1. Introduction

Infrastructures, especially highways, are crucial to national economic development [

1]. As a country emerging from war, construction and development projects are abundant in Iraq. The sudden rise in infrastructure construction results in natural resources, such as aggregates and asphalt binders, being at risk of depleting. Consequently, the recycling waste materials trend is expanding. The pavement industry is a major source of emissions of carbon dioxide (CO

2) [

2]. For example, hot-mix asphalt (HMA) manufacturing was estimated to require 99 KWh (356 MJ) energy and produce 23.8 kg of CO

2 per tonne [

3]. On account of this, pavement recycling is essential for sustainable pavement building, particularly with heightened concerns for environmental protection and sustainable development [

4,

5,

6]. Studies have reported that replacing a portion of virgin components with RAP produced through grinding end-of-life (EoL) pavements is conceivable [

7]. Nonetheless, reclaimed asphalt pavement (RAP) contains aged asphalt that differs from virgin asphalt (VA) in terms of physical and rheological qualities and distinctive composition [

8]. The loss of features leads to significant and early discomfort, such as cracking, spalling, and ravelling, which reduces driving safety and increases maintenance expenses [

9]. Furthermore, asphalt binder ageing is a disadvantage of RAP binders. Asphalt binder ageing could be separated into oxidative and thermoreversible. Thermoreversible ageing has also been termed physical, steric, and thixotropic hardening [

10].

A potential approach to preventing the negative impacts of RAP employment is incorporating rejuvenating agents [

11,

12,

13]. Rejuvenator-added binders containing RAP demonstrated reduced stiffness and resistance to rutting and improved resistance to thermal cracking [

14,

15]. Most rejuvenating agents are oil-based organic substances primarily composed of components such as high-penetration asphalt, low-viscosity oil, and rich aromatic compounds. Depending on the application procedure, rejuvenators could partly to entirely return the oxidised asphalt binder characteristics to their original viscoelastic condition [

16,

17]. The restorative effects could be achieved by regenerating volatiles and oils, during which adhesion attributes of the binders are preserved. This technique also allows the feasibility of reverting the asphaltene-to-maltene ratios of aged binders to their original condition [

18,

19]. Chemically, rejuvenating agents are similar to the maltene fraction in asphalt binders. The substances also could soften aged asphalt binders. Moreover, rejuvenating agents have been reported to enhance binder cracking resistance regardless of the type [

16]. Although the utilisation of professional rejuvenation chemicals could lead to softer RAP, it is economically disadvantageous due to its high cost compared to employing new asphalt and aggregate during road construction [

20]. Consequently, it is essential to develop cost-effective and ecologically friendly high-performance rejuvenating agents to increase RAP levels in reclaimed asphalt mixtures and guarantee their functionality [

21].

The influences of rejuvenators and crude oil on aged asphalt have been the subject of several scientific investigations, given their identical chemical structure [

4,

22]. Waste engine oil (WEO), heavy fuel oils, aromatic extract, tall oil, and maltene are examples of rejuvenating agents [

23]. Yin et al. [

24] investigated the effectiveness of aromatic extracts and tall oil. Their report recorded diminished asphalt rigidity and restored original qualities following the incorporation of the substances. Nonetheless, the effectiveness of the rejuvenators declined with time. Wang et al. [

25] observed that employing WEO as a rejuvenator in incrementing aromatic contents increased the ductility of the aged asphalt samples assessed. The study reported that the optimal WEO concentration was influenced by sample characteristics (e.g., stiffness), and excess WEO resulted in a smooth pavement with degraded performance. Furthermore, the anti-stripping ingredient improved the WEO–asphalt adhesion; however, it failed at high temperatures. In another study, Li et al. [

26] assessed the influences of varying WEO addition amounts on aged asphalt properties. Standard performance evaluations demonstrated that the waste oil’s regeneration effect was obvious. The regeneration process was identified using microscopic and chemical structure analysis. Their report also suggested that incorporating a proper WEO amount might enhance the traditional physical characteristics of the asphalt. Moreover, standard asphalt performance at varying ages was restored primarily due to the inclusion of WEO, which supplemented the light elements in the aged asphalt. The study also documented that adding waste oil did not result in further chemical interactions. Nonetheless, excess WEO might lead to unwanted asphalt viscosity reduction; hence, the 1–4% dose was advised. The physical, rheological, and chemical aspects were assessed when the integration of WEO and maltene to revitalise the characteristics of recycled asphalt was examined in an investigation [

27]. The attributes of the reclaimed asphalt were essentially found to be comparable to VA with the addition of the appropriate amounts of a hybrid rejuvenating agent. Nevertheless, the agent decreased the chemical ageing index (CAI) and asphalt content of the regenerated asphaltene. The thermogravimetric analysis (TGA) results also demonstrated that the rejuvenated specimens were more temperature-sensitive than the recycled asphalt.

In most cases, the ability of a rejuvenating agent to both enhance the characteristics of aged asphalt and reverse the effects of aging can determine the suitability of the agent. Vacuum residue (VR), often called vacuum tower distillation bottom (VTB), has received very little attention from researchers as a rejuvenating agent. The name VR denotes the products that remain after a vacuum distillation method. Based on the refining method and crude oil, the residue might range from very hard to very soft asphalt [

18]. The VR composition varies greatly and has an essential effect on the mechanical properties and microstructure of asphalt binders [

28]. The VR from oil-rich country refineries has been reported to record penetration up to 300 dmm and a 600 mm

2/s viscosity at 135 °C. Nevertheless, the substance is considered a waste by-product [

28] and is limited for paving utilisation alone [

18]. VR could be employed as a rejuvenating agent, considering its potential restorative capabilities for aged asphalt. In light of the aforementioned principles, the present study aims to incorporate VR as a rejuvenating agent into an asphalt mixture with 40% RAP. Physical and rheological evaluations were executed to determine the optimal concentration of VR to rejuvenate aged asphalt. The current study also used analytical techniques to establish mechanical performance assessment data, followed by a simple economic analysis.

2. The Objectives of the Study

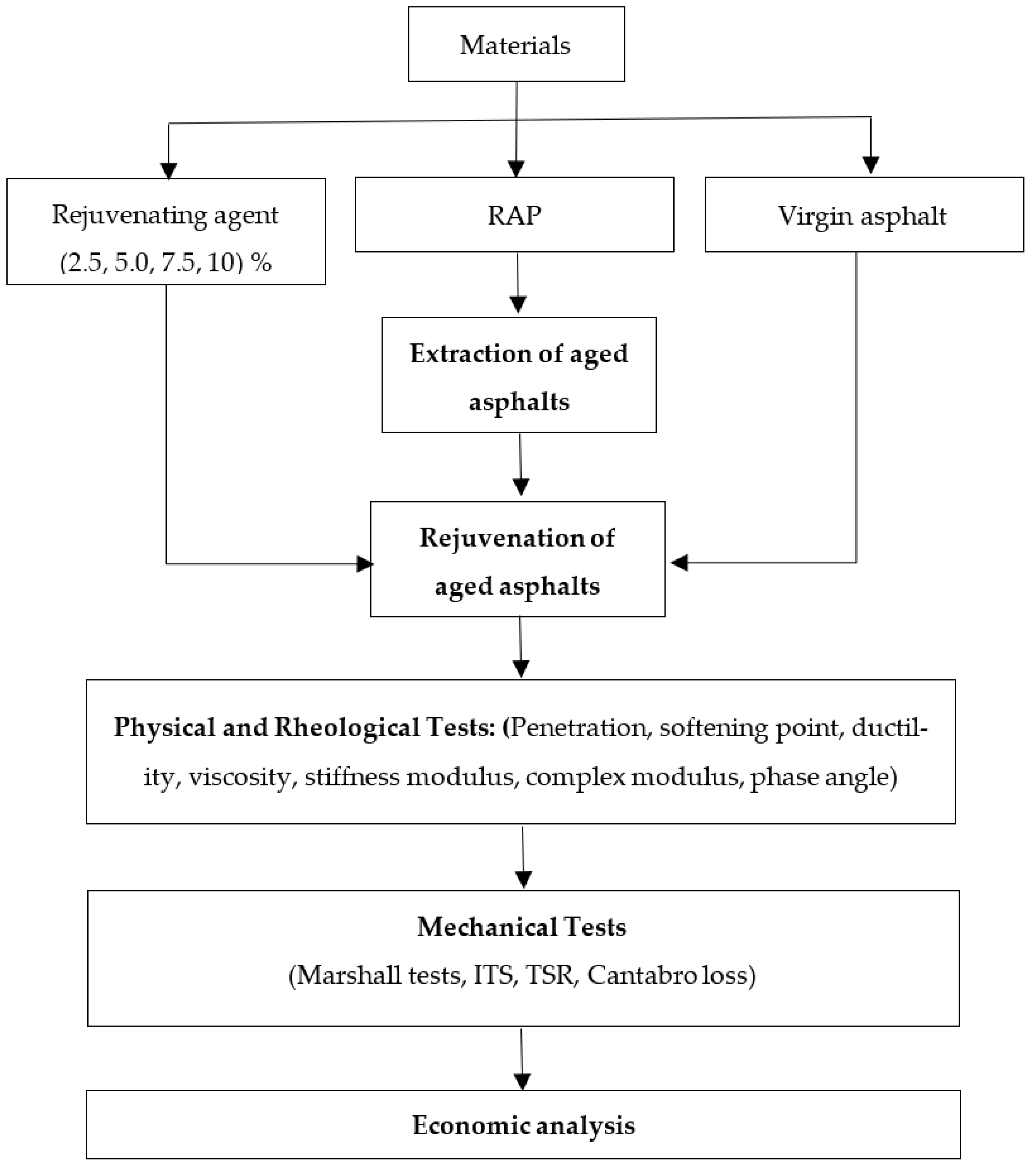

This study aimed to determine the efficiency of using VR to improve the attributes of asphalt and asphalt mixtures containing 40% RAP. To attain this goal, mixes were created by combining different amounts of aged asphalt (40%) and virgin asphalt (60%) with various percentages of VR. It was established that the penetration, softening point, and ductility were the best metrics to determine the optimal dosage of the rejuvenating agent. Then, viscosity measurements, the storage stability, stiffness modulus, complex modulus, and phase angle were investigated. Next, tests such as the Marshal test, indirect tensile strength (ITS), moisture damage, and Cantabro loss measures were used to determine the mechanical performance of rejuvenated HMA mixes containing 40% aged binder. Finally, a cost comparison study was carried out to assess the price difference between asphalt mixes including VR and those that did not contain VR.

4. Binder Test and Analysis Methods

The physical properties of asphalt binders and the optimal rejuvenating agent content were determined by conducting the following asphalt binder tests on both the aged asphalt and all of the rejuvenated asphalt specimens: penetration at 25 °C (ASTM D5), softening point (ASTM D36), and ductility (ASTM D113). In this part of the experiment, three repetitions for each type of asphalt binder were carried out, and the mean values of these values were computed. During this time, a dynamic viscosity test was carried out using a Brookfield Rotational Viscometer to characterize the rheology of the asphalt binders using ASTM D4402. The test was carried out over a temperature range of 135 to 165 °C at a shear rate of 20 rpm. In the meantime, ASTM D4124 was used to identify the fractions of maltene and asphaltene.

In contrast, the feasibility of rejuvenation of the aged asphalt using VR was investigated based on the stiffness modulus parameters via the nomographs for asphalt features established by Van der Poel [

30]. The present study measured the stiffness of three different types of asphalt binders—virgin, aged, and rejuvenated—at minimal and elevated temperatures with various loading scenarios based on the results of penetration, softening point, and penetration index (PI). The elevated temperature is the median of the hottest seven-day period in Mosul, Iraq, of the previous five years, while the low temperature represents the average of the minimum one-day air temperature. Moreover, the complex modulus and phase angle of the specimens were calculated depending on the mean of the warmest seven-day period in Mosul, Iraq, of the previous five years using BitProps V2 software.

Following this, mixture tests were carried out to gauge the impact of VR on the HMA mixtures’ mechanical characteristics and moisture damage. The process of producing the asphalt mixtures involved the following steps. Initially, RAP and virgin aggregate were heated at 125 °C and 163 °C for 2 h. Then, the optimal amount of VR was combined with RAP for 1 min. Afterward, the RAP rejuvenated by VR was mixed with virgin aggregates before adding virgin asphalt to the mixture. Four different mixtures, virgin, 100% RAP, 40% RAP, and rejuvenated asphalt mixtures, were prepared. Twelve Marshall samples were prepared to assess stability, flow, and stiffness as per ASTM D6927. In addition, additional specimens were constructed with 7% ± 0.5% air voids for ITS testing to determine how susceptible the asphalt mixtures are to moisture. Both dry and wet tests were conducted on two different sets of samples. Furthermore, the Cantabro test was conducted (using the UCL method [

31]) to assess the resistance of the mixtures to abrasion loss. Finally, a straightforward economic analysis was conducted to determine the economic advantages of employing RAP. The experimental program employed in this work is summarized in

Figure 1.