Flotation Sludges from Precious Metal Recovery Processes: From Waste to Secondary Raw Material in Ceramics

Abstract

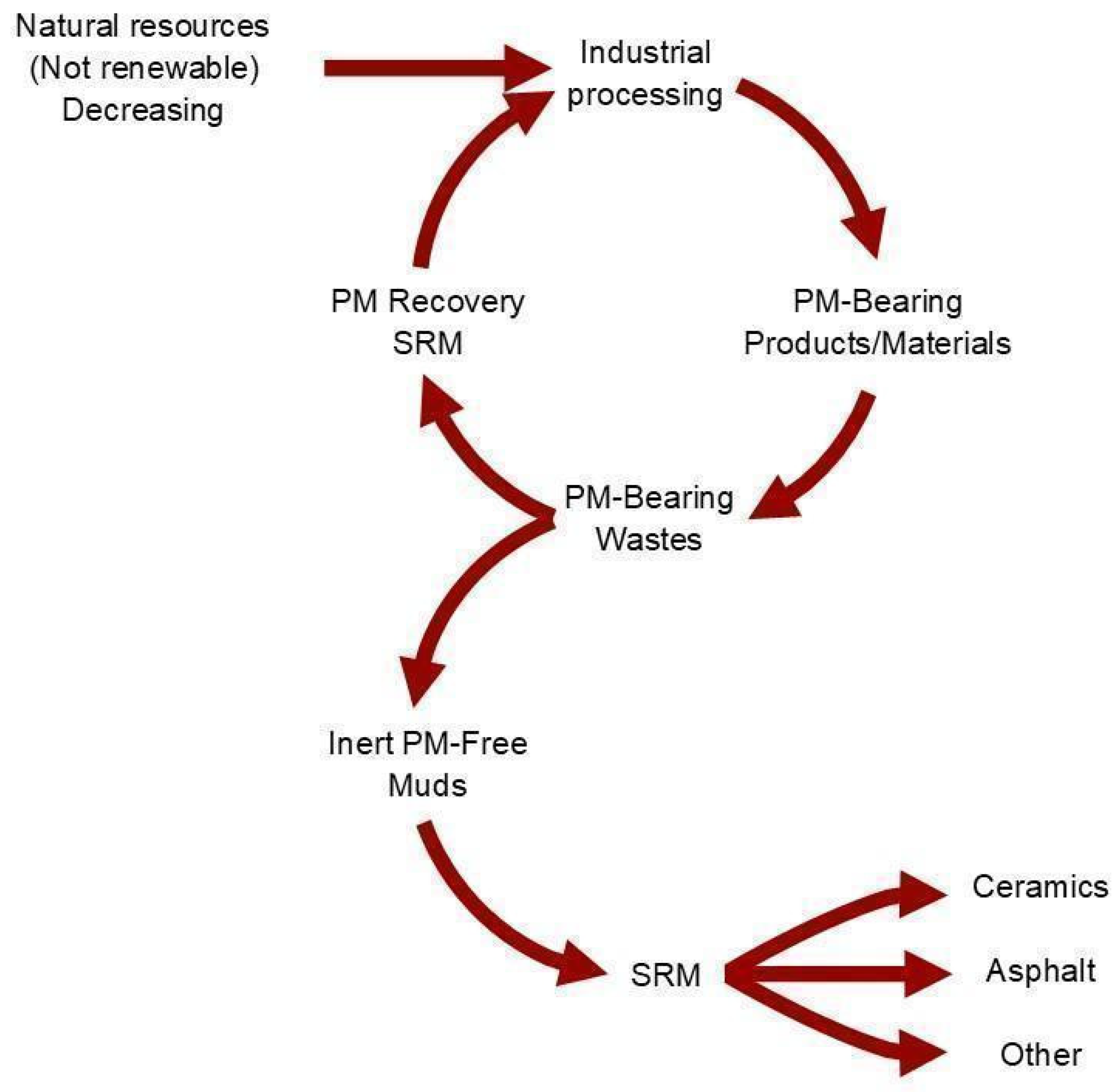

:1. Introduction

2. Materials and Methods

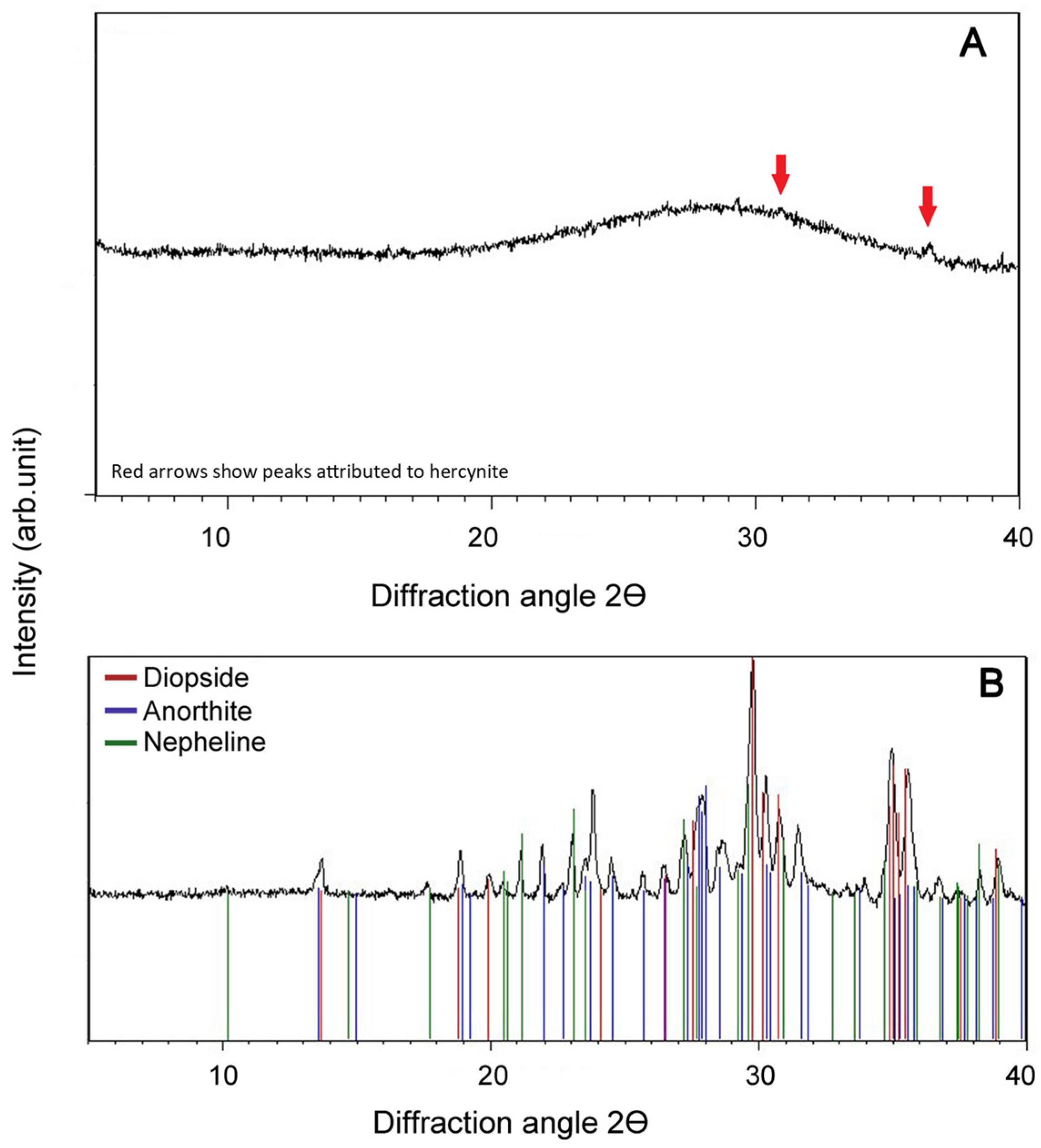

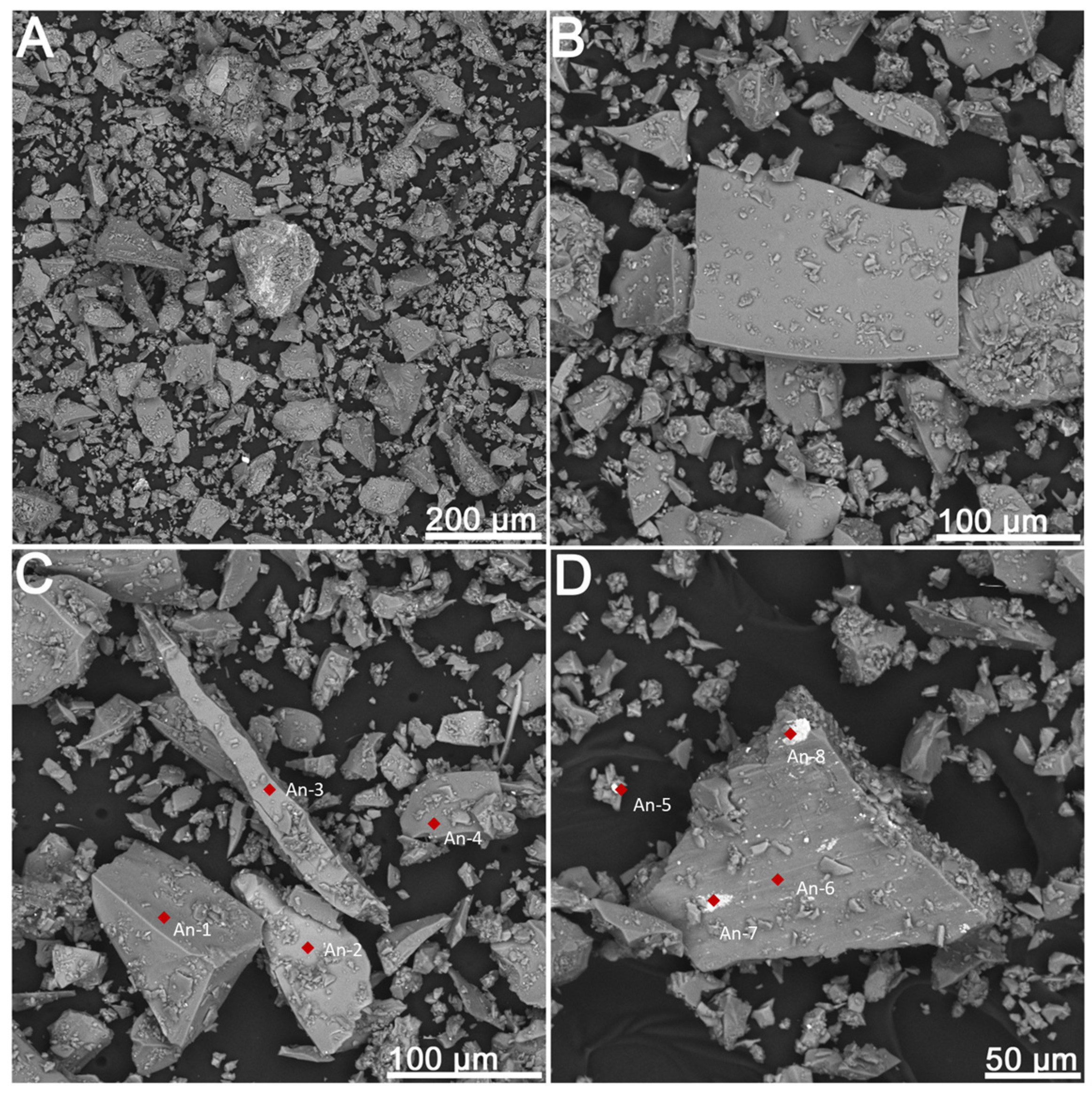

3. Flotation mud Wastes: Chemical Composition and Microstructure

4. Characteristics of Ceramic Products Obtained Using Flotation Muds as SRM

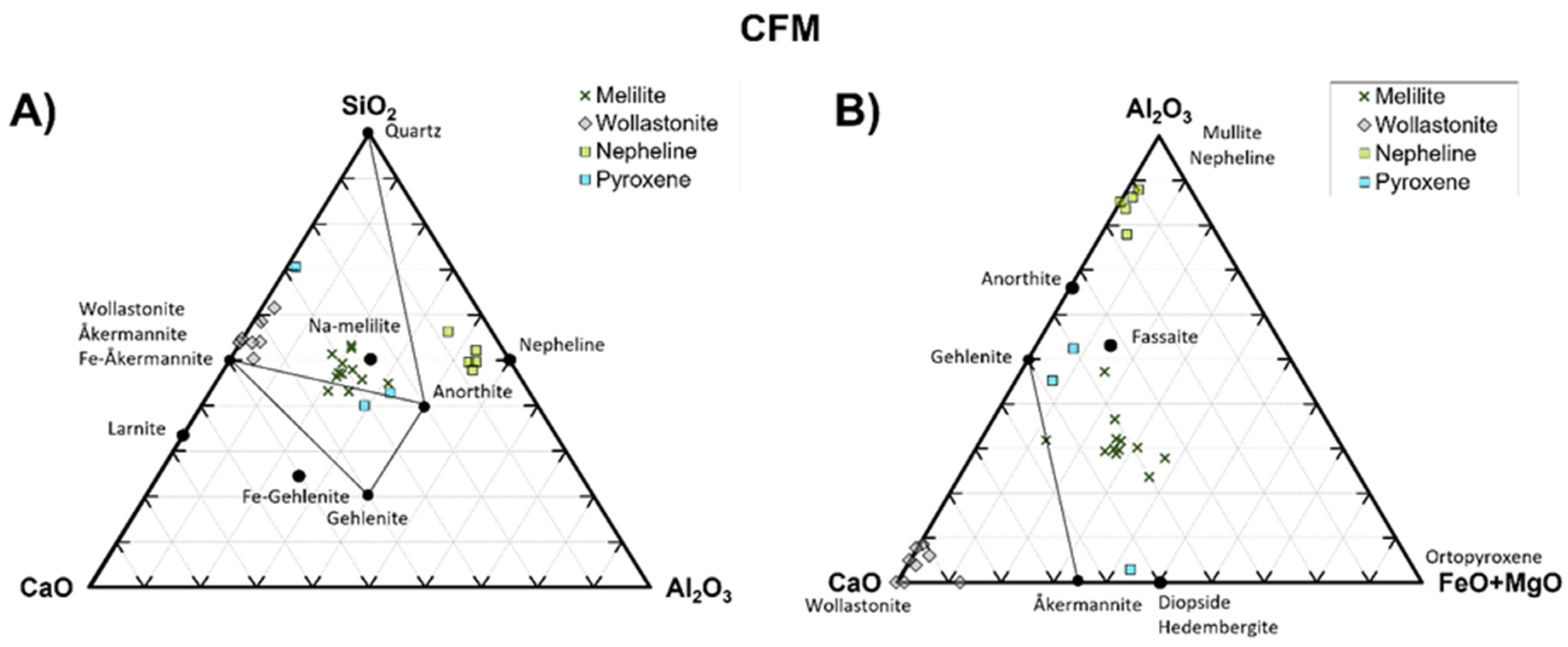

4.1. Chemical, Mineralogical and Microstructural Features

4.2. Physical and Mechanical Test

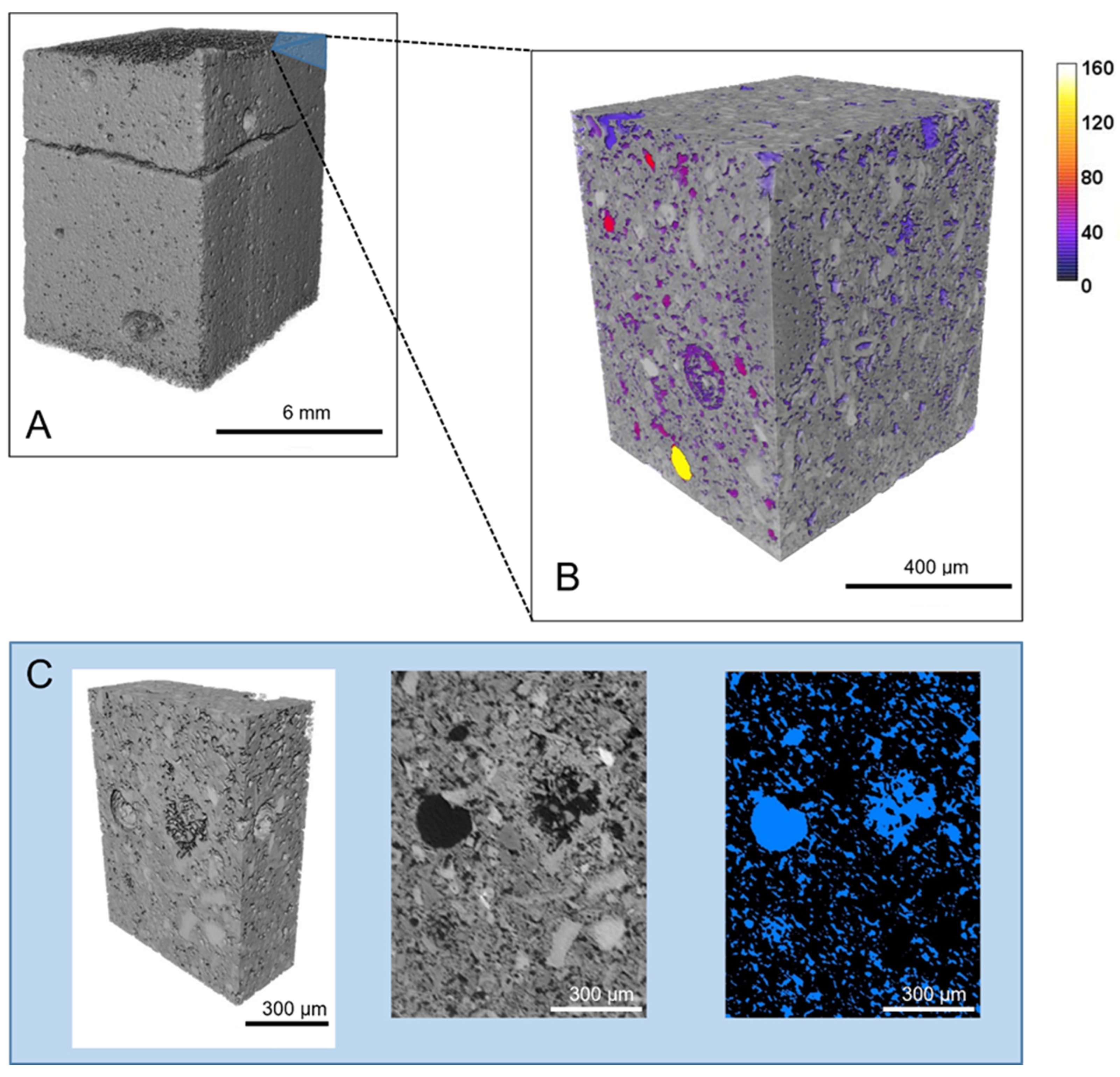

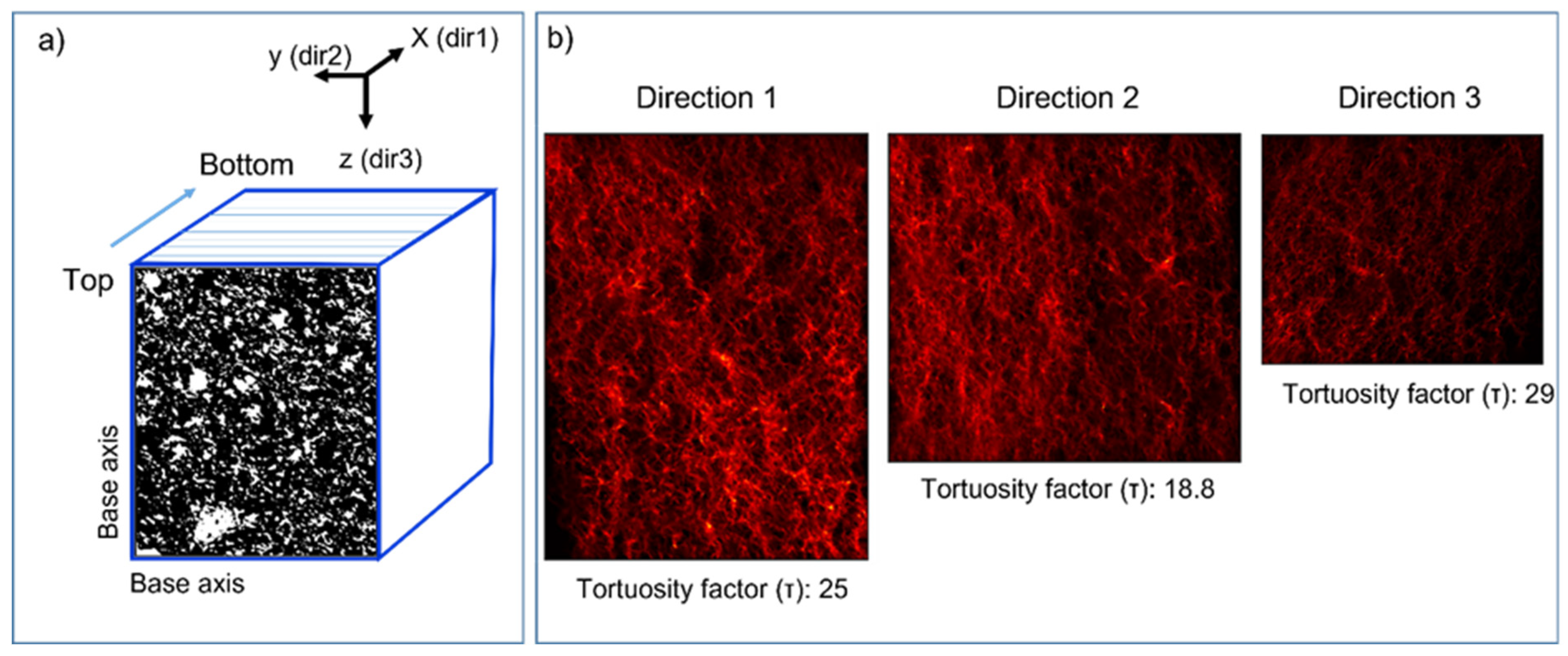

4.3. Porosity

5. Discussion

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ponomarenko, T.; Nevskaya, M.; Jonek-Kowalska, I. Mineral Resource Depletion Assessment: Alternatives, Problems, Results. Sustainability 2021, 13, 862. [Google Scholar] [CrossRef]

- ISPRA Istituto Superiore per la Protezione e la Ricerca Ambientale. Rapporto Rifiuti Speciali; ISPRA: Roma, Italy, 2021. [Google Scholar]

- Ding, Y.; Zhang, S.; Liu, B.; Zheng, H.; Chang, C.-C.; Ekberg, C. Recovery of Precious Metals from Electronic Waste and Spent Catalysts: A Review. Resour. Conserv. Recycl. 2019, 141, 284–298. [Google Scholar] [CrossRef]

- Diaz, L.A.; Lister, T.E.; Parkman, J.A.; Clark, G.G. Comprehensive Process for the Recovery of Value and Critical Materials from Electronic Waste. J. Clean. Prod. 2016, 125, 236–244. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Ding, Y.; Liu, B.; Chang, C.-C. Supply and Demand of Some Critical Metals and Present Status of Their Recycling in WEEE. Waste Manag. 2017, 65, 113–127. [Google Scholar] [CrossRef]

- Saidani, M.; Kendall, A.; Yannou, B.; Leroy, Y.; Cluzel, F. Closing the Loop on Platinum from Catalytic Converters: Contributions from Material Flow Analysis and Circularity Indicators. J. Ind. Ecol. 2019, 23, 1143–1158. [Google Scholar] [CrossRef]

- Ciabatti, I.; Fontani, M.; Martini, C. The Arezzo Seminar on Precious Metals. Substantia 2019, 3, 7–10. [Google Scholar]

- Yousif, A.M. Recovery and Then Individual Separation of Platinum, Palladium, and Rhodium from Spent Car Catalytic Converters Using Hydrometallurgical Technique Followed by Successive Precipitation Methods. J. Chem. 2019, 2019, 2318157. [Google Scholar] [CrossRef]

- Trinh, H.B.; Lee, J.C.; Suh, Y.J.; Lee, J. A Review on the Recycling Processes of Spent Auto-Catalysts: Towards the Development of Sustainable Metallurgy. Waste Manag. 2020, 114, 148–165. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 0080970540. [Google Scholar]

- Iacopo Ciabatti. Il Recupero Dei Metalli Preziosi Dagli Scarti Della Lavorazione Orafa. La Chim. E L’industria Online 2018, 5, 39–43. [Google Scholar]

- Jeon, S.; Ito, M.; Tabelin, C.B.; Pongsumrankul, R.; Kitajima, N.; Park, l.; Hiroyoshi, N. Gold Recovery from Shredder Light Fraction of E-Waste Recycling Plant by Flotation-Ammonium Thiosulfate Leaching. Waste Manag. 2018, 77, 195–202. [Google Scholar] [CrossRef]

- Burat, F.; Baştürkcü, H.; Özer, M. Gold&silver Recovery from Jewelry Waste with Combination of Physical and Physicochemical Methods. Waste Manag. 2019, 89, 10–20. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Singh, K.K.; Ramachandrarao, P. Synthesis of Cordierite from Fly Ash and Its Refractory Properties. J. Mater. Sci. Lett. 2000, 19, 1263–1265. [Google Scholar] [CrossRef]

- Erol, M.; Küçükbayrak, S.; Ersoy-Meriçboyu, A. Comparison of the Properties of Glass, Glass-Ceramic and Ceramic Materials Produced from Coal Fly Ash. J. Hazard. Mater. 2008, 153, 418–425. [Google Scholar] [CrossRef] [PubMed]

- Khater, G.A. The Use of Saudi Slag for the Production of Glass-Ceramic Materials. Ceram. Int. 2002, 28, 59–67. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Petitmermet, M.; Wintermantel, E. Glass-ceramics from municipal incinerator fly ash. Am. Ceram. Soc. Bull. 1997, 76, 75–81. [Google Scholar]

- Andreola, F.; Barbieri, L.; Corradi, A.; Lancellotti, I.; Manfredini, T. The Possibility to Recycle Solid Residues of the Municipal Waste Incineration into a Ceramic Tile Body. J. Mater. Sci. 2001, 36, 4869–4873. [Google Scholar] [CrossRef]

- Montanaro, L.; Bianchini, N.; Rincon, J.M.; Romero, M. Sintering Behaviour of Pressed Red Mud Wastes from Zinc Hydrometallurgy. Ceram. Int. 2001, 27, 29–37. [Google Scholar] [CrossRef]

- Peixin, Z.; Jiaqiang, Y. Mössbauer and Infrared Spectroscopy Investigation on Glass Ceramics Using Red Mud. Z. Für Met. 2000, 91, 764–768. [Google Scholar]

- Rawlings, R.D.; Wu, J.P.; Boccaccini, A.R. Glass-Ceramics: Their Production from Wastes—A Review. J. Mater. Sci. 2006, 41, 733–761. [Google Scholar] [CrossRef] [Green Version]

- Sarrigani, G.V.; Amiri, I.S. Literature Review of Glass-Ceramic and Willemite Production from Waste Materials. In Willemite-Based Glass Ceramic Doped by Different Percentage of Erbium Oxide and Sintered in Temperature of 500-1100C; Springer: Berlin/Heidelberg, Germany, 2019; pp. 13–27. [Google Scholar]

- Andreola, F.; Barbieri, L.; Lancellotti, I.; Leonelli, C.; Manfredini, T. Recycling of Industrial Wastes in Ceramic Manufacturing: State of Art and Glass Case Studies. Ceram. Int. 2016, 42, 13333–13338. [Google Scholar] [CrossRef]

- Zanelli, C.; Conte, S.; Molinari, C.; Soldati, R.; Dondi, M. Waste Recycling in Ceramic Tiles: A Technological Outlook. Resour. Conserv. Recycl. 2021, 168, 105289. [Google Scholar] [CrossRef]

- Drif, B.; Taha, Y.; Hakkou, R.; Benzaazoua, M. Integrated Valorization of Silver Mine Tailings through Silver Recovery and Ceramic Materials Production. Miner. Eng. 2021, 170, 107060. [Google Scholar] [CrossRef]

- da Silva, F.L.; Araújo, F.G.S.; Teixeira, M.P.; Gomes, R.C.; von Krüger, F.L. Study of the Recovery and Recycling of Tailings from the Concentration of Iron Ore for the Production of Ceramic. Ceram. Int. 2014, 40, 16085–16089. [Google Scholar] [CrossRef]

- Taha, Y.; Benzaazoua, M.; Hakkou, R.; Mansori, M. Coal Mine Wastes Recycling for Coal Recovery and Eco-Friendly Bricks Production. Miner. Eng. 2017, 107, 123–138. [Google Scholar] [CrossRef]

- Loutou, M.; Taha, Y.; Benzaazoua, M.; Daafi, Y.; Hakkou, R. Valorization of Clay By-Product from Moroccan Phosphate Mines for the Production of Fired Bricks. J. Clean. Prod. 2019, 229, 169–179. [Google Scholar] [CrossRef]

- Lemougna, P.N.; Yliniemi, J.; Ismailov, A.; Levanen, E.; Tanskanen, P.; Kinnunen, P.; Roning, J.; Illikainen, M. Recycling Lithium Mine Tailings in the Production of Low Temperature (700–900 °C) Ceramics: Effect of Ladle Slag and Sodium Compounds on the Processing and Final Properties. Constr. Build. Mater. 2019, 221, 332–344. [Google Scholar] [CrossRef]

- Liu, S.; Guan, X.; Zhang, S.; Xu, C.; Li, H.; Zhang, J. Sintering Red Mud Based Imitative Ceramic Bricks with CO2 Emissions below Zero. Mater. Lett. 2017, 191, 222–224. [Google Scholar] [CrossRef]

- Bernasconi, A.; Pellegrino, L.; Vergani, F.; Campanale, F.; Marian, N.M.; Galimberti, L.; Perotti, M.; Viti, C.; Capitani, G. Recycling Detoxified Cement Asbestos Slates in the Production of Ceramic Sanitary Wares. Ceram. Int. 2023, 49, 1836–1845. [Google Scholar] [CrossRef]

- Marian, N.M.; Perotti, M.; Indelicato, C.; Magrini, C.; Giorgetti, G.; Capitani, G.; Viti, C. From High-Volume Industrial Waste to New Ceramic Material: The Case of Red Gypsum Muds in the TiO2 Industry. Ceram. Int. 2023; in press. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An Open-Source Platform for Biological-Image Analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Arganda-Carreras, I.; Kaynig, V.; Rueden, C.; Eliceiri, K.W.; Schindelin, J.; Cardona, A.; Sebastian Seung, H. Trainable Weka Segmentation: A Machine Learning Tool for Microscopy Pixel Classification. Bioinformatics 2017, 33, 2424–2426. [Google Scholar] [CrossRef] [PubMed]

- Swainson, I.P.; Dove, M.T.; Schmahl, W.W.; Putnis, A. Neutron Powder Diffraction Study of the Åkermanite-Gehlenite Solid Solution Series. Phys. Chem. Miner. 1992, 19, 185–195. [Google Scholar] [CrossRef]

- Dondi, M.; Ercolani, G.; Fabbri, B.; Marsigli, M. Chemical Composition of Melilite Formed during the Firing of Carbonate-Rich and Iron-Containing Ceramic Bodies. J. Am. Ceram. Soc. 1999, 82, 465–468. [Google Scholar] [CrossRef]

- Rathossi, C.; Pontikes, Y. Effect of Firing Temperature and Atmosphere on Ceramics Made of NW Peloponnese Clay Sediments: Part II. Chemistry of Pyrometamorphic Minerals and Comparison with Ancient Ceramics. J. Eur. Ceram. Soc. 2010, 30, 1853–1866. [Google Scholar] [CrossRef]

- Backeberg, N.R.; Iacoviello, F.; Rittner, M.; Mitchell, T.M.; Jones, A.P.; Day, R.; Wheeler, J.; Shearing, P.R.; Vermeesch, P.; Striolo, A. Quantifying the Anisotropy and Tortuosity of Permeable Pathways in Clay-Rich Mudstones Using Models Based on X-ray Tomography. Sci. Rep. 2017, 7, 14838. [Google Scholar] [CrossRef] [Green Version]

- Cooper, S.J.; Bertei, A.; Shearing, P.R.; Kilner, J.A.; Brandon, N.P. TauFactor: An Open-Source Application for Calculating Tortuosity Factors from Tomographic Data. SoftwareX 2016, 5, 203–210. [Google Scholar] [CrossRef]

- Barry, T.I.; Cox, J.M.; Morrell, R. Cordierite Glass-Ceramics-Effect of TiO2 and ZrO2 Content on Phase Sequence during Heat Treatment. J. Mater. Sci. 1978, 13, 594–610. [Google Scholar] [CrossRef]

- Fernandes, H.R.; Tulyaganov, D.U.; Ferreira, J.M.F. The Role of P2O5, TiO2 and ZrO2 as Nucleating Agents on Microstructure and Crystallization Behaviour of Lithium Disilicate-Based Glass. J. Mater. Sci. 2013, 48, 765–773. [Google Scholar] [CrossRef]

- MacDowell, J.F. Microwave Heating of Nepheline Glass-Ceramics. Am. Ceram. Soc. Bull. 1984, 63, 282–286. [Google Scholar]

- Moo-Chin, W.; Nan-Chung, W.; Min-Hsiung, H. Preparation of Nepheline Glass-Ceramics and Their Application as Dental Porcelain. Mater. Chem. Phys. 1994, 37, 370–375. [Google Scholar] [CrossRef]

- Hamzawy, E.M.A.; El-Meliegy, E.A.M. Preparation of Nepheline Glass–Ceramics for Dental Applications. Mater. Chem. Phys. 2008, 112, 432–435. [Google Scholar] [CrossRef]

- Martín-Márquez, J.; Rincón, J.M.; Romero, M. Effect of Firing Temperature on Sintering of Porcelain Stoneware Tiles. Ceram. Int. 2008, 34, 1867–1873. [Google Scholar] [CrossRef] [Green Version]

- Fuertes, V.; Reinosa, J.J.; Fernández, J.F.; Enríquez, E. Engineered Feldspar-Based Ceramics: A Review of Their Potential in Ceramic Industry. J. Eur. Ceram. Soc. 2022, 42, 307–326. [Google Scholar] [CrossRef]

- Morimoto, N. Nomenclature of Pyroxenes. Mineral. Petrol. 1988, 39, 55–76. [Google Scholar] [CrossRef]

- Romero, M.; Martín, M.I.; Barbieri, L.; Andreola, F.; Lancellotti, I.; López-Delgado, A. Valorization of Al Slag in the Production of Green Ceramic Tiles: Effect of Experimental Conditions on Microstructure and Crystalline Phase Composition. J. Am. Ceram. Soc. 2021, 104, 776–784. [Google Scholar] [CrossRef]

- Taha, Y.; Benzaazoua, M.; Hakkou, R.; Mansori, M. Natural Clay Substitution by Calamine Processing Wastes to Manufacture Fired Bricks. J. Clean. Prod. 2016, 135, 847–858. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, J.; Liu, L.; Ma, J.; Shen, B. Preparation of Additive-Free Glass-Ceramics from MSW Incineration Bottom Ash and Coal Fly Ash. Constr. Build. Mater. 2020, 254, 119345. [Google Scholar] [CrossRef]

- Gao, H.T.; Liu, X.H.; Chen, J.Q.; Qi, J.L.; Wang, Y.B.; Ai, Z.R. Preparation of Glass-Ceramics with Low Density and High Strength Using Blast Furnace Slag, Glass Fiber and Water Glass. Ceram. Int. 2018, 44, 6044–6053. [Google Scholar] [CrossRef]

- Zhang, W.; He, F.; Xie, J.; Liu, X.; Fang, D.; Yang, H.; Luo, Z. Crystallization Mechanism and Properties of Glass Ceramics from Modified Molten Blast Furnace Slag. J. Non. Cryst. Solids 2018, 502, 164–171. [Google Scholar] [CrossRef]

- Ponsot, I.; Bernardo, E.; Bontempi, E.; Depero, L.; Detsch, R.; Chinnam, R.K.; Boccaccini, A.R. Recycling of Pre-Stabilized Municipal Waste Incinerator Fly Ash and Soda-Lime Glass into Sintered Glass-Ceramics. J. Clean. Prod. 2015, 89, 224–230. [Google Scholar] [CrossRef]

- Qin, J.; Cui, C.; Cui, X.; Hussain, A.; Yang, C.; Yang, S. Recycling of Lime Mud and Fly Ash for Fabrication of Anorthite Ceramic at Low Sintering Temperature. Ceram. Int. 2015, 41, 5648–5655. [Google Scholar] [CrossRef]

- Sutcu, M.; Alptekin, H.; Erdogmus, E.; Er, Y.; Gencel, O. Characteristics of Fired Clay Bricks with Waste Marble Powder Addition as Building Materials. Constr. Build. Mater. 2015, 82, 1–8. [Google Scholar] [CrossRef]

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | Cl | K2O | CaO | TiO2 | Cr2O3 | MnO | Fe2O3 | NiO | |

| FM | 1.99 | 2.88 | 25.95 | 30.31 | 0.39 | 0.42 | 0.79 | 0.27 | 23.65 | 0.96 | 0.41 | 0.16 | 4.91 | 0.30 |

| CFM | 3.33 | 4.00 | 21.12 | 35.43 | 0.65 | 0.63 | 0.01 | 0.67 | 21.18 | 0.89 | 0.39 | 0.11 | 6.11 | 0.36 |

| CuO | ZnO | SrO | ZrO2 | SnO2 | Sb2O3 | BaO | CeO2 | PbO | WO3 | SeO2 | Y2O3 | LOI | Total | |

| FM | 0.30 | 0.19 | 0.12 | 2.57 | 0.27 | n.d. | 0.55 | 1.25 | 0.10 | 0.29 | 0.07 | 0.05 | 0.87 | 100.00 |

| CFM | 0.22 | 0.25 | 0.10 | 1.87 | 0.32 | n.d. | 0.43 | 1.20 | 0.07 | 0.27 | n.d. | 0.04 | 0.38 | 100.00 |

| FM | ||||||||

|---|---|---|---|---|---|---|---|---|

| Wt% Oxides | An-1 | An-2 | An-3 | An-4 | An-5 | An-6 | An-7 | An-8 |

| Cl | n.d. | n.d. | n.d. | 1.68 | n.d. | n.d. | n.d. | 0.88 |

| Cu | n.d. | n.d. | n.d. | n.d. | 8.31 | n.d. | n.d. | n.d. |

| Ag | n.d. | n.d. | n.d. | n.d. | 2.15 | n.d. | n.d. | n.d. |

| MgO | 2.87 | 2.92 | 2.36 | 3.37 | n.d. | 2.53 | 0.59 | 3.21 |

| Al2O3 | 20.66 | 16.78 | 14.69 | 28.48 | 1.97 | 20.36 | 4.68 | 27.57 |

| SiO2 | 45.56 | 43.56 | 35.50 | 32.72 | n.d. | 44.00 | 6.65 | 33.74 |

| FeO | 8.54 | 6.58 | 26.28 | 1.83 | n.d. | 9.80 | 79.50 | 7.98 |

| CaO | 11.22 | 12.58 | 12.55 | 23.93 | n.d. | 12.18 | 3.70 | 19.73 |

| TiO2 | n.d. | 0.85 | n.d. | 0.73 | n.d. | n.d. | n.d. | 0.66 |

| SO3 | n.d. | 0.59 | n.d. | n.d. | 39.83 | n.d. | n.d. | n.d. |

| Na2O | 5.13 | 5.36 | 3.08 | 4.01 | n.d. | 3.80 | 0.62 | 2.62 |

| MnO | n.d. | 0.05 | n.d. | n.d. | n.d. | n.d. | 0.91 | n.d. |

| Cr2O3 | n.d. | 0.01 | n.d. | n.d. | n.d. | n.d. | 3.36 | 0.29 |

| ZrO2 | 2.76 | 4.75 | 3.31 | 2.62 | n.d. | 2.91 | n.d. | 2.98 |

| Ce2O3 | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| K2O | 0.61 | 0.73 | 0.68 | 0.62 | n.d. | 0.63 | n.d. | 0.33 |

| NiO | 2.63 | 2.38 | 1.54 | n.d. | 44.71 | 3.78 | n.d. | n.d. |

| SnO2 | n.d. | 2.87 | n.d. | n.d. | 3.03 | n.d. | n.d. | n.d. |

| V2O3 | n.d. | 0.00 | n.d. | n.d. | n.d. | n.d. | n.d. | n.d. |

| CFM | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt% Oxides | Mll11 | Mll12 | Mll37 | Wo21 | Wo5 | Wo6 | Ne1 | Ne5 | Ne6 | Di9 | Cpx39 | Glass4 | Glass10 | Fe-ox8 | Fe-ox9 | Fe-ox40 |

| SiO2 | 40.95 | 37.81 | 35.60 | 48.54 | 53.91 | 54.43 | 41.84 | 39.96 | 40.02 | 57.29 | 38.57 | 72.92 | 74.39 | 2.28 | 4.24 | 0.61 |

| TiO2 | - | - | - | - | - | - | - | - | - | - | 1.13 | - | - | - | - | - |

| Al2O3 | 15.58 | 15.78 | 16.15 | 4.10 | - | 34.28 | 34.50 | 35.54 | 1.25 | 29.11 | 7.17 | 7.81 | 1.82 | 3.32 | 1.57 | |

| Cr2O3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.63 | - |

| FeO | 8.02 | 8.99 | 7.29 | - | - | 0.79 | 0.68 | 0.70 | - | 1.88 | - | - | 94.05 | 86.13 | 96.17 | |

| MnO | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 0.57 | - |

| MgO | 4.45 | 5.03 | 6.44 | 0.41 | - | 0.73 | - | - | - | 18.06 | 2.24 | 2.18 | 1.92 | - | 1.70 | 0.86 |

| CaO | 20.39 | 23.04 | 25.02 | 43.70 | 46.09 | 44.84 | 3.87 | 6.01 | 4.93 | 22.60 | 22.29 | 3.15 | 3.03 | 1.85 | 3.41 | 0.79 |

| BaO | 1.51 | 1.19 | 1.42 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Na2O | 4.55 | 2.16 | 2.14 | 1.05 | - | - | 15.01 | 14.51 | 14.37 | 0.81 | 3.09 | 7.76 | 6.22 | - | - | - |

| K2O | 1.92 | 1.67 | 0.51 | 2.20 | - | - | 4.21 | 4.34 | 4.44 | - | 0.29 | 6.82 | 6.63 | - | - | - |

| NiO | - | - | 1.43 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| SO3 | - | - | - | - | - | - | - | - | - | - | 0.72 | - | - | - | - | - |

| ZrO2 | 2.64 | 4.33 | 4.00 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| Sample | Point Load (kN) | Compressive Strength (MPa) | |

|---|---|---|---|

| A | 150.0 | 55.3 | |

| B | 190.0 | 73.9 | |

| C | 140.0 | 53.2 | |

| D | 140.0 | 53.3 | |

| E | 190.0 | 73.4 | |

| F | 180.0 | 67.3 | |

| Avg Compressive strength (MPa) | 62.73 | ||

| Sample | Point load (kN) | Flexural strength (MPa) | |

| A | 3000.0 | 9.1 | |

| C | 3840.0 | 11.1 | |

| Avg Flexural strength (MPa) | 10.1 | ||

| Sample | Grain size class | Micro-Deval Abrasive charge (g) | Result |

| Aggregate | 11.2/16.0 | 5400 ± 5 | MDE = 24 |

| Waste Raw Materials | Additives | Sintering Conditions | Crystalline Phases | Compressive Strength (MPa) | Flexural Strength (MPa) | Ref |

|---|---|---|---|---|---|---|

| Flotation muds | Aluminum silicates of Ca, Mg and Fe, amorphous silica, Na-silicates, B2O3, Na2O, SnO2, ZnO | 1000 °C for 30 min | Diopside, Anorthite, Nepheline + minor Wollastonite, Melilite | 53.2–73.4 | 10.1 | This work |

| Silver mine tailings | Clay, barium carbonate BaCO3, water | 900 °C, 950 °C, 1000 °C, 1050 °C for 3 h | - | - | 4.9–18.6 | [25] |

| Municipal solid waste incineration bottom and coal fly ashes | Free of additives | 850–950 °C for 3 h | Anorthite, Diopside | 122.76–299.09 | 2.48–2.61 | [50] |

| Blast furnace slag, glass fiber, water glass | TiO2, ZrO2 and CaF2 | Crystallized at 780 °C for 90 min, nucleated at 920 °C for 90 min | Åkermannite, TiO2, Diopside, Perovskite, Melilite, Al3Mg2, Al3Ti, Anorthite, Labradorite, Augite | 12–68 | - | [51] |

| Blast furnace slag | Chemical reagents, such as CaO, Sb2O3, etc | 960 °C, 975 °C, 990 °C | Åkermannite, Augite, Diopside, Gehlenite | - | 26–89 | [52] |

| (1) Calamine mine processing tailings (CMPT) and (2) treated calamine mine process tailings (TCMPT) | Free of additives, just water | (1) and (2) 950 °C, 1000 °C, 1050 °C for 3 h | (1) and (2) Anhydrite, Magnetite, Augite, Gehlenite, Hematite, Quartz (in different proportions) | - | 1) 4,6–23,3 2) 3,1 | [49] |

| Municipal solid waste incineration fly ash | Pure kaolin clay, soda-lime glass, water | 800–1100 °C for 30 min | Wollastonite, Anorthite, Albite, Cristobalite | - | 38.2 ± 5 | [53] |

| Lime mud and fly ash | Free of additives | 900 °C, 1000 °C, 1050 °C, 1100 °C, 1150 °C, 1200 °C, 1250 °C for 2 h | Anorthite, Gehlenite, Wollastonite | 0.43–14.83 | - | [54] |

| Waste marble powder | Brick clay, Waste marble powder (CaCO3) | 950 °C, 1050 °C for 2 h | Quartz, Hematite, Anorthite, Gehlenite, Wollastonite, Calcium Silicate | 6.2–34.2 | - | [55] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Perotti, M.; Iacoviello, F.; Marian, N.M.; Indelicato, C.; Capitani, G.; Salvini, R.; Zampini, M.; Viti, C. Flotation Sludges from Precious Metal Recovery Processes: From Waste to Secondary Raw Material in Ceramics. Recycling 2023, 8, 35. https://doi.org/10.3390/recycling8020035

Perotti M, Iacoviello F, Marian NM, Indelicato C, Capitani G, Salvini R, Zampini M, Viti C. Flotation Sludges from Precious Metal Recovery Processes: From Waste to Secondary Raw Material in Ceramics. Recycling. 2023; 8(2):35. https://doi.org/10.3390/recycling8020035

Chicago/Turabian StylePerotti, Matteo, Francesco Iacoviello, Narcisa M. Marian, Carlo Indelicato, Giancarlo Capitani, Riccardo Salvini, Marco Zampini, and Cecilia Viti. 2023. "Flotation Sludges from Precious Metal Recovery Processes: From Waste to Secondary Raw Material in Ceramics" Recycling 8, no. 2: 35. https://doi.org/10.3390/recycling8020035

APA StylePerotti, M., Iacoviello, F., Marian, N. M., Indelicato, C., Capitani, G., Salvini, R., Zampini, M., & Viti, C. (2023). Flotation Sludges from Precious Metal Recovery Processes: From Waste to Secondary Raw Material in Ceramics. Recycling, 8(2), 35. https://doi.org/10.3390/recycling8020035