Abstract

The pollution of the environment by plastics is a global problem that is real and needs to be resolved urgently. The authors argue that banning the use of plastic is not a reasonable and rational solution for the problem because plastics have many useful applications. Solutions to the problem must involve developing scientific approaches as well as global efforts and strategies. The world’s approach needs to be guided by an economic model that eliminates or minimizes the amount of plastics in the waste stream. As long as most plastic materials are not made from a single polymer, then the idea of “recycling 100% of plastics” is so far an unrealistic solution. The development of biodegradable plastics is still far from being an effective solution because besides being expensive and having limitations in engineering applications when compared to petroleum-based ones, biodegradable plastics still require specific conditions for their biodegradation. Comprehensive studies on microplastic particles are needed, focusing mainly on the source of the particles, their distribution, transport, fate in different environments, and toxicological effects and mechanisms. Since plastic pollution is a global problem, its minimization will require an increased international cooperation platform and partnerships at a global level. While current technologies and strategies are not solving the environmental problem caused by waste plastic, the most effective solution would be to adopt the first two levels of the waste management hierarchy, which are “reduce” and “reuse”.

1. Introduction

Since the discovery, mass production, and commercialization of the first fully synthetic plastic in 1907 [1], plastic materials have brought numerous benefits to modern societies worldwide in more ways than one can imagine, having also provided innovative sustainable solutions for the various industrial segments. Plastics are regarded as one of the world’s greatest industrial innovations of the 21st century and they are an integral part of the daily life of human beings. They are gradually replacing traditional materials such as metals, ceramics, wood, concrete, glass, natural fibers, and paper in many applications. Plastics are present in various forms in means of transportation (e.g., planes, cars, ships, motorbikes, bicycles, etc.), in hospitals, homes, household utensils, furniture, computers, cellphones, clothes, electrical and electronic goods, as well as in the food supply chain (e.g., packaging) [2].

Given their important role in human life’s daily activities, plastic materials are the most widely produced and used when compared to other barrier materials. The global production of plastics has increased twenty-fold since the 1960s [3]. In 2022, for instance, the world registered a global plastic production of about 400.3 million t [4,5], and if this production trend continues, it is expected to double by 2035, and almost quadruple by 2050 [6,7]. The global explosion of plastic production and its massive use is driven by its remarkable combination of properties and characteristics. Its ease of processing (can be easily shaped into a wide variety of forms) and production, high strength-to-weight ratio, durability, light weight, chemical resistance, low permeability to liquids, high resistance to physical and chemical degradation, relatively low manufacturing cost, and odor free, are just some examples of such properties and characteristics [8].

Despite the recognized social benefits indicated above and its contribution to the growth of the world economy, the massive production of plastic and inappropriate disposal practices after its end of life are resulting in growing adverse effects on human health and the environment, including climate change, marine pollution, biodiversity, and chemical contamination [2], propelling these materials to the top of the international waste management agenda. Plastic pollution is one of the most pressing environmental and social challenges of the twenty-first century. In the last two decades, for example, it has become nearly impossible to go a single day without seeing or hearing negative news or a story about plastic materials, whether on television, radio, in print or electronic newspapers, or even on social media platforms that are available all over the world. Images of plastic materials floating in seas, oceans, lakes, and urban rivers; polluting beaches; flooding parks and gardens; blocking drainage ditches, gutters, and waterways; flooding landfills; polluting the land; frozen in polar ice; and harming wildlife are just some examples of more resounding pollution scenarios in the aforementioned media around the world [9,10].

The marine environment, therefore, appears to be the biggest destination for plastic waste. The United Nations Environment Programme (UNEP) has now recognized plastic materials as one of the most problematic pollutants affecting the oceans worldwide [11]. Some studies suggest that between 7 and 13 million metric t of plastic waste, which corresponds to about 3% of global plastic production, may be entering the oceans per year [12,13,14,15]. This amount, which accounts for over 80% of marine litter [13], is undoubtedly very large and is pointed out as being responsible for the death of 20–30% of marine life. If the global plastic production trend continues to grow in the current rhythm, the sea would have more plastics than fish and over 97% of the seabirds would have consumed them [4,16,17]. According to UNEP [18], at a global level, the damage and negative impacts to marine environments caused by plastic pollution are enormous, and this accounts for around USD 13 billion per year, which essentially includes losses incurred by fisheries and tourism due to plastic littering, as well as beach clean-up costs.

One of the major emerging concerns for the World Health Organization (WHO) regarding the plastic pollution issue is related to the possible negative effects on human health deriving from multiple exposures to plastic materials. Since most plastics are resistant to degradation, mainly the conventional petroleum-based ones, these materials can take half a century or a millennium to decompose, leaving behind adverse effects on ecosystems [12]. Thus, in the marine or other environments, plastic materials will break down into microplastics and occasionally nanoplastic particles [19]. Although still limited and somewhat inconclusive, preliminary findings of some studies have already pointed out microplastics and their associated contaminants, such as persistent organic pollutants, as potential sources of soil and freshwater contamination, including in tap and bottled water [6]. In the face of this stark reality, cries for help coming from environmental activists, the general public, politicians, governments, and civil society organizations to end plastic pollution have been heard all over the world. There is a global consensus that plastic pollution is a global problem and challenge, and thus, action must be taken urgently to protect the environment from further contamination.

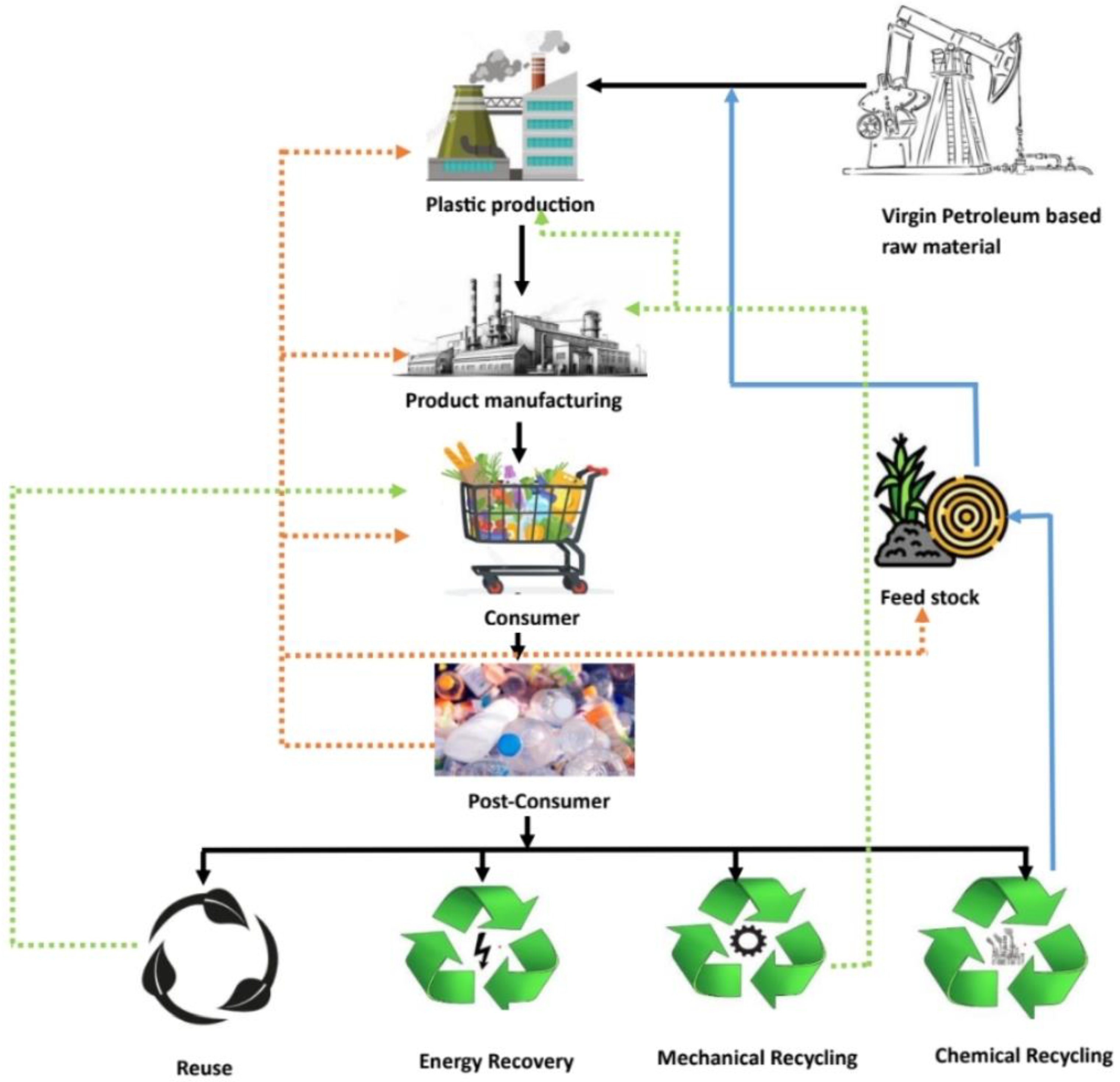

To minimize the problem, some countries at a global level have been carrying out a series of actions, which include the banning of single-use plastics or changing petroleum-based plastics to alternative, safer, and more sustainable and environmentally friendly products such as biodegradable plastics. Improving waste collection systems to ensure that, at the end of their life, plastics are appropriately collected and safely reprocessed or disposed of is also part of these actions. However, due to uncertainties about the effectiveness of the solutions mentioned here, most of them have often been received with some skepticism by businessmen, governments, or civil society, leaving many questions regarding the suitable solutions to be taken globally to successfully deal with the growing problem of plastic pollution. The skepticism is even greater for developing countries where policies/strategies, legal instruments, and infrastructure for waste management such as recycling are scarce or non-existent. Therefore, this review aims to provide an overview of the plastic material lifecycle, highlighting the benefits brought by plastics to humanity as well as the associated negative impacts on human health, the environment, and the economy if their wastes are not properly managed. Several successful and unsuccessful stories and interventions that are currently being employed for plastic waste management in several countries are shared in the paper. Similarly, a critical discussion is provided on current advances in technologies to produce plastic materials that are more sustainable and environmentally friendly than petroleum-based ones, including current challenges for the collection, sorting, and reprocessing of plastic waste. The emphasis, therefore, is given to plastic recycling processes and bio- and bio-degradable plastic production, as these have by far been seen as the most promising approaches to the plastic pollution problem that society is currently grappling with. Finally, possible solutions for sustainable plastic waste management are proposed.

Challenges and opportunities for plastic waste management have been reviewed in several papers [1,7,8,12,13,20,21,22,23,24,25,26,27,28]. However, most of them have focused on implementing the circular economy concept instead of the linear one. Other actions include reduction in material use through downgauging, product reuse, design for end-of-life recyclability, and revised risk assessment approaches; energy recovery as fuel; formulation of systems for the collection, sorting, and reprocessing of recyclable plastics; formulation of laws, policies, and regulations for plastic products; consumer information and education regarding the proper use of plastics; the role of international co-operation and trade; effective and innovative investments and incentive schemes; innovative solutions such as the introduction of biodegradable polymers and other alternatives, especially for packaging. The present review, in addition to reinforcing with new ideas a large part of the solutions highlighted by the articles mentioned above, has the merit of proposing concrete technological solutions that aim, for example, to increase current levels of recycling through advanced polymer processes such as co-injection molding and nanotechnology; improve the properties of biodegradable plastics using nanotechnology; convert recycled plastic into new products such as nanofoam, carbon nanotubes, synthetic fuels, and chemicals that can serve as raw material for other industries.

2. Methods

For the compilation and discussion of the relevant ideas that embody this article, several source materials and databases related to the topic were consulted. This included policy documents, government documents, reports, web pages, electronic books, electronic articles, and other related relevant documents. All materials related to the production of plastic materials, their consumption, challenges associated with plastic waste, health issues connected to plastic waste, plastic recycling, benefits of proper plastic waste management (socioeconomic and environmental), and mitigation measures were explored. The relevant documents considered in the present review were from 1947 to 2024, showing a rich balance between the fundamentals and the actuality on the topic. From this, a total of 415 documents were consulted and meticulously analyzed, of which only 219 were selected as support material to compose this review. From this analysis, discussion around the main challenges facing the world in terms of plastic waste management was provided. The emerging solutions and current practices for plastic waste management, including advances in technologies to produce alternative materials that are more sustainable and environmentally friendly than petroleum-based ones, are also discussed. Finally, possible solutions for sustainable plastic waste management are proposed.

3. Generalities about Plastics

3.1. Plastics and Polymers: What Is the Primary Difference?

Plastics are “polymeric materials that may contain other substances to improve performance and/or reduce costs”, according to the International Union of Pure and Applied Chemistry (IUPAC) [29]. Polymers are defined as long-chain chemical compounds with high molecular weights composed of a large number of smaller repeating units (monomers), which can be identical or of different types, and are joined together in a long chain by consecutive covalent bonds formed by various addition or condensation reactions [30]. Polymers are substances made from organic, synthetic, or natural macromolecules based on carbon, hydrogen, and other non-metallic elements like oxygen, nitrogen, and silicon. Synthetic polymers include adhesives, lubricants, paints, films, fibers, plastics, and rubber, whereas natural polymers include leather, silk, hemp, horn, cotton, wool, cellulose, wood, and natural rubber [31]. The term “polymer” is derived from the Greek prefix “poly”, which means “many”, and the suffix “-mer”, which means “parts”. Young and Lovell [32] define a polymer as a substance composed of molecules which have long sequences of one or more species of atoms or groups of atoms linked to each other by primary, usually covalent, bonds. The emphasis upon “substance” in this definition is to highlight that although the words polymer and macromolecule are used interchangeably, the latter strictly defines the molecules of which the former is composed. In addition to containing polymers, plastics may include additives such as colorants, antioxidants, stabilizers, and so forth. Plastics, often known as polymers due to their long-chained nature, are completely manmade materials that do not occur naturally. Some of the most well-known forms of plastic are polyethylene terephthalate (PET), vinyl, polyvinyl chloride (PVC), polypropylene (PP), and polycarbonates such as bisphenol A (BPA). This implies that all plastics are polymers; however, not all polymers are plastics. A plastic is thus a distinct sort of polymer.

3.2. Classification of Plastics According to Their Properties and Sources

The two primary types of plastic materials are thermoplastics and thermosetting plastics. Thermoplastics consist of tangled thread-like chain molecules. When heated to their melting point, thermoplastics soften into a liquid state, allowing them to be molded or reshaped repeatedly to fit a desired mold before hardening again as they cool. This process is reversible, which means that they may be warmed, remolded, and recycled repeatedly [8,33]. Polyethylene (PE), polyamide (PA), polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), ethylene vinyl alcohol (EVOH), styrene-acrylonitrile resin (SAN), polyether ether ketone (PEEK), polyoxymethylene (POM), expanded polystyrene (EPS), polyarylsulfone (PSU), polystyrene (PS), thermoplastic elastomers (TPE), polyethylene terephthalate (PET), polymethylmethacrylate (PMMA), polyvinylchloride (PVC), fluoropolymers, and polybutylene terephthalate (PBT) are just a few examples of plastics that fall into this category [3]. Thermosetting polymers, on the other hand, are a type of plastic that changes chemically when heated, forming a three-dimensional network with a high degree of crosslinking structure that severely limits chain mobility. They are stiff materials with all chains connected by covalent connections in a network; hence, thermosets cannot be reprocessed [30,31,32,33,34,35]. When molten, thermosetting polymers can be molded into the forms into which they were deposited before cooling, but they then harden permanently. If heated again, thermosets become brittle or disintegrate [8]. Polyurethane (PU), epoxy resins, vinyl esters, silicone, melamine resin, unsaturated polyesters, phenolic resins, urea-formaldehyde resins, acrylic resin, and phenol-formaldehyde resins are the most prevalent examples of this type of plastic [3].

Plastic materials may be divided into two categories based on their raw material origin: fossil-derived plastics and bio-derived plastics. Fossil-derived polymers are made from fossil fuels such as crude oil or petroleum hydrocarbons, gas, and, on occasion, coal. However, the majority of plastics in this category are manufactured from petroleum hydrocarbons, and this includes PE, PP, polyester, PVC, PS, nylon, acrylic, polytetrafluoroethylene (PTFE), and epoxy [36]. Bioplastics, on the other hand, are a type of plastic made from renewable resources such as sugar cane, maize starch, vegetable fats and oils, cellulose, straw, woodchips, recycled food waste, and so on, rather than petroleum [37,38,39,40,41,42,43,44,45,46]. Important examples of polymers in this family include polyamide-11, polyamide-12, dimer fatty acid polyamide, polylactic acid, and polyaniline. It is vital to highlight that bioplastics and biodegradable plastics are not interchangeable. Biodegradable plastics, also known as compostable or edible plastics, are materials whose physical and chemical properties deteriorate and completely degrade when exposed to microorganisms through carbon dioxide (aerobic) processes, methane (anaerobic processes), or water (aerobic and anaerobic processes). The word “biodegradability” of a plastic refers to the ability of bacteria and fungi to metabolize its chemical structure and convert it into shorter polymer segments. Bioplastics, on the other hand, can be biodegradable (e.g., polylactic acid) or non-degradable (e.g., biopolyethylene); however, not all biodegradable plastics are bio-based. Polycaprolactone (PCL) and poly (butylene succinate-PBS) are two excellent examples of biodegradable polymers that are petroleum-based [46,47].

4. World Plastic Production

Plastic materials have been transforming modern societies and the global economy since Bakelite, the first synthetic plastic, that was commercially produced in 1907. Plastics are an integral and important part of the daily life of human beings. Today, it is almost impossible to live without plastic. Owing to the combination of good characteristics and properties such as low production cost, versatility, light weight, affordability, corrosion resistance, durability, and high strength-to-weight ratio, plastic materials are increasingly being demanded in numerous uses and industrial applications such as the packaging, construction, transportation, healthcare, and electronics sectors [7,28,48]. As a result of this demand, in recent decades, the global production and consumption of plastic materials have witnessed an exponential increase never seen before.

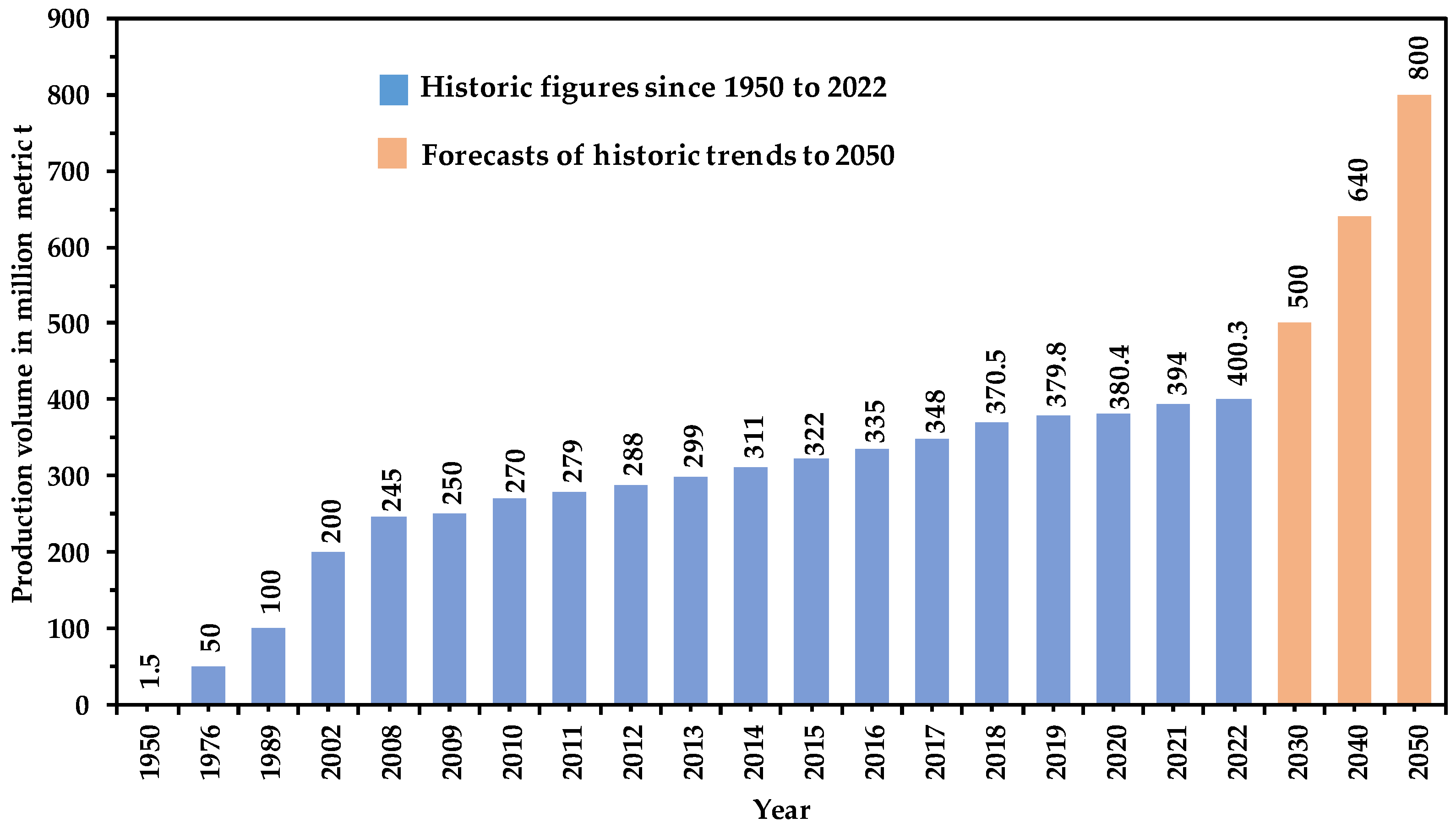

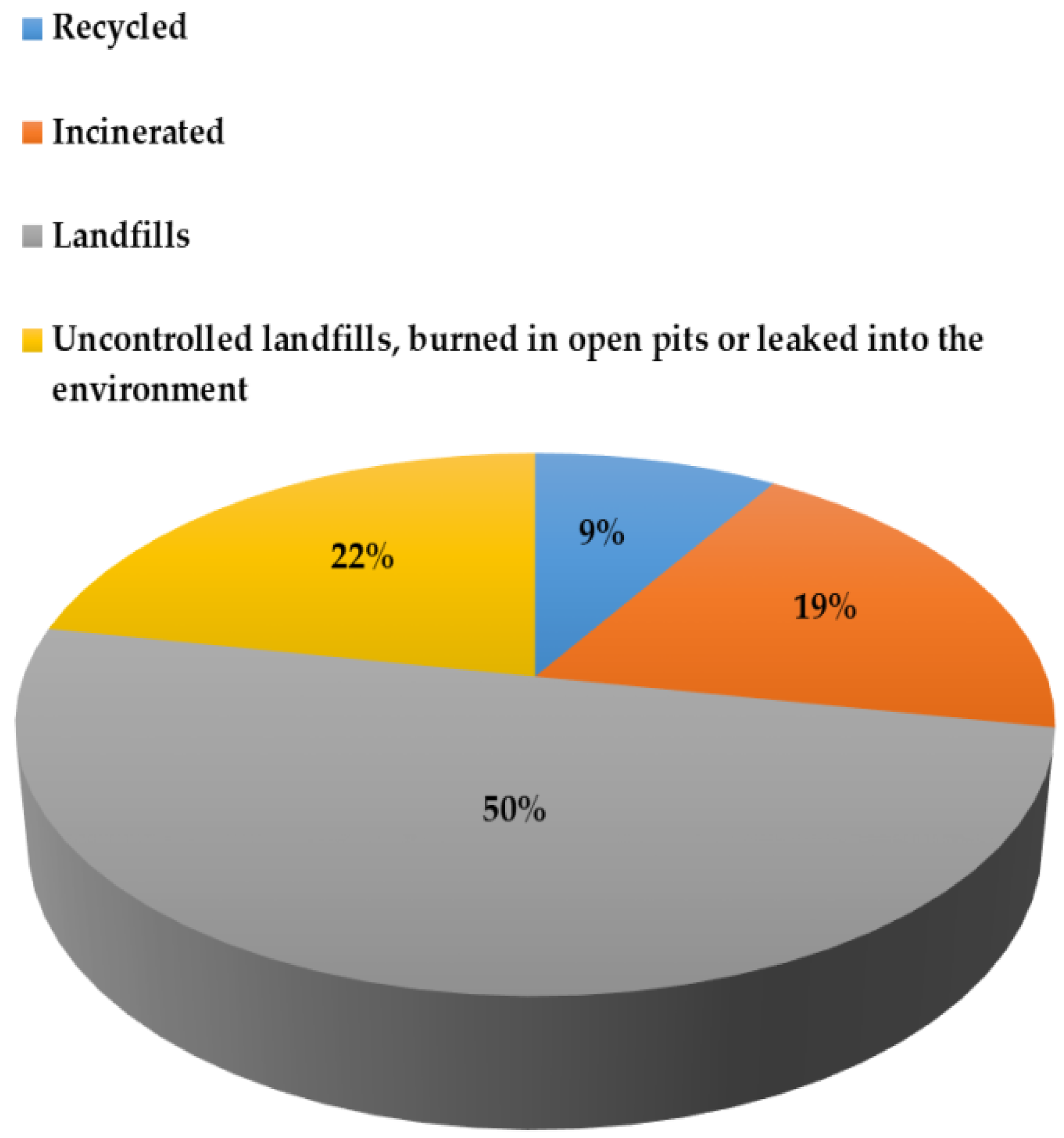

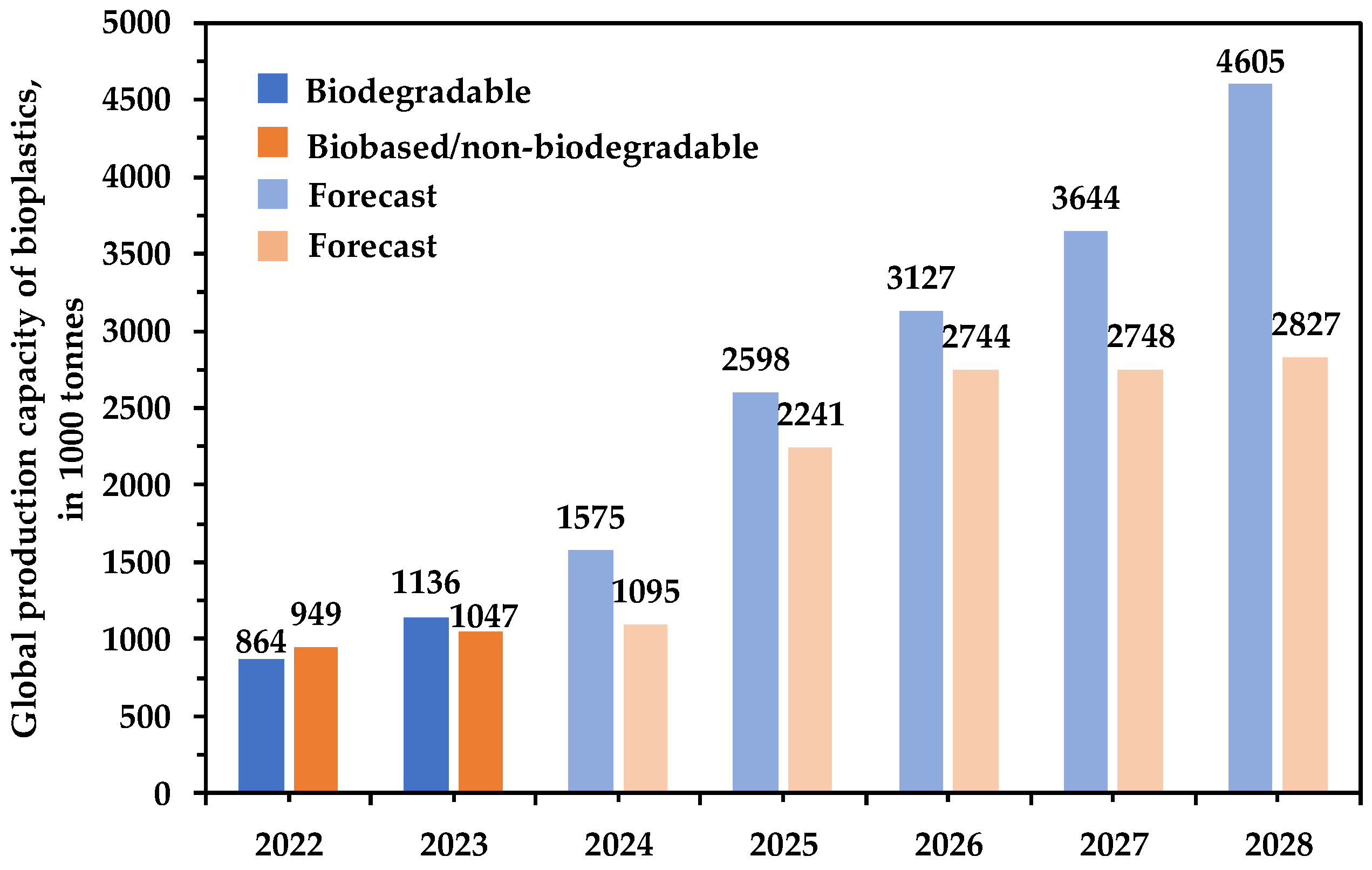

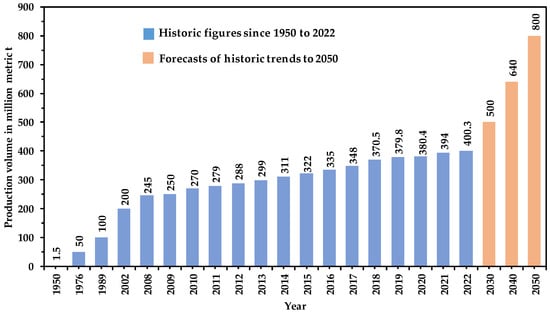

Figure 1 shows the cumulative plastic production (in million metric t) from 1950 to 2022. The global production of plastics has increased twentyfold since the 1960s. In 2022, for instance, the amount of plastics produced worldwide reached 400.3 million metric t [3,49]. It should be noted that about 40% of the amount of plastic materials produced and used globally are single-use plastics [2]. The drop in oil price, especially after World War II, may justify the significant increase in global production when compared to the other materials [1].

Figure 1.

Cumulative plastic production in million metric t. Source: authors’ own elaboration based on data obtained from references [4,7,50].

Experts indicate that plastic production will continue to increase and if the actual trend continues, the cumulative production worldwide could reach 500, 640, and 800 million metric t, respectively, in 2030, 2040, and 2050, as show in Figure 1 [6,7]. For the first time in the plastic industry’s history, the production in 2020 recorded a minimum growth of around 0.6 million metric t, a resounding growth in the order of 0.16% compared to the production volumes recorded in 2019. The rising energy costs and restrictions imposed by the COVID-19 pandemic that plagued the world since December 2019 are pointed out by experts as being the main factors behind this situation. Despite the timing of the COVID-19 pandemic, in 2021, the production registered an increase, having reached 394 million metric t, the equivalent of almost 3.6% when compared to the year 2020. This increase may be related to the huge demand for plastic-based products and devices during the COVID-19 pandemic outbreak, such as life-saving medical devices, face masks, plastic screens, food and product packaging in supermarkets and restaurants, etc. With the reduction in the adverse effects of the COVID-19 pandemic, an increase in production rates was expected in 2022. However, it was all an illusion, as production dropped by almost half when compared to 2021 production, as shown in Figure 1. The supply chain issues, as a result of the ongoing war in Ukraine, which started in February 2022, appear to have had a direct impact on the production of plastics.

4.1. Plastic Production by Regions of the World

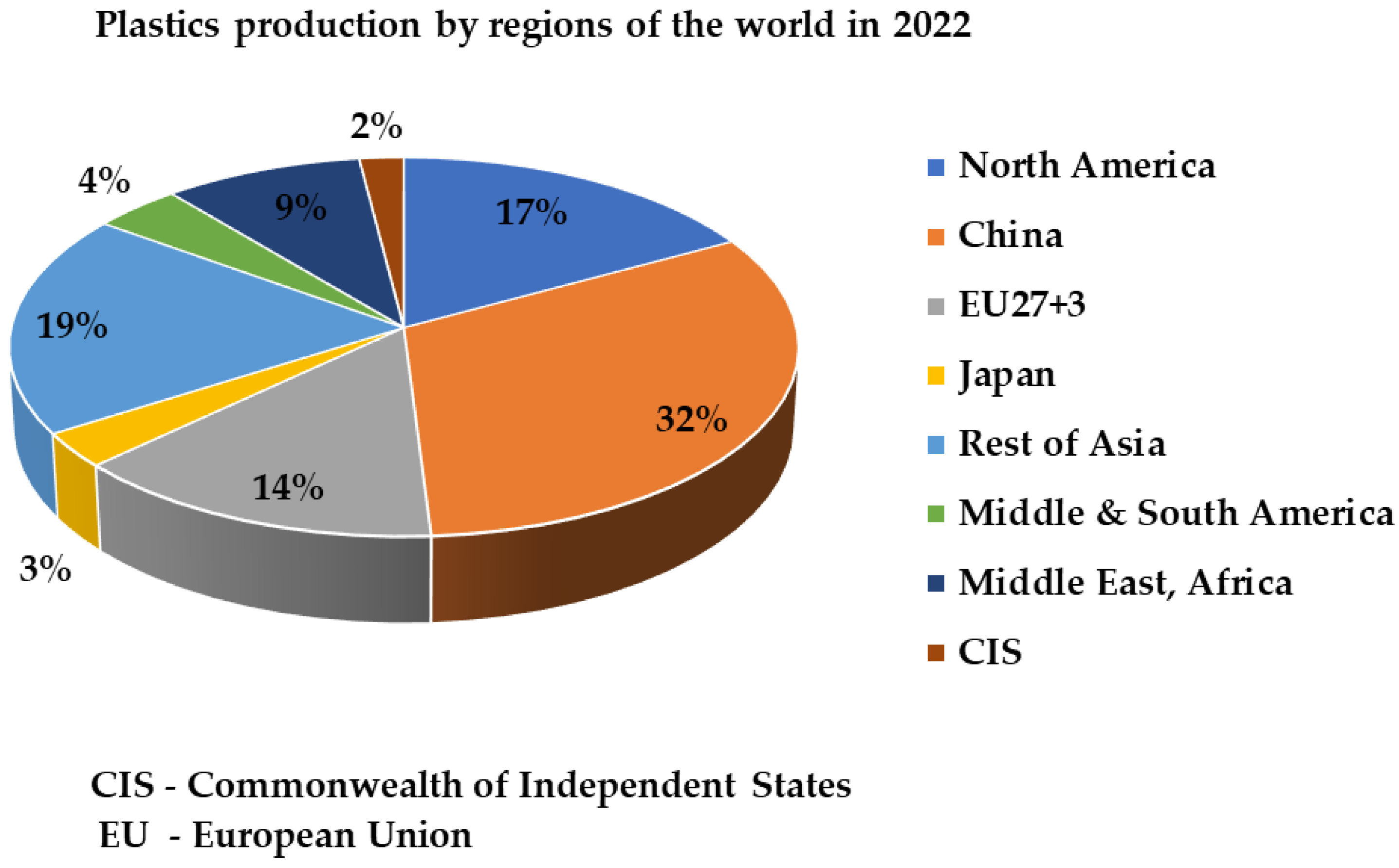

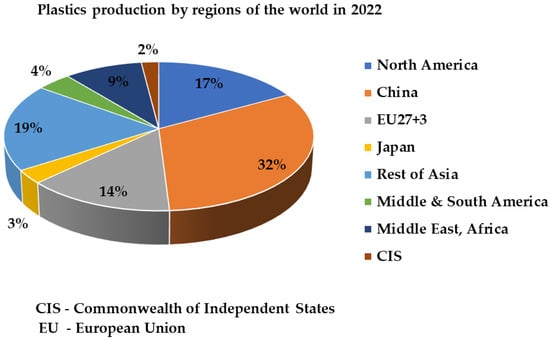

In the past, plastics were mostly produced in Europe and the United States (North American Free Trade Agreement—NAFTA). However, the scenario has now shifted to the Asian continent. In 2018, for instance, Asia produced the equivalent of 51%, i.e., more than half of global production, with China leading the production with 30%, while the rest of Asia, including Japan, produced 21%. In the same year, Europe and NAFTA were on a similar level, each with a production of around 17% and 18%, respectively. The remaining portion belonged to the Commonwealth of Independent States (CIS), Latin America, the Middle East, and Africa, with 3%, 4%, and 7%, respectively [3].

Figure 2 shows the global plastic production by regions of the world in 2022. As can be seen, the trend continued. The Asian continent produced the equivalent of 54%, an increase in the order of 3% compared to 2018. China once again led production, having alone reached 32%, 2% more than in 2018, while the rest of Asia, including Japan, produced 22%. EU and North America recorded reductions in production, each with 14% and 17%, reductions of around 3% and 1%, respectively, compared to 2018. The remaining production belonged to the Commonwealth of Independent States (CIS), Middle and South America, the Middle East, and Africa, with 2%, 4%, and 9%, respectively [50].

Figure 2.

Global plastic production by regions of the world in 2022. The data reported here includes fossil-based, recycled (mechanically and chemically), bio-based, and bio-attributed plastics. Source: authors’ own elaboration based on data obtained from references [50].

The key plastic companies that collectively hold the largest market share include [51] BASF SE, Ludwigshafen (Germany), SABIC, Riyadh (Saudi Arabia), Dow, Inc., Midland, MI (USA), DuPont, Wilmington, DE (USA), Evonik Industries AG, Essen, North Rhine-Westphalia (Germany), Sumitomo Chemical Co., Ltd., Tokyo (Japan), Arkema, Colombes (France), Celanese Corporation, Irving, TX (USA), Eastman Chemical Company, Kingsport, TN (USA), Chevron Phillips Chemical Co., LLC, The Woodlands, TX (USA), Lotte Chemical Corporation, Seoul (Republic of Korea), Exxon Mobil Corporation, Spring, TX (USA), Formosa Plastics Corporation, Livingston, NJ (USA), Covestro AG, Leverkusen (Germany), Toray Industries, Inc., Tokyo (Japan), Mitsui & Co. Plastics Ltd., Tokyo (Japan), Teijin Limited, Tokyo (Japan), INEOS Group, London (UK), Eni S.p.A., Rome (Italy), LG Chem, Seoul (Republic of Korea), LANXESS, Cologne (Germany), CHIMEI, Tainan (Taiwan), Huntsman International LLC, The Woodlands, TX (USA), Chevron Phillips Chemical Co., LLC, The Woodlands, TX (USA), LyondellBasell Industries Holdings B.V., Houston, TX (USA) and London (UK) and RTP Company, Winona, MN (USA). As can be seen, USA companies dominate the list.

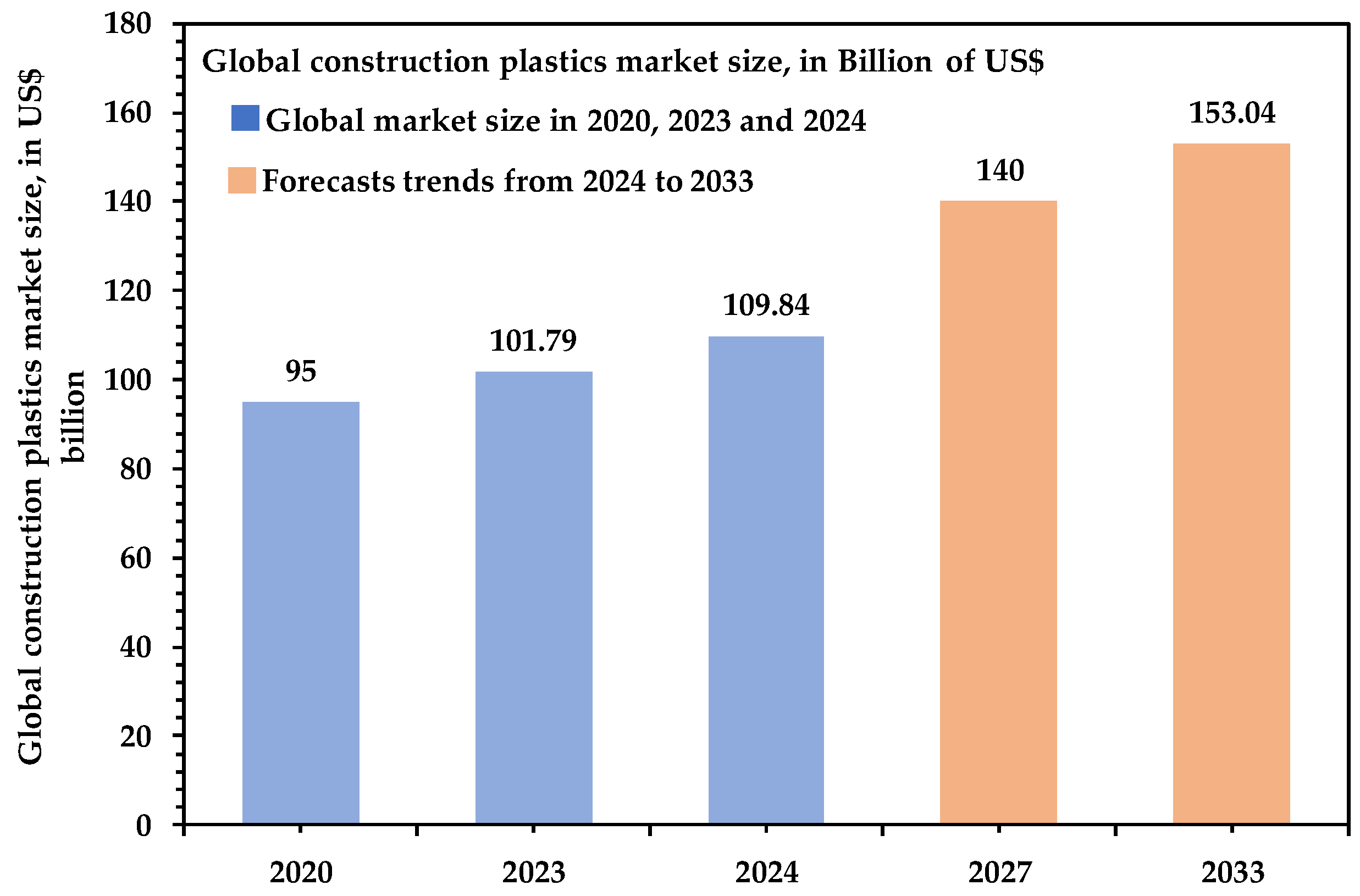

4.2. Global Plastic Market Size

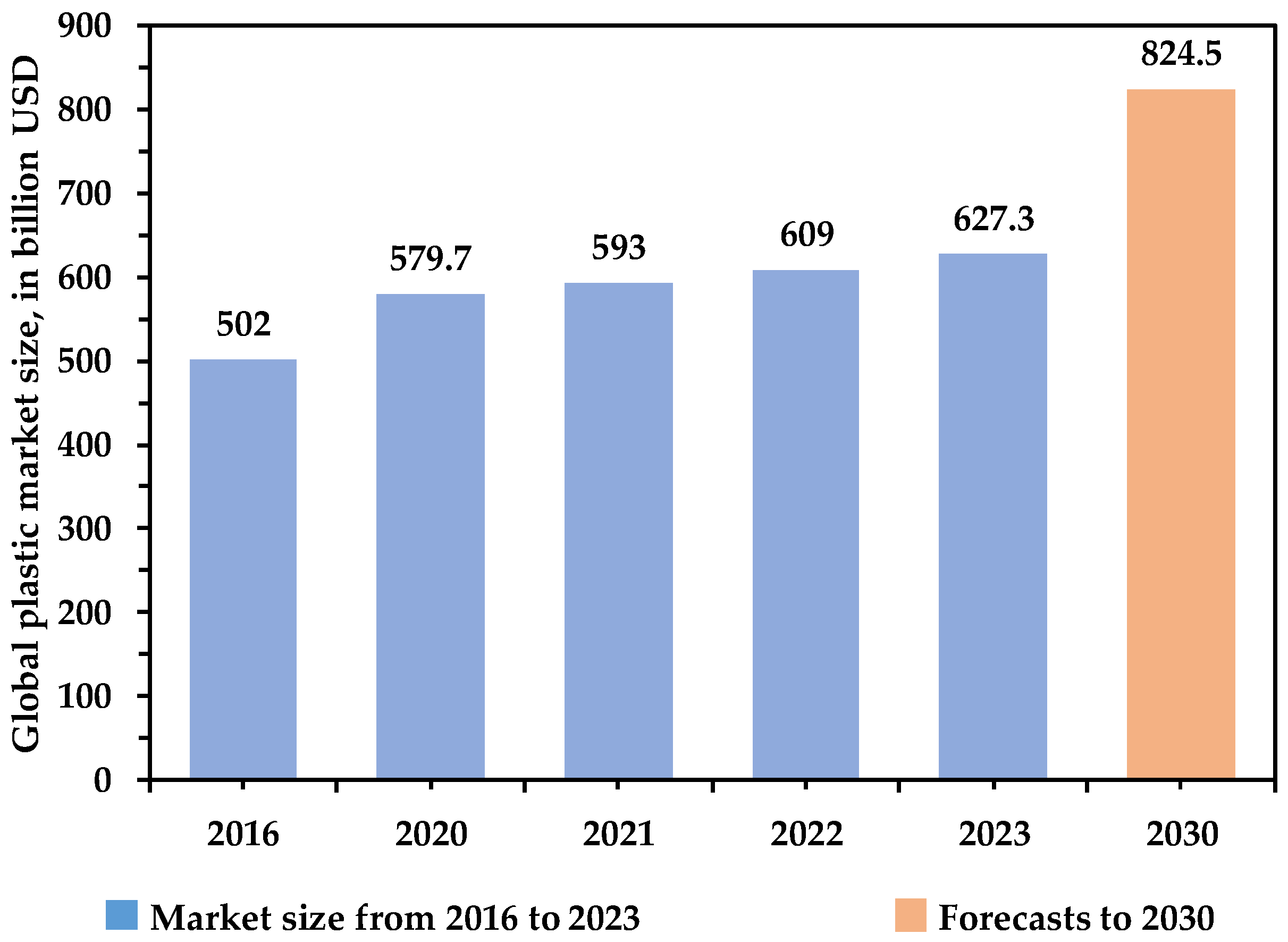

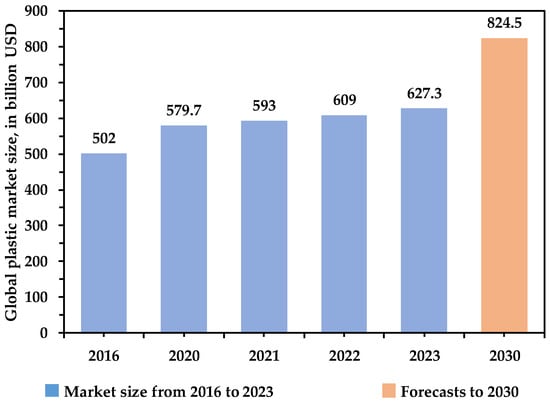

Figure 3 shows the global plastic market size in the period between 2016 and 2023.

Figure 3.

Global plastic market size (in billion USD), taking into account a regional context, covering regions such as North America, Europe, East Asia (China), Asia Pacific excluding China, Caribbean, Central and South America, Middle East and Africa (blue bars indicate the historic figures in 2016 and 2023; orange bars indicate the forecasts of historic trends to 2030). Source: authors’ own elaboration based on data obtained from reference [4,51].

The global plastic market size increased from approximately USD 502 billion in 2016 to USD 579.7 billion in 2020, representing a growth of about 15%. From 2020 to 2022, the market registered a slowdown, as growth was no more than 2%. The impact of COVID-19 and the ongoing war in Ukraine may also have negatively affected the market. In the post-COVID-19 period, the market increased sharply, having recorded a growth of around 3% in 2023 when compared to 2022. The figure is expected to increase to a value more than USD 824 billion by 2030, at a compound annual growth rate (CAGR) of 4.0% from 2023. In the regional context, similar to global plastic production, the Asian continent dominated the plastic market, having accounted for over 45.2% share of the global revenue in 2022, leaving behind regions such as North America, Europe, Caribbean, Central and South America, Middle East and Africa [4,51].

In terms of end-use segment, packaging, construction, consumer goods, automotive, electrical and electronics, utility, agriculture, medical devices, and furniture and bedding are the segments with the most market demand in 2022 compared to other segments. Meanwhile, the packaging end-use segment held the largest market share, having accounted for more than 36.3% in terms of revenue, while polyethylene (high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE)) was the most sought-after polymer, having recorded a market share of more than 25.3%. The large proportion of the packaging sector in the global plastics market may explain the greater demand for polyethylene. Polyethylene is the most used polymer in the sector for the production, for example, of containers and bottles, plastic bags, plastic films, geomembranes, etc. [51].

5. Plastic Waste Generation Profile

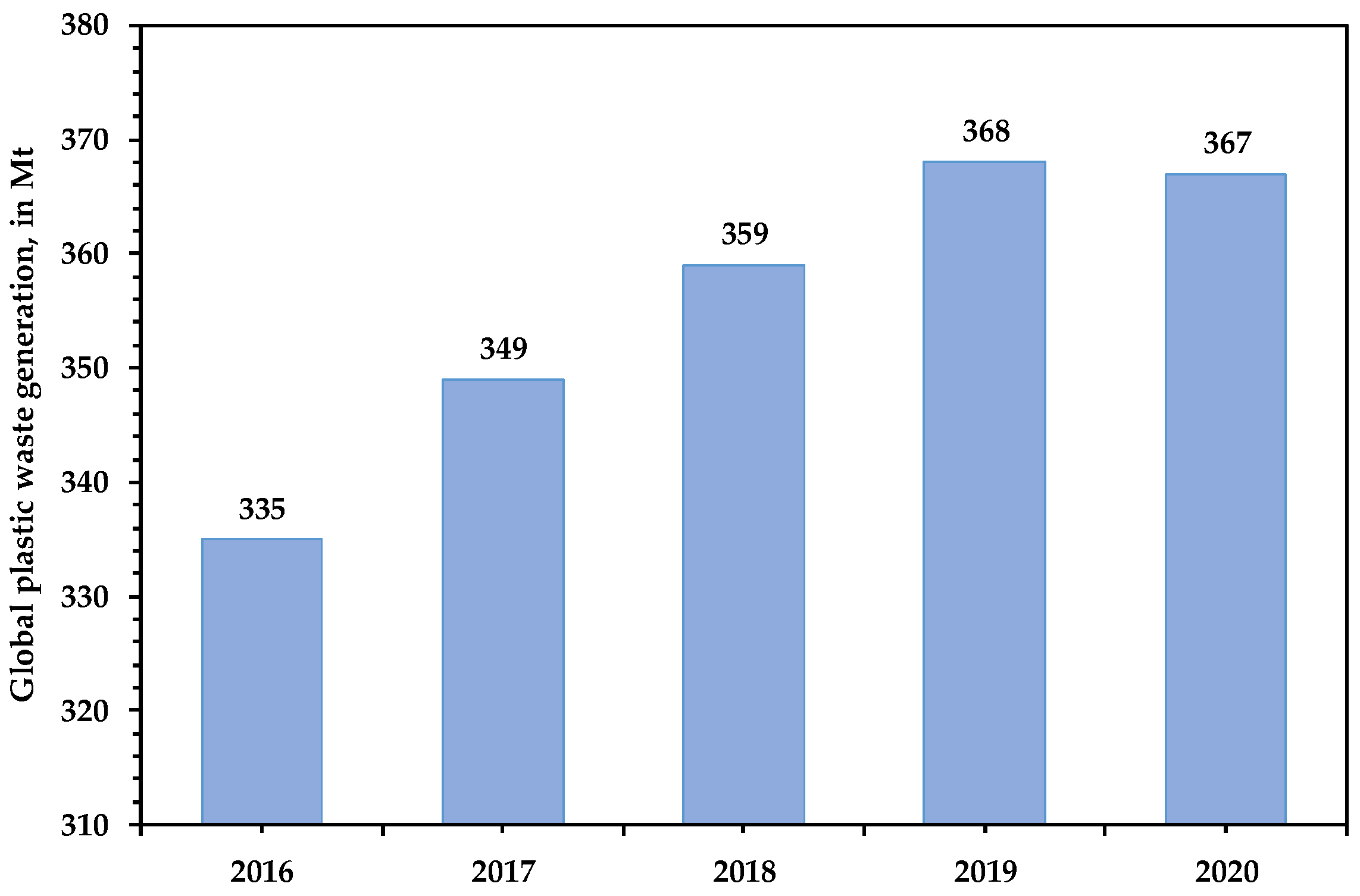

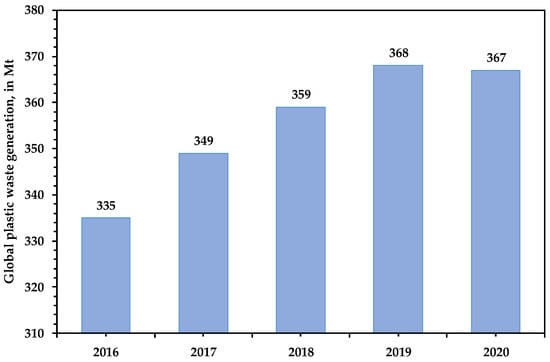

With the growth of the global population and that of urban settlements following the same trend and aiming for high living standards, the amount of plastic waste generated also increases correspondingly. In 2016, for instance, the world generated around 335 million metric t of plastic waste. In 2019, the generation of plastic waste registered an increase of around 10%, reaching 368 million metric to, as shown in Figure 4 [52,53]. Experts indicate that if the current trend continues, by 2050, the generation of plastic waste will double when compared to 2016 [6]. By comparison, the amount of plastic waste generated is practically the same as global production.

Figure 4.

Global plastic waste generation (in million metric t). Source: authors’ own elaboration based on data obtained from reference [52].

The slowdown in economic activity due to the outbreak of the COVID-19 pandemic caused the demand for plastic materials to drop, a situation that also contributed to the slight reduction in global plastic waste generation, reaching 367 million metric tons in 2020. However, food takeaway packaging and plastic medical equipment such as disposable syringes, gloves, protective gowns, facemasks, plastic sampling swaps for wide-scale COVID-19 testing, plastic screens, etc., have increased littering [52,53].

In the regional context, previous research points to the Asian continent as being the one that contributes the most to plastic waste worldwide. However, coastal countries are the most problematic, with China, India, Japan, Philippines, Indonesia, and Vietnam being the critical countries [54].

5.1. Top 20 Countries That Produced the Most Plastic Waste and with the Most Plastic Waste per Capita

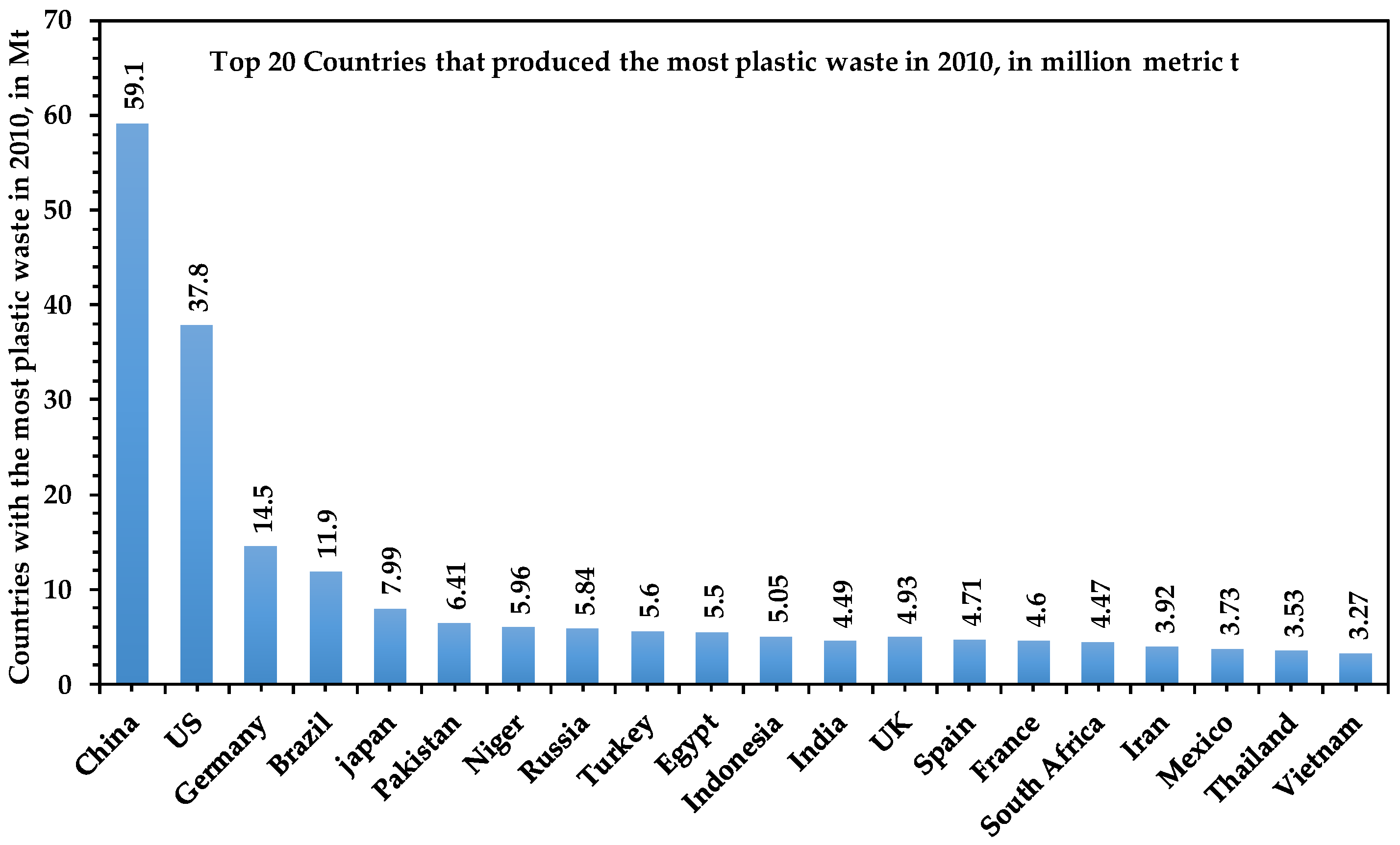

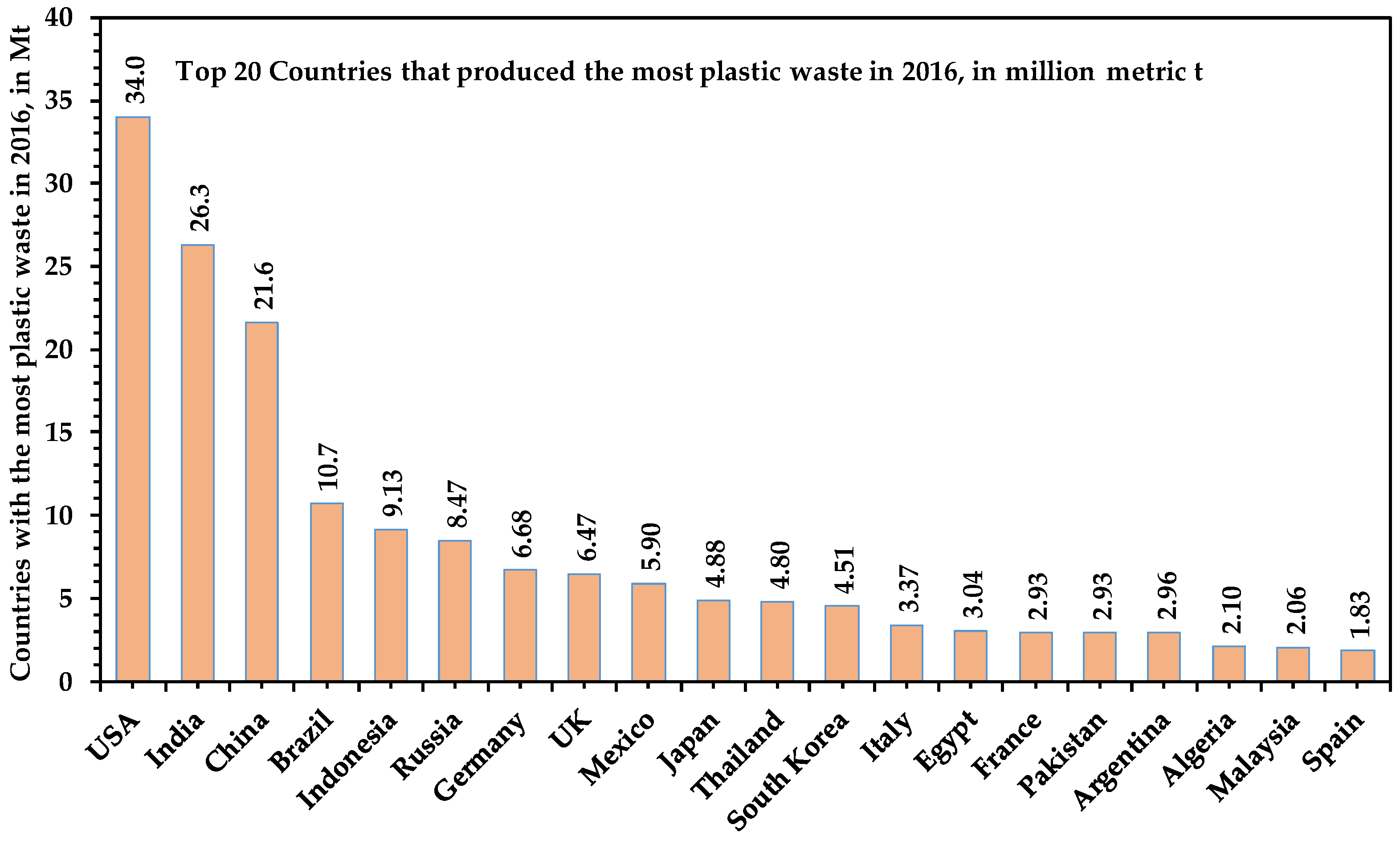

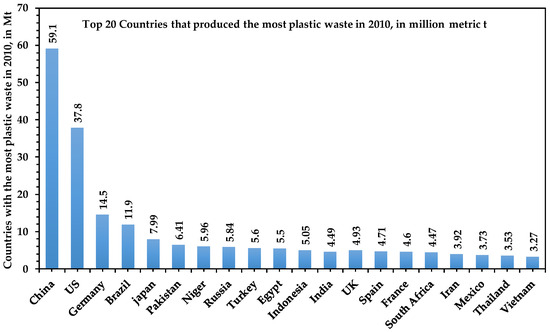

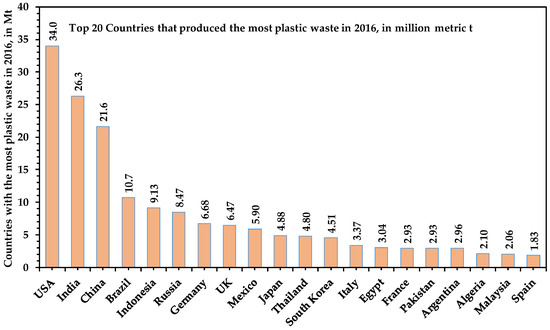

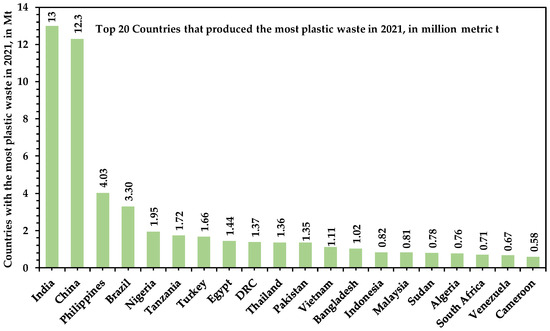

Figure 5, Figure 6 and Figure 7 show the top 20 countries that produced the most plastic waste in 2010, 2016, and 2021 (in million metric t), respectively. In 2010, China was responsible for the highest quantities of plastic waste production, having reached 59.08 million t of plastic waste, nearly double that produced by the USA (37.83 million t), four times that produced by Germany (14.5 million t), and almost five times the amount produced by Brazil (11.9 million t).

Figure 5.

Top 20 countries that produced the most plastic waste in 2010, in million metric t (Mt). Source: authors’ own elaboration based on data obtained from reference [49].

Figure 6.

Top 20 countries that produced the most plastic waste in 2016, in million metric t (Mt). Source: authors’ own elaboration based on data obtained from reference [49].

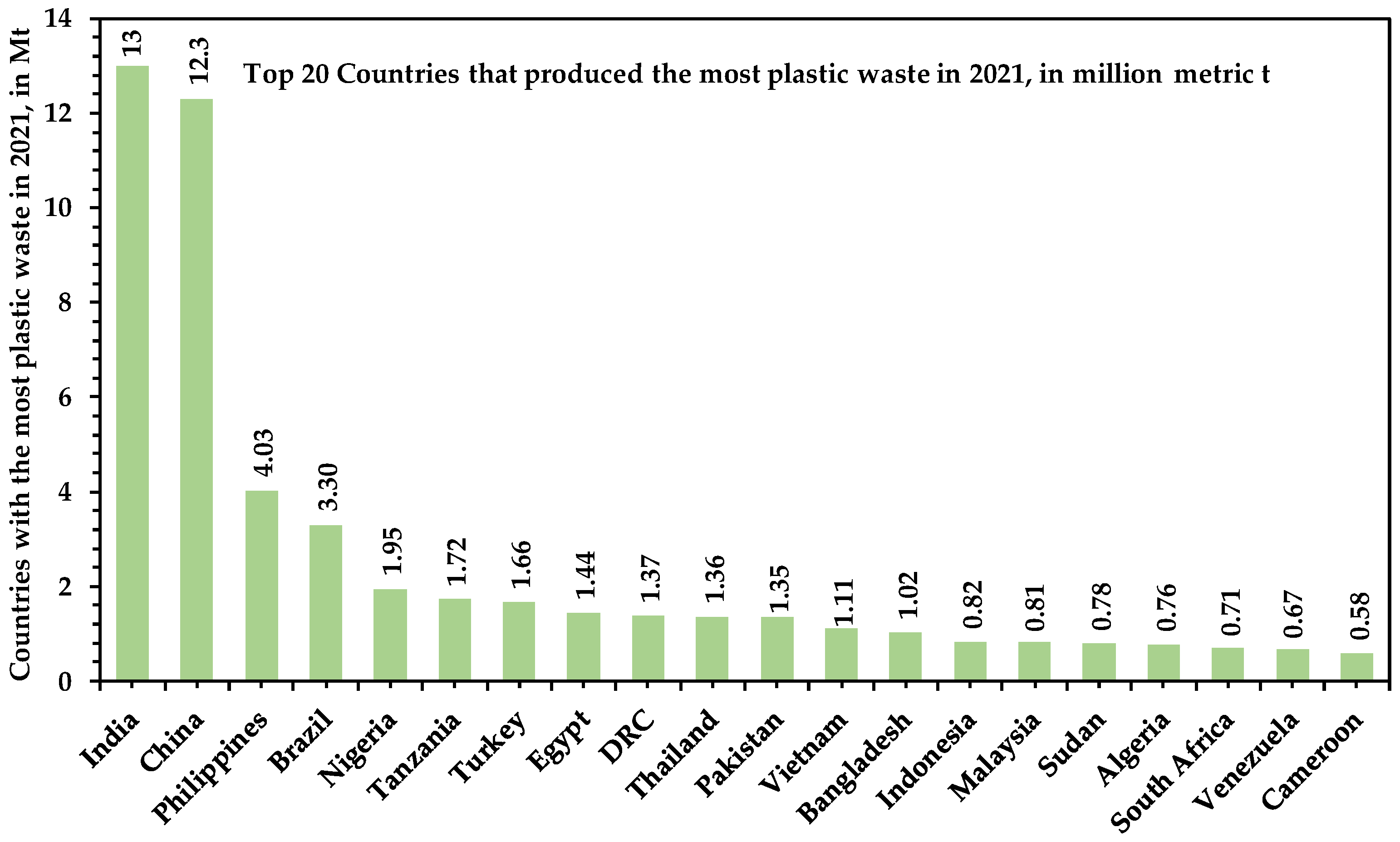

Figure 7.

Top 20 countries that produced the most plastic waste in 2021, in million metric t (Mt). Source: authors’ own elaboration based on data obtained from reference [49].

In 2016, the positions of the largest producers of plastic waste changed. China’s global generation had fallen from 59.1 million t to 21.6 million t, as shown in Figure 6, a reduction of around 37.5 million t.

In turn, the USA went from 37.8 million t in 2010 to 34 million t in 2016, a reduction of almost 4 million t. With 34 million t in 2016, the USA became the largest generator of plastic waste in the world, followed by India, with 26.3 million t. The various actions taken by China to reduce the generation of plastic waste, such as the ban on single-use plastic straws and the ban on non-degradable bags in all cities and towns in 2020 and later in 2022, can justify the drastic reduction in waste generated by the country in 2016 when compared to 2010. The USA is one of the largest exporters of plastic waste collected by other countries, with an emphasis on Asian countries. This situation distorts the view of the real quantities of waste generated in that country and the real reasons behind the reduction in the quantities of waste generated.

If, for some reason, some countries reduced their amounts of waste in 2016 and others did not, the production of plastic waste registered increases instead of decreasing. For example, for countries like India, Indonesia, Russia, the UK, and Mexico, their production rose from about 4.49, 5.05, 5.84, 4.93, and 3.73 million t of plastic waste, respectively, in 2010 to nearly 26.3, 9.13, 8.47, 6.47, and 5.9 million t in 2016. In the specific case of India, the country went from thirteenth place in 2010 to second in 2016.

In 2021, the volume of plastic waste generated fell drastically, as shown in Figure 7, a clear demonstration of the countries’ commitment to the fight against the harm caused by plastic waste. Countries like the USA, UK, Russia, Mexico, and France, for example, have even disappeared from the ranking. Asian countries continued to be at the top of the ranking, with India leading the list with around 13 million t of plastic waste, followed by China and the Philippines with around 12 and 4 million t, respectively. When compared to 2016, India and China reduced their plastic waste volumes by almost half.

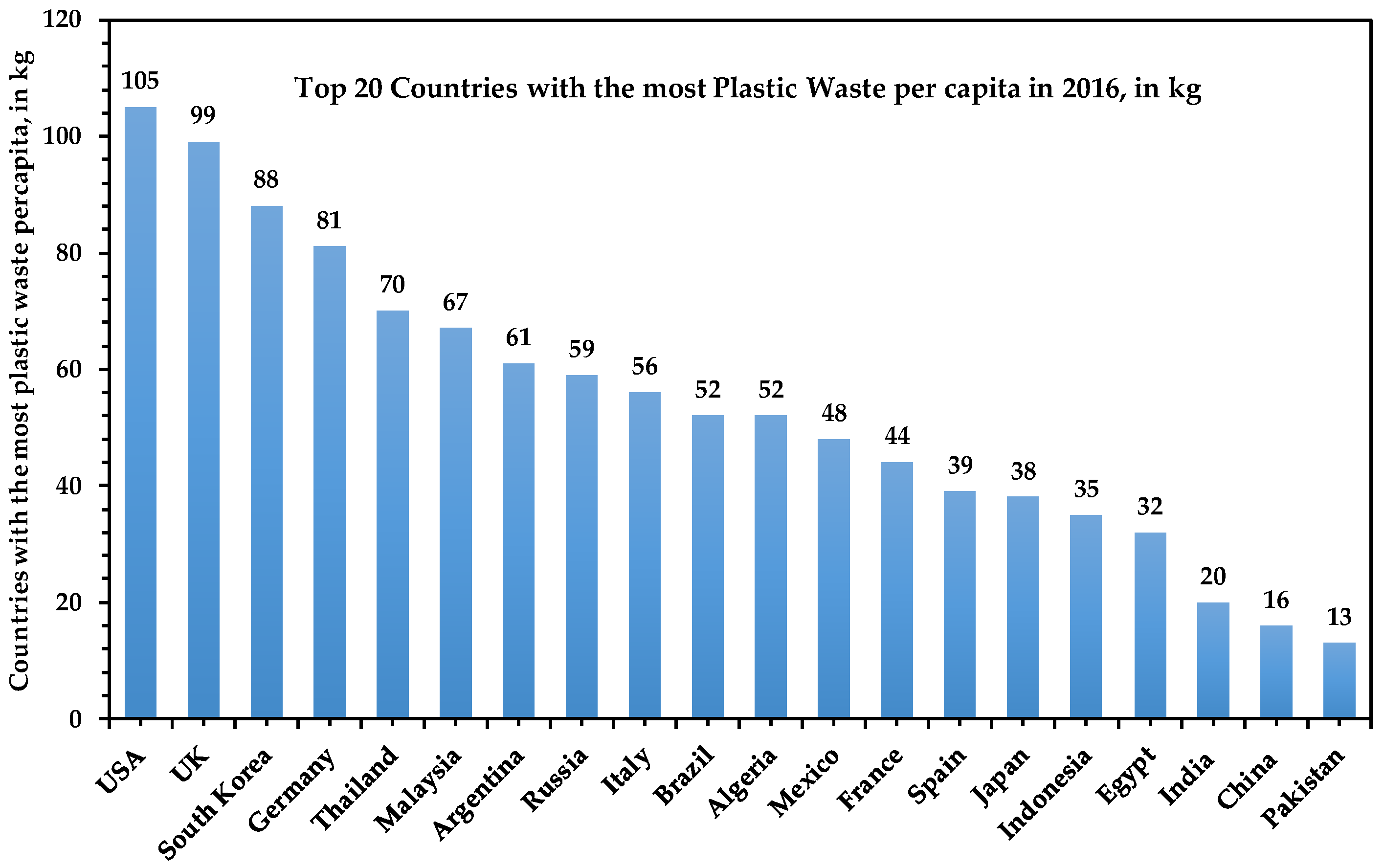

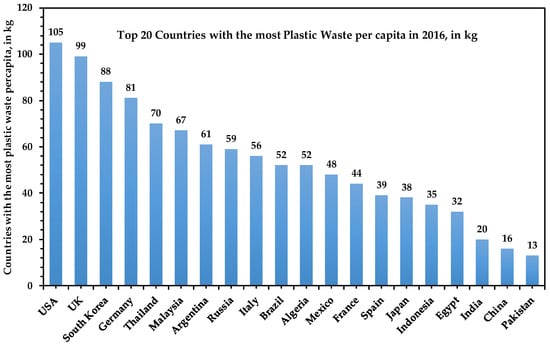

Figure 8 shows the top 20 countries with the most plastic waste per capita in 2016, in kg. As can be seen, the USA, UK, Republic of Korea, and Germany produced more plastic waste per person than any other major country in the world, reaching 105, 99, 88, and 81 kg a year, respectively. Even though India and China are the countries with the largest populations in the world, accounting for 18% of the world’s population each, and with China presumably being the world’s largest manufacturer of plastic, both countries are far behind the USA (with 4% of the world’s population) in terms of plastic waste generation per capita. The two countries are ranked 18th and 19th, with 20 and 16, respectively.

Figure 8.

Top 20 countries with the most plastic waste per capita in 2016, in million metric t (Mt). Source: authors’ own elaboration based on data obtained from reference [49].

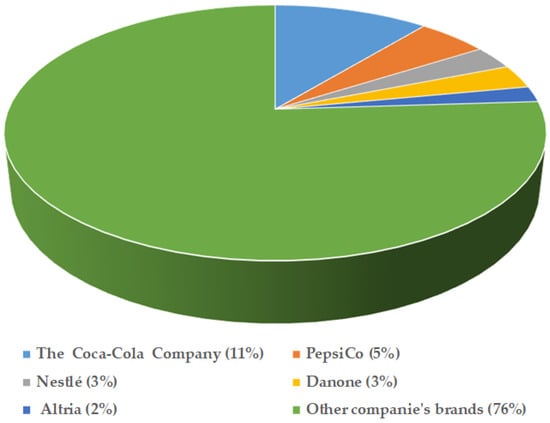

5.2. Plastic Waste Generation by Company Product Brand

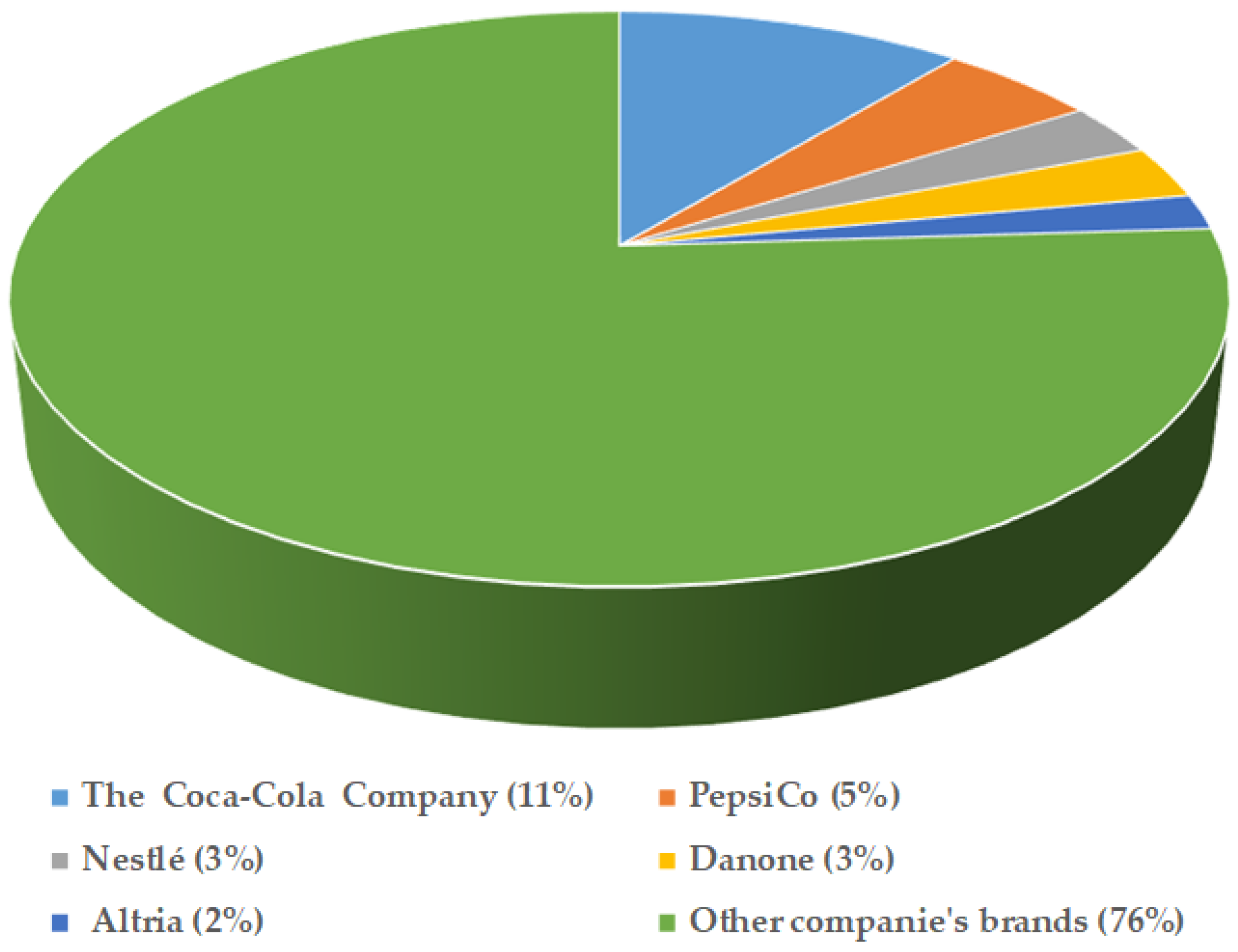

Plastic waste generation is a two-sided problem in the consumer goods industry. One of the issues has to do with the disposal of waste for multiple reasons by societies. The other side is related to the generation of plastic waste through branded product packaging from companies. In this way, there has been an increasing amount of single-use plastic and waste produced by companies worldwide. Moreover, because the packaging industry is the one that generates the most waste, as described in Section 4, the situation is becoming increasingly worrying. A recent study, entitled “Global producer responsibility for plastic pollution” [55], which looked at the relationship between companies’ annual production of plastic and their branded plastic pollution, indicated food and beverage companies as being the ones that generate the most plastic waste for the environment. Companies such as the Coca-Cola Company, PepsiCo, Nestlé, Danone, and Altria occupied the top five (Figure 9) in terms of pollution of brands associated with their companies globally.

Figure 9.

The global percentage of the top five companies’ branded plastic waste generated throughout their value chain. Source: authors’ own elaboration based on data obtained from reference [55].

The Coca-Cola Company accounted for 11% of the total, followed by PepsiCo, Nestlé, Danone, and Altria, with 5%, 3%, 3%, and 2%, respectively, with these five companies alone accounting for 24% of the global branded count. The remaining 76% belonged to other companies, which were not mentioned in the study. As can be seen in the figure, the first four companies belong to the food and beverage sector and the fifth (Altria) to the tobacco industry. The study analyzed around 1.87 million items of plastic waste found in the environment, recorded between 2018 and 2022, in 84 countries worldwide. Half of the items analyzed came from 56 companies. The study also found that 52% of the items analyzed did not have an identifiable brand, which highlights the pressing need for better transparency about the production and labeling of plastic products to improve their traceability and corporate accountability.

5.3. Main Sources of Plastic Waste Generation

Kibria et al. [56] presented a comprehensive overview of the main sources of plastic waste generation. The main sources of plastic waste generation include five categories, namely (i) household plastic wastes; (ii) industrial plastic wastes; (iii) agricultural plastic wastes; (iv) medical plastic wastes; and (v) electrical plastic wastes.

5.3.1. Household Plastic Wastes

Household plastic waste is basically characterized by plastic waste generated in homes resulting from its use in household activities. Household plastic waste comprises packaging from different food items (such as processed meat packages, milk bottles, plastic soft drinks, water bottles, salad dressing containers, margarine containers, yogurt containers, bread bags, sweet trays, frozen food bags, egg cartons, fast food trays, fruit plastic packaging, caps for containers, etc.), shopping bags, disposable plastic silverware, printed matters, nappies, clothing, furniture, carpet, shrink-wraps, garment bags, shampoo bottles, detergent bottles, toys, toothbrushes, toothpastes, paper, packaging for electronics and household appliances, etc. The main plastic materials involved in the manufacture of the above items include, among others, PET, HDPE, LDPE, PVC, PP, and PS.

5.3.2. Industrial Plastic Waste

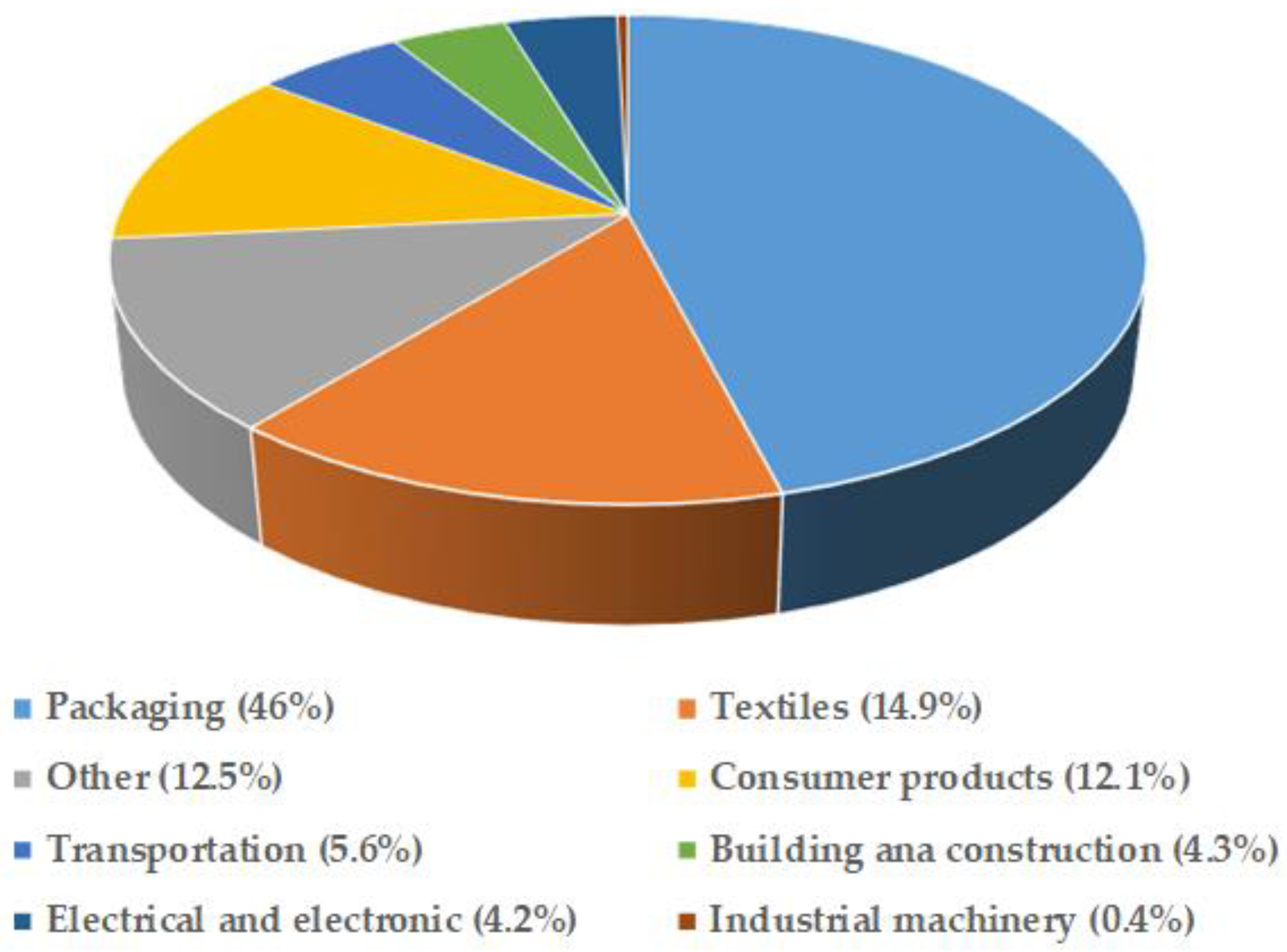

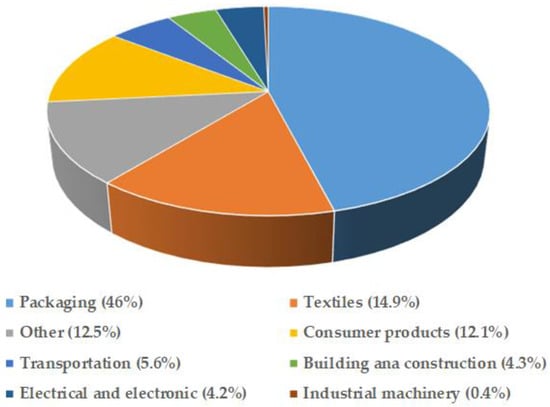

Industrial plastic waste includes materials arising from mass production, processing, and packaging industry activities. Much of this waste results from the packaging industry, construction sector (building or destroying infrastructure), the automotive and aeronautical industry, the electrical and electronics industry, etc. The main waste in this category includes plastic bags, sacks, wraps, packaging items, bottles, electrical cables, plumbing tubes, celling materials, etc. [56]. It is important to note that the packaging sector is the main source of plastic waste generation of the industrial segment [52,57]. Figure 10 shows the distribution of plastic waste generation worldwide in 2018, by industrial sector. As can be seen, the packaging sector contributed a significant amount of plastic waste, reaching around 46%, followed by the textile sector in second place, with almost 15% of the total.

Figure 10.

Distribution of plastic waste generation worldwide in 2018, by industrial sector. Source: authors’ own elaboration based on data obtained from reference [58].

5.3.3. Agricultural Plastic Wastes

Agricultural plastic waste is waste that comes from agricultural activities. Waste results from agrochemical packaging, seed packaging, fertilizer bags, irrigation activities, mulching, silage covering, crop protection, post-harvesting operations, etc. It is important to note that a large amount of plastic waste results from nets used to protect crops from adverse weather conditions, insects, and animals. The main plastic materials involved in the manufacture of the above items include, among others, PE, HDPE, LDPE, PVC, PP, and PS.

5.3.4. Medical Plastic Wastes

Medical plastic waste results from health sector activities. The main waste from this sector includes personal protection equipment, gloves, syringes, cannula pipes, medicine coverings, facemasks, hand sanitizer bottles, plastic takeout bags, food and pharmaceutical product containers, reagent kits, etc. The main plastic materials involved in the manufacture of the above items include, among others, PET, PE, ABS, HDPE, LDPE, PVC, PP, and PS.

As can be seen above, packaging materials are present in three of the five categories. This is not surprising at all, since, on the one hand, the packaging industry is the one that consumes the largest portion of the total global volume of production of plastic, on the other hand, proportionally, it is the sector that generates the most plastic waste. The saddest part of this situation is that only 14% of the total waste generated from the sector is collected for recycling. The remaining part ends up in the environment (buried in dumps or landfills (40%), incinerated (14%), or leaked into the ecosystem (32%)).

5.3.5. Electrical Plastic Wastes

Electrical plastic waste is one of the fastest growing waste streams worldwide. The main waste in this category includes cell phones, computers, monitors, televisions, cameras, printers, and photocopiers, among others. According to Kibria et al. [56], secondary scraps derived from electrical and electronics items such as copper, steel, other metals, and plastic glasses can also be included in this category.

5.4. Export and Import of Plastic Waste

At a time where environmental pollution has become a global concern and the treatment of solid waste is almost a requirement for states and nations, the export of plastic waste to countries with lower treatment rates or with other policies that do not involve waste treatment is an increasingly frequent reality. The export of plastic waste is part of a platform called “Global plastic waste trade”. Global plastic waste trade is the international trade of plastic waste between countries for further treatment, disposal, or recycling. In fact, the export of plastic waste to developing countries that lack efficient waste management infrastructure is nothing more than a move that aims to reduce costs involved in its management, reduce pressure on local recycling facilities and landfills, dissipate responsibilities, and reduce pollution in the environment of each of the exporting countries from a strictly local perspective. Researchers point out the most industrialized and economically developed countries as those that produce and export the most plastic waste.

For destination countries, the so-called importing countries, on the other hand, the import of plastic waste comes with certain financial benefits too. The import of plastic waste has seen a positive impact on the economic growth of many countries, including low-income countries. The use of recycled plastic in the manufacture of goods, for example, is seen as a cheaper option for industries instead of importing virgin plastic. However, not everything is a bed of roses in these countries. For example, when exporting countries send unusable and non-recyclable contaminated plastics, importing countries only incur financial losses, associated with environmental degradation.

Table 1 shows the world’s top 10 exports of plastic waste from 2016 to 2018, 2020, and 2022. As can be seen, in 2016 and 2017, Hong Kong, the USA, Japan, Germany, and Mexico were the countries that led the first five positions in terms of exports of plastic waste, with cumulative amounts of around 3.41, 3.13, 1.73, 0.89, and 0.60 million t, respectively. In 2018, Hong Kong left first place and dropped to fifth, and Japan took its place, followed by the USA and Germany in the second and third positions, respectively. In 2020, Germany moved to first place, with 0.85 million t, followed by Japan and the USA, with 0.82 and 0.62 million tons, respectively. In 2022, Germany continued to lead the ranking, with shipments totaling over 0.73 million t, followed by the Netherlands and Japan, with 0.68 and 0.60 million t. In regional terms, Germany is the largest exporter on the European continent in the period under review, while the USA leads the American continent. Asia’s largest plastic exports are from Japan.

Table 1.

The world’s top 10 exports of plastic waste (10,000 t) from 2016 to 2018, 2020, and 2022 [59,60,61].

The largest destinations for Germany’s exports are the Netherlands, Poland, Austria, Switzerland, Turkey, and Malaysia. Japan’s exports go to neighboring countries such as Malaysia, Vietnam, Thailand, and the Republic of Korea. In turn, the USA’s exports are destined for Canada, Mexico, Malaysia, Vietnam, India, Hong Kong, and Indonesia [60].

Although the data in the table come from different sources, overall, there is a clear trend towards a reduction in exports in the period under evaluation. With the emergence of new policies or laws on the production and management of waste in destination countries, global pressure on the need to preserve the environment through adequate management of plastic waste may be behind this situation. On the other hand, the amendment to the Basel Convention in May 2019, the so-called “Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal”, which now includes plastic waste, may also be restricting the main players in this market.

It is obvious that if there are exporting countries, it is because there are destination countries, that is, the so-called receiving countries, or simply importing countries. As previously stated, importing plastics brings certain financial benefits to importing countries. One of the benefits that stands out most is the fact that recycled plastics can be reused in the manufacture of goods, a much cheaper option for industries than buying newly manufactured plastics, which are expensive.

Table 2 shows the world’s top 10 imports of plastic waste from 2016 to 2018, 2020, and 2022. In 2016 and 2017, China and Hong Kong were the world’s largest importers of plastic waste, with cumulative amounts of around 13.24 and 12.08 million t for China and Hong Kong, respectively, followed by Germany, Japan, and the Netherlands, with cumulative amounts of around 3.54, 2.96, and 2.07 million t, respectively. It is important, however, to note that China’s leadership in waste plastic exports dates back to 1990. However, things changed completely when, in 2017, China announced a ban on foreign waste imports. With this measure, from 2018 to 2022, China completely disappeared from the ranking, and surprisingly, Malaysia began to lead imports, having imported in 2018 and 2020, respectively, around 0.87 and 0.72 million t of plastic waste. In 2022, and also surprisingly, for the very first time, Sri Lanka appeared to lead the top 10, pushing countries such as Malaysia, Hong Kong, the Netherlands, Germany, and Turkey into the first three places.

Table 2.

The world’s top 10 imports of plastic waste (10,000 tons) from 2016 to 2018, 2020,er and 2022 [59,60,62].

In the regional context, the Asian continent leads the ranking, with China, Hong Kong, Malaysia, and now Sri Lanka being the main players, followed by the European continent, where the market is led by Germany and the Netherlands, and finally by the American continent (north and south), which is being led by the USA.

The presence of countries belonging to the world’s top 10 exporters of plastic waste in Table 2 should not be seen as a surprise, and the explanation is very simple. Industrialized and economically stable countries export waste plastic as a way of getting rid of their legal and environmental responsibilities and many other factors, however, when it comes to specific plastic recycling capabilities and needs, so while they might export some plastic waste, they also import others that are useful for the consumer goods manufacturing industry.

6. The Environmental Problems of Plastic Waste

Despite the multiple positive effects provided by plastic materials to the growth of the world economy, their massive production and use, in combination with poor end-of-life waste management, has resulted in growing adverse effects on human health and the natural environment, including on climate change, marine pollution, endangering biodiversity, and chemical contamination as well as economic losses [2,3,7,8]. Plastic waste contaminates all major ecosystems on the planet, with concern increasing about its potential impacts on wildlife and human health, as smaller and more widespread plastic particles are identified in both the natural and built environment [63]. The scenario becomes critical for developing countries, especially for African countries where infrastructure for waste management such as recycling is scarce or non-existent.

One of the biggest concerns related to plastics is associated with the toxicity component. Although this concern often focuses on only two types of plastics, namely PVC and PS, experts say that, in principle, all plastics are toxic, and as is natural, some are worse than others. Preliminary data from an ongoing study indicate that there are around 16,000 identifiable chemicals of concern in plastic. Two-thirds of them have not been assessed for safety at all, a quarter are classified as hazardous in some way, while the remaining part is classified as less hazardous or not classified as hazardous but not fully assessed. Some of the chemicals described here are used as ingredients in the polymerization process, while others are additives to impart unique qualities or properties to plastic materials, such as strength, flexibility, color, etc. Some of them appear as contaminants contained in raw materials used for the production of plastics such as oil and natural gas. Unreacted monomers that stay in the final product and some accidental byproducts of production are also part of the chemicals mentioned here [64,65]. In the following subsections, the negative impacts of plastic waste in various environments are described and discussed in more detail.

6.1. Plastic Waste’s Negative Impact on the Soil and Terrestrial Environment

The vast majority of plastic waste is non-biodegradable. Non-biodegradable plastics are almost completely derived from petrochemicals produced from fossil oil, gas, and occasionally coal. It is estimated that about 300 million t of non-biodegradable plastic waste are generated annually worldwide. From 1950 to 2018, the world generated around 6 billion t of non-biodegradable plastic waste [23,66]. To date, nobody knows exactly how long non-biodegradable plastics can take to disintegrate when they are disposed of as litter in the natural environment. But there is evidence that these materials can take half a century or a millennium to decompose, having adverse effects on the terrestrial environment, especially in agricultural soils [10,67,68].

When discarded in the terrestrial environment, plastic wastes have great potential to cause seasonal flooding and proliferation of mosquitoes and pests, as they block drainages, waterways, land spaces, and pipes [27,69]. Poor disposal of plastic waste is also pointed out as being responsible for the emergence and transmission of vector-borne diseases and toxic chemicals, including persistent organic pollutants. Plastic waste, in addition to harming the beauty and visibility of urban centers, also interferes negatively with the biogeochemical cycle of terrestrial ecosystems [22,70,71].

The presence of plastic waste in the soil can negatively affect crucial soil properties such as porosity and soil binding properties due to possible soil aggregation and changes in the dynamics of water contained in the soil. The problem becomes even more complex when plastic waste is present in the form of microplastics. As is very well known, microplastics contain toxic additives and hazardous contaminants, including polybrominated diphenyl ether (PBDE), perfluorochemicals (PFOS), and heavy metals like copper, zinc, and lead, so the interaction of these particles with the soil matrix can contribute to the degradation of soil fertility by affecting the growth of earthworms and other useful microorganisms [56].

6.2. Plastic Waste’s Negative Impact on Water Sources and the Marine Environment

Reliable data on the actual amount of plastic material that enters the ocean, including the mechanisms of its transport and distribution in the ocean and the respective sources of origin, are still scarce. However, there is very strong evidence that on a global scale, the amounts of plastic entering the ocean are very high. As mentioned previously, estimates indicate that the ocean receives annually between 7 and 13 million metric t of plastic waste, coming from both high- and low-income countries. If the situation continues at this rate, the global accumulated amount of plastic waste in the ocean will be equal to the amount of fish by 2035 [7,14], and there will be more plastics (by weight) than fish by 2050 [8]. The marine environment is estimated to already contain over 150 million t of plastic [72], of which around 250,000 t are fragmented into 5 trillion micro- (less than 5 mm) or macro-plastic particles [73].

Statistical data derived from [15] show very interesting ocean pollution facts:

- (a)

- About 75 to 199 million tons of plastic waste are in our oceans.

- (b)

- There are around 33 billion pounds of plastic waste entering the marine environment every single year.

- (c)

- By 2050, plastic waste will likely outweigh all fish in the sea.

- (d)

- Almost 1000 species of marine animals are impacted by ocean pollution, and over 500 locations are recorded as dead zones where marine life cannot exist.

- (e)

- About 17% of the species affected by plastic in the ocean are on the International Union for Conservation of Nature Red List of Threatened Species.

- (f)

- Around 80% of global marine pollution comes from agriculture runoff, untreated sewage, and discharge of nutrients and pesticides.

- (g)

- The oceans absorb as much as a quarter of all artificial carbon emissions, which changes the pH of surface waters and leads to acidification.

- (h)

- Around 20% of the ocean’s plastic waste pollution comes from industrial fishing.

- (i)

- Between 1950 and 1998, over 100 nuclear blast tests occurred in the oceans.

- (j)

- If current trends continue, ocean plastic pollution will triple over 40 years, with waste exceeding one billion t.

- (k)

- Ocean pollution affects more than 817 animal species worldwide.

- (l)

- Marine plastic waste pollution has affected 100% of marine turtles, 59% of whales, 36% of seals, and 40% of seabird species.

- (m)

- Only 1% of marine litter floats. Everything else sinks to the sea floor.

- (n)

- Approximately 5000 items of marine plastic pollution have been found per mile of beach in the UK.

- (o)

- About 500 marine locations are now recorded as dead zones globally, currently the size of the UK’s surface (245,000 km2).

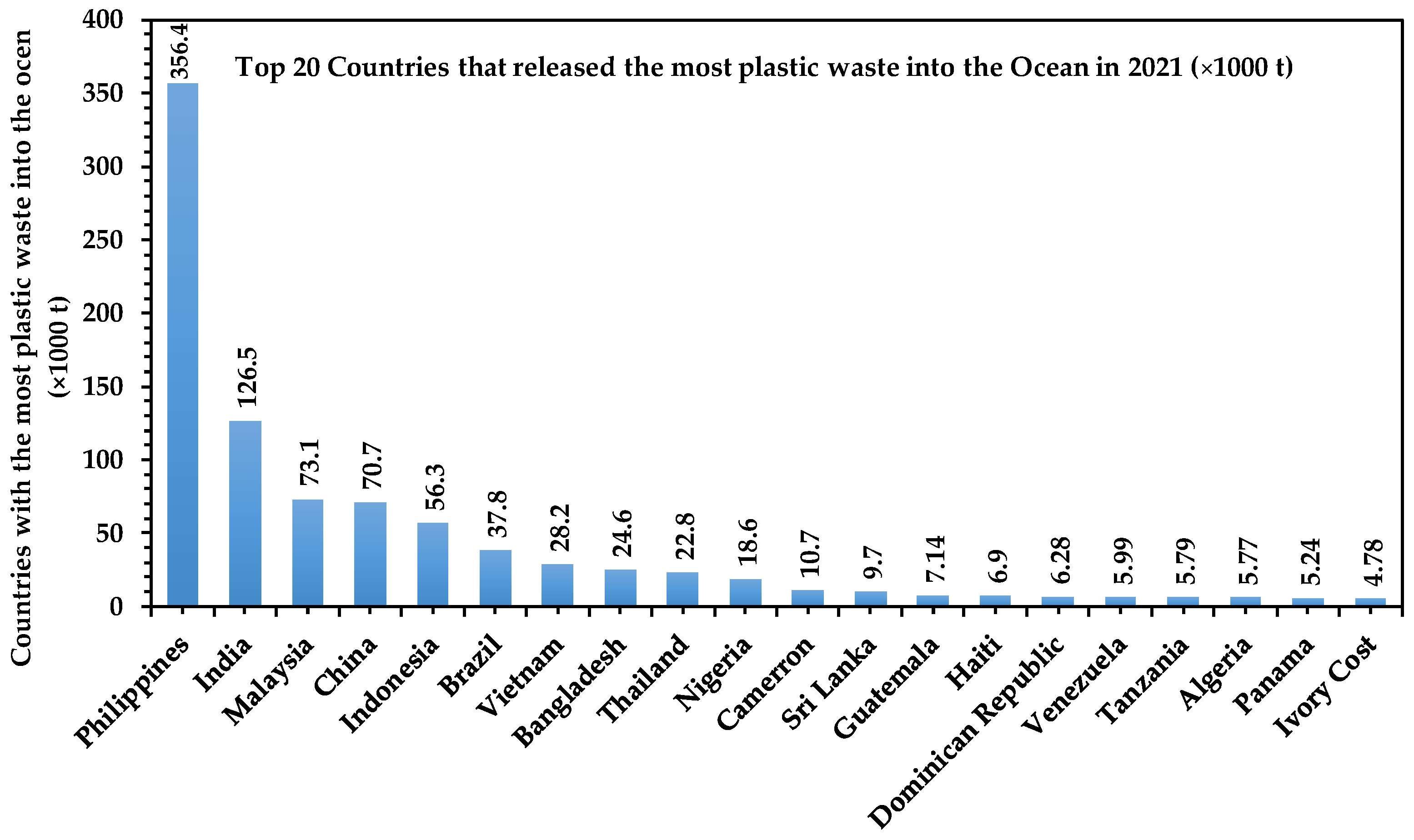

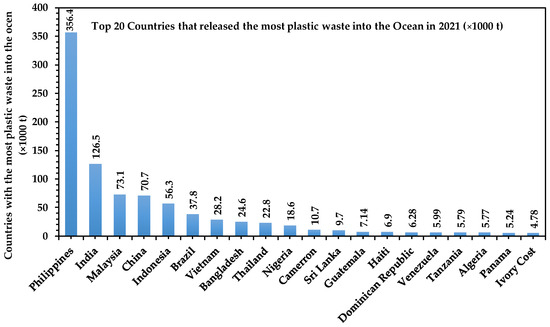

Figure 11 shows the top 20 countries that released the most plastic waste into the ocean in 2021, in thousands of t. The Philippines introduced more plastic waste into the ocean than the 19 other countries, reaching around 356.4 thousand t. From the figure, it is clear that Asian countries, in particular the coastal ones, were responsible for the highest quantities of plastic pollution in the ocean, with the Philippines, India, Malaysia, China, and Indonesia among the worst culprits. The data presented here corroborate research carried out in 2017 and 2021, which concluded that 80% of mismanaged plastic in the ocean came from Asian countries such as China, Thailand, Vietnam, Indonesia, and the Philippines [49].

Figure 11.

Top 20 countries that released the most plastic waste into the ocean in 2021, in thousands of t. Source: authors’ own elaboration based on data obtained from reference [15,49].

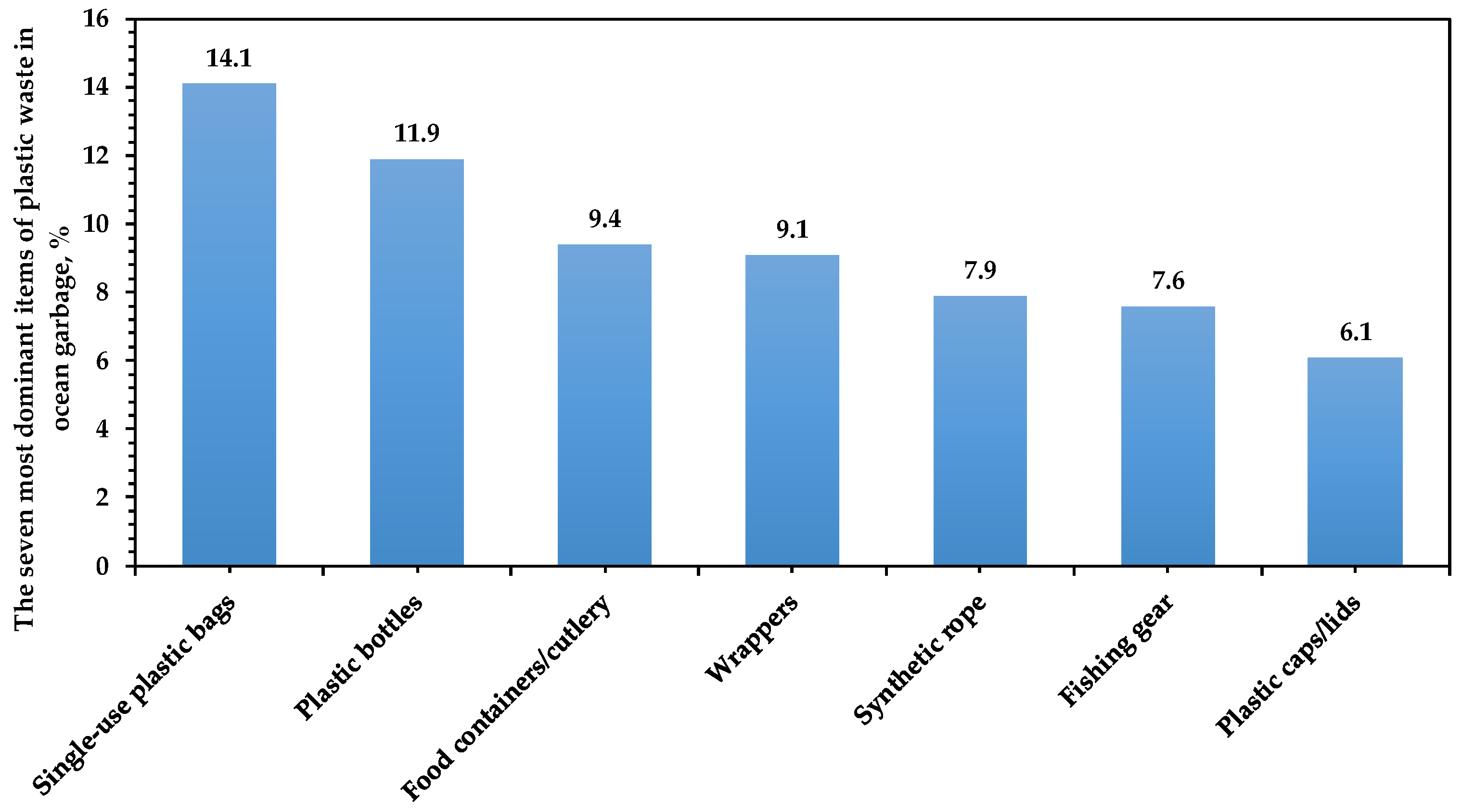

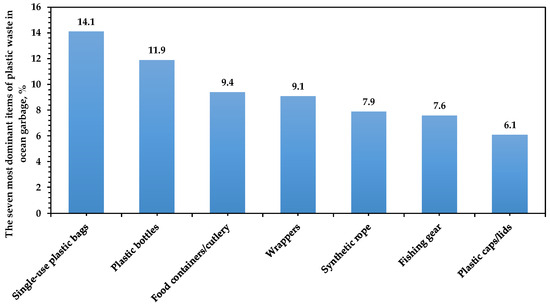

It is important to note that a large part of ocean pollution comes from plastic waste, estimated at almost 66% of the total. The remaining portion is from chemical pollution, oil spills, thing pollution, and climate change. Figure 12 shows the seven most dominant items of plastic waste in ocean garbage. The data show that single-use plastic bags and plastic bottles are the items that share the largest portion of plastic waste that ends up in the oceans.

Figure 12.

The seven most dominant items of plastic waste in ocean garbage. Source: authors’ own elaboration based on data obtained from reference [15].

The main sources of more than 80% of the plastic that enters the ocean are land-based sources such as rivers, groundwater run-off, combined municipal sewer overflows, cluttering, wastewaters from industries, solid waste disposal and landfills, fisheries, aquaculture, commercial cruise or private ships [13,74], wind, rain, and floods. However, rivers are the biggest carriers of plastic into the oceans. A study carried out by Meijer and colleagues [75] used a modelling approach, which included geographically distributed data on plastic waste, land use, wind, precipitation, and rivers. By calculating the probability for plastic waste reaching a river and subsequently the ocean, the group found that more than 1000 rivers, including small urban rivers, account for 80% of global riverine plastic emissions annually.

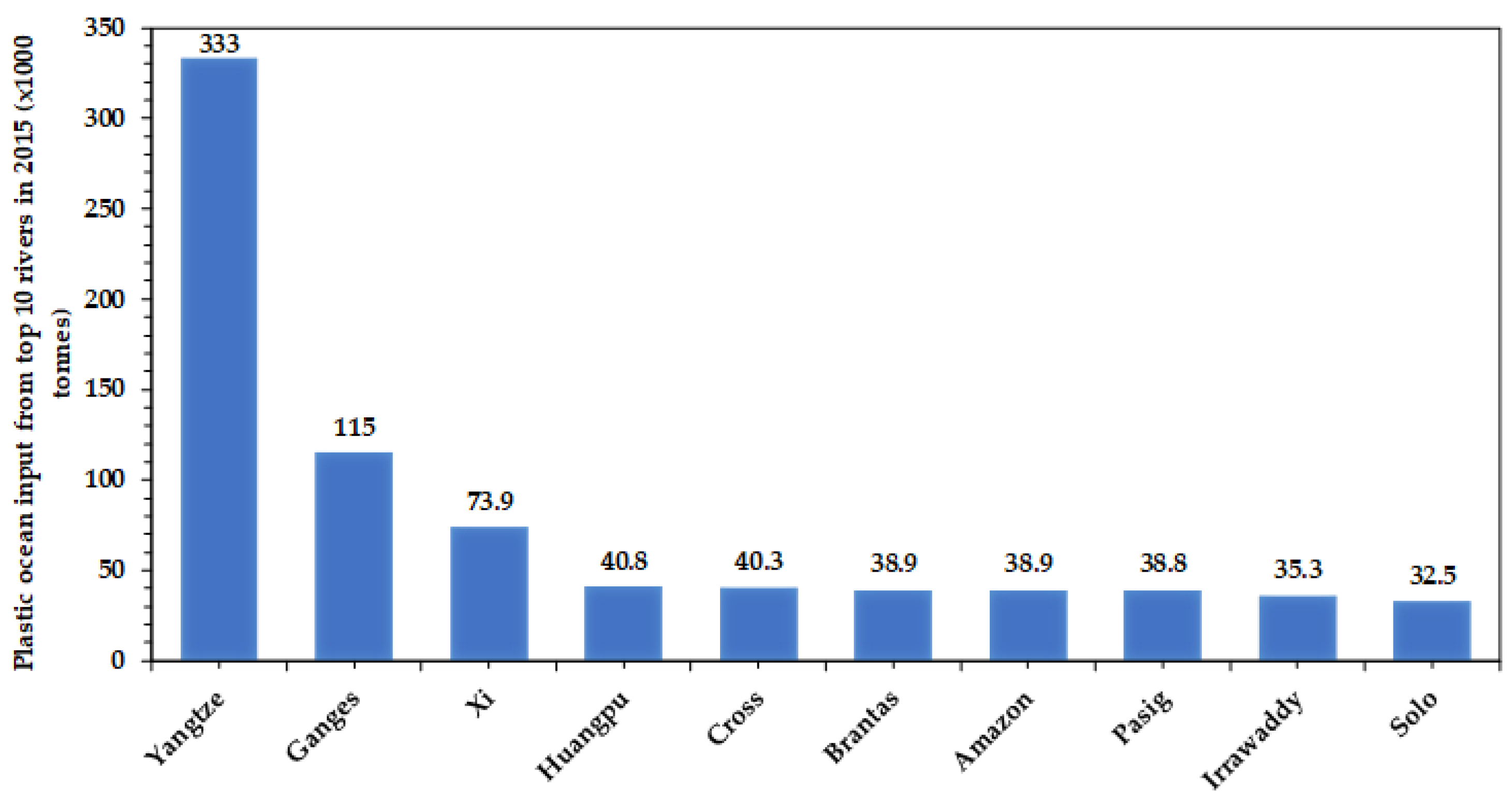

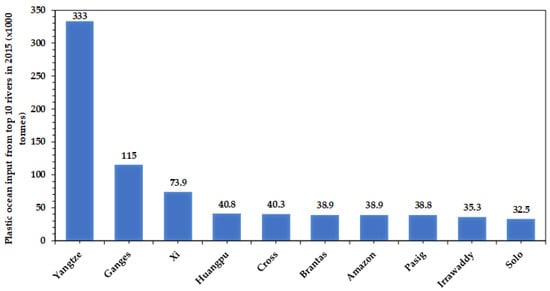

A recent study [56] presented the top 10 rivers in the world that throw the most plastic waste into the ocean and the contribution from different continents in 2015. The rivers that make up the top 10 include (a) Yangtze (China), (b) Ganges (India and Bangladesh), (c) Xi (China), (d) Huangpu (China), (e) Cross (Nigeria, Cameroon), (f) Brantas (Indonesia), (g) Amazon (Brazil, Peru, Colombia, Ecuador), (h) Pasig (Philippines), (i) Irrawaddy (Myanmar), and (j) Solo (Indonesia). Figure 13 shows the respective numbers, in kilo t. From the figure, it is clear that the rivers that flow in Asian countries are the ones that dump the most waste plastic into the ocean and that contribute more to marine pollution than other rivers.

Figure 13.

Plastic Ocean input from top 10 rivers in 2015, in kilo t. Source: authors’ own elaboration based on data obtained from reference [56].

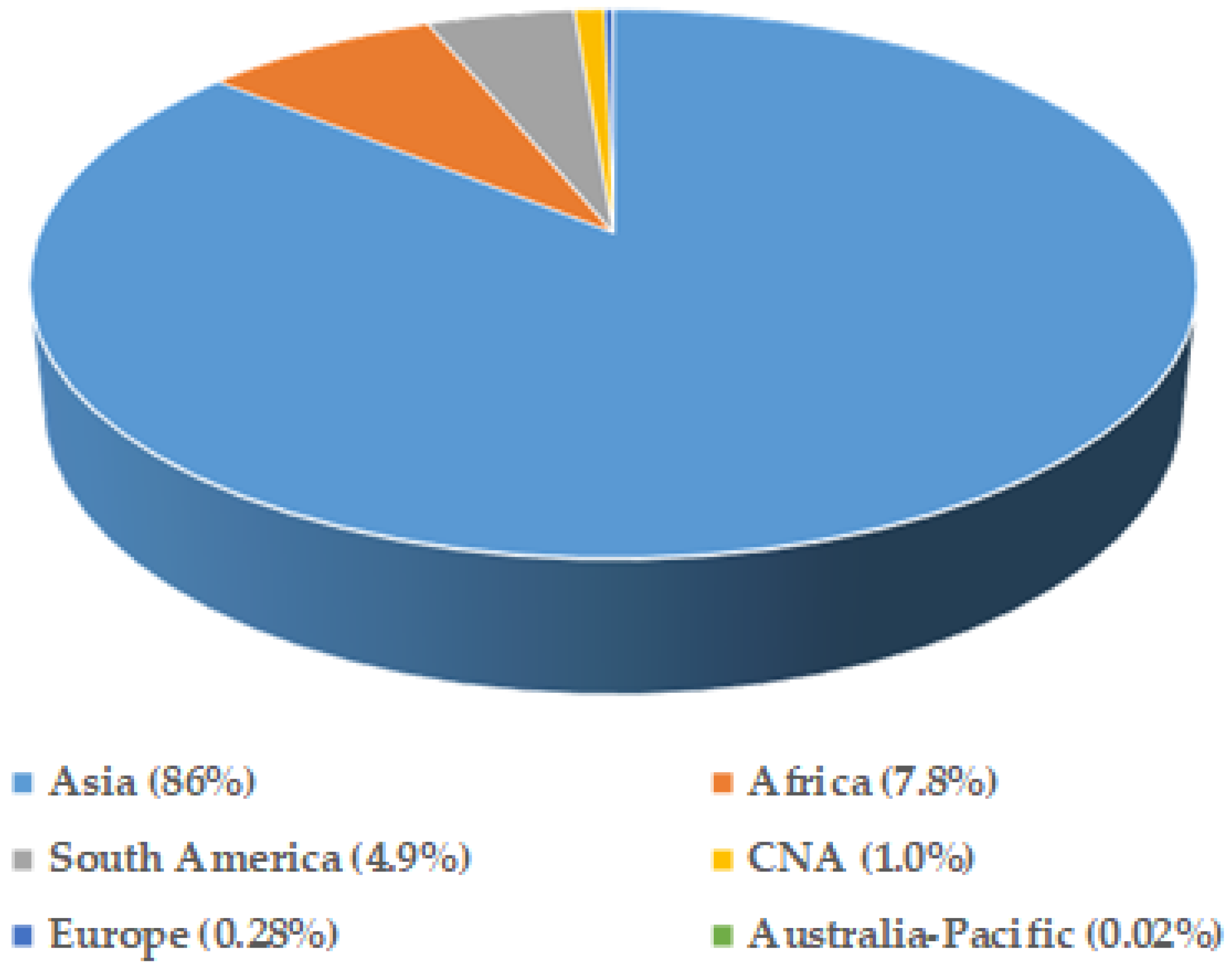

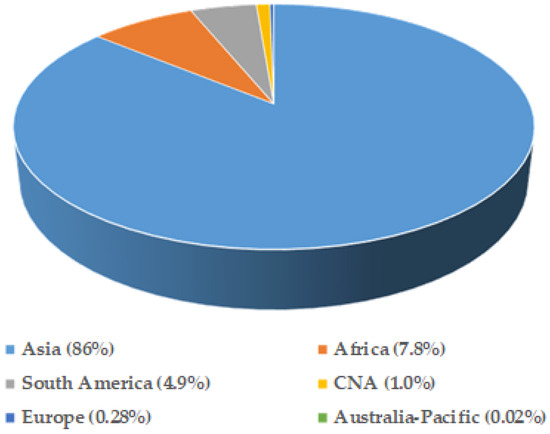

Figure 14 shows Plastic Ocean input from rivers in the regional context in 2015. As can be seen, the scenario has not changed. The rivers of the most populous continent in the world injected more plastic waste than all other regions combined, having reached 86% of the total, followed by Africa, South America, Central and North America, Europe, and Australia-Pacific, with 7.8%, 4.8%, 0.95%, 0.28%, and 0.02%, respectively [56].

Figure 14.

Plastic Ocean input from rivers in the regional context in 2015 (in %). Source: authors’ own elaboration based on data obtained from reference [56]. (CAN—Central and North America).

A recent study estimates that more than 109 million metric t of plastic waste has accumulated in rivers worldwide [52], a clear demonstration that if the current trend continues, the leakage into the ocean will increase drastically for decades to come, even if mismanaged plastic waste could be significantly reduced. Since plastic materials may contain a variety of harmful chemicals such as polychlorinated biphenyls, polychlorodibenzofurans, quaternary ammonium compounds heavy metals, etc., if their wastes are not properly disposed of, they can release toxic substances into the soil. Over time, these toxic substances could flow into groundwater or be carried away by rain or wind and pollute other surrounding water sources such as rivers, oceans, lakes, streams, etc. The direct implications of this scenario are the negative impacts on organisms that directly depend on these water sources, such as humans, animals, and plants [8], as well as on the overall sustainability of fisheries.

The presence of plastic wastes in aquatic environments such as oceans and rivers leads to suffocation and prevents the free movement of aquatic organisms like fish, seabirds, turtles, mussels, crustaceans, and sea mammals [75,76]. In the specific case of marine fauna, the scenario is of great concern. About 700 marine species are believed to be interacting with plastic waste [77]. Ecological and aesthetic damage, including losses in coastal tourism revenue, are also associated with marine plastic litter [6,78,79].

6.3. Plastic Waste’s Negative Impact on Air Pollution

The air we breathe is one of the most precious assets on planet Earth. Without it, the existence of living beings would be impossible. However, in recent decades, air pollution has been one of the biggest threats to human health. Recent studies, including those from the World Health Organization, indicate that seven million people die from air pollution every year, and it is estimated that 92% of the global population breathe toxic air. Around the world, the Bahamas have the cleanest air, while Bangladesh has the worst air quality [54]. This scenario makes it clear that billions of people suffer from the effects of poor air quality.

Waste plastic is also one of the materials that most contributes to air pollution. In many countries around the world, especially low-income ones, burning solid waste in open environments is a common practice. The burning of solid waste, including plastics, is often used as an alternative method to waste management, a situation motivated by the lack of appropriate solid waste management infrastructure such as recycling as well as the need to overcome landfill challenges such as land occupancy and soil fertility [80]. Poor families in developing countries burn plastic to use it as an energy source for cooking or heating purposes. However, sometimes the burning of plastic waste in many urban centers happens as a result of stubbornness and sabotage by the people.

Unfortunately, this practice happens without the slightest notion of the side-effects arising from the combustion process of plastic materials. The incineration of plastic waste in an open field is a major source of air pollution. The burning of plastics releases into the atmosphere harmful chemicals such as dioxins, polycyclic aromatic hydrocarbons (PAHs), furans, mercury, ammonium substances, PVC, soot, solid residue ash, and polychlorinated biphenyls, substances that possess a high potential to negatively impact vegetative systems, human and animal health, and the environment as a whole. Depending on the prevailing atmospheric conditions, the released substances resulting from the combustion of plastic wastes can travel thousands of kilometers and reach other more distant locations [8,81,82]. The wind is the main medium responsible for depositing the emissions of particulate plastic material into the atmosphere, for example, from farms through soil dust during agricultural processes. Particulate plastic material can also reach the atmospheric environment from seawater, also carried by air. This happens when plastic particles are sitting on the top layer of the seawater where they are tossed into the air by sea waves [83].

The direct implications resulting from the scenarios described above are the negative impacts on human and animal health and the environment as a whole. According to a pilot study of beach recreation [84], during the PVC combustion process, for example, hazardous halogens are released, with great potential to affect negatively the air. The burning of polystyrene releases toxic gases with a negative impact on the nervous system, while the hazardous brominated compounds act as carcinogens and mutagens. On the other hand, dioxins, which are lethal persistent organic pollutants, associated with the worst components, such as 2, 3, 7, 8 tetrachlorodibenzo-p-dioxin, can settle on crops and in waterways, where they may eventually migrate up the food chain and cause catastrophic effects on human health.

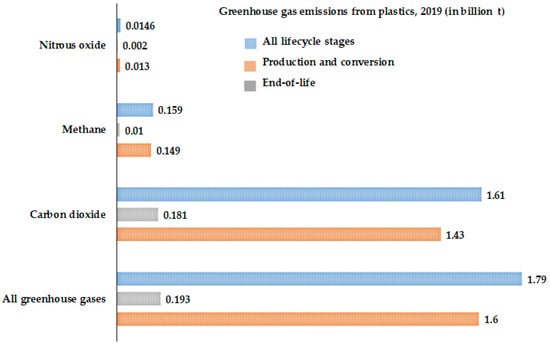

6.4. Plastic Waste and Greenhouse Gas Emissions

The greenhouse effect is a natural process that occurs when certain gases present in the atmosphere, such as carbon dioxide (CO2), methane (CH4), and water vapor (H2O), retain part of the solar radiation reflected by the Earth’s surface. The greenhouse effect is an essential natural process to keep the planet at a desirable temperature for the beings that live on it. Without the greenhouse effect, planet Earth would be extremely cold, making life unviable for many species. However, the excessive emission of these gases into the atmosphere intensifies the greenhouse effect, making it difficult to release heat into space, resulting in global warming and climate change. At a global level, the largest emitters of gases that intensify the greenhouse effect result from anthropogenic activities, and these include (a) combustion of fossil fuels; (b) deforestation; (c) livestock activities; (d) agricultural activities; (e) decomposition of organic waste; and (f) industrial activities. A large part of CO2 emissions, one of the most common greenhouse gas (GHG) emissions, results from the combustion of fossil fuels, such as coal and oil. CH4 gas, with 20 times more power to raise temperatures than CO2, comes from activities linked to landfills, dumps, and livestock farming. N2O, with the potential to increase temperatures by 265 times more than CO2, results from agricultural activities such as soil cultivation, use of nitrogen fertilizers and waste treatment. Fluoridated gases resulting from industrial activities include hydrofluorocarbons, used in cooling and refrigeration systems; sulfur hexafluoride, used in the electronics industry; perfluorocarbon, emitted in aluminum production; and chlorofluorocarbon (CFC), which causes a hole in the ozone layer. In turn, water vapor, whose concentration varies with atmospheric temperature, is the main GHG. It also contributes to the greenhouse effect by forming clouds that then retain heat [84].

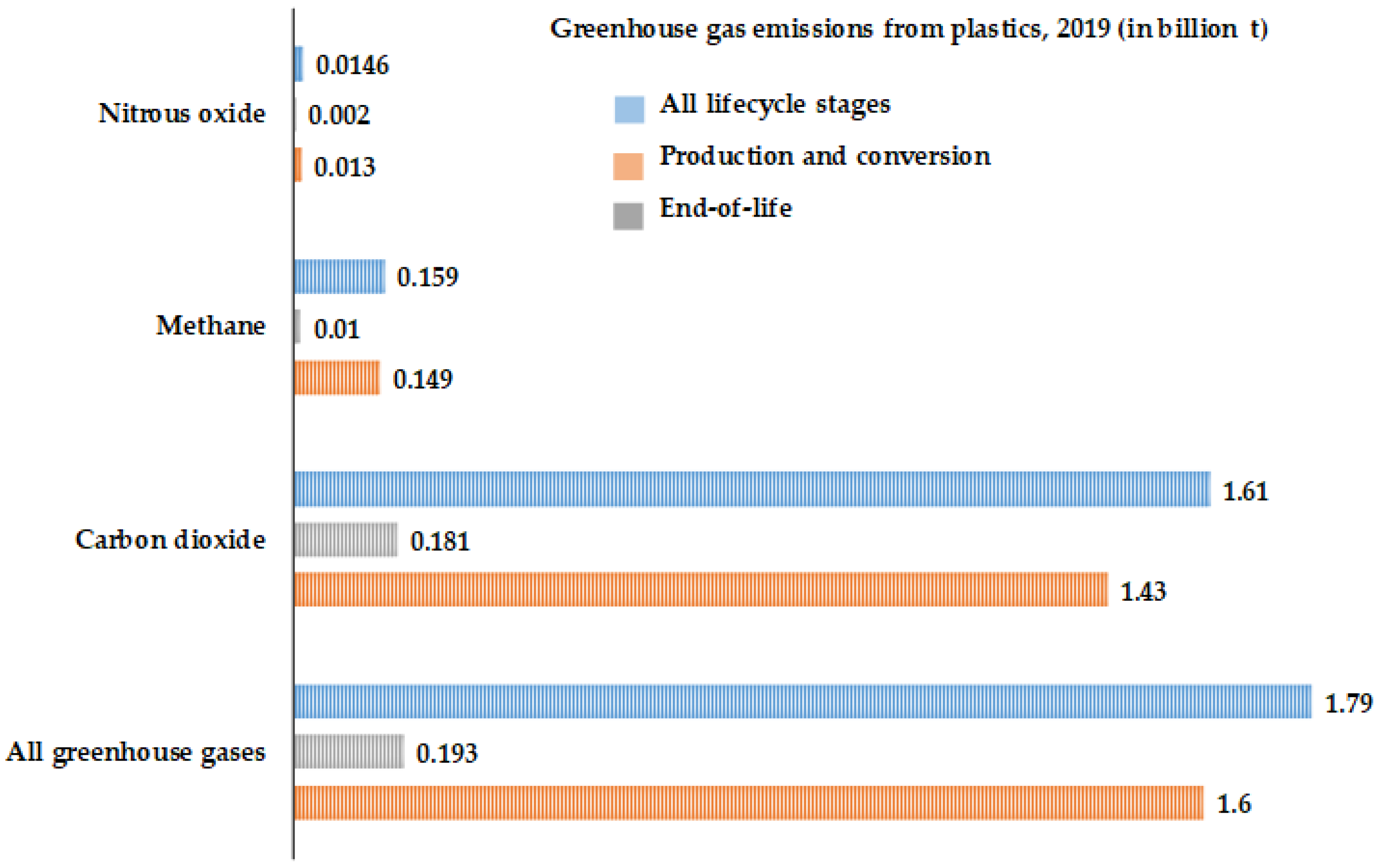

In addition to contaminating oceans, rivers, animals, and humans, plastic also contributes to climate change, and the explanation for this scenario is very simple, as 99% of what makes up current plastic materials comes from fossil fuels. The main greenhouse gas emissions occur throughout the lifecycle of plastic materials, which includes resin production, conversion, and end-of-life phase. The end of life of plastic materials includes disposal in landfills and incineration. Figure 15 shows the greenhouse gas emissions (in billion t) from plastics in 2019 that occurred at all lifecycle stages of the plastic materials. As can be seen from the figure, the production and conversion phases (orange bars) are the phases with the highest emissions when compared to the end-of-life phase (grey bars). The explanation for this scenario is simple; resin production is the phase in which the most emissions are produced, estimated at around 61%, a percentage that can be achieved mainly when virgin polymers are processed. The conversion phase contributes 30% and the end of life around 9% [5]. That is, the production and conversion phases together contribute 91%.

Figure 15.

Greenhouse gas emissions (in billion t) from plastics in 2019 (emissions measured in t of carbon dioxide-equivalents (CO2-e). The numbers that appear in the figure mean billions of t of greenhouse gas emitted. Source: authors’ own elaboration based on data obtained from references [85,86].

The above observations clearly show that GHG emissions from the plastics industry will continue. In fact, environmental experts argue that at the current rate of growth in the global demand for plastics, by 2050, 15% of GHG emissions (around 6.5 Gt of CO2-e) will come from this industry alone, compared to the current 3.5%, equivalent to 1.7 Gt of CO2-e [5].

6.5. Plastic Waste’s Negative Impact on Animals

Improper disposal of plastic wastes associated with their harmful chemicals also has a negative impact on animals’ health. Millions of animals, from terrestrial to aquatic, are killed by plastic wastes annually. Land animals such as cattle, sheep, and goats, and aquatic animals like fish, dolphins, turtles, seabirds, mussels, crustaceans, and sea mammals, have been reported to die after ingesting plastics, which become entangled in their stomachs [22,87]. The situation is more critical in the marine environment. While Gall and Thompson [77] believe that about 700 marine species are currently interacting with plastic waste, Jambeck and co-workers [14] projected that marine litter may harm almost 600 species by 2050; 90% of seabirds will be under threat due to plastic ingestion, and approximately 15% of the marine species come under endangered categories because of the ingestion and entanglement of plastics.

Animals are exposed to plastic debris via ingestion and entanglement, ingestion being the most common way. Marine animals, for instance, ingest plastic debris because they mistake it for food. Since plastic wastes contain toxic chemicals, including persistent organic pollutants, the ingestion of plastic could be very deadly for marine species. Excessive ingestion of plastic makes the animal’s digestive system become blocked, leading to starvation. The massive presence of plastic in the sea reduces the free movement of aquatic organisms to search for food or to escape from their predators, a situation that sometimes leads to mortalities by hunger or by predators. The massive presence of plastic waste in the sea may also make aquatic species become trapped, creating injuries and infections in them due to the abrasiveness of the plastic particles [13,88]. In addition, the presence of plastic waste in aquatic environments is responsible for decreasing the amount of light penetrating the water as well as the amount of oxygen content in the subsurface, which are extremely important factors for the aquatic species that inhabit there.

6.6. Plastic Waste’s Negative Impact on Human Health

The life of human beings is largely sustained by four different spheres, namely the atmosphere, lithosphere, hydrosphere, and biosphere. It is from these spheres that food is produced, where the breathed air comes from, as well as other products that provide for the well-being of societies. From here, it is clear that any environmental threat to these four spheres will pose direct threats to human health. Plastic waste pollution poses serious risks to human health. For instance, the toxins released from plastic waste combustion could increase the risk of heart diseases and aggravate respiratory ailments such as asthma and emphysema [82,89,90,91]. Moreover, plastics can have various negative effects on human health, including endocrine disruption. Some types of plastics contain chemicals called endocrine disruptors, which can interfere with the body’s hormonal balance. These chemicals can mimic hormones or block their function, leading to a variety of health problems such as developmental disorders, reproductive issues, neurological disorders, obesity, and increased risk of certain cancers [92,93,94,95]. Toxins can also damage the kidney, liver, reproductive and nervous system, skin, and cause rashes, nausea, headaches, and possibly death [22,96,97]. In addition, plastic waste blocking drainages, waterways, land spaces, and pipes, which are responsible for seasonal flooding, also poses a threat to human health, as residents are at risk of catching malaria as a result of mosquito bites in malaria-prone areas or they can become infected by water-borne diseases such as diarrhea [98,99].

One of the major concerns for the World Health Organization (WHO) regarding the plastic pollution issue is related to the possible chemical bioaccumulation in the food chain, with great potential to pose a threat to human health. It is believed that humans are exposed to plastic chemicals via the consumption of sea and terrestrial food products, drinking water, and the air. Chemicals derived from plastic particles have been found in human blood, seafood such as fish and shellfish [100,101,102] and terrestrial animals such as cows and pigs [103], in tap water and bottled water, as well as sea salts [8,104], where in some cases, it is not even known exactly the mechanism by which the particles entered such products.

6.7. Microplastic Particles: An Emerging Threat to the Environment and Human Health

One of the emerging problems related to plastic is associated with its very small fragments, which are generated from the breakdown of mismanaged waste. Given their synthetic nature, plastics do not decompose completely. Over time, they continually fragment into smaller and smaller pieces, commonly called microplastics [83]. Microplastics are plastic particles which contain less than 5 mm in diameter, including nanoplastics, which are less than 0.1 μm [105].

As for the source of origin, microplastics can be categorized into two main families, namely primary and secondary microplastics. Primary microplastics are originally manufactured in a particular size for specific applications, which include pellets used to manufacture plastic products and microbeads that are used in cosmetic, personal cleansing, and household products [106]. Fragmentation into smaller and smaller pieces by photochemical, mechanical, and biological processes, typical of non-biodegradable plastics, whether in the terrestrial or marine environment, results in secondary microplastics. Synthetic fibers released by wastewater resulting from washing clothes and discarding the wastewater in terrestrial or aquatic environments are also part of secondary microplastics [107].

Microplastics are found in the regular cycles of the four different spheres of the earth, circulating around the planet like air or water. Microplastics have been found in underground water streams [108], in deep ocean waters [109], in the atmospheric environment, in the blood of farm animals, including cows and pigs [103], etc. Ocean and riverine systems, urban dust, civil runoff, tires, road wear particulates, and recently the atmosphere have been highlighted as diffuser sources and transporters of microplastic pollution [14,110,111,112]. Microplastics can travel thousands of miles in the open sea and, depending on their degree of degradation, they can remain at various depths of the ocean surface [113]. There are many sources of microplastics, but the main and best known and identified to date include [29]:

- (a)

- Industrial abrasives;

- (b)

- Specific medical products;

- (c)

- Personal care and cleaning products;

- (d)

- Drilling fluids;

- (e)

- Plastic resin pellets;

- (f)

- Packaging;

- (g)

- General littering;

- (h)

- Plastic waste dumping;

- (i)

- Discarded fishing gear;

- (j)

- Abrasion in landfill and recycling sites and facilities;

- (k)

- Abrasion of vehicles tires;

- (l)

- Fibers released from synthetic textiles;

- (m)

- Ship-generated litter;

- (n)

- Fibers from hygiene products;

- (o)

- Plastic material from organic waste;

- (p)

- Abrasion during paint removal;

- (q)

- Weathering of different kinds of paints;

- (r)

- Bottled water;

- (s)

- Polymers found in compost additives.

Microplastics threaten the sustainability of ecosystems and they are seen as vectors for absorbed environmental pollutants. Like macroplastics, microplastics or nanoplastics may contain chemical additives and contaminants, including some known endocrine disruptors that may be harmful to marine biota at extremely low concentrations. This poses potential risks to marine ecosystems, biodiversity, and food availability [13]. In addition, and since microplastics tend to bioaccumulate and biomagnify through the food chain there is also concern about human exposure [114,115].

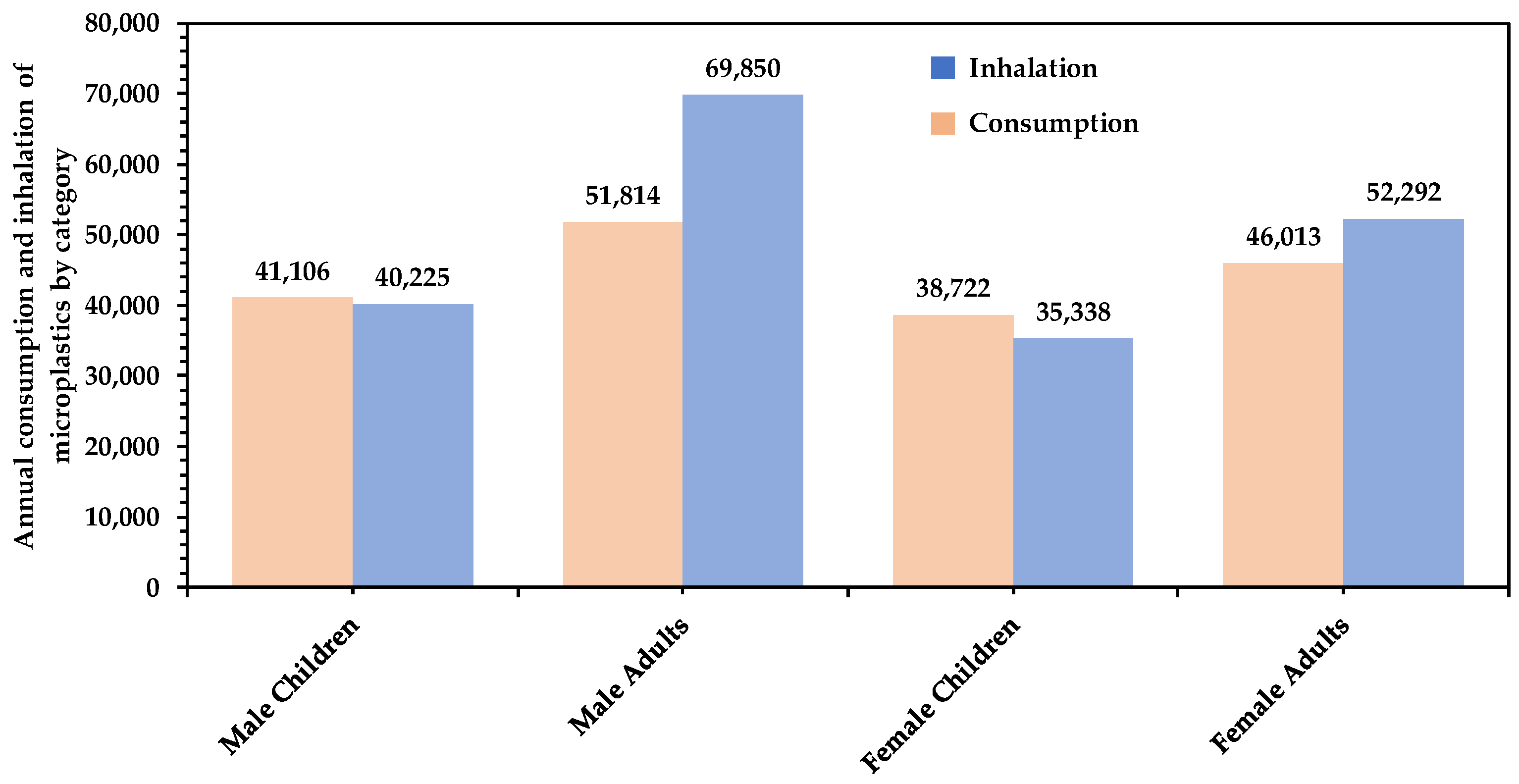

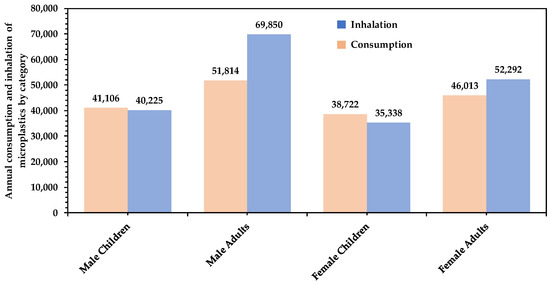

The negative influence of microplastics on soil processes and food production [116,117,118]; on the human food chain, including marine and terrestrial chains [119,120]; on the microbial community composition [121,122,123]; and biota [124] has been reported. Since day-to-day human life is intimately dependent on a large part of the above-mentioned segments, there is no doubt that microplastics and their associated contaminants are inevitably consumed by humans. Even though the impact that microplastics could have on the health of human beings is still unclear, there is undoubtedly a great potential to cause adverse health effects [125,126]. Estimates indicate that a person may be consuming and inhaling around 94,000 microplastic particles annually, with the largest proportion resulting from inhalation. However, the amount of particles consumed or inhaled depends on the age and sex of the individual. Figure 16 shows estimated annual consumption and inhalation of microplastic particles by category (female and male, children and adults) [7]. The average consumption and inhalation for the four categories are 44.414 and 49.426, respectively. As can be seen from the figure, contact between humans and microplastic particles is more through inhalation than through consumption. Adults, however, consume and inhale more microplastic particles than children. The types of activities carried out by this category of individuals may be behind this situation.

Figure 16.

Estimated annual consumption and inhalation of microplastic particles for female and male, children and adults. Source: authors’ own elaboration based on data obtained from reference [7].

For individuals who rely entirely on water from plastic bottles, in addition to the 94,000 particles annually, they may be consuming an additional amount of around 90,000 microplastic particles annually and around 4000 for those who consume tap water [7]. The presence of higher amounts of plastic particles in plastic water bottles than in tap water is not at all surprising. Scientists say drinking water sold in plastic bottles is a potential source of microplastics because it contains thousands of tiny plastics. A recent study, for example, carried out by Columbia University revealed frightening results. The results showed that a single bottle of water could contain nearly a quarter of a million microscopic particles of plastic [127]. These particles appear to originate primarily from the bottle itself and the reverse osmosis filters.

In the marine environment, for instance, microplastics may absorb and concentrate toxic organic pollutants and thus increase their toxicity by a factor of 10, posing a great threat to human health [128]. The presence of microplastics in the human body may make people more resistant to antibiotics [129]. When compared to aquatic environments, the terrestrial ones seem to be the most contaminated. This is justified by the fact that plastic products are mostly produced and used in terrestrial environments [130]. A new dataset estimates 24 trillion pieces of microplastics in the ocean, the equivalent of roughly 30 billion 500 mL plastic water bottles [131].

6.8. Plastic Waste’s Negative Impact on Socioeconomic Issues

Plastic waste causes serious socio-economic problems globally, which results from damage to the tourism industry, fishing activities, shipping activities, and the environment in general. At a global level, the damage and negative impacts on marine environments caused by waste plastic pollution (except for microplastics or nanoplastics) are enormous, and this totals around USD 13 billion per year, which essentially includes losses incurred by fisheries and tourism due to plastic littering, as well as beach clean-up costs [12]. Meanwhile, the reduction in services provided by aquatic ecosystems resulting from microplastic or nanoplastic pollution caused financial losses estimated at USD 2.5 trillion [132]. Europe alone spends around USD 293 annually on cleaning plastic waste from coasts and beaches, while the failure to recycle costs USD 116 billion [29]. The negative impact caused by plastic waste on the tourism industry and fishing activities, including the costs of coastal cleaning activities, for the Asian-Pacific Rim alone stands at USD 1.26 billion per year [133].

High levels of plastic pollution in the ocean can affect people’s social well-being in several ways. According to [67], plastic waste left or washed up on the coast can affect residents’ quality of life by reducing recreational opportunities and can demoralize coastal visitors. This reduces their access to the health benefits associated with outdoor activity, as well as potentially affecting the tourism industry.

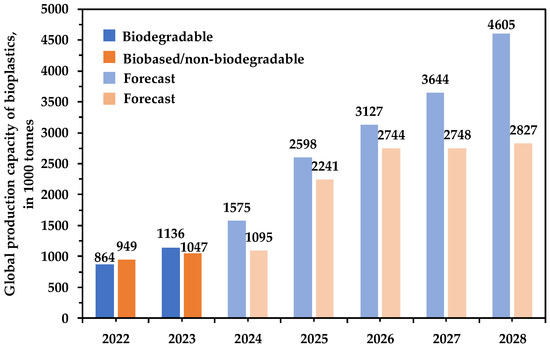

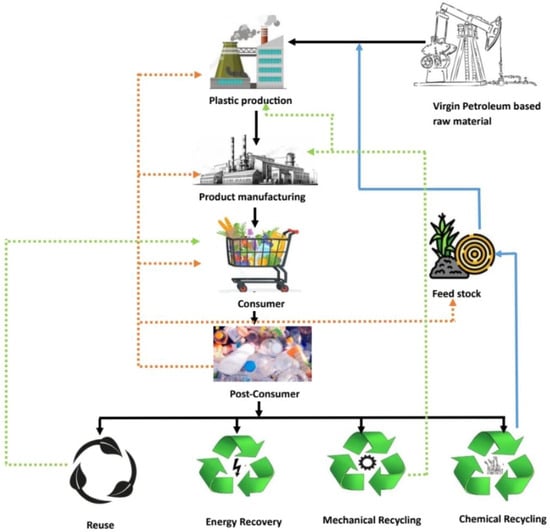

7. Benefits of Plastic Materials to Humanity