Abstract

The circular business model (CBM) is one of the main building blocks of circular economy (CE), and recycling is one of the main strategies for achieving it. CBM literature is currently evolving, and recycling-oriented discussion has been found in a scattered manner. This review article aims to identify critical components of the recycling-focused business model in CE and evaluate potential business and research opportunities in the area. Data collection was undertaken from the Web of Science (WoS) core collection and ScienceDirect database. Results of the study showed that efficiency of municipal solid waste management, reporting mechanism of recyclers cost of recycled materials, the establishment of a plastic hub, implementation of extended producer responsibility, strategic partnership, incentives, and product design were highlighted as critical requirements for efficient recycling operated business models, especially for waste solar PV panels, e-waste, textile waste, and vehicles and battery sector. It also identified the benefits of using recycled materials in reducing carbon footprint, energy consumption, and achieving low environmental impact. Three-dimensional printing, sensor-based RFID tags, digital twins, additive manufacturing, Industry 4.0, and the Internet of Things (IoT) were found as state-of-the-art technological innovations applied to recycling-oriented circular business models. This article provides critical practical solutions for new business model development and indicates vital future research directions along with a conceptual framework development, which would be helpful for policymakers, business entities, and research academics.

1. Introduction

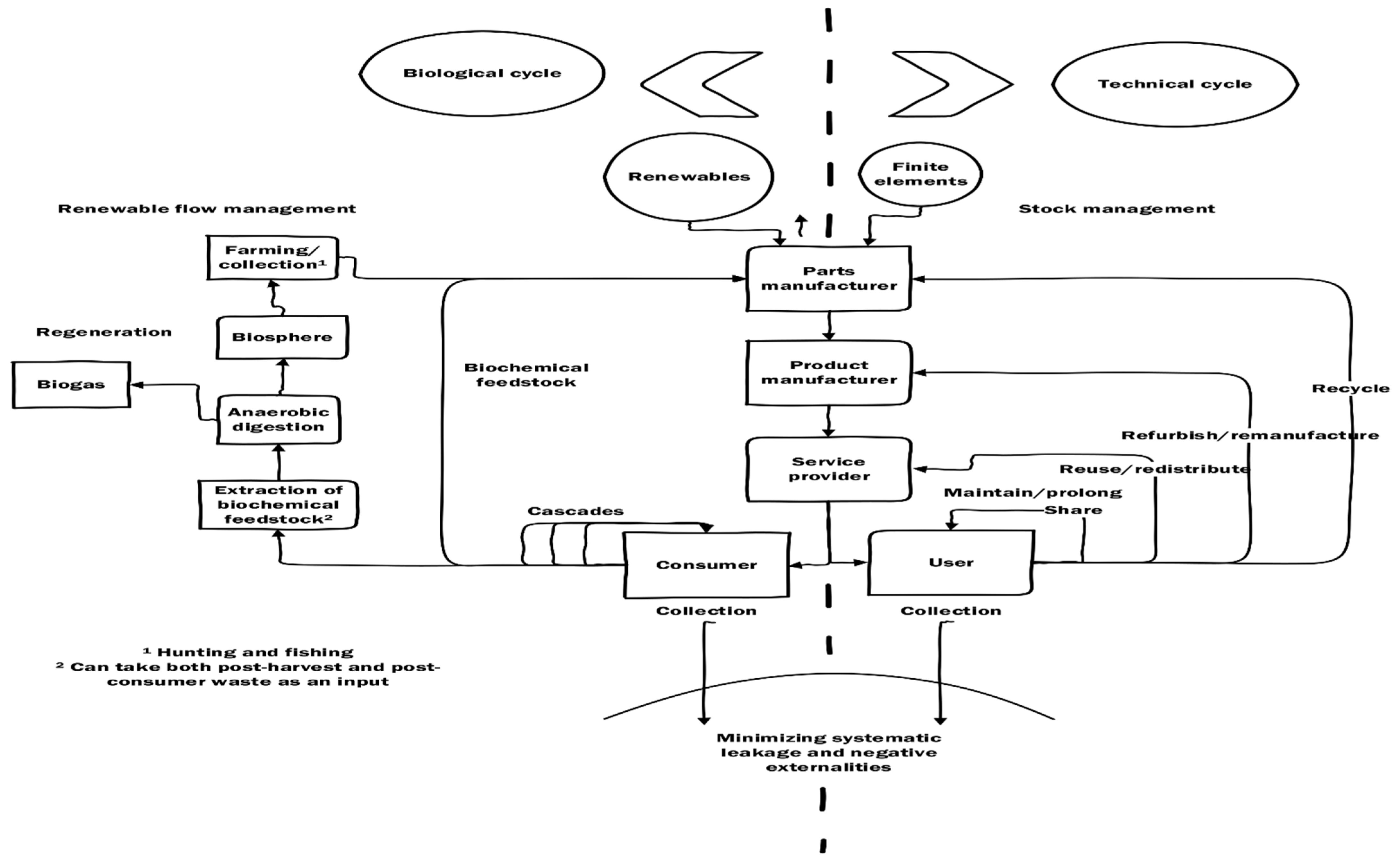

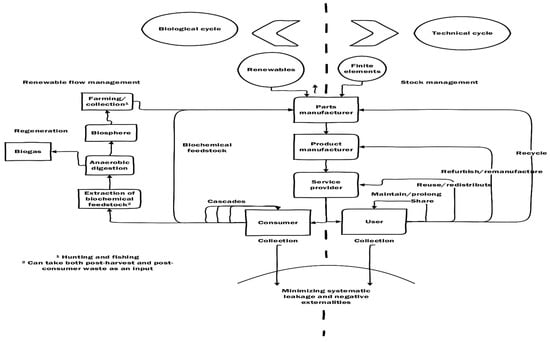

Current production and consumption (P&C) patterns of products, materials, and services in a linear economy connect the operational process of ‘take–make–dispose,’ economy/lifestyle which involves widespread inefficiencies in the value chain (starting from resource extraction and product design to end-of-life disposal). Therefore, profitability over sustainability is a primary focus of a linear economy that puts increased pressure on finite resources. Furthermore, two critical problems arise from the linear P&C practices: (1) limited scope for resource recovery due to ill-fated product design (i.e., a polyester-cotton textile product that is made with bio-based and fossil fuel-based PET plastic material resulting in composite products) and (2) non-regenerative activities within the natural ecosystem damaging soil health (i.e., food waste, cotton waste and other types of waste mixed and sent to landfills). On the other hand, circular economy (CE) “is a system of production and consumption which aims to maximize efficient use of resources and waste through closed-loop, regenerative and shared approaches, and at the same time, avoids unnecessary consumption of natural resources (e.g., energy, water, and materials) and generation of waste through the optimization of processes and exchange of technologies—consequently, reduction of costs” [1]. Originating from industrial ecology-based conceptual thinking in public policy and business concepts, CE has recently been re-popularized [2]. According to Bocken, et al. [3], “CE is an alternative paradigm to help slow, close and narrow resource loops”. The Ellen MacArthur Foundation (EMF) illustrated a butterfly diagram of CE, presented in Figure 1 [4]. There are two different cycles in CE, the technical cycle (the right side of the diagram) and the biological cycle on the left. Sharing, maintaining/prolonging, reusing/redistributing, and remanufacturing/refurbishing are the strategies that are associated with slowing the loop, while recycling refers to “closing the loop” as per Geissdoerfer, et al. [5], which is the last resort of material circularity and one of the critical aspects pursuing and promoting CE [3,6,7]. Recycling predominately focuses on the technical cycle, which supplies (recycled) materials to the parts manufacturers. Recycling is one of the critical paths of CE and directly connects with many activities and actors, such as waste collection, parts manufacturers, and users [8]. Under various R-strategies in the traditional waste management system, recycling (and recycled material as a resource) is one of the central concepts [9]. There are numerous benefits of recycling for resource recovery and material circulation. For example, recycling and reusing (as recycled material) beverage packaging largely contribute to greenhouse gas emissions and reduction in resource consumption [10]. At the city and regional level, recycled plastics, glass, and metals reduce the demand for raw materials [11]. Material recycling practices are becoming popular due to consumers’ concerns about sustainability [5].

Figure 1.

Circular economy—an industrial system that is restorative and regenerative by design, redrawn and adapted from [12].

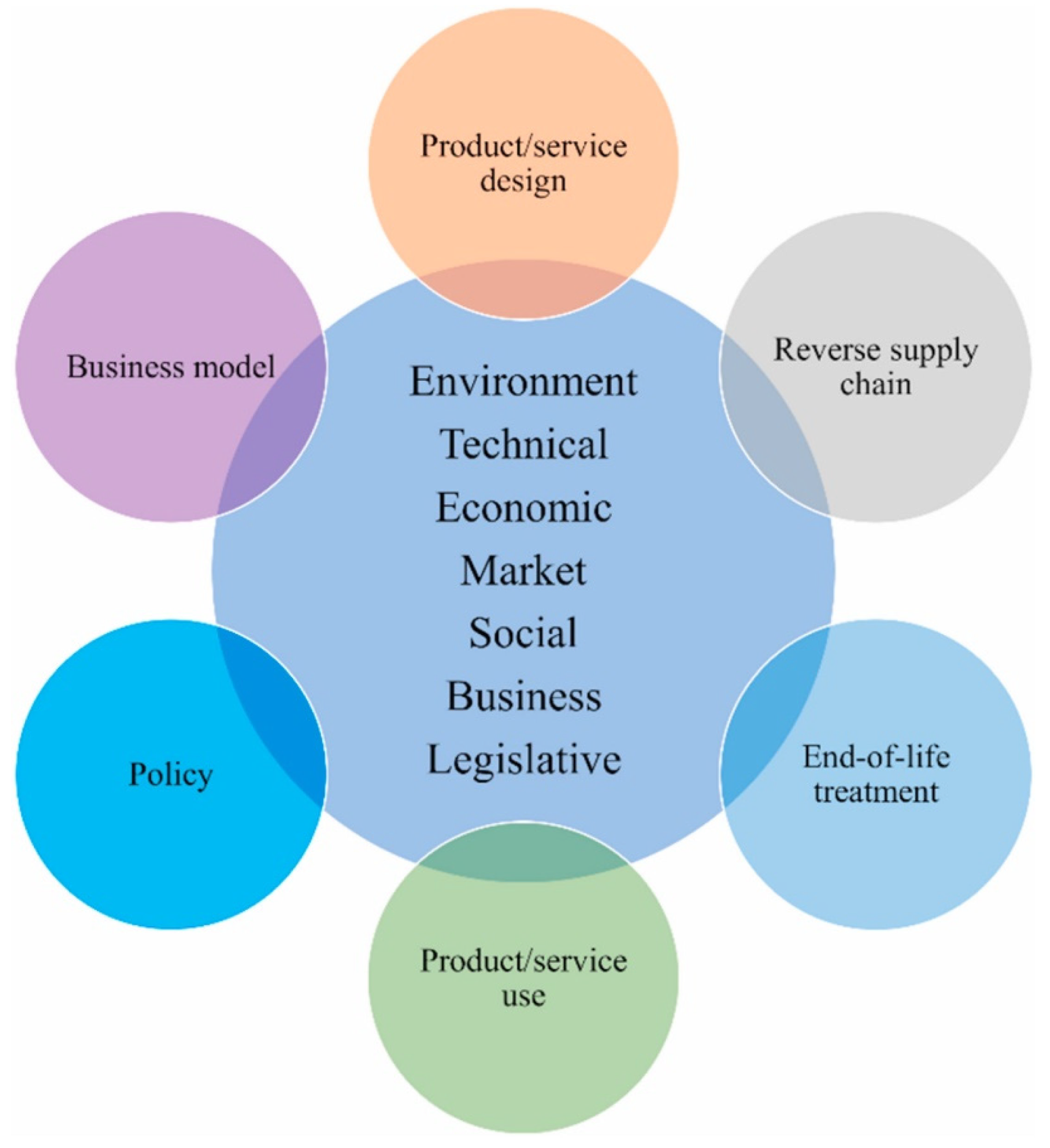

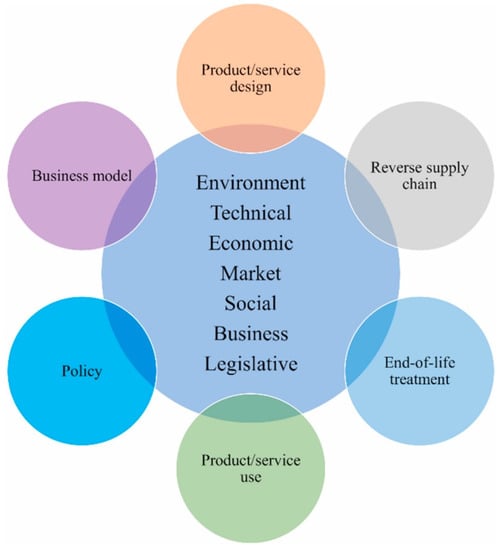

From business model perspectives, there are two specific domains identified by Geissdoerfer, et al. [13], sustainable business model and circular business model. According to the authors, sustainable business model is defined as “business models that incorporate pro-active multi-stakeholder management, the creation of monetary and non-monetary value for a broad range of stakeholders and hold a long-term perspective”. On the other hand, circular business models (CBM) can be defined as “business models that are cycling, extending, intensifying, and/or dematerializing material and energy loops to reduce the resource inputs into and the waste and emission leakage out of an organizational system. This comprises recycling measures (cycling), use phase extensions (extending), a more intense use phase (intensifying), and the substitution of products by service and software solutions (dematerializing)” [5]. Figure 2 shows the building blocks of CE (the outside small circles) which are based on CE principles [14] and the elements placed in the central circle represent decision factors associated with the effective post-used products recovery plan [15]. Alamerew and Brissaud [16] mentioned that a common understanding of the interactions of the building blocks and information on the factors is required for successful implementation of CE principles among product designers, policy makers, researchers, and decision makers.

Figure 2.

Building blocks of circular economy. Adapted with permission from Ref. [22]. © 2021 Elsevier Ltd.

Recycling is a CBM strategy that retains material value [17]. Upadhyay, et al. [18] mentioned that moving towards improved recycling is one of the main propositions of a CBM. Recycling companies have a crucial role in the CE, as identified in the butterfly diagram of the Ellen MacArthur Foundation [19]. “Product recycling/Recycling 2.0” is one of the nine archetypes of CBM [5]. Substituting inputs and increasing the share of renewable and recycled resources in new product development is a critical element of CE [20]. Sustainable consumption practices and recycling are core factors for driving systemic change in the current socioeconomic model [21].

CE for businesses implies that they must encompass their activities based on reused, recycled, or repaired materials and products [23]. The business model in the CE, making profits through the flow of resources, materials, and products over time, including reusing goods and recycling resources [23]. Rosa, Sassanelli and Terzi [7] identified and reviewed 29 CBM articles focusing on recycling. Recycling practices are considered under the “loop” action of the macro category of the ReSOLVE framework proposed by EMF, which is created to support developing CE policies from the companies’ and governments’ perspectives. Eco-efficient value creation approach is one of the most critical aspects of circular business model design, with some inherent elements to be considered while designing it, such as the trade-off between product level and social level, fierce market competition, perceived customer value, and environment-friendly product/service [24]. “The total recycling of resources” is associated with the value creation segment of circular business models and in that case, industrial symbiosis plays an important role [25]. The circular economy is illustrated as a combination of reducing, reusing, and recycling activities [26].

The primary motivation of this article is to investigate the key elements of “recycling” (mainly sector-level barriers, enablers, and system-level requirements for reverse logistics, policy, and innovation) from the “circular business model” perspectives (business practices, cost, and resource use minimization, actors and stakeholder’s collaboration, recycled material use, and strategic alignment with circularity and sustainability principles). More details of CBM are provided in Table S1 in the supplementary material of the article. For the selection here, articles selected were titled “circular business model” OR “circular business model innovation”. However, despite the importance of recycling, in the “review articles,” which is the central unit of analysis for this present study, there is hardly any specific focus given to recycling in CBM studies, with few exceptions, such as the study by Rosa, Sassanelli and Terzi [7]. To eliminate this gap and have a better understanding of interrelations between recycling and CBM, this article formulated the following research questions:

RQ1: Based on the published articles, how did researchers analyze the issues of recycling from CBM underpinnings, regardless of the sector?

RQ2: What were the key themes and sectors that emerged from a recycling perspective of circular business models?

RQ3: What are the potential CBM and research opportunities in recycling?

This article is organized in the following manner. Following this introduction, the research method is described in Section 2; Section 3 provides an in-depth analysis of the literature. A conceptual framework is presented in Section 4. Section 5 identifies potential research and business opportunities in recycling focused CBM, and Section 6 concludes the paper.

2. Research Method

Geissdoerfer, Vladimirova and Evans [13] showed that, from the business model perspective, a sustainable business model primarily encompasses several aspects, such as sustainable value, proactive multi-stakeholder management, and long-term perspective. In addition to these aspects, the CBM research domain considers closing, slowing, intensifying, dematerializing, and narrowing resource loops. The authors also mentioned that these two business model domains have imperfect overlap, and CBM is the sub-category of a sustainable business model. Bocken, Strupeit, Whalen and Nussholz [3] further mentioned that CBM is one of the sustainable business models. Diaz Lopez, et al. [27] identified that business model innovation within CE has received increasing attention in the past five years. When it comes to “closing the resource loop”, according to Bocken, et al. [28], recycling is considered a viable strategy for recirculating material resources in the production system. This level of understanding evolved by integrating terminology and framework around circular product design, circular business model, closed-loop design, and business models for closed loop [28], which might not be clearly understood from a sustainable business model standpoint due to the extensive and broad operational definition (i.e., stakeholder management and long-term view on business sustainability) and limited specificity (what could be major pathways/strategies creating value at stakeholder and supply chain-level). Therefore, the research focus of this present review article narrowed its scope (i.e., recycling perspectives of CBM) in the recent evolution of the CBM research trend. As the focus of this present study (this review article) is on recycling, investigating perspectives from CBM rather than the sustainable business model would be more justified.

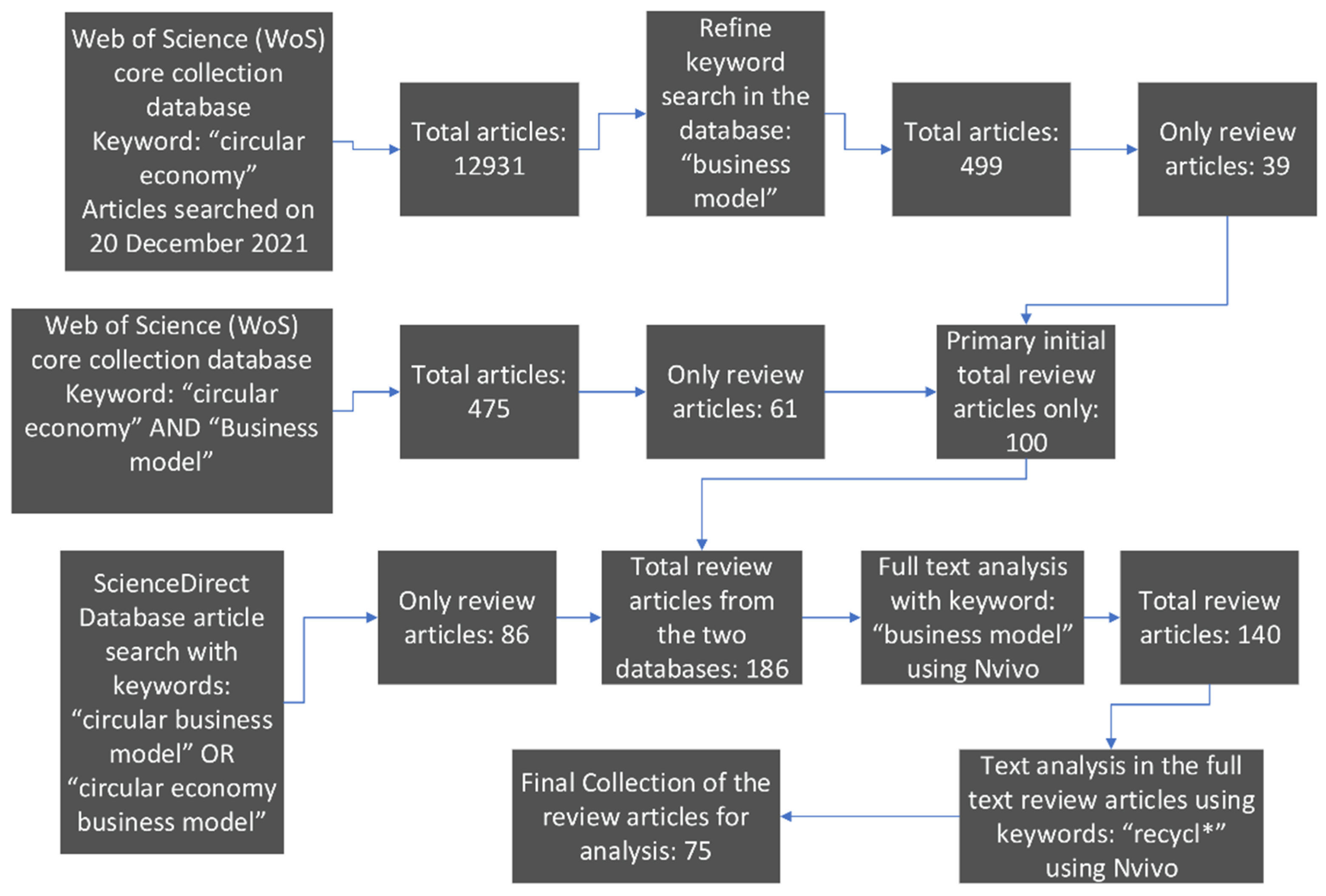

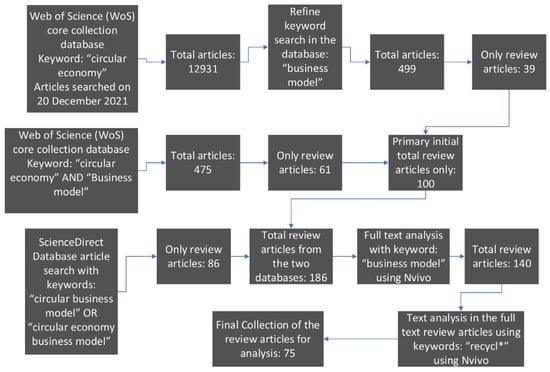

The data collection method of this article is shown in Figure 3. A total of 75 articles are reviewed in this research. This article followed the content analysis method for conducting the literature review prescribed by Mayring [29]. The method was previously applied by Islam and Huda [30], Agrawal, et al. [31], and Gold, et al. [32]. In addition to content analysis, a text mining approach was initiated for which NVivo software was utilized. Text search query and framework matrix were utilized in the software. To collect all the relevant review articles on the research issue, two sets of keywords were used in the Web of Science (WoS) core collection database, as seen in Figure 3 (i.e., first set with “circular economy” then further refinement with “business model” in the database and second set containing “circular economy” AND “business model”). For first set of keywords, WoS’s in-built “Refine results” search box was utilized, while in the second set of the keywords, AND operator was employed to restrict the CE business model-related papers. On the other hand, in the ScienceDirect database, as there is no scope for “refine search result option” within the database, to identify potential missing articles that should be included in the collection, relatively broad keyword strings such as “circular business model” OR “circular economy business model” were utilized. The reason for selecting only the review articles for the present study is that as CBM-related research is growing considerably from various disciplines, it is essential to integrate multi-disciplinary knowledge and understanding in one place. It is believed that such an approach may be beneficial for future researchers in the field. Furthermore, review articles are rich in research-specific issues and direct multiple avenues of the research agenda (i.e., a review paper published only on reverse logistics or product design). The progress of subject-specific issues needs periodic assessment and analysis to track progress, which is sometimes not possible when analyzing original articles.

Figure 3.

Data collection from WoS and ScienceDirect database.

One of the critical issues was that even though the articles’ title, abstract, and keywords show the content related to CBM, in the full text, little discussion is being had about recycling, which has been excluded in the final selection. In other words, despite the absence of the exact wording of ‘circular business model’, many of the authors introduced circular business model-related issues in the discussion, which left no other options but to analyze the full text of the article. It must be noted that initial material collection and final selection of the articles are always subjective; however, objectivity was ensured with the text mining approach of the full text of the articles.

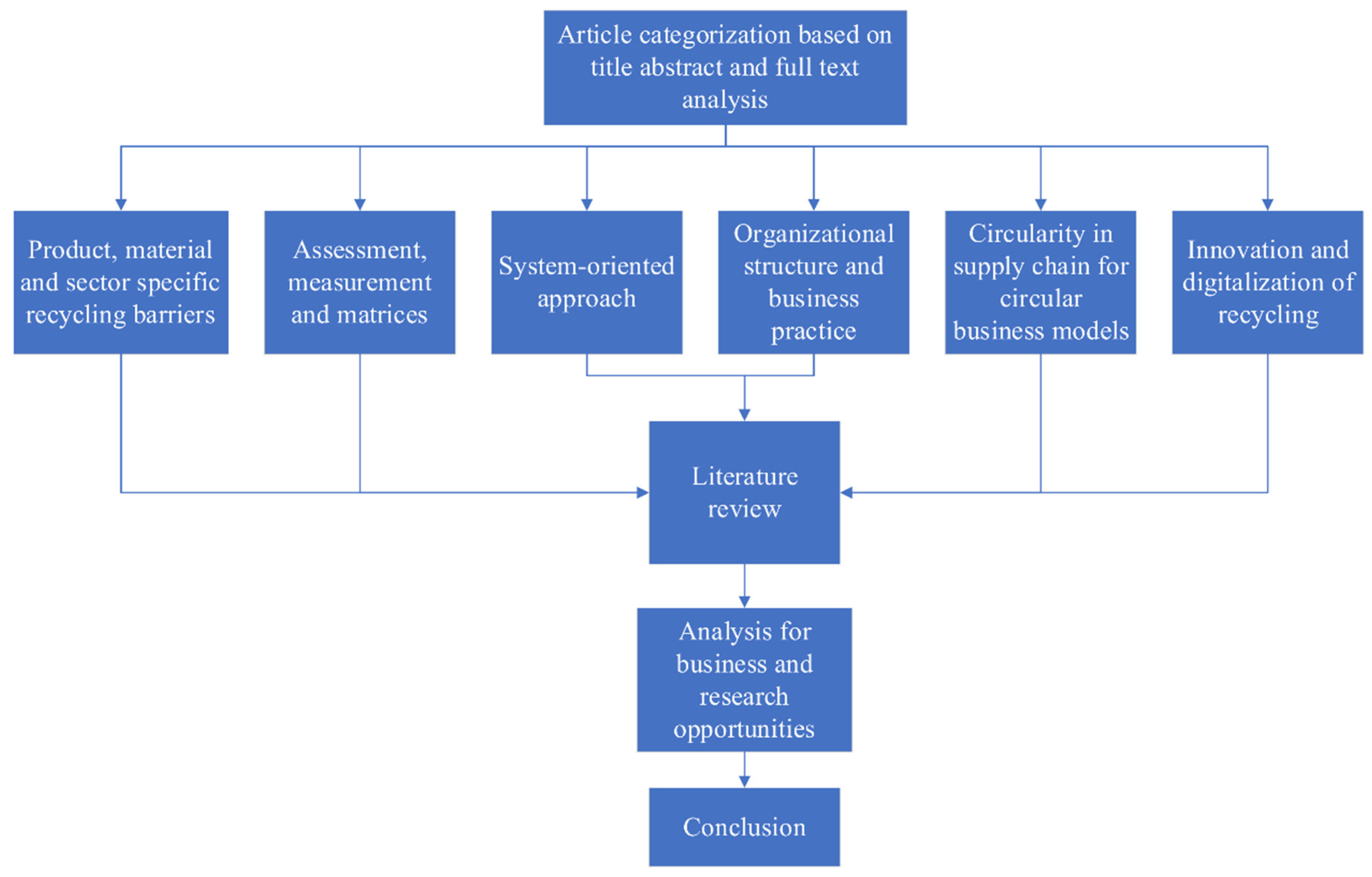

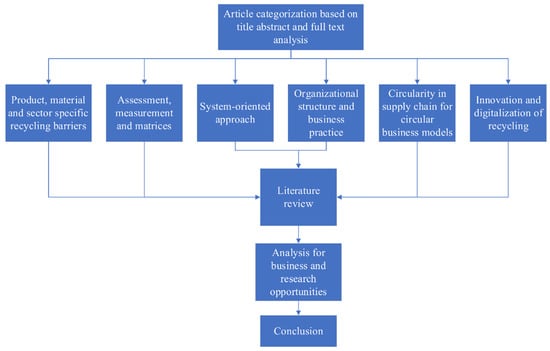

After the initial screening and complete text analysis, articles were categorized into themes or contents. In total, six significant themes were identified in the literature with a focus on recycling in CBM, which are (1) product, material, and sector-specific recycling barriers; (2) assessment and measurement; (3) system-oriented approach in recycling; (4) organizational structure and business practice; (5) circularity in the supply chain for recycling-focused CBM; and (6) innovation and digitalization of recycling. The research framework is presented in Figure 4 to conduct an in-depth literature view and subsequent identification of the gaps and research and business opportunities in the research field.

Figure 4.

Research framework of the study.

Descriptive Analysis

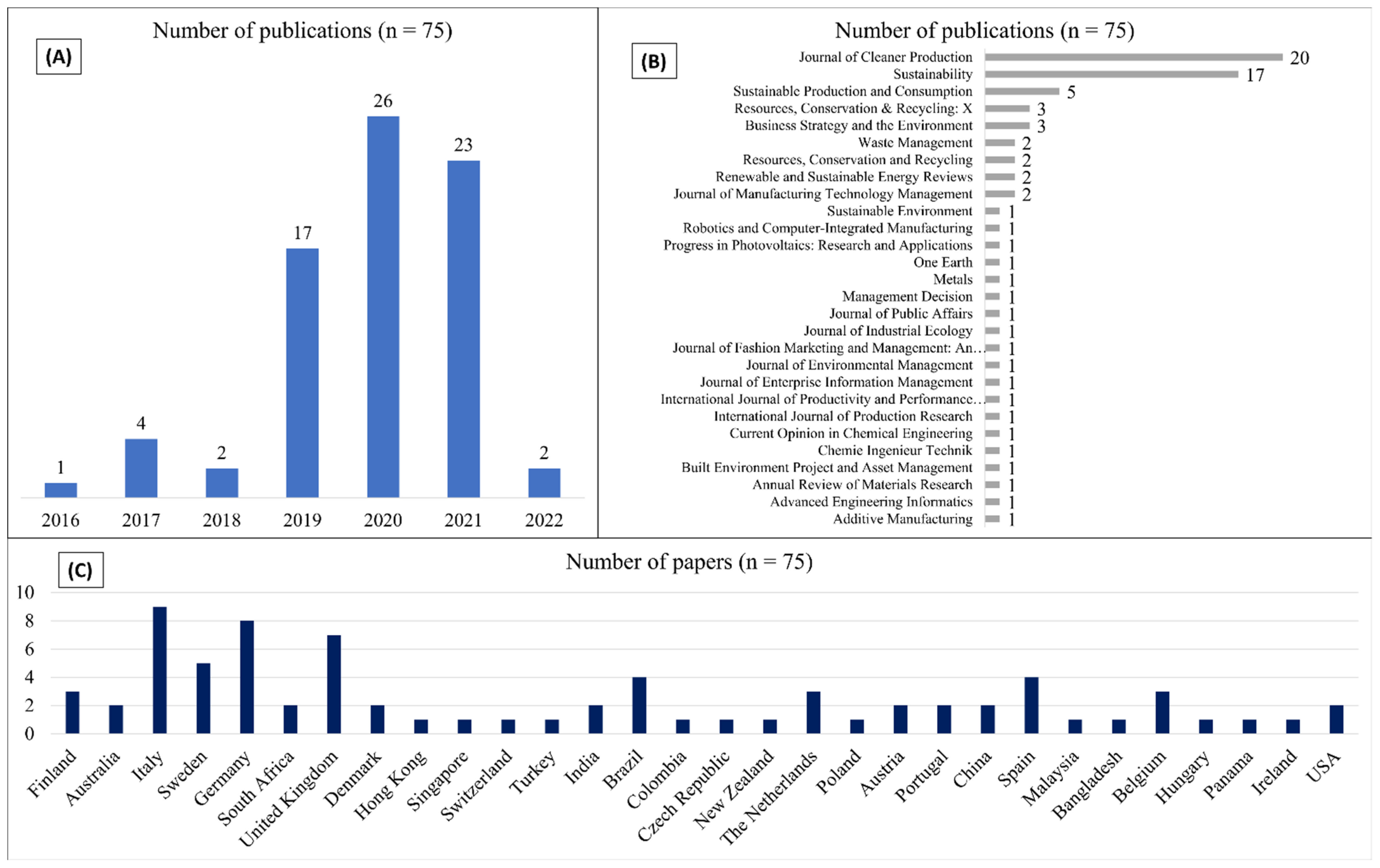

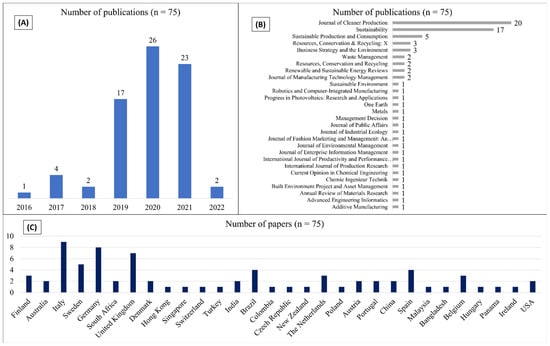

In CBM-related research, the focus on recycling is proliferating, especially in the last couple of years (2019–2021) in the selected articles (Figure 5A). It is expected that this increase will experience exponential growth in the coming years. Among the various journals, most of the selected articles were published in the Journal of Cleaner Production (20), followed by Sustainability (17) and Sustainable Consumption and Production (5) (Figure 5B). Researchers from European countries dominated the research field, mainly those who were based in the United Kingdom, Germany, Italy, Spain, and Belgium (Figure 5C). This assessment was undertaken according to the first authors’ country affiliation identified from the articles. In the next section, a detailed analysis of the articles has been undertaken based on the themes described in the previous section.

Figure 5.

Descriptive statistics of the selected article: (A) year of publications; (B) journal outlets of the selected articles; and (C) country of publications.

3. In-Depth Analysis of the Literature

3.1. Product, Material, and Sector Specific Recycling Barriers

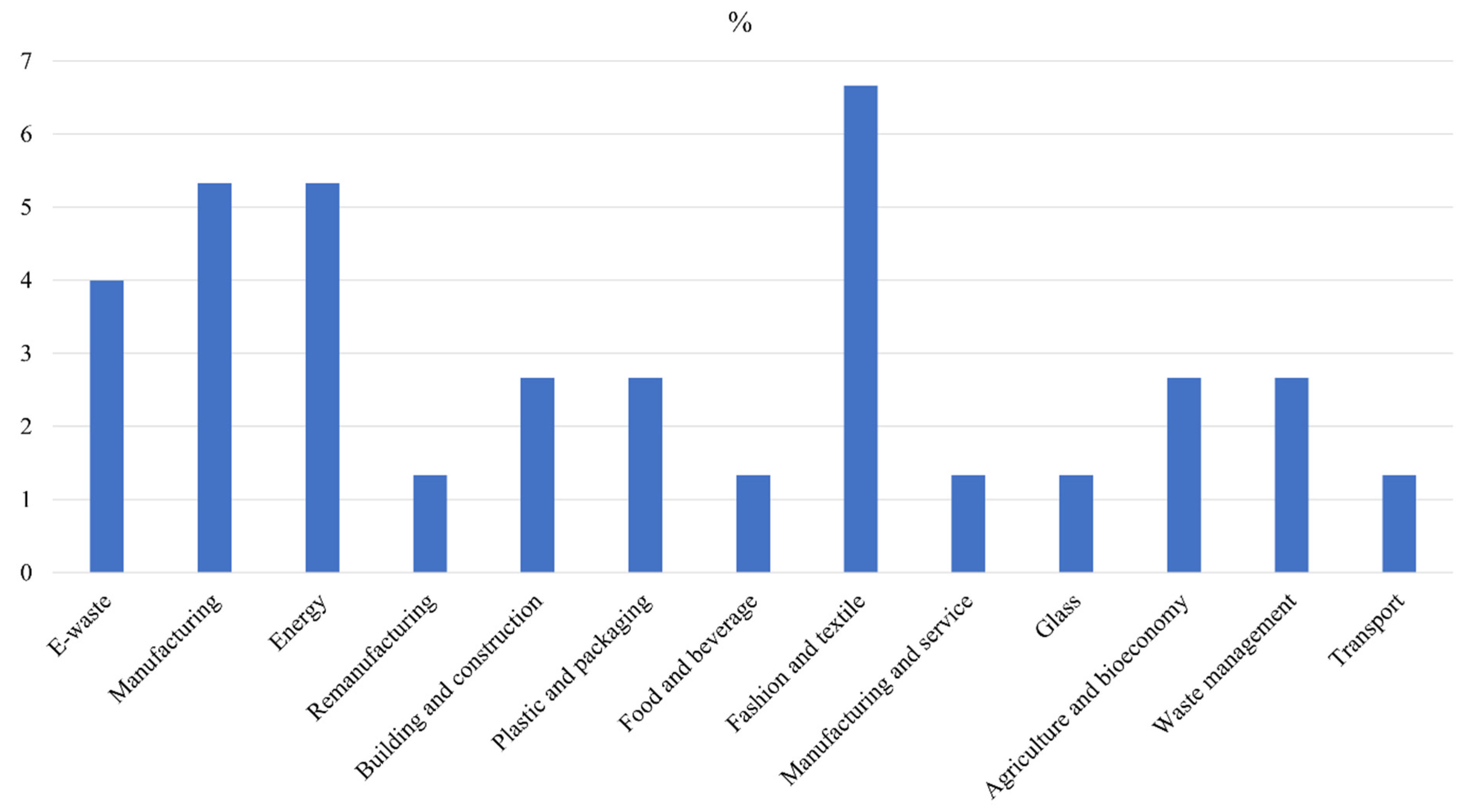

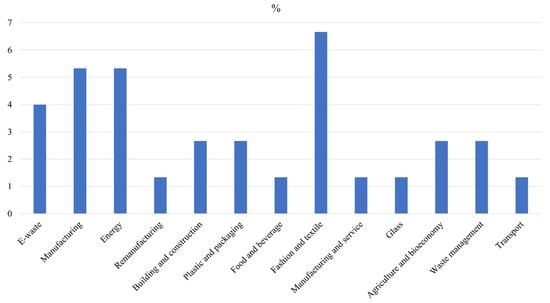

Due to the diverse and complex product structures, the recycling process, including collection, is becoming more complex and sometimes economically infeasible. Current product-focused business models hardly allow product recycling and other options, such as product maintenance, refurbishing, and take-back [33]. Figure 6 shows the distribution of sector-specific recycling-focused business model-related discussion from this literature review. It is seen that fashion and textile was the most widely discussed sector in the literature. In the selected articles, over 30% were categorized as “not applicable” and “general” that referred to studies that were primarily related to the discussion on CBM theories, definition, typology in recycling and recycling without specifying any sector, respectively. Recycling specific barriers and enablers have been described in Table 1.

Figure 6.

Various sectors for recycling focused CBM heighted in the articles.

Table 1.

Summary of barriers and enablers of recycling specific CBM.

3.1.1. E-Waste

E-waste has a significant recycling economic potential in terms of the overall value of raw materials [66]. ‘Design-for recycling’ and Extended Producer Responsibility (EPR) are the two competing strategies associated with e-waste recycling [56]. ‘Design-for-EoL’ was not seen to be a priority to implement, despite the struggle of recycling techniques catching up with the ever-advancing product design [56]. Disassembly is an integral part of recycling, and modular design is an essential factor in this matter [9]. There are losses and residues of uneconomic value involved [9].

3.1.2. Manufacturing

By reviewing 215 papers, Acerbi and Taisch [67] identified 12 circular manufacturing (CM) strategies adopted by manufacturing firms, which were circular design, remanufacture, disassembly, reuse, recycle, resource efficiency, cleaner production, servitization-based business models, industrial symbiosis, and closed-loop supply chain. Authors found that the interaction of the customers (as external actors of a business) and companies ensure resource return flows and in that case data and information circulation are critical.

Florén, et al. [68] reviewed 288 publications to identify interaction between additive manufacturing and business models and concluded that digital manufacturing, firms, and industries are showing considerable interest; however, research on adoption and use of additive manufacturing technology (AMT) is in its infancy and more empirical research is required to understand the impact AMT has on business models. Research conducted by Savolainen and Collan [47] showed additive manufacturing (AM) as a business model. They concluded that case-based evidence is scarce in the research related to additive manufacturing business models and the business potential of the technology was critically fragmented. The authors also found that there would be incremental adoption of AM in a closed business environment, especially in spare parts service where 3D-printing service providers operated and led by original equipment manufacturers (OEM). However, there are challenges associated with the sharing of intellectual property rights (IPR) and not meeting the quality requirements of the customers and manufacturers. Hernandez Korner, et al. [69] integrated the business model innovation concepts and AM from the perspective of Industry 4.0. They concluded that AM offers flexibility (as an enabler in manufacturing process) in redistributed manufacturing, tool design, repair, and refurbishment of metal parts, on-demand production, and design freedom. Business models that adopt AM have multiple opportunities in manufacturing such as customized products development, capability of material reuse, and low-cost small batch parts production.

3.1.3. Energy Sector

Spooren, Binnemans, Björkmalm, Breemersch, Dams, Folens, González-Moya, Horckmans, Komnitsas and Kurylak [35] highlighted the issue of near-zero-waste processing in CE. Developing technologies and processes for clean mineral residue for further valorization is required, and, recently, “technology metals” from wind turbines, solar photovoltaic cells, electricity grids, and batteries (in renewable energy technologies) have received immense attention. According to the authors, novel metallurgical processes from urban mining (recycling processes); new technologies and processes for metal extraction and recovery from secondary resources, especially low-grade material streams, require substantial attention. Due to large scale deployment of solar PV panels, waste generated from solar panels is considered as one of the future challenging waste streams.

3.1.4. Remanufacturing

To support smart remanufacturing in line with the CBM and emerging information and communication infrastructures, Kerin and Pham [43] suggested that there is need to understand the interconnection between cyber-physical systems and IoT. In product-service type business models, companies provide aftersales services, and in that case, flexibility of additive manufacturing (AM) is critical as it renders rapid design modification opportunity. For repair and reuse associated business models, information exchange among customers is critical. Business model that provides technology-enabled high quality durable products or services are perceived as models that follow CE principles. Enterprise information systems (EIS) is found to be particularly useful for product stewardship business models; however, there are concerns over data management and compatibility of stakeholders. According to the authors, cloud-based manufacturing systems have tremendous potential.

3.1.5. Building and Construction

Antwi-Afari, Ng and Hossain [65] found that there is a lack of practical CE approaches that integrate performance assessment tools with CBM in the construction sector. Collaboration and technological innovation, waste elimination from supply chain, and adoption of product service systems addressing sustainability issues (environmental, social, and economic) were found critical to CBM. Furthermore, product design, demolition, economics, and modular integrated construction were less researched issues for the sector. From a construction material use perspective, waste pozzolan and such other recycling materials can be used for concrete manufacturing [65]. However, recycled materials must meet technical guidelines and regulations that fulfill the products and/or structures [65]. Suárez-Eiroa, Fernández and Méndez [20] identified that a higher percentage of waste recycling or improving recycling techniques in building and construction sector is considered as general action under the CE strategy of “closing the system”.

3.1.6. Plastics and Packaging

Plastic and packaging are critical sectors for which, globally, a wide range of activities are being considered. In the EU, it is one of the key sectors targeted to achieve a circular economy [70].

Kleinhans, Demets, Dewulf, Ragaert and De Meester [34] identified that non-household-related plastic waste (generated from business, industry, or institution) has tremendous potential for high-quality recycling and contributes to CE by increasing the plastic recycling rate. Non-household plastic waste has a high chance of being excluded from suitable recycling schemes [34]. The waste stream would contribute 10–30% of the recycling rate of the EU, and according to the authors, these quantities will be the same in the USA and in Southeast Asian countries [34]. However, most of the data gathering, policymaking, and research are related to post-household plastic waste and its recycling rate. In terms of generation and estimation of plastic waste, businesses’ number, type, and sizes are critical factors for non-household plastic waste. A study by Liu, Liu and Osmani [45] mentioned that material recovery rates in plastic recycling could be improved by distributed recycling and 3-D printing technology.

3.1.7. Food and Beverage

Ada, Kazancoglu, Sezer, Ede-Senturk, Ozer and Ram [58] identified that limited business model application (by company management) is one of the sub-barriers under business finance. Other barriers in the category include high cost of receiving recycled products, weak economic incentives, uneven return and profit, large investment cost, and high cost of R&D. During the transition to a CE, businesses also experience high initial investment and complex stakeholder structures in the supply chain. In the supply chain for CBM, the authors mentioned that novel cooperation and collaboration methods are particularly required. The authors identified the productivity of food manufacturing sector (mainly food product consistency and production efficiency) with new emerging technologies. Technology, especially those related to Industry 4.0 and Internet of Things (IoT) enhance innovation abilities among businesses and create scope for new business model development.

3.1.8. Fashion and Textile

As materials and products are critical challenges in the fashion and textile industries, innovations in the yarn and fabric manufacturing stages play a critical role. For improved product sustainability performance, recycled polyester/nylon fiber and eco-friendly and renewable raw materials such as organic cotton can be utilized. Islam, Perry and Gill [39] mentioned a lack of feasible paths of recycling fabric from old garments by transforming it into the fabric for new garments. Eco-friendly processes, chemicals recyclability, and recycling technology adoption were identified as the core of recycling processes. Global Organic Textile Standard (GOTS)-certified organic cotton and Bluesign® products were developed using recycled materials, focusing on high quality and longevity fostering environmental commitments. In the study, most of the discussions are around forward supply chains and product manufacturing with a narrow focus on recycling-specific discussion on fashion and textile products and materials. Another study by Hultberg and Pal [17] concluded a need for an increased share of garment products using recycled post-consumer textile fibers. Clothing disassembly and cutting fabrics into smaller pieces are some steps to recycling textile waste [55]. In addition, recycled materials for textiles are developed through chemical recycling processes, converting plastic bottles into recycled PETs. However, due to a lack of technological capabilities (e.g., separating mixtures, additives and finishing, and quality restorations), some brands find it challenging to develop internal recycling initiatives. On the other hand, high cost of recycling, makes processes, commercially infeasible [55]. In addition, post-consumer recycling technologies have difficulties delivering quality products per consumer demand [55]. System costs and inefficiencies in textile separation, lack of support structure for the collection, and recyclable clothing production are some of the critical barriers currently existing in the textile recycling sector. To some extent, reducing energy consumption, cutting packaging waste, using recycled materials in production (i.e., improved resource use via sustainable operations in the supply chain), and increasing consumer awareness were identified as mitigating measures [55]. Incentives should be given to support cooperative business organizations and the recycling of waste resources [61].

3.1.9. Manufacturing and Service

Recycling-oriented strategies do not always incur large-scale start-up investments (as perceived by the management) but are instead based on cost-driven models of adoption and reactive approaches. For example, recycling practices are triggered in hotel industries by recycling receptacles in guest rooms. In the steel recycling industry, metal recycling is still a barrier despite having huge potential to be circular and profitable. By conducting an in-depth review, Farooque, Zhang, Thürer, Qu and Huisingh [52] found that a robust forecasting model, research and development in metals, enforcement of EPR, and regulatory interventions with effective taxation strategies can be applied as mitigating measures.

3.1.10. Glass

To mitigate future business challenges associated with the container glass industries in Europe, both upstream (technologies related to lightweight products, emission reduction, and energy efficiency) and downstream initiatives (comprehensive support for waste glass packaging management) need to be considered to achieve global competitiveness and sustainability in the sector [41]. Testa, Malandrino, Sessa, Supino and Sica [41] also mentioned that energy-intensive industries should adopt sustainability as a business imperative, enhance environmental profile, implement system-oriented changes, and create common value towards CE. The authors emphasized the reverse-cycle activities for recycling which can lead to CBMs. Collaborative network and partnerships of stakeholders that work towards achieving goals for business and environment was found to be essential.

3.1.11. Agriculture and Bioeconomy

Recycling biofertilizer for circular agriculture is a good example of recycling in the biological cycle. China’s recycling programs focus on manure biogas production, which is an efficient way of generating electricity [71].

There are two types of components in the CE, biological nutrients (i.e., biodegradable materials) in the biological material cycle and technical materials in the technical cycle. Through integrated biorefineries (e.g., anaerobic digestion and biogas plant) and cascading use of biomass, the biological nutrients undergo a regeneration process. On the other hand, the second one can stay in the technical cycle, suitable for recycling and reuse, which also require collection, separation, and recycling schemes. However, currently, such a scheme is not economically feasible on a large scale due to an inadequate number of bio-based products (with technical nutrients) and a small market share [62]. Only bioplastics and construction and building materials are produced on a large scale compared to other product groups. They are comparatively easy to recover, thus increasing the likelihood of recycling and cascading, mainly depending on product design, suitable collection, separation, and recycling systems [62].

Gwara, et al. [72] argued that nutrients derived from safe recovery and valorization of human excreta has the potential for agricultural use; however, in that case, farmers’ willingness to pay (WTP) for the nutrients and business model of the sanitation sector including incentives, funding, and infrastructure are prerequisites. Community-based and -led sanitation approaches as inclusive business model could lead to better resource recovery, waste management, and sanitation service provision.

3.1.12. Waste Management

Waste solar PV recycling approaches either lie between the classification of (1) bulk recycling (recovery of high mass fraction materials) or (2) semi-conductor and precious metals recovery (referred to as high-value recycling). Activities surrounding PV waste recycling are categorized as: “(i) extraction of the encapsulant from the laminated module structure, by applying standard thermal, mechanical, or chemical methods and (ii) recovery of the metals from the crystalline-silicon (c-Si) cells matrix (for c-Si PV modules) or recovery of the metals and the glass substrate (for thin-film PV modules)” [73]. PV CYCLE comprises a Joint Producer Responsibility system and a recycling pioneer, which has established a downstream PV module recycling and waste logistics process throughout the EU [73]. However, there are several barriers associated with the product stream.

Salim, Stewart, Sahin and Dudley [49] concluded that inadequate and poor market structure of refurbished and recycled products, energy-intensive recycling process, lack of recycling infrastructure and process complexity in recycling, lack of profitability, high cost of chemicals used in the recycling process, capital cost establishing recycling plants and equipment, low level of recovered materials, high cost of recovery (e.g., manual labor and transportation cost), limited environmental awareness concerning consumers recycling behavior, and willingness to pay for recycling system were identified as some of the critical barriers in the waste solar PV and battery storage system sector. Another study by Franco and Groesser [33] identified that solar PV recycling is experiencing some difficulties, such as (1) perception that new products developed with recycled material will provide less performance, (2) effectiveness of the recycling process due to high manual labor activities, (3) due to the presence of hazardous elements in PV panel waste, there would be high recycling, transportation and dismantling cost. Currently, from manufacturers’ and recyclers’ perspectives, solar PV recycling is an unattractive and unprofitable activity due to low volume generation, design dissimilarities (panel architecture), and early-stage recycling technologies and infrastructure [33]. Tsanakas, van der Heide, Radavičius, Denafas, Lemaire, Wang, Poortmans and Voroshazi [73] reviewed business challenges in PV recycling, re-certification aspects for second-life PV modules, and repair/refurbishment. Research on optimal solar PV panel EoL management due to the fact of (1) long lifespan (of the panel (>20 years) and associated inverters (10 years or more)) and (2) limited predictable capabilities of failure and defects in fielded PV components.

3.1.13. Transport

In the transport sector, it is observed that vehicles and batteries related issues have received significant attention among researchers. End-of-life (EOL) EV batteries represent a disruptive technology to the automotive and energy industries, as there is a lack of availability of a cost-effective energy storage system (ESS). In such a context, the electric vehicle battery’s second use was found to be a cheaper solution to electricity storage from renewables [59]. Battey second use (B2U) delays the recycling efforts as it utilizes a higher residual value of the battery. Large car manufacturing companies have demonstrated, through pilots, viable innovative business models regarding battery second use [59]. Creating a secondary market for retired EV batteries is associated with stakeholder relationships that could result in new market opportunities [59]. Along with the recycling companies, this product stream (considering second-hand use in the value chain) represents an attractive market and innovative business opportunity for other stakeholders such as original equipment manufacturers (OEMs), electricity producers, grid operators, and service providers. Stakeholders’ interests were the most critical factors around articulating effective business models. Currently, there is a lack of a proper environmentally sound and economically feasible recycling framework for automotive lithium-ion batteries on a large scale because recycling is often motivated by economic revenues [59].

3.2. Assessment, Measurement, and Matrices

To be competitive in the current business environment, as a circular business model example, one business must take necessary measures and steps to assess the performance of their business based on integrating existing performance criteria into core business activities. Furthermore, as circular business model typology, definition, and (industry) standards are evolving rapidly, new business performance measurement criteria would need to be introduced that conform with the circular economy standard and measurement. In this section, measurement, and assessment-related issues with a specific focus on recycling have been reviewed.

3.2.1. Indicators

Kristensen and Mosgaard [36] comprehensively assessed the micro-level indicators for the circular economy. According to the authors, recycling is measured in “a ratio” or “in percentage.” The recycling rate is measured in percentage, a well-applied concept in waste management. [36]. The authors identified that in waste management, Material Circularity Indicator (MCI) and The Sustainability Indicators for CE (SICE) are the two indicators applied while, for remanufacturing, Product-Level Circularity Metric (PLCM) and Combination Matrix (CM); and for reuse, SICE and Circularity Calculator (CC) indicators are utilized. There is a trade-off between CE coverage and practical usability at the company level (micro indicators are considered). A short description of the indicators is presented in Table 2.

Table 2.

Micro-level indicators, adopted with permission from Ref. [36] © 2020 Elsevier Ltd.

3.2.2. Complementary Assessment and Decision-Making Methods

For analyzing recycling systems, Ferreira, Fernandes, Veiga and Hughes [24] stated that lifecycle assessment (LCA) is the best-defined system which is also suitable for analyzing circular systems and product-service systems. LCA is a method that is described as “a tool for the analysis of the environmental burden of products at all stages in their life cycle from the extraction of resources, through the production of materials, product parts and the product itself, and the use of the product to the management after it is discarded, either by reuse, recycling or final disposal (in effect, therefore, ‘from the cradle to the grave’)” [19].

Palafox-Alcantar, et al. [78] reviewed the applications of game theory as a complementary decision-making method in CE, providing some examples about recycling. The effects of uncertainty from remanufacturing technology and recycled product quality were studied using game theory to set recommendations on varying regulatory situations [78]. For identifying the best strategy of the municipality to minimize landfill-derived carbon emissions, game theory was applied in which recyclables from two domestic waste generation scenarios were considered.

On the other hand, a reliable harmonization method to calculate material-specific recycling rates is primarily influenced by end-of-life processing and product type/design [9]. The authors suggested that iFixit and Greenpeace can be used as examples for categorizing and defining product design assessment scenarios for reparability and recyclability, respectively. For laptops, iFixit provides a laptop reparability score between 0 and 10 where 0 means unrepairable, while 10 means easiest to repair [79]. On the hand, Greenpeace developed a guideline measuring critical impact areas such as energy use, resource consumption, and chemicals use, holistically attached to product design and responsible supply chain management for electrical and electronic devices [80].

In assessing the intention-behavior gap, willingness to participate in formal e-waste recycling, recycling behavior of the young population, and theory of planned behavior (TPB) were some of the essential research methods utilized for the e-waste-related research [56]. Mies and Gold [38] mentioned that despite the availability of social impact assessment tools, i.e., social LCA (SLCA) and socio-organizational LCA (SOLCA), social issues that affect multiple actors along the value chain was less focused, other than worker- and health-related aspects.

3.2.3. Data and Information—Source Acquisition and Capture

Recycling product management and life cycle information conversion and exchange were identified as some of the applications of the digital economy (DE) and CE under the “Whole Life Cycle Stage” [45]. Furthermore, the current recycling data might not be able to be extrapolated for the future, as fewer defects are detected in the panels [73]. A multielement context of techno-economically viable flowsheets is required to understand the holistic product-centric view of closed-loop recycling [9]. Quality of product recycling, design of recycling process (including collection process), and performance of the recycling tasks can be improved by attaching sensors and product composition information to intelligent products [63].

Munaro and Tavares [37] proposed a material passport model targeting specific stakeholders for improved material recovery and use. They mentioned that in the construction and built environment sector, information (e.g., identification and documentation from EPDs and the buildings as material bank (BAMB) online platform) on building material, products, and systems-level is essential, which is currently lacking in the scientific community. Environmental statements on the use of recycled materials and materials LCA was one of the critical items included in the model. Esmaeilian, Wang, Lewis, Duarte, Ratti and Behdad [60] highlighted the necessity of uninterrupted information flow using product embedded information devices (PEIDs), by which on-time collection, governance, and environmentally viable handling processes can be developed. The authors provided one example of feedback from recycling experts, and service providers can return to designers after the product sale [60]. Inverse Manufacturing Product Recycling Information System (IMPRIS), Recycling Passport, and Integrated Recycling Data Management System (ReDaMa) are some of the recycling-focused product lifecycle information systems [19].

3.3. Digitalization of Recycling

3.3.1. Three-Dimensional Printing

Three-dimensional (3D) printing and its application to recycling systems were highlighted by the study of Suchek, Fernandes, Kraus, Filser and Sjögrén [21] and sustainable consumption practices and recycling were identified as two of the critical factors for systematic change of the socio-economic system. According to the authors, these could be fostered by eco-innovation. Waste polymer recycling, 3-D printing of recycled materials, and recycled polymers in 3-D printing were some of the applications of integrated CE and digital economy [45].

3.3.2. Sensor-Based RFID Tagging

Some companies have combined various CBM archetypes. For example, EON (one of the clothing start-ups) has integrated recycling into their service pool of clothes rental business model where they partner with specific external recyclers who can meet the technical requirements of recycling RFID tag-based clothing [81]. From their review, Jia, Yin, Chen and Chen [61] identified that the development of information sharing and communication technology would play a critical role in the circular supply chain in the textile industry, where traceability is ensured by using Universal Product Codes, radio frequency identifiers, and 2-D barcodes. Those tags relate to sensors, and data are collected via Internet protocols, such as IoT. These data are essential for recycling, identifying asset status, location, accessibility, and product protection across the value chain. These technologies also make it convenient to report the exact fabrics and manufacturing procedures of recyclable parts applied in the merchandise production process [61].

3.3.3. Additive Manufacturing and Industry 4.0

Savolainen and Collan [47] mentioned that, unlike conventional manufacturing, in the case of additive manufacturing (AM), raw material costs directly relate to the production volume. The authors mentioned that several industries would not be impacted by AM implementation. For scrap metal and e-waste reuse and recycling, Florén, Barth, Gullbrand and Holmén [68] stated that Industry 4.0 technologies have tremendous potential integrating with the sustainability perspective for developing CBM. The authors mainly focused on additive manufacturing technologies (AMT) to be applied in CBM, and AMT is part of Industry 4.0.

3.3.4. Internet of Things (IoT)

IoT (Internet of Things) solutions are essential strategies for PSS suppliers to implement recycling strategies and achieve sustainability via controlling resources consumption [82]. Intelligent reconfiguration (e.g., automatic engineering change management), smart remanufacturing (e.g., predictive maintenance), and intelligent recycling (e.g., smart recovery or end-of-life prediction) are critical aspects of achieving a circular economy in the PSS [63]. Liu, Liu and Osmani [45] identified that recycling-specific research themes are emerging with other themes such as digital twin, product-service systems (PSS), and servitization in the integrated theme of CE and DE. Kerin and Pham [43] emphasized that an IoT-linked remanufacturing monitoring system could collect data on dismantled parts that are correctly recycled and collect recycling data. Industry 4.0 connects customers with supply chains and severely regulated and self-regulated businesses. The author provided an example of embedded telematics for the automotive industry by which data can be obtained and can be utilized for life extension (remote roadside assistant and diagnostics) and end-of-life (EoL) decision-making [43].

3.4. Organizational Structure and Business Practice

3.4.1. Collaboration and Partnership

If any defects in collaboration have been identified, especially in the CBMs which are dealing with the resource recovery through industrial symbiosis and closed-loop recycling (transforming waste materials into recycled materials), this is a critical risk which might make the whole business model [23]. Recycling activities are connected with take-back schemes, and Kühl, Bourlakis, Aktas and Skipworth [46] gave one of the examples of H&M and other companies that implemented the schemes under the textile product-service system. Avoidance of waste recovery and competition laws instead of collaboration had negatively impacted servitization in the circular supply chain [46]. Participation of all stakeholders is essential for demonstrations and pilots of any project. Baldassarre, et al. [83] gave an example of a plastic cups festival where new services implementation was assessed by life cycle analysis and stakeholder analysis and done including all stakeholders in the supply chain, including recycling agencies. Collaboration is the main determining factor for resource acquisition and undertaking recycling-oriented activities. More like a gap exploiter business model, some businesses perform off-site recycling (i.e., collected industrial wastes at the post-consumer stage from one company), then sell the recycled materials to other companies [19]. Stakeholders’ engagement is critical for the design and testing of potential approaches and, most importantly, for the promotion of accepting recycled material and reused products to realize CE [9]. Carlsberg, the Danish multinational brewer, maintains a collaboration with packaging suppliers for quality (recyclable and reusable) product development and value recovery [84]. To materialize the value proposition, ecosystem members can adopt a recycling-oriented circular strategy; however, members must follow legislation imposed on waste recycling established by the government [84].

3.4.2. Organizational Benefits

Upadhyay, Akter, Adams, Kumar and Varma [18] coined the term “Product renovation” to help businesses innovate in enhanced sustainable technologies and use more recyclable raw materials in production. After the useful life, these materials can be reused internally or externally by other organizations for new product manufacturing. In this, waste material remains in the loop for a longer time. Bansal, Jain, Garg and Srivastava [57] identified that by retaining assets in the form of recycled materials, manufacturing products using reusable material (recycled material with circular product design), and co-creation of customers and green human resource management, a firm can attain a competitive advantage in CBM development mechanism. Although limited, several companies and industries introduced recycling processes in the respective production process for efficient and sustainable resource management, which results in environmental and economic benefits [85].

Recycling companies are better off than manufacturing companies in terms of meeting the requirements of CBM [23]. Manufacturers are closely working with collaborators and third-party collection firms (for waste collection and recycling) [23]. Resource investments in financial, human, and physical resources must integrate information technology in firms’ activities and be aligned with the reverse logistics process for better communications and response [23]. Lahti, Wincent and Parida [23] also mentioned that incumbent firms developing CBM should consider some important sustainability actions in their model, such as redesigning a product, using bio-based materials, increasing the lifetime of a product, and adding recycling functionality. Examples of CBM in some companies include the following: (1) H&M is targeting 100% recycled and sustainably source materials, (2) Coca Cola and Carlsberg focused on design innovation for recyclable packaging, (3) DELL initiated a large-scale computer equipment recycling and refurbishing program, and (4) fabric-recycling factory (for used cotton and viscose into biodegradable pulp) and new chemical process development for the recycling of cotton and polyester blends into new fibers (i.e., H&M is working in association with Hong Kong Research Institute of Textiles and Apparel) [23]. When considering cradle to cradle, reuse or recycling options are included in the new product development to achieve a “zero-emission” strategy to maximize resource utilization and minimize waste production [86].

3.5. System-Oriented Approach

3.5.1. Industrial Symbiosis

Trapp and Kanbach [48] concluded that by optimizing recycling activities, the environmental value could be captured, and many of the companies in an agro-park cluster are doing so. The biogas plant was found to be an essential component in the cluster, transforming by-products into high-value inputs such as electricity. In addition, economic value is captured utilizing generated electricity. Commercially, recycling and reuse system development and collaboration with new suppliers for green product innovation in a closed-loop model were the main success factors of a successful circular company, such as Interface, the carpet manufacturing company.

3.5.2. Material Substitution

Santa-Maria, et al. [87] identified that developing the recyclable product with 100% recycled content (including recyclable packaging product line), implementing a take-back scheme, and a key focus on maintenance and repair of equipment could make a company carbon neutral. Standardization and warranties for recycled products, more effective marketing of upcycled products, and higher value secondary market development were identified as crucial recycling-focused and CE-oriented business models [88]. Most of the recycling is downcycling where the quality of the recycled material degrades over time, and in that case, upfront activities in production/distribution and consumption processes should be scrutinized before performing recycling [26].

Material substitution has trade-offs, especially from a recycling perspective [89]. For example, if cobalt is replaced by nickel in the battery, battery recycling might decrease economic potential [89]. Babbitt, Althaf, Cruz Rios, Bilec and Graedel [89] highlighted some of the strategies around product design and critical material recycling: increasing recycling efficiency, economic incentives for recycling, trans-sectoral recycling partnerships, diversification of suppliers, and circularity passports. The authors provided an example of HydroWEEE as a highly automated mobile recycling plant that works as a decentralized facility. No long-distance hauling and large-scale expansive centralized facilities are required for this model.

3.5.3. Deposit-Refund System

Deposit-refund system was considered as a means for fulfilling of extended producer responsibility, in which final waste disposal is transferred to recycling facilities [10]. Zhou, Gu, Wu, Gong, Mu, Han and Chang [10] mentioned that specific attention should be given to informal recycling enterprises in the implementation stage of the deposit recovery system. Specific control measures are required (via intelligent system) for value creation and value capture in the bottle-to-bottle resource recycling. A deposit-refund system is a formal (waste, mainly bottles, and cans) collection process that is guided by recycling behavior, which is rewarded by a refund [10]. There are three categories of deposit-refund system available: “Reverse Logistics Mode” (in Germany where producers are responsible for deposit receipt and recycling), “Retail Recycling Mode” (in Sweden where retailers and depots support the consumer deposit and waste recycling), and “Repo Recycling Mode” (in Australia where consumer return the EoL beverage packaging in designated collection centers) [10].

3.6. Circularity in Supply Chain for Circular Business Models

3.6.1. Circular Supply Chain—Principles and Practices

Circularity in the supply chain is based on two pillars: (a) keeping materials in use for a longer duration of time and (b) enhancing the durability of products. Recycling is considered as one of the critical elements of the first one. A complex supply chain network is considered the main factor of environmental degradation in the whole value chain, for example, in the automotive industry [40]. “Circular value chains,” as one of the circular business models, have promising prospects for local businesses with waste [34]. Salim, Stewart, Sahin and Dudley [49] mentioned that the supply chain associated with waste solar PV streams would also create jobs supporting local economies. However, there are tremendous opportunities to improve recycling technologies from the perspective of technical, economic, and environmental feasibility. Low amount of PV waste generation, economic limitations, limited advanced PV recycling processes, and lack of recycling capacity were some of the main reasons large companies are going down the path of waste PV panel recycling [73].

Supply loops can gain additional value (in terms of profit) from the product, component, and material flows when recycled materials are used, and recovery of own assets (from the company perspective) are maximized [19]. Nosratabadi, et al. [90] provided an example of a company applying closed-loop supply chain principles to prolong the life cycle of waste and send it to third parties rather than directly to recycling companies. They modified the value capture model so that back-office software adjusted the price per material to avoid potential losses for both parties (third party and recycling companies), but the recycling companies earned guaranteed income for an extended period.

3.6.2. Regional Focus of Recycling

Container glass is one example of circular products made using cullet treatment plants (CTP), and Europe has the highest recycling rates in the world [41]. Testa, Malandrino, Sessa, Supino and Sica [41] investigated the performance of the Italian container glass industry from the perspective of cullet recycling (to produce container glass) and, thus, new CBM focusing on reverse-cycle activities for recycling. From the Republic of Korea’s perspective, Herrador, Cho and Park [44] mentioned that improving the recycling system would reduce elevated GHG emissions. Better infrastructure (especially for single-family homes) for senior citizens’ initial sorting and economic mechanisms in a transparent, efficient system are necessary for better recycling. In Latin American countries, recycling policies target minimization packaging impact on the environment and explore schemes related to shared producer responsibility [91]. In the EU, stockpiling of used e-products is one of the many reasons for lower collection and recycling rates [56]. Recycling targets incentivize industries to set up recycling loops in specific sectors such as plastics and glass and at regional levels such as the EU [2].

3.6.3. Recycled Material Use

Resource consumption and pollution generation would be minimized by reusing recycled material. In some cases, to ensure the system is fully circular, hybrid strategies have to be deliberated. For example, repurposing is a combined strategy of reuse and recycling when there are some economic or technical feasibility barriers for which the product cannot directly be reused [67]. Hernandez Korner, Lambán, Albajez, Santolaria, Ng Corrales and Royo [69] found that research in sustainability is focusing on the investigation of raw materials made from recycled materials and polymers to help with CE implementation processes. Recycled material used product value after period X is considered one of the key performance indicators of new (circular) business models [19]. Increasing the share of recycled materials in production contributes to low environmental impact and reduced energy consumption, as a positive impact [54]. R&D and purchasing efforts are the two main activities that household appliance manufacturing companies achieved to increase recycled material use in production lines, primarily motivated by implementing circular product design [54]. By using recycled fishing nets, Ecoalf (a company that transforms ocean waste into fabrics and products) has saved more than 25 percent of natural resources and reduced greenhouse gas emissions by 28 percent [92]. Reducing carbon footprint is one of the circular textiles and fashion industry outcomes where recycling or closing the loop has been used as a successful strategy [92].

There is widespread consumer perception of low performance from products made from recycled products/material and refurbished products [33]. In some cases, that might be the actual scenario. For example, decreasing fiber length was identified as a side effect of recycling paper, which leads to reduced recycled paper strength [11].

3.6.4. Product Design and Disassembly

Liu, Liu and Osmani [45] mentioned that poor product design and a lack of recovery infrastructure were the main barriers to the e-waste material recovery rate. Solar PV waste recycling technologies must adopt the changing regulatory requirements; however, there is a disproportional growth between development of recycling technologies vs. manufacturing technology [73]. Despite much focus on recycling waste lithium ion batteries (LIBs), except a few large companies such as Umicore, Sony, and Accurec, there is a lack of battery recycling industry infrastructure at a sizeable commercial scale [59]. Hjorth and Chrysostomou [85] mentioned that a conventional recycling setup such as shredding takes around 20 s while 3 min is required for disassembling a product. Disassembly is seen as a potential means of creating more jobs opportunities [93]. Higher purity of recycled materials can be attained by intelligent sorting and disassembly under Smart PSS [63].

3.6.5. Reverse Logistics

Electronic waste recycling is a multibillion-dollar industry in Europe that involves introducing reverse logistics to collect and renovate e-waste [66]. Collection and recycling costs could be dramatically reduced (i.e., cost associated with the transport distance covered between collection centers to recycling plants in remote and regional areas) by implementing centralized and decentralized plants, considered as critical enablers for recycling [49]. Monitoring and reporting systems and the development of reverse logistics networks with geographically close nodes and recycling centers are required for waste solar PV panels [33]. When it comes to closing of material loops, Lewandowski [19] mentioned that in addition to product development using a specific recycling process, recycled material use, reverse logistics systems, and maintaining relationships (i.e., collaboration with other companies and customers) are critical. Conditional cash transfers as financial incentives can potentially increase the volume of materials processed to reduce collection logistics. However, developing efficient payment mechanisms with minimal regressive distribution of wealth is still a matter of empirical research in recycling systems [72]. Travel distance, final fate, resulting in value leakage, and network topology are some of the critical areas of information related to reverse logistics and recycling [60].

3.6.6. Recycling Infrastructure and Technologies

Testa, Malandrino, Sessa, Supino and Sica [41] argued that glass packaging is a resource-efficient (as it has the resource base of endlessly recyclable glass) industry that can operate as an efficient closed-loop system if municipal solid waste management works effectively and efficiently. The high cost of receiving recycling products is one of the barriers associated with significant initial investment for the supply chain to be circular [58]. Kerin and Pham [43] reported that the actual recycling rate in a recycling system is always lower than the reported value as the recyclers themselves prepare it. In the beverage packaging recycling industry chain, the formal recycling of beverage packaging at the end of use has become a significant issue, and areas such as efficient and convenient recycling systems and improving the standard recycling rate of beverage packaging should be considered as the highest priority [10]. Kleinhans, Demets, Dewulf, Ragaert and De Meester [34] introduced the concept of a local plastic hub where plastic makers and waste owners come together to create circular plastic values. Decision-makers should consider opening a recycling system for plastics to recycle content used in the production system.

3.6.7. Schemes, Policy, and Regulations

EPR was initially believed to incentivize actors in the collection and recycling process to redefine their business model and make necessary product designs, so that waste treatment costs decrease; however, that has not happened. In other words, under the collective scheme, no incentives were given to the actors for improving resource recovery [56]. Salim, Stewart, Sahin and Dudley [49] concluded that extended producer responsibility (EPR), mandatory joint collection and recycling schemes, and shared responsibility among stakeholders would promote participation in the end-of-life collection and recycling activities of solar PV and battery storage systems. The EU is at the forefront of developing circular strategies, and CEWASTE—an EU-funded project—is developing a voluntary certification scheme for waste treatment, in which critical raw material recycling received the utmost attention. In 2021, Volkswagen initiated the first battery recycling plant. The battery recycling business is considered a separate business entity within the company with a provision of public share [50]. The points reward system and online e-waste recycling platforms are product return strategies applied for e-waste [56].

3.6.8. Social Dimensions in CBM

According to Mies and Gold [38], social aspects of sustainability and circular economy are poorly assessed in the literature and indicated by job creation, workers’ safety, and manufacturers’ recycling intentions. Product recyclability, product return for recycling, quality, and performance of the new (recycled) products were identified as critical aspects of consumer behavior towards recycling and the use of recycled products. In some countries, recycling has become a social norm, and people can be denounced for not recycling household waste [56]. The increasing use of recycled plastic comes as a reflection of the changing awareness of the consumer for the environmental and social impact [94].

Consumers’ environmental awareness largely contributes to purchasing remanufactured products, and in that way, companies would be incentivized to promote collection and recycling activities [49]. Consumer awareness of responsibility for recycling was one of the benchmarks for waste management infrastructures [21]. Incentives were always the recycling motive for customers. Nosratabadi, Mosavi, Shamshirband, Kazimieras Zavadskas, Rakotonirainy and Chau [90] gave an example of low-income customers exchanging recyclable waste for discounts on electrical bills. However, consumers still prefer to buy new products rather than recycled or reused products [95]. Due to a lack of knowledge about the recycling program, resource conservation-related education was critical for consumers’ recycling behavior [22]. A social campaign related to cell phone recycling has been successfully implemented for metal extraction [91].

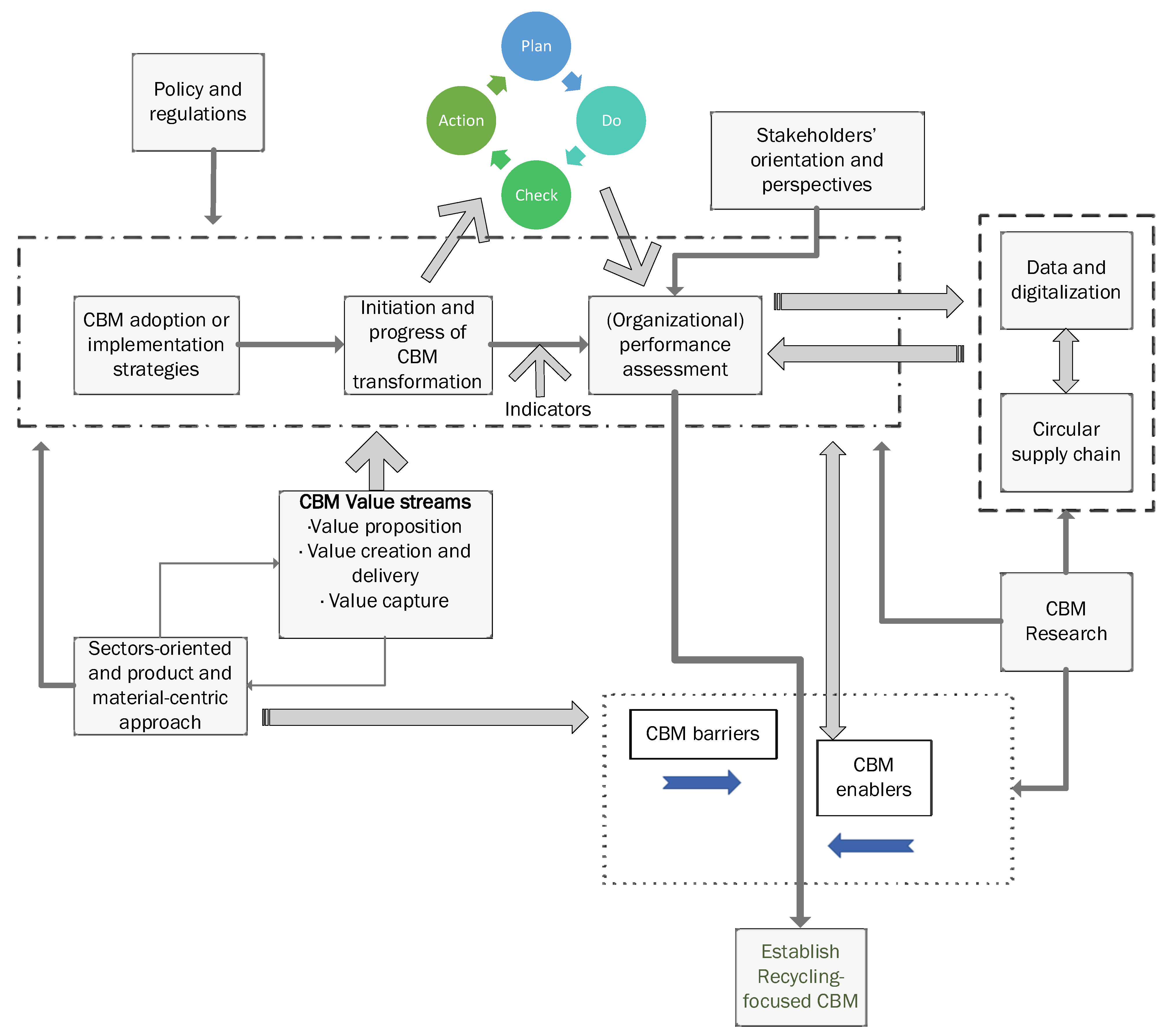

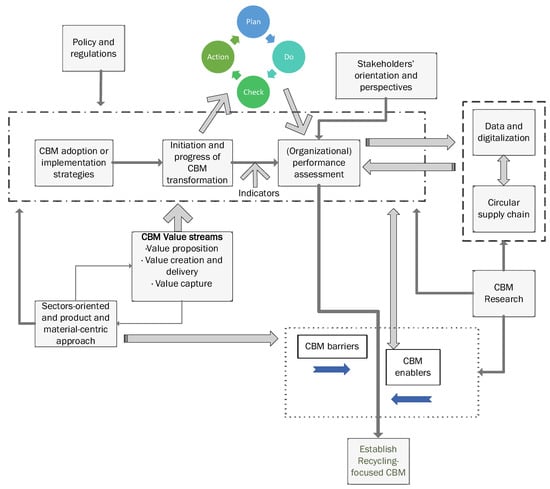

4. Conceptual Framework Development

A general framework for recycling focused CBM development roadmap is presented in Figure 7. The core elements of the framework are presented in tables (Table S2.1 through Table S2.10) in the Supplementary Material of the article. Specific barriers and enables were described in Table 1.

Figure 7.

Conceptual framework towards developing recycling focused CBM.

The process of CBM across businesses starts with CBM adoption or implementation strategies which were identified and presented in Table S2.1. Companies’ motivations and various internal (sectoral perspective and product and material-centric approaches) and external factors (e.g., policy and regulation) are associated with influences on the strategy development. The initiation and process of CBM development is considered as a group of tasks that are also undertaken based on detailed cost structure and techno-economic assessment that can be tracked and monitored with various indicators. Organizational performance towards achieving CE encompasses various micro-level factors starting from top management’s visionary role, consistency around innovation and CBM design practice. The two blocks, initiation and progress of CBM transformation and performance assessment, are the two key blocks that require a constant evaluation process and the PDCA (Plan-Do-Check-Action)-based approach is essential to tracking the progress as well as persistent evolution in both micro and macro-level components of the organizations. Nevertheless, stakeholders’ perspective and orientation have a crucial impact on organizational performance. The performance criteria also underpin the continuous interaction with the data and digitalization platform and circular supply chains which again signifies the contribution of external service providers present in the value chain and transparency and usability of data and information for planning and decision-making.

The first three components (e.g., CBM implementation and adoption strategies, initiation, and progress of CBM transformation, and organizational performance assessment) together is considered as a “black box” (referred to as a foundational strategic direction setting) at organizational level and elements presented in the table might vary substantially as this box is directly connected with value streams of the business depending on the sectors. Case study analysis of various businesses could highlight special elements or types of value proposition, value creation, and delivery and value capture-related activities. This framework should be considered as a simple non-exhaustive process flow chart towards developing recycling-focused CBM which might vary in real-world scenario and major findings from empirical research targeting entities in closed-loop supply chain. Through to the final recycling focused CBM development from the previous step (organizational performance assessment), several barriers and enablers are present that can be solved by research and development. Specific sector-wise enablers and barriers were already identified and presented in Table 1. The diversity of the barriers and enablers also varies significantly across sectors, products, and materials which also requires constant business model experimentation at organizational level as well as in academic disciplines, as many of the concepts around CBM are newly emerging and require in-depth understanding through case studies and empirical research.

5. Discussions and Future Research on Business Model Perspectives

Based on the extensive literature review in this section, several issues from the circular business model perspectives have been discussed and few potential future research, and business model directions are prescribed in the following sub-sections.

5.1. Circularity Measurement and Performance Assessment Methodologies

There should be a set of measurement parameters (dedicated micro-level indicators) that need to be developed around recycling (currently as the recycling rate of municipal waste (%), which is mainly connected to waste management) so that new CBM could utilize it (at company level), according to the requirements set by the parameters. Indicators should have practical applicability and match with respective business practices. One potential option could be using resource efficiency indicators for recycling. Typically, resource efficiency indicators are defined as the benefits (handprint) over burdens (footprint) to measure the materials’ life cycle performance. Moraga, et al. [96] developed a methodology to show the benefits and burdens of using materials as resource efficiency indicators. Using such approaches, a business’s performance comprising recycled material could be measured.

In waste management, material flow analysis (MFA) is widely applied [97] and in Switzerland, MFA is used in recycling activities [98]. As recycling rate is a measurement criteria/scale recognized in waste management, the MFA application will provide a clear and holistic picture around policy and business planning in terms of mass fraction or volume as the measurement. For target setting and environmental impact assessment of the whole recycling process (starting from waste collection to recycled material production), the combination of MFA and LCA could largely contribute to elevating system-level performance [99], transparency, and standardization of the data which would be beneficial for future planning. Although an essential strategy of CE, embodied energy and many critical raw materials are generally lost in the recycling process [56].

At the regional and national levels, forecasting modelling on waste generation is a crucial research and policy-level hotspot that needs to be identified and applied [100]. In this context, the generation estimation model should apply the direct waste analysis method [101] rather than mathematical modelling, despite the time-consuming and expansive nature of data collection for a project. MFA and other multicriteria decision-making (MCDM) models could be applied to prioritize product/material-specific recycling [102]. Such forecasting outputs can encourage business entities to operate in the area (i.e., identifying business opportunities, recycling plant establishment). There is hardly any generation estimation model developed on textile waste generation. The application of machine learning for waste generation estimation is getting popular [103,104]. A specific research focus is required in this regard on a sectoral basis.

5.2. Circular Bioeconomy

There is also some confusion around when closed-loop recycling would be called a resource-efficient cycle (biological or technical). Nußholz [105] mentioned that it is not clear whether either resource efficiency strategy that does not necessarily and fully encompass “closing a loop at value chain” is entitled to be an example of the circular business model. Conceptually in the CE strategy, reuse, recycling, and remanufacturing collectively account for CE’s close-loop motive, and strategies overlap. For the biological cycle-based recycling (in biorefineries), referred to as cascading is connected with the activities related to factory-internal recycling and recovery loops and co-production [62].

Although recycling is more connected with the technical cycle of the CE, in circular bioeconomy, there is an emerging trend of developing new products with technical nutrients such as bioplastics, which requires further attention in terms of collection, schemes, and recycling system, as bioplastics might not be necessarily considered as biodegradable plastics. Overall, there is less focus on recycling in the bio-economy-related sector. The connected sectors with bio-economy, such as agriculture, are not being considered extensively from the CBM perspectives, with few exceptions (e.g., Stegmann, Londo and Junginger [62]), which provides an opportunity for future research. Recycling and valorization of agricultural waste using various waste-to-energy technology [106] and anerobic digestion [107] should be devoted to identifying barriers and enablers from CBM aspects (by-products and co-products development and utilization). In the circular bio-economy, circular product design, design for durability, and prolonged and shared product use did not appear to be a significant topic of discussion [62]. Material recycling is done in reactors and separators at the process level to maximize product yield and minimize by-products, which is a general example of circular design [11]. Localized bioeconomy development is a critical opportunity which should be considered by policymakers.

5.3. Reverse Supply Chain Management

The associated factors for reverse logistics processes are cost, location (network topology), partnership, and product development. Cost minimization in reverse logistics operation for recycling is a critical factor identified in this review. Considering this, Islam and Huda [30] comprehensively identified various analytical modeling techniques (both open-loop and closed-loop supply chain), such as mixed-integer linear programming (MILP), Stochastic—mixed-integer programming (MIP), Multi-objective integer programming (MOIP), and others. With the modeling schemes, CO2 emission reduction from transportation can also be quantified [108]. Third-party recycling service providers (as businesses) could potentially utilize such methods. Various scenarios could be analyzed using the abovementioned techniques where waste material is collected from various sources, and recycled material is delivered to manufacturing facilities for new (circular) product manufacturing.

Particular attention should be given to schemes and collection system development from the industrial plastic waste stream as the collected materials are relatively pure [34]. Under the industrial symbiosis concept, contaminated secondary residue streams are complex and challenging to recycle. Industrial plastic waste can be collected by establishing a plastic hub (as a distributed recycling system) in the industrial park. There is a need for a specific methodology to estimate plastic waste generation in the industries. Inter-organization information sharing on an online platform (information management) system could be developed for such instances. An empirical study on plastic waste generation via direct waste analysis could be essential for future research. A business model around plastic recycling could be developed following a gap exploiter model (start-up/business that works as an external recycler) for multiple companies or as a data-driven service provider. This type of model can also be applied to other sectors, such as textile or e-waste which may also generate a market.

5.4. Product Design

In product design, material traceability should be ensured so that, in the downstream recycling, operators have clarified information on the volume/amount of recoverable material. Sensor-based bin collection mechanism developed for solid waste could be applied in this regard to textile waste [109]. RFID tags [81], blockchain technology [110], material passport [37], and online data platforms could be applied in this regard. Alcayaga, Wiener and Hansen [81] provided the example of RFID tags being utilized for textile waste, but e-waste can also be considered [111].

5.5. Consumer Behavior

Whenever any business tries to identify a business opportunity, besides TPB, conjoint analysis, analytical hierarchy process (AHP) could be applied to ensure consumers’ recycling pattern and motivations (including elements such as incentives). Across sectors, the methods could also be utilized for available waste streams (e-waste, solar PV waste, and electric vehicle batteries). TPB application was only observed in e-waste [56], at a considerable level; however, could be utilized in fast fashion textile waste to understand behavioral response of the consumers regarding fast fashion disposal and recycling.

5.6. Emerging Waste Streams and Technology Management

The problems that were experienced by other e-waste streams (e.g., computers, mobile phones, and others) [22], must not happen for solar PV waste. As solar PV is an emerging waste stream, short-term and long-term planning is required. Residual value acquisition of end-of-life solar PV panels should be employed. The product design perspective is also an explicit requirement that needs to be understood from the design-for-EoL concept. As more and more consumers are expected to use solar PV with battery storage systems at the household level [112], an integrated approach focusing on solar PV and battery storage systems should be pursued. It would then become a high-value waste stream (i.e., batteries have lithium, cobalt, and other components together), attracting many businesses to recycle those in an integrated manner. This would resolve the lack of profitability issues within the business. Nevertheless, the advancement of recycling technologies would be the main factor [33]. Human–robot interaction could dramatically reduce manual labor requirements [113]. In waste management, AI and machine learning (ML) is being utilized in various aspects [114,115]. Individual (new) businesses can provide such a solution through collaborative approach.