium in the full cells, so that every lithium consumption process induces a capacity fade. Within half cells, a larger difference, especially in long-term cycling, is expected.

Based on these full cell results, the electrochemical performance of the prepared Si@Gr and Si@Gr/C composite materials is not sufficient for commercial applications and needs to be further optimized. However, it is important to show full cell results of Si containing electrodes, because the literature mainly focuses on half cells and non-scalable processes at the laboratory scale. Within this study, a correlation of the specific surface area of Si@Gr composites with the ICE and initial discharge capacity was found. Furthermore, it was shown that a reduction in particle size can have a positive impact on performance, but the effect is not that pronounced for Si@Gr anodes. Furthermore, it could be shown that Si containing anodes have the feasibility of using higher charging rates. In order to improve the performance, a further optimization of the carbon coating and particle structure is necessary. Moreover, a prelithiation could decrease the problem of lacking lithium in full cells.

After long-term cycling, the electrodes were washed inside a glovebox and SEM pictures were taken. In order to investigate the morphological changes, the SEM pictures of the cycled electrodes were compared to pristine ones. The resulting pictures are shown in

Figure 7 and also in higher magnification in

Figure S5. While for Gr almost no change in electrode height can be noted, the volume expansion of the Si containing anodes is clearly visible. The relative thickness increases in the anodes are 4.0, 27.0, 48.2 and 87.2% for Si@Gr with 0, 5, 10 and 15 wt.% Si (

Table S1), which is again almost a linear increase. A higher Si content leads to more pronounced swelling of the electrode, which can cause electrical isolation, continuous SEI growth and pulverization of particles. All in all, this leads to increased degradation and capacity fading. Compared to the other electrodes, the particles within the Si@Gr/C electrode seem to be more spherical. This can only be caused by the pitch coating.

Lastly, the specific energies (Wh kg−1) and energy densities (Wh L−1) of the full cells are calculated. In order to extend the range of electrical vehicles per battery charge, both parameters need to be increased. The replacement of Gr by Si is advantageous for both performance indicators. In the case of using anodes consisting mainly of Gr with small amounts of Si, as carried out in this study, the influence on energy density is more pronounced than on specific energy. As only small cells with a preassembled separator, which incorporates a lithium reference, and an excess of electrolyte are used, both the separator and electrolyte are not considered within the calculation. Consequently, both the energy density and the specific energy solely refer to the electrodes (anode and cathode). Furthermore, only one half of the substrate is considered, because within multilayer cells the substrate would be coated on both sides.

The calculated energy densities are shown in

Figure 8 at four different cycles (4, 18, 71, 122), which are all carried out at 0.1 C. As expected, the initial energy densities are enhanced from 552.1 Wh L

−1 for pure Gr to 619.5, 688.5 and 727.4 Wh

−1 for higher Si contents (5, 10, 15 wt.% Si). This relates to a relative enhancement of about 32% at 15 wt.% Si. The reason behind this is the reduction in electrode thickness. As discussed before, when the silicon content is increased at a fixed areal capacity, the electrode thickness decreases. The measured electrode thicknesses can be found in

Table S1. This improvement is, however, only present in the beginning. As already noted in

Figure 5b, the Si containing electrodes suffer from severe capacity losses, causing a decline in energy density over cycling. In contrast to this, the energy density of Gr remains almost stable. In the end, this leads to the situation that the energy density of all Si@Gr cells has dropped below Gr. The variation of the Si particle size shows no real impact on the energy density (

Figure 8b). Compared to Si@Gr cells, the additional carbon coating of Si@Gr/C leads to an initial decrease in energy density. This is related to the higher mass loading and thus electrode thickness. The carbon coating was considered as an inactive material, so that in order to achieve the same areal capacity, the mass loading was increased. Other than that, the same decline is visible as for the Si@Gr cells as the slightly better specific capacity (

Figure 5c) is contradicted by the higher mass loading and electrode height.

For the specific energy, which is evaluated at the same cycles, no change in the initial values either by the variation of Si content, Si particle size or the addition of a carbon coating is evident (

Figure S7). As previously mentioned, the anodes mainly consist of Gr with small amounts of Si (≤15 wt.% Si), so that the impact on the anode mass is not that pronounced. However, a higher Si content leads to a stronger decrease in specific energy during cycling. Even more important than the active mass of the anode is that of the cathode, which is about two times higher than the active mass of a pure Gr anode and even four times higher than for a Si@Gr anode with 15 wt.% Si. Hence, an optimization of the cathode mass has a larger impact on the specific energy than the anode and a mutual enhancement needs to be carried out for optimizing both energy density and specific energy.