Recycling of WEEE Plastics Waste in Mortar: The Effects on Mechanical Properties

Abstract

:1. Introduction

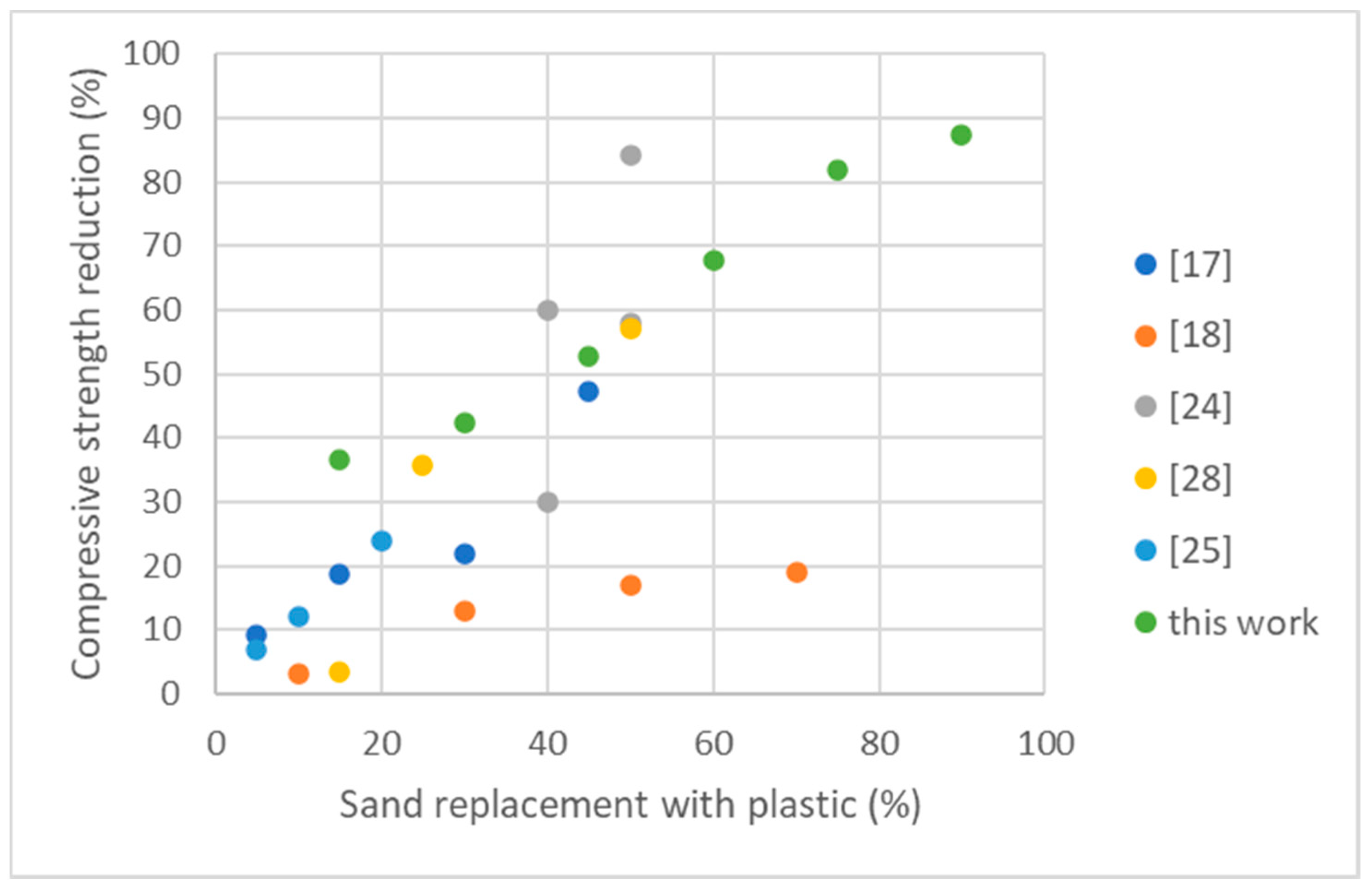

2. Results and Discussion

Mechanical Properties

3. Materials and Methods

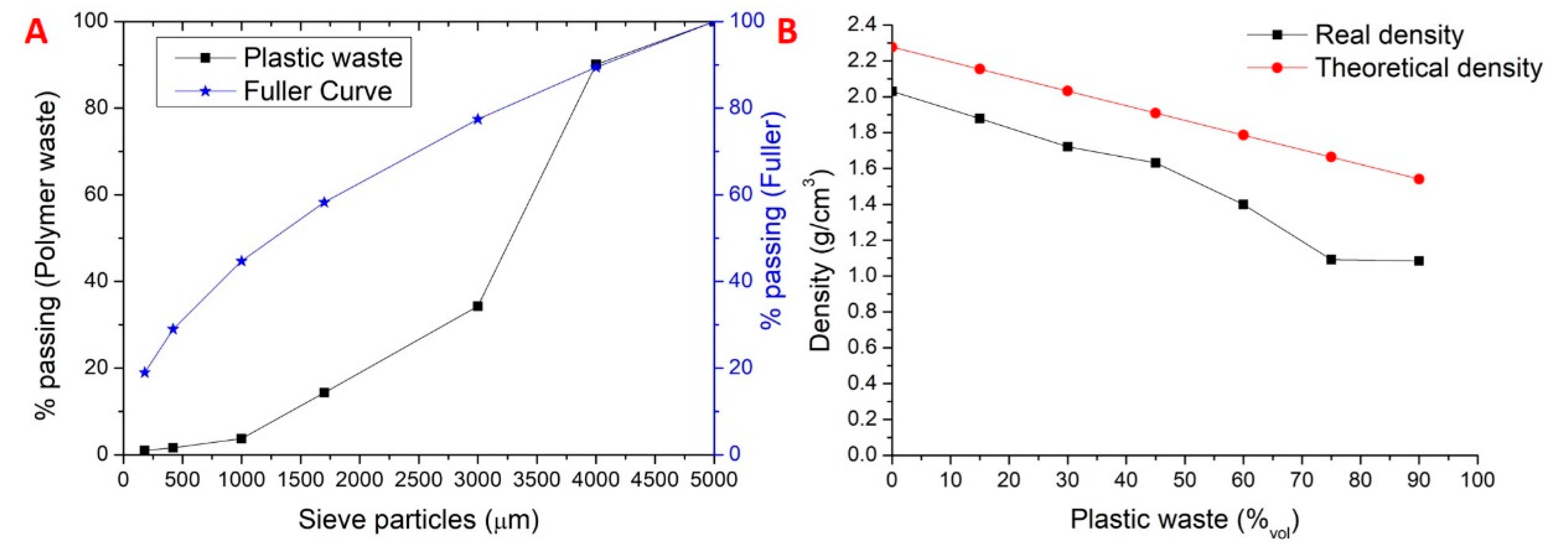

3.1. Materials

3.2. Preparation of Specimens

3.3. Density and Mechanical Properties and Optical Characterization

3.4. Characterization of Plastic Waste

4. Conclusions

- The use of plastic in the substitution of the aggregates reduces the density of the mortar and also decreases the need for natural resources, but still allows maintain mechanical properties sufficient for use in non-structural applications to be maintained, for instance, for use in screeds or substrates in the construction sector.

- It was demonstrated that the lower mechanical properties of plastic aggregates and in particular the lack of adhesion at the interface are the main causes of the reduction in mechanical properties of the mortars. The low adhesion of the interface generates additional porosity and reduces the mechanical contribution of the plastic itself, overall leading to a strong reduction in strength even at rather low plastic content (15%vol).

- The comparison of experimental data with the main models describing the mechanical properties of porous materials confirmed the low mechanical contribution of plastic aggregates.

- To tackle the mechanical issues and to improve the properties for plastic-substitute mortars (thus allowing a more widespread use of these materials in the building sector), low-cost strategies are necessary.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- PlasticEurope an Analysis of European Plastics Production, Demand and Waste Data. 2019. Available online: https://www.plasticseurope.org/application/files/9715/7129/9584/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 8 September 2021).

- Anuar Sharuddin, S.D.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A Review on Pyrolysis of Plastic Wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. Recycling and Recovery Routes of Plastic Solid Waste (PSW): A Review. Waste Manag. 2009, 29, 2625–2643. [Google Scholar] [CrossRef]

- Gu, L.; Ozbakkaloglu, T. Use of Recycled Plastics in Concrete: A Critical Review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Dan Gavriletea, M. Environmental Impacts of Sand Exploitation. Analysis of Sand Market. Sustainability 2017, 9, 1118. [Google Scholar] [CrossRef] [Green Version]

- Ferrè, F.; Via, A.; Ausiello, G.; Brannetti, B.; Zanzoni, A.; Helmer-Citterich, M. Sustainable Development and the Exploitation of Mineral and Energy Resources: A Review. Int. J. Earth Sci. 2002, 91, 723–745. [Google Scholar] [CrossRef]

- Puneeth, H.C.; Mahendra, S.P.; Rohith, M.; Naveenkumar, K. Replacement of Fine Aggregates by Recycled Construction and Demolition Waste in Pavement Quality Concrete; Das, B.B., Neithalath, N., Eds.; Springer: Singapore, 2019; ISBN 978-981-13-3317-0. [Google Scholar]

- Lavagna, L.; Nisticò, R.; Sarasso, M.; Pavese, M. An Analytical Mini-Review on the Compression Strength of Rubberized Concrete as a Function of the Amount of Recycled Tires Crumb Rubber. Materials 2020, 13, 1234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nisticò, R.; Lavagna, L.; Versaci, D.; Ivanchenko, P.; Benzi, P. Chitosan and Its Char as Fillers in Cement-Base Composites: A Case Study. Boletín De La Soc. Española De Cerámica Y Vidr. 2020, 59, 186–192. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Recycling of Waste Glass as a Partial Replacement for Fine Aggregate in Concrete. Waste Manag. 2009, 29, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Nisticò, R.; Lavagna, L.; Boot, E.A.; Ivanchenko, P.; Lorusso, M.; Bosia, F.; Pugno, N.M.; D’Angelo, D.; Pavese, M. Improving Rubber Concrete Strength and Toughness by Plasma-induced End-of-life Tire Rubber Surface Modification. Plasma Process. Polym. 2021, 18, 2100081. [Google Scholar] [CrossRef]

- Suarez-Riera, D.; Merlo, A.; Lavagna, L.; Nisticò, R.; Pavese, M. Mechanical Properties of Mortar Containing Recycled Acanthocardia Tuberculata Seashells as Aggregate Partial Replacement. Boletín De La Soc. Española De Cerámica Y Vidr. 2021, 60, 206–210. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of Different Forms of Waste Plastic in Concrete—A Review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Liguori, B.; Iucolano, F.; Capasso, I.; Lavorgna, M.; Verdolotti, L. The Effect of Recycled Plastic Aggregate on Chemico-Physical and Functional Properties of Composite Mortars. Mater. Des. 2014, 57, 578–584. [Google Scholar] [CrossRef]

- Badache, A.; Benosman, A.S.; Senhadji, Y.; Mouli, M. Thermo-Physical and Mechanical Characteristics of Sand-Based Lightweight Composite Mortars with Recycled High-Density Polyethylene (HDPE). Constr. Build. Mater. 2018, 163, 40–52. [Google Scholar] [CrossRef]

- Benosman, A.S.; Taïbi, H.; Senhadji, Y.; Mouli, M.; Belbachir, M.; Bahlouli, M.I. Plastic Waste Particles in Mortar Composites: Sulfate Resistance and Thermal Coefficients. Prog. Rubber Plast. Recycl. Technol. 2017, 33, 171–202. [Google Scholar] [CrossRef]

- Kou, S.C.; Lee, G.; Poon, C.S.; Lai, W.L. Properties of Lightweight Aggregate Concrete Prepared with PVC Granules Derived from Scraped PVC Pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef]

- Senhadji, Y.; Siad, H.; Escadeillas, G.; Benosman, A.S.; Chihaoui, R.; Mouli, M.; Lachemi, M. Physical, Mechanical and Thermal Properties of Lightweight Composite Mortars Containing Recycled Polyvinyl Chloride. Constr. Build. Mater. 2019, 195, 198–207. [Google Scholar] [CrossRef]

- Agarwal, L.K.; Felix, P.S. Strength and Behavior of Concrete Contains Waste Plastic (High Density PVC) Aggregates As Partial Replacement of Coarse Aggregates. Int. J. Eng. Res. Technol. 2019, 8, 1044–1049. [Google Scholar]

- Najjar, A.M.K.; Basha, E.A.; Milad, B.K. Rigid Polyvinyl Chloride Waste for Partial Replacement of Natural Coarse Aggregate in Concrete Mixture. Int. J. Chem. Environ. Eng. 2013, 4, 399–403. [Google Scholar]

- Bolat, H.; Erkus, P. Use of Polyvinyl Chloride (PVC) Powder and Granules as Aggregate Replacement in Concrete Mixtures. Sci. Eng. Compos. Mater. 2016, 23, 209–216. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; Etli, S.; Alhassan, M. Mechanical and Fracture Characteristics of Self-Compacting Concretes Containing Different Percentage of Plastic Waste Powder. Constr. Build. Mater. 2017, 140, 562–569. [Google Scholar] [CrossRef]

- Merlo, A.; Lavagna, L.; Suarez-Riera, D.; Pavese, M. Mechanical Properties of Mortar Containing Waste Plastic (PVC) as Aggregate Partial Replacement. Case Stud. Constr. Mater. 2020, 13, e00467. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mohamed, A.M. Eco-Friendly Concrete Containing Recycled Plastic as Partial Replacement for Sand. J. Mater. Res. Technol. 2020, 9, 4631–4643. [Google Scholar] [CrossRef]

- Mustafa, M.A.-T.; Hanafi, I.; Mahmoud, R.; Tayeh, B.A. Effect of Partial Replacement of Sand by Plastic Waste on Impact Resistance of Concrete: Experiment and Simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Senhadji, Y.; Escadeillas, G.; Benosman, A.S.; Mouli, M.; Khelafi, H.; Kaci, S.O. Effect of Incorporating PVC Waste as Aggregate on the Physical, Mechanical, and Chloride Ion Penetration Behavior of Concrete. J. Adhes. Sci. Technol. 2015, 29, 625–640. [Google Scholar] [CrossRef]

- Hussein, H.H.; Ahmed, M.K. Mechanical, Thermal and Acoustical Properties of Concrete with Fine Polyvinyl Chloride (PVC). Iraqi J. Civ. Eng. 2016, 12, 81–91. [Google Scholar]

- Abed, J.M.; Khaleel, B.A.; Aldabagh, I.S.; Sor, N.H. The Effect of Recycled Plastic Waste Polyethylene Terephthalate (PET) on Characteristics of Cement Mortar. J. Phys. Conf. Ser. 2021, 1973, 012121. [Google Scholar] [CrossRef]

- Dawood, A.O.; AL-Khazraji, H.; Falih, R.S. Physical and Mechanical Properties of Concrete Containing PET Wastes as a Partial Replacement for Fine Aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Waste Polyethylene Terephthalate as an Aggregate in Concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef] [Green Version]

- Balshin, M.Y. Relation of Mechanical Properties of Powder Metals and Their Porosity and the Ultimate Properties of Porous Metal-Ceramic Materials. Dokl. Akad. Nauk SSSR 1949, 67, 831–834. [Google Scholar]

- RYSHKEWITCH, E. Compression Strength of Porous Sintered Alumina and Zirconia. J. Am. Ceram. Soc. 1953, 36, 65–68. [Google Scholar] [CrossRef]

- HASSELMAN, D.P.H. Griffith Flaws and the Effect of Porosity on Tensile Strength of Brittle Ceramics. J. Am. Ceram. Soc. 1969, 52, 457. [Google Scholar] [CrossRef]

- Chen, X.; Wu, S.; Zhou, J. Influence of Porosity on Compressive and Tensile Strength of Cement Mortar. Constr. Build. Mater. 2013, 40, 869–874. [Google Scholar] [CrossRef]

- Schiller, K.K. Strength of Porous Materials. Cem. Concr. Res. 1971, 1, 419–422. [Google Scholar] [CrossRef]

- Song, Y.; Zhou, J.; Bian, Z.; Dai, G. Pore Structure Characterization of Hardened Cement Paste by Multiple Methods. Adv. Mater. Sci. Eng. 2019, 2019, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Winslow, D.; Liu, D. The Pore Structure of Paste in Concrete. Cem. Concr. Res. 1990, 20, 227–235. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of Plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: A Review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Almeshal, I.; Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Mustafa Mohamed, A.; Alaskar, A. Use of Recycled Plastic as Fine Aggregate in Cementitious Composites: A Review. Constr. Build. Mater. 2020, 253, 119146. [Google Scholar] [CrossRef]

- Odler, I.; Rossler, M. Investigations on the Relationship between Porosity, Structure and Strength of Hydrated Portland Cement Pastes 1. Effect of Porosity. Cem. Concr. Res. 1985, 15, 320–330. [Google Scholar] [CrossRef]

- Thorneycroft, J.; Orr, J.; Savoikar, P.; Ball, R.J. Performance of Structural Concrete with Recycled Plastic Waste as a Partial Replacement for Sand. Constr. Build. Mater. 2018, 161, 63–69. [Google Scholar] [CrossRef]

| Property | Type of Porosity | Balshin | Ryshkewitch | Hasselman | Zheng | Schiller |

|---|---|---|---|---|---|---|

| Flexural strength | Only extra-porosity | 0.8987 | 0.9094 | 0.7478 | 0.8595 | 0.9492 |

| Extra-porosity + plastic | 0.9570 | 0.9766 | 0.9170 | 0.9779 | 0.8459 | |

| Compressive strength | Only extra-porosity | 0.8899 | 0.9012 | 0.7547 | 0.8573 | 0.9438 |

| Extra-porosity + plastic | 0.9539 | 0.9739 | 0.9201 | 0.9761 | 0.8401 | |

| Young’s modulus | Only extra-porosity | 0.9160 | 0.9193 | 0.6196 | 0.7794 * | 0.9184 |

| Extra-porosity + plastic | 0.9819 | 0.9944 | 0.8373 | 0.9795 | 0.8608 |

| σ0 (MPa) | E0 (GPa) | |||||

|---|---|---|---|---|---|---|

| f | Compression Strength | Flexural Strength | Ryshkewitch | Zheng | ||

| Ryshkewitch | Zheng | Ryshkewitch | Zheng | |||

| 0 | 25.2 | 23.5 | 6.59 | 6.09 | 29.6 | 19.3 * |

| 0.1 | 26.1 | 24.6 | 6.80 | 6.36 | 29.8 | 21.5 * |

| 0.2 | 26.5 | 25.3 | 6.89 | 6.54 | 29.9 | 23.6 * |

| 0.3 | 26.8 | 25.7 | 6.95 | 6.66 | 30.0 | 25.4 * |

| 0.4 | 26.9 | 26.1 | 6.99 | 6.74 | 30.0 | 27.0 * |

| 0.5 | 27.0 | 26.3 | 7.02 | 6.81 | 30.1 | 28.5 * |

| 0.6 | 27.1 | 26.5 | 7.04 | 6.86 | 30.1 | 29.7 * |

| 0.7 | 27.2 | 26.7 | 7.06 | 6.90 | 30.1 | 29.2 |

| 0.8 | 27.3 | 26.8 | 7.07 | 6.93 | 30.1 | 29.2 |

| 0.9 | 27.3 | 26.9 | 7.08 | 6.95 | 30.2 | 29.3 |

| 1 | 27.3 | 26.9 | 7.09 | 6.97 | 30.2 | 29.3 |

| Oxide | (wt.%) | Phase | (wt.%) |

|---|---|---|---|

| SiO2 | 21.7 | C3S | 66 |

| CaO | 62.9 | C2S | 18 |

| Al2O3 | 3.2 | C3A | 7 |

| Fe2O3 | 2.7 | C4AF | 9 |

| MgO | 4.3 | ||

| SO3 | 2.2 | ||

| Na2O | 0.54 | ||

| Loss on ignition | 0.74 | ||

| Insoluble residue | 0.14 |

| Name of Sample | Cement (g) | Water (g) | Sand (g) | PW (g) |

|---|---|---|---|---|

| 0 PW | 71.2 | 35.6 | 213.7 | 0 |

| 15 PW | 71.2 | 35.6 | 181.7 | 14.8 |

| 30 PW | 71.2 | 35.6 | 149.6 | 29.6 |

| 45 PW | 71.2 | 35.6 | 117.6 | 44.39 |

| 60 PW | 71.2 | 35.6 | 85.5 | 59.18 |

| 75 PW | 71.2 | 35.6 | 53.4 | 73.97 |

| 90 PW | 71.2 | 35.6 | 21.4 | 88.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merlo, A.; Lavagna, L.; Suarez-Riera, D.; Pavese, M. Recycling of WEEE Plastics Waste in Mortar: The Effects on Mechanical Properties. Recycling 2021, 6, 70. https://doi.org/10.3390/recycling6040070

Merlo A, Lavagna L, Suarez-Riera D, Pavese M. Recycling of WEEE Plastics Waste in Mortar: The Effects on Mechanical Properties. Recycling. 2021; 6(4):70. https://doi.org/10.3390/recycling6040070

Chicago/Turabian StyleMerlo, Alessandra, Luca Lavagna, Daniel Suarez-Riera, and Matteo Pavese. 2021. "Recycling of WEEE Plastics Waste in Mortar: The Effects on Mechanical Properties" Recycling 6, no. 4: 70. https://doi.org/10.3390/recycling6040070

APA StyleMerlo, A., Lavagna, L., Suarez-Riera, D., & Pavese, M. (2021). Recycling of WEEE Plastics Waste in Mortar: The Effects on Mechanical Properties. Recycling, 6(4), 70. https://doi.org/10.3390/recycling6040070