The Impact of Industry 4.0 on the Steel Sector: Paving the Way for a Disruptive Digital and Ecological Transformation

Abstract

:1. Introduction

- −55% reduction in greenhouse gas emissions (compared to 1990);

- +32% renewable energy;

- +32.5% improvement in energy efficiency

2. Literature Review

2.1. Industry 4.0 and the Path towards Sustainability

- Robotics: with a great range of capabilities, robots can fulfill tasks autonomously and even collaborate with humans in the same working environment, facilitating strenuous and dangerous activities;

- Simulation: time for machine set-up and product as well as process configuration can be reduced through virtual simulations, which can replicate real conditions very precisely;

- Vertical and horizontal systems integration: engineering and automation make production phases and systems more integrated; digital platforms enable the real-time information exchange in the supply chain;

- Industrial Internet of Things (IoT): sophisticated sensors and embedded cyber-physical systems make machines and products interact with each other and human beings by employing wireless communication;

- Cybersecurity: articulated and encrypted protocols, control, and identification procedures should protect real-time connected systems from cyber-crime attacks, which can endanger production and business continuity;

- Cloud: cloud-based software enables high-speed analytics and data-driven manufacturing systems, decreasing maintenance costs and enhancing Information Technology architecture security;

- Additive manufacturing: 3D printing leads to customized product design, supporting manufacturing decentralization and stock reduction and increases the lightness of material weight;

- Augmented reality: virtual reality is connected to the concrete world through human–machine interfaces (like glasses and tablets), creating opportunities for better maintenance and training directly on the plant.

- Big Data Analytics: from different heterogeneous sources large amounts of data can be collected and interpreted in order to gain internal efficiency and durable competitive advantage.

- Climate change mitigation;

- Climate change adaptation;

- Sustainable use and protection of water resources;

- Circular Economy transition;

- Pollution prevention;

- Protection of biodiversity ecosystems.

2.2. Digitization and Sustainable Business Models in the Steel Sector

3. Methodology

4. Main Findings

4.1. Environmental Sustainability as the Key to Successful Business Performance

- SDG 6: Clean Water and sanitation.

- SDG 7: Affordable and Clean Energy.

- SDG 8: Decent Work and Economic Growth.

- SDG 9: Industry, Innovation, and Infrastructure.

- SDG 12: Responsible Consumption and Production.

- SDG 13: Climate Action.

- SDG 17: Partnerships for the Goals.

4.2. Industry 4.0 Concrete Applications: Reconciliation with Sustainability Strategy

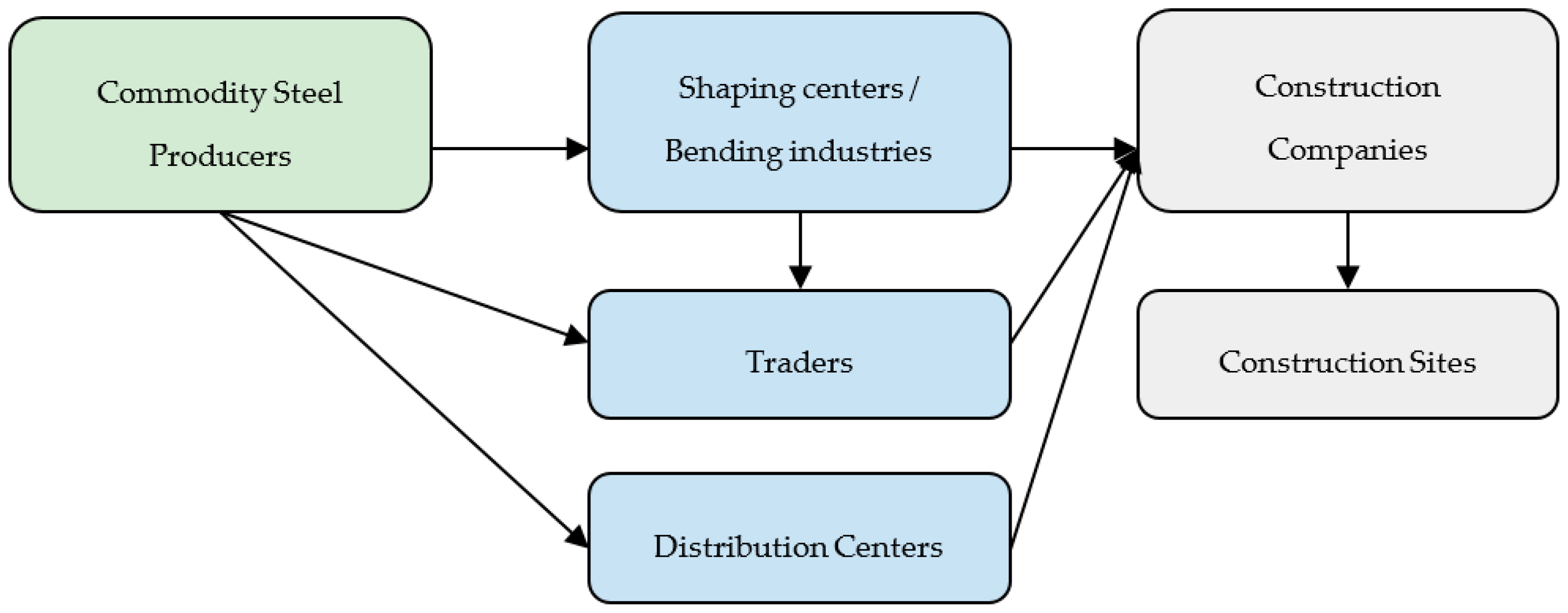

4.3. Sustainable Business Models through Supply Chain Integration: The Role of Industry 4.0

4.4. Final Discussion: Industry 4.0 Benefits and Sustainability Strategy

- -

- Environmental: more efficient production process and use of resources, enhancing CE, energy efficiency, and CO2 emissions reduction practices;

- -

- Social: safer working conditions and higher data transparency and exchange in and outside the organization;

- -

- Economic: enhanced efficacy in technical and organizational processes, including the employment of more affordable regenerated raw materials.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

- APPENDIX 1: Questionnaire for Feralpi managerAPPENDIX 2: Questionnaire for business partnersAPPENDIX 1: QUESTIONNAIRE TO ITALIAN AND GERMAN FERALPI MANAGERS

- (1)

- What does the term “sustainability” mean for you and which role does it play in your company?

- (2)

- What are, in your opinion, the essential objectives of your company, considered the economic, environmental and social sustainability dimension? Which is the most relevant dimension?

- (3)

- Which Industry 4.0 technology does enable sustainability objectives? What are the challenges and opportunities? Are opportunities measurable?

- (4)

- How has the sustainability strategy modified or will modify the business model of your company?

- (5)

- How will the sustainability and Industry 4.0 strategy develop in your company in the next future? Do you already have related strategic projects and do you think you should apply for NGEU funds (as a reminder Next Generation EU funds represent almost €2 billion for EU members in order to recover from the COVID-19 pandemic crisis)?

- APPENDIX 2: QUESTIONNAIRE TO ITALIAN AND GERMAN FERALPI BUSINESS PARTNERS

- (1)

- What does the term “sustainability” mean for you and which role does it play in your company?

- (2)

- What are, in your opinion, the essential objectives of your company, considered the economic, environmental and social sustainability dimension? Which is the most relevant dimension?

- (3)

- Which Industry 4.0 technology does enable sustainability objectives? What are the challenges and opportunities? Are opportunities measurable?

- (4)

- How has the sustainability strategy modified or will modify the business model of your company?

- (5)

- How will the sustainability and Industry 4.0 strategy develop in your company in the next future?

- (6)

- Do you already have related strategic projects and do you think you should apply for NGEU funds (as a reminder Next Generation EU funds represent almost 2€ billion for EU members in order to recover from the COVID-19 pandemic crisis)?

- (7)

- Which projects realized with Feralpi could enable the sustainability objectives of your company? Could be they achieved thanks to Industry 4.0 technologies?

- (8)

- Which kind of projects have you in plan with Feralpi for the future concerning sustainable and digital development? Do you think you should apply for NGEU funds?

References

- Allain-Dupré, D.; Chatry, I.; Michalun, V.; Moisio, A. The Territorial Impact of COVID-19: Managing the Crisis across Levels of Government; OECD: Paris, France, 2020. [Google Scholar]

- OECD. One Year of SME and Entrepreneurship Policy Responses to COVID-19: Lessons Learned to “Build Back Better”; OECD: Paris, France, 2021. [Google Scholar]

- Skip to Main Content. Available online: https://joebiden.com/made-in-america/# (accessed on 1 January 2023).

- D’alfonso, A.; Erbach, G.; Halleux, V.; Heflich, A.; Jensen, L.; Karamfilova, E.; Lomba, N.; Mceldowney, J.; Simoes, H.A.M.; Muller, K.; et al. EU Climate Action Policy: Responding to the Global Emergency. Available online: https://policycommons.net/artifacts/1426796/eu-climate-action-policy/2041321/ (accessed on 13 June 2023).

- Porras-Gómez, A.M. The EU Recovery Instrument and the Constitutional Implications of its Expenditure. Eur. Const. Law Rev. 2022, 19, 1–24. [Google Scholar] [CrossRef]

- European Commission. The EU’s 2021–2027 Long-Term Budget and NextGenerationEU. Facts Fig. 2021. Available online: https://data.europa.eu/doi/10.2761/808559 (accessed on 3 January 2023).

- Di Mascio, F.; Natalini, A. Implementing the NRRP from the Draghi government to the government of Giorgia Meloni: Italian public administration under the pressure of too large a volume of resources. Contemp. Ital. Politics 2023, 15, 237–251. [Google Scholar] [CrossRef]

- Piano Nazionale di Ripresa e Resilienza #Nextgenerationitalia. 23 April 2021. Available online: https://www.governo.it/sites/governo.it/files/PNRR.pdf. (accessed on 2 January 2023).

- Schramm, L. Economic ideas, party politics, or material interests? Explaining Germany’s support for the EU corona recovery plan. J. Eur. Public Policy 2023, 30, 84–103. [Google Scholar] [CrossRef]

- Jochheim, U.; Mildebrath, H.A. BRIEFING Next Generation EU (NGEU) Delivery-How Are the Member States Doing? EPRS European Parliamentary Research Service. PE 698.849. December 2021. Available online: https://www.europarl.europa.eu/RegData/etudes/BRIE/2021/698849/EPRS_BRI(2021)698849_EN.pdf (accessed on 2 February 2023).

- Hodžić, S.; Šikić, T.F.; Dogan, E. Green environment in the EU countries: The role of financial inclusion, natural resources and energy intensity. Resour. Policy 2023, 82, 103476. [Google Scholar] [CrossRef]

- Meshalkin, V.P.; Kulov, N.N.; Guseva, T.V.; Tikhonova, I.O.; Burvikova, Y.N.; Bhimani, C.; Shchelchkov, K.A. Best Available Techniques and Green Chemical Technology: Possibilities for Convergence of Concepts. Theor. Found. Chem. Eng. 2022, 56, 964–970. [Google Scholar] [CrossRef]

- Lesch, V.; Züfle, M.; Bauer, A.; Iffländer, L.; Krupitzer, C.; Kounev, S. A literature review of IoT and CPS—What they are, and what they are not. J. Syst. Softw. 2023, 200, 111631. [Google Scholar] [CrossRef]

- Song, Z.; Mishra, A.R.; Saeidi, S.P. Technological capabilities in the era of the digital economy for integration into cyber-physical systems and the IoT using decision-making approach. J. Innov. Knowl. 2023, 8, 100356. [Google Scholar] [CrossRef]

- The Links with Environment and Development I. The Population Perspective II. Available online: http://www.un-documents.net/wced-ocf.htm (accessed on 20 December 2022).

- Pinto, J. Key to Effective Organizational Performance Management Lies at the Intersection of Paradox Theory and Stakeholder Theory. Int. J. Manag. Rev. 2019, 21, 185–208. [Google Scholar] [CrossRef]

- Zott, C.; Amit, R.; Massa, L. The business model: Recent developments and future research. J. Manage. 2011, 37, 1019–1042. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N. Sustainable Business Models. In Decent Work and Economic Growth; Leal Filho, W., Azeiteiro, U., Azul, A.M., Brandli, L., Özuyar, P., Wall, T., Eds.; Springer: Cham, Switerland, 2021; pp. 963–975. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F. Sustainable entrepreneurship, innovation, and business models: Integrative framework and propositions for future research. Bus. Strategy Environ. 2020, 29, 665–681. [Google Scholar] [CrossRef]

- Prieto-Sandoval, V.; Jaca, C.; Santos, J.; Baumgartner, R.J.; Ormazabal, M. Key strategies, resources, and capabilities for implementing circular economy in industrial small and medium enterprises. Corp. Soc. Responsib. Environ. Manag. 2019, 26, 1473–1484. [Google Scholar] [CrossRef] [Green Version]

- Aguilar-Hernandez, G.A.; Dias Rodrigues, J.F.; Tukker, A. Macroeconomic, social and environmental impacts of a circular economy up to 2050: A meta-analysis of prospective studies. J. Clean. Prod. 2021, 278, 123421. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.M.P.; Short, S.W.; Rana, P.; Evans, S. A literature and practice review to develop sustainable business model archetypes. J. Clean. Prod. 2014, 65, 42–56. [Google Scholar] [CrossRef] [Green Version]

- Schröder, P.; Bengtsson, M.; Cohen, M.; Dewick, P.; Hoffstetter, J.; Sarkis, J. Degrowth within—Aligning circular economy and strong sustainability narratives. Resour. Conserv. Recycl. 2019, 146, 190–191. [Google Scholar] [CrossRef]

- Gunasekara, L.; Robb, D.J.; Zhang, A. Used product acquisition, sorting and disposition for circular supply chains: Literature review and research directions. Int. J. Prod. Econ. 2023, 260, 108844. [Google Scholar] [CrossRef]

- Asgari, A.; Asgari, R. How circular economy transforms business models in a transition towards circular ecosystem: The barriers and incentives. Sustain. Prod. Consum. 2021, 28, 566–579. [Google Scholar] [CrossRef]

- Mondal, C.; Giri, B.C. Pricing and used product collection strategies in a two-period closed-loop supply chain under greening level and effort dependent demand. J. Clean. Prod. 2020, 265, 121335. [Google Scholar] [CrossRef]

- Sony, M.; Antony, J.; Mc Dermott, O.; Garza-Reyes, J.A. An empirical examination of benefits, challenges, and critical success factors of industry 4.0 in manufacturing and service sector. Technol Soc. 2021, 67. [Google Scholar] [CrossRef]

- Beier, G.; Niehoff, S.; Ziems, T.; Xue, B. Sustainability aspects of a digitalized industry—A comparative study from China and Germany. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 227–234. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M.; Mubarak, M.F.; Mubarik, M.; Rejeb, A.; Nilashi, M. Identifying industry 5.0 contributions to sustainable development: A strategy roadmap for delivering sustainability values. Sustain. Prod. Consum. 2022, 33, 716–737. [Google Scholar] [CrossRef]

- Grybauskas, A.; Stefanini, A.; Ghobakhloo, M. Social sustainability in the age of digitalization: A systematic literature Review on the social implications of industry 4.0. Technol. Soc. 2022, 70, 101997. [Google Scholar] [CrossRef]

- Gajdzik, B. Key Directions in Changes from Steelworks 3.0 to Steelworks 4.0 with Analysis of Selected Technologies of Digitalizing the Steel Industry in Poland. Manag. Syst. Prod. Eng. 2022, 30, 46–53. [Google Scholar] [CrossRef]

- Lopez, G.; Galimova, T.; Fasihi, M.; Bogdanov, D.; Breyer, C. Towards defossilised steel: Supply chain options for a green European steel industry. Energy 2023, 273, 127236. [Google Scholar] [CrossRef]

- Liu, Y.; Li, H.; An, H.; Guan, J.; Shi, J.; Han, X. Are the environmental impacts, resource flows and economic benefits proportional? Analysis of key global trade routes based on the steel life cycle. Ecol. Indic. 2021, 122, 107306. [Google Scholar] [CrossRef]

- Gajdzik, B.; Wolniak, R. Transitioning of steel producers to the steelworks 4.0—literature review with case studies. Energies 2021, 14, 4109. [Google Scholar] [CrossRef]

- Horst, D.J.; de Andrade Júnior, P.P. Sustainability of the Steel Industry: A Systematic Review. Biointerface Res. Appl. Chem. 2023, 13, 525. [Google Scholar] [CrossRef]

- Colla, V.; Pietrosanti, C.; Malfa, E.; Peters, K. Environment 4.0: How digitalization and machine learning can improve the environmental footprint of the steel production processes. Mater. Tech. 2020, 108, 507. [Google Scholar] [CrossRef]

- Kagermann, H.; Anderl, R.; Gausemeier, J.; Schuh, G.; Wahlster, W. Acatech STUDY Industrie 4.0 in a Global Context Strategies for Cooperating with International Partners; Herbert Utz Verlag: Munich, Germany, 2016. [Google Scholar]

- Pérez-Lara, M.; Saucedo-Martínez, J.A.; Marmolejo-Saucedo, J.A.; Salais-Fierro, T.E.; Vasant, P. Vertical and horizontal integration systems in Industry 4.0. Wirel. Netw. 2020, 26, 4767–4775. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart factory performance and Industry 4.0. Technol. Forecast Soc. Change 2020, 150, 119790. [Google Scholar] [CrossRef]

- Raja Santhi, A.; Muthuswamy, P. Influence of Blockchain Technology in Manufacturing Supply Chain and Logistics. Logistics 2022, 6, 15. [Google Scholar] [CrossRef]

- Cohen, Y.; Faccio, M.; Galizia, F.G.; Mora, C.; Pilati, F. Assembly system configuration through Industry 4.0 principles: The expected change in the actual paradigms. In Proceedings of the 20th IFAC World Congress, Toulouse, France, 9–14 July 2017; Elsevier B.V.: Amsterdam, The Netherlands, 2017; Volume 50, pp. 14958–14963. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 20, pp. 233–238. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0 The Future of Productivity and Growth in Manufacturing Industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Vannella, F. Productive Technologies for Industry 4.0; Alta Scuola Politecnica; Politecnico di Torino: Turin, Italy, 2018; Available online: https://www.researchgate.net/publication/326711341 (accessed on 3 January 2023).

- Zott, C.; Amit, R. Business Model Innovation: How to Create Value in a Digital World. NIM Mark. Intell. Rev. 2017, 9, 18–23. [Google Scholar] [CrossRef] [Green Version]

- Vaska, S.; Massaro, M.; Bagarotto, E.M.; Dal Mas, F. The Digital Transformation of Business Model Innovation: A Structured Literature Review. Front. Psychol. 2021, 11, 539363. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 and sustainable development: A systematic mapping of triple bottom line, Circular Economy and Sustainable Business Models perspectives. J. Clean. Prod. 2021, 297, 126655. [Google Scholar] [CrossRef]

- Hanelt, A.; Bohnsack, R.; Marz, D.; Antunes Marante, C. A Systematic Review of the Literature on Digital Transformation: Insights and Implications for Strategy and Organizational Change. J. Manag. Stud. 2021, 58, 1159–1197. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.I. Development of a risk framework for Industry 4.0 in the context of sustainability for established manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef] [Green Version]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Satyro, W.C.; de Almeida, C.M.V.B.; Pinto, M.J.A., Jr.; Contador, J.C.; Giannetti, B.F.; de Lima, A.F.; Fragomeni, M.A. Industry 4.0 implementation: The relevance of sustainability and the potential social impact in a developing country. J. Clean. Prod. 2022, 337, 130456. [Google Scholar] [CrossRef]

- Asif, M. Are QM models aligned with Industry 4.0? A perspective on current practices. J. Clean. Prod. 2020, 258, 120820. [Google Scholar] [CrossRef]

- Industry 4.0 How to Navigate Digitization of the Manufacturing Sector; McKynsey&Company: Munich, Germany, 2015.

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Yadav, G.; Luthra, S.; Jakhar, S.K.; Mangla, S.K.; Rai, D.P. A framework to overcome sustainable supply chain challenges through solution measures of industry 4.0 and circular economy: An automotive case. J. Clean. Prod. 2020, 254, 120112. [Google Scholar] [CrossRef]

- Di Maria, E.; De Marchi, V.; Galeazzo, A. Industry 4.0 technologies and circular economy: The mediating role of supply chain integration. Bus. Strategy Environ. 2022, 31, 619–632. [Google Scholar] [CrossRef]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Nara, E.O.B.; da Costa, M.B.; Baierle, I.C.; Schaefer, J.L.; Benitez, G.B.; Santos, L.M.A.L.D.; Benitez, L.B. Expected impact of industry 4.0 technologies on sustainable development: A study in the context of Brazil’s plastic industry. Sustain. Prod. Consum. 2021, 25, 102–122. [Google Scholar] [CrossRef]

- Bocken, N.; Short, S.; Rana, P.; Evans, S. A value mapping tool for sustainable business modelling. Corp. Gov. 2013, 13, 482–497. [Google Scholar] [CrossRef]

- EBA Report on Management and Supervision of ESG Risks for Credit Institutions and Investment Firms EBA/REP/2021/18; EBA: Paris, France, 2021.

- I (Legislative Acts) Regulations Regulation (EU) 2020/851 of the European Parliament and of the Council of 18 June 2020 Amending Regulation (EC); No 862/2007 on Community Statistics on Migration and International Protection (Text with EEA Relevance); European Commission: Brussels, Belgium, 2020.

- Founding Partners of the Ellen MacArthur Foundation. Circular Economy towards the Economic and Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Wight, UK, 2013. [Google Scholar]

- How the Circular Economy Tackles Climate Change; Ellen MacArthur Foundation: Wight, UK, 2013.

- Spaltini, M.; Poletti, A.; Acerbi, F.; Taisch, M. A quantitative framework for Industry 4.0 enabled Circular Economy. Procedia CIRP. 2021, 98, 115–120. [Google Scholar] [CrossRef]

- Enyoghasi, C.; Badurdeen, F. Industry 4.0 for sustainable manufacturing: Opportunities at the product, process, and system levels. Resour. Conserv. Recycl. 2021, 166, 105362. [Google Scholar] [CrossRef]

- Cagno, E.; Neri, A.; Negri, M.; Bassani, C.A.; Lampertico, T. The role of digital technologies in operationalizing the circular economy transition: A systematic literature review. Appl. Sci. 2021, 11, 3328. [Google Scholar] [CrossRef]

- Toth-Peter, A.; Torres de Oliveira, R.; Mathews, S.; Barner, L.; Figueira, S. Industry 4.0 as an enabler in transitioning to circular business models: A systematic literature review. J. Clean. Prod. 2023, 393, 136284. [Google Scholar] [CrossRef]

- Massaro, M.; Secinaro, S.; Dal Mas, F.; Brescia, V.; Calandra, D. Industry 4.0 and circular economy: An exploratory analysis of academic and practitioners’ perspectives. Bus. Strategy Environ. 2021, 30, 1213–1231. [Google Scholar] [CrossRef]

- Transforming Our World: The 2030 Agenda for Sustainable Development Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015.

- Dantas, T.E.T.; de-Souza, E.D.; Destro, I.R.; Hammes, G.; Rodriguez, C.M.T.; Soares, S.R. How the combination of Circular Economy and Industry 4.0 can contribute towards achieving the Sustainable Development Goals. Sustain. Prod. Consum. 2021, 26, 213–227. [Google Scholar] [CrossRef]

- Piccarozzi, M.; Silvestri, C.; Aquilani, B.; Silvestri, L. Is this a new story of the ‘Two Giants’? A systematic literature review of the relationship between industry 4.0, sustainability and its pillars. Technol. Forecast. Soc. Change 2022, 177, 121511. [Google Scholar] [CrossRef]

- Khan, I.S.; Ahmad, M.O.; Majava, J. Industry 4.0 innovations and their implications: An evaluation from sustainable development perspective. J. Clean. Prod. 2023, 405, 137006. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177. [Google Scholar] [CrossRef]

- Amjad, M.S.; Rafique, M.Z.; Khan, M.A. Leveraging Optimized and Cleaner Production through Industry 4.0. Sustain. Prod. Consum. 2021, 26, 859–871. [Google Scholar] [CrossRef]

- Branca, T.A.; Fornai, B.; Colla, V.; Murri, M.M.; Streppa, E.; Schröder, A.J. The challenge of digitalization in the steel sector. Metals 2020, 10, 288. [Google Scholar] [CrossRef] [Green Version]

- John, N.; Wesseling, J.H.; Worrell, E.; Hekkert, M. How key-enabling technologies’ regimes influence sociotechnical transitions: The impact of artificial intelligence on decarbonization in the steel industry. J. Clean. Prod. 2022, 370, 296–302. [Google Scholar] [CrossRef]

- Smol, M. Towards Zero Waste in Steel Industry: Polish Case Study. J. Steel Struct. Constr. 2015, 1, 2472-0437. [Google Scholar] [CrossRef] [Green Version]

- 2022 World Steel in Figures. World Steel Association: Brussels, Belgium. Available online: https://worldsteel.org/wp-content/uploads/World-Steel-in-Figures-2022.pdf (accessed on 2 January 2023).

- Decarbonization Challenge for Steel Hydrogen as a Solution in Europe; McKinsey & Company: New York, NY, USA, 2020.

- The Future of the European Steel Industry How to Ensure Sustainability in the Future; McKinsey & Company: New York, NY, USA, 2021.

- Vögele, S.; Grajewski, M.; Govorukha, K.; Rübbelke, D. Challenges for the European steel industry: Analysis, possible consequences and impacts on sustainable development. Appl. Energy 2020, 264, 114633. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Khan, K.; Amin, M.N.; Saleem, M.U.; Qureshi, H.J.; Al-Faiad, M.A.; Qadir, M.G. Effect of fineness of basaltic volcanic ash on pozzolanic reactivity, ASR expansion and drying shrinkage of blended cement mortars. Materials 2019, 12, 2603. [Google Scholar] [CrossRef] [Green Version]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-Silica-Modified Concrete: A Bibliographic Analysis and Comprehensive Review of Material Properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef]

- Eisenhardt, K.M.; Graebner, M.E.; Sonenshein, S. Grand challenges and inductive methods: Rigor without rigor mortis. Acad. Manag. J. 2016, 59, 1113–1123. [Google Scholar] [CrossRef]

- Hammersley, M.; Atkinson, P. Ethnography: Principles in Practice, 3rd ed.; Routledge: Abingdon, UK, 2007. [Google Scholar]

- Feralpi Tra Gli Europe’s Climate Leaders 2022 Del Financial Times. Available online: www.feralpigroup.com (accessed on 1 January 2023).

- Oscar di Bilancio 2022: Feralpi Group Premiata Come Miglior “Grande Impresa Non Quotata” Sviluppo Temi ESG, Efficace Comunicazione e Integrazione Dei Report Finanziari e Non Finanziari Tra le Motivazioni Feralpi è Stata Anche Finalista Nel Premio Speciale DNF. Available online: www.feralpigroup.com (accessed on 12 December 2022).

- Feralpi Group Abstract. Voluntary Consolidated Non-Financial Statement. FY 2021. Available online: https://www.feralpigroup.com/sites/default/files/media/documents/2023-05/feralpi-abstract-digit-en-96dpi.pdf (accessed on 2 February 2023).

- The Feralpi Group & Its Climate Strategy 100 Million Euro for a Low-Impact Energy Mix The Investment Is Directed at the Production of Renewable Energy in Italy. The 5-Year Target: To Install New Self-Consumption Capability to Cover 20% of the Group’s Energy Requirements in Its Production Sites in Italy. Production Above Pre-COVID Levels 2021 Progressing Positively. Available online: www.feralpigroup.com (accessed on 2 December 2022).

- Eisenhardt, K.M. What is the Eisenhardt Method, really? Strateg. Organ. 2021, 19, 147–160. [Google Scholar] [CrossRef]

- Feralpi Group. Consolidated Financial Statements 2021. Available online: https://www.feralpigroup.com/sites/default/files/media/documents/2022-07/Feralpi%20Group%20-%20Consolidated%20Financial%20Statements%202021.pdf. (accessed on 2 December 2022).

- Essential Guide to Qualitative Methods in Organizational Research; SAGE: Thousand Oaks, CA, USA, 2004.

- Yin, R.K. Case Study Research: Design and Methods; SAGE: Thousand Oaks, CA, USA, 2009. [Google Scholar]

- Brown, T.; Katz, B. Change by design. J. Prod. Innov. Manag. 2011, 28, 381–383. [Google Scholar] [CrossRef]

- Mayring, P. Qualitative Content Analysis-Theoretical Foundation, Basic Procedures and Software Solution. Available online: https://www.researchgate.net/publication/266859800 (accessed on 3 December 2022).

- Eisenhardt, K.M.; Graebner, M.E. Theory Building from Cases: Opportunities and Challenges. Acad. Manag. J. 2007, 50, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Alcayaga, A.; Wiener, M.; Hansen, E.G. Towards a framework of smart-circular systems: An integrative literature review. J. Clean. Prod. 2019, 221, 622–634. [Google Scholar] [CrossRef]

- Gioia, D.A.; Corley, K.G.; Hamilton, A.L. Seeking Qualitative Rigor in Inductive Research: Notes on the Gioia Methodology. Organ. Res. Methods 2013, 16, 15–31. [Google Scholar] [CrossRef]

- Gortsos, C.V.; Kyriazis, D. EBI Working Paper Series. Available online: https://ssrn.com/abstract=4381950 (accessed on 1 March 2023).

- Di Meneghini, L. A Critical Analysis of the EU Green Taxonomy: Is It Fit for Purpose? Rivista Diritto del Risparmio. Fasciolo 2/2022. Available online: Dirittodelrisparmio.it (accessed on 3 January 2023).

- Maldonado-Mariscal, K.; Cuypers, M.; Götting, A.; Kohlgrüber, M. Skills Intelligence in the Steel Sector. Machines 2023, 11, 335. [Google Scholar] [CrossRef]

- Lüdeke-Freund, F.; Gold, S.; Bocken, N.M.P. A Review and Typology of Circular Economy Business Model Patterns. J. Ind. Ecol. 2019, 23, 36–61. [Google Scholar] [CrossRef] [Green Version]

- Palea, V.; Santhià, C.; Miazza, A. Are circular economy strategies economically successful? Evidence from a longitudinal panel. J. Environ. Manage. 2023, 337, 117726. [Google Scholar] [CrossRef]

- Stahl, H. Für Eine Starke Stahl Industrie in Deutschland Und Europa! Available online: www.bmwi.de (accessed on 22 November 2022).

- Frederico, G.F.; Garza-Reyes, J.A.; Kumar, A.; Kumar, V. Performance measurement for supply chains in the Industry 4.0 era: A balanced scorecard approach. Int. J. Product. Perform. Manag. 2021, 70, 789–807. [Google Scholar] [CrossRef]

- Boons, F.; Lüdeke-Freund, F. Business models for sustainable innovation: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2013, 45, 9–19. [Google Scholar] [CrossRef]

- FY 2021 Voluntary Consolidated Non-Financial Statement Index Content Map; Feralpi Group: Brescia, Italy, 2022.

- Torres, L.; Ripa, D.; Jain, A.; Herrero, J.; Leka, S. The potential of responsible business to promote sustainable work—An analysis of CSR/ESG instruments. Saf. Sci. 2023, 164, 106151. [Google Scholar] [CrossRef]

- Abstract Voluntary Consolidated Non-Financial Statement 2020; Feralpi Group: Brescia, Italy, 2021.

- FY 2020 Voluntary Consolidated Non-Financial Statement Index Content Map; Feralpi Group: Brescia, Italy, 2020.

- Bag, S.; Yadav, G.; Dhamija, P.; Kataria, K.K. Key resources for industry 4.0 adoption and its effect on sustainable production and circular economy: An empirical study. J. Clean. Prod. 2021, 281, 125233. [Google Scholar] [CrossRef]

- Wang, X.; Yu, B.; An, R.; Sun, F.; Xu, S. An integrated analysis of China’s iron and steel industry towards carbon neutrality. Appl. Energy 2022, 322, 119453. [Google Scholar] [CrossRef]

- Romero, C.A.T.; Castro, D.F.; Ortiz, J.H.; Khalaf, O.I.; Vargas, M.A. Synergy between circular economy and industry 4.0: A literature review. Sustainability 2021, 13, 4331. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Securing the Future of German Manufacturing Industry. Recommendations for Implementing the Strategic Initiative; INDUSTRIE 4:0. Final Report of the Industrie 4.0 Working Group; Federal Ministry of Education and Research: Berlin, Germany, 2013. [Google Scholar]

- Bai, C.; Zhou, H.; Sarkis, J. Evaluating Industry 4.0 technology and sustainable development goals–a social perspective. Int. J. Prod. Res. 2023, 1–21. [Google Scholar] [CrossRef]

- Shringi, A.; Arashpour, M.; Golafshani, E.M.; Dwyer, T.; Kalutara, P. Enhancing Safety Training Performance Using Extended Reality: A Hybrid Delphi–AHP Multi-Attribute Analysis in a Type-2 Fuzzy Environment. Buildings 2023, 13, 625. [Google Scholar] [CrossRef]

- Altaha, S.; Hafizur Rahman, M.M. A Mini Literature Review on Integrating Cybersecurity for Business Continuity. In Proceedings of the 5th International Conference on Artificial Intelligence in Information and Communication, ICAIIC 2023, Bali, Indonesia, 20–23 February 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 353–359. [Google Scholar] [CrossRef]

- Behrend, C.R.; Cuypers, M.; Wright, S.; Kohlgrüber, M.; Götting, A. Understanding Future Skills and Enriching the Skills Debate Deliverable 6.1-3 Rd Report Final Version Title: Understanding Future Skills and Enriching the Skills Debate. 2022. Available online: https://beyond4-0.eu/publications (accessed on 12 December 2022).

- Ghobakhloo, M.; Fathi, M.; Iranmanesh, M.; Maroufkhani, P.; Morales, M.E. Industry 4.0 ten years on: A bibliometric and systematic review of concepts, sustainability value drivers, and success determinants. J. Clean. Prod. 2021, 302, 559–571. [Google Scholar] [CrossRef]

- Engwall, M.; Kaulio, M.; Karakaya, E.; Miterev, M.; Berlin, D. Experimental networks for business model innovation: A way for incumbents to navigate sustainability transitions? Technovation 2021, 108, 102330. [Google Scholar] [CrossRef]

- Da Giau, A.; Foss, N.J.; Furlan, A.; Vinelli, A. Sustainable development and dynamic capabilities in the fashion industry: A multi-case study. Corp. Soc. Responsib. Environ. Manag. 2020, 27, 1509–1520. [Google Scholar] [CrossRef]

- Beske, P. Dynamic capabilities and sustainable supply chain management. Int. J. Phys. Distrib. Logist. Manag. 2012, 42, 372–387. [Google Scholar] [CrossRef]

- Winter, J. The evolutionary and disruptive potential of industrie 4.0. Hung. Geogr. Bull. 2020, 69, 83–97. [Google Scholar] [CrossRef]

- Probst, L.; Pedersen, B.; Bohn, N.; Verzijl, D. Skills for Smart Industrial Specialisation and Digital Transformation; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar] [CrossRef]

- Dzwigol, H.; Dzwigol-Barosz, M.; Miskiewicz, R.; Kwilinski, A. Manager competency assessment model in the conditions of industry 4.0. Entrep. Sustain. Issues 2020, 7, 2630–2644. [Google Scholar] [CrossRef]

- Shet, S.V.; Pereira, V. Proposed managerial competencies for Industry 4.0—Implications for social sustainability. Technol. Forecast. Soc. Change 2021, 173, 121080. [Google Scholar] [CrossRef]

- Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Understanding the sustainable consumption of energy resources in global industrial sector: Evidences from 114 countries. Environ. Impact Assess. Rev. 2021, 90, 106609. [Google Scholar] [CrossRef]

- Atif, S.; Ahmed, S.; Wasim, M.; Zeb, B.; Pervez, Z.; Quinn, L. Towards a conceptual development of industry 4.0, servitisation, and circular economy: A systematic literature review. Sustainability 2021, 13, 6501. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 2022, 334, 128624. [Google Scholar] [CrossRef]

- Grewal, J.; Serafeim, G. Research on Corporate Sustainability: Review and Directions for Future Research. Found. Trends Account. 2020, 14, 73–127. [Google Scholar] [CrossRef]

- Gerlitz, L. Design management as a domain of smart and sustainable enterprise: Business modelling for innovation and smart growth in Industry 4.0. Entrep. Sustain. Issues 2016, 3, 244–268. [Google Scholar] [CrossRef]

- Aragón-Correa, J.A.; Sharma, S. A Contingent Resource-Based View of Proactive Corporate Environmental Strategy. Acad. Manag. Rev. 2003, 28, 71. [Google Scholar] [CrossRef] [Green Version]

- Črešnar, R.; Dabić, M.; Stojčić, N.; Nedelko, Z. It takes two to tango: Technological and non-technological factors of Industry 4.0 implementation in manufacturing firms. Rev. Manag. Sci. 2022, 1–27. [Google Scholar] [CrossRef]

- Snihur, Y.; Bocken, N. A call for action: The impact of business model innovation on business ecosystems, society and planet. Long Range Plann. 2022, 55, 102182. [Google Scholar] [CrossRef]

- Sosna, M.; Trevinyo-Rodríguez, R.N.; Velamuri, S.R. Business model innovation through trial-and-error learning: The naturhouse case. Long Range Plann. 2010, 43, 383–407. [Google Scholar] [CrossRef]

- Tesch, J.F.; Brillinger, A.S.; Bilgeri, D. Internet of things business model innovation and the stage-gate process: An exploratory analysis. Int. J. Innov. Manag. 2017, 21, 1740002. [Google Scholar] [CrossRef] [Green Version]

| Main Chances and Challenges of Industry 4.0-Related Technologies | ||

|---|---|---|

| Chances | Challenges | |

| IoT | Production integration and control | Integration with existing technology |

| Advances in Automation (Robots and Vertical Integration) | Enhanced safety, standardization, speed | Cooperation with human operators |

| Data Platforms (horizontal integration) | Data integration in the supply chain | Homogeneous digital level of maturity of own business partners |

| Cybersecurity | Business continuity | Decision on the level of systems security |

| Additive Manufacturing | Customized production | Still higher production costs than the standards processes |

| Simulation | Spare of prototypes and resources | Setting the right parameters |

| The Cloud | Integration of all technological devices | Data privacy control |

| Augmented Reality | Simulation of dangerous activities | Still implementation costs |

| Big Data | Live information availability | Data interpretation and reliability |

| Company | Department | Functional Focus | |

|---|---|---|---|

| A | Italian Business Partner (black slag regeneration) | f Production | CE, Innovation |

| B | Italian Customer (Drawing Mill) | Board | Innovation, Sustainability |

| C | Italian Supplier (metal carpentry) | Board | Innovation, Sustainability |

| D | Italian Supplier (Digital Service) | Board | Digitization, Industry 4.0 |

| E | Italian Business Partner (Polymers) | Business Development Department | Innovation, CE, Digitization |

| F | German Supplier (Disposal Services) | Board | CE, Digitization |

| G | Feralpi Group | Board | Innovation, Sustainability |

| H | Feralpi Group | Group Technical department | Innovation, Industry 4.0, CE |

| I | Feralpi Group | CSR | Sustainability, CE |

| J | Feralpi Group | Information Technology | Digitization, Industry 4.0 |

| K | Feralpi Group | Board | Innovation, Sustainability, Digitization |

| L | Feralpi Group | Finance and Administration | Sustainability, CE |

| M | Feralpi Italy | Environmental department | CE, Sustainability |

| N | Feralpi Italy | Technical department | Sustainability, CE, Industry 4.0 |

| O | Feralpi Italy | Steel plant | CE, Sustainability, Industry 4.0 |

| P | Feralpi Italy | R&D | Industry 4.0, Innovation |

| Q | Feralpi Germany | Environmental department | CE, Sustainability |

| R | Feralpi Germany | Board | Sustainability, Innovation |

| S | Feralpi Germany | Technical department | CE, Industry 4.0 |

| Main Industry 4.0 Technologies Used at Feralpi Group and Related Sustainability Benefits | ||

|---|---|---|

| Type of Technology (Date of Adoption) | Triple Bottom Line Level | Main Sustainability Benefits |

| Simulations | Economic and Environmental | More efficient production process, enhanced product quality, and optimization of resources |

| Advanced Robotics | Economic and Social | Safer and more comfortable workplace, enhanced productivity |

| Cloud | Economic and Social | Enhancing collaboration and facilitating information integration, exchange and transparency, among departments, subsidiaries, and potentially with suppliers and customers |

| IoT | Economic and Environmental | Monitoring of emissions and energy parameters |

| Machine Learning and Artificial Intelligence | Economic and Environmental | Production phases integration and quality enhancement, energy consumption, resource optimization |

| Big Data Analysis | Economic and Environmental | Energy consumption |

| Cybersecurity | Economic and Social | Guarantee of business continuity, intended in an economic perspective and in protection of the workplace from cyberattacks |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tolettini, L.; Di Maria, E. The Impact of Industry 4.0 on the Steel Sector: Paving the Way for a Disruptive Digital and Ecological Transformation. Recycling 2023, 8, 55. https://doi.org/10.3390/recycling8040055

Tolettini L, Di Maria E. The Impact of Industry 4.0 on the Steel Sector: Paving the Way for a Disruptive Digital and Ecological Transformation. Recycling. 2023; 8(4):55. https://doi.org/10.3390/recycling8040055

Chicago/Turabian StyleTolettini, Laura, and Eleonora Di Maria. 2023. "The Impact of Industry 4.0 on the Steel Sector: Paving the Way for a Disruptive Digital and Ecological Transformation" Recycling 8, no. 4: 55. https://doi.org/10.3390/recycling8040055

APA StyleTolettini, L., & Di Maria, E. (2023). The Impact of Industry 4.0 on the Steel Sector: Paving the Way for a Disruptive Digital and Ecological Transformation. Recycling, 8(4), 55. https://doi.org/10.3390/recycling8040055