An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization

Abstract

:1. Introduction

2. Procedure in the Disassembly of Battery Packs

2.1. Legal Framework

- Specification of the carbon footprint of the manufacturing process

- Specification of the recyclate use from 2027 and from 2030 onwards

- Information on the durability and performance

- Easy removal and replacement of batteries from devices at the end-of-life

- Increasing the recycling efficiencies for lithium-ion batteries of 65% (from 2025) and 70% (from 2030) and material recovery rates for individual battery components (e.g., lithium, 70% from 2026 [4])

- Battery passport to provide basic information about the battery

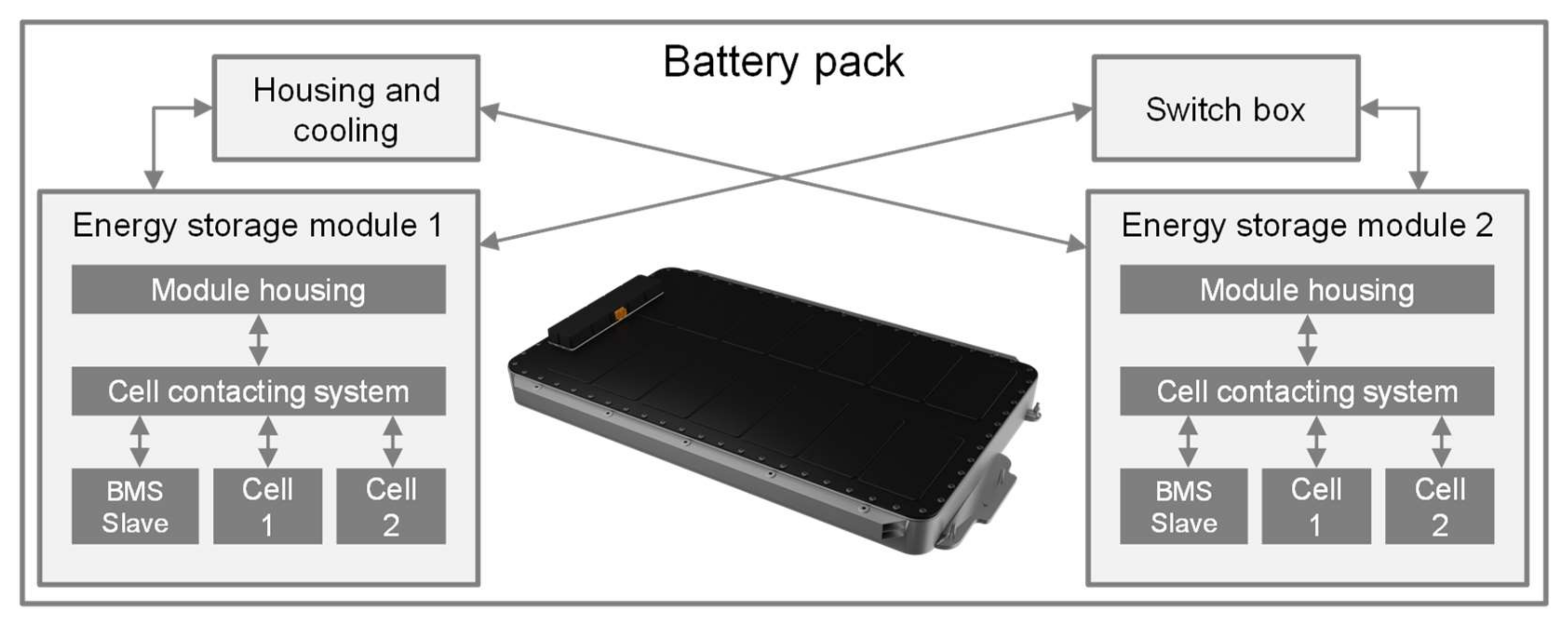

2.2. Disassembly Process of Lithium-Ion Traction Batteries

2.3. Challenges in Automating the Lithium-Ion Traction Battery Disassembly Process

3. Methodical Approach for an Automated Disassembly and Intelligent Sorting Process

3.1. Framework Approach and Tools for a Digitization of the Process

3.1.1. Image Capture: Depth Sensor Selection

- Structured Light: The camera has a projector and a 2D camera (see Figure 7). The projector sends light patterns onto the scene, while the camera captures the distortion of this pattern that is created by the underlying geometry. Based on this, the point cloud is calculated.

- Output: High resolution 3D RGB point cloud → in comparison many high resolution point clouds of other camera models do not inhibit RGB information

- Increased robustness against reflections

- Lightweight (mounting on robot)

- Advanced hand-eye-calibration-API (mounting on robot)

- No translucent objects

- Depth image acquisition only in stationary mode, i.e., the camera must be motionless (on-the-fly data acquisition not possible)

- Limited use with highly reflective surfaces

- Should not be used outside or with direct light incidence

3.1.2. Instance Segmentation

- Screws on the lid

- Switch box

- Modules

- Busbars, six different types

- Plugs

- Case interface

- BMS Slave mounting

- Main power wire consisting of side parts, a middle part, pipes and clips

3.1.3. Point Cloud Registration

3.2. Sensor-Based Material Detection

- Busbars

- Wires

- Screws

- Housing

- Electronic (e.g., battery management system)

- Residues (e.g., rubber)

3.3. Labeling as a Support of Disassembly and Sorting Process

- Identification of the individual battery pack

- General information about the battery pack (including discharging information)

- Battery module

- Battery cell (including the detailed cell chemistry)

- Disassembly instructions

- 0 = no danger

- 1 = electric shock (can lead to death of a person or overheating of the battery up to fire)

- 2 = chemical hazard (e.g., leakage of electrolyte or carcinogenic substances (cobalt, lithium)

- 3 = thermal hazard (due to mechanical hazard and leaking electrolyte, the carbonates of the electrolyte are highly flammable and form an explosive atmosphere with aerial oxygen)

- Uniform and comprehensible entry of data into the database

- Updating/maintenance of the battery pack data over the entire life cycle (e.g., when components are replaced)

- Ensuring the legibility of the label and the availability of data over the entire life cycle of the battery (cover of the pack housing)

- Regulation of access to the database (only authorized third parties)

- Gaining the acceptance of the vehicle/battery manufacturers (partly prescribed by law via battery regulation).

4. Results and Discussion

4.1. Validation of the Vision Pipeline in a Demonstrator Setup for Automation of Disassembly

4.2. Sensor-Based Material Composition Detection

5. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Climate Action Programme 2030. Available online: https://www.bundesregierung.de/breg-en/issues/climate-action (accessed on 1 April 2022).

- Directive 2006/66/EC of the European Parliament and of the Council of 6 September 2006 on Batteries and Accumulators and Waste Batteries and Accumulators and Repealing Directive 91/157/EEC: Battery Directive. 2006. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02006L0066-20131230&rid=1 (accessed on 1 April 2022).

- Proposal for a Regulation of the European Parliament and of Thecouncil Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020. 2020. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:4b5d88a6-3ad8-11eb-b27b-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 1 April 2022).

- Batteries and Waste Batteries ***I Amendments Adopted by the European Parliament on 10 March 2022 on the Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020 (COM(2020)0798–C9-0400/2020–2020/0353(COD)): First Reading. 2022. Available online: https://www.europarl.europa.eu/doceo/document/TA-9-2022-0077_EN.pdf (accessed on 2 April 2022).

- Gerbers, R.; Wegener, K.; Dietrich, F.; Dröder, K. Safe, Flexible and Productive Human-Robot-Collaboration for Disassembly of Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries: The LithoRec Way; Kwade, A., Diekmann, J., Eds.; Springer: Cham, Switzerland, 2018; pp. 99–126. ISBN 978-3-319-70571-2. [Google Scholar]

- Baum, Z.J.; Bird, R.E.; Yu, X.; Ma, J. Lithium-Ion Battery Recycling─Overview of Techniques and Trends. ACS Energy Lett. 2022, 7, 712–719. [Google Scholar] [CrossRef]

- Kampker, A.; Wessel, S.; Fiedler, F.; Maltoni, F. Battery pack remanufacturing process up to cell level with sorting and repurposing of battery cells. J. Remanuf. 2021, 11, 1–23. [Google Scholar] [CrossRef]

- Zwicker, M.; Moghadam, M.; Zhang, W.; Nielsen, C.V. Automotive battery pack manufacturing–A review of battery to tab joining. J. Adv. Join. Process. 2020, 1, 100017. [Google Scholar] [CrossRef]

- Schäfer, J.; Singer, R.; Hofmann, J.; Fleischer, J. Challenges and Solutions of Automated Disassembly and Condition-Based Remanufacturing of Lithium-Ion Battery Modules for a Circular Economy. Procedia Manuf. 2020, 43, 614–619. [Google Scholar] [CrossRef]

- Li, L.; Zheng, P.; Yang, T.; Sturges, R.; Ellis, M.W.; Li, Z. Disassembly Automation for Recycling End-of-Life Lithium-Ion Pouch Cells. JOM 2019, 71, 4457–4464. [Google Scholar] [CrossRef] [Green Version]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef] [Green Version]

- Wegener, K.; Chen, W.H.; Dietrich, F.; Dröder, K.; Kara, S. Robot Assisted Disassembly for the Recycling of Electric Vehicle Batteries. Procedia CIRP 2015, 29, 716–721. [Google Scholar] [CrossRef]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Wegener, K.; Andrew, S.; Raatz, A.; Dröder, K.; Herrmann, C. Disassembly of Electric Vehicle Batteries Using the Example of the Audi Q5 Hybrid System. Procedia CIRP 2014, 23, 155–160. [Google Scholar] [CrossRef] [Green Version]

- Hellmuth, J.F.; DiFilippo, N.M.; Jouaneh, M.K. Assessment of the automation potential of electric vehicle battery disassembly. J. Manuf. Syst. 2021, 59, 398–412. [Google Scholar] [CrossRef]

- Abdelbasir, S.M.; Hassan, S.S.M.; Kamel, A.H.; El-Nasr, R.S. Status of electronic waste recycling techniques: A review. Environ. Sci. Pollut. Res. Int. 2018, 25, 16533–16547. [Google Scholar] [CrossRef]

- Steward, D.; Mayyas, A.; Mann, M. Economics and Challenges of Li-Ion Battery Recycling from End-of-Life Vehicles. Procedia Manuf. 2019, 33, 272–279. [Google Scholar] [CrossRef]

- Blankemeyer, S.; Wiens, D.; Wiese, T.; Raatz, A.; Kara, S. Investigation of the potential for an automated disassembly process of BEV batteries. Procedia CIRP 2021, 98, 559–564. [Google Scholar] [CrossRef]

- Gerlitz, E.; Greifenstein, M.; Hofmann, J.; Fleischer, J. Analysis of the Variety of Lithium-Ion Battery Modules and the Challenges for an Agile Automated Disassembly System. Procedia CIRP 2021, 96, 175–180. [Google Scholar] [CrossRef]

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meng, K.; Xu, G.; Peng, X.; Youcef-Toumi, K.; Li, J. Intelligent disassembly of electric-vehicle batteries: A forward-looking overview. Resour. Conserv. Recycl. 2022, 182, 106207. [Google Scholar] [CrossRef]

- Zivid. See More. Do More. Zivid Two Industrial 3D Camera-Zivid. Available online: https://www.zivid.com/zivid-two (accessed on 19 April 2022).

- GitHub. GitHub-Wkentaro/Labelme: Image Polygonal Annotation with Python (Polygon, Rectangle, Circle, Line, Point and Image-Level Flag Annotation). Available online: https://github.com/wkentaro/labelme (accessed on 19 April 2022).

- GitHub. GitHub-Joheras/CLoDSA. Available online: https://github.com/joheras/CLoDSA (accessed on 19 April 2022).

- GitHub. GitHub-Zjhuang22/Maskscoring_rcnn: Codes for Paper “Mask Scoring R-CNN”. Available online: https://github.com/zjhuang22/maskscoring_rcnn (accessed on 19 April 2022).

- Huang, Z.; Huang, L.; Gong, Y.; Huang, C.; Wang, X. Mask Scoring R-CNN. In CVPR 2019, Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019; IEEE Computer Society: Los Alamitos, CA, USA; Washington, DC, USA; Tokyo, Japan, 2019; pp. 6402–6411. ISBN 978-1-7281-3293-8. [Google Scholar]

- GitHub. GitHub-Open-Mmlab/Mmdetection: OpenMMLab Detection Toolbox and Benchmark. Available online: https://github.com/open-mmlab/mmdetection (accessed on 19 April 2022).

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask R-CNN. arXiv 2017, arXiv:1703.06870v3. [Google Scholar]

- Liu, Z.; Lin, Y.; Cao, Y.; Hu, H.; Wei, Y.; Zhang, Z.; Lin, S.; Guo, B. Swin Transformer: Hierarchical Vision Transformer Using Shifted Windows. arXiv 2021, arXiv:2103.14030. [Google Scholar]

- Chen, Y.; Medioni, G. Object Modeling by Registration of Multiple Range Images. Image Vis. Comput. 1992, 10, 145–155. [Google Scholar] [CrossRef]

- Rusu, R.B.; Blodow, N.; Beetz, M. Fast Point Feature Histograms (FPFH) for 3D registration. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation (ICRA), Kobe, Japan, 12–17 May 2009; pp. 3212–3217. [Google Scholar]

- Berwanger, M.; Maul, A. Principles of visual sensor technolgy. In Sensor Technologies: Impulses for the Raw Materials Industry; Nienhaus, K., Ed.; Shaker: Aachen, Germany, 2014; pp. 101–123. ISBN 9783844025637. [Google Scholar]

- Diekmann, J.; Sander, S.; Sellin, G.; Kwade, A. Material Separation. In Recycling of Lithium-Ion Batteries: The LithoRec Way, 1st ed.; Kwade, A., Diekmann, J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-70571-2. [Google Scholar]

- Hering, E.; Schönfelder, G. Sensoren in Wissenschaft und Technik: Funktionsweise und Einsatzgebiete; Springer: Berlin/Heidelberg, Germany, 2012; ISBN 978-3-8348-0169-2. [Google Scholar]

- Köpcke, M.; Warcholik, M.; Knapp, H. Principles of X-ray transmission. In Sensor Technologies: Impulses for the Raw Materials Industry; Nienhaus, K., Ed.; Shaker: Aachen, Germany, 2014; pp. 54–63. ISBN 9783844025637. [Google Scholar]

- Uepping, R. Sensorgestützte Sortiertechnik. In Recycling und Rohstoffe; Thomé-Kozmiensky, K.J., Goldmann, D., Eds.; TK-Verl.: Neuruppin, Germany, 2013; pp. 371–383. ISBN 9783935317979. [Google Scholar]

- Neubert, K.; Knapp, H.; Fietz, N. Principles of X-ray fluorescence analysis. In Sensor Technologies: Impulses for the Raw Materials Industry; Nienhaus, K., Ed.; Shaker: Aachen, Germany, 2014; pp. 88–100. ISBN 9783844025637. [Google Scholar]

- Schropp, C.; Raulf, K.; Robben, M. Principles of near infrared. In Sensor Technologies: Impulses for the Raw Materials Industry; Nienhaus, K., Ed.; Shaker: Aachen, Germany, 2014; pp. 131–140. ISBN 9783844025637. [Google Scholar]

- Steinert GmbH. E-Scrap Recycling & Sorting: Separation & Sorting through All Fractions in Electrical Scrap. Available online: https://steinertglobal.com/metal-recycling/e-scrap-recycling/ (accessed on 20 April 2022).

- Kranert, M. Einführung in die Kreislaufwirtschaft: Planung-Recht-Verfahren; Springer: Berlin/Heidelberg, Germanay, 2017; ISBN 978-3834818379. [Google Scholar]

- Secondary Cells and Batteries-Marking Symbols for Identification of Their Chemistry, IEC 62902. 2019. Available online: https://webstore.iec.ch/publication/29912 (accessed on 1 April 2022).

- Wang, X.; Gaustad, G.; Babbitt, C.W. Targeting high value metals in lithium-ion battery recycling via shredding and size-based separation. Waste Manag. 2016, 51, 204–213. [Google Scholar] [CrossRef] [Green Version]

- Koehler, U. Lithium-ion battery system design. In Lithium-Ion Batteries: Basics and Applications, 1st ed.; Korthauer, R., Ed.; Springer: Berlin, Germany, 2018; ISBN 978-3-662-53069-6. [Google Scholar]

- Hauck, D.; Kurrat, M. Overdischarging Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries: The LithoRec Way; Kwade, A., Diekmann, J., Eds.; Springer: Cham, Switzerland, 2018; ISBN 978-3-319-70571-2. [Google Scholar]

- Fleischer, J.; Gerlitz, E.; Rieβ, S.; Coutandin, S.; Hofmann, J. Concepts and Requirements for Flexible Disassembly Systems for Drive Train Components of Electric Vehicles. Procedia CIRP 2021, 98, 577–582. [Google Scholar] [CrossRef]

- Gaines, L.; Richa, K.; Spangenberger, J. Key issues for Li-ion battery recycling. MRS Energy Sustain. 2018, 5, 12. [Google Scholar] [CrossRef] [Green Version]

- Diekmann, J.; Grützke, M.; Loellhoeffel, T.; Petermann, M.; Rothermel, S.; Winter, M.; Nowak, S.; Kwade, A. Potential Dangers during the Handling of Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries: The LithoRec Way, 1st ed.; Kwade, A., Diekmann, J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 39–51. ISBN 978-3-319-70571-2. [Google Scholar]

- IDIS 2 Group. IDIS|The International Dismantling Information System. Available online: https://www.idis2.com/index.php (accessed on 29 March 2022).

- Karrach, L.; Pivarčiová, E.; Nikitin, Y.R. Comparing the impact of different cameras and image resolution to recognize the data matrix codes. J. Electr. Eng. 2018, 69, 286–292. [Google Scholar] [CrossRef] [Green Version]

- Karygiannis, A.T.; Eydt, B.; Barber, G.; Bunn, L.; Phillips, T. Guidelines for Securing Radio Frequency Identification (RFID) Systems; NIST: Gaithersburg, MD, USA, 2007. [Google Scholar]

- GitHub. FlexBE. Available online: https://github.com/FlexBE (accessed on 19 April 2022).

- MoveIt Motion Planning Framework. Available online: https://moveit.ros.org/ (accessed on 19 April 2022).

| Sensor | Physical Principal and Separation Feature | Conditions and Limitations |

|---|---|---|

| Color (RGB) |

|

|

| 3D laser trian-gulation (3D-LT) |

|

|

| X-ray transmission (XRT) |

| |

| X-ray fluorescence (XRF) |

|

|

| Induction (IND) |

|

|

| Near-infrared (NIR) |

|

|

| Material Flow | Precondition | RGB | 3D-LT | XRT | XRF | LIBS | IND | NIR |

|---|---|---|---|---|---|---|---|---|

| Busbars | Crushing, magnetic, and eddy current separation | x | (x) | (x) | x | |||

| Wires | Crushing, magnetic, and eddy current separation | x | x | x | x | |||

| Hou-sing | Crushing | x | x | x | ||||

| Electronics | Crushing, magnetic, and eddy current separation | x | x | x | x |

| Measuring Point | Fe [%] | Al [%] | Mg [%] | Mn [%] | Zn [%] | C [%] | Si [%] | Cr [%] |

|---|---|---|---|---|---|---|---|---|

| 1 | 97.89 | 0.44 | n/a | 0.60 | 0.60 | n/a | 0.21 | 0.04 |

| 2 | 0.21 | 97.89 | 0.60 | 0.6 | n/a | 0.04 | 0.44 | n/a |

| 3 | n/a | 98.02 | 0.55 | n/a | n/a | n/a | 0.85 | n/a |

| Module | Al [%] | Fe [%] | Cr [%] | Ni [%] | Mg [%] | Mn [%] | C [%] | Si [%] | Cu [%] | Sn [%] | V [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (a) | 92.76 | 0.23 | 0.21 | n/a | 5.96 | 0.49 | n/a | 0.27 | n/a | n/a | n/a |

| (b) | n/a | 71.88 | 17.97 | 8.18 | n/a | 1.98 | 0.33 | n/a | 0.21 | 0.12 | 0.11 |

| Switch Box | Al [%] | Si [%] | Fe [%] | Mn [%] |

|---|---|---|---|---|

| 87.32 | 11.76 | 0.21 | 5.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zorn, M.; Ionescu, C.; Klohs, D.; Zähl, K.; Kisseler, N.; Daldrup, A.; Hams, S.; Zheng, Y.; Offermanns, C.; Flamme, S.; et al. An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling 2022, 7, 48. https://doi.org/10.3390/recycling7040048

Zorn M, Ionescu C, Klohs D, Zähl K, Kisseler N, Daldrup A, Hams S, Zheng Y, Offermanns C, Flamme S, et al. An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling. 2022; 7(4):48. https://doi.org/10.3390/recycling7040048

Chicago/Turabian StyleZorn, Merle, Christina Ionescu, Domenic Klohs, Konstantin Zähl, Niklas Kisseler, Alexandra Daldrup, Sigrid Hams, Yun Zheng, Christian Offermanns, Sabine Flamme, and et al. 2022. "An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization" Recycling 7, no. 4: 48. https://doi.org/10.3390/recycling7040048

APA StyleZorn, M., Ionescu, C., Klohs, D., Zähl, K., Kisseler, N., Daldrup, A., Hams, S., Zheng, Y., Offermanns, C., Flamme, S., Henke, C., Kampker, A., & Friedrich, B. (2022). An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling, 7(4), 48. https://doi.org/10.3390/recycling7040048