Abstract

Polymers are ideal solutions for architects and constructors in the marine field who require materials that can achieve light and stable structures owing to their unique advantages. For instance, they possess a high strength-to-weight ratio, high wear resistance and fatigue strength, resistance to corrosion, ease of fabrication, and superior vibration damping behavior. These properties make polymers well suited for marine-based applications. However, polymers have their disadvantages, such as contributing to plastic pollution, which has a detrimental impact on the environment. In recent times, various concurrent methods have been employed to advance the future of polymers. This review explores (i) an overall view of polymers used in marine industries, (ii) a focus on reducing plastic wastage, (iii) challenges involved in recycling polymers and ensuring their sustainability, and (iv) the development of renewable plastics.

1. Introduction

Contradictorily, the environmental debate, which should have been a great contributor to evolving an environmental strategy and implementing it, has turned out to be a firm barrier. The reason for this could be the fact that environmental issues have departed from a scientific approach and become a topic of interest for political groups. Clearly, the requirement is not sympathetic contribution for the benefits of the ecosystem but for the protection of the balance of the biosphere. Though the ever-increasing human population is expected to flatten out around the start of the twenty-second century, the most dominant species on Earth faces an imminent environmental catastrophe.

Even if the population flattens out due to the expected reduction in population growth rates in developing countries, it is estimated to be an alarming 10.4 billion in the year 2100 [1]. Mankind relies on nature for all its energy needs, from food obtained through different phases of the food chain to other energy sources due to sophistication in modern lifestyle. The main energy sources are fossil fuels, which took millions of years to form. However, the current demand depletes them at a much faster rate than they can be created, contributing to high environmental pollution and generating significant waste. Currently, these issues are turning into a global transboundary problem.

Polymers are a real alternative solution to traditional materials such as steel, aluminum, etc., in numerous applications due to their better performance and competitive costs compared to their counterparts [2]. The production of polymers always includes energy as an important cost element, but the expected shortfall in fossil fuels denotes severe conservation issues [3]. As most industries depend on fuel, the fuel crises have highlighted fuel on the conservation agenda. The polymer industry, especially the plastic sector, depends not only on energy but also on raw materials. This sector has been aware of its requirement for fossil hydrocarbons for a long time. It is known that although engineers have deployed energy-efficient techniques in individual plants, the true energy demand assessment could only be carried out with proper consideration of all production steps from the extraction of raw materials to the final polymer [4]. This strengthens a prevailing argument that puts the actual cost of plastics produced in terms of natural resources utilized. Additionally, the production of polymers, mainly synthetic, enhances pollution, starting from the synthesis step. The end products are also believed to cause plastic pollution [5]. Earth, which possesses a complex ecology, is blessed to have recycling processes naturally occurring due to radiation from the solar system. However, any deviation between resources and their utilization, even by a small ratio, can affect their availability. Hence, it is essential to configure new methods and technologies to achieve competitiveness in cost and enhance performance [6]. This is influenced by corporate sectors as well. All of these rising concerns to find an alternate solution have led to polymer-based composites [7]. The possibility of using green composites based on polymeric matrices by incorporating polymers with animal or vegetal marine wastes could be a solution for the biodegradability of materials [8]. Alejandro Barandiaran et al. [9] fabricated composites with poly(lactide) (PLA) and Posidonia oceanica fibers using reactive extrusion in the presence of dicumyl peroxide (DCP) and subsequent injection molding. Field emission scanning electron microscopy (FESEM) showed that the reactive extrusion enhanced PO/PLA interaction which diminished the gap between the fibers and the matrix. Also, there were noticeable plasticizing effects, including a significant increase in the elongation at break from 7.1% of neat PLA to 31.1% and a considerable decrease in the glass transition temperature from 61.1 °C of neat PLA to 41.6 °C. Roberto Scaffaro et al. [10] claims that recently sought technologies, like 3D printing of green composites, with the feasibility to valorize agricultural and marine waste as green fillers could contribute to reduce bioplastic costs. This could also be attained without compromising their mechanical performance. Biocomposites made from plant- or wood-based fibers have numerous advantages over synthetic additives. Though the raw materials used are mostly from land sources, aquatic biomass, which includes marine plants, could be an ideal alternative due to the chemical composition of their fibers, which is very much similar to that of other lignocellulosic materials [11].

Globally, there has been an ever-increasing demand for polymers in marine applications since the introduction of glass–fiber-reinforced plastics for navy personnel boats as early as the Second World War period. Ever since, polymers have found applications in low-signature and low-cost marine vessels that are about 300 feet long and 1200 tons in displacement. Composites have been used for constructing pleasure boats since before 1965, and there is an increasing trend in the use of composites for building passenger and recreation vessels [12]. Specific applications of polymers include canoes, kayaks, sailboats, and powerboats. Due to their lightweight nature, powerboats and sailboats are built using polymer composites. Commercial applications of polymers include fishing vessels, passenger ferries, submersibles for industrial research, cargo vessels, and tankers. Military applications have been successful in keeping costs at a minimum. Other applications of polymers have been witnessed in marine aviation vehicles and offshore structures [13]. A major challenge that acts as an obstacle to the development of polymer-based materials for marine applications includes achieving a light structure, which is a similar challenge in other engineering sectors. Marine structures are subjected to numerous damages because of various loads acting throughout their entire service life. However, polymeric materials are flexible, with a low modulus of elasticity, and manifesting higher failure strain and yield strength, making polymers an attractive choice for marine applications. However, polymeric materials possess low fire resistance, which raises questions about their usage in some critical applications. To counter this, we find blends of elastomeric materials and their composites with flame-retardant (FR) additives. Additionally, polymeric materials have a high strength-to-weight ratio, good impact properties, low infrared, magnetic, and radar signatures, enhanced durability, and resilience to extreme loads.

Marine pollution is defined as any plastic article such as detergent containers, ropes, fishing nets, buckets, thin and thick gauge sheets, cosmetic containers, food containers, oil containers, water containers, miscellaneous unidentified items, etc., (as shown in Figure 1) entering the marine environment. In recent times, the deposition of plastic waste in the marine environment has been rapidly increasing. It is believed that marine pollution is caused by picnickers and casual visitors. Also, it is observed that the deposited plastic materials would remain in the sea where they are discarded forever unless the plastics are collected [14].

Figure 1.

Litter such as plastic detergent bottles, crates, buoys, combs, water bottles, and blankets in Kanapou Bay, on the Island of Kaho’olawe in Hawaii. This region is a hot-spot for marine debris accumulation [15].

In general, environmental sustainability is related to interactions between humans and nature in terms of effective utilization of resources. Earth, which has a complex ecology, is gifted with natural recycling processes using solar radiation. Any disturbance in the ratio between available resources and their consumption can affect their availability.

2. The Need for Polymers

The need for polymers arises from the consequences of unmonitored population growth, which has triggered uncontrollable urbanization, leading to an energy crisis. Earth, functioning as an open thermodynamic system, relies on continuous natural recycling processes fueled by solar radiation to sustain its intricate ecology. In contemporary terms, sustainability entails judicious resource utilization, focusing solely on applications of utmost importance. According to Keslar, the viability of future resources depends on the balance between recorded resources and their annual consumption [16]. Recycling plays a crucial role in minimizing energy usage, as only minimal energy is expended in processing already synthesized materials, contributing significantly to energy conservation [17]. Despite environmental concerns surrounding polymer-related industries, especially synthetic ones, which account for only 4% of the total global petroleum production for their utilization, this rate is minimal compared to other industrial sectors dependent on petroleum-based products.

3. Marine Sectors

Usually, discussions about marine applications are always oriented toward on-shore vessels, but there are equally significant marine applications like marine aviation industries and off-shore construction as well. The shipping vessels are classified broadly into cargo and passenger vessels. The import and export activities worldwide are entirely dependent on cargo transportation due to the enormous volume handled. Moreover, the cheapest form of transportation is navigation. However, there is a decline in demand for passenger vessels due to people’s preference for fast-paced transportation.

3.1. Marine Environment

The marine environment is saline with varying water densities. The ocean is calm typically but is rough during extreme and aggressive weather conditions. There are also chances for sudden impact loads during rough weather. Besides, the marine environment is inaccessible regarding immediate help in the deep sea.

3.2. Damage to Marine Structures

Sometimes, the damage to marine structures is uncertain, with environmental load being the wider cause for their damage [18]. Other than environmental load, marine structures are subjected to (i) dead and live functional loads, and (ii) accidental loads. Thus, marine structures are exposed to extreme loads whose magnitude and direction are unpredictable. The performance of marine structures is highly reduced as they are subjected to extreme loads. Apart from these environmental loads, the moisture content of seawater and humidity have their share in causing havoc structurally. However, thermoplastic composites have gained the rank as the best choice for marine applications, especially for beneath-the-water-surface applications, though there have been doubts raised over their tensile, compressive behavior and water sensitivity [19]. Also, polymer composites are subjected to static and fluctuating loads in the marine environment because of the initiated cracks that keep propagating. Thus, both hydrostatic as well as hydrokinetic pressures affect the mechanical behaviors of polymer composites.

3.3. Prerequisites for Marine Applications

The maritime industry requires materials that could increase the durability, contribute toward weight reduction, and minimize production costs of marine structures. The search for a realistic alternative by naval architects and vessel builders, with properties that are prerequisites for marine applications, has created competition to fabricate new materials [20]. Earlier, steel was predominantly preferred as the traditional material for marine applications. Presently, not only marine applications but also other engineering sectors have been working on minimizing structural weight. It has been proven to be a useful tool for energy efficiency since lighter structures improve fuel economy and decrease environmental emissions. In addition to these aspects, reducing structural weight has become the choice of vessel owners as it provides space for more payload to increase revenue generation. The materials should possess the following:

- The ability to withstand extreme weather conditions and environmental loads;

- Corrosion-resistant properties;

- Higher resistance to wear and fatigue;

- High strength-to-weight ratio;

- Ease of fabrication;

- Superior noise and vibrational damping behavior;

- Enhanced radar/acoustic transparency;

- Good resistance to impact loads.

Also, materials for marine applications are under intense public scrutiny with expectations to preserve the marine ecosystem and to conform to the strict norms of marine governing agencies.

3.3.1. Environment-Based Prerequisites

The prospects of attaining sustainability in the future, when energy expenditures are stringently controlled, as in the case of synthesizing polymers or recycling, also result in the quick exhaustion of material resources. This is because production indirectly involves the utilization of natural resources, resulting in depletion and disturbing the supply chain of natural resources.

3.3.2. Economy-Based Prerequisites

If synthesizing or recycling is not economical, it is necessary to develop new technologies geared toward sustainability and cost-effectiveness. For example, in the case of the abandonment of fishing nets made from natural fibers, they were subsequently replaced with nylon and polyolefin during the early 1940s, increasing the “catchability” by an average factor of 2–12-fold, with durable and robust fishing gear manufactured using a comparatively less volume of plastic resin addition [21]. This increased the profitable income of the industry. We often find that quantitative data supporting positive impacts, such as concerns and magnitudes, have been found to be missing.

4. Polymers

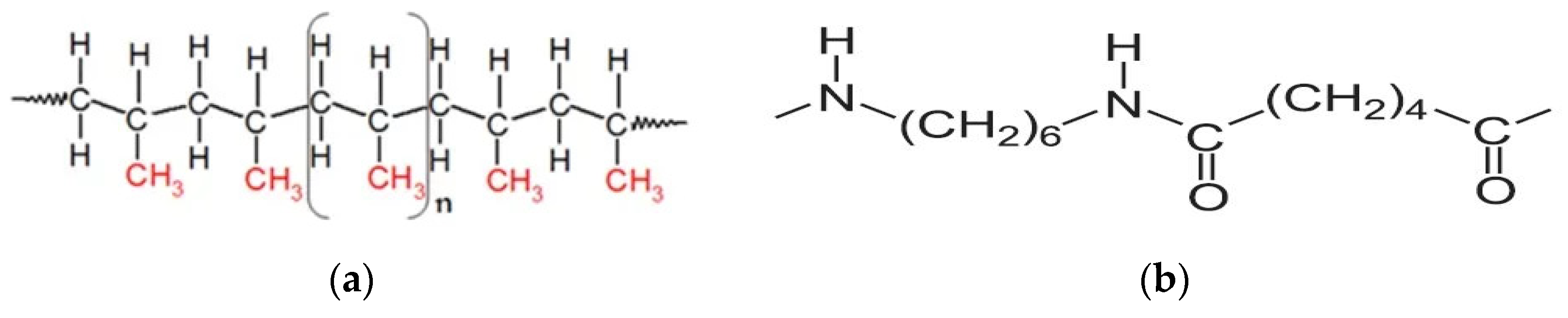

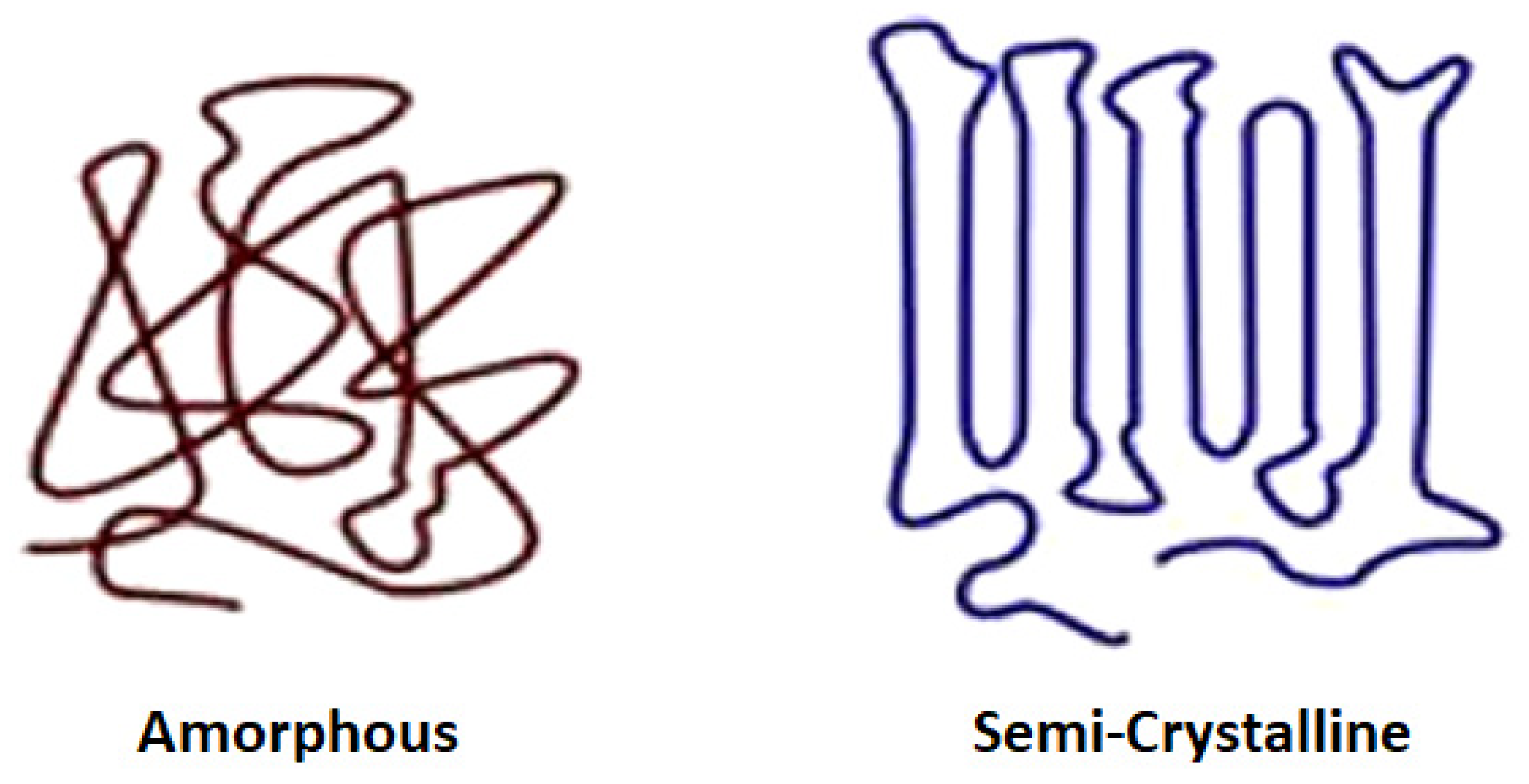

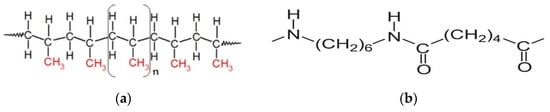

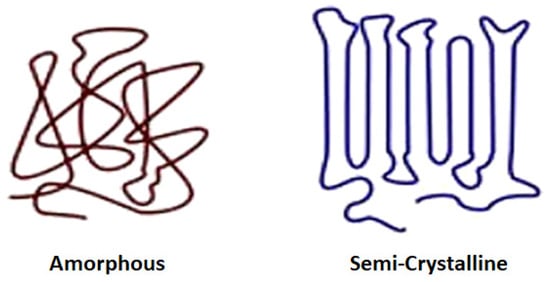

Polymers are defined as compound substances with a molecular structure, such as a molecule with a long chain consisting of a single or n-numbers of repeating units of atoms (Figure 2). These multiple similar units are bonded together by strong covalent bonds. Polymer molecules with similar chemical structures but of different lengths in large numbers denote a polymeric material. This polymeric material is commonly referred to as plastic. These molecules are arranged in space in their solid state. The arrangement (Figure 3) may be as follows:

Figure 2.

Examples of repeating units in polymer molecules. (a) A polypropylene (PP) molecule [22]; (b) a nylon 6,6 molecule [23].

Figure 3.

Arrangement of molecules in amorphous polymers and semi-crystalline polymers [24].

- Amorphous, where random arrangement exists;

- Crystalline, where an orderly arranged folded chain exists.

Nevertheless, various segments of a polymer molecule exhibit a randomly excited state on a sub-microscopic scale. Also, with increasing temperature, several polymer segments tend to exhibit an increase in both their frequency and intensity. Hence, this phenomenon strengthens the argument for polymers being temperature-dependent [25].

4.1. Emergence of Polymers

Some polymers are naturally synthesized, and others are artificially synthesized to meet specific requirements [2]. Phenol formaldehyde resin was the first recorded synthesized polymer that found its application as shellac in electrical wiring, telephonic dials, and other electrical accessories. Today, widely available polymers are the results of hard work invested during the Second World War period.

- The sequence includes ethylene-derived vinyl plastics, homopolymer polyvinyl chloride (PVC), polyethylene, which was followed by low-density polyethylene (LDPE), high-density polyethylene (HDPE), and intermittent linear low-density copolymers of ethylene (LLDP).

- PP, copolymers of ethylene, and a homopolymer of propylene emerged later. Polyolefins refer to polyethylene and PP (and their conventional copolymers). Polymethylmethacrylate (PMMA) and the introduction of nylons happened around the same time, resulting in a material that arguably served the allied war effort.

Recently, a new polyethylene with metallocene as a catalyst and polycarbonate was synthesized [1].

4.2. Classification of Polymers

Though polymers include plastics and elastomers, plastics are highly pronounced due to their extensive visibility to human eyes. Polymers are widely classified into the following categories according to Michael Tolinski [26]; traditional commercial polymers are simply classified as thermosets and thermoplastics.

- Thermosets are thermosetting engineering plastics that include traditional thermosets and cannot be recycled after being synthesized once. Unreinforced thermosets like epoxies, polyurethanes, and unsaturated polyesters are examples of engineering thermosetting plastics.

- Thermoplastics further include commodity thermoplastics and engineering thermoplastics. Both commodity thermoplastics and engineering thermoplastics can be reprocessed or recycled. Combined, they dominate the polymer market with their high-volume demand. Polyethylene, PP, polyvinyl chloride, polystyrene (PS), polyethylene terephthalate (PET), and related polyesters are examples of commodity thermoplastics. Engineering thermoplastics utilize petroleum products for synthesizing but are in low-volume demand when compared with commodity thermoplastics. Nylon or polyamide, acrylonitrile-butadiene-styrene, and polycarbonate are examples of engineering thermoplastics.

Thermoplastics also include bioresins, which are of biochemical origin and synthesized biologically or conventionally with resources from natural and non-fossil substances and hence referred to as biopolymers. Hence, they are classified under biopolymers. Though they exhibit engineering properties, polylactic acid, polyhydroxyalkanoates, starch, protein, and algae-based polymers, as well as blends of these, are examples of biopolymers.

4.3. Advanced Polymers

Composites obtained using thermoset matrix resins like epoxies, polyimides, and bismaleimides dominate the advanced polymer market and have gained considerable demand in applications such as marine, aerospace, and corps. The challenges have given polymers new dimensions and new forms over the years, especially to make thermoset-based composites perfect for various applications. Despite these advancements, certain deficiencies remain, which are as follows [27]:

- Restricted shelf life;

- Low toughness;

- Low strain at failure;

- Processing complexity.

4.4. Common Controversies of Plastics

Despite the ever-increasing demand for plastics, they are under intense public scrutiny due to their ingredients, which are believed to have negative impacts on human health and the environmental ecosystem. This negative outlook has only continued to increase over the years. For example, additives like lead-based stabilizers, cadmium-based stabilizers, and colorants extensively used in PVC have raised concerns. Opposition to the use of heavy metal-based additives and halogenated flame-retardant additives in electronics items has resulted in their elimination [28]. Plastics have started to lose favor among manufacturers due to worries about the impact of their constituent chemicals on the environment. Calls against the use of PVC continue due to the emission of chlorinated compounds. The use of expanded foam PS is also disliked due to concerns about its carcinogenic nature, non-biodegradability, and the use of ozone-layer-depleting blowing agents. However, biobased plastic foams could be an alternative for expanded PS to achieve lightweight insulation properties. Still, confidence in plastic foam remains uncertain [26]. To address this, ingredients under scrutiny have been sidelined, ultimately leading to the acceptance of those introducing new forms of plastics. Thus, these new forms of plastics have gained significant demand in the market.

Banning single-use plastic bags is considered one possible way to eliminate plastics. Polyethylene, which is blown to form single-use lightweight film bags, is considered a low-value product by consumers. The cheaper the manufacturing becomes, the higher the controversies. These bags are easily carried far from places by the wind or water bodies, leading to litter accumulation in beaches and ocean gyres. Such plastic pollution creates havoc on essential issues like marine life and wildlife through ingestion and disrupts water seepage into the ground, affecting the water table. Various bans on widely used non-biodegradable plastic bags have come into effect in coastal and land areas across the world since 2011.

Alternatives such as bioplastics made from bioresin-blown film have been introduced. Although biobased or biodegradable plastics are considered alternatives for grocery or shopping bags, experts claim that they are costlier and require more energy and water for processing. Moreover, biodegradable bags are argued to take more time to degrade completely. Questions have also been raised about elevated levels of lead in reusable cloth bags, which consumers habitually use. Polymer degradation in the marine environment influences bioremediation approaches to reduce microplastic pollution. Plastic degradation occurs through three mechanisms: forming a biofilm on the polymer surface, abiotic hydrolysis of functional groups, and photodegradation due to exposure to UV light and oxygen [29].

- Forming a biofilm on the polymer surface results in the colonization of plastics using microorganisms. This induces biodegradation through surface erosion.

- Abiotic hydrolysis of functional groups such as esters, carbonates, and amides results in the reduction in molecular weight. This is influenced by the presence of hydroxide ions.

- Photodegradation due to exposure to UV light and oxygen results in the reduction in molecular weight of the material and causes cracks in them.

Chamas et al. [30] summarized data on polymer degradation, calculating the specific surface degradation rate (SSDR) to estimate the half-life of polymers in different environments. The report showed that the SSDR of LDPE with a typical thickness of 100 µm was 11 μm per year for polymer buried in the land, 22 μm per year (min 1.68; max 83) in land accelerated by UV or heat, 15 μm per year (min 0; max 37) in the marine environment, and 10 μm per year (min 9; max 12) in the marine environment accelerated by UV and/or heat.

5. Structure of Polymer Composites for Marine Applications

The application of polymer composites has steadily increased in marine industries due to their conformance to properties that are prime prerequisites for marine applications. In general, composite materials are hybrid structures with various materials, combining individual advantages in a single structure [31]. They consist of a resin matrix reinforced with fibers such as carbon, glass, or polymer. The strength is contributed by the fibers, which are held together by the resin matrix [25]. The properties of the final materials are combined depending on the individual materials. Continuous fibers are reinforced with a resin matrix in advanced composite materials to achieve better strength and stiffness. The selection of composite materials depends on the suitable reinforcing fiber and the matrix requirements in the right proportion for any application [32]. In practice, polymer composites, commonly referred to as plastics, are widely used. Fiber-reinforced polymers consist of a polymer-based matrix and reinforcement from fibers. The performance of any polymer blend generally depends on (i) the dispersion mechanism of the polymers, (ii) the interaction between the harder discontinuous reinforcement and the continuous matrices, and (iii) the behavior of their parent polymers. Mahesh et al. [33] fabricated biocomposite laminates involving polymer rubber (‘B’ stage cured prepregs) as the matrix and natural woven jute (density of 1450 kg/m3 and areal density of 350 g/m2) for reinforcement. The fabrication involved compression molding at a temperature of 138 °C and with a pressure of 25 kg/cm2. The reports revealed an increase in energy absorption and ballistic limit, with a decrease in residual velocity due to the addition of rubber and jute. This led to increased resistance against damage, making it ideal for applications in high-speed crafts and structures facing ballistic loads.

A computational 3D reconstruction by Nosouhi Dehnavi et al. [34] involved composite specimens with efficient polydisperse convex particles. The fast Fourier transform (FFT) homogenization method developed predicted effective thermal properties of the composite specimen at low volume fractions. Xu et al. [35] demonstrated an approach involving PP, acrylonitrile-butadiene rubber (NBR), and maleic anhydride-grafted PP (MA-g-PP) as a compatibilizer. The approach, intended to improve stability, was carried out in the presence of zinc dimethacrylate (ZDMA), which contributed to interfacial bonding. The incorporation of MA-g-PP contributed to better mechanical performance due to the change in the PP phase during melting. This, along with an improvement in viscosity and being lightweight with high stiffness, made the composites suitable for applications in hull structures.

5.1. Fiber Reinforcements

Fibers, which occupy around 30–70% of the matrix volume in any composite, are generally chopped, woven, stitched, and/or braided. They are treated with sizing agents such as starch, gelatine, oil, or wax, which act as binders. The sizing improves bonding, while binders aid in handling. Fiberglass, aramid, and carbon are the most commonly used fibers [36].

- Fiberglass is cheaper, with a low thermal expansion coefficient compared to steel; however, it experiences a decrease in strength and modulus as temperature increases.

- Aramid fibers are in the lower grades of carbon fiber and are human-made by spinning fiber from a chemical blend. They have high specific strengths due to low density, good impact resistance, excellent fatigue, and creep resistance, but face difficulties in bonding with the resin.

- Carbon is expensive, with low thermal expansion coefficients compared to glass and aramid fibers. It has a transverse modulus lower than its longitudinal modulus, high fatigue, and high creep resistance. Tensile strength decreases as the modulus increases, resulting in low strain at rupture. Carbon composites are effective with adhesive bonding, eliminating mechanical fastening. Other fibers like boron, with a higher strength and modulus, are currently chosen due to economic competitiveness.

Fiber reinforcements are combined with conventional or biobased additives and fillers to create a more stable structure, often referred to as plastic. Additives act as heat stabilizers, impact modifiers, flame retardants, colorants, lubricants, anti-blocking agents, anti-static agents, antioxidants, etc. To claim a material as natural, the entire structure, including additives and fillers, should be of bio-origin or be renewable. Fillers partially occupy the resin volume in a product to reduce costs; common fillers include calcium carbonate, talc, and mica. Reinforcement combinations, such as glass/carbon fiber and natural fibers like jute, kenaf, hemp, bamboo, wheat straw, sisal, agave, abaca, cottonseed, coir, wood fiber, etc., have yielded superior results. Nanoclay fillers contribute to the formation of nanocomposites.

5.2. Resin Systems

Resin, another essential constituent of composite materials, primarily falls into two types [37]: (i) thermoplastics and (ii) thermosets. Thermoplastics are solid at standard conditions and melt when heated. They do not cure permanently because their long chains do not cross-link chemically. In contrast, thermosets cure permanently and do not reverse at higher temperatures, making them preferable for structural stability. Polyesters, epoxies, and vinyl esters are commonly preferred, while polyurethanes and phenolics are less favored.

The primary advantage of composite materials lies in the complementary nature of the combined advantages provided by their constituent components. For instance, glass fibers offer good tensile strength but are susceptible to damage, while most polymer resins have low tensile strength but are tough and malleable. A composite that combines these materials exhibits properties more useful than the individual components possess.

6. Prospects of Polymers in Marine Applications

However, the requirements of the recreational marine industry primarily revolve around economic and operational factors, whereas those for commercial and naval shipbuilding differ significantly. Polymers have gained importance for being lightweight and, as a result, for replacing wood and metal structures. What has further enhanced the appeal of polymers is their ease of repair. Galanis summarizes the advantages of polymer composites for marine applications, highlighting their properties in Table 1 [38]. Chukov et al. [39] introduced a novel technique involving the low-temperature carbonization of elastomeric materials with a higher percentage of carbon fillers and dispersed silicon carbide (SiC) within a nitrile butadiene rubber (NBR) matrix. The reports revealed higher tensile and flexural strengths along with the ease of obtaining complex shapes with less machining, making elastomeric composites an attractive choice for various marine applications, including propulsion shafts, fuel pipes, cooling system pipelines (such as freshwater and seawater pipes), oil supply lines, lubricating systems, shaft generator couplings, masts, and superstructures of ferries. Additionally, these composites find applications in refineries, such as ducts and transfer pipelines laid between refineries and mother vessels.

Table 1.

Specific advantages of polymer composites for marine applications.

Fiber-reinforced polymer composites have found extensive use in various marine structures exposed to UV radiations. UV radiations can lead to mechanical degradation and impact the structural integrity of these composites. An investigation on vinyl ester composites was conducted to study the cumulative effect of moisture, cyclic loads, and UV radiation [40]. The investigation reported that the synergistic effect of moisture and UV resulted in accelerated fatigue damage. Altunsaray et al. [41] reported on the fatigue behaviors of fiber-reinforced plastic composites consisting of E-glass non-crimp reinforcements and polyester resin using the hand-layup technique. However, the report indicated that the fatigue behavior of the composites was not affected by the thickness or the direction of the material. Moreover, the magnetic field plays a significant role in marine applications. Stanier et al. [42] fabricated composites incorporated with various thermoplastics and carbonyl iron powder using melt blending with a twin-screw extruder. An investigation on tensile, magnetic, and mechanical behavior was conducted both in the presence and absence of a magnetic field. The report showed that the Young’s modulus increased as the magnetic field strength increased.

7. Predicaments Acting as Challenges for Polymers in Marine Applications

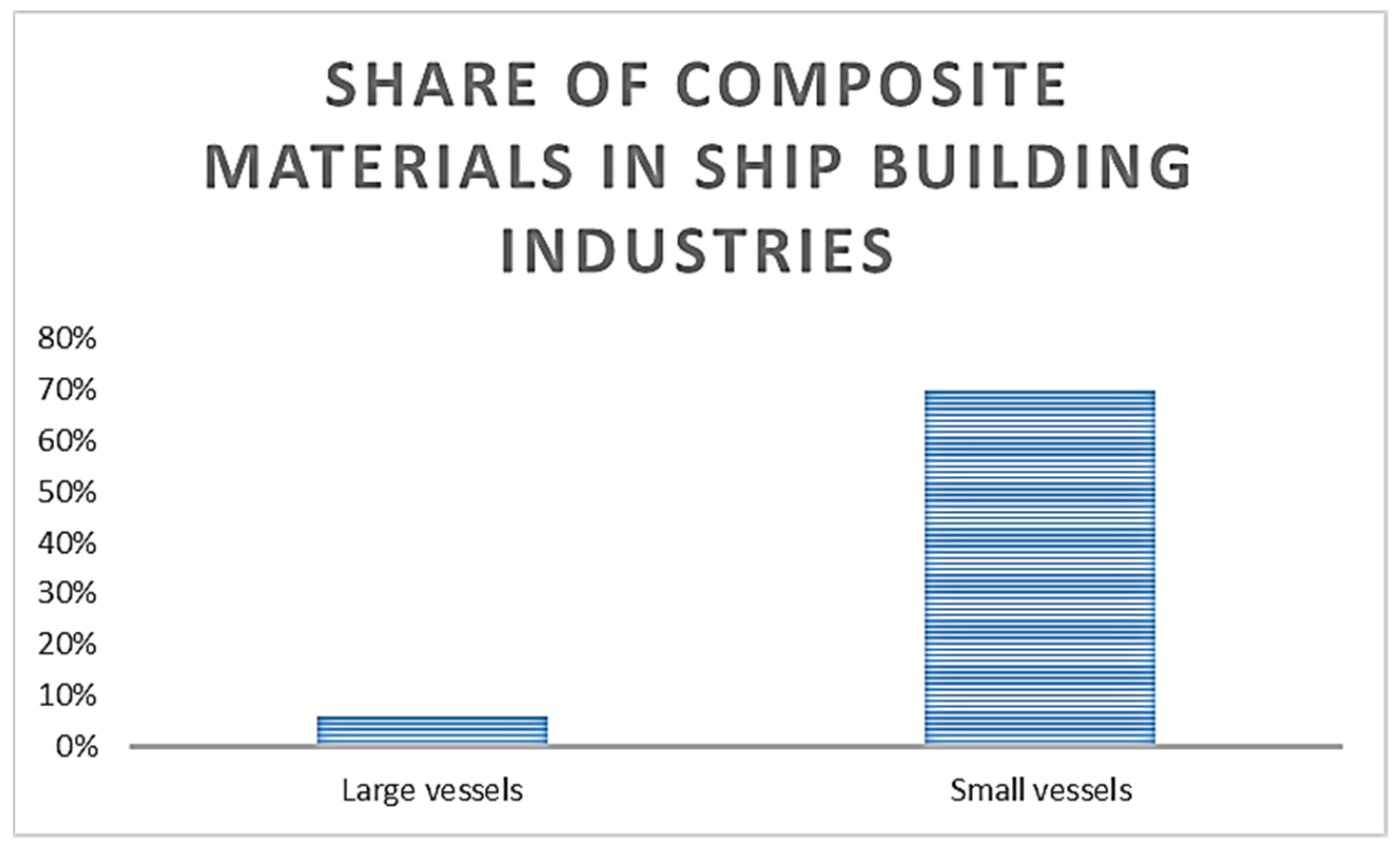

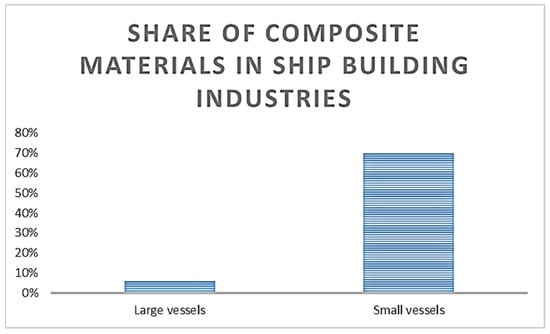

The challenges for polymers in marine applications are largely dependent on the rules set by marine governing bodies, such as the United Nations’ International Maritime Organization (IMO), which establishes regulatory conventions like the International Convention for the Prevention of Pollution from Ships (MARPOL), International Organization for Standardization (ISO), United Nations Environment Programme (UNEP), and the Water Framework Directive of the European Commission (EU). These rules vary based on the size of vessels. For instance, larger vessels are expected to have non-inflammable hulls and bulkheads, raising questions about the suitability of polymeric composites. However, regulations are more lenient for smaller vessels. Cerracchio et al. found that only 6% of composites are used in larger vessel building sectors, while in small vessel building sectors (involving crafts up to an overall length of 50 m), the share of composites is as high as 70% [43]. This is shown in Figure 4.

Figure 4.

Market share of composite materials in marine vessel construction.

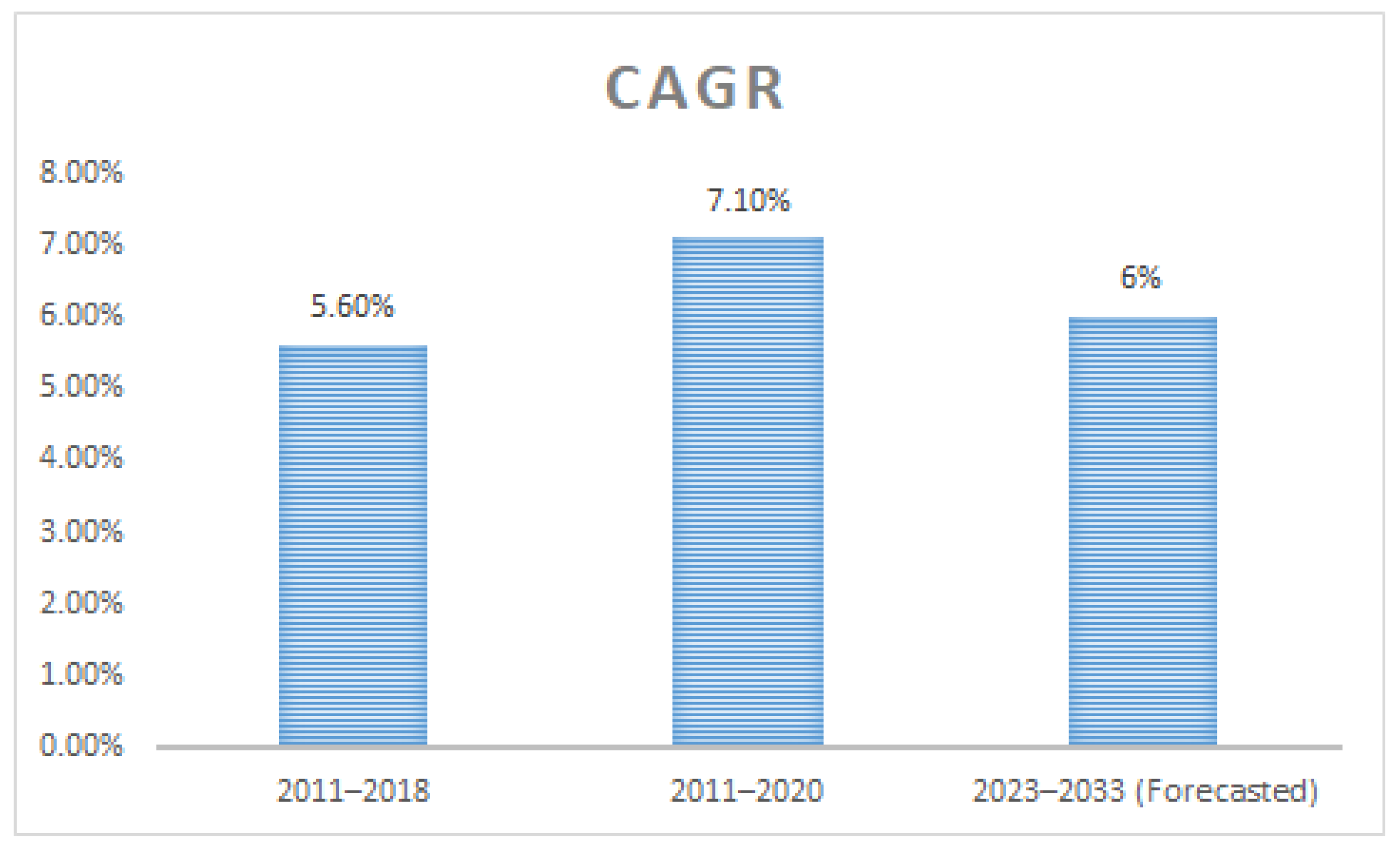

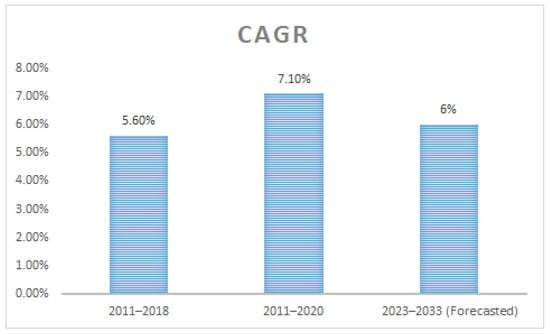

Therefore, the share of composite materials for vessel building depends on the size of vessels, ranging from fiber boats to ultra-large crude carriers (ULCC), and is dictated by the rules and regulations formulated by marine governing bodies. Figure 5 gives compound annual growth rate (CAGR) of composites in marine market. The marine composites market has experienced growth from approximately 135,000 tons in 2011 to close to 200,000 tons in 2020, with a CAGR of 5.6%. This growth is reflected in overall revenue, which increased from approximately US$900 million in 2011 to about $1500 million in 2018 at a CAGR of 7.1%. The global market for marine composites is forecasted to grow at a CAGR of 6% between 2023 and 2033, reaching a value of about $8.5 billion in 2033 from $4.8 billion in 2023, assuming definite penetration of composites usage [44].

Figure 5.

Composite materials’ market in marine.

However, there are critical challenges in marine polymer composites in the future, as identified by Zini et al. [45]. Design constraints based on flexibility pose a significant challenge, as fiber-reinforced polymers deflect about 10 to 12 times more than steel when two hull structures of equivalent thickness are considered. Fire retardancy of composite materials for marine applications is crucial, and stringent regulations have been put in place to ensure the safety of ships at sea (SOLAS protocols—safety of life at sea). The norms and protocols strictly restrict the use of materials that do not meet guidelines for non-combustion, potentially affecting the flag state registry of ships and their entry into relevant water bodies.

Presently, the International Maritime Organization (IMO) regulated High-Speed Craft (IMO-HSC) Code allows the use of composites as part of fire restricting materials in compartment linings and bulkhead applications, provided they meet fire test safety standards. However, the stability and withstanding capacity of polymer composites during significant fires remain highly questionable [46]. Additionally, fabricating flame-retarding polymer composites without compromising their mechanical performance and cost-effectiveness poses a formidable challenge [47]. Araby et al. [48] fabricated a polymeric composite with a low-cost graphite intercalation compound (GIC) using the melt compounding technique. A cone calorimeter was employed to simulate actual fire conditions. The GIC was expected to improve both the mechanical behavior and fire resistivity of composites. The investigation reported significant improvements in tensile strength, Young’s modulus, elongation at the break, and tear strength by 230%, 100%, 220%, and 200%, respectively. The study also highlighted important improvements in the fire performance index, reductions in average heat release rate at the peak, and a decrease in the rate of mass loss. The improvement in the fire resistivity of composites could be attributed to the occurrence of an endothermal chemical reaction as the GIC expanded and the formation of a char layer over the composite, aiding in the protection of underlying layers. Some of the disadvantages of polymer composites for marine applications, highlighting their properties are given in in Table 2.

Table 2.

Some disadvantages of polymer composites for marine applications.

There are also two other significant challenges for the usage of composites:

- First, from an economic point of view, the CAPEX (capital expenditure) and OPEX (operating costs) of ships are to be made sure, optimized with satisfying material specification leads, including that of boats, and other artifacts.

- Second, from an environmental point of view, the interest in sustainability is ever-increasing.

There can be five technical challenges for modeling based on the above economic and environmental considerations, such as the following [45]:

- An understanding of the fundamental load transfer mechanisms to confirm theoretical capabilities.

- Modeling of concepts for better safety, but this could count as sacrificing both material and structural performance.

- The entire life cycle of composite structures should be analyzed to find better modeling, which could serve meritoriously to better manage the impacts on the environment regarding energy consideration.

- The concept of concurrent engineering being developed could reflect on the interaction of design and production, resulting in a cost-effective optimal choice.

7.1. Plastics, Packing, and Marine Pollution

It was reported that over 300 million tons of plastics are produced every year, with half of the plastics used for single-use, such as shopping bags, water containers, etc. It was also observed that over 8 million tons of plastics end up in the ocean, and most of the plastics are found to have sedimented from the top surface of the ocean to the deep ocean. The remaining plastics accumulate along the shorelines of the ocean; a higher number of plastic debris is noticed in picnic places as well as more densely populated areas. Among the different types of plastic pollution in the marine environment, floating plastic debris is found to be the highest in number. Plastic pollution is also caused by beach visitors, illegal dumping of plastics by industries, nautical activities, the fishing industry, construction, and aquaculture. Since plastics are based on petroleum products, they contribute to global warming. Moreover, these plastics generate carbon emissions when burned into the atmosphere. Plastic pollution can damage the esthetic value of tourist places and diminish tourism income [1,49,50].

The problem due to plastics would become more acute for another reason, namely, solar ultraviolet radiation, wind, and other natural factors. Due to these reasons, plastic fragments could become tiny pieces termed as microplastics (the size of the particle is <5 mm) and nanoplastics (the size of the particle is <100 nm) [49].

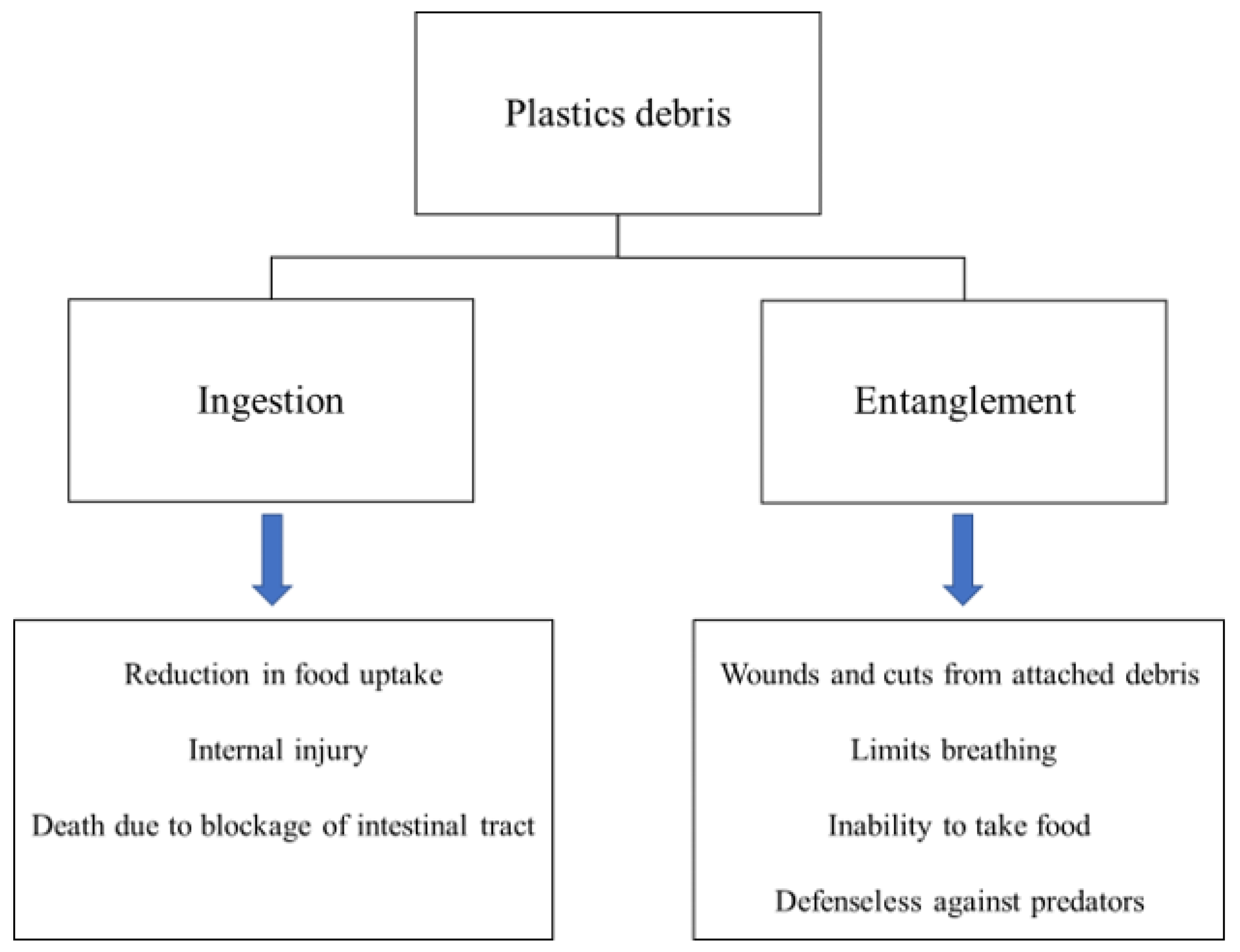

Due to plastic pollution, numerous species were found to have suffered. According to the researcher [51], at least 247 marine species suffered worldwide due to entanglement and ingestion of plastic debris. Entanglements can cause death due to (i) hunger, (ii) sinking, (iii) suffocation. Due to entanglement, seals, birds, and whale species frequently lose their ability to find and eat their food in the ocean. For instance, Figure 6 shows the consequences of entanglement for a seal which was entangled by a nylon rope. Further, it was observed that the nylon rope cut the flesh and damaged the backbone [52].

Figure 6.

A nylon rope entangled a seal [52].

Figure 7a–d show an entangled whale which was entirely wrapped by a nylon rope around the head. Also, the nylon ropes had cut deeply into the body and caused the animal’s death. It was identified that the name of the animal was the Humpback Whale, which was found to be a rare species in the North Sea [53].

Figure 7.

(a–d) Nylon ropes entangled humpback whale [53].

In addition to the impact on species, marine industries were also damaged due to plastic debris, specifically, plastic nets entangled in the propellers. It was reported that about USD 1.26 billion worth of equipment is damaged annually in marine industries in the Asia–Pacific regions [54,55]. Quantifying the effect of ingestion in the ocean is very difficult compared to plastic entanglements because ingestions cannot be observed directly. The exact plastic entanglements are also not easy to identify due to marine pollution, as these entanglements are anticipated to occur in remote areas where human activities are less [56,57].

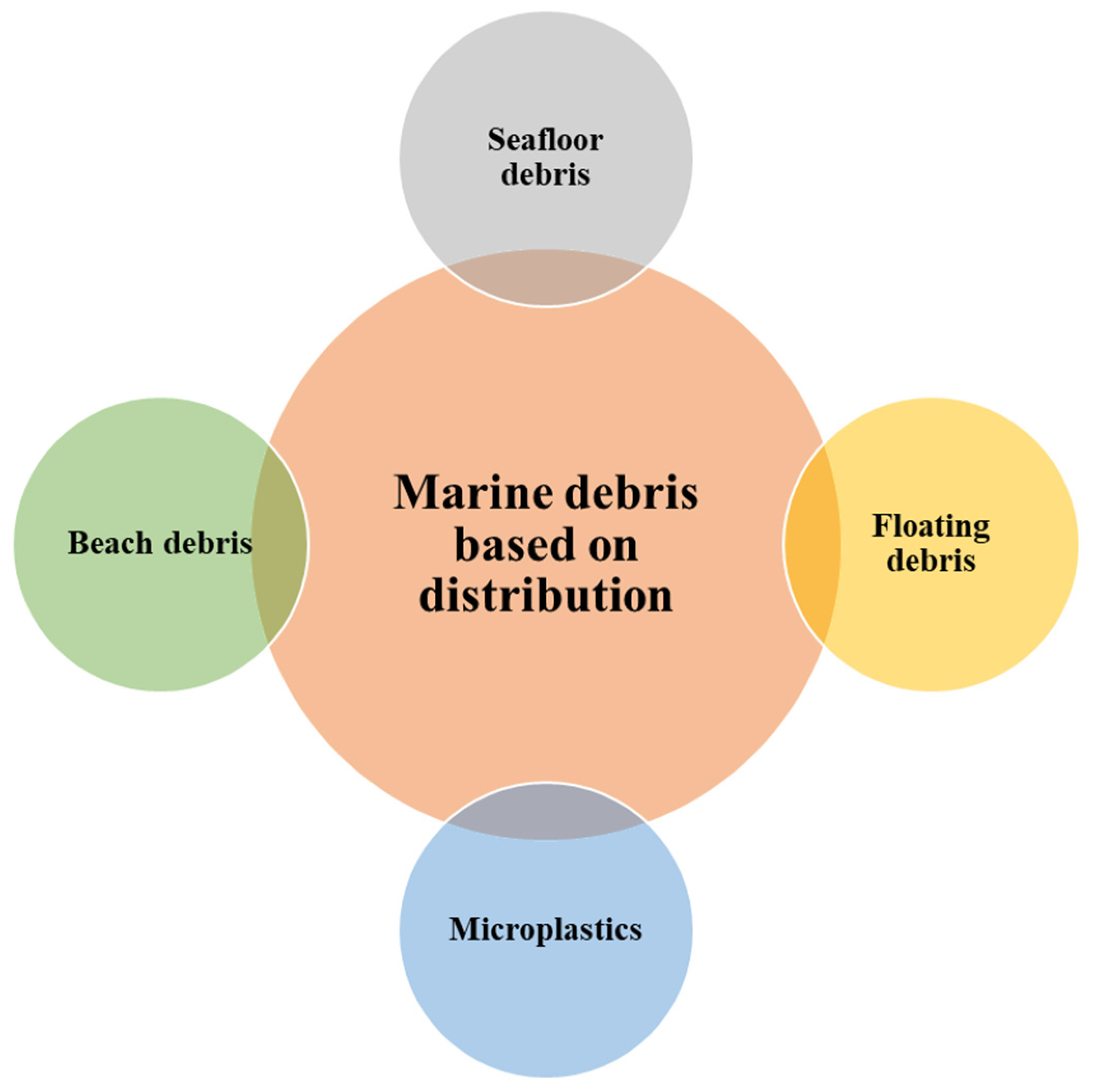

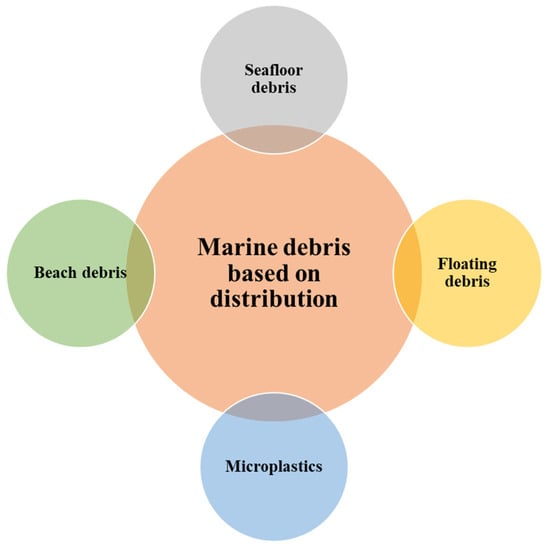

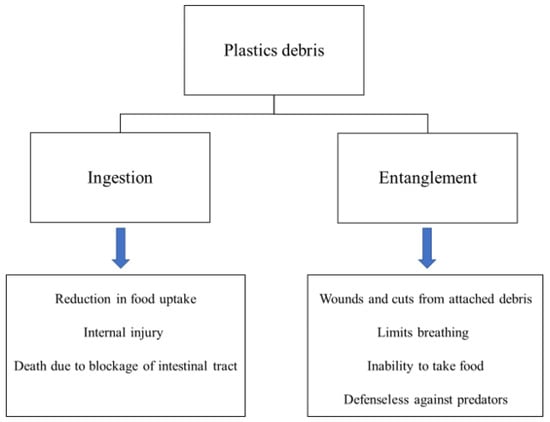

7.2. Marine Debris

Marine debris or litter enters the marine ecosystem through waste dumping from ships, waste outlet tubes from various industrial and municipal sources, point and diffuse sources, and other installations [58]. Marine debris or litter can be classified in terms of distribution, as shown in Figure 8. It is an issue of increasing global concern because the ecosystem of marine environments is severely affected by man-made refuse worldwide. These are mainly plastic items, including water bottles, beverage cans, packing bags, balloons, rubber, cigarette pipes, and other materials. This debris mixes with fishing gear and other materials lost on land or nearby, either intentionally or unintentionally, and ends up being thrown into the ocean and along the coast. Marine debris has severe impacts on marine organisms and habitats [59]. In particular, plastic debris harms living organisms in the marine ecosystem, as shown in Figure 9. When the global population was smaller and less concentrated, the quantity of disposed waste was biodegradable, and the environmental consequences were considered of less significance. It was believed that the ocean had an infinite capacity to accept water due to its widespread geography. Moreover, it was believed that the ocean was self-cleaning the waste as it assimilated. Though awareness of environmental issues related to the marine ecosystem has developed since the 1950s, it started gaining importance only in the 1960s, and questions on ocean health have persisted since. Marine debris is found to include mainly PS, LDPE and HDPE, PP, PET, and PVC.

Figure 8.

Marine debris based on the distribution.

Figure 9.

Impact of plastic debris on the living organisms in the marine ecosystem.

Recent studies have shown that invisible plastics have been noticed in seawater, including the Arctic Ocean. It is well known that plastics are made using various chemicals. Furthermore, plastic debris poses a potential risk of transfer to humans through the consumption of seafood, leading to severe health problems. With increasing awareness of environmental protection, the use of plastics is being minimized nationwide. Additionally, numerous legal efforts are being made to reduce marine pollution at both national and international levels. Several approaches to minimize marine pollution include the following [60]:

- Plastic recycling is the right choice to reduce pollution.

- Adequate litter and recycling bins are mandatory near coastal areas.

- Educational research institutions and industries are working collaboratively on developing biobased plastics; they are also exploring ways to reduce the disposal of microplastics.

- The degradation of plastics should be accelerated by introducing new plastics. This can help restore the natural balance.

It is the responsibility of each country to enforce laws addressing marine pollution.

8. Recycling and Renewable Plastics as an Effective Solution to Achieve Sustainability

Though plastic has now become an essential component of today’s day-to-day activities, it poses significant dangers to mankind [61]. However, its impact can be minimized, especially in the marine environment. Some efficient techniques include the following:

- Preventing debris from entering the marine environment can be achieved through outreach activities supported by governmental efforts at local, state, and national levels. Coordination and education initiatives can help raise awareness about the harmful after-effects of marine debris.

- Improving waste management involves identifying and implementing need-based technological solutions.

- Recycling is a crucial practice to mitigate environmental impacts, as the reuse of materials reduces the need for new production and minimizes energy consumption by avoiding new synthesis. This approach contributes to sustainability. After years of conducting various trials and exclusive research on recycling plastics, three technologies have been identified: mechanical processes, chemical treatment, and thermal processes [62].

- Bioplastics offer a potential long-awaited solution by utilizing plastics of bio-origin or renewable sources. These degradable plastics do not disrupt the marine ecosystem.

- Conversion involves exploring ways to transform marine debris into economically viable and eco-friendly materials.

- Humans need to take responsibility for marine debris, which is a byproduct of human activity. Therefore, it is essential to prioritize the manual clean-up of coastlines and the seafloor, as well as implementing school and public awareness programs on marine ecology and its importance.

Additional tools for managing marine debris include the implementation of anti-dumping campaigns and rallies, efforts to minimize lost fishing gear, and the introduction of incentives to encourage better practices in debris reduction. Eco-composites, or green composites, are composed of natural reinforcements or a natural matrix. Biocomposites offer various advantages, such as cost-effectiveness, greater dimensional stability, higher thermal stability, a lower frictional coefficient, and low density [63,64]. The structure of biofriendly composites provides lower thermal conductivity, making them highly sought after for marine applications, such as lifeboats and utility boats.

Jakkid Sanetuntikul et al. [65] investigated the influence of incorporating ground metalized-plastic film (MF) as a filler and reinforcement, along with recycled PP (rPP) ranging from 2 to 10 wt%. The incorporation process utilized a twin-screw extruder and an injection molding machine to produce a new material through a circular economy. Significant shifts in crystallization and melting peaks, along with a reduction in the degree of crystallinity (Xc), were observed according to the DSC results. The study reported a maximum increase in tensile strength by 33% at 8 wt% of MF, while elongation at break decreased with increasing MF loading. Tongsai Jamnongkan et al. [66] investigated the mechanical properties of PP as a matrix blended with recycled PP (rPP) at various concentrations up to 40 wt%. FTIR spectra revealed no chemical reaction between carbon black and the PP chains. The results suggested that the composites demonstrated good electrical performance, and the DSC results showed that rPP and carbon black acted as nucleating agents to increase the degree of crystallinity of PP. The study reported an increase in melt flow index (MFI) as rPP content increased. There was a noticeable decrease in the modulus and tensile strength of PP with increasing rPP content, while elongation at break increased up to 30.68% at a 40 wt% rPP content. This could be attributed to the interfacial adhesion between PP and rPP during the blending process. Additionally, the electrical conductivity of the blend significantly improved with the addition of carbon black into the rPP matrices, impacting their mechanical and electrical properties. A shift from ductile to brittle behavior, as indicated by stress–strain curves, may be caused by the poor interfacial interaction between rPP and carbon black in the composites. Yunusa Adamu Ugya et al. [67] conducted a review on the challenges of large-scale production of microalgae-based bioplastics, with a primary focus on quality and economic feasibility. Evaluation techniques included life cycle analysis (LCA), ecological footprint analysis, resource flow analysis, and resource accounting. The study reflected significant environmentally sustainable benefits with the use of microalgae biofilm for the production of bioplastics.

9. Conclusions

Recycling stands out as an effective solution among various options. One of the most reliable recycling techniques is thermal degradation, which operates without causing additional environmental disturbance or pollution. However, enforcement of this method requires the implementation of stringent measures by legislative bodies. It is imperative for each individual to recognize the importance of marine ecology in maintaining global balance, self-educate, assume individual responsibilities, and adhere to protective and preventive measures without compromise.

Furthermore, finding real alternatives, such as biodegradable plastics, that are environmentally friendly or developing new technologies to completely break down hazardous substances into non-hazardous ones is necessary. The use of plastic should be restricted to situations where it is deemed highly necessary. However, it should not be considered a viable alternative to break it down into non-hazardous substances for the sake of natural environmental benefits.

Author Contributions

Conceptualization, A.D. and S.K.; methodology, T.K.S.; writing—review and editing, D.P.; validation, S.M.K.T., C.M. and R.K.; formal analysis, S.A.; investigation, S.M.K.T.; resources, S.A.; data curation, T.K.S.; writing—original draft preparation, S.K.; writing—review and editing, A.D. and R.K.; visualization, D.P.; supervision, C.M.; project administration, S.A. and R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The authors confirm that the data supporting the findings of this study are available within this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Andrady, A.L. Plastics and Environmental Sustainability; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Subramanian, K.; Krishnasamy, S.; Thiagamani, S.M.K.; Pradeepkumar, C.; Dhandapani, A.; Muthukumar, C.; Siengchin, S. Tribo Performance Analysis on Polymer-Based Composites. In Polymer-Based Composites; CRC Press: Boca Raton, FL, USA, 2021; pp. 115–130. [Google Scholar]

- Lambert, S. Environmental Risk of Polymer and Their Degradation Products. No. May, 1–198. 2013. Available online: http://etheses.whiterose.ac.uk/4194/ (accessed on 14 January 2024).

- Ojeda, T. Polymers and the Environment. In Polymer Science; InTech Open: London, UK, 2013; pp. 1–34. [Google Scholar] [CrossRef]

- Stanton, T.; Kay, P.; Johnson, M.; Chan, F.K.S.; Gomes, R.L.; Hughes, J.; Meredith, W.; Orr, H.G.; Snape, C.E.; Taylor, M.; et al. It’s the product not the polymer: Rethinking plastic pollution. Wiley Interdiscip. Rev. Water 2021, 8, e1490. [Google Scholar] [CrossRef]

- Schmaltz, E.; Melvin, E.C.; Diana, Z.; Gunady, E.F.; Rittschof, D.; Somarelli, J.A.; Virdin, J.; Dunphy-Daly, M.M. Plastic pollution solutions: Emerging technologies to prevent and collect marine plastic pollution. Environ. Int. 2020, 144, 106067. [Google Scholar] [CrossRef] [PubMed]

- Scott, G. Plastics packaging and coastal pollution. Int. J. Environ. Stud. 1972, 3, 35–36. [Google Scholar] [CrossRef]

- Scaffaro, R.; Citarrella, M.C.; Catania, A.; Settanni, L. Green composites based on biodegradable polymers and anchovy (Engraulis encrasicolus) waste suitable for 3D printing applications. Compos. Sci. Technol. 2022, 230, 109768. [Google Scholar] [CrossRef]

- Barandiaran, A.; Lascano, D.; Montanes, N.; Balart, R.; Selles, M.A.; Moreno, V. Improvement of the Ductility of Environmentally Friendly Poly(lactide) Composites with Posidonia oceanica Wastes Plasticized with an Ester of Cinnamic Acid. Polymers 2023, 15, 4534. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Gulino, E.F.; Alaimo, G.; Morreale, M. Green composites based on pla and agricultural or marine waste prepared by fdm. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Mirpoor, S.F.; Giosafatto, C.V.L.; Di Pierro, P.; Di Girolamo, R.; Regalado-González, C.; Porta, R. Valorisation of posidonia oceanica sea balls (Egagropili) as a potential source of reinforcement agents in protein-based biocomposites. Polymers 2020, 12, 2788. [Google Scholar] [CrossRef]

- Bai, Y.; Jin, W.-L. Marine Composite Materials and Structure. In Marine Structural Design; Butterworth-Heinemann: Oxford, UK, 2016; pp. 19–37. [Google Scholar] [CrossRef]

- Zawahid, M. A Conceptual Design of a Fibre Reinforced Plastic Fishing Boat for Traditional Fisheries in Malaysia; UNU-FTP: Reykjavík, Iceland, 2003; pp. 1–53. [Google Scholar]

- Andrady, A.; Fisher, M. Plastics and the Environment|Planète Énergies; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- National Oceanic and Atmospheric Administration U.S. Department of Commerce. Ocean Pollution and Marine Debris. Available online: https://www.noaa.gov/education/resource-collections/ocean-coasts/ocean-pollution (accessed on 1 July 2023).

- Kesle, S.E. Mineral supply and demand into the 21st century. In US Geological Survey Circular; Department of Geological Sciences, University of Michigan: Ann Arbor, MI, USA, 2007. [Google Scholar]

- Stein, R.S. Environmental aspects of polymer science and engineering. J. Plast. Film Sheeting 2015, 31, 355–362. [Google Scholar] [CrossRef]

- Dhandapani, A.; Krishnasamy, S.; Muthukumar, C.; Thiagamani, S.M.K.; Nagarajan, R.; Siengchin, S. Plastics in Marine Engineering. Encycl. Mater. Plast. Polym. 2022, 4, 225–236. [Google Scholar] [CrossRef]

- Ghazlan, A.; Ngo, T.D.; Tran, P. Three-dimensional Voronoi model of a nacre-mimetic composite structure under impulsive loading. Compos. Struct. 2016, 153, 278–296. [Google Scholar] [CrossRef]

- Aravind, D.; Senthilkumar, K.; Rajini, N.; Kumar, T.S.M.; Chandrasekar, M.; Ismail, S.O.; Yeetsorn, R.; Parameswaranpillai, J.; Siengchin, S.; Devi, M.I. Feasibility of elastomeric composites as alternative materials for marine applications: A compendious review on their properties and opportunities. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2022, 2022, 839–855. [Google Scholar] [CrossRef]

- Klust, G. Netting Materials for Fishing Gear, 2nd ed.; Wiley: Hoboken, NJ, USA, 1994. [Google Scholar]

- Available online: https://www.globalplasticsheeting.com/our-blog-resource-library/topic/polyethylene-and-polypropylene-101 (accessed on 5 August 2023).

- Polyamides. Available online: https://www.essentialchemicalindustry.org/polymers/polyamides.html (accessed on 5 July 2020).

- focus2.jpg (500 × 283). Available online: https://plasticsdecorating.com/images/022015/focus2.jpg (accessed on 5 July 2020).

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Tolinski, M. Foams Seek Sustainability. Plast. Eng. 2009, 65, 6–8. [Google Scholar] [CrossRef]

- Béland, S. High Performance Thermoplastic Resins and Their Composites; William Andrew Publishing: London, UK, 1990. [Google Scholar] [CrossRef]

- Tolinski, M. Plastics and Sustainability; Scrivener Publishing & Wiley: Beverly, MA, USA, 2012. [Google Scholar]

- Viel, T.; Manfra, L.; Zupo, V.; Libralato, G.; Cocca, M.; Costantini, M. Biodegradation of Plastics Induced by Marine Organisms: Future Perspectives for Bioremediation Approaches. Polymers 2023, 15, 2673. [Google Scholar] [CrossRef] [PubMed]

- Chamas, A.; Moon, H.; Zheng, J.; Qiu, Y.; Tabassum, T.; Jang, J.H.; Abu-Omar, M.; Scott, S.L.; Suh, S. Degradation Rates of Plastics in the Environment. ACS Sustain. Chem. Eng. 2020, 8, 3494–3511. [Google Scholar] [CrossRef]

- Civgin, F. Analysis of Composite Bars in Torsion; Graduate School of Natural and Applied Sciences, Dokuz Eylül University: Konak, Turkey, 2005; p. 141. [Google Scholar]

- Ratwani, M.M. Composite Materials and Sandwich Structures—A Primer. Rto-En-Avt 2010, 156, 1–16. [Google Scholar]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Damage mechanics and energy absorption capabilities of natural fiber reinforced elastomeric based bio composite for sacrificial structural applications. Def. Technol. 2021, 17, 161–176. [Google Scholar] [CrossRef]

- Dehnavi, F.N.; Safdari, M.; Abrinia, K.; Sheidaei, A.; Baniassadi, M. Numerical study of the conductive liquid metal elastomeric composites. Mater. Today Commun. 2020, 23, 100878. [Google Scholar] [CrossRef]

- Xu, C.; Cao, X.; Jiang, X.; Zeng, X.; Chen, Y. Preparation, structure and properties of dynamically vulcanized polypropylene/acrylonitrile butadiene rubber/zinc dimethacrylate ternary blend composites containing maleic anhydride grafted polypropylene. Polym. Test. 2013, 32, 507–515. [Google Scholar] [CrossRef]

- Ekşi, S.; Genel, K. Comparison of mechanical properties of unidirectional and woven carbon, glass and aramid fiber reinforced epoxy composites. Acta Phys. Pol. A 2017, 132, 879–882. [Google Scholar] [CrossRef]

- Dhandapani, A. Desirability of Tribo-Performance of Natural Based Thermoset and Thermoplastic Composites: A Concise Review. Appl. Sci. Eng. Prog. 2021, 14, 606–613. [Google Scholar] [CrossRef]

- Galanis, K. Hull Construction with Composite Materials for Ships over 100 m in length by. Ocean Eng. 2002, 1987, 1–119. [Google Scholar]

- Chukov, D.I.; Stepashkin, A.A.; Salimon, A.I.; Kaloshkin, S.D. Highly filled elastomeric matrix composites: Structure and property evolution at low temperature carbonization. Mater. Des. 2018, 156, 22–31. [Google Scholar] [CrossRef]

- Afshar, A.; Alkhader, M.; Korach, C.S.; Chiang, F.P. Synergistic effects of fatigue and marine environments on carbon fiber vinyl-ester composites. J. Eng. Mater. Technol. Trans. ASME 2015, 137, 1–8. [Google Scholar] [CrossRef]

- Altunsaray, E.; Neser, G.; Erbil, C.; Gürsel, K.T.; Ünsalan, D. Umweltbedingtes Dauerfestigkeitsverhalten knitterfreier, E-glasfaserverstärkter Polyester-Verbundwerkstoffe für maritime Anwendungen. Materwiss. Werksttech. 2012, 43, 1053–1058. [Google Scholar] [CrossRef]

- Stanier, D.C.; Ciambella, J.; Rahatekar, S.S. Fabrication and characterisation of short fibre reinforced elastomer composites for bending and twisting magnetic actuation. Compos. Part A Appl. Sci. Manuf. 2016, 91, 168–176. [Google Scholar] [CrossRef]

- Cerracchio, P.; Gherlone, M.; Di Sciuva, M.; Tessler, A. A novel approach for displacement and stress monitoring of sandwich structures based on the inverse Finite Element Method. Compos. Struct. 2015, 127, 69–76. [Google Scholar] [CrossRef]

- Marine Composites Market. Available online: https://www.factmr.com/report/marine-composites-market#:~:text=MarineCompositesMarketGrowthOutlook,US%244.8billionin2023 (accessed on 5 November 2023).

- Zini, E.; Scandola, M.; Zimniewska, M. Textile Composites—An Emerging Need of Engineering. Compos. Part B 2003, 6, 113–127. [Google Scholar] [CrossRef]

- Gu, J.; Liang, C.; Zhao, X.; Gan, B.; Qiu, H.; Guo, Y.; Yang, X.; Zhang, Q.; Wang, D.-Y. Highly thermally conductive flame-retardant epoxy nanocomposites with reduced ignitability and excellent electrical conductivities. Compos. Sci. Technol. 2017, 139, 83–89. [Google Scholar] [CrossRef]

- Araby, S.; Li, J.; Shi, G.; Ma, Z.; Ma, J. Graphene for flame-retarding elastomeric composite foams having strong interface. Compos. Part A Appl. Sci. Manuf. 2017, 101, 254–264. [Google Scholar] [CrossRef]

- Araby, S.; Wang, C.-H.; Wu, H.; Meng, Q.; Kuan, H.-C.; Kim, N.K.; Mouritz, A.; Ma, J. Development of flame-retarding elastomeric composites with high mechanical performance. Compos. Part A Appl. Sci. Manuf. 2018, 109, 257–266. [Google Scholar] [CrossRef]

- IUCN. Marine Plastics: What Is the Issue? Why Is This Important? What Can Be Done? International Union for Conservation of Nature. 2018. Available online: https://www.iucn.org/resources/issues-brief/marine-plastic-pollution (accessed on 14 January 2024).

- North, E.J.; Halden, R.U. Plastics and environmental health: The road ahead. Rev. Environ. Health 2013, 28, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Laist, D.W. Impacts of marine debris: Entanglement of marine life in marine debris including a comprehensive list of species with entanglement and ingestion records. In Marine Debris; Springer: Berlin/Heidelberg, Germany, 1997; pp. 99–139. [Google Scholar]

- Wolf, D. Zeehond Met Zwerfvuil. 2008. Available online: https://www.salkodewolf.nl/ (accessed on 30 November 2023).

- Bruin, D. Aanspoelen Bultrug Op De Vliehors; Vlieland, The Netherlands, 2004. [Google Scholar]

- McIlgorm, A.; Campbell, H.F.; Rule, M.J. The economic cost and control of marine debris damage in the Asia-Pacific region. Ocean Coast. Manag. 2011, 54, 643–651. [Google Scholar] [CrossRef]

- Johnson, A.; Salvador, G.; Kenney, J.; Robbins, J.; Kraus, S.; Landry, S.; Clapham, P. Fishing gear involved in entanglements of right and humpback whales. Mar. Mammal Sci. 2005, 21, 635–645. [Google Scholar] [CrossRef]

- Hammer, J.; Kraak, M.H.S.; Parsons, J.R. Plastics in the marine environment: The dark side of a modern gift. In Reviews of Environmental Contamination and Toxicology; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1–44. [Google Scholar]

- Derraik, J.G.B. The pollution of the marine environment by plastic debris: A review. Mar. Pollut. Bull. 2002, 44, 842–852. [Google Scholar] [CrossRef] [PubMed]

- Bergmann, M.; Gutow, L.; Klages, M. Marine Anthropogenic Litter; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–447. [Google Scholar] [CrossRef]

- Pawar, P.R.; Shirgaonkar, S.S.; Patil, R.B. Plastic marine debris: Sources, distribution and impacts on coastal and ocean biodiversity. Pencil Publ. Biol. Sci. 2016, 3, 40–54. [Google Scholar]

- EPA. Municipal Solid Waste Generation, Recycling, and Disposal in the United States: Facts and Figures for 2012; United States Environmental Protection Agency: Washington, DC, USA, 2014; pp. 1–13. [Google Scholar]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased Recyclable Polymers for Plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef] [PubMed]

- Neşer, G. Polymer based composites in marine use: History and future trends. Procedia Eng. 2017, 194, 19–24. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-Friendly Bio-Composites Using Natural Rubber (NR) Matrices and Natural Fiber Reinforcements; Woodhead Publishing: London, UK, 2014. [Google Scholar]

- Liang, S.L.; Cook, W.D.; Thouas, G.A.; Chen, Q.Z. The mechanical characteristics and in vitro biocompatibility of poly(glycerol sebacate)-Bioglass® elastomeric composites. Biomaterials 2010, 31, 8516–8529. [Google Scholar] [CrossRef]

- Sanetuntikul, J.; Ketpang, K.; Naknaen, P.; Narupai, B.; Petchwattana, N. A circular economy use of waste metalized plastic film as a reinforcing filler in recycled polypropylene packaging for injection molding applications. Clean. Eng. Technol. 2023, 17, 100683. [Google Scholar] [CrossRef]

- Jamnongkan, T.; Intraramongkol, N.; Samoechip, W.; Potiyaraj, P.; Mongkholrattanasit, R.; Jamnongkan, P.; Wongwachirakorn, P.; Sugimoto, M.; Ito, H.; Huang, C.-F. Towards a Circular Economy: Study of the Mechanical, Thermal, and Electrical Properties of Recycled Polypropylene and Their Composite Materials. Polymers 2022, 14, 5482. [Google Scholar] [CrossRef]

- Ugya, Y.A.; Chen, H.; Sheng, Y.; Ajibade, F.O.; Wang, Q. A review of microalgae biofilm as an eco-friendly approach to bioplastics, promoting environmental sustainability. Environ. Res. 2023, 236, 116833. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).