Recycling Water Hyacinth as Supplementary Cementitious Material, Admixture, and Fiber in Mortar and Concrete: Current Trends and Research Gaps

Abstract

:1. Introduction

2. Water Hyacinth Composition

3. Water Hyacinth as Supplementary Cementitious Materials

3.1. Concrete

3.2. Mortar

4. Water Hyacinth as an Admixture

4.1. Concrete

4.2. Mortar

5. Water Hyacinth Fibers

6. Water Hyacinth Microstructure

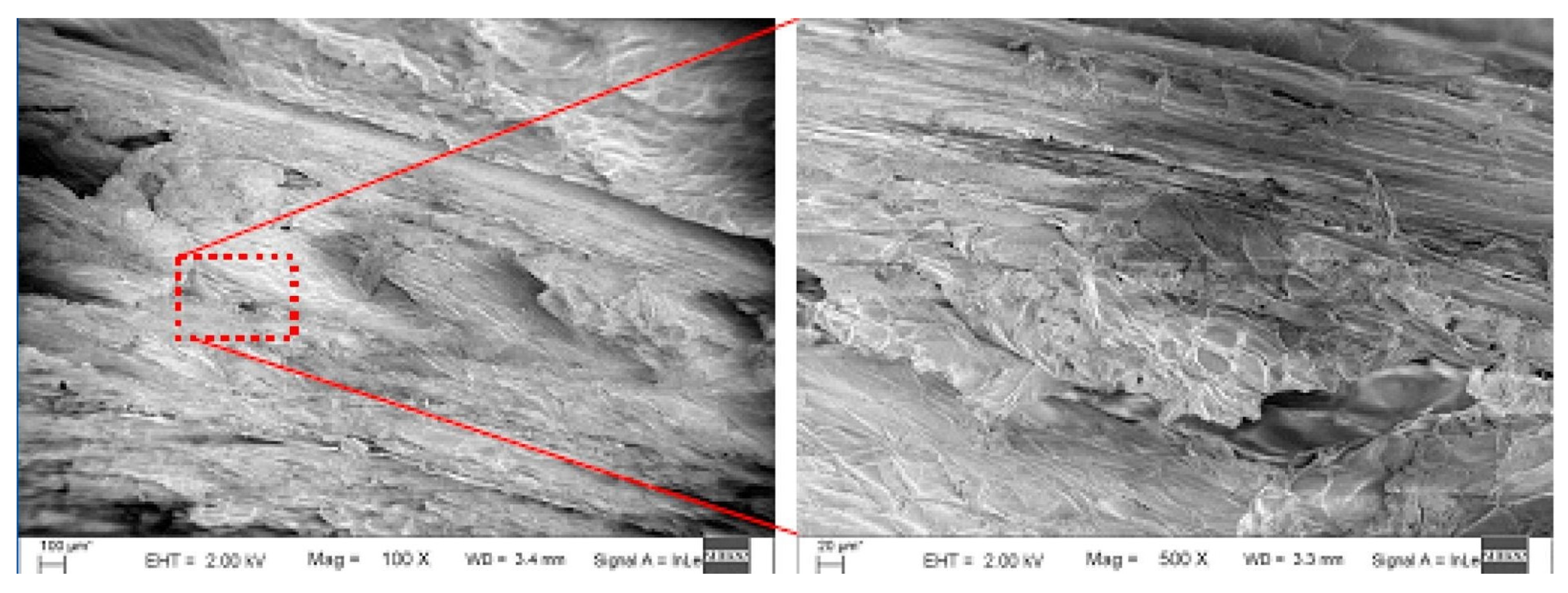

6.1. Water Hyacinth Fibers

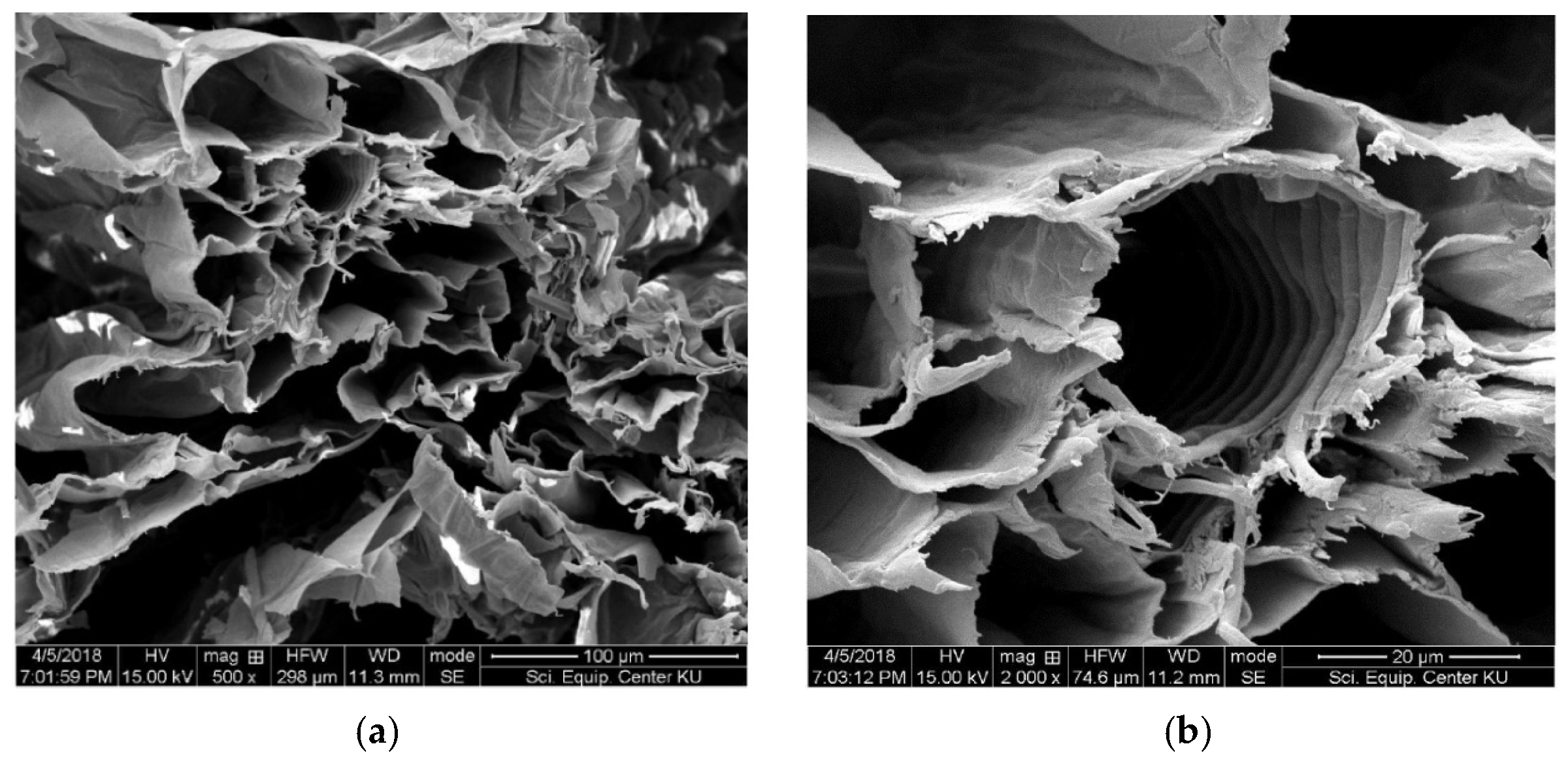

6.2. Water Hyacinth Ash

7. Environmental Assessment

8. Other Applications

8.1. Masonry

8.2. Water Replacement in Concrete

9. Conclusions

- WH holds significant potential as a sustainable material in cement-based applications. Its composition and properties make it suitable for use as an addition, admixture, and fiber reinforcement in concrete.

- WH as SCM improves workability and mechanical properties at optimal dosages. It should be noted that the type of WH-based SCM manufacturing can positively or negatively affect the properties in the hardened state. There are better results when the size of the SCM is under 150 µm.

- There are contradictory results regarding the use of WHAD in concrete. It should be taken into account that, as in the case of WH-based SCM, the manufacturing process of the admixtures can have a great influence on the mechanical and fresh state behavior of the concrete.

- The positive or negative effect of using WHF will depend on whether they are pre-treated, the fiber length, and its quantity. No more than 0.5%vol WFH should be used to have adequate results.

- Microstructure analysis showed the effect of different treatments on the surface of WFH. However, studies showcasing this information are scarce, so it is recommended that future research address this topic.

- Environmental analysis in the literature demonstrates that the use of WH biochar as SCM can reduce the GPW emissions both in cement and concrete manufacturing.

- Further studies should be conducted on the effects of WH-SCM, WHF, and WHAD on the durability of both concrete and mortar. These studies will provide a better understanding of the long-term effects of this material, thus enabling the proposal of practical applications for the construction industry.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Cement and Concrete Association. Cement and Concrete Around the World. 2024. Available online: https://gccassociation.org/concretefuture/cement-concrete-around-the-world/ (accessed on 6 December 2024).

- García, G.; Cabrera, R.; Rolón, J.; Pichardo, R.; Thomas, C. Systematic review on the use of waste foundry sand as a partial replacement of natural sand in concrete. Constr. Build. Mater. 2024, 430, 136460. [Google Scholar] [CrossRef]

- Forum, W.E. Net-Zero Industry Tracker 2024 Edition. 2024. Available online: https://www.weforum.org/publications/net-zero-industry-tracker-2024/ (accessed on 19 January 2025).

- Althoey, F.; Ansari, W.S.; Sufian, M.; Deifalla, A.F. Advancements in low-carbon concrete as a construction material for the sustainable built environment. Dev. Built Environ. 2023, 16, 100284. [Google Scholar] [CrossRef]

- Del Angel, G.G.; Thomas, C. The use of foundry sand for recycled aggregate concrete. In The Structural Integrity of Recycled Aggregate Concrete Produced with Fillers and Pozzolans; Woodhead Publishing: Sutton, UK, 2022; pp. 3–24. [Google Scholar] [CrossRef]

- Del Angel, G.G.; Sainz-aja, J.A.; Tamayo, P.; Cimentada, A.; Cabrera, R.; Pestana, L.R.; Thomas, C. Effect of Recycled Foundry Sand on the Workability and Mechanical Properties of Mortar. Appl. Sci. 2023, 13, 3436. [Google Scholar] [CrossRef]

- Oliveira, L.A.P.-D.; Nepomuceno, M.; Rangel, M. An eco-friendly self-compacting concrete with recycled coarse aggregates. Inf. De La Constr. 2013, 65, 31–41. [Google Scholar] [CrossRef]

- Yang, K.-H.; Chung, H.-S.; Ashour, A.F. Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater. J. 2008, 105, 289–296. [Google Scholar] [CrossRef]

- Ciocan, V.; Burlacu, A.; Bărbuță, M.; Verdeș, M.; Șerbănoiu, A.A.; Ștefan, I. Eco-friendly concrete from wastes. Environ. Eng. Manag. J. 2018, 17, 2969–2976. [Google Scholar] [CrossRef]

- Koh, T.; Shin, M.; Bae, Y.; Hwang, S. Structural performances of an eco-friendly prestressed concrete sleeper. Constr. Build. Mater. 2016, 102, 445–454. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- García, G.; Cabrera, R.; Rolón, J.; Pichardo, R.; Thomas, C. Natural fibers as reinforcement of mortar and concrete: A systematic review from Central and South American regions. J. Build. Eng. 2024, 98, 111267. [Google Scholar] [CrossRef]

- Arvizu-Montes, A.; Martinez-Echevarria, M.J. Vegetable Fibers in Cement Composites: A Bibliometric Analysis, Current Status, and Future Outlooks. Materials 2025, 18, 333. [Google Scholar] [CrossRef]

- Sheridan, J.; Sonebi, M.; Taylor, S.; Amziane, S. The effect of a polyacrylic acid viscosity modifying agent on the mechanical, thermal and transport properties of hemp and rapeseed straw concrete. Constr. Build. Mater. 2020, 235, 117536. [Google Scholar] [CrossRef]

- de Aguiar, A.L.D.; da Silva, N.A.; Gomes, B.M.C.; da Gloria, M.Y.R.; Hasparyk, N.P.; Filho, R.D.T. Assessment of Wood Bio-Concrete Properties Modified with Silane–Siloxane. Materials 2023, 16, 6105. [Google Scholar] [CrossRef] [PubMed]

- Velumani, M.; Mohanraj, R.; Krishnasamy, R.; Yuvaraj, K. Durability Evaluation of Cactus-infused M25 Grade Concrete as a Bio-admixture. Period. Polytech. Civ. Eng. 2023, 67, 1066–1079. [Google Scholar] [CrossRef]

- Abu-Bakr, M.; Mahmood, H.F.; Mohammed, A.A.; Ahmed, S.A. Evaluation of mechanical properties and shear-bond strength of mortar containing natural extract admixture. Constr. Build. Mater. 2024, 418, 135377. [Google Scholar] [CrossRef]

- Gaoussou, S.; Koteng, D.O.; Sanewu, I.F. Effect of Sisal Juice on the Fresh and Hardened Properties of Concrete. Int. J. Eng. Trends Technol. 2023, 71, 40–48. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Koh, H.J. Application of biochar from food and wood waste as green admixture for cement mortar. Sci. Total Environ. 2018, 619–620, 419–435. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W. Combination of Biochar and Silica Fume as Partial Cement Replacement in Mortar: Performance Evaluation Under Normal and Elevated Temperature. Waste Biomass Valorization 2020, 11, 2807–2824. [Google Scholar] [CrossRef]

- Salas-Ruiz, A.; Barbero-Barrera, M.M.; Sánchez-Rojas, M.I.; Asensio, E. Water Hyacinth–Cement Composites as Pollutant Element Fixers. Waste Biomass Valorization 2020, 11, 3833–3851. [Google Scholar] [CrossRef]

- Bakrim, W.B.; Ezzariai, A.; Karouach, F.; Sobeh, M.; Kibret, M.; Hafidi, M.; Kouisni, L.; Yasri, A. Eichhornia crassipes (Mart.) Solms: A Comprehensive Review of Its Chemical Composition, Traditional Use, and Value-Added Products. Front. Pharmacol. 2022, 13, 842511. [Google Scholar] [CrossRef] [PubMed]

- Ajithram, A.; Jappes, J.T.W.; Kumar, S.D.; Chithra, G.K. Water hyacinth plant powder particle with moringa filler powder reinforced epoxy polymer composite absorption properties. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Hemalatha, D.; Narayanan, R.M.; Sanchitha, S. Removal of Zinc and Chromium from industrial wastewater using water hyacinth (E. crassipes) petiole, leaves and root powder: Equilibrium study. Mater. Today Proc. 2020, 43, 1834–1838. [Google Scholar] [CrossRef]

- Harun, I.; Pushiri, H.; Amirul-Aiman, A.J.; Zulkeflee, Z. Invasive water hyacinth: Ecology, impacts and prospects for the rural economy. Plants 2021, 10, 1613. [Google Scholar] [CrossRef]

- Wu, H.; Ding, J. Abiotic and Biotic Determinants of Plant Diversity in Aquatic Communities Invaded by Water Hyacinth [Eichhornia crassipes (Mart.) Solms]. Front. Plant Sci. 2020, 11, 1306. [Google Scholar] [CrossRef]

- Serafini, L.F.; Arrobas, M.; Rodrigues, M.Â.; Feliciano, M.; Miguens, F.; Oliveira, V.; Santos, D.; De Tuesta, J.L.D.; Gonçalves, A. The Composting of Water Hyacinth: A Life Cycle Assessment Perspective. Waste Biomass Valorization 2024, 16, 507–523. [Google Scholar] [CrossRef]

- Stohlgren, T.J.; Pyšek, P.; Kartesz, J.; Nishino, M.; Pauchard, A.; Winter, M.; Pino, J.; Richardson, D.M.; Wilson, J.; Murray, B.R.; et al. Globalization Effects on Common Plant Species. In Encyclopedia of Biodiversity, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2013; pp. 700–706. [Google Scholar] [CrossRef]

- Merry, N.; Mitan, M. Water hyacinth: Potential and Threat. Mater. Today Proc. 2019, 19, 1408–1412. [Google Scholar] [CrossRef]

- Ali, Y.M.; Khedr, I.S.E.-D. Estimation of water losses through evapotranspiration of aquatic weeds in the Nile River (Case study: Rosetta Branch). Water Sci. 2018, 32, 259–275. [Google Scholar] [CrossRef]

- Center, T.D.; Hill, M.P. Field efficacy and predicted host range of the pickerelweed borer, Bellura densa, a potential biological control agent of water hyacinth. BioControl 2002, 47, 231–243. [Google Scholar] [CrossRef]

- Laitinen, J.; Moliis, K.; Surakka, M. Resource efficient wastewater treatment in a developing area—Climate change impacts and economic feasibility. Ecol. Eng. 2017, 103, 217–225. [Google Scholar] [CrossRef]

- Kokou, K.; Afiademanyo, K.M.; Agboyi, L.K. Invasive Alien Species in Togo (West Africa). In Invasive Alien Species; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; Available online: https://api.semanticscholar.org/CorpusID:238776696 (accessed on 20 December 2024).

- Güereña, D.; Neufeldt, H.; Berazneva, J.; Duby, S. Water hyacinth control in Lake Victoria: Transforming an ecological catastrophe into economic, social, and environmental benefits. Sustain. Prod. Consum. 2015, 3, 59–69. [Google Scholar] [CrossRef]

- Gbiete, D.; Sprafke, J.; Kongnine, D.M.; Narra, S.; Kpelou, P.; Mouzou, E.; Agboka, K. Potential for Biogas Production from Water Hyacinth and Banana Peels: A Case Study of Substrates Harvested from Lomé, Togo. Fuels 2024, 5, 494–507. [Google Scholar] [CrossRef]

- Faridah-Hanum, I.; Latiff, A. Invasive Alien Species in Malaysia. In Invasive Alien Species; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2021; pp. 151–167. [Google Scholar] [CrossRef]

- Djuangsih, N. Understanding the state of river basin management from an environmental toxicology perspective: An example from water pollution at Citarum river basin, West Java, Indonesia. Sci. Total Environ. 1993, 134, 283–292. [Google Scholar] [CrossRef]

- Román, S.; Ledesma, B.; Álvarez, A.; Coronella, C.; Qaramaleki, S.V. Suitability of hydrothermal carbonization to convert water hyacinth to added-value products. Renew. Energy 2020, 146, 1649–1658. [Google Scholar] [CrossRef]

- Ajithram, A.; Jappes, J.T.W.; Brintha, N.C. Water hyacinth (Eichhornia crassipes) natural composite extraction methods and properties—A review. Mater. Today Proc. 2021, 45, 1626–1632. [Google Scholar] [CrossRef]

- Ajithram, A.; Jappes, J.T.W.; Brintha, N.C. Investigation on utilization of water hyacinth aquatic plants towards various bio products—Survey. Mater. Today Proc. 2021, 45, 2040–2045. [Google Scholar] [CrossRef]

- Harikrishnan, M.P.; Raghunathan, R.; Warrier, A.S.; Basil, M.; Sahoo, S.K.; Pandiselvam, R.; Venkatesh, T.; Pillai, S.; Kundu, P.; Kothakota, A. Reinforced water hyacinth based biodegradable cutlery: Green alternative to single-use plastics. Food Packag. Shelf Life 2023, 40, 101211. [Google Scholar] [CrossRef]

- Ilo, O.P.; Simatele, M.D.; Nkomo, S.L.; Mkhize, N.M.; Prabhu, N.G. The benefits of water hyacinth (Eichhornia crassipes) for Southern Africa: A review. Sustainability 2020, 12, 9222. [Google Scholar] [CrossRef]

- Rathod, V.P.; Bhale, P.V.; Mehta, R.S.; Harmani, K.; Bilimoria, S.; Mahida, A.; Champaneri, H. Biogas Production from Water Hyacinth in the Batch type Anaerobic Digester. Mater. Today Proc. 2018, 5, 23346–233350. [Google Scholar] [CrossRef]

- Hasan, S.; Girindran, R.; Zacharia, P.U.; Jaya, H.; Kooren, R.; Sayooj, P.; Benny, S.; Joseph, D.; Hussain, S.V. Climate resilient products development through valorization of Eichhornia crassipes to biofuel and biochar. Int. J. Environ. Sci. Technol. 2022, 19, 7617–7624. [Google Scholar] [CrossRef]

- Pal, D.B.; Tiwari, A.K.; Srivastava, N.; Ahmad, I.; Abohashrh, M.; Gupta, V.K. Biomass valorization of Eichhornia crassipes root using thermogravimetric analysis. Environ. Res. 2022, 214, 114046. [Google Scholar] [CrossRef]

- Djihouessi, M.B.; Olokotum, M.; Chabi, L.C.; Mouftaou, F.; Aina, M.P. Paradigm shifts for sustainable management of water hyacinth in tropical ecosystems: A review and overview of current challenges. Environ. Chall. 2023, 11, 100705. [Google Scholar] [CrossRef]

- Romero-Borbón, E.; Oropeza-González, A.E.; González-García, Y.; Córdova, J. Thermochemical and Enzymatic Saccharification of Water Hyacinth Biomass into Fermentable Sugars. Processes 2022, 10, 210. [Google Scholar] [CrossRef]

- Lara-Serrano, J.S.; Rutiaga-Quiñones, O.M.; López-Miranda, J.; Fileto-Pérez, H.A.; Pedraza-Bucio, F.E.; Rico-Cerda, J.L.; Rutiaga-Quiñones, J.G. Physicochemical Characterization of Water Hyacinth (Eichhornia crassipes (Mart.) Solms). Bioresources 2016, 11, 7214–7223. [Google Scholar] [CrossRef]

- Ruan, T.; Zeng, R.; Yin, X.-Y.; Zhang, S.-X.; Yang, Z.-H. Water hyacinth as biofuel feedstock. Bioresources 2016, 11, 2372–2380. [Google Scholar] [CrossRef]

- Bordoloi, S.; Kashyap, V.; Garg, A.; Sreedeep, S.; Wei, L.; Andriyas, S. Measurement of mechanical characteristics of fiber from a novel invasive weed: A comprehensive comparison with fibers from agricultural crops. Measurement 2018, 113, 62–70. [Google Scholar] [CrossRef]

- Nigam, J.N. Bioconversion of water-hyacinth (Eichhornia crassipes) hemicellulose acid hydrolysate to motor fuel ethanol by xylose-fermenting yeast. J. Biotechnol. 2002, 97, 107–116. [Google Scholar] [CrossRef] [PubMed]

- Omondi, E.A.; Ndiba, P.K.; Njuru, P.G. Characterization of water hyacinth (E. crassipes) from Lake Victoria and ruminal slaughterhouse waste as co-substrates in biogas production. SN Appl. Sci. 2019, 1, 848. [Google Scholar] [CrossRef]

- Verdian, R.; Muin, R.B. The effect of variation in the length of water hyacinth fiber twisted on split tensile strength high performance fiber concrete. ASTONJADRO 2023, 12, 546–557. [Google Scholar] [CrossRef]

- Sukarni, S.; Zakaria, Y.; Sumarli, S.; Wulandari, R.; Permanasari, A.A.; Suhermanto, M. Physical and Chemical Properties of Water Hyacinth (Eichhornia crassipes) as a Sustainable Biofuel Feedstock. IOP Conf. Ser. Mater. Sci. Eng. 2019, 515, 012070. [Google Scholar] [CrossRef]

- Harikaran, M.; Mukesh, P.; kumar, P.S.; Suganth, R.S.; Nithishkumar, R.; Vijay, V. Study of structural bonding strength with tyre rubber instead of coarse aggregate and water hyacinth ash instead of cement. Mater. Today Proc. 2022, 68, 1330–1334. [Google Scholar] [CrossRef]

- Hohhod, H.; Anwar, M.; Makhlouf, A. Application of Water Hyacinth Ash as Cement Additive. 2000, pp. 1725–1734. Available online: https://www.researchgate.net/publication/353821141_APPLICATION_OF_WATER_HYACINTH_ASH_AS_CEMENT_ADDITIVE (accessed on 6 December 2024).

- Murugesh, V.; Balasundaram, N. Bonding characteristics of water hyacinth ash on concrete by replacing cement. Int. J. Recent. Technol. Eng. 2019, 8, 4977–4979. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Majdi, A.; Alsharari, F.; Alsulamy, S.; Arbili, M.M. Effect of fly ash and waste glass powder as a fractional substitute on the performance of natural fibers reinforced concrete. Ain Shams Eng. J. 2023, 14, 102247. [Google Scholar] [CrossRef]

- Topçu, I.B.; Boga, A.R. Effect of ground granulate blast-furnace slag on corrosion performance of steel embedded in concrete. Mater. Des. 2010, 31, 3358–3365. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- Lou, Y.; Khan, K.; Amin, M.N.; Ahmad, W.; Deifalla, A.F.; Ahmad, A. Performance characteristics of cementitious composites modified with silica fume: A systematic review. Case Stud. Constr. Mater. 2023, 18, e01753. [Google Scholar] [CrossRef]

- Chung, D.D.L. Improving cement-based materials by using silica fume. J. Mater. Sci. 2002, 37, 673–682. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A. Effect of Volcanic Ash and Natural Pozzolana on mechanical properties of sustainable cement concrete: A comprehensive review. Case Stud. Constr. Mater. 2023, 19, e02425. [Google Scholar] [CrossRef]

- Thirukumaran, T.; Krishnapriya, S.; Priya, V.; Britto, A.S.F.; Anandhalakshimi, R.; Dinesh, S.; Poomalai, R.; Vivek, S.; Saravanan, S. Utilizing rice husk ash as a bio-waste material in geopolymer composites with aluminium oxide. Glob. NEST J. 2023, 25, 119–129. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Belgacem, M.N.; Siqueira, G.; Bras, J.; Savastano, H.; Lahr, F.A.R. Processing and dimensional changes of cement based composites reinforced with surface-treated cellulose fibres. Cem. Concr. Compos. 2013, 37, 68–75. [Google Scholar] [CrossRef]

- Jaberizadeh, M.M.; Danoglidis, P.A.; Shah, S.P.; Konsta-Gdoutos, M.S. Eco-efficient cementitious composites using waste cellulose fibers: Effects on autogenous shrinkage, strength and energy absorption capacity. Constr. Build. Mater. 2023, 408, 133504. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Novel biochar-concrete composites: Manufacturing, characterization and evaluation of the mechanical properties. Sci. Total Environ. 2018, 616–617, 408–416. [Google Scholar] [CrossRef]

- Sirico, A.; Bernardi, P.; Sciancalepore, C.; Vecchi, F.; Malcevschi, A.; Belletti, B.; Milanese, D. Biochar from wood waste as additive for structural concrete. Constr. Build. Mater. 2021, 303, 124500. [Google Scholar] [CrossRef]

- He, X.; Wang, Y.; Tai, M.H.; Lin, A.; Owyong, S.; Li, X.; Leong, K.; Yusof, M.L.M.; Ghosh, S.; Wang, C.H. Integrated applications of water hyacinth biochar: A circular economy case study. J. Clean. Prod. 2022, 378, 134621. [Google Scholar] [CrossRef]

- Perez, E.A.; Suarez-Dominguez, J.; Perez-Sanchez, F.; Varela-Tovar, A.M. Analysis of the mechanical properties of concrete mix added with water lily ash (Eichornnia crassipes). Civil Eng. Archit. 2021, 9, 1389–1394. [Google Scholar] [CrossRef]

- Hodhod, H.; Anwar, M.; Makhlouf, A. Durability of Water Hyacinth Ash in Concrete. Eng. Res. J. 2003, 87, 144–156. [Google Scholar]

- Shaban, A.; Abdel, Y. Impact of water hyacinth on properties of concrete made with various gravel to dolomite ratios. In Proceedings of the Third International Conference Advances in Civil, Structural and Mechanical Engineering; Institute of Research Engineers and Doctors, LLC: New York, NY, USA, 2015; pp. 76–80. [Google Scholar] [CrossRef]

- Yehualaw, M.D.; Alemu, M.; Hailemariam, B.Z.; Vo, D.H.; Taffese, W.Z. Aquatic Weed for Concrete Sustainability. Sustainability 2022, 14, 5501. [Google Scholar] [CrossRef]

- Krishnan, S.S.; Murugesh, V. Experimental Study on Strength of Water Hyacinth Ash as Partial Replacement of Cement in Concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 1866–1870. [Google Scholar] [CrossRef]

- Murugesh, V.; Balasundaram, N.; Vadivel, T.S. Experimental Studies on Durability Studies of Concrete with Partial Replacement of Cement by Water Hyacinth Ash. Int. J. Eng. Technol. 2018, 7, 22–24. [Google Scholar] [CrossRef]

- Das, N.; Singh, S. Evaluation of water hyacinth stem ash as pozzolanic material for use in blended cement. J. Civ. Eng. Sci. Technol. 2016, 7, 1–8. [Google Scholar] [CrossRef]

- Abana, E.; Vega, W.; Gacias, J.; Rañon, P.J.; Talattad, J.D.; Orata, H.; Perez, J. Pulverized Water Hyacinth as an Admixture for Concrete. Int. J. Integr. Eng. 2021, 13, 298–303. [Google Scholar] [CrossRef]

- Del Ángel, G.G.; Aghajanian, A.; Cabrera, R.; Tamayo, P.; Sainz-Aja, J.A.; Thomas, C. Influence of Partial and Total Replacement of Used Foundry Sand in Self-Compacting Concrete. Appl. Sci. 2023, 13, 409. [Google Scholar] [CrossRef]

- Varghese, N.; Vasudev, R. Experimental investigation on properties of concrete with rice husk ash and water hyacinth ash. Sustain. Agri Food Environ. Res. 2023, 12. [Google Scholar] [CrossRef]

- Priya, I.D.A.; Akshaya, S.; Neya, S.H.; Vanitha, S.; Priya, P.K.; Johnson, J.N. Experimental investigation on replacement of PET aggregate as fine aggregate and water hyacinth as bio plasticizer in concrete. Int. Rev. Appl. Sci. Eng. 2023, 14, 358–365. [Google Scholar] [CrossRef]

- Jędrzejczak, P.; Collins, M.N.; Jesionowski, T.; Klapiszewski, Ł. The role of lignin and lignin-based materials in sustainable construction—A comprehensive review. Int. J. Biol. Macromol. 2021, 187, 624–650. [Google Scholar] [CrossRef] [PubMed]

- Okwadha, G.D.O.; Makomele, D.M. Evaluation of water hyacinth extract as an admixture in concrete production. J. Build. Eng. 2018, 16, 129–133. [Google Scholar] [CrossRef]

- Lamichhane, A.; Motra, B.; Khadka, T.B. Evaluation of Water Hyacinth Extract of Nepalese Lakes as an Admixture in Concrete Production. In Proceedings of the 8th IOE Graduate Conference, Online, 5–7 June 2020; Volume 8. [Google Scholar]

- Sathya, A.; Bhuvaneshwari, P.; Niranjan, G.; Vishveswaran, M. Influence of Bio Admixture on Mechanical Properties of Cement and Concrete. Asian J. Appl. Sci. 2014, 7, 205–214. [Google Scholar] [CrossRef]

- Zheng, Y.; Lv, X.; Hu, S.; Zhuo, J.; Wan, C.; Liu, J. Mechanical properties and durability of steel fiber reinforced concrete: A review. J. Build. Eng. 2024, 82, 108025. [Google Scholar] [CrossRef]

- Sainz-Aja, J.A.; Sanchez, M.; Gonzalez, L.; Tamayo, P.; Del Angel, G.G.; Aghajanian, A.; Diego, S.; Thomas, C. Recycled Polyethylene Fibres for Structural Concrete. Appl. Sci. 2022, 12, 2867. [Google Scholar] [CrossRef]

- Ishaya, A.A.; Elinwa, A.U.; Mohammed, I.Y. Water Hyacinth Plant Fibre Characterization. Int. J. Res. Sci. Innov. 2024, 11, 1172–1190. [Google Scholar] [CrossRef]

- Dewi, L.; Mareta, S.; Amni, D.; Yulianti, S.; Zebua, D.K.; Santosa, T.A.; Suryono, W.; Nurtamam, M.E. Increased Concrete Strength with the Addition of Hyacinth Natural Fibers. PKM J. Community Serv. 2023, 1, 9–13. [Google Scholar]

- Dewi, K.; Raharjo, W.W.; Kusharjanta, B. The Effect of Heating Variations on the Mechanical Strength of Hyacinth Fibers. E3S Web Conf. 2023, 485, 01029. [Google Scholar] [CrossRef]

- Niyasom, S.; Tangboriboon, N. Development of biomaterial fillers using eggshells, water hyacinth fibers, and banana fibers for green concrete construction. Constr. Build. Mater. 2021, 283, 122627. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, L.H.; Chu, H.Q.; Chen, L. Mechanical properties of fiber reinforced lightweight aggregate concrete. Key Eng. Mater. 2011, 477, 274–279. [Google Scholar] [CrossRef]

- Kiptum, C.K.; Rosasi, L.; Joseph, O.; Odhiamba, E. Some mechanical characteristics of concrete reinforced with dried water hyacinth and quarry dust as fine aggregates. J. Civ. Eng. Sci. Technol. 2019, 10, 94–100. [Google Scholar] [CrossRef]

- Ajithram, A.; Jappes, J.T.W.; Chithra, G.K.; Daphne, R. Serious environmental threat water hyacinth (Eichhornia crassipes) plant natural fibress: Different extraction methods and morphological properties for polymer composite applications. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Mohit, H.; Rangappa, S.M.; Yorseng, K.; Siengchin, S.; Marwani, H.M.; Khan, A.; Asiri, A.M. Discarded water hyacinth/pineapple fibers and carbon/innegra fabrics and TiC nanoparticles reinforced UV resistant polyester composites. J. Mater. Res. Technol. 2023, 24, 5059–5081. [Google Scholar] [CrossRef]

- Ajithram, A.; Jappes, J.T.W.; Siva, I.; Khan, M.A.; Brintha, N.C. Investigation of water, chemical absorption and mechanical properties of water hyacinth (Eichhornia crassipes) aquatic plant powder, ash composites for commercial applications. Mater. Today Proc. 2022, 60, 1339–1346. [Google Scholar] [CrossRef]

- Petroche, D.M.; Ramirez, A.D. The Environmental Profile of Clinker, Cement, and Concrete: A Life Cycle Perspective Study Based on Ecuadorian Data. Buildings 2022, 12, 311. [Google Scholar] [CrossRef]

- Li, C.; Cui, S.; Nie, Z.; Gong, X.; Wang, Z.; Itsubo, N. The LCA of portland cement production in China. Int. J. Life Cycle Assess. 2015, 20, 117–127. [Google Scholar] [CrossRef]

- Witte, A.; Garg, N. Quantifying the global warming potential of low carbon concrete mixes: Comparison of existing life cycle analysis tools. Case Stud. Constr. Mater. 2024, 20, e02832. [Google Scholar] [CrossRef]

- Goel, G.; Kalamdhad, A.S. A practical proposal for utilisation of water hyacinth: Recycling in fired bricks. J. Clean. Prod. 2018, 190, 261–271. [Google Scholar] [CrossRef]

- Ayyadurai, A.; Saravanan, M.M.; Devi, M. Integrated method for waste water treatment using water hyacinth and its application in concrete. Int. J. Adv. Technol. Eng. Explor. 2023, 10, 1742–1757. [Google Scholar] [CrossRef]

- Ayyadurai, A.; Saravanan, M.M.; Devi, M. Efficient Wastewater Treatment through Integrated Water Hyacinth Systems: Advances and Applications in Concrete. Mater. Tehnol. 2024, 58, 173–184. [Google Scholar] [CrossRef]

| Cellulose (%) | Hemicellulose (%) | Lignin (%) | Ash (%) | Ref. |

|---|---|---|---|---|

| 18.73–27.08 | 17.61–25.73 | 4.47–5.77 | - | [35] |

| 20 | 48.00 | 3.50 | 29.50 | [40] |

| 24 | 30.00 | 16.00 | 20.00 | [43] |

| 32.14 | - | 0.31 | 19.63 | [44] |

| 13–16 | 24.00–27.50 | 8.00–14.00 | 14.00–26.00 | [48] |

| 46.00 | 21.00 | 11.00 | 11.00 | [50] |

| 12.20 | 48.70 | 3.50 | 31.90 | [51] |

| 32 | 23.00 | 9.90 | 26.00 | [52] |

| 24.5 | 34.00 | 8.60 | 1.50 | [49] |

| 64.50 | - | 7.69 | 12.00 | [53] |

| Element | [40] | [43] | [45] | [54] |

|---|---|---|---|---|

| C | 40–42.5 | 38.4 | 24 | 14.4 |

| O | 27–29 | 38.1 | 70 | 49.5 |

| N | 1.2–4.6 | 2.9 | 0.6 | - |

| H | 5.2–6.5 | 5.85 | 4 | - |

| S | - | 0.47 | 0.70 | - |

| P | - | 0.77 | - | - |

| K | - | 2.78 | - | 8.26 |

| Ca | - | 1.32 | - | 4.73 |

| Na | - | 1.44 | - | 0.58 |

| Mg | - | - | - | 1.96 |

| Al | - | - | - | 2.32 |

| Zr | - | - | - | 2.24 |

| Cl | - | - | - | 5.58 |

| Si | - | - | - | 5.33 |

| Te | - | - | - | 0.27 |

| Fe | - | - | - | 4.71 |

| CaO | SiO2 | K2O | Cl | Al2O3 | SO3 | MgO | Fe2O3 | LOI | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| 7.84 | 24.31 | 16.92 | 3.84 | 7.94 | 6.04 | 6.34 | 3.06 | 11.15 | [21] a |

| 11.46 | 33.52 | 6.83 | 0.34 | 9.30 | 1.78 | 8.83 | 3.75 | 13.81 | [21] b |

| 12.03 | 33.56 | 5.31 | 0.07 | 10.14 | 0.74 | 9.69 | 4.13 | 13.12 | [21] c |

| 25.73 | 23.38 | 10.90 | 8.94 | 8.85 | 7.95 | 5.85 | 3.74 | 4.51 | [55] |

| 10.08 | 33.89 | 9.83 | 3.82 | 6.77 | - | 5.40 | 5.77 | 17.96 | [56] d |

| 12.15 | 34.80 | 11.55 | 4.12 | 7.04 | - | 5.40 | 6.15 | 8.88 | [56] e |

| 22.61 | 4.40 | 14.82 | - | 2.20 | 3.09 | 14.01 | 1.27 | - | [57] |

| WHA% wt. | Slump (mm) | Compressive Strength (MPa) | Split Tensile Strength (MPa) | Water Absorption (%) | Ref. |

|---|---|---|---|---|---|

| 0 | - | 20.90 | - | - | [77] |

| 0.5 | - | 21.40 | - | - | |

| 1 | - | 21.70 | - | - | |

| 0 | - | 37.20 | 2.97 | - | [79] |

| 5 | - | 37.90 | 3.25 | - | |

| 10 | - | 40.31 | 3.56 | - | |

| 15 | - | 42.73 | 3.78 | - | |

| 20 | - | 32.50 | 2.71 | - | |

| 0 | 50 | 30.40 | 2.75 | - | [72] |

| 0.5 | 40 | 25.50 | 2.55 | - | |

| 1 | 30 | 28.37 | 2.84 | - | |

| 2 | 30 | 35.30 | 3.04 | - | |

| 5 | 20 | 27.97 | 2.75 | - | |

| 0 | 35 | 33.10 | - | 4.50 | [73] |

| 5 | 48 | 34.50 | - | 3.77 | |

| 10 | 65 | 35.70 | - | 3.62 | |

| 15 | 92 | 34.60 | - | 3.56 | |

| 0 | - | 30.43 | 2.97 | - | [74] |

| 10 | - | 31.95 | 3.50 | - | |

| 20 | - | 27.13 | 2.44 | - |

| WHA% | Compressive Strength (MPa) | Flexural Strength (MPa) | Water Absorption (%) | Ref. |

|---|---|---|---|---|

| 0 | 59.61 | - | 5.20 | [21] |

| 25 | 29.22 | - | 6.24 | |

| 0 | 39.43 | 7.13 | - | [69] |

| 2 a | 38.43 | 7.00 | - | |

| 2 b | 46.96 | 8.11 | - | |

| 0 | 43.50 | - | 7.31 | [76] |

| 10 | 38.00 | - | 6.76 | |

| 15 | 29.00 | - | 6.451 | |

| 20 | 25.00 | - | 6.24 | |

| 25 | 22.50 | - | 5.93 |

| WHAD% | Slump and Slump Diameter (mm) | Compressive Strength (MPa) | Ref. |

|---|---|---|---|

| 0 | 80 | 39.80 | [80] |

| 10 | 70 | 41.84 | |

| 20 | 67 | 43.84 | |

| 0 | 520 | 27.00 | [82] * |

| 10 | 535 | 40.00 | |

| 15 | 565 | 51.00 | |

| 20 | 620 | 57.00 | |

| 25 | 670 | 48.00 | |

| 0 | 47 | 28.60 | [83] |

| 0.25 | 120 | 29.10 | |

| 0.50 | 140 | 28.50 | |

| 0.75 | 158 | 14.90 | |

| 1 | 170 | 10.20 |

| WHF% | Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Ref. |

|---|---|---|---|

| 0 | 45.42 | 3.74 | [53] * |

| 0.75 a | 36.90 | 3.65 | |

| 0.75 b | 38.99 | 3.47 | |

| 0.75 c | 40.53 | 2.76 | |

| 0 | 12.15 | 1.51 | [91] * |

| 2 d | 12.45 | 1.44 | |

| 0 | 17.96 | 1.59 | |

| 2 e | 17.75 | 1.70 | |

| 0 | 28.06 | 1.37 | [92] ** |

| 0.10 f | 27.05 | 1.50 | |

| 0.20 f | 24.80 | 1.37 | |

| 0.30 f | 23.95 | 1.21 | |

| 0 | 26.18 | 1.25 | |

| 0.10 g | 18.94 | 1.08 | |

| 0.20 g | 18.12 | 0.79 | |

| 0.30 g | 16.32 | 0.64 | |

| 0 | 30.00 | 3.00 | [88] ** |

| 0.25 | 35.00 | 3.50 | |

| 0.50 | 40.00 | 4.00 | |

| 0.75 | 45.00 | 4.50 |

| WHTW% | Compressive Strength (MPa) | Ref. | ||

|---|---|---|---|---|

| 7 Days | 14 Days | 28 Days | ||

| 0 | 13.00 | 18.00 | 23.00 | [100] |

| 20 | 11.00 | 16.00 | 17.50 | |

| 40 | 12.50 | 17.00 | 18.00 | |

| 60 | 13.00 | 17.50 | 20.00 | |

| 80 | 14.00 | 19.00 | 23.00 | |

| 100 | 13.00 | 18.50 | 19.00 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, G.; Cabrera, R.; Rolón, J.; Pichardo, R. Recycling Water Hyacinth as Supplementary Cementitious Material, Admixture, and Fiber in Mortar and Concrete: Current Trends and Research Gaps. Recycling 2025, 10, 18. https://doi.org/10.3390/recycling10010018

García G, Cabrera R, Rolón J, Pichardo R. Recycling Water Hyacinth as Supplementary Cementitious Material, Admixture, and Fiber in Mortar and Concrete: Current Trends and Research Gaps. Recycling. 2025; 10(1):18. https://doi.org/10.3390/recycling10010018

Chicago/Turabian StyleGarcía, Gilberto, René Cabrera, Julio Rolón, and Roberto Pichardo. 2025. "Recycling Water Hyacinth as Supplementary Cementitious Material, Admixture, and Fiber in Mortar and Concrete: Current Trends and Research Gaps" Recycling 10, no. 1: 18. https://doi.org/10.3390/recycling10010018

APA StyleGarcía, G., Cabrera, R., Rolón, J., & Pichardo, R. (2025). Recycling Water Hyacinth as Supplementary Cementitious Material, Admixture, and Fiber in Mortar and Concrete: Current Trends and Research Gaps. Recycling, 10(1), 18. https://doi.org/10.3390/recycling10010018