Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks

Abstract

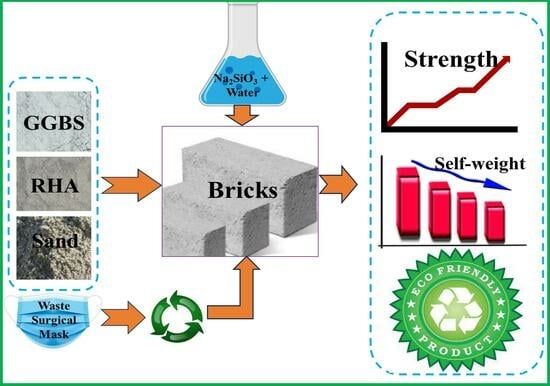

:1. Introduction

2. Significance of Research

3. Materials and Methods

3.1. Mix Proportion for Bricks

3.2. Brick Preparation

3.3. Test Methods

3.3.1. Strength and Density of Bricks

3.3.2. Durability of Bricks

3.3.3. Sustainability Assessment

4. Results and Discussions

4.1. Strength and Density of Bricks

4.2. Durability of Bricks

4.3. Sustainability Assessment

5. Conclusions

- 1-

- The incorporation of RSM enhanced the strength of geopolymer bricks. The maximum enhancement of 16.6% in compressive strength and 40.86% in flexural strength was observed for bricks with 4% RSM when compared to bricks with 0% RSM.

- 2-

- The addition of RSM has caused a maximum reduction of 4.97% in the self-weight of the bricks. The reduction in the self-weight with enhancement in the strength will improve the service life of buildings.

- 3-

- The addition of RSM increased the water absorption of bricks. The maximum increase in water absorption was 14.4% for bricks with 4% RSM when compared to bricks with 0% RSM.

- 4-

- The RSM did not significantly influence the degree of efflorescence in the bricks since all the specimens exhibited similar levels of leaching of alkalis.

- 5-

- The RSM played a role in reducing the shrinkage in the bricks, which is attributed to the internal shear resistance offered by the RSM fibers.

- 6-

- The sustainability aspect of the brick was quantified by determining the embodied carbon dioxide parameter, i.e., kgCO2/ton·MPa (Cf). The results demonstrate that the addition of RSM has brought about a significant reduction of 12% to 40% in the Cf values when compared to bricks without RSM. Such findings are indicative of the fact that RSM can be considered a sustainable additive since it can improve the material’s performance with minimal carbon emissions.

- 7-

- On the whole, RSM should be considered a valuable resource for the construction industry since it plays a catalytic role in augmenting the material performance. Such behavior can contribute to the development of low-carbon materials in the construction industry. Further, this will be useful in reducing the harmful effects of disposed surgical masks on the environment and can be helpful in the mitigation of plastic pollution.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Surgical Masks Market Size, Share & Trends Analysis Report by Product (Basic, Fluid/Splash Resistant), by Distribution Channel (Online, Offline), by Region, and Segment Forecasts, 2022–2030. Available online: https://www.grandviewresearch.com/industry-analysis/surgical-masks-market (accessed on 22 May 2023).

- Potluri, P.; Needham, P. Technical textiles for protection. In Textiles for Protection; Woodhead Publishing: Sawston, UK, 2005; pp. 151–175. [Google Scholar] [CrossRef]

- Leoni, C.; Majorani, C.; Cresti, R.; Marcello, I.; Berardi, E.; Fava, L.; Attias, L.; D’Ilio, S. Determination and risk assessment of phthalates in face masks: An Italian study. J. Hazard. Mater. 2023, 443, 130176. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; Silva, A.L.P.; Walker, T.R.; Duarte, A.C.; Rocha-Santos, T. COVID-19 pandemic repercussions on the use and management of plastics. Environ. Sci. Technol. 2020, 54, 7760–7765. [Google Scholar] [CrossRef]

- Nghiem, L.D.; Iqbal, H.M.N.; Zdarta, J. The shadow pandemic of single use personal protective equipment plastic waste: A blue print for suppression and eradication. Case Stud. Chem. Environ. Eng. 2021, 4, 100125. [Google Scholar] [CrossRef]

- Ardusso, M.; Forero-López, A.; Buzzi, N.; Spetter, C.; Fernández-Severini, M. COVID-19 pandemic repercussions on plastic and antiviral polymeric textile causing pollution on beaches and coasts of South America. Sci. Total Environ. 2021, 763, 144365. [Google Scholar] [CrossRef]

- Ben-Haddad, M.; De-la-Torre, G.E.; Abelouah, M.R.; Hajji, S.; Alla, A.A. Personal Protective Equipment (PPE) Pollution Associated with the COVID-19 Pandemic along the Coastline of Agadir, Morocco. Sci. Total Environ. 2021, 798, 149282. [Google Scholar] [CrossRef]

- Aragaw, T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020, 159, 111517. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Chen, F.; Xu, H.; Jiang, H.; Liu, J.; Li, P.; Chen, C.C.; Pan, K. Face masks as a source of nanoplastics and microplastics in the environment: Quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021, 288, 117748. [Google Scholar] [CrossRef] [PubMed]

- Shen, M.C.; Zeng, Z.T.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.X.; Zeng, G.N.; Xiao, R. Neglected microplastics pollution in global COVID-19: Disposable surgical masks. Sci. Total Environ. 2021, 790, 148130. [Google Scholar] [CrossRef]

- Wu, X.; Lu, J.; Du, M.; Xu, X.; Beiyuan, J.; Sarkar, B.; Bolan, N.; Xu, W.; Xu, S.; Chen, X.; et al. Particulate plastics-plant interaction in soil and its implications: A review. Sci. Total Environ. 2021, 792, 148337. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Grady, B.P. Waste plastics in asphalt concrete: A review. SPE Polym. 2021, 2, 4–18. [Google Scholar] [CrossRef]

- Salim, K.; Houssam, A.; Belaid, A.; Brahim, H. Reinforcement of building plaster by waste plastic and glass. Procedia Struct. Integr. 2019, 17, 170–176. [Google Scholar] [CrossRef]

- Almohana, A.I.; Abdulwahid, M.Y.; Galobardes, I.; Mushtaq, J.; Almojil, S.F. Producing sustainable concrete with plastic waste: A review. Environ. Chall. 2022, 9, 100626. [Google Scholar] [CrossRef]

- Akinwumi, I.I.; Domo-Spiff, A.H.; Salami, A. Marine Plastic Pollution and Affordable Housing Challenge: Shredded Waste Plastic Stabilized Soil for Producing Compressed Earth Bricks. Case Stud. Constr. Mater. 2019, 11, e00241. [Google Scholar] [CrossRef]

- Miah, M.J.; Pei, J.; Kim, H.; Sharma, R.; Jang, J.G.; Ahn, J. Property assessment of an eco-friendly mortar reinforced with recycled mask fiber derived from COVID-19 single-use face masks. J. Build. Eng. 2023, 66, 105885. [Google Scholar] [CrossRef]

- Ajam, L.; Trabelsi, A.; Kammoun, Z. Valorisation of face mask waste in mortar. Innov. Infrastruct. Solut. 2022, 7, 130. [Google Scholar] [CrossRef]

- El Aal, A.A.; Alsaiari, M.A.; Radwan, A.E.; Fenais, A. Smart waste management perspective of COVID-19 healthy personal protective materials in concrete for decorative landscape pavements and artificial rocks. Sci. Rep. 2023, 13, 2904. [Google Scholar] [CrossRef] [PubMed]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Koniorczyk, M.; Bednarska, D.; Masek, A.; Cichosz, S. Performance of concrete containing recycled masks used for personal protection during coronavirus pandemic. Constr. Build. Mater. 2022, 324, 126712. [Google Scholar] [CrossRef]

- Castellote, M.; Jiménez-Relinque, E.; Grande, M.; Rubiano, F.J.; Castillo, A. Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern. Materials 2022, 15, 1371. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Lim, C. Effective recycling of disposable medical face masks for sustainable green concrete via a new fiber hybridization technique. Constr. Build. Mater. 2022, 344, 128245. [Google Scholar] [CrossRef] [PubMed]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Saberian, M.; Rahat, M.H.H.; Massarra, C.; Buckhalter, C.; Farrington, J.; Collins, T.; Johnson, J. Use of COVID-19 single-use face masks to improve the rutting resistance of asphalt pavement. Sci. Total Environ. 2022, 826, 154118. [Google Scholar] [CrossRef] [PubMed]

- Ncube, A.; Matsika, R.; Mangori, L.; Ulgiati, S. Moving towards resource efficiency and circular economy in the brick manufacturing sector in Zimbabwe. J. Clean. Prod. 2021, 281, 125238. [Google Scholar] [CrossRef]

- Li, Y.; Li, S.; Xia, S.; Li, B.; Zhang, X.; Wang, B.; Ye, T.; Zheng, W. A Review on the Policy, Technology and Evaluation Method of Low-Carbon Buildings and Communities. Energies 2023, 16, 1773. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Endres, H.J. Plastics in the Context of the Circular Economy and Sustainable Plastics Recycling: Comprehensive Review on Research Development, Standardization and Market. Compos. Part C 2021, 6, 100168. [Google Scholar] [CrossRef]

- Orsini, F.; Marrone, P. Approaches for a low-carbon production of building materials: A review. J. Clean. Prod. 2019, 241, 118380. [Google Scholar] [CrossRef]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Saadaoui, M.; Khaldoun, A. Thermal performance of unfired lightweight clay bricks with HDPE & PET waste plastics additives. J. Build. Eng. 2020, 30, 101251. [Google Scholar] [CrossRef]

- Thoudam, K.; Hossiney, N.; Lakshmish Kumar, S.; Alex, J.; Bhalkikar, A.; Fathima, A. Assessing performance of alkali-activated bricks incorporated with processed surgical masks. J. Mater. Res. Technol. 2023, 25, 6432–6445. [Google Scholar] [CrossRef]

- Mahdi, S.N.; Babu, R.D.V.; Hossiney, N.; Abdullah, M.M.A.B. Strength and Durability Properties of Geopolymer Paver BlockMade with Fly Ash and Brick Kiln Rice Husk Ash. Case Stud. Constr. Mater. 2022, 16, e00800. [Google Scholar] [CrossRef]

- Fernando, S.; Nasvi, M.C.M.; Gunasekara, C.; Law, D.W. Systematic Review on Alkali-Activated Binders Blended with Rice Husk Ash. J. Mater. Civ. Eng. 2021, 33, 04021229. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Venkatesan, R.; Pazhani, K. Strength and durability properties of geopolymer concrete made with Ground Granulated Blast Furnace Slag and Black Rice Husk Ash. KSCE J. Civ. Eng. 2016, 20, 2384–2391. [Google Scholar] [CrossRef]

- Bahar, R.; Benazzoug, M.; Kenai, S. Performance of compacted cement-stabilised soil. Cem. Concr. Compos. 2004, 26, 811–820. [Google Scholar] [CrossRef]

- Thejas, H.K.; Hossiney, N. Alkali-Activated Bricks Made with Mining Waste Iron Ore Tailings. Case Stud. Constr. Mater. 2022, 16, e00973. [Google Scholar] [CrossRef]

- Zhong, X.; Hu, M.; Deetman, S.; Steubing, B.; Lin, H.X.; Hernandez, G.A.; Harpprecht, C.; Zhang, C.; Tukker, A.; Behrens, P. Global greenhouse gas emissions from residential and commercial building materials and mitigation strategies to 2060. Nat. Commun. 2021, 12, 6126. [Google Scholar] [CrossRef] [PubMed]

- Xiao, R.; Ma, Y.; Jiang, X.; Zhang, M.; Zhang, Y.; Wang, Y.; Huang, B.; He, Q. Strength, microstructure, efflorescence behavior and environmental impacts of waste glass geopolymers cured at ambient temperature. J. Clean. Prod. 2020, 252, 119610. [Google Scholar] [CrossRef]

- Korniejenko, K.; Lin, W.; Šimonová, H. Mechanical Properties of Short Polymer Fiber-Reinforced Geopolymer Composites. J. Compos. Sci. 2020, 4, 128. [Google Scholar] [CrossRef]

- Haddaji, Y.; Hamdane, H.; Majdoubi, H.; Mansouri, S.; Allaoui, D.; El Bouchti, M.; Tamraoui, Y.; Manoun, B.; Oumam, M.; Hannache, H. Eco-friendly geopolymer composite based on non-heat-treated phosphate sludge reinforced with polypropylene fibers. Silicon 2021, 13, 2389–2400. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Ali, S.; Ciacci, L.; Fishman, T.; Heeren, N.; Masanet, E.; Asghari, F.N.; Olivetti, E.; Pauliuk, S.; Tu, Q.; et al. Material efficiency strategies to reducing greenhouse gas emissions associated with buildings, vehicles, and electronics—A review. Environ. Res. Lett. 2019, 14, 043004. [Google Scholar] [CrossRef]

- Kani, E.N.; Allahverdi, A.; Provis, J.L. Efflorescence control in geopolymer binders based on natural pozzolan. Cem. Concr. Compos. 2012, 34, 25–33. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2021, 36, 345–369. [Google Scholar] [CrossRef]

- Doan, H.N. Medical Face Masks Can Be Reused with Microwave Method: Expert. 2020. Available online: https://vietnamnews.vn/society/654072/medical-face-masks-can-be-reused-with-microwave-method-expert.html (accessed on 16 November 2023).

- SimaPro. AGRIBALYSE v3.0.1 French LCI Database for the Agriculture and Food Sector Provided by ADEME: France openLCA Nexus: The Source for LCA Data Sets. 2022. Available online: https://simapro.com/products/agribalyse-agricultural-database (accessed on 15 July 2023).

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. 3D concrete printing of eco-friendly geopolymer containing brick waste. Cem. Concr. Compos. 2023, 138, 104943. [Google Scholar] [CrossRef]

- Yang, K.-H.; Song, J.-K.; Song, K.-I. Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 2013, 39, 265–272. [Google Scholar] [CrossRef]

- Fawer, M.; Concannon, M.; Rieber, W. Life cycle inventories for the production of sodium silicates. Int. J. Life Cycle Assess. 1999, 4, 207–212. [Google Scholar] [CrossRef]

- Gajjar, C.; Sheikh, A. India Specific Road Transport Emission Factors; India GHG Program: Mumbai, India, 2015. [Google Scholar] [CrossRef]

| Brick Type | GGBS | RHA | Sand | RSM | Na2SiO3 | Water |

|---|---|---|---|---|---|---|

| Wt.% | ||||||

| RMGB0 | 59.5 | 10.5 | 30 | 0 | 8 | 10 |

| RMGB1 | 59.5 | 10.5 | 30 | 1 | 8 | 10 |

| RMGB2 | 59.5 | 10.5 | 30 | 2 | 8 | 10 |

| RMGB3 | 59.5 | 10.5 | 30 | 3 | 8 | 10 |

| RMGB4 | 59.5 | 10.5 | 30 | 4 | 8 | 10 |

| Brick Type | GGBS | RHA | Sand | RSM | Na2SiO3 | Water |

|---|---|---|---|---|---|---|

| kg/m3 | ||||||

| RMGB0 | 797 | 65 | 587 | 0 | 127 | 100 |

| RMGB1 | 797 | 65 | 587 | 1 | 127 | 100 |

| RMGB2 | 797 | 65 | 587 | 2 | 127 | 100 |

| RMGB3 | 797 | 65 | 587 | 3 | 127 | 100 |

| RMGB4 | 797 | 65 | 587 | 4 | 127 | 100 |

| Inputs/Outputs | Inventory | Unit | Emission Factor | Unit | Embodied Carbon | Unit |

|---|---|---|---|---|---|---|

| Sterilization | 0.52 | kWh | 1.04348 | kgCO2eq/kWh | 0.543 | kgCO2eq/kg |

| Grinding | 0.332 | 1.04348 | 0.346 | |||

| Total | 0.889 | |||||

| Inventory | Emission Factor | |||||||

|---|---|---|---|---|---|---|---|---|

| Inputs/ Outputs | RMGB0 | RMGB1 | RMGB2 | RMGB3 | RMGB4 | Units | Units | |

| GGBS | 0.505 | 0.5048 | 0.5045 | 0.5043 | 0.5041 | ton | 26.50 | kg CO2/ton |

| RHA | 0.042 | 0.0417 | 0.0415 | 0.0413 | 0.0411 | 0.00 | ||

| Sand | 0.372 | 0.371 | 0.371 | 0.371 | 0.371 | 26 | ||

| Na2SiO3 | 0.081 | 0.081 | 0.081 | 0.081 | 0.081 | 930 | ||

| RSM | 0.00 | 0.00064 | 0.00128 | 0.00192 | 0.00256 | 889.04 | ||

| Truck | 20.732 | 20.735 | 20.738 | 20.741 | 20.744 | ton·km | 0.088 | kgCO2/ton·km |

| Inputs/ Outputs | RMGB0 | RMGB1 | RMGB2 | RMGB3 | RMGB4 | Unit |

|---|---|---|---|---|---|---|

| GGBS | 13.38 | 13.38 | 13.37 | 13.37 | 13.36 | kgCO2/ton |

| RHA | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Sand | 9.67 | 9.67 | 9.66 | 9.66 | 9.65 | |

| Na2SiO3 | 75.33 | 75.33 | 75.33 | 75.33 | 75.33 | |

| RSM | 0.00 | 0.57 | 1.14 | 1.71 | 2.28 | |

| Truck | 1.82 | 1.82 | 1.82 | 1.82 | 1.82 | kgCO2/ton·km |

| Total | 100.20 | 100.76 | 101.32 | 101.88 | 102.44 | kgCO2/ton |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thoudam, K.; Hossiney, N.; Lakshmish Kumar, S.; Alex, J.; Prakasan, S.; Chandra, S.; Urs, Y.; Arunkumar, A.S. Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks. Recycling 2023, 8, 93. https://doi.org/10.3390/recycling8060093

Thoudam K, Hossiney N, Lakshmish Kumar S, Alex J, Prakasan S, Chandra S, Urs Y, Arunkumar AS. Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks. Recycling. 2023; 8(6):93. https://doi.org/10.3390/recycling8060093

Chicago/Turabian StyleThoudam, Kritish, Nabil Hossiney, Srinidhi Lakshmish Kumar, Jacob Alex, Sanoop Prakasan, Sarath Chandra, Yogeshraj Urs, and A. S. Arunkumar. 2023. "Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks" Recycling 8, no. 6: 93. https://doi.org/10.3390/recycling8060093

APA StyleThoudam, K., Hossiney, N., Lakshmish Kumar, S., Alex, J., Prakasan, S., Chandra, S., Urs, Y., & Arunkumar, A. S. (2023). Recycled Surgical Mask Waste as a Resource Material in Sustainable Geopolymer Bricks. Recycling, 8(6), 93. https://doi.org/10.3390/recycling8060093