Influence of Guayule Resin as a Bio-Based Additive on Asphalt–Rubber Binder at Elevated Temperatures

Abstract

:1. Introduction

1.1. Overview

1.2. Guayule Resin vs. Asphalt Economics

1.3. Guayule as a Binder Additive

1.4. CRM as an Asphalt Modifier

1.5. Significance of Studying Whole Matrix and Liquid Phase

1.6. Objective

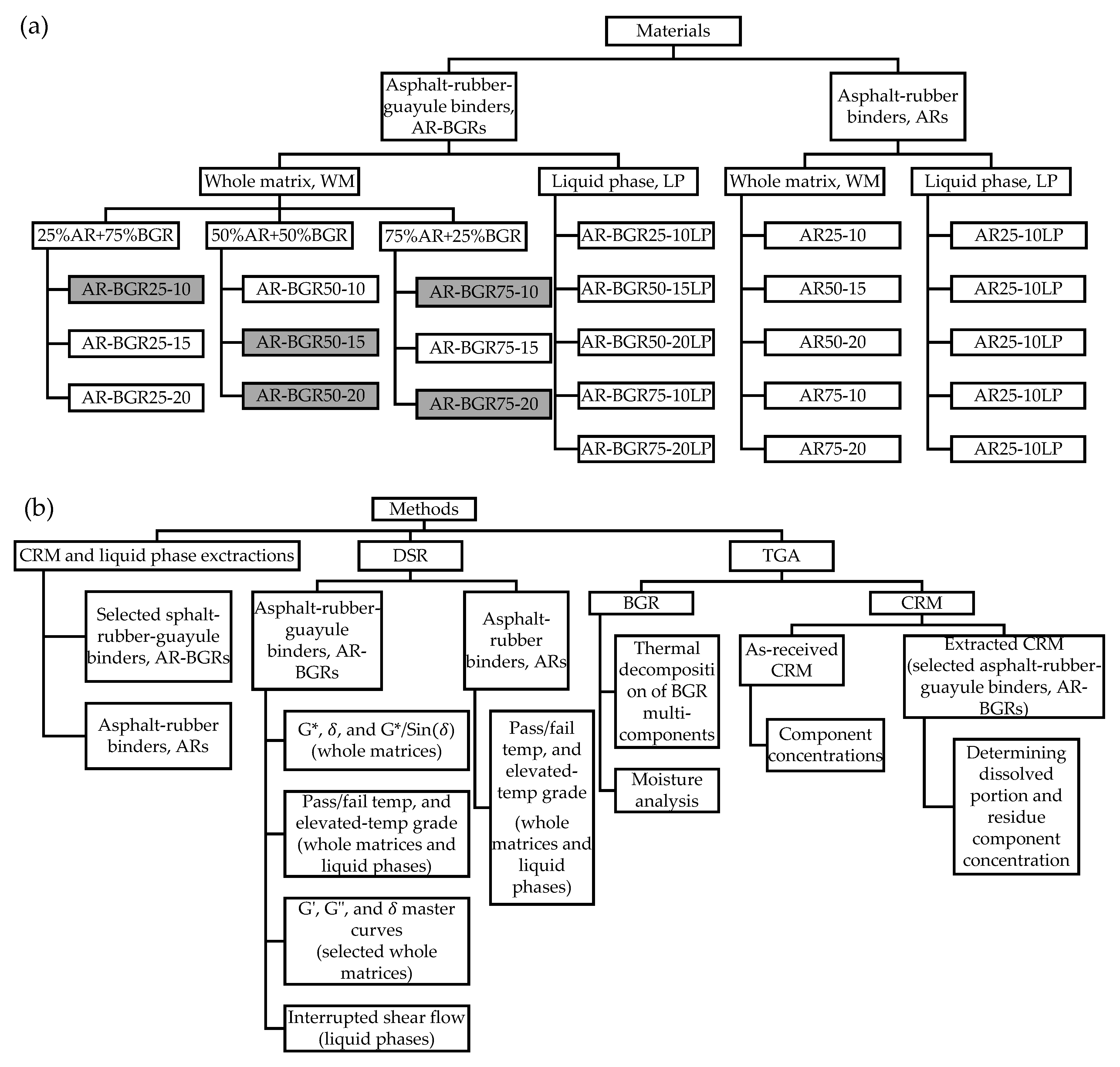

2. Experimental Plan

2.1. Mixing Process

2.2. Sampling

2.2.1. Asphalt–Rubber–Guayule Binder

2.2.2. Asphalt–Rubber Binder

2.3. Methods

2.3.1. CRM and Liquid Phase Extractions, Solubility, and Phase Separation

- CRM Extraction Stepwise

- 10 ± 2 g of modified asphalt is diluted in 100 g of trichloroethylene for 25 min.

- The modified asphalt solution passes through mesh #200 (75 µm).

- Retained CRM particles are washed with extra trichloroethylene until the filtrate becomes colorless.

- Washed CRM particles are kept in an oven at 60 °C for 12 h to ensure a complete solvent removal.

- Liquid Phase Extraction Stepwise

- The required amount of the binder is heated to 165 °C.

- That heated binder is drained through mesh #200 (75 µm) in the oven at 165 °C for 25 min.

- Extracted liquid phase is stored at −12 °C immediately to prevent any unwanted aging or reaction.

2.3.2. Dynamic Shear Rheometer (DSR)

2.3.3. Thermo-Gravimetric Analysis (TGA)

3. Results and Discussion

3.1. Elevated Temperature Tests

3.2. Proceeding with Selected Asphalt–Rubber–Guayule Binders and Asphalt–Rubber Binders

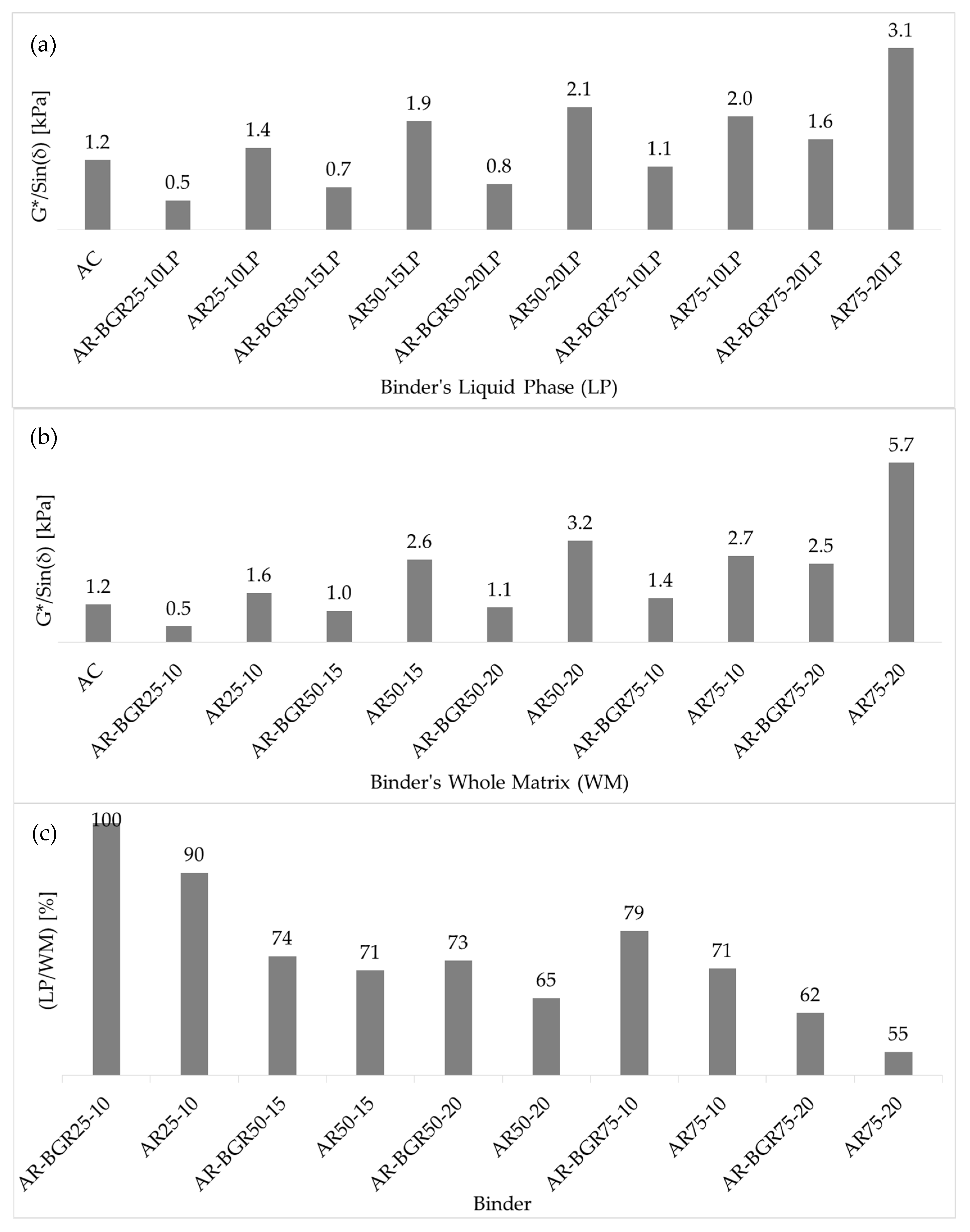

3.2.1. Whole Matrix vs. Liquid Phase Grade Susceptibility

3.2.2. Rutting Parameters: Asphalt–Rubber–Guayule Binders vs. Asphalt–Rubber Binders

3.2.3. Master Curves

3.2.4. Guayule Resin Privilege

3.2.5. Interrupted Shear Flow

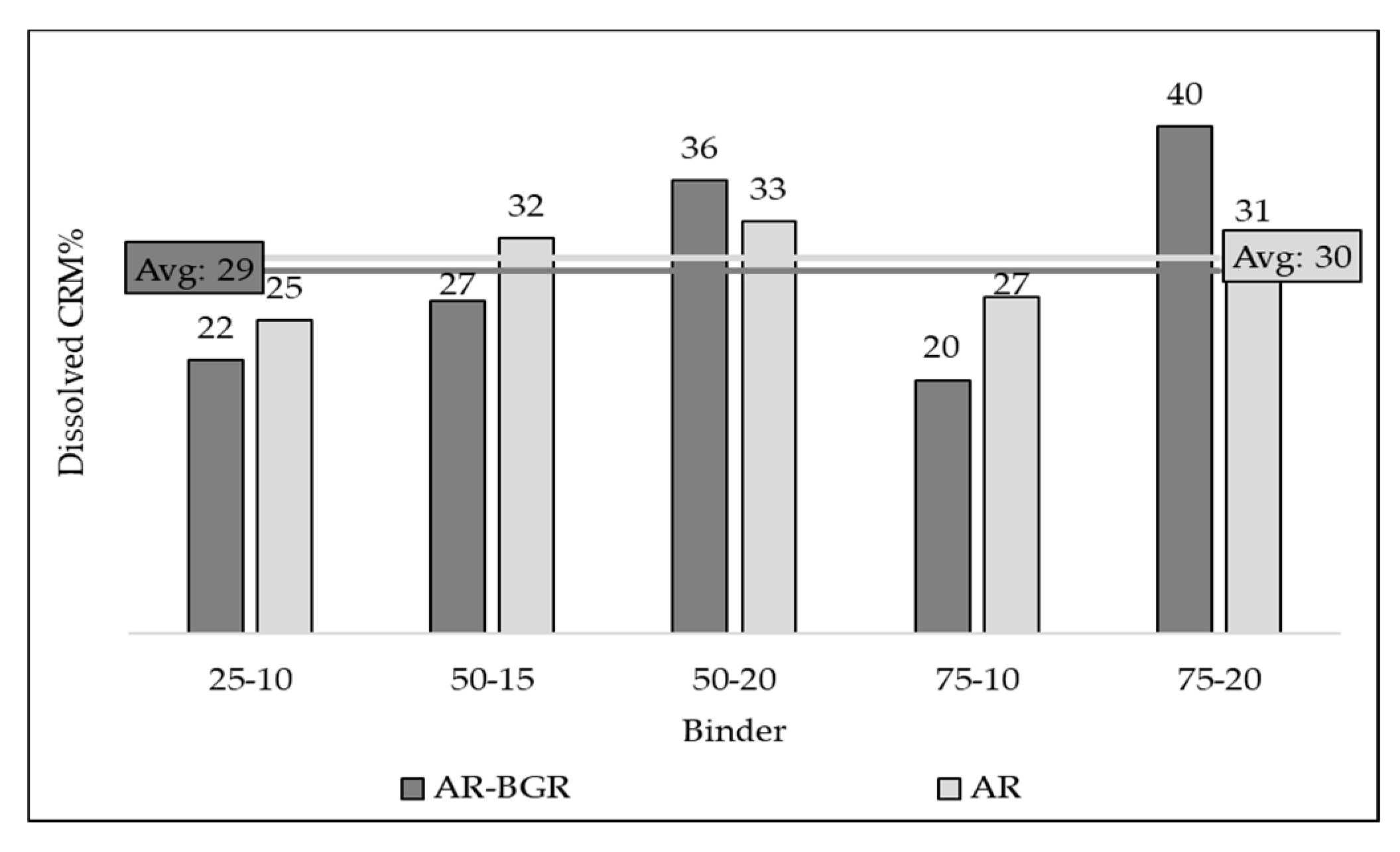

3.2.6. CRM Dissolution: Asphalt–Rubber–Guayule Binders vs. Corresponding Asphalt–Rubber Binders

3.3. TGA

3.3.1. TGA of Guayule Resin

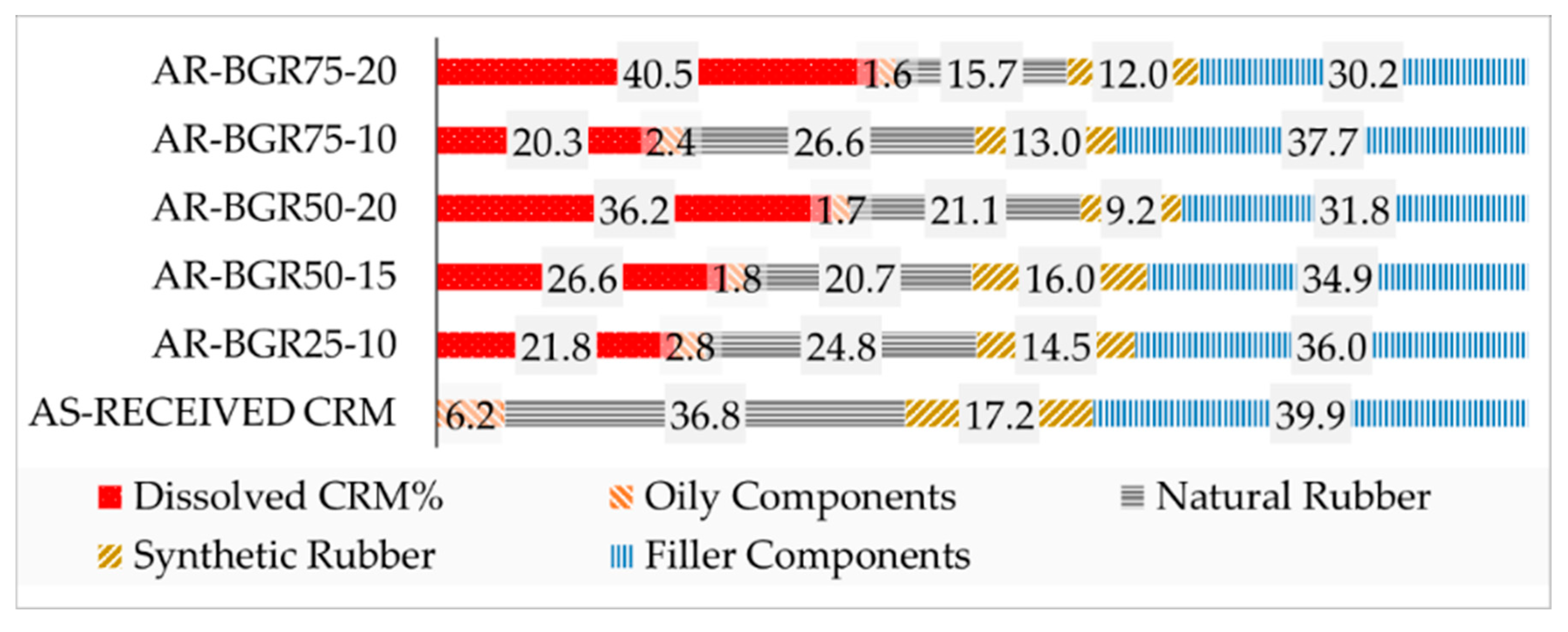

3.3.2. TGA Analysis of CRM

a. As-Received CRM

b. Extracted CRM

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nakayama, F. Guayule future development. Ind. Crop. Prod. 2005, 22, 3–13. [Google Scholar] [CrossRef]

- Tullo, A.H. Guayule gets ready to hit the road. Chem. Eng. News 2015, 93, 18–19. [Google Scholar]

- Schloman, W.W., Jr.; Garrot, D.J., Jr.; Ray, D.T.; Bennett, D.J. Seasonal effects on guayule resin composition. J. Agric. Food Chem. 1986, 34, 177–179. [Google Scholar] [CrossRef]

- Costa, E.; Aguado, J.; Ovejero, G.; Cañizares, P. Conversion of guayule resin to C1-C10 hydrocarbons on zeolite based catalysts. Fuel 1992, 71, 109–113. [Google Scholar] [CrossRef]

- Gumbs, R.W. Guayule Resin Multipolymer. Patent EP2205679A1, 16 April 2009. [Google Scholar]

- Lusher, S.M. Guayule Plant Extracts as Binder Modifiers in Flexible (Asphalt) Pavement Mixtures. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2018. [Google Scholar]

- Schloman, W.W., Jr.; Hively, R.A.; Krishen, A.; Andrews, A.M. Guayule byproduct evaluation: Extract characterization. J. Agric. Food Chem. 1983, 31, 873–876. [Google Scholar] [CrossRef]

- Richardson, D.N.; Lusher, S.M. The Guayule Plant: A Renewable, Domestic Source of Binder Materials for Flexible Pavement Mixtures; Transportation Research Board: Washington, DC, USA, 2013. [Google Scholar]

- Hemida, A.; Abdelrahman, M. A Threshold to Utilize Guayule Resin as a New Binder in Flexible Pavement Industry. Int. J. Eng. Res. Appl. 2018, 8, 83–94. [Google Scholar]

- Wright, N.; Fansler, S.; Lacewell, R. Guayule Economics. Guayule Natural Rubber; Office of Arid Lands Studies: Tucson, AZ, USA, 1991; pp. 351–365. [Google Scholar]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Riddell, A.; Ronson, S.; Counts, G.; Spenser, K. Towards Sustainable Energy: The Current Fossil Fuel Problem and the Prospects of Geothermal and Nuclear Power. Available online: http://web.stanford.edu/class/e297c/trade_environment/energy/hfossil.html (accessed on 25 May 2019).

- Asphalt and Fuel Index: Asphalt Cement Price Index. Available online: http://www.dot.ga.gov/PS/Materials/AsphaltFuelIndex (accessed on 25 May 2019).

- Putman, B.J.; Amirkhanian, S.N. Characterization of the Interaction Effect of Crumb Rubber Modified Binders Using HP-GPC. J. Mater. Civ. Eng. 2010, 22, 153–159. [Google Scholar] [CrossRef]

- Ragab, M. Enhancing the Performance of Crumb Rubber Modified Asphalt through Controlling the Internal Network Structure Developed; North Dakota State University: Fargo, ND, USA, 2016. [Google Scholar]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Mechanism of Crumb Rubber Modifier Dissolution into Asphalt Matrix and Its Effect on Final Physical Properties of Crumb Rubber–Modified Binder. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 92–101. [Google Scholar] [CrossRef]

- Ragab, M.; Abdelrahman, M.; Ghavibazoo, A. New Approach for Selecting Crumb-Rubber-Modified Asphalts for Rutting and Permanent Deformation Resistance. Adv. Civ. Eng. Mater. 2013, 2, 360–378. [Google Scholar] [CrossRef]

- Zanzotto, L.; Kennepohl, G. Development of Rubber and Asphalt Binders by Depolymerization and Devulcanization of Scrap Tires in Asphalt. Transp. Res. Rec. J. Transp. Res. Board 1996, 1530, 51–58. [Google Scholar] [CrossRef]

- Ragab, M.; Abdelrahman, M.; Ghavibazoo, A. Performance Enhancement of Crumb Rubber–Modified Asphalts through Control of the Developed Internal Network Structure. Transp. Res. Rec. J. Transp. Res. Board 2013, 2371, 96–104. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M. Composition analysis of crumb rubber during interaction with asphalt and effect on properties of binder. Int. J. Pavement Eng. 2013, 14, 517–530. [Google Scholar] [CrossRef]

- Attia, M.; Abdelrahman, M. Enhancing the performance of crumb rubber-modified binders through varying the interaction conditions. Int. J. Pavement Eng. 2009, 10, 423–434. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Effect of Crumb Rubber Modifier Dissolution on Storage Stability of Crumb Rubber–Modified Asphalt. Transp. Res. Rec. J. Transp. Res. Board 2013, 2370, 109–115. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M.; Ragab, M. Changes in composition and molecular structure of asphalt in mixing with crumb rubber modifier. Road Mater. Pavement Des. 2016, 17, 906–919. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M. Effect of Crumb Rubber Dissolution on Low-Temperature Performance and Aging of Asphalt–Rubber Binder. Transp. Res. Rec. J. Transp. Res. Board 2014, 2445, 47–55. [Google Scholar] [CrossRef]

- Abdelrahman, M.; Katti, D.R.; Ghavibazoo, A.; Upadhyay, H.B.; Katti, K.S. Engineering Physical Properties of Asphalt Binders through Nanoclay–Asphalt Interactions. J. Mater. Civ. Eng. 2014, 26, 4014099. [Google Scholar] [CrossRef]

- ASTM. ASTM D2042-15, Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- AASHTO. AASHTO T44-13, Standard Method of Test for Solubility of Bituminous Material; American Association of State Highway Transportation Officials (AASHTO): Washington, DC, USA, 2013. [Google Scholar]

- ASTM. ASTM D7173-14, Standard Practice for Determining the Separation Tendency of Polymer from Polymer Modified Asphalt; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Ragab, M.; Abdelrahman, M. Enhancing the crumb rubber modified asphalt’s storage stability through the control of its internal network structure. Int. J. Pavement Res. Technol. 2018, 11, 13–27. [Google Scholar] [CrossRef]

- Hansen, C.M. 50 Years with solubility parameters—Past and future. Prog. Org. Coat. 2004, 51, 77–84. [Google Scholar] [CrossRef]

- Zhang, C.; Kessler, M.R. Bio-based Polyurethane Foam Made from Compatible Blends of Vegetable-Oil-Based Polyol and Petroleum-Based Polyol. ACS Sustain. Chem. Eng. 2015, 3, 743–749. [Google Scholar] [CrossRef]

- Zhao, G.; Ni, H.; Ren, S.; Fang, G. Correlation between Solubility Parameters and Properties of Alkali Lignin/PVA Composites. Polymers 2018, 10, 290. [Google Scholar] [CrossRef]

- Duong, D.T.; Walker, B.; Kim, C.; Purushothaman, B.; Nguyen, T.-Q.; Lin, J.; Love, J.; Anthony, J.E.; Nguyen, T. Molecular solubility and hansen solubility parameters for the analysis of phase separation in bulk heterojunctions. J. Polym. Sci. Part B Polym. Phys. 2012, 50, 1405–1413. [Google Scholar] [CrossRef]

- Hansen, C.M. Solubility Parameters: A User’s Handbook; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- AASHTO. AASHTO T315-12, Standard Method of Test for Determining the Rheological Properties of Asphalt Binder Using a Dynamic Shear Rheometer (DSR); American Association of State Highway Transportation Officials (AASHTO): Washington, DC, USA, 2013. [Google Scholar]

- Wekumbura, C.; Stastna, J.; Zanzotto, L. Destruction and Recovery of Internal Structure in Polymer-Modified Asphalts. J. Mater. Civ. Eng. 2007, 19, 227–232. [Google Scholar] [CrossRef]

- Jasso, M.; Bakoš, D.; Stastna, J.; Zanzotto, L. Conventional asphalt modified by physical mixtures of linear SBS and montmorillonite. Appl. Clay Sci. 2012, 70, 37–44. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S. The influence of crumb rubber modifier (CRM) microstructures on the high temperature properties of CRM binders. Int. J. Pavement Eng. 2005, 6, 265–271. [Google Scholar] [CrossRef]

- Lee, S.-J.; Amirkhanian, S.N.; Shatanawi, K.; Kim, K.W. Short-term aging characterization of asphalt binders using gel permeation chromatography and selected Superpave binder tests. Constr. Build. Mater. 2008, 22, 2220–2227. [Google Scholar] [CrossRef]

- Diab, A.; You, Z. Small and large strain rheological characterizations of polymer- and crumb rubber-modified asphalt binders. Constr. Build. Mater. 2017, 144, 168–177. [Google Scholar] [CrossRef]

- Ghavibazoo, A.; Abdelrahman, M. Monitoring Changes in Composition of Crumb Rubber Modifier During Interaction with Asphalt and Its Effect on Final Modified Asphalt Performance. In Proceedings of the 91st Annual Meeting of the Transportation Research Board, Washington, DC, USA, 22–26 January 2012. [Google Scholar]

- Parkes, G.M.B.; Barnes, P.A.; Charsley, E.L. New Concepts in Sample Controlled Thermal Analysis: Resolution in the Time and Temperature Domains. Anal. Chem. 1999, 71, 2482–2487. [Google Scholar] [CrossRef]

| Group | Subgroup/Code | Binder Proportions | ||||

|---|---|---|---|---|---|---|

| AR% by wt. of Blend | BGR% by wt. of Blend | CRM% by wt. of AC | CRM% by wt. of Blend | AC% by wt. of Blend | ||

| 25% AR + 75% BGR | AR-BGR25-10 1 | 25 | 75 | 10 | 2.3 | 22.7 |

| AR-BGR25-15 1 | 25 | 75 | 15 | 3.3 | 21.7 | |

| AR-BGR25-20 1 | 25 | 75 | 20 | 4.2 | 20.8 | |

| AR25-10 2 | 100 | 0 | 2.4 | 2.3 | 97.7 | |

| 50% AR + 50% BGR | AR-BGR50-10 1 | 50 | 50 | 10 | 4.5 | 45.5 |

| AR-BGR50-15 1 | 50 | 50 | 15 | 6.5 | 43.5 | |

| AR-BGR50-20 1 | 50 | 50 | 20 | 8.3 | 41.7 | |

| AR50-15 2 | 100 | 0 | 7 | 6.5 | 93.5 | |

| AR50-20 2 | 100 | 0 | 9.1 | 8.3 | 91.7 | |

| 75% AR + 25% BGR | AR-BGR75-10 1 | 75 | 25 | 10 | 6.8 | 68.2 |

| AR-BGR75-15 1 | 75 | 25 | 15 | 9.8 | 65.2 | |

| AR-BGR75-20 1 | 75 | 25 | 20 | 12.5 | 62.5 | |

| AR75-10 2 | 100 | 0 | 7.3 | 6.8 | 93.2 | |

| AR75-20 2 | 100 | 0 | 14.3 | 12.5 | 87.5 | |

| Binder | Binder Code | Temp [°C] | G* [kPa] | [°] | G*/sin(δ) [kPa] | Pass/Fail Temp [°C] | Elevated-Temp Grad |

|---|---|---|---|---|---|---|---|

| Original Asphalt | AC | 46 | 14.8 | 81 | 15.0 | 65.6 | 64 |

| 52 | 6.1 | 83 | 6.2 | ||||

| 58 | 2.7 | 85 | 2.7 | ||||

| 64 | 1.2 | 87 | 1.2 | ||||

| 70 | 0.6 | 88 | 0.6 | ||||

| BGR (Unconditioned) | B(U) | 46 | 5.1 | 85 | 5.1 | 55.0 | 52 |

| 52 | 1.7 | 87 | 1.7 | ||||

| 58 | 0.6 | 87 | 0.6 | ||||

| BGR-600-160(2 h) 1 | B(2) | 46 | 8.5 | 85 | 8.5 | 57.2 | 52 |

| 52 | 2.5 | 87 | 2.5 | ||||

| 58 | 0.9 | 87 | 0.9 | ||||

| BGR-600-160(4 h) 1 | B(4) | 46 | 9.4 | 85 | 9.5 | 57.4 | 52 |

| 52 | 2.7 | 86 | 2.7 | ||||

| 58 | 0.9 | 87 | 0.9 | ||||

| 25% AR (10% CRM) + 75% BGR 2 | AR-BGR25-10 | 46 | 10.8 | 84 | 10.9 | 59.3 | 58 |

| 52 | 3.5 | 85 | 3.6 | ||||

| 58 | 1.2 | 87 | 1.2 | ||||

| 64 | 0.5 | 87 | 0.5 | ||||

| 50% AR (10% CRM) + 50% BGR 2 | AR-BGR50-10 | 46 | 13.1 | 81 | 13.3 | 62.3 | 58 |

| 52 | 4.6 | 84 | 4.7 | ||||

| 58 | 1.8 | 85 | 1.8 | ||||

| 64 | 0.8 | 87 | 0.8 | ||||

| 75% AR (10% CRM) + 25% BGR 2 | AR-BGR75-10 | 46 | 18.9 | 75 | 19.6 | 67.0 | 64 |

| 52 | 7.5 | 79 | 7.7 | ||||

| 58 | 3.2 | 82 | 3.2 | ||||

| 64 | 1.4 | 85 | 1.4 | ||||

| 70 | 0.7 | 86 | 0.7 | ||||

| 25% AR (15% CRM) + 75% BGR 2 | AR-BGR25-15 | 46 | 10.7 | 82 | 10.8 | 60.2 | 58 |

| 52 | 3.7 | 84 | 3.7 | ||||

| 58 | 1.4 | 86 | 1.4 | ||||

| 64 | 0.6 | 87 | 0.6 | ||||

| 50% AR (15% CRM) + 50% BGR 2 | AR-BGR50-15 | 46 | 14.4 | 78 | 14.7 | 64.0 | 64 |

| 52 | 5.4 | 80 | 5.5 | ||||

| 58 | 2.2 | 82 | 2.2 | ||||

| 64 | 1.0 | 84 | 1.0 | ||||

| 70 | 0.5 | 85 | 0.5 | ||||

| 75% AR (15% CRM) + 25% BGR 2 | AR-BGR75-15 | 46 | 23.0 | 70 | 24.6 | 70.9 | 70 |

| 52 | 10.0 | 72 | 10.5 | ||||

| 58 | 4.6 | 76 | 4.7 | ||||

| 64 | 2.2 | 79 | 2.2 | ||||

| 70 | 1.1 | 82 | 1.1 | ||||

| 76 | 0.6 | 84 | 0.6 | ||||

| 25% AR (20% CRM) + 75% BGR 2 | AR-BGR25-20 | 46 | 10.9 | 82 | 11.0 | 61.0 | 58 |

| 52 | 3.9 | 84 | 4.0 | ||||

| 58 | 1.5 | 85 | 1.5 | ||||

| 64 | 0.6 | 86 | 0.6 | ||||

| 50% AR (20% CRM) + 50% BGR 2 | AR-BGR50-20 | 46 | 15.0 | 76 | 15.5 | 64.7 | 64 |

| 52 | 5.8 | 79 | 5.9 | ||||

| 58 | 2.4 | 81 | 2.4 | ||||

| 64 | 1.1 | 83 | 1.1 | ||||

| 70 | 0.5 | 85 | 0.5 | ||||

| 75% AR (20% CRM) + 25% BGR 2 | AR-BGR75-20 | 46 | 22.6 | 68 | 24.5 | 72.2 | 70 |

| 52 | 10.3 | 70 | 10.9 | ||||

| 58 | 4.9 | 73 | 5.1 | ||||

| 64 | 2.4 | 77 | 2.5 | ||||

| 70 | 1.2 | 79 | 1.3 | ||||

| 76 | 0.7 | 82 | 0.7 |

| Binder | Binder Code | Justification for Selection (Upon Study Limitations) |

|---|---|---|

| 75% AR (10% CRM) + 25% BGR | AR-BGR75-10 | Low concentrations of CRM (10% by wt. of AC) and guayule resin (25% by wt. of blend) that could significantly achieve the same high grade of the original asphalt. |

| 50% AR (20% CRM) + 50% BGR | AR-BGR50-20 | High CRM concentration (20%) and average guayule resin concentration, 50% that could significantly achieve the same grade of the original asphalt. |

| 50% AR (15% CRM) + 50% BGR | AR-BGR50-15 | Compared to the last, the CRM was lowered to 15%, the critical requirement (very close to G*/Sin(δ) of 1 kPa at 64 °C) could be accomplished. |

| 25% AR (10% CRM) + 75% BGR | AR-BGR25-10 | Low concentrations of CRM (10%) and asphalt (25%) to show results away from achieving that of the original asphalt. |

| 75% AR (20% CRM) + 25% BGR | AR-BGR75-20 | Highest concentrations of CRM (20%) and asphalt (75%) that could go beyond the original asphalt performance. |

| Binder | Binder Code | CRM% by wt. of Blend | Whole Matrix | Liquid Phase | LP% 1 | ||

|---|---|---|---|---|---|---|---|

| Pass/Fail Temp [°C] | PG | Pass/Fail Temp [°C] | PG | ||||

| 25% AR (10% CRM) + 75% BGR | AR-BGR25-10 | 2.3 | 59.3 | 58 | 59.1 | 58 | 99.6 |

| 25% AR (10% CRM) + 75% AC | AR25-10 | 2.3 | 67.8 | 64 | 66.9 | 64 | 98.7 |

| 50% AR (15% CRM) + 50% BGR | AR-BGR50-15 | 6.5 | 64.0 | 64 | 61.8 | 58 | 96.5 |

| 50% AR (15% CRM) + 50% AC | AR50-15 | 6.5 | 72.3 | 70 | 69.1 | 64 | 95.7 |

| 50% AR (20% CRM) + 50% BGR | AR-BGR50-20 | 8.3 | 64.7 | 64 | 62.2 | 58 | 96.2 |

| 50% AR (20% CRM) + 50% AC | AR50-20 | 8.3 | 74.4 | 70 | 70.2 | 70 | 94.3 |

| 75% AR (10% CRM) + 25% BGR | AR-BGR75-10 | 6.8 | 67.0 | 64 | 64.7 | 64 | 96.6 |

| 75% AR (10% CRM) + 25% AC | AR75-10 | 6.8 | 72.9 | 70 | 69.5 | 64 | 95.3 |

| 75% AR (20% CRM) + 25% BGR | AR-BGR75-20 | 12.5 | 72.2 | 70 | 67.6 | 64 | 93.6 |

| 75% AR (20% CRM) +25% AC | AR75-20 | 12.5 | 80.5 | 76 | 73.5 | 70 | 91.3 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hemida, A.; Abdelrahman, M. Influence of Guayule Resin as a Bio-Based Additive on Asphalt–Rubber Binder at Elevated Temperatures. Recycling 2019, 4, 38. https://doi.org/10.3390/recycling4030038

Hemida A, Abdelrahman M. Influence of Guayule Resin as a Bio-Based Additive on Asphalt–Rubber Binder at Elevated Temperatures. Recycling. 2019; 4(3):38. https://doi.org/10.3390/recycling4030038

Chicago/Turabian StyleHemida, Ahmed, and Magdy Abdelrahman. 2019. "Influence of Guayule Resin as a Bio-Based Additive on Asphalt–Rubber Binder at Elevated Temperatures" Recycling 4, no. 3: 38. https://doi.org/10.3390/recycling4030038

APA StyleHemida, A., & Abdelrahman, M. (2019). Influence of Guayule Resin as a Bio-Based Additive on Asphalt–Rubber Binder at Elevated Temperatures. Recycling, 4(3), 38. https://doi.org/10.3390/recycling4030038