Journal Description

Recycling

Recycling

is an international, peer-reviewed, open access journal on the recycling and reuse of material resources, including circular economy published bimonthly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), FSTA, Inspec, AGRIS, and other databases.

- Journal Rank: CiteScore - Q1 (Management, Monitoring, Policy and Law)

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 20.9 days after submission; acceptance to publication is undertaken in 4.9 days (median values for papers published in this journal in the first half of 2025).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

4.6 (2024);

5-Year Impact Factor:

4.9 (2024)

Latest Articles

Second-Generation Recycled Concrete Aggregates: Comprehensive Characterization of Physical, Mechanical, and Microstructural Properties

Recycling 2025, 10(5), 193; https://doi.org/10.3390/recycling10050193 - 15 Oct 2025

Abstract

The rapid expansion of concrete production has intensified the depletion of natural aggregate (NA) resources, necessitating sustainable alternatives in the construction industry. Recycling construction and demolition (C&D) waste offers a solution to enhance environmental sustainability and resource efficiency. Most existing studies have mainly

[...] Read more.

The rapid expansion of concrete production has intensified the depletion of natural aggregate (NA) resources, necessitating sustainable alternatives in the construction industry. Recycling construction and demolition (C&D) waste offers a solution to enhance environmental sustainability and resource efficiency. Most existing studies have mainly focused on first-generation RCAs (RCA1), with little work on second-generation RCAs (RCA2), especially fine fractions. This study examined the properties of recycled concrete aggregates (RCAs) across first and second recycling cycles, focusing on their upcycling potential. Therefore, commercially sourced NAs and RCA1 were compared with lab-produced RCA2, both coarse and fine, derived from further recycling of first-generation recycled aggregate concrete (RAC1). Comprehensive tests assessed morphology and physical, mechanical, and microstructural properties to provide a clear insight into how RCA2 differs from RCA1. Average sphericity for coarse RCA1 was 0.81, an 8% decrease from NA’s 0.88, while RCA2 had an average sphericity of 0.76, a 14% decrease. The results revealed a progressive decline in aggregate quality with each cycle. RCA1 exhibited water absorption of 9.53% (fine) and 5.55% (coarse), while RCA2 showed higher absorption at 13.16% (fine) and 6.88% (coarse). RCA1’s crushing value was 25.9%, a 41% rise over NA’s 18.09%, while RCA2’s reached 29.2%, a 61% increase. Coarse RCA2 contained 51.03% attached old mortar, 50% more than the 33.95% in RCA1. Fine RCA2 showed significant performance reductions, limiting these aggregates to non-structural downcycling applications. Microstructure analyses confirmed RCA2’s porous structure, attributed to increased adhered old mortar, including multiple weak interfaces, and numerous microcracks compared to RCA1, necessitating careful consideration when using coarse RCA2 for upcycling in sustainable construction.

Full article

(This article belongs to the Topic Solid Waste Recycling in Civil Engineering Materials)

►

Show Figures

Open AccessArticle

Valorization of Industrial Wastewater Treatment Sludge in Eco-Friendly Mortars: Enhancing Thermal Insulation and Sustainability

by

El Mokhtar El Hafidi, Abdelhadi Mortadi, Brahim Lizoul, El Ghaouti Chahid and Said Laasri

Recycling 2025, 10(5), 192; https://doi.org/10.3390/recycling10050192 - 15 Oct 2025

Abstract

►▼

Show Figures

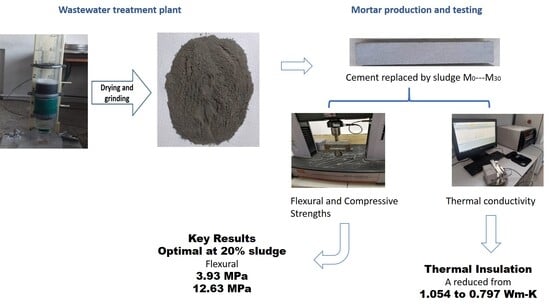

The construction industry increasingly seeks sustainable solutions to reduce environmental impact and energy consumption. This study explores the innovative use of industrial sludge generated from the wastewater treatment of detergent manufacturing as a partial substitute for Portland cement in mortar production. The sludge,

[...] Read more.

The construction industry increasingly seeks sustainable solutions to reduce environmental impact and energy consumption. This study explores the innovative use of industrial sludge generated from the wastewater treatment of detergent manufacturing as a partial substitute for Portland cement in mortar production. The sludge, characterized by high SiO2 (46.58%) and CaO (28.66%) content, was incorporated at substitution rates of 0% to 30%. Mortars were prepared and tested according to NF EN 196-1 standards for mechanical strength, and thermophysical properties were assessed using the Hot Disk TPS 1500 system. The results demonstrate that up to 20% sludge replacement maintains acceptable mechanical performance (compressive strength: 12.63 MPa at 28 days vs. 13.91 MPa for the control; flexural strength: 3.93 MPa vs. 4.65 MPa) while significantly enhancing thermal insulation. Thermal conductivity decreased from 1.054 W/m·K (0% sludge) to 0.797 W/m·K (20% sludge), and thermal diffusivity dropped from 0.6096 mm2/s to 0.504 mm2/s. XRD analysis revealed the formation of new phases, such as gismondine, indicating beneficial pozzolanic activity. These findings highlight the dual benefit of valorizing detergent sludge and improving building energy efficiency, offering an eco-efficient alternative to traditional mortars aligned with circular economy and low-carbon construction goals.

Full article

Graphical abstract

Open AccessArticle

Wood Waste Valorization Using Organosolv Pretreatment and Enzymatic Hydrolysis: Experimental and Process Evaluation

by

Aron Pazzaglia, Giacomo Fabbrizi, Mattia Gelosia, Tiziano Galmacci, Tommaso Giannoni, Alessandro Iapino, Andrea Nicolini and Beatrice Castellani

Recycling 2025, 10(5), 191; https://doi.org/10.3390/recycling10050191 - 13 Oct 2025

Abstract

►▼

Show Figures

Wood is a versatile resource within the circular economy, widely used across various applications. However, in the European Union, demand for wood continues to rise, leading to increased reliance on imports. The pulp and paper industry, closely linked to wood production, is also

[...] Read more.

Wood is a versatile resource within the circular economy, widely used across various applications. However, in the European Union, demand for wood continues to rise, leading to increased reliance on imports. The pulp and paper industry, closely linked to wood production, is also experiencing supply shortages. To address these challenges, this study explores the use of wood waste (WW) as an alternative feedstock for pulp and glucose production. WW was collected from a mechanical treatment plant in Perugia, Italy, and processed using the organosolv method. This approach yielded a cellulose pulp with improved quality compared to previous research, achieving a cellulose content of 79.33% and a cellulose recovery rate of 94.59%. The optimized pulp was then subjected to enzymatic hydrolysis, producing 20.66 g of glucose per 100 g of initial WW, corresponding to a glucose concentration of 44.08 g/L and a cellulose digestibility of 51.03%. Additionally, a simulation model of a pilot-scale process was developed using Aspen PLUS software, assuming an annual processing capacity of approximately 5500 t of wood waste—equivalent to the quantity managed annually by a local waste treatment company in Perugia. This study highlights the potential of wood waste as a sustainable raw material for pulp and glucose production, supporting circular economy goals and laying the groundwork for future scale-up investigations.

Full article

Figure 1

Open AccessArticle

Sustainable Valorization of Bovine–Guinea Pig Waste: Co-Optimization of pH and EC in Biodigesters

by

Daniela Geraldine Camacho Alvarez, Johann Alexis Chávez García, Yoisdel Castillo Alvarez and Reinier Jiménez Borges

Recycling 2025, 10(5), 190; https://doi.org/10.3390/recycling10050190 - 10 Oct 2025

Abstract

►▼

Show Figures

The agro-industry is among the largest methane emitters, posing a critical challenge for sustainability. In rural areas, producers lack effective technologies to manage daily organic waste. Anaerobic digestion (AD) offers a circular pathway by converting waste into biogas and biofertilizers; however, its adoption

[...] Read more.

The agro-industry is among the largest methane emitters, posing a critical challenge for sustainability. In rural areas, producers lack effective technologies to manage daily organic waste. Anaerobic digestion (AD) offers a circular pathway by converting waste into biogas and biofertilizers; however, its adoption is limited by inappropriate designs and insufficient operational control. Theoretical-applied research addresses these barriers by improving the design and operation of small-scale biodigesters, elevating pH and Electrical Conductivity (EC) from passive indicators to first-order control variables. Based on the design of a compact biodigester previously validated in the Chillón Valley and replicated in Huaycán under a utility model patent process (INDECOPI, Exp. 001087-2025/DIN), a stoichiometric NaHCO

Figure 1

Open AccessArticle

Investigation of Aqueous Delamination Processes for Lithium-Ion Battery Anodes

by

Eric Trebeck, Anting Grams, Jan Talkenberger, Sricharana Prakash, Julius Eik Grimmenstein, Thomas Krampitz, Holger Lieberwirth and Adrian Valenas

Recycling 2025, 10(5), 189; https://doi.org/10.3390/recycling10050189 - 7 Oct 2025

Abstract

Recycling of lithium-ion batteries (LIBs) requires efficient separation of active material from current collectors to enable high-quality recovery of both the coating and the metal foil. In this study, a water-based delamination process for anode foils was systematically investigated under variations in temperature,

[...] Read more.

Recycling of lithium-ion batteries (LIBs) requires efficient separation of active material from current collectors to enable high-quality recovery of both the coating and the metal foil. In this study, a water-based delamination process for anode foils was systematically investigated under variations in temperature, particle size, ultrasonic power, and prior mechanical stressing of the particles. Mechanically cut and pre-folded foil pieces were treated in a batch setup at different temperatures (room temperature to 100 °C) and ultrasonic power levels (50 and 100%). Results show that higher temperatures strongly promote delamination, with 100% removal of the active layer achieved on the smooth foil side at 80 °C without ultrasonic treatment. Ultrasonic treatment at moderate power (50%) yielded greater delamination than at full power (100%), likely due to more effective cavitation dynamics at moderate intensity. Mechanical pre-stressing by folding significantly reduced delamination, with three folds effectively preventing separation. In comparison, mechanically comminuted particles from a granulator achieved similar delamination to three-folded particles after 5 min treatment, and higher delamination after 30 min. These findings highlight the importance of process parameters in achieving efficient aqueous delamination, providing insights for scaling low-energy recycling processes for LIB production scrap.

Full article

(This article belongs to the Special Issue Lithium-Ion and Next-Generation Batteries Recycling)

►▼

Show Figures

Figure 1

Open AccessReview

Integrated Bioprocesses for Urban Food Waste: Insights into Biological Pathways, Process Integration, and Circular Economy Perspectives

by

Sophia Bezerra da Silva, Rayssa Karla Silva, Íthalo Barbosa Silva de Abreu, Maria Helena de Sousa, Emmanuel Damilano Dutra, Allan Almeida Albuquerque, Marcos Antonio de Morais Junior and Rafael Barros de Souza

Recycling 2025, 10(5), 188; https://doi.org/10.3390/recycling10050188 - 2 Oct 2025

Abstract

►▼

Show Figures

Food waste (FW) presents a critical issue, representing an environmental liability and a largely untapped resource. Its heterogeneity and low valorization rate among main-stream alternative treatments challenge its integration into economically and environmentally sustainable bioprocesses. We explore biorefineries as a solution that can

[...] Read more.

Food waste (FW) presents a critical issue, representing an environmental liability and a largely untapped resource. Its heterogeneity and low valorization rate among main-stream alternative treatments challenge its integration into economically and environmentally sustainable bioprocesses. We explore biorefineries as a solution that can address the complexity of urban food waste through biological strategies capable of converting food waste into valuable products. Exploring the current landscape of FW biorefineries, this study focused on the interplay between feedstock heterogeneity, pretreatment strategies, microbial dynamics, and integration potential. We propose a framework distinguishing between robust fermentations that can use minimally treated FW and tailored fermentations, which require refined media pretreatment and/or supplementation to yield higher-value compounds. Drawing on recent techno-economic and life cycle assessments, this article evaluates process viability and environmental impacts across multiple scales, reinforcing the need for robust analysis to support decision-making. Real-world initiatives and policy frameworks are analyzed to contextualize technological advances within regulatory and infrastructural realities. By linking practical constraints to biochemical and operational strategies, this work outlines how food waste biorefineries can contribute meaningfully to circular economy goals. Instead of treating FW as an intractable problem, it is seen as a versatile feedstock that demands integration, investment, and adaptive process design.

Full article

Figure 1

Open AccessReview

Unconventional Mining of End-of-Life Aircrafts: A Systematic Review

by

Silvia Zecchi, Giovanni Cristoforo, Carlo Rosso, Alberto Tagliaferro and Mattia Bartoli

Recycling 2025, 10(5), 187; https://doi.org/10.3390/recycling10050187 - 29 Sep 2025

Abstract

►▼

Show Figures

Advancements in material science have allowed us to exploit the potential of new era for aircraft production. High-performance composites and alloys have allowed us to improve the performance and durability of aircraft, but they have become more and more precious with time. These

[...] Read more.

Advancements in material science have allowed us to exploit the potential of new era for aircraft production. High-performance composites and alloys have allowed us to improve the performance and durability of aircraft, but they have become more and more precious with time. These materials can provide significant advantages in use but are costly, energy-intensive to produce, and their recovery and reuse has become a critical step to be addressed. Accordingly, a new approach in which end-of-life aircrafts represent unconventional mines rather than a disposal challenge is becoming increasingly relevant, providing access to high-value strategic raw materials and aligning with circular economy principles including European Green Deal and the United Nations Sustainable Development Goals. The complexity of dismantling and processing hybrid structures composed of metal alloys, ceramics, and advanced composites requires multiple approaches able to integrate chemical, mechanical, and thermal recovery routes. Accordingly, this review critically discusses the state of the art of the routes of end-of-life aircraft treatments, evaluating the connections between technology and regulation, and positions material recycling and reuse as central pillars for advancing sustainability in aerospace. Furthermore, this review provides a comprehensive reference for addressing the technical, economic, and policy challenges of waste management in aviation, contributing to broader goals of resource circularity and environmental preservation set forth by international sustainability agendas.

Full article

Graphical abstract

Open AccessArticle

Treatment of Agro-Industrial Residue and Organic Community Waste Using Black Soldier Fly Larvae: Overall Performance Assessment

by

Rathanit Sukthanapirat, Natpapat Chansakhatana, Somchai Baotong, Wannapa Pukdee, Kanda Lokaewmanee, Ramin Sriyoha, Ekkachai Kanchanatip and Samonporn Suttibak

Recycling 2025, 10(5), 186; https://doi.org/10.3390/recycling10050186 - 29 Sep 2025

Abstract

►▼

Show Figures

The growing global population and rising organic waste generation necessitate innovative and sustainable waste management solutions. This study investigated the potential of black soldier fly larvae (BSFL) as a bioconversion agent for agro-industrial and community organic waste, with an emphasis on optimizing substrate

[...] Read more.

The growing global population and rising organic waste generation necessitate innovative and sustainable waste management solutions. This study investigated the potential of black soldier fly larvae (BSFL) as a bioconversion agent for agro-industrial and community organic waste, with an emphasis on optimizing substrate composition for enhanced treatment performance of BSFL. Six rearing substrates were formulated by mixing brewery waste, vegetable and fruit waste, food waste, and sugar filter cake in varying ratios. The performance of BSFL was assessed using five key performance indicators, and an overall performance score was derived to compare substrate suitability across three dimensions: biomass yield, waste reduction, and larval development time. The results revealed that BSFL survival exceeded 97% for all substrates. The highest waste reduction rate of 67.52% was achieved with a 50:50 mixture of brewery waste and food waste. This mixture also attained an overall performance score of 0.77 out of 1, classified as “good”. In contrast, sugar filter cake proved unsuitable for BSFL rearing due to its low nutritional value. These findings offer practical guidelines for selecting optimal waste mixtures to improve the efficiency of BSFL-based waste management.

Full article

Figure 1

Open AccessArticle

Obtaining Nutraceutical Compounds from Agroindustrial Waste by Biotransformation with Pleurotus djamor

by

Byanka A. Cruz-Moreno, Benito Parra-Pacheco, Linda Gilary Acosta-Lizárraga, Juan C. Silva-Jarquín, Juan Fernando García-Trejo, Humberto Aguirre-Becerra and Ana A. Feregrino-Pérez

Recycling 2025, 10(5), 185; https://doi.org/10.3390/recycling10050185 - 28 Sep 2025

Abstract

►▼

Show Figures

This study explores the production of nutritious edible mushrooms from mixtures of agave bagasse, an abundant agroindustrial byproduct, through the biotechnological application of solid-state fermentation using the edible mushroom Pleurotus djamor. The ability of the fungus to biotransform different mixtures of agave

[...] Read more.

This study explores the production of nutritious edible mushrooms from mixtures of agave bagasse, an abundant agroindustrial byproduct, through the biotechnological application of solid-state fermentation using the edible mushroom Pleurotus djamor. The ability of the fungus to biotransform different mixtures of agave bagasse and corn stover into secondary metabolites of nutraceutical interest, such as polyphenols, organic acids, and bioactive polysaccharides, was evaluated. Biological efficiency (BE), morphological change, texture, and antioxidant capacity were also assessed, correlating the results with the impact of substrates and fungal developmental stages. The color, size, and margin of P. djamor basidiomas were observed to vary among treatments; BE progressively decreased from T0 (106.5%) to T4 (33.16%). Treatments with higher amounts of agave bagasse (T4) generated firmer fungi, with a fracture toughness of 7.06 ± 3.06 newtons. During fungal development, phenols, flavonoids, and tannins fluctuated. Treatment T0 showed the highest concentration of phenols (5.41 ± 0.92 mg GAE g−1). Treatment T4 stood out for its high antioxidant capacity (DPPH) (61.83 ± 12.16% inhibition). Finally, 17 non-phenolic secondary metabolites were found: L-valine, L-leucine, L-isoleucine, L, D-phenylalanine, L-proline, alanine, L-asparagine, serine, glutamic acid, linoleic acid, palmitic acid, butanoic acid, propanoic acid, pyrimidine, succinic acid, hexanedioic acid, and phosphoric acid. In conclusion, P. djamor can biotransform agroindustrial waste into edible fungi containing nutraceutical compounds.

Full article

Figure 1

Open AccessArticle

Recycling of Post-Consumer Silica Gel Desiccants as Reinforcing Filler in Natural Rubber Composites: The Effect of Coupling Agents and Comparison with Commercial Silicas

by

Dener da Silva Souza, Ricardo Henrique dos Santos, Marcos Alves dos Santos, Gleyson Tadeu de Almeida Santos, Naiara Lima Costa, Samara Araújo Kawall, Abubakar Muhammad Dadile, Gabriel Deltrejo Ribeiro, Leila Maria Sotocorno e Silva, Fernando Sérgio Okimoto, Leandro Ferreira Pinto, Carlos Toshiyuki Hiranobe, Erivaldo Antônio da Silva and Renivaldo José dos Santos

Recycling 2025, 10(5), 184; https://doi.org/10.3390/recycling10050184 - 28 Sep 2025

Abstract

►▼

Show Figures

This study presents, for the first time, a systematic investigation of the use of micronized post-consumer silica gel as a reinforcing filler in natural rubber composites, in direct comparison with commercial silicas. Thirteen formulations were prepared using three types of silica (recycled, Copasil,

[...] Read more.

This study presents, for the first time, a systematic investigation of the use of micronized post-consumer silica gel as a reinforcing filler in natural rubber composites, in direct comparison with commercial silicas. Thirteen formulations were prepared using three types of silica (recycled, Copasil, and ZC-185P) and three coupling agents (TESPT, VTMO, and Chartwell C-515.71HR®). The recycled silica exhibited high purity (97.33% Si) and irregular morphology but resulted in lower crosslink density (0.47–0.59 × 10−4 mol·cm−3) and inferior mechanical performance, with tensile strength up to 7.9 MPa and high abrasion loss (878–888 mm3). In contrast, ZC-185P silica combined with TESPT achieved the best results, with a tensile strength of 18.5 MPa, tear resistance of 99.36 N·mm−1, and minimum abrasion loss of 170 mm3. Although less efficient in reinforcement, composites containing recycled silica were successfully applied in the production of a functional rubber mat, demonstrating their practical viability. The results confirm the potential for valorization of spent silica gel as an alternative raw material for sustainable composites, contributing to the circular economy.

Full article

Figure 1

Open AccessArticle

Decarbonising Island Kitchens: Assessing the Small-Scale Flexible Balloon Digester’s Clean Cooking Potential in Fiji

by

Rinal Rinay Prasad, Ramendra Prasad, Malvin Kushal Nadan, Shirlyn Vandana Lata, Antonio Comparetti and Dhrishna Charan

Recycling 2025, 10(5), 183; https://doi.org/10.3390/recycling10050183 - 28 Sep 2025

Abstract

►▼

Show Figures

Access to clean cooking technologies is crucial for achieving SDG7 for remote households in small Pacific Islands like Fiji and for developed countries alike. Many small households in Fiji still rely on traditional biomass for cooking. This study explores the environmental sustainability and

[...] Read more.

Access to clean cooking technologies is crucial for achieving SDG7 for remote households in small Pacific Islands like Fiji and for developed countries alike. Many small households in Fiji still rely on traditional biomass for cooking. This study explores the environmental sustainability and clean cooking potential of the Home Biogas 2.0 flexible balloon digester installed at Kamil Muslim College in Ba, Fiji. Comparative bench experiments were also performed. The bench-scale experiments produced higher biogas yields than the digester trials, with optimal outputs recorded from fresh cow dung (541 mL of cumulative biogas) and vegetable waste excluding rice (125 mL). When scaled, annual energy production from fresh cow dung reached 4644.64 MJ, equivalent to replacing 7.82 standard LPG cylinders, while vegetable waste produced 3763.76 MJ, offsetting 6.34 cylinders. Notably, biogas from cow dung exceeded the estimated annual household cooking demand of 3840 MJ for a family of four persons. The biogas produced from fresh cow dung provided an average cooking duration of 1 h 29 min, while biogas from vegetable waste lasted for 1 h 21 min. The economic analysis indicated that combining liquid digestate, used as biofertiliser, and biogas from cow dung resulted in the highest financial return, with a 67% Internal Rate of Return, a Net Present Value of $12,364.30, a Benefit Cost Ratio of 5.12, and a Discounted Payback Period of 1.28 years. This indicates the potential of Home Biogas 2.0 as a climate-smart technology that integrates renewable energy production, waste reduction, and sustainable agriculture, making it particularly suitable for rural and remote communities.

Full article

Figure 1

Open AccessArticle

Upcycling RDF with Mill Scale and Waste Glass for Eco-Friendly Ferrosilicon Alloy Synthesis via Carbothermic Reduction

by

Krishmanust Sunankingphet, Thanaporn Chandransu, Sitichoke Amnuanpol and Somyote Kongkarat

Recycling 2025, 10(5), 182; https://doi.org/10.3390/recycling10050182 - 25 Sep 2025

Abstract

This study investigates the valorization of refuse-derived fuel (RDF), waste glass, and mill scale for sustainable ferrosilicon alloy production, contributing to zero-waste practices. RDF was blended with anthracite at ratios of 100, 90, 80, 70, 60 and 50 wt% (designated R1–R6) and applied

[...] Read more.

This study investigates the valorization of refuse-derived fuel (RDF), waste glass, and mill scale for sustainable ferrosilicon alloy production, contributing to zero-waste practices. RDF was blended with anthracite at ratios of 100, 90, 80, 70, 60 and 50 wt% (designated R1–R6) and applied as a reducing agent in the carbothermic reduction of SiO2 and Fe2O3, thereby decreasing reliance on conventional fossil-based reductants. Ferrosilicon synthesis was conducted at 1550 °C using glass–mill scale blends with reducing agents R1–R6, producing samples named blends A–F. XRD analysis confirmed that the metallic products consisted predominantly of the FeSi intermetallic phase, with characteristic (110) and (310) peaks at 2θ ≈ 45.02° and 78°. The metallic products appeared as numerous small, shiny droplets, with yields ranging from 14.85 to 19.47 wt%; blends D–F exhibited the highest yields. In contrast, blends A–C produced metals with higher Si contents (23.34–27.11 wt%) due to enhanced SiO2 reduction and efficient Si incorporation into the Fe matrix. Gas analysis and oxygen removal showed that blend B achieved the highest CO generation and reduction extent. Cl removal during RDF heat treatment indicated minimal potential for dioxin and furan formation. Overall, blends A and C were identified as optimal, providing high Si content, satisfactory metallic yield, and reduced CO/CO2 emissions, demonstrating the effectiveness of RDF-based carbons for environmentally friendly ferrosilicon production.

Full article

(This article belongs to the Topic Converting and Recycling of Waste Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

Determination of Quantitative Ratios (Mechanical and Dissolved) of Copper, Gold and Silver Losses in Vanyukov Furnace Slags Under the Conditions of the Balkhash Copper Smelter in Kazakhstan

by

Nurlan Dosmukhamedov, Bakhtiyar Shambulayev, Leonid Dityatovskiy, Yerzhan Zholdasbay and Aidar Argyn

Recycling 2025, 10(5), 181; https://doi.org/10.3390/recycling10050181 - 25 Sep 2025

Abstract

►▼

Show Figures

This article focuses on the problem of processing slag waste from non-ferrous metallurgy, in particular, the loss of copper, gold and silver with slag during autogenous smelting in the Vanyukov furnace at the Balkhash Copper Smelter (BMZ). An analysis of factors affecting metal

[...] Read more.

This article focuses on the problem of processing slag waste from non-ferrous metallurgy, in particular, the loss of copper, gold and silver with slag during autogenous smelting in the Vanyukov furnace at the Balkhash Copper Smelter (BMZ). An analysis of factors affecting metal losses, including electrochemical and mechanical components, is presented. This paper offers a comprehensive study of the distribution of Cu, Pb, As, Au and Ag between matte and slag, taking into account the unique characteristics of the raw material and the technological conditions of the copper smelter, which distinguishes it from previous studies. This paper establishes numerical values of dissolved and mechanical losses of valuable metals. It has been established that the most important quantitative result of smelting polymetallic raw materials in a Vanyukov furnace is the proportion of mechanical copper losses in the slag, which is approximately 75–80% of the total copper content in the slag. Mathematical models are proposed to predict the distribution of metals in the process of smelting and loss of copper, gold and silver with slag. It is proposed to integrate model representations into the technology control loop, which will optimize the process of metal recovery. This will lead to an increase in profitability and a reduction in the negative impact on the environment during copper production.

Full article

Figure 1

Open AccessArticle

Recycling Disassembled Automotive Plastic Components for New Vehicle Components: Enabling the Automotive Circular Economy

by

Neeki Meshkat, Matthew Korey, Amber M. Hubbard, Kathryn Slavny, Ashish L. S. Anilal, Arit Das, Logan Kearney, Soydan Ozcan and Uday Vaidya

Recycling 2025, 10(5), 180; https://doi.org/10.3390/recycling10050180 - 25 Sep 2025

Abstract

As the automotive industry increasingly relies on plastic components to meet fuel efficiency and emissions targets, the challenge of managing end-of-life vehicle (ELV) plastics continues to grow. Currently, more than 80% of ELV plastics in the U.S. are landfilled due to limited economic

[...] Read more.

As the automotive industry increasingly relies on plastic components to meet fuel efficiency and emissions targets, the challenge of managing end-of-life vehicle (ELV) plastics continues to grow. Currently, more than 80% of ELV plastics in the U.S. are landfilled due to limited economic incentives and technical barriers to recycling. This study examines a mechanical recycling pathway for thermoplastic components disassembled from ELVs and assesses their usability for reintegration into new vehicle parts. Four representative materials were chosen based on material labels embedded in recovered parts and aligned with their virgin industrial equivalents: polypropylene (PP), 10% talc-filled PP (PP-T10), 20% talc-filled PP (PP-T20), and a 20% glass-/mineral-filled polyamide (PA6 + GF7 + MF13). The materials underwent shredding, drying, and injection molding before being characterized by particle size analysis, density measurement, thermal analysis (TGA, DSC), mechanical testing, and heat deflection temperature (HDT) evaluation. The results in this work indicated that minor differences in crystallinity were observed and small differences between model materials and ELV materials could have contributed to these changes. Mechanical testing revealed that neat polypropylene suffered a 15–20% reduction in stiffness and tensile strength, but talc-filled polypropylene and glass/mineral-filled nylon retained >90% of their modulus, strength, and heat deflection temperature values relative to virgin controls. Differences between virgin and ELV materials could have been attributed to use life degradation, contamination during use life, or even chemical/processing differences in model materials and ELV materials. However, these findings suggest that mechanically recycled, disassembled ELV plastics can retain sufficient structural performance to support circularity efforts in the automotive sector.

Full article

(This article belongs to the Special Issue Challenges and Opportunities in Plastic Waste Management)

►▼

Show Figures

Figure 1

Open AccessArticle

Enhanced Waste Sorting Technology by Integrating Hyperspectral and RGB Imaging

by

Georgios Alexakis, Marina Pellegrino, Laura Rodriguez-Turienzo and Michail Maniadakis

Recycling 2025, 10(5), 179; https://doi.org/10.3390/recycling10050179 - 22 Sep 2025

Abstract

►▼

Show Figures

Identifying the material composition of objects is crucial for many recycling sector applications. Traditionally, object classification relies either on hyperspectral imaging (HSI), which analyses the chemometric properties of objects to infer material types, or on RGB imaging, which captures an object’s visual appearance

[...] Read more.

Identifying the material composition of objects is crucial for many recycling sector applications. Traditionally, object classification relies either on hyperspectral imaging (HSI), which analyses the chemometric properties of objects to infer material types, or on RGB imaging, which captures an object’s visual appearance and compares it to a reference sample. While both approaches have their strengths, each also suffers from limitations, particularly in challenging scenarios such as robotic municipal waste sorting, where objects are often heavily deformed or contaminated with various forms of dirt, complicating material recognition. This work presents a novel method for material-based object classification that jointly exploits HSI and RGB imaging. The proposed approach aims to mitigate the weaknesses of each technique while amplifying their respective advantages. It involves the real-time alignment of HSI and RGB data streams to ensure reliable result correlation, alongside a machine learning framework that learns to exploit the strengths and compensate for the weaknesses of each modality across different material types. Experimental validation on a municipal waste sorting facility demonstrates that the combined HSI–RGB approach significantly outperforms the individual methods, achieving robust and accurate classification even in highly challenging conditions.

Full article

Figure 1

Open AccessArticle

Harnessing Wheat Bran as a Phytochemical Bioresource: Release of Ferulic Acid Using Organosolv Treatment with Acidic/Alkaline Deep Eutectic Solvents

by

Spyros Grigorakis and Dimitris P. Makris

Recycling 2025, 10(5), 178; https://doi.org/10.3390/recycling10050178 - 22 Sep 2025

Abstract

►▼

Show Figures

Wheat bran (WB) is a very abundant residual biomass, resulting from wheat processing. Although it can be used as feed without further processing, the utilization of WB as a bioresource of high valued-added chemicals would require task-specific treatments. In this context, the present

[...] Read more.

Wheat bran (WB) is a very abundant residual biomass, resulting from wheat processing. Although it can be used as feed without further processing, the utilization of WB as a bioresource of high valued-added chemicals would require task-specific treatments. In this context, the present work aimed to used two newly reported deep eutectic solvents (DESs) for the effective organosolv treatment of WB to achieve a high-performance polyphenol recovery. One of the DESs used was alkaline, composed of glycerol and sodium carbonate (GL-SCar), and the other one was acidic, composed of glycerol and oxalic acid (GL-OA), and the treatments carried out were evaluated based on severity. Further optimization with a response surface methodology showed that treatment with GL-SCar could afford a maximum total polyphenol yield of 24.30 ± 2.34 mg ferulic acid equivalents per g of dry WB mass, the optimal settings being t = 172 min and T = 90 °C. Likewise, the GL-OA treatment yielded 23.21 ± 3.82 mg ferulic acid equivalents per g of dry WB mass, with the corresponding optimal conditions being t = 180 min and T = 90 °C. The examination of the polyphenolic profile of the extracts obtained revealed important differences in the composition, as the extract obtained with GL-SCar treatment was dominated by ferulic acid, whereas the extract produced with GL-OA treatment was enriched in a ferulate derivative, previously identified as a ferulate pentose ester. However, both treatments were shown to liberate only part of the bound phenolics, as judged by comparison with a reference alkaline hydrolysis. The difference in composition most probably defined the antioxidant effects of the extracts, with the GL-OA extract displaying more powerful antiradical and ferric-reducing power activity, despite the significantly lower polyphenolic concentration. The evidence that emerged from this investigation pointed to both DESs as solvents with high potency in polyphenol recovery from WB, yet further improvements are required to maximize yield. Moreover, it was shown that, due to their different nature (alkaline/acidic), both DESs could be suitably tuned for delivering extracts enriched in different phytochemicals.

Full article

Figure 1

Open AccessArticle

Characterisation of Fibre Mechanical Recycled Cotton Denim Fibres and the Effects of Their Properties on Yarns and Knits

by

Ella Kärkkäinen, Taina Kamppuri, Lea Heikinheimo, Carla Joana Silva and Joana M. Gomes

Recycling 2025, 10(5), 177; https://doi.org/10.3390/recycling10050177 - 19 Sep 2025

Abstract

►▼

Show Figures

The purpose of this study was to obtain a holistic view of mechanically recycled cotton from denim fabrics and the repurposing and recycling methods for similar fibres. A pre-consumer denim and three types of post-consumer denims were shredded into new fibres, which were

[...] Read more.

The purpose of this study was to obtain a holistic view of mechanically recycled cotton from denim fabrics and the repurposing and recycling methods for similar fibres. A pre-consumer denim and three types of post-consumer denims were shredded into new fibres, which were characterised with single-fibre tensile testing, SEM imaging and DSC analysis. The opened cotton fibres were then blended with primary cotton with varying ratios and spun into yarns of 40 tex with a ring spinning machine. A ratio of 75/25 of recycled fibres to virgin fibres was obtained, with promising tensile strength results. Further, the yarns were knitted into single jersey fabrics, and abrasion testing was performed to evaluate their wearing out. Best abrasion resistance was obtained for knits consisting of 100% virgin cotton fibres and the knits consisting of a blend of pre-consumer and virgin fibres. The results suggest the yarns made with mechanically opened fibres are suitable for single jersey knits. SEM and DSC confirm the input of mechanical recycling defines the output. Moreover, the SEM pictures indicate there is little to no damage to single fibres caused by mechanical shredding, causing no further barriers for secondary use as raw materials.

Full article

Figure 1

Open AccessArticle

Technical Evaluation and Recycling Potential of Polyolefin and Paper Separation in Mixed Waste Material Recovery Facilities

by

Anna-Maria Lipp, Dominik Blasenbauer, Hana Stipanovic, Gerald Koinig, Alexia Tischberger-Aldrian and Jakob Lederer

Recycling 2025, 10(5), 176; https://doi.org/10.3390/recycling10050176 - 12 Sep 2025

Cited by 1

Abstract

►▼

Show Figures

Mixed municipal solid waste (MSW) of cities and tourist-heavy areas typically contains elevated amounts of recyclable materials. In Austria, numerous material recovery facilities exist for processing this waste; however, they primarily focus on separating metals, neglecting the recovery potential of other recyclables. To

[...] Read more.

Mixed municipal solid waste (MSW) of cities and tourist-heavy areas typically contains elevated amounts of recyclable materials. In Austria, numerous material recovery facilities exist for processing this waste; however, they primarily focus on separating metals, neglecting the recovery potential of other recyclables. To evaluate such potential for polyolefins and paper-based materials, two pilot-scale trials were conducted in a model region in Tyrol, Western Austria, accompanied by comprehensive sampling, waste characterisation, and material flow analysis. Pre-concentrates with up to 70% purity were obtained using two stages of near-infrared sorting, although challenges arose due to the presence of textiles and composite materials. This study found that separating polyolefins from mixed MSW could increase recycling rates in the region by up to 16% (absolute). Paper recovery also showed a modest increase. Polyolefin recovery slightly lowered, whereas paper recovery moderately raised the heating value. Recycling such materials is technically feasible, and forthcoming legislative changes are expected to create a market for these materials. Although fundamental questions remain regarding the optimal balance between recycling and refuse-derived fuel, as well as concerns about microbiological or chemical hazards, it can enhance resource efficiency, develop circularity, and aid comparison in regions with similar demographic and tourism characteristics.

Full article

Figure 1

Open AccessArticle

Integrated Circuits from Lighting Equipment: Presence and Characterisation of Precious Metals (Ag, Au, Pd, and Pt)

by

Konstantinos M. Sideris, Konstantinos A. Liogas, Dimitrios Fragkoulis, Vassilis N. Stathopoulos and Panagiotis Sinioros

Recycling 2025, 10(5), 175; https://doi.org/10.3390/recycling10050175 - 12 Sep 2025

Abstract

►▼

Show Figures

To reduce energy consumption in buildings and to maintain comfortable conditions, lighting equipment that includes light-emitting diode (LED) lamps and lighting management equipment is utilised. In this study, integrated circuits detached from lighting equipment were characterised for the presence of precious metals (silver,

[...] Read more.

To reduce energy consumption in buildings and to maintain comfortable conditions, lighting equipment that includes light-emitting diode (LED) lamps and lighting management equipment is utilised. In this study, integrated circuits detached from lighting equipment were characterised for the presence of precious metals (silver, gold, palladium, and platinum). Their digestion was carried out with HNO3 and aqua regia solution on a hot plate and characterised using inductively coupled plasma optical emission spectroscopy (ICP-OES). The concentration of each element as a function of the type and origin of the integrated circuits varied as follows: silver, 652–3876 mg/kg; gold, 0–993 mg/kg; palladium, 0–74 mg/kg; and platinum was detected at a concentration below the quantification limit. These results indicate the need for selective removal and separate recycling processes for integrated circuits from the lighting equipment.

Full article

Graphical abstract

Open AccessReview

Recycling Mineral Wool Waste: Towards Sustainable Construction Materials

by

Martina Milat, Sandra Juradin, Nives Ostojić-Škomrlj and Anže Tesovnik

Recycling 2025, 10(5), 174; https://doi.org/10.3390/recycling10050174 - 12 Sep 2025

Abstract

►▼

Show Figures

This literature review critically examines the incorporation of mineral wool waste (MWW), a byproduct of insulation materials, into new construction materials as a sustainable recycling strategy. Covering research published between 2000 and 2025, the review focuses on the effects of MWW on various

[...] Read more.

This literature review critically examines the incorporation of mineral wool waste (MWW), a byproduct of insulation materials, into new construction materials as a sustainable recycling strategy. Covering research published between 2000 and 2025, the review focuses on the effects of MWW on various material properties and performance, including concrete, mortar, alkali-activated materials (AAMs), geopolymers (GPs), building ceramics, and asphalt. Experimental evidence demonstrates that MWW can enhance or alter the performance of these materials, offering promising opportunities for waste valorization. The review also identifies challenges related to optimizing material compositions and production methods, and highlights the need for further research to facilitate the industrial-scale application of MWW-recycled construction materials. By synthesizing current knowledge, this work aims to inform sustainable development and circular economy practices in the construction sector.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Materials, Mining, Recycling, Resources, Sustainability, Minerals, Geosciences, Environments

Sustainable Recycling and Reuse of Industrial By-Products or Waste from Geo-Resource Exploitation

Topic Editors: Sossio Fabio Graziano, Rossana Bellopede, Giovanna Antonella Dino, Nicola CaredduDeadline: 30 November 2025

Topic in

Clean Technol., Materials, Molecules, Recycling, Water, Nanomaterials, Catalysts

Advanced Composites for Waste Valorization and Pollutant Degradation

Topic Editors: Iwona Kuzniarska-Biernacka, Ana Sofia MestreDeadline: 31 January 2026

Topic in

J. Compos. Sci., Materials, Molecules, Nanomaterials, Polymers, Processes, Recycling

Science and Technology of Polymeric Blends, Composites, and Nanocomposites

Topic Editors: Roberto Scaffaro, Emmanuel Fortunato GulinoDeadline: 28 February 2026

Topic in

Energies, Materials, Recycling, Sustainability, Waste

Circular Economy in Interdisciplinary Perspective: Valorization of Raw Materials, Sustainable Products, and Pro-Ecological Industrial Developments

Topic Editors: Krzysztof Pielichowski, Piotr Duda, Michał Łach, Tomasz Mariusz Majka, Tomasz Zdeb, Giovanni De FeoDeadline: 30 March 2026

Conferences

Special Issues

Special Issue in

Recycling

Rubber Waste and Tyre Stewardship

Guest Editor: Shifeng WangDeadline: 31 October 2025

Special Issue in

Recycling

Sustainability Education for Recycling: Multidisciplinary Approaches and Innovative Practices

Guest Editor: Giovanni De FeoDeadline: 15 December 2025

Special Issue in

Recycling

Recycled Materials in Sustainable Pavement Innovation

Guest Editors: José Neves, Ana Cristina FreireDeadline: 31 December 2025

Special Issue in

Recycling

Biomass Revival: Rethinking Waste Recycling for a Greener Future

Guest Editor: Salustiano Mato De La IglesiaDeadline: 1 May 2026