Rapid Waste Motor Oil Conversion into Diesel-Range Hydrocarbons Using Hydrochar as Catalyst: Kinetic Study and Product Characterization

Abstract

:1. Introduction

2. Results and Discussion

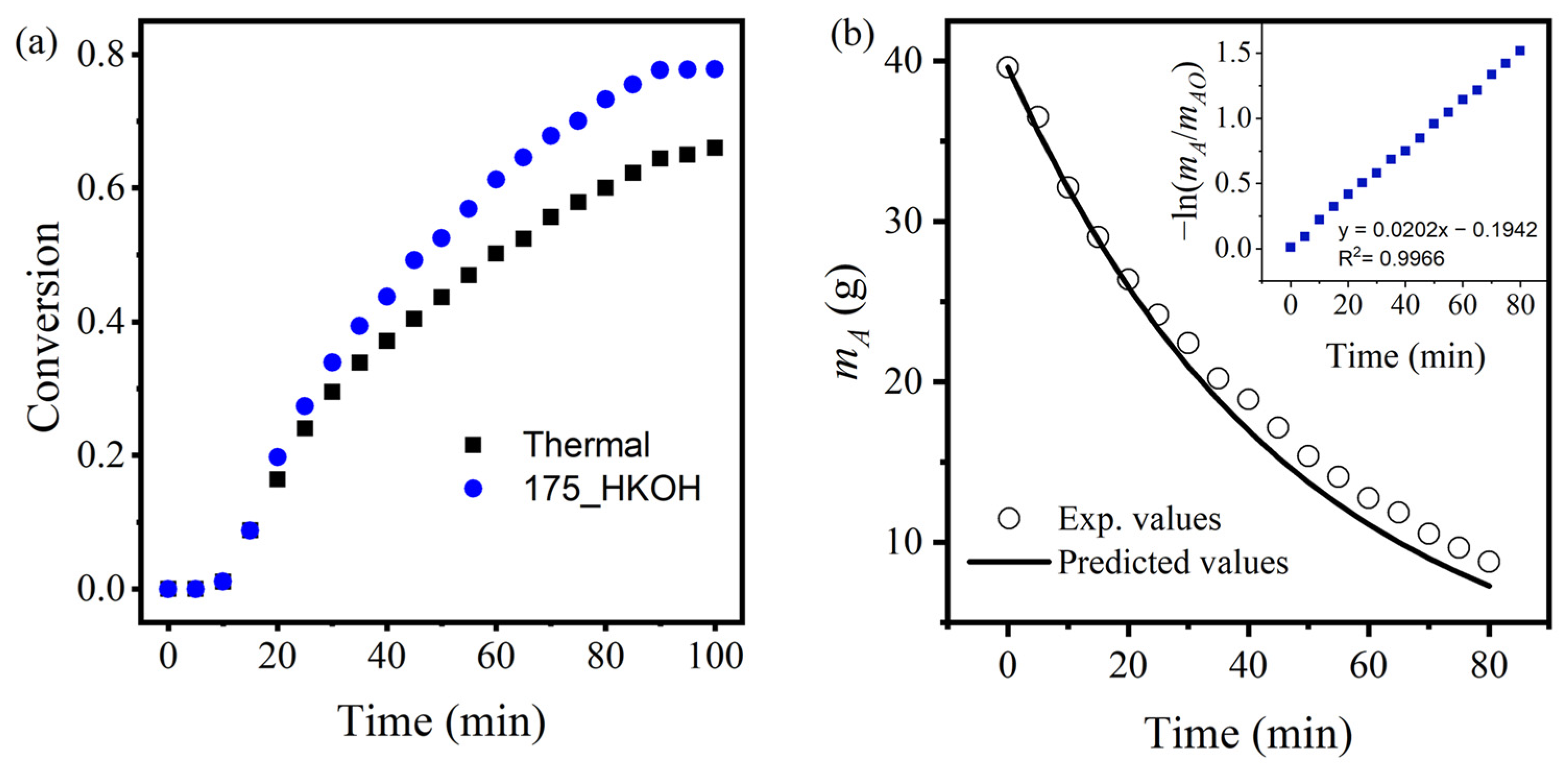

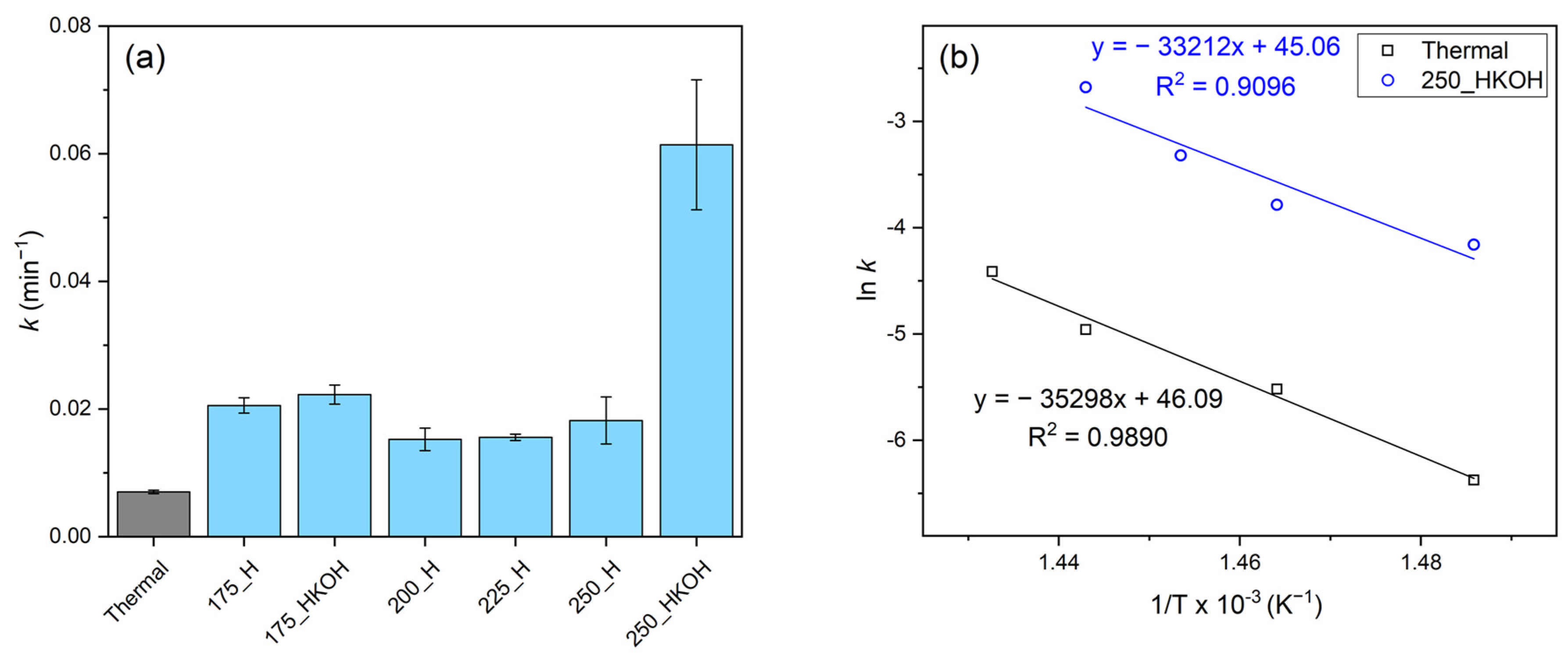

2.1. Catalytic Cracking of WMO and Kinetic Study

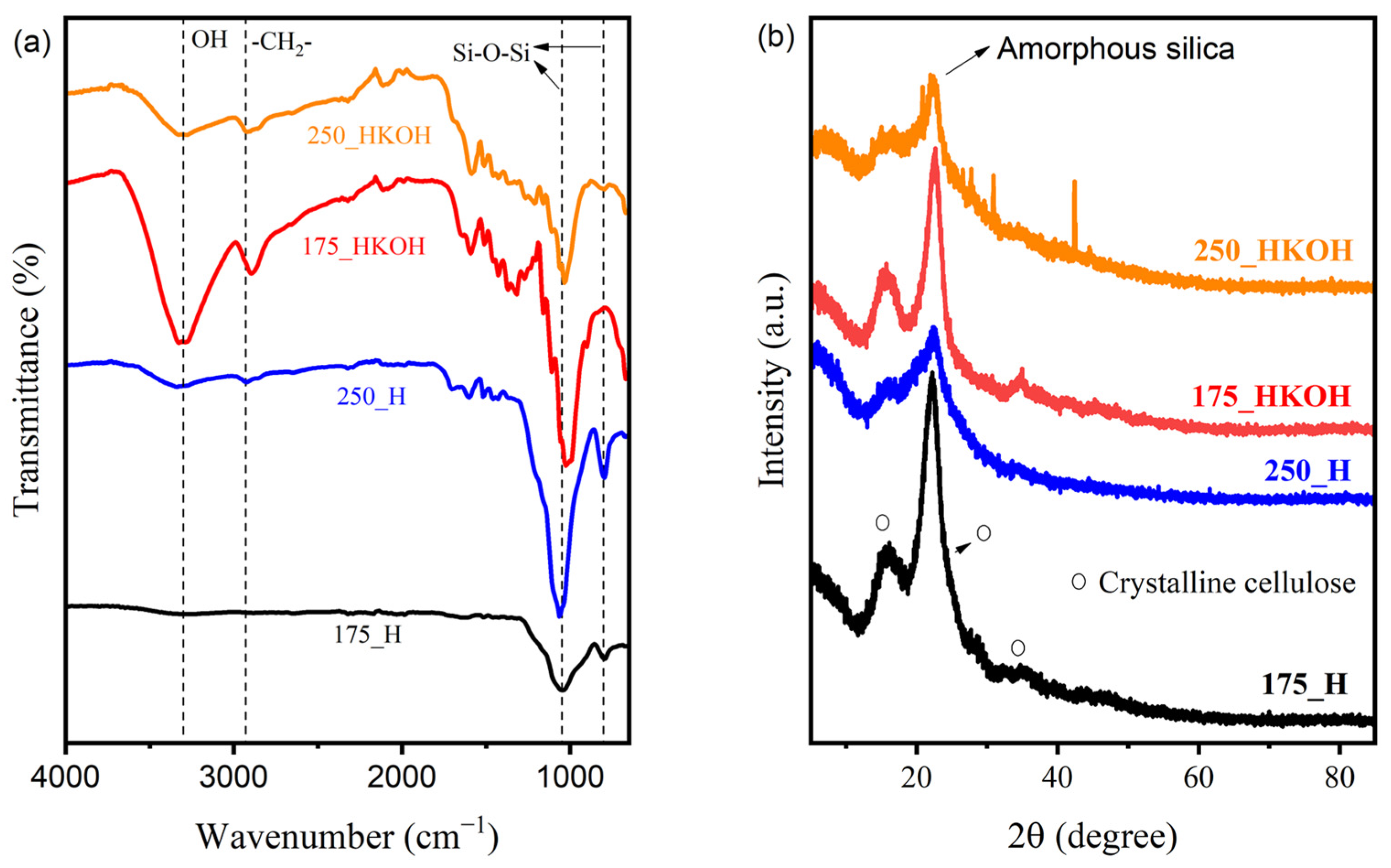

2.2. Hydrochar Catalyst Characterization

2.3. DLF Characterization

3. Materials and Methods

3.1. Hydrochar Preparation

3.2. Hydrochar Preparation and Alkali Treatment

3.3. Experimental Setup for Catalytic Cracking of WMO and Kinetic Analysis

3.4. Analytical Methods for Hydrochar and DLF Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Murillo, H.A.; Pagés-Díaz, J.; Díaz-Robles, L.A.; Vallejo, F.; Huiliñir, C. Valorization of Oat Husk by Hydrothermal Carbonization: Optimization of Process Parameters and Anaerobic Digestion of Spent Liquors. Bioresour. Technol. 2022, 343, 126112. [Google Scholar] [CrossRef]

- Xia, Y.; Yang, T.; Zhu, N.; Li, D.; Chen, Z.; Lang, Q.; Liu, Z.; Jiao, W. Enhanced Adsorption of Pb(II) onto Modified Hydrochar: Modeling and Mechanism Analysis. Bioresour. Technol. 2019, 288, 121593. [Google Scholar] [CrossRef] [PubMed]

- Masoumi, S.; Borugadda, V.B.; Nanda, S.; Dalai, A.K. Hydrochar: A Review on Its Production Technologies and Applications. Catalysts 2021, 11, 939. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, J.; Qian, J.; Zhao, Y.; Wang, T.; Zhai, Y. Biowaste Hydrothermal Carbonization for Hydrochar Valorization: Skeleton Structure, Conversion Pathways and Clean Biofuel Applications. Bioresour. Technol. 2021, 324, 124686. [Google Scholar] [CrossRef] [PubMed]

- Sulaiman, N.S.; Hashim, R.; Mohamad Amini, M.H.; Danish, M.; Sulaiman, O. Optimization of Activated Carbon Preparation from Cassava Stem Using Response Surface Methodology on Surface Area and Yield. J. Clean. Prod. 2018, 198, 1422–1430. [Google Scholar] [CrossRef]

- Shen, R.; Lu, J.; Yao, Z.; Zhao, L.; Wu, Y. The Hydrochar Activation and Biocrude Upgrading from Hydrothermal Treatment of Lignocellulosic Biomass. Bioresour. Technol. 2021, 342, 125914. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Ye, J.; Zhang, Y.; Chang, J. Preparation of Biomass Hydrochar Derived Sulfonated Catalysts and Their Catalytic Effects for 5-Hydroxymethylfurfural Production. RSC Adv. 2013, 3, 7360–7366. [Google Scholar] [CrossRef]

- Gai, C.; Zhang, F.; Guo, Y.; Peng, N.; Liu, T.; Lang, Q.; Xia, Y.; Liu, Z. Hydrochar-Supported, in Situ-Generated Nickel Nanoparticles for Sorption-Enhanced Catalytic Gasification of Sewage Sludge. ACS Sustain. Chem. Eng. 2017, 5, 7613–7622. [Google Scholar] [CrossRef]

- Norouzi, O.; Heidari, M.; Martinez, M.; Dutta, A. New Insights for the Future Design of Composites Composed of Hydrochar and Zeolite for Developing Advanced Biofuels from Cranberry Pomace. Energies 2020, 13, 6600. [Google Scholar] [CrossRef]

- Mishra, A.; Siddiqi, H.; Kumari, U.; Behera, I.D.; Mukherjee, S.; Meikap, B.C. Pyrolysis of Waste Lubricating Oil/Waste Motor Oil to Generate High-Grade Fuel Oil: A Comprehensive Review. Renew. Sustain. Energy Rev. 2021, 150, 111446. [Google Scholar] [CrossRef]

- Maceiras, R.; Alfonsín, V.; Morales, F.J. Recycling of Waste Engine Oil for Diesel Production. Waste Manag. 2017, 60, 351–356. [Google Scholar] [CrossRef]

- Sarkar, S.; Datta, D.; Deepak, K.S.; Mondal, B.K.; Das, B. Comprehensive Investigation of Various Re-Refining Technologies of Used Lubricating Oil: A Review. J. Mater. Cycles Waste Manag. 2023, 25, 1935–1965. [Google Scholar] [CrossRef]

- Tekin, K.; Ucar, S.; Karagöz, S. Influence of Co-Pyrolysis of Waste Tetra Pak with Waste Motor Oil on Product Distribution and Properties for Fuel Application. Energy Fuels 2019, 33, 11101–11112. [Google Scholar] [CrossRef]

- Almeida Streitwieser, D.; Arteaga, A.; Gallo-Cordova, A.; Hidrobo, A.; Ponce, S. Chemical Recycling of Used Motor Oil by Catalytic Cracking with Metal-Doped Aluminum Silicate Catalysts. Sustainability 2023, 15, 10522. [Google Scholar] [CrossRef]

- Vargas, D.C.; Alvarez, M.B.; Hidrobo Portilla, A.; Van Geem, K.M.; Almeida Streitwieser, D. Kinetic Study of the Thermal and Catalytic Cracking of Waste Motor Oil to Diesel-like Fuels. Energy Fuels 2016, 30, 9712–9720. [Google Scholar] [CrossRef]

- Rodriguez, Y.; Guerra, R.; Vizuete, K.; Debut, A.; Streitwieser, D.A.; Mora, J.R.; Ponce, S. Kinetic Study of the Catalytic Cracking of Waste Motor Oil Using Biomass-Derived Heterogeneous Catalysts. Waste Manag. 2023, 167, 46–54. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhao, P.; Li, T.; Lei, M.; Yan, W.; Ge, S. Pyrolysis Behavior of Hydrochar from Hydrothermal Carbonization of Pinewood Sawdust. J. Anal. Appl. Pyrolysis 2020, 146, 104771. [Google Scholar] [CrossRef]

- Xiao, L.-P.; Shi, Z.-J.; Xu, F.; Sun, R.-C. Hydrothermal Carbonization of Lignocellulosic Biomass. Bioresour. Technol. 2012, 118, 619–623. [Google Scholar] [CrossRef]

- Hu, X.; Xu, J.; Wu, M.; Xing, J.; Bi, W.; Wang, K.; Ma, J.; Liu, X. Effects of Biomass Pre-Pyrolysis and Pyrolysis Temperature on Magnetic Biochar Properties. J. Anal. Appl. Pyrolysis 2017, 127, 196–202. [Google Scholar] [CrossRef]

- Yang, L.; Shuang, E.; Liu, J.; Sheng, K.; Zhang, X. Endogenous Calcium Enriched Hydrochar Catalyst Derived from Water Hyacinth for Glucose Isomerization. Sci. Total Environ. 2022, 807, 150660. [Google Scholar] [CrossRef]

- Alfredo Quevedo-Amador, R.; Elizabeth Reynel-Avila, H.; Ileana Mendoza-Castillo, D.; Badawi, M.; Bonilla-Petriciolet, A. Functionalized Hydrochar-Based Catalysts for Biodiesel Production via Oil Transesterification: Optimum Preparation Conditions and Performance Assessment. Fuel 2022, 312, 122731. [Google Scholar] [CrossRef]

- Safari, F.; Javani, N.; Yumurtaci, Z. Hydrogen Production via Supercritical Water Gasification of Almond Shell over Algal and Agricultural Hydrochars as Catalysts. Int. J. Hydrogen Energy 2018, 43, 1071–1080. [Google Scholar] [CrossRef]

- Meng, S.; Li, W.; Xu, H.; Li, Z.; Li, Y.; Jarvis, J.; Song, H. Non-Thermal Plasma Assisted Catalytic Reforming of Naphtha and Its Model Compounds with Methane at near Ambient Conditions. Appl. Catal. B 2021, 297, 120459. [Google Scholar] [CrossRef]

- Ardila-Suárez, C.; Pablo Villegas, J.; Lins de Barros Neto, E.; Ghislain, T.; Lavoie, J.-M. Waste Surgical Masks to Fuels via Thermochemical Co-Processing with Waste Motor Oil and Biomass. Bioresour. Technol. 2022, 348, 126798. [Google Scholar] [CrossRef] [PubMed]

- Rimez, B.; Breyer, S.; Vekemans, O.; Haut, B. Co-Pyrolysis of Low-Density Polyethylene and Motor Oil—Investigation of the Chemical Interactions between the Components. Recycling 2020, 5, 33. [Google Scholar] [CrossRef]

- Li, Y.; Hagos, F.M.; Chen, R.; Qian, H.; Mo, C.; Di, J.; Gai, X.; Yang, R.; Pan, G.; Shan, S. Rice Husk Hydrochars from Metal Chloride-Assisted Hydrothermal Carbonization as Biosorbents of Organics from Aqueous Solution. Bioresour. Bioprocess. 2021, 8, 99. [Google Scholar] [CrossRef] [PubMed]

- Teng, F.; Zhang, Y.; Wang, D.; Shen, M.; Hu, D. Iron-Modified Rice Husk Hydrochar and Its Immobilization Effect for Pb and Sb in Contaminated Soil. J. Hazard. Mater. 2020, 398, 122977. [Google Scholar] [CrossRef]

- Naranjo, J.; Juiña, E.; Loyo, C.; Romero, M.; Vizuete, K.; Debut, A.; Ponce, S.; Murillo, H.A. Preparation of Adsorbent Materials from Rice Husk via Hydrothermal Carbonization: Optimization of Operating Conditions and Alkali Activation. Resources 2023, 12, 145. [Google Scholar] [CrossRef]

- Wathakit, K.; Sukjit, E.; Kaewbuddee, C.; Maithomklang, S.; Klinkaew, N.; Liplap, P.; Arjharn, W.; Srisertpol, J. Characterization and Impact of Waste Plastic Oil in a Variable Compression Ratio Diesel Engine. Energies 2021, 14, 2230. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Pan, Z. A Comprehensive Study of Fuel Composition, Combustion and Soot Nanostructure Characteristics of a Diesel/Light Hydrocarbons Premixed Charge Compression Ignition Engine. Fuel 2020, 274, 117858. [Google Scholar] [CrossRef]

- Ying, W.; Longbao, Z.; Hewu, W. Diesel Emission Improvements by the Use of Oxygenated DME/Diesel Blend Fuels. Atmos. Environ. 2006, 40, 2313–2320. [Google Scholar] [CrossRef]

- ASTM D4809-18; Standard Test Method for Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb Calorimeter (Precision Method). American Society for Testing Materials: West Conshohocken, PA, USA, 2018.

| Catalyst | Conversion (%) | k (min−1) | krel |

|---|---|---|---|

| Thermal cracking (without catalyst) | 66.85 ± 1.78 | 0.0088 ± 2.8 × 10−4 | 1.00 |

| 175_H | 75.79 ± 2.46 | 0.0206 ± 1.2 × 10−3 | 2.34 |

| 175_HKOH | 74.96 ± 3.84 | 0.0223 ± 1.5 × 10−3 | 2.53 |

| 200_H | 73.69 ± 0.84 | 0.0153 ± 1.8 × 10−3 | 1.74 |

| 225_H | 74.02 ± 6.44 | 0.0156 ± 4.9 × 10−4 | 1.77 |

| 250_H | 73.41 ± 7.16 | 0.0182 ± 3.7 × 10−3 | 2.07 |

| 250_HKOH | 80.41 ± 6.61 | 0.0614 ± 1.01 × 10−2 | 6.98 |

| Al/Si + Zn * | 84 | 0.0159 | 1.8 |

| RH-KOH * | 86 | 0.0249 | 2.8 |

| Kinetic Parameters | |||||

|---|---|---|---|---|---|

| Catalyst | Temperature (°C) | k (min−1) | k0 (min−1) | (kJ mol−1) | |

| Thermal cracking (without catalyst) | 400 | 0.0017 ± 1.4 × 10−4 | 1.04 × 1020 | 293.48 | 0.9890 |

| 410 | 0.0040 ± 4.6 × 10−4 | ||||

| 420 | 0.0070 ± 4.2 × 10−4 | ||||

| 425 | 0.0121 ± 2.0 × 10−4 | ||||

| 250_HKOH | 400 | 0.0156 ± 8.5 × 10−4 | 3.69 × 1019 | 276.12 | 0.9096 |

| 410 | 0.0227 ± 4.4 × 10−3 | ||||

| 415 | 0.0361 ± 7.8 × 10−4 | ||||

| 420 | 0.0686 ± 4.2 × 10−3 | ||||

| Recycling Method | Feedstock | Conditions | Target Product | Kinetic Constant (min−1) | Ref. |

|---|---|---|---|---|---|

| Co-pyrolysis | WMO + Tetra pack | 500 °C | Diesel | NA | [13] |

| Fixed bed reactor | |||||

| Co-pyrolysis | WMO + Surgical mask/Woody biomass | 400 °C | Diesel | NA | [24] |

| Batch reactor | |||||

| Gasification | WMO | 800–1200 °C | Syngas | NA | [10] |

| Co-pyrolysis | LDPE | 650 °C | Diesel | NA | [25] |

| Catalytic cracking | WMO + AlSi-Zn catalyst | 420 °C | Diesel | 0.0159 | [15] |

| Catalytic cracking | WMO + alkali-biochar catalyst | 420 °C | Diesel | 0.0249 | [16] |

| Catalytic cracking | WMO + 250H_KOH catalyst | 420 °C | Diesel | 0.0614 | This study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Murillo, H.A.; Juiña, E.; Vizuete, K.; Debut, A.; Echeverría, D.; Taco-Vasquez, S.; Ponce, S. Rapid Waste Motor Oil Conversion into Diesel-Range Hydrocarbons Using Hydrochar as Catalyst: Kinetic Study and Product Characterization. Recycling 2024, 9, 39. https://doi.org/10.3390/recycling9030039

Murillo HA, Juiña E, Vizuete K, Debut A, Echeverría D, Taco-Vasquez S, Ponce S. Rapid Waste Motor Oil Conversion into Diesel-Range Hydrocarbons Using Hydrochar as Catalyst: Kinetic Study and Product Characterization. Recycling. 2024; 9(3):39. https://doi.org/10.3390/recycling9030039

Chicago/Turabian StyleMurillo, Herman A., Evelyn Juiña, Karla Vizuete, Alexis Debut, Daniel Echeverría, Sebastian Taco-Vasquez, and Sebastian Ponce. 2024. "Rapid Waste Motor Oil Conversion into Diesel-Range Hydrocarbons Using Hydrochar as Catalyst: Kinetic Study and Product Characterization" Recycling 9, no. 3: 39. https://doi.org/10.3390/recycling9030039

APA StyleMurillo, H. A., Juiña, E., Vizuete, K., Debut, A., Echeverría, D., Taco-Vasquez, S., & Ponce, S. (2024). Rapid Waste Motor Oil Conversion into Diesel-Range Hydrocarbons Using Hydrochar as Catalyst: Kinetic Study and Product Characterization. Recycling, 9(3), 39. https://doi.org/10.3390/recycling9030039