Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization

Abstract

1. Introduction

2. Results and Discussion

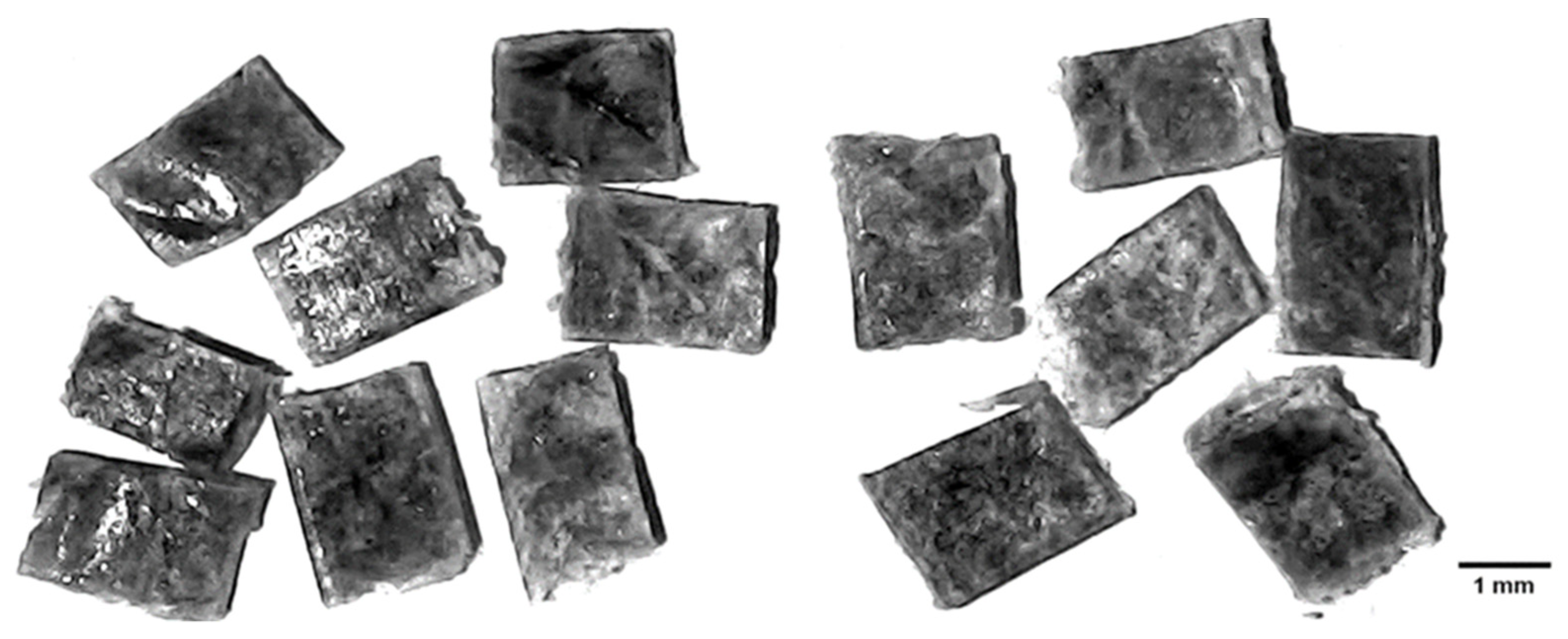

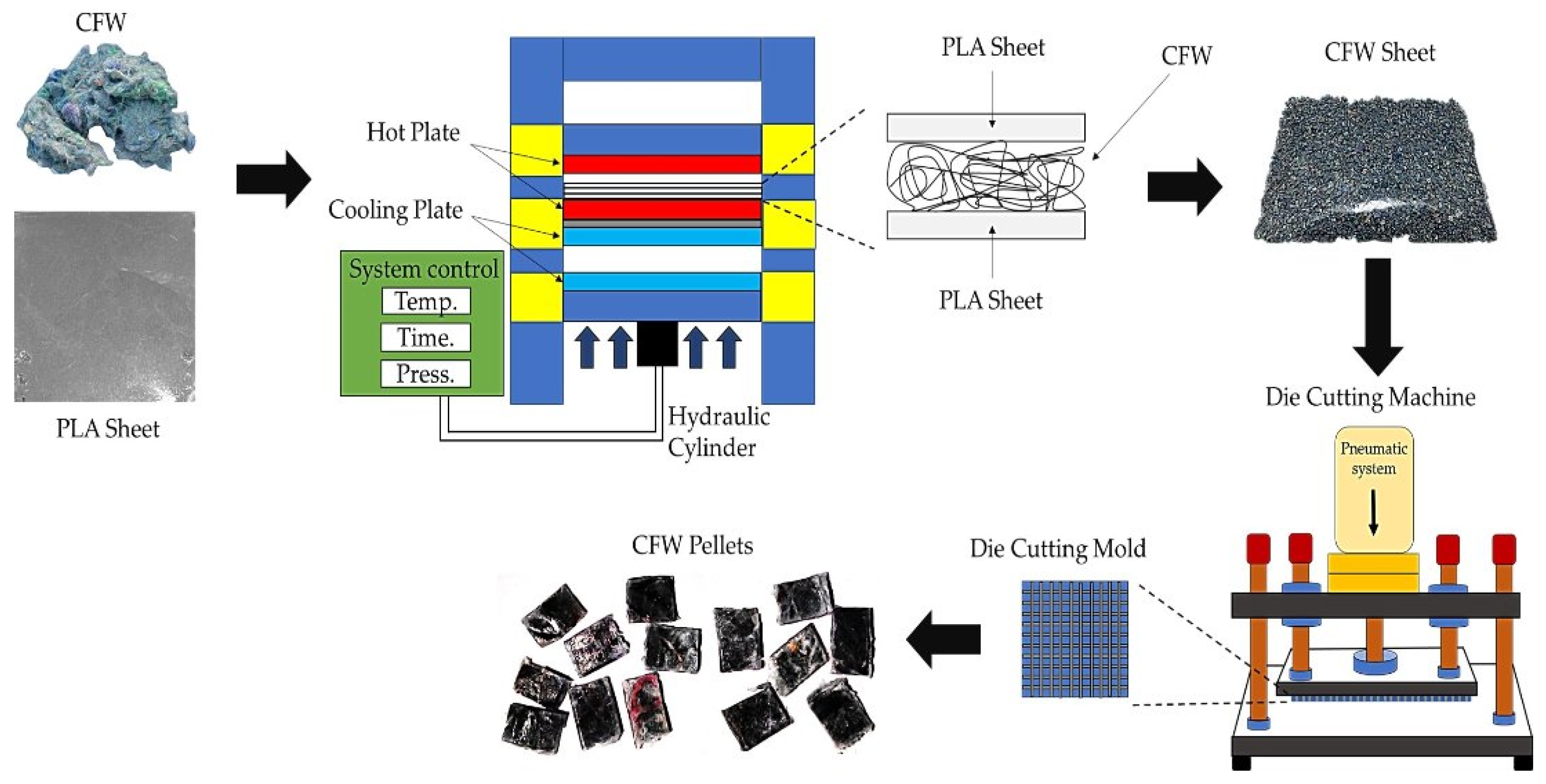

2.1. CFW Pellets Characterization

2.2. Melt Flow Index

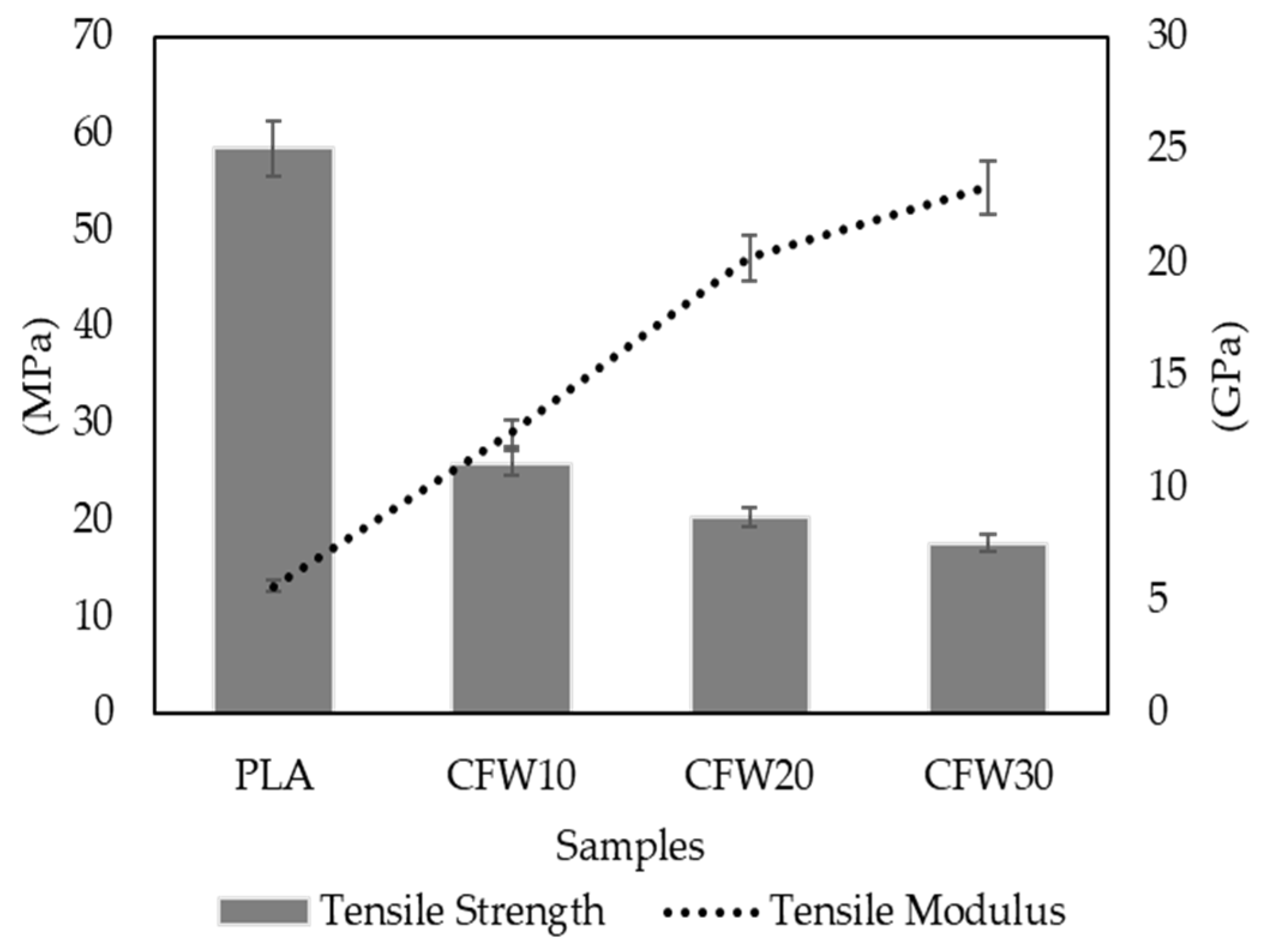

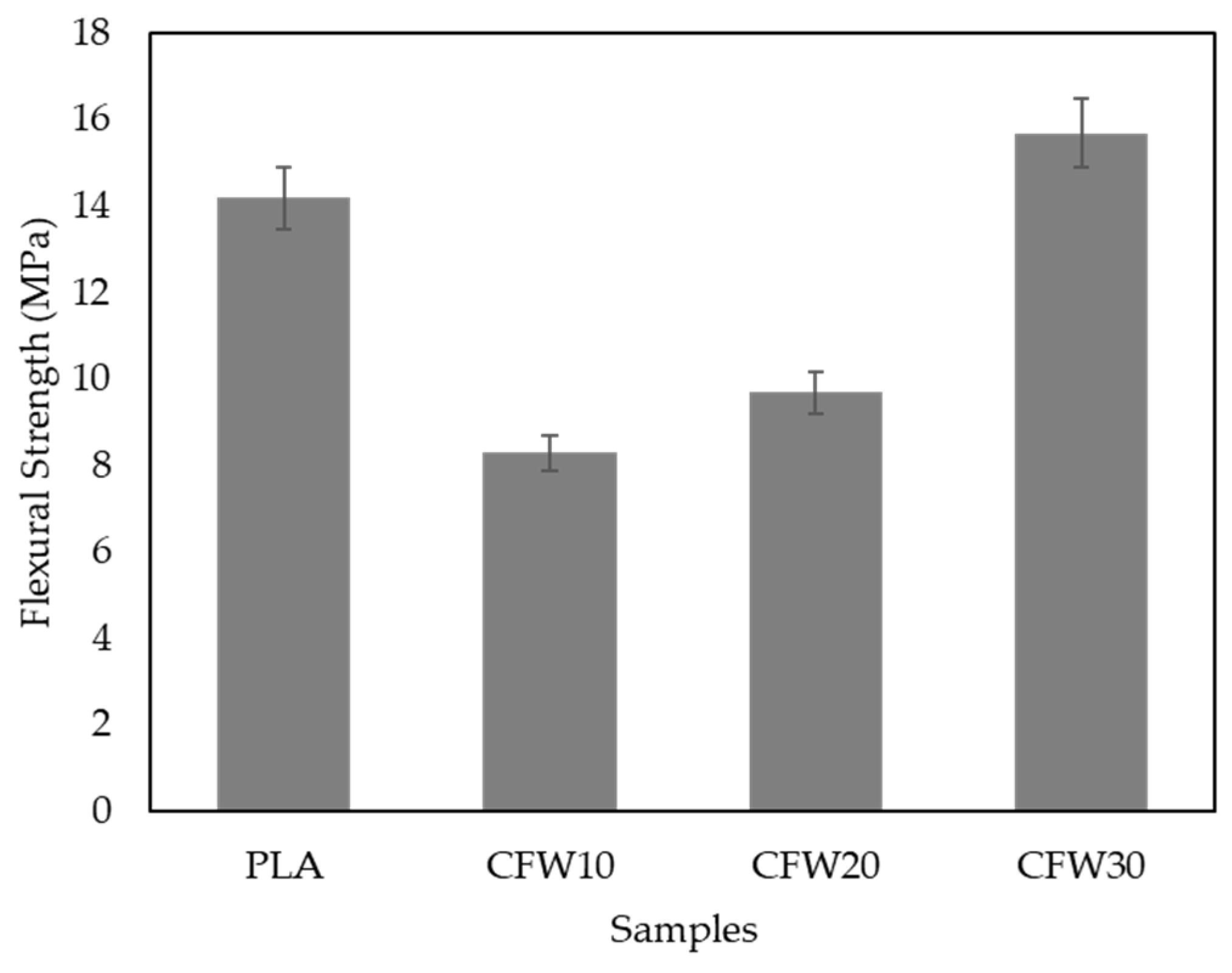

2.3. Mechanical Properties

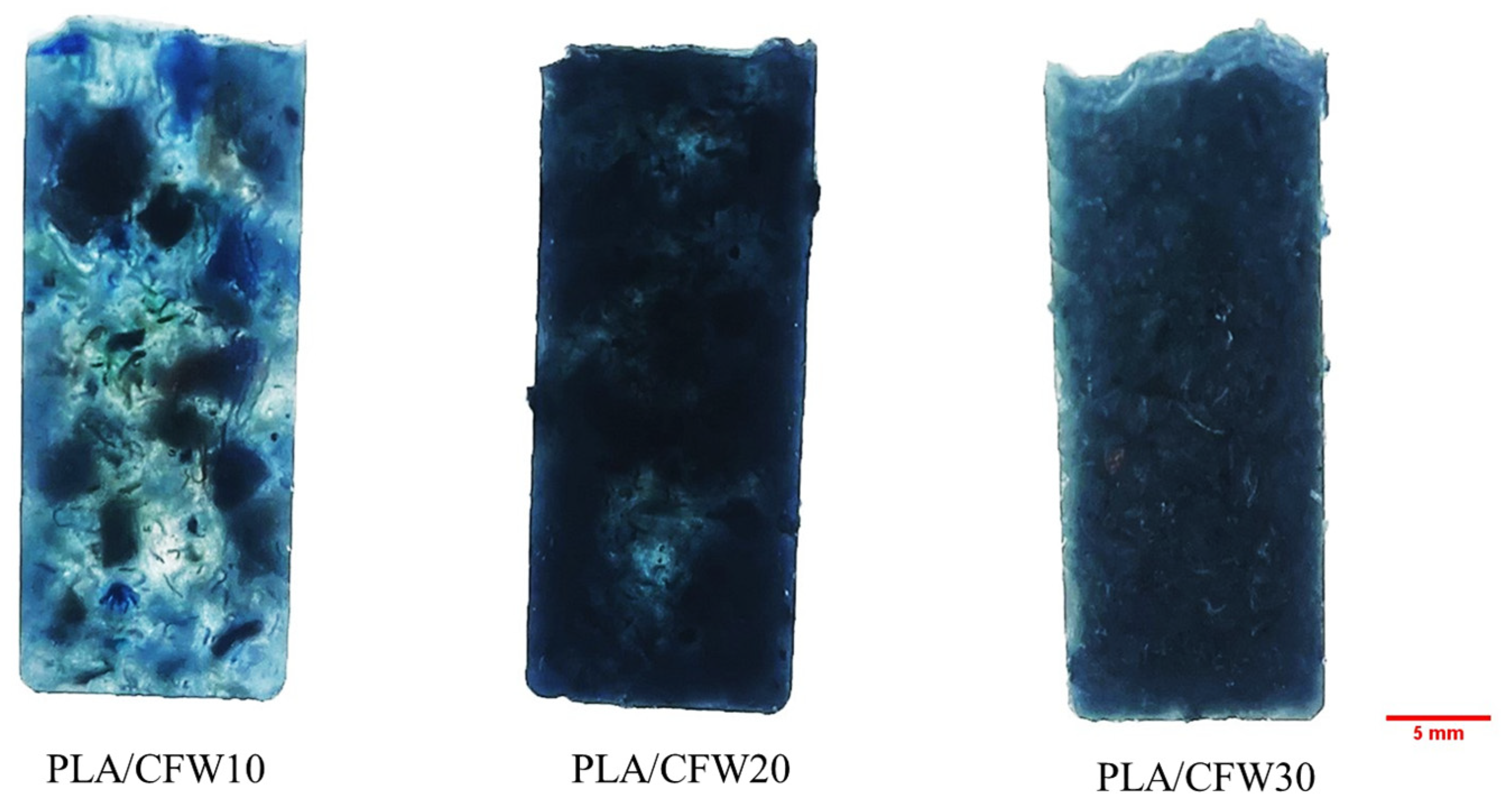

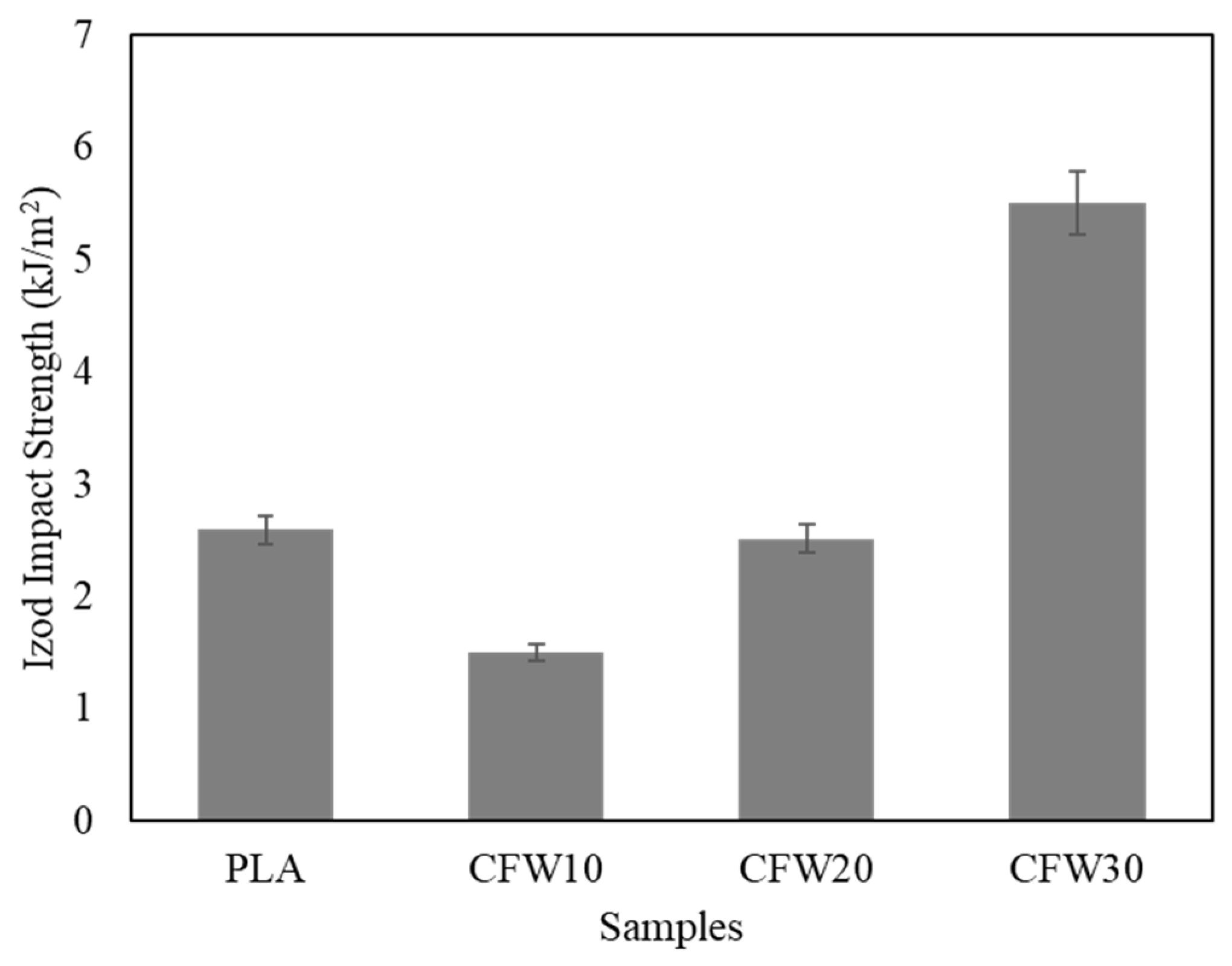

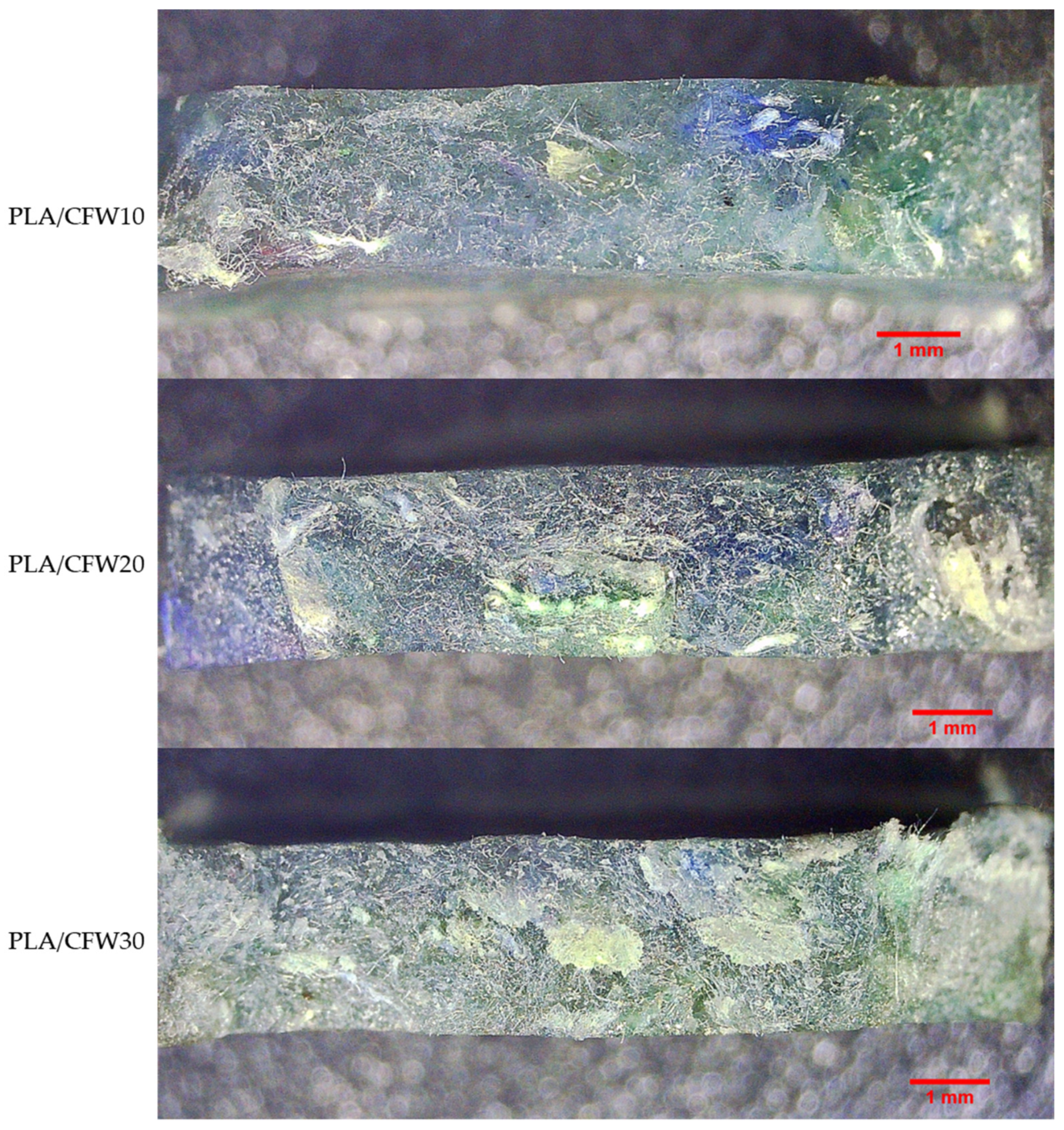

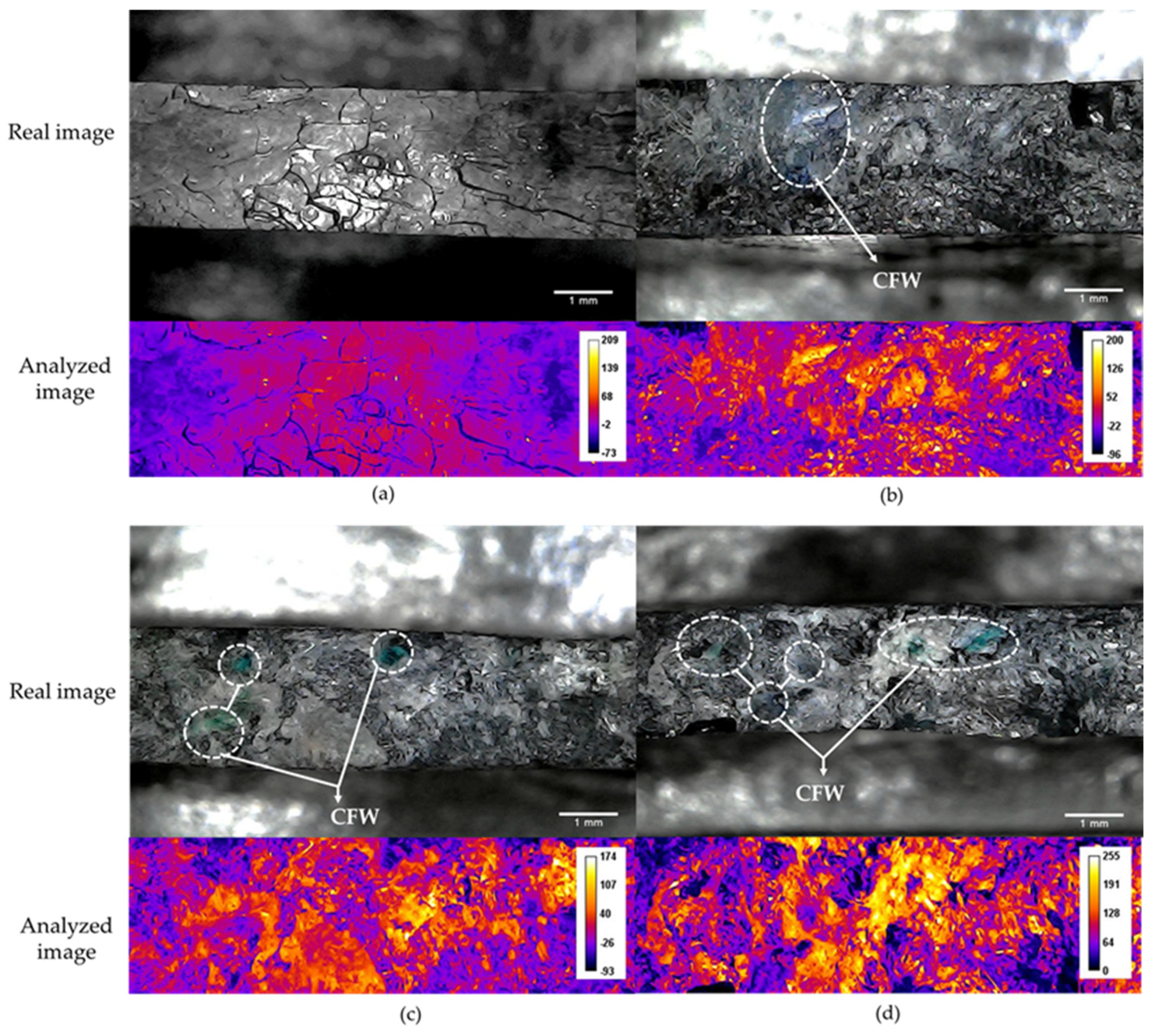

2.4. Fracture Morphology

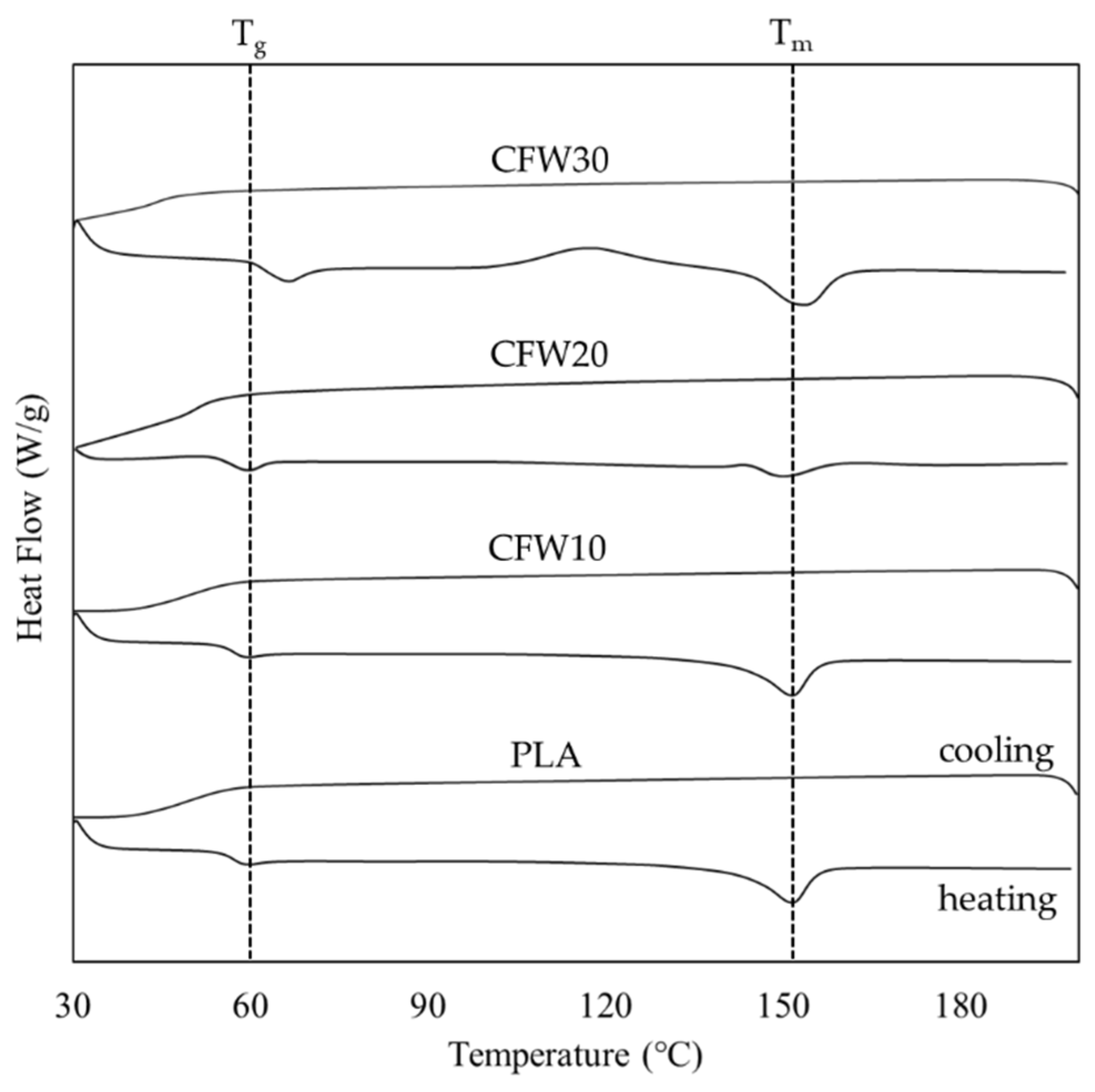

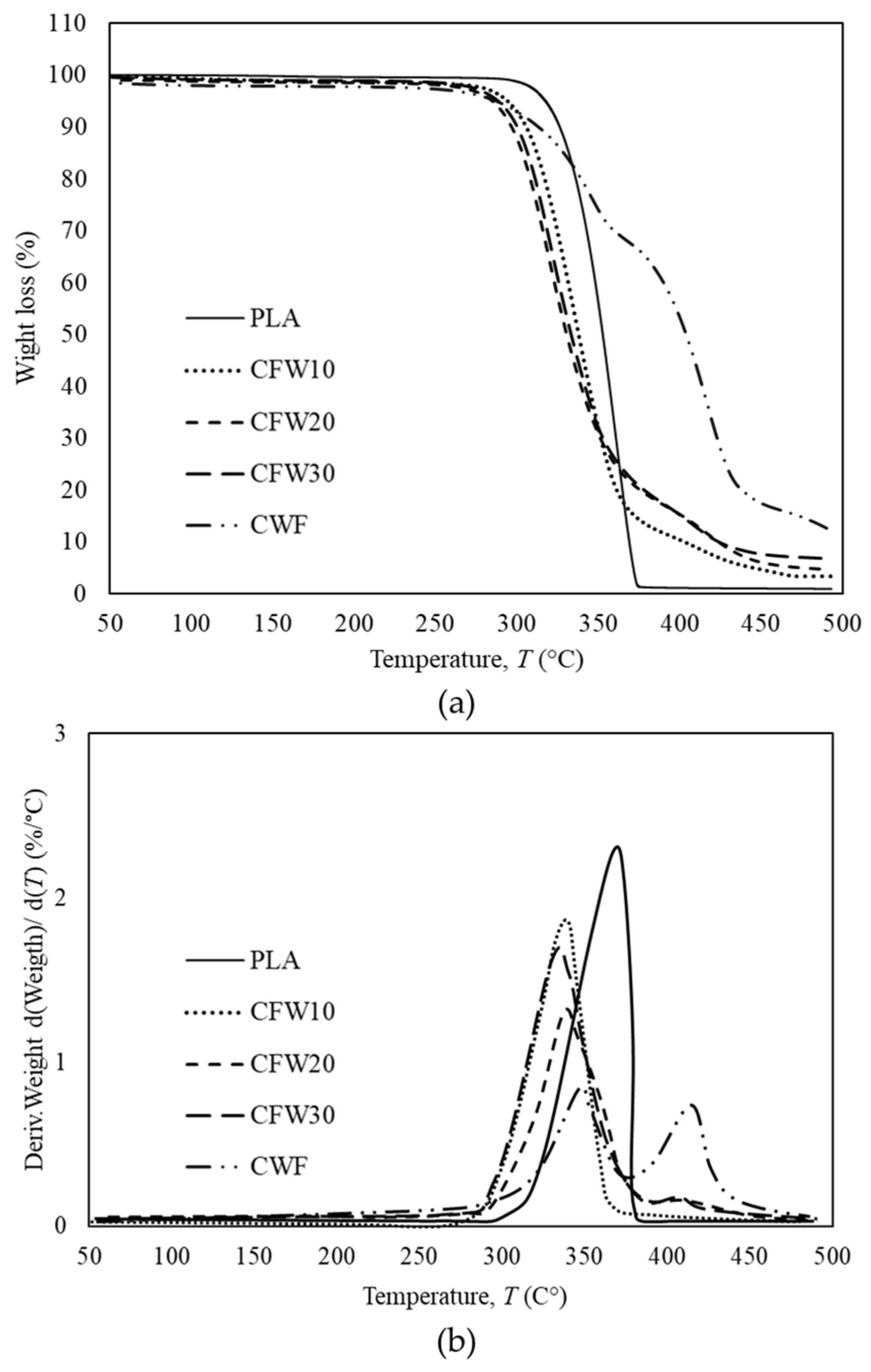

2.5. Thermal Properties

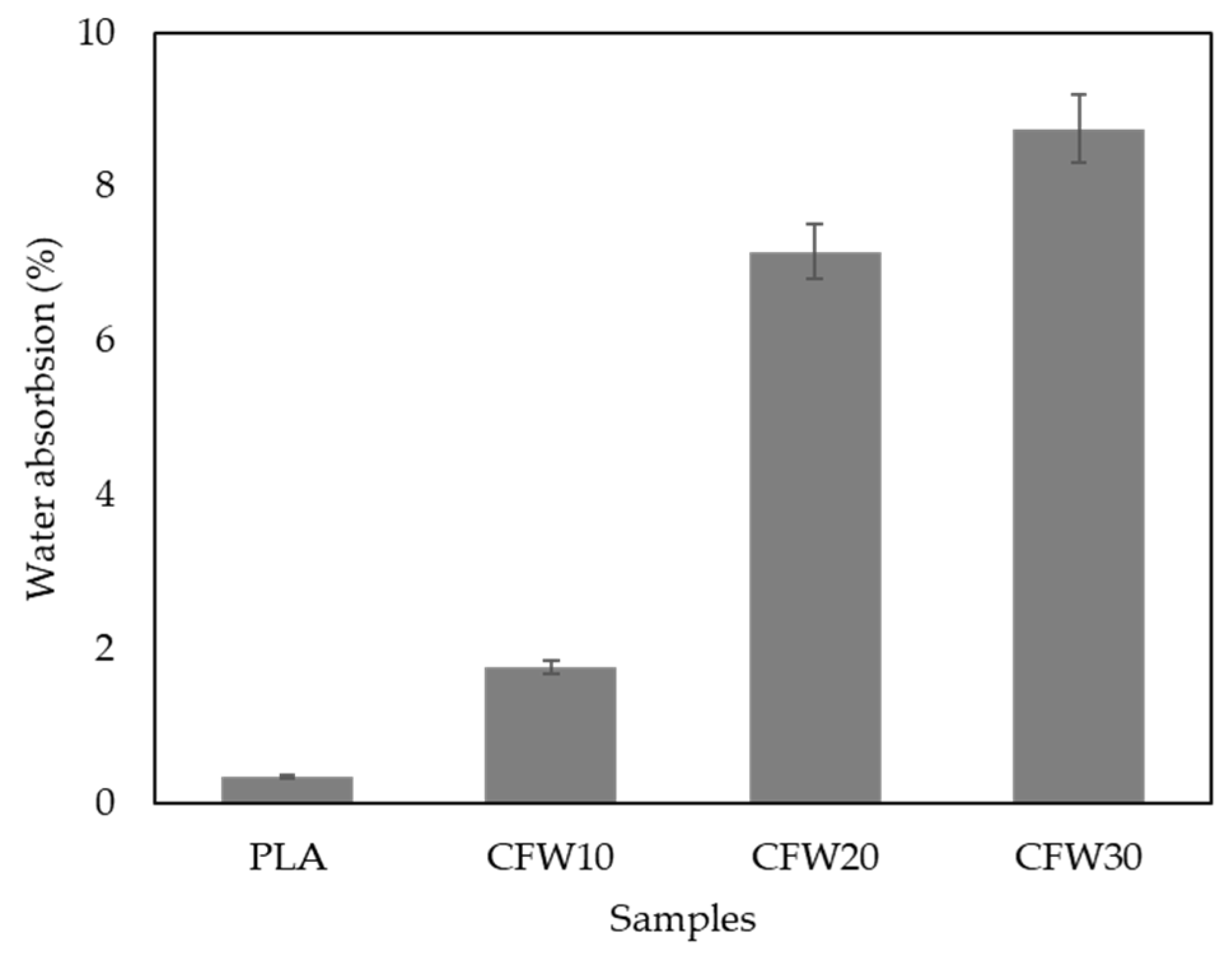

2.6. Water Absorption

3. Materials and Methods

3.1. Materials

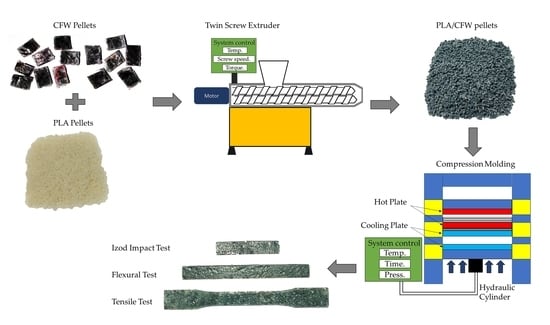

3.2. Method

3.3. Characterization

3.3.1. CFW Pellets Characterization

3.3.2. Melt Flow Test

3.3.3. Mechanical Properties

3.3.4. Fracture Morphology

3.3.5. Thermal Properties

3.3.6. Water Absorption Testing

4. Conclusions

- -

- The melt flow testing showed that an increase in the CFW contents caused the melt flow rate of the composites to decrease.

- -

- The mechanical testing showed that CFW could improve the tensile modulus, flexural strength, and Izod impact strength of PLA. The above mechanical properties of the composites also increased with an increase in the CFW content.

- -

- A fracture morphology observation of the composites showed that an increase in the CFW content caused greater phase separation and roughness on the fracture surface area.

- -

- Thermal property testing, in terms of DSC, showed that an increase in the CFW content caused the Tg and Tm of the composites to slightly increase; the highest were 66.31 °C and 153.54 °C, respectively. The crystallinity increased by approximately 36% compared with pure PLA, but an increase in the CFW content did not clearly change the results. The DSC thermograms of the composites showed one peak, indicating an immiscible blend of PLA and CFW. This could imply that the finishing and dying agents that may remain in CFW did not affect the melting point of the composite. In terms of the TGA, the result showed the decomposition of the composites to be lower than pure PLA. The temperature of both the Tonset and Tpeak of the composites decreased with an increase in the CFW content. The decomposition of the composites was shown in a range of 302.41 to 361.22 °C.

- -

- Water absorption testing showed that an increase in the CFW content resulted in the composites having greater water absorption; the highest was 8.76% when compared with pure PLA.

- -

- Based on these results, we expected the green composite based on PLA/CFW can produce the household products such as home decorations and food trays, etc. Moreover, if we can improve the compatibility or toughness of PLA/CFW, it will make more options for manufacturing products.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Zhou, X.; Deng, J.; Fang, C.; Lei, W.; Song, Y.; Zhang, Z.; Huang, Z.; Li, Y. Additive manufacturing of CNTs/PLA composites and the correlation between microstructure and functional properties. J. Mater. Sci. Technol. 2021, 60, 27–34. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, S.G.; Kim, S.H. Isothermal crystallization behavior and mechanical properties of polylactide/carbon nanotube nanocomposites. Compos. Part A Appl. Sci. Manuf. 2013, 46, 11–18. [Google Scholar] [CrossRef]

- Kaseem, M.; Hamad, K.; Ur Rehman, Z. Review of recent advances in polylactic acid/TiO2 composites. Materials 2019, 12, 3659. [Google Scholar] [CrossRef]

- Buzarovska, A.; Grozdanov, A. Biodegradable poly (L-lactic acid)/TiO2 nanocomposites: Thermal properties and degradation. J. Appl. Polym. Sci. 2012, 123, 2187–2193. [Google Scholar] [CrossRef]

- Zhuang, W.; Liu, J.; Zhang, J.H.; Hu, B.X.; Shen, J. Preparation, characterization, and properties of TiO2/PLA nanocomposites by in situ polymerization. Polym. Compos. 2009, 30, 1074–1080. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid)(PLA) composites: A comparative study. Compos. Sci. Technol. 2006, 66, 1813–1824. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Ariffin, H.; Sapuan, S.; Asim, M.; Saba, N. Natural fiber reinforced polylactic acid composites: A review. Polym. Compos. 2019, 40, 446–463. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, X.; Ma, X.; Fang, J. Influence of carbon black on the properties of plasticized poly (lactic acid) composites. Polym. Degrad. Stab. 2008, 93, 1044–1052. [Google Scholar] [CrossRef]

- Muller, J.; González-Martínez, C.; Chiralt, A. Combination of poly (lactic) acid and starch for biodegradable food packaging. Materials 2017, 10, 952. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.S. Plastics derived from starch and poly. In Bio-Based Polymers and Composites; Academic Press: Cambridge, MA, USA, 2005; p. 369. [Google Scholar]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- La Mantia, F.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Bajpai, S.; Mary, G.; Chand, N. The use of cotton fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 320–341. [Google Scholar]

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A review on textile recycling practices and challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Aziz, S.H.; Ansell, M.P. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: Part 1—Polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.; Fangueiro, R. PLA composites reinforced with flax and jute fibers—A review of recent trends, processing parameters and mechanical properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Abdullah, L.C.; Aung, M.M.; Ratnam, C.T. Mechanical and physical properties of Kenaf-reinforced Poly (lactic acid) plasticized with epoxidized Jatropha Oil. BioResources 2019, 14, 9001–9020. [Google Scholar]

- Tawakkal, I.S.M.; Talib, R.A.; Abdan, K.; Ling, C.N. Mechanical and physical properties of kenaf-derived cellulose (KDC)-filled polylactic acid (PLA) composites. BioResources 2012, 7, 1643–1655. [Google Scholar] [CrossRef]

- Bajracharya, R.M.; Bajwa, D.S.; Bajwa, S.G. Mechanical properties of polylactic acid composites reinforced with cotton gin waste and flax fibers. Procedia Eng. 2017, 200, 370–376. [Google Scholar] [CrossRef]

- Piekarska, K.; Piorkowska, E.; Krasnikova, N.; Kulpinski, P. Polylactide composites with waste cotton fibers: Thermal and mechanical properties. Polym. Compos. 2014, 35, 747–751. [Google Scholar] [CrossRef]

- Zhang, X.; Shen, J.; Yang, T.; Ye, B.; Lin, Z.; Tan, S. Characteristics of poly(lactic acid) reinforced composites with waste cotton. J. Polym. Eng. 2011, 31, 531–537. [Google Scholar] [CrossRef]

- Qian, J.; Yu, M.M.; Ge, Z.; Xu, M.J.; Zhang, H.H.; Yang, G.S.; Shao, H.L. Preparation and properties of cotton fiber/poly (lactic acid) composites. Mater. Sci. Forum 2014, 789, 100–105. [Google Scholar] [CrossRef]

- Siddika, S.; Mansura, F.; Hasan, M. Physico-mechanical properties of jute-coir fiber reinforced hybrid polypropylene composites. Eng. Technol. 2013, 73, 1145–1149. [Google Scholar]

- Rahman, M.; Mondol, M.; Hasan, M. Mechanical properties of chemically treated coir and betel nut fiber reinforced hybrid polypropylene composites. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Dhaka, Bangladesh, 1–3 March 2018; p. 012025. [Google Scholar]

- McKeen, L.W. The Effect of Sterilization on Plastics and Elastomers, 3rd ed.; William Andrew: Oxford, UK, 2012; pp. 57–84. [Google Scholar]

- Richards, R. Polyethylene—Structure, crystallinity and properties. J. Appl. Chem. 1951, 1, 370–376. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Panayiotou, C. Effect of compatibilization on the performance of biodegradable composites using cotton fiber waste as filler. J. Appl. Polym. Sci. 2003, 88, 1825–1835. [Google Scholar] [CrossRef]

- Ceylan, Ö.; Van Landuyt, L.; Rahier, H.; De Clerck, K. The effect of water immersion on the thermal degradation of cotton fibers. Cellulose 2013, 20, 1603–1612. [Google Scholar] [CrossRef]

- Shahedifar, V.; Rezadoust, A.M. Thermal and mechanical behavior of cotton/vinyl ester composites: Effects of some flame retardants and fiber treatment. J. Reinf. Plast. Compos. 2013, 32, 681–688. [Google Scholar] [CrossRef]

- Jansri, E.; Narongchai, O. Polypropylene/polyethylene two-layered by one-step rotational molding. J. Polym. Eng. 2018, 38, 685–694. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

| Samples | Melt Flow Rate (g/10 min) 210 °C/2.16 kg |

|---|---|

| PLA | 6.19 ± 0.20 |

| CFW10 | 5.37 ± 0.08 |

| CFW20 | 3.98 ± 0.21 |

| CFW30 | 1.91 ± 0.05 |

| Samples | Arithmetic Means Of Surface Roughness, Ra (Micron) |

|---|---|

| PLA | 16.02 |

| CFW10 | 34.11 |

| CFW20 | 40.47 |

| CFW30 | 52.53 |

| Samples | Differential Scanning Calorimetry (DSC) | Thermogravimetric Analysis (TGA) | ||||

|---|---|---|---|---|---|---|

| Tg (°C) | Tm (°C) | Crystallinity (%Xc) | Weight Loss (%) | Temperature Decomposition (Tonset) (°C) | Temperature Decomposition (Tpeak) (°C) | |

| PLA | 58.87 | 148.61 | 1.09 | 98.93 | 333.56 | 372.12 |

| CFW | - | - | - | 87.88 | 314.75 | 431.75 |

| CFW10 | 61.11 | 150.03 | 3.56 | 93.85 | 315.24 | 361.22 |

| CFW20 | 63.52 | 152.91 | 1.73 | 93.83 | 306.98 | 359.10 |

| CFW30 | 66.31 | 153.54 | 1.68 | 93.07 | 302.41 | 356.57 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

O-Charoen, N.; Kampeerapappun, P.; Charoenlarp, K.; Petchwattana, N.; Jansri, E. Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization. Recycling 2022, 7, 78. https://doi.org/10.3390/recycling7050078

O-Charoen N, Kampeerapappun P, Charoenlarp K, Petchwattana N, Jansri E. Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization. Recycling. 2022; 7(5):78. https://doi.org/10.3390/recycling7050078

Chicago/Turabian StyleO-Charoen, Narongchai, Piyaporn Kampeerapappun, Khanittha Charoenlarp, Nawadon Petchwattana, and Ektinai Jansri. 2022. "Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization" Recycling 7, no. 5: 78. https://doi.org/10.3390/recycling7050078

APA StyleO-Charoen, N., Kampeerapappun, P., Charoenlarp, K., Petchwattana, N., & Jansri, E. (2022). Green Composites Based on PLA and Cotton Fabric Waste: Preparation and Characterization. Recycling, 7(5), 78. https://doi.org/10.3390/recycling7050078