Abstract

The automotive industry is under growing pressure from regulatory agencies to improve the recyclability of its plastic components. Simultaneously, manufacturers are adopting natural fiber composites in vehicles to reduce their carbon footprint and decrease reliance on petroleum-based materials. This presents a challenge at vehicle end-of-life, however, as natural fiber-reinforced polymers are substantially more difficult to recycle than their unreinforced counterparts. This study investigated the development of a mechanical recycling process for paper fiber-reinforced polypropylene composites, focusing on the impact of injection molding parameters—specifically, injection temperature and rate—on the thermal, mechanical, and water uptake properties of the composites. The results showed that processing temperature had a greater influence on composite performance than injection rate, with some limited interaction effects between the two. Higher processing intensity damaged the paper fibers, increasing the number of nucleation sites and resulting in greater polypropylene crystallinity. These structural changes reduced tensile properties at higher intensities, while flexural properties improved. Objective function analysis was applied to identify optimal processing conditions, balancing these competing trends. Overall, the findings demonstrate that paper fiber-reinforced polypropylene composites can be recycled into automotive-relevant injection molding compounds using conventional plastic manufacturing techniques, though careful tuning of processing parameters is essential to achieve optimal performance.

Keywords:

recycling; polypropylene; composites; paper fibers; injection molding; sustainability; automotive 1. Introduction

The automotive industry has become increasingly interested in using natural fiber-reinforced composites in recent years, as the industry moves toward a goal of net-zero carbon emissions by the mid-twenty-first century. Natural fibers offer advantages over conventional reinforcement materials, such as glass or carbon, including comparatively low cost, low density, favorable acoustic properties, wide global availability, and an inherently low carbon footprint [1,2]. There are considerable disadvantages associated with natural fibers, however, such as material variability, high moisture sensitivity, low microbial resistance, low degradation temperature, and limited compatibility with polymer matrices [3,4,5,6]. The low thermal stability of natural fibers in particular presents a problem for recycling, as reprocessing via standard polymer manufacturing techniques can lead to significant fiber degradation and poor material performance [7]. New European Union (EU) regulations require automotive manufacturers to increase the circularity of vehicle materials, with a specific focus on ensuring that the plastic used in vehicles comes from recycled sources and is recyclable at the vehicles’ end-of-life (EoL) [8].

Our previous work studied the viability of paper-based composites for automotive applications [9]. For the automotive industry, paper fibers offer benefits over other commonly used natural fibers, such as hemp, flax, or jute. Paper is produced at a substantially larger volume than these other fibers, at 500 million tons per year in 2020, as opposed to flax (830,000 tons/year), jute (2.5 million tons/year), and hemp (215,000 tons/year) [10,11]. The pulp and paper industry also has well-developed quality control standards and methods that alleviate the variability issues typically seen with natural fibers [12]. Our previous study demonstrated that paper composites composed of 60 wt.% market pulp and 40% polypropylene exhibit promising material properties, including flexural strength, impact resistance, and water uptake suitable for automotive interior applications [13]. However, to ensure the successful commercialization of these composites, a comprehensive evaluation of EoL pathways and recycling feasibility is imperative. This is particularly true for automotive parts intended for the European market, given the EU’s forthcoming end-of-life vehicle (ELV) regulations, which require automotive companies to design vehicles for reuse and recycling [8].

As previously mentioned, natural fiber composites present unique recycling challenges due to their limited thermal stability. This is especially true when focusing on mechanical recycling methods such as extrusion, injection molding or other techniques that involve melting and reforming the material, rather than chemically breaking down the polymer into monomers or other molecular components. Despite this, mechanical re-cycling remains the most studied type of recycling within the natural fiber composites community given its wide industrial applicability. A recent review by Zhao et al. de-scribes the complex interplay of factors affecting recycled composite behavior, including changes in properties such as mechanical behavior, thermal stability, crystallinity, hygroscopicity, durability during UV exposure, and rheological properties [14]. The general trends reported in the natural fiber recycling studies are presented in Table 1. It should be noted that different material systems can experience conflicting trends, as different polymers and fiber types can behave differently under identical conditions. For instance, Augier et al. report that a wood-filled PVC composite experiences an in-crease in glass transition temperature with mechanical recycling, likely due to polymer crosslinking, while other research shows that similar systems with different matrix materials, such as polypropylene (PP) or polylactide (PLA), instead display a decrease in glass transition temperature (Tg) due to chain scission during reprocessing [15]. As such, it is important to study the behavior of a specific natural fiber composite system during mechanical recycling, as behavior cannot be predicted from previous literature unless the material systems are identical.

Table 1.

Reported material property changes during mechanical recycling of natural fiber composites. Fiber types used in the respective studies are included for reference.

This research aimed to develop an industrially relevant method for mechanically recycling the paper fiber-reinforced polypropylene composites that we previously developed into an injection molding compound with automotive-relevant properties. Non-woven mats were produced from 60% market pulp and 40% polypropylene, and then compression-molded to produce composite laminates. These laminates were then size-reduced and compounded with additional polypropylene to produce an injection molding compound. This material was injection-molded under various processing conditions to determine the bounds of the processing window. The thermal, mechanical, and moisture uptake properties of the samples produced were studied to characterize trends in the structure–property relationships of these composites. This led to the identification of processing conditions that balance, achieving a high degree of polymer crystallinity in the samples while minimizing fiber degradation, the combination of which results in optimal mechanical properties. We anticipate that these results will pave the way for future adoption of both virgin composite laminates and their recycled counterparts within the automotive industry.

2. Results and Discussion

2.1. Recycling Process Development

The goal of this work was to develop industrially viable recycling processes for paper-reinforced polypropylene composites and identify limitations and challenges along the way. This started with the size reduction of the composite laminates. The initial effort focused on the use of a Conair–Wortex granulator, a piece of equipment commonly used in the injection molding industry for regrinding production scrap to create post-industrial recyclate [25]. However, the resulting “fluffy” flake posed challenges in material feeding during the extrusion process due to its size. To address this, we therefore added a second step, in which we used a knife mill to further reduce the size of the granulate to ~4.5 × 2.5 × 1 mm. At this point, the granulate was still low bulk density, but it fed into the extruder without bridging or clogging issues seen in previous tests.

Following size reduction, the granulate was compounded with polypropylene pellets and maleic anhydride copolymer (MAPP), the latter of which acted as a coupling agent between the paper fibers and the polypropylene matrix. We processed the material under the lowest possible temperature profile in the twin screw extruder, as detailed in Section 3.2. The reason for this was to minimize thermal degradation of paper fibers while preventing excessive torque on the extruder motor. The addition of MAPP was necessary to prevent severe “shark-skinning” of extrudate, a phenomenon that occurs due to melt fracture of the polymer when exiting the extruder die [26]. The extrudate was pelletized with an in-line unit, generating feedstock for the subsequent injection molding stage.

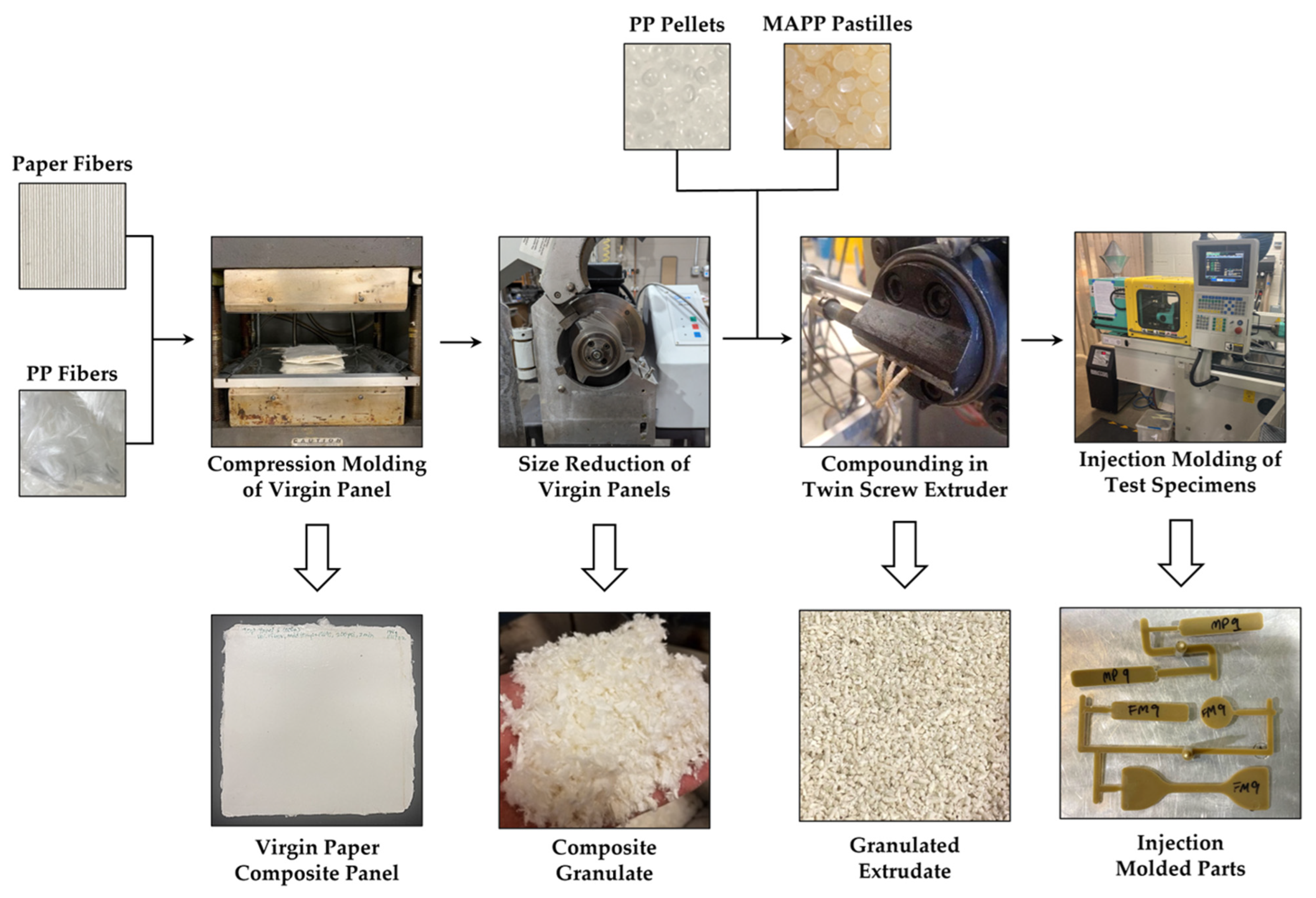

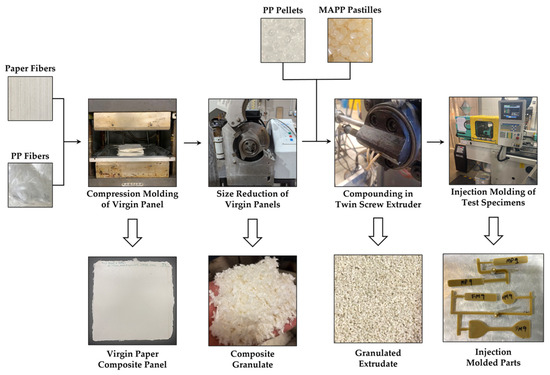

As with extrusion, we aimed to injection-mold the paper–polypropylene composite at the lowest possible temperature. This was ultimately determined to be 200 °C, as lower temperatures resulted in “short shots”—parts in which the material was unable to completely fill the mold cavity. From this baseline, we were able to investigate the different combinations of temperature and injection rate on the processability of the composite material, with the goal of identifying the upper limit of the processing window. The composite material processed well until we reached 240 °C, at which point we were only able to produce parts at injection rates of 32.8–49.2 mL/s (2–3 in3/s), as the material would not inject properly at either 16.4 or 65.6 mL/s (1 or 4 in3/s). The full recycling process is shown below in Figure 1.

Figure 1.

Overview of the manufacturing process used in this research. Step 1 the represents production of virgin paper composites, while steps 2–4 represent the recycling process.

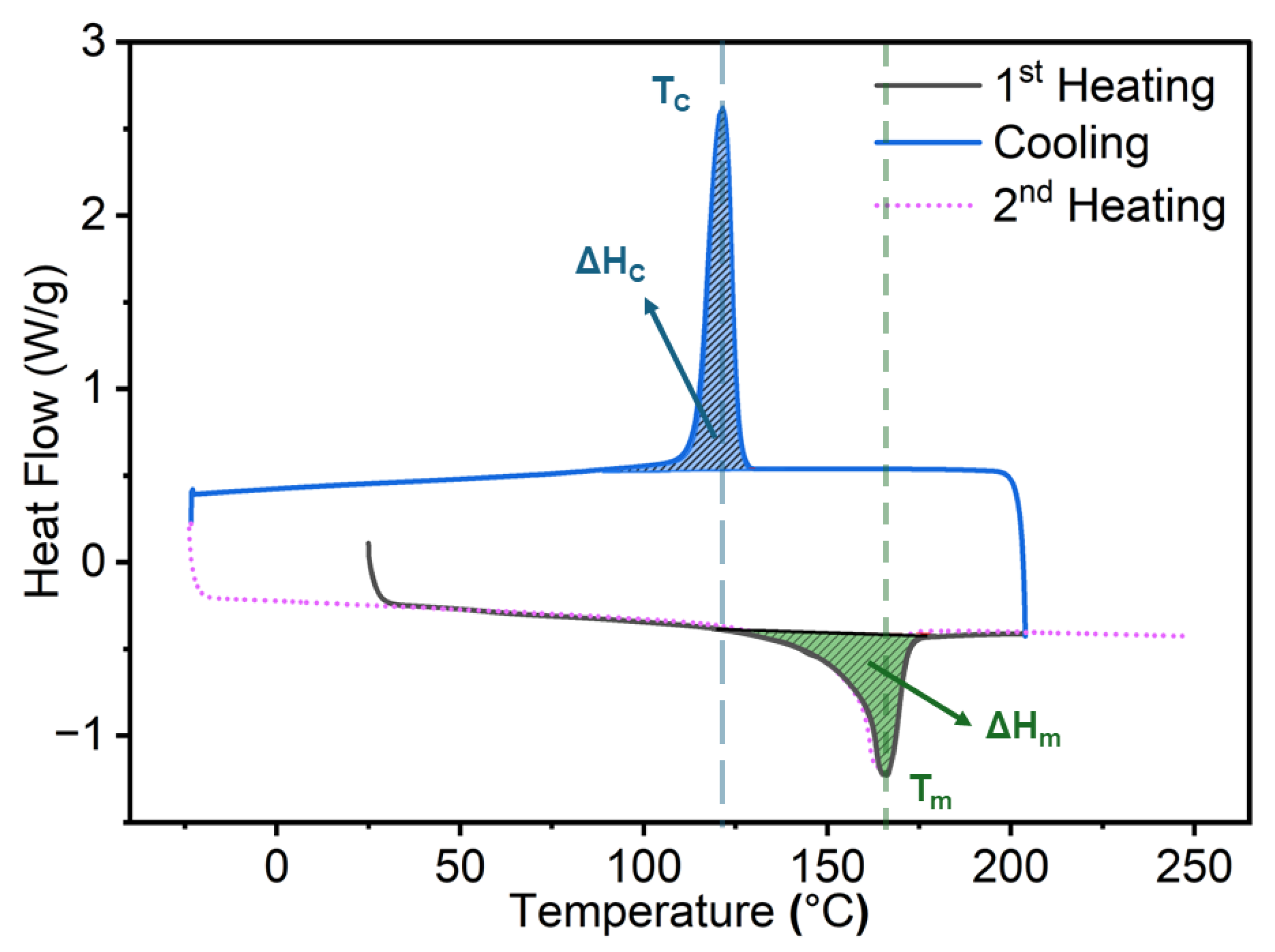

2.2. Impact of Injeciton Molding Parameters on Composite Thermal Behavior

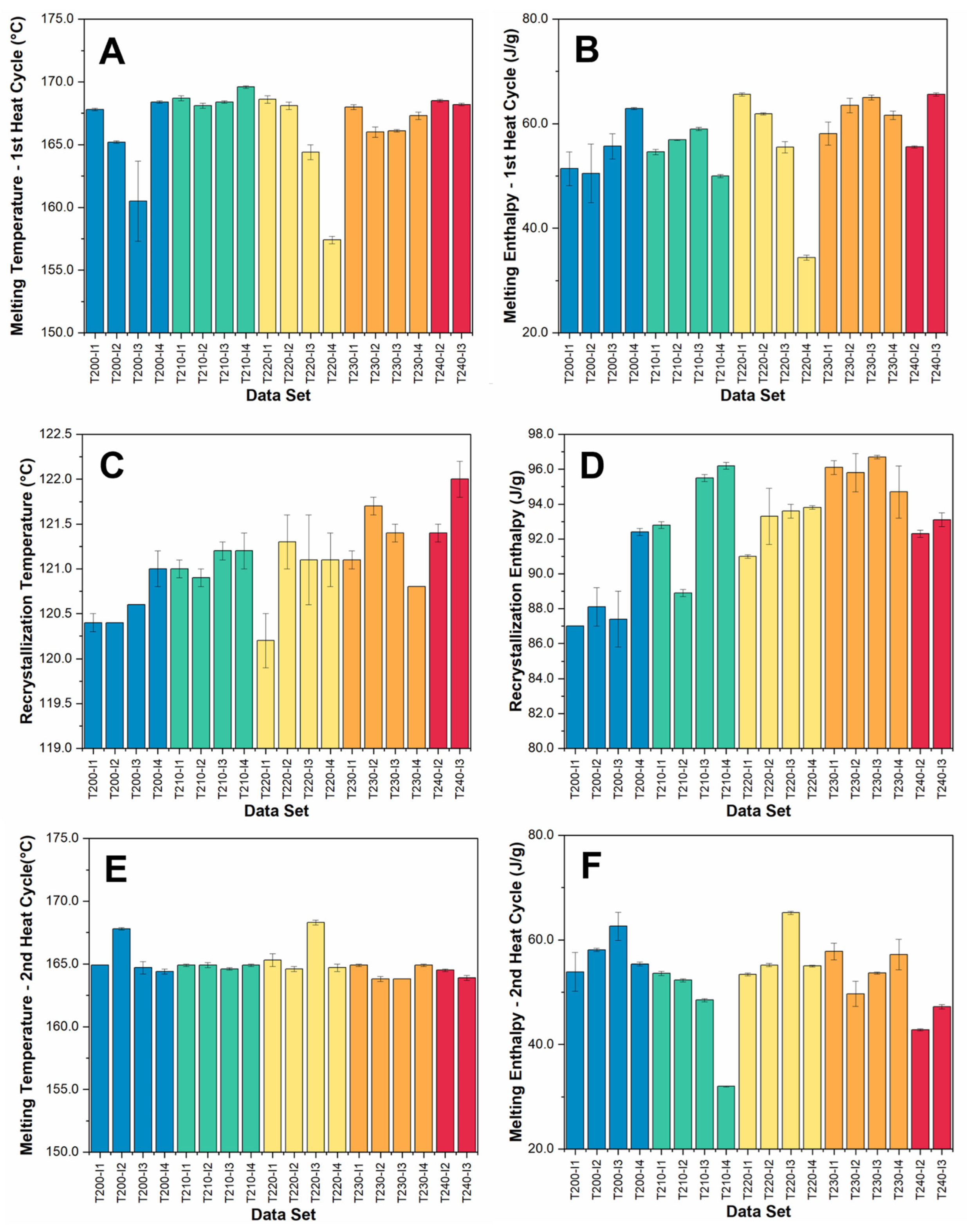

The thermal properties of the injection-molded specimens were measured using differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA). DSC was used to study the melting and crystallization behavior, while TGA was used to characterize the thermal stability of the materials. Figure 2 shows the results of the DSC testing, with melt temperatures and enthalpies reported for both heating cycles, and crystallization temperatures and enthalpies reported for the sole cooling cycle. TGA data are reported in Supplementary Information (Table S2), as no statistical significance was seen in the results.

Figure 2.

Thermal properties of injection-molded samples: (A) Melting temperatures of the 1st heat cycle, (B) melting enthalpies for the 1st heating cycle, (C) recrystallization temperatures, (D) recrystallization enthalpies, (E) melting temperatures of the 2nd heat cycle, and (F) melting enthalpies for the 2nd heating cycle.

Overall, thermal analysis shows subtle correlations between the processing conditions and the resulting properties. The most notable analysis outcome is the positive correlation between the processing temperature and both recrystallization temperature and enthalpy, as seen in Figure 2C,D. Likewise, it appears that both of the recrystallization properties are positively correlated with the injection rate, although this is more difficult to detect visually. The impacts of processing parameters on the melting temperature and enthalpy during both the first and second heating cycles are not visually obvious. Regression analysis was employed to further elucidate the complex relationships between processing parameters and material properties. For this, we considered both linear (temperature, injection rate) and interactions between the two (temperature × injection rate) terms. The p-values for each term are presented in Table 2, where bold values indicate statistical significance at a level of p < 0.05. Additionally, Table 2 includes the direction of correlation (↑ for positive, ↓ for negative) for all statistically significant terms. This convention will be used throughout the remainder of the paper.

Table 2.

p-values and correlation direction for the effects of temperature, injection rate, and their interaction on thermal properties. Statistically significant terms are bolded for clarity (p < 0.05).

Processing temperature has the most significant impact on melting and recrystallization behavior of the samples. As regards the melting behavior, the processing temperature is positively correlated with the melting enthalpy in the first heat cycle and negatively correlated with the re-melting temperature in the second heat cycle. It is also positively correlated with both recrystallization temperature and recrystallization enthalpy. ΔHm (1st heat) corresponds to the thermal history of cooling the polymer in the injection molding tool. At higher processing temperatures, the polymer reaches a lower viscosity during injection molding. This improves the ability of the polymer to crystallize while cooling due to improved chain mobility with decreased viscosity [27].

The inverse correlation between processing temperature and Tm (2nd heat) is likely due to a decrease in PP molecular weight from thermo-oxidative degradation. Previous literature has noted that polypropylene molecular weight is relatively stable up to processing temperatures of 230 °C; however, above this point, chain scission rises rapidly with increasing temperature [28]. These changes in molecular weight are not apparent in the first heating cycle as the effects are masked by the different temperature differentials () associated with different processing temperatures during injection molding, which leads to disparate cooling experiences between different processing conditions. Conversely, the cooling cycle in the DSC leads to uniform thermal histories and reveals the differences between melting temperatures during the second heating cycle. The positive correlation between processing temperature and recrystallization behavior (Tc and ΔHc) is also likely due to this decreasing molecular weight, which allows for improved nucleation of PP crystals during cooling.

The injection rate shows a less statistically significant impact on the thermal properties, however there are a few key relationships that can be observed. The injection rate is negatively correlated with Tm in the first heating cycle only, while it is positively correlated with both Tc and ΔHc. The injection rate and associated shear likely have a greater impact on the reinforcing fibers than on the polymer matrix and would be expected to decrease the fiber length, in turn increasing the number of nucleation sites available. The increasing shear rate also favors the formation of β-phase crystalline structure in the polypropylene matrix [29]. The combination of these two effects explains both the changes in melting temperature and the recrystallization behavior. The increase in nucleation sites will improve nucleation efficiency, increasing the crystallization rate and resulting in a corresponding increase in crystallization temperature and enthalpy [30]. Likewise, the β-crystals of polypropylene are known to melt at a lower temperature than α-crystals; hence the depression of the melting temperature [31]. This effect is only seen in the first heat cycle, however, as there are no shear forces during the DSC experiment to re-induce the β crystallite structure. It is also possible that the depression of the melting point is due to the formation of α-crystals with an imperfect crystal structure, as these defects will also reduce the melting temperature [32].

2.3. Impact of Injeciton Molding Parameters on the Chemical Composition of Composites

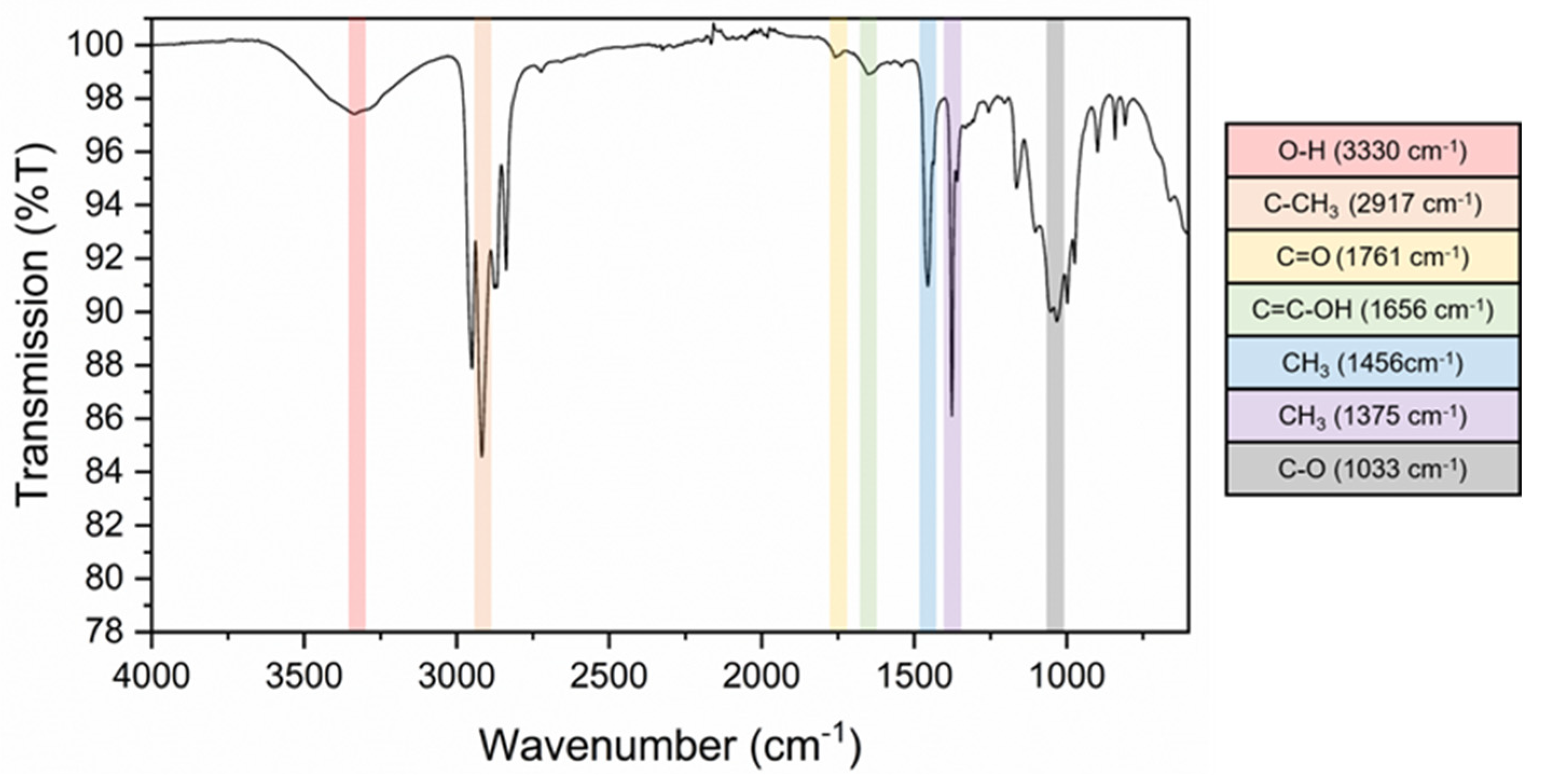

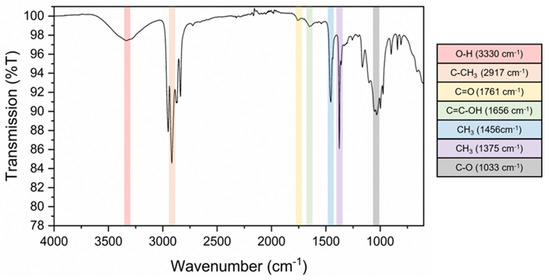

Fourier Transform Infrared Spectroscopy (FTIR) was used to analyze the chemical changes in the injection-molded samples. This technique measures the characteristic vibrational frequencies of molecules, allowing for the identification of various functional groups present in the composites. The peaks of interest were identified as 3330 cm−1 (O-H stretch), 2917 cm−1 (C-CH3 stretch), 1761 cm−1 (C=O stretch), 1656 cm−1 (enolic groups), 1456 cm−1 (CH2 bend), 1375 cm−1 (CH3 bend), and 1033 cm-1 (C-O stretch) [33]. An example plot with these peaks highlighted is shown in Figure 2. We chose to normalize against the C-CH3 peak at 2917 cm−1 for further analysis, as it appears in all the raw materials and is not expected to change significantly with oxidation. The carbonyl index (CI), a measure of the relative amount of carbonyl groups (C=O) present in the material, was calculated for each sample using Equation (1).

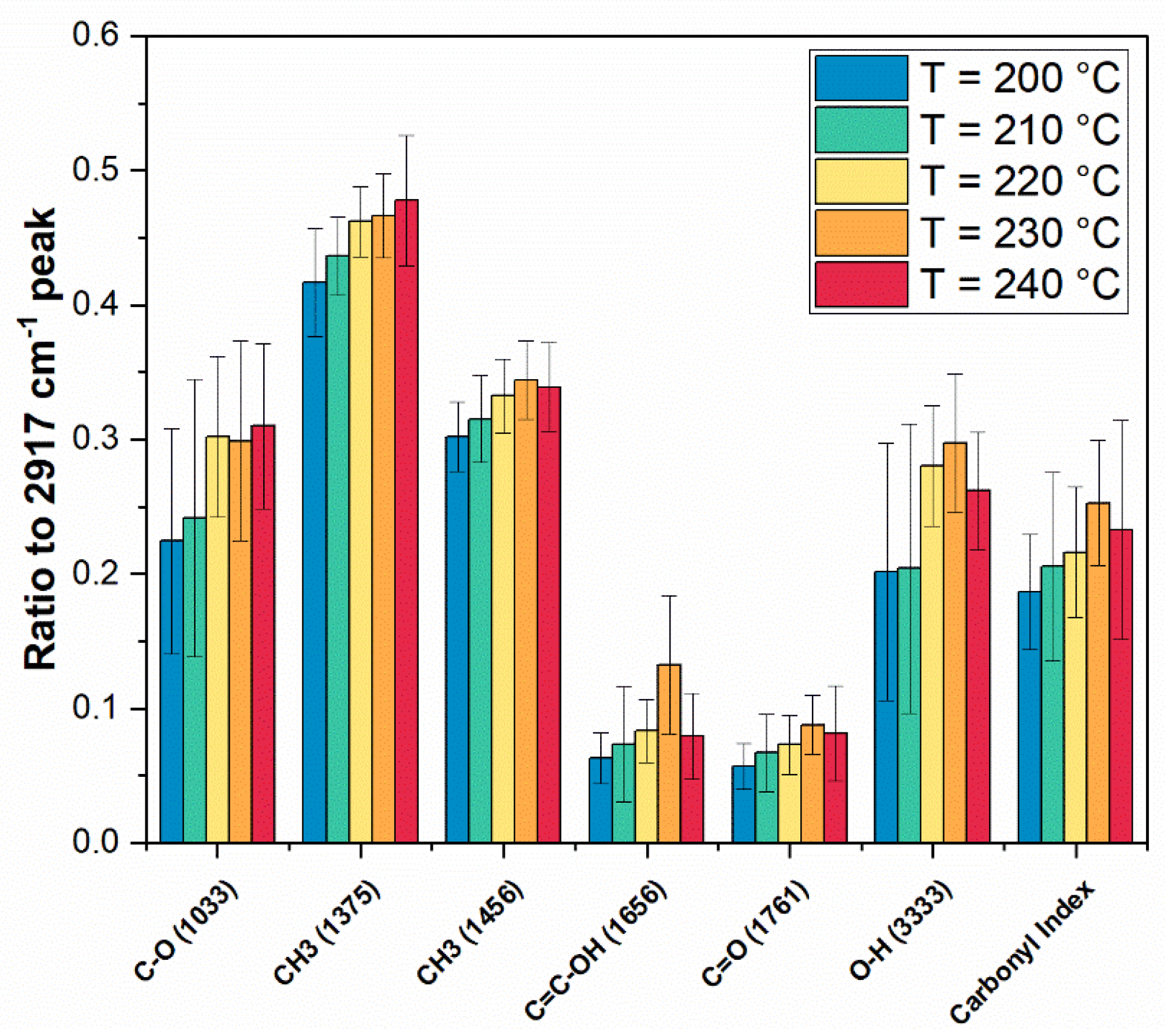

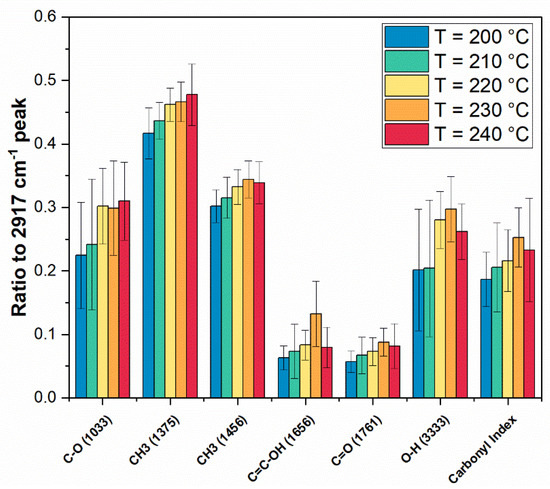

The full results of both the normalization and CI calculation are included in the supplemental analysis; however, Figure 3 shows the trends observed in the samples molded at 2 in3/s which are representative of the overall trends observed across all injection rates. Finally, as with the thermal analysis, regression analysis was used to determine the statistical impact of the processing parameters on the studied peak intensities and CI values. The p-values and correlation directions for this analysis are reported in Table 3.

Figure 3.

Example spectra of T230−I2 with relevant peaks identified.

Table 3.

p-values and correlation directions for the effects of temperature, injection rate, and their interaction on FTIR peak intensities. Statistically significant terms are bolded for clarity (p < 0.05).

Overall, injection molding temperature was the only processing parameter that had a statistically significant impact on the chemical composition of the samples. Increasing injection molding temperature led to increases in all FTIR peaks associated with degradation, as well as a pronounced rise in the carbonyl index. The peak at 1761 cm−1 is associated with the formation of carbonyl groups during the oxidative degradation of both polypropylene and paper fibers [34,35]. The 1656 cm−1 peak is associated with the formation of enolic or conjugated ketone groups during cellulose oxidative and hydrothermal degradation [36]. The peaks at 1465 and 1375 cm−1 are associated with CH2 scissoring and C-H bending in cellulose and are strongly correlated with cellulose crystallinity [37]. When the paper fibers are exposed to a thermo-oxidative environment, the amorphous regions of the cellulose degrade at lower temperatures, leaving behind a larger portion of the crystalline cellulose, thus resulting in increases in the 1465 and 1375 cm−1 peaks. Similar effects have been seen in wood degradation, although they were outsized in comparison to this study, as wood has a much higher lignin and hemicellulose content than the paper fibers used in this study [38]. Overall, the FTIR results suggest that the material experiences a higher degree of oxidative degradation with increased temperature, as expected. Furthermore, the results seem to suggest that the oxidative degradation primarily affects the paper fibers rather than the polypropylene matrix.

2.4. Impact of Injection Molding Parameters on Composite Mechanical Behavior

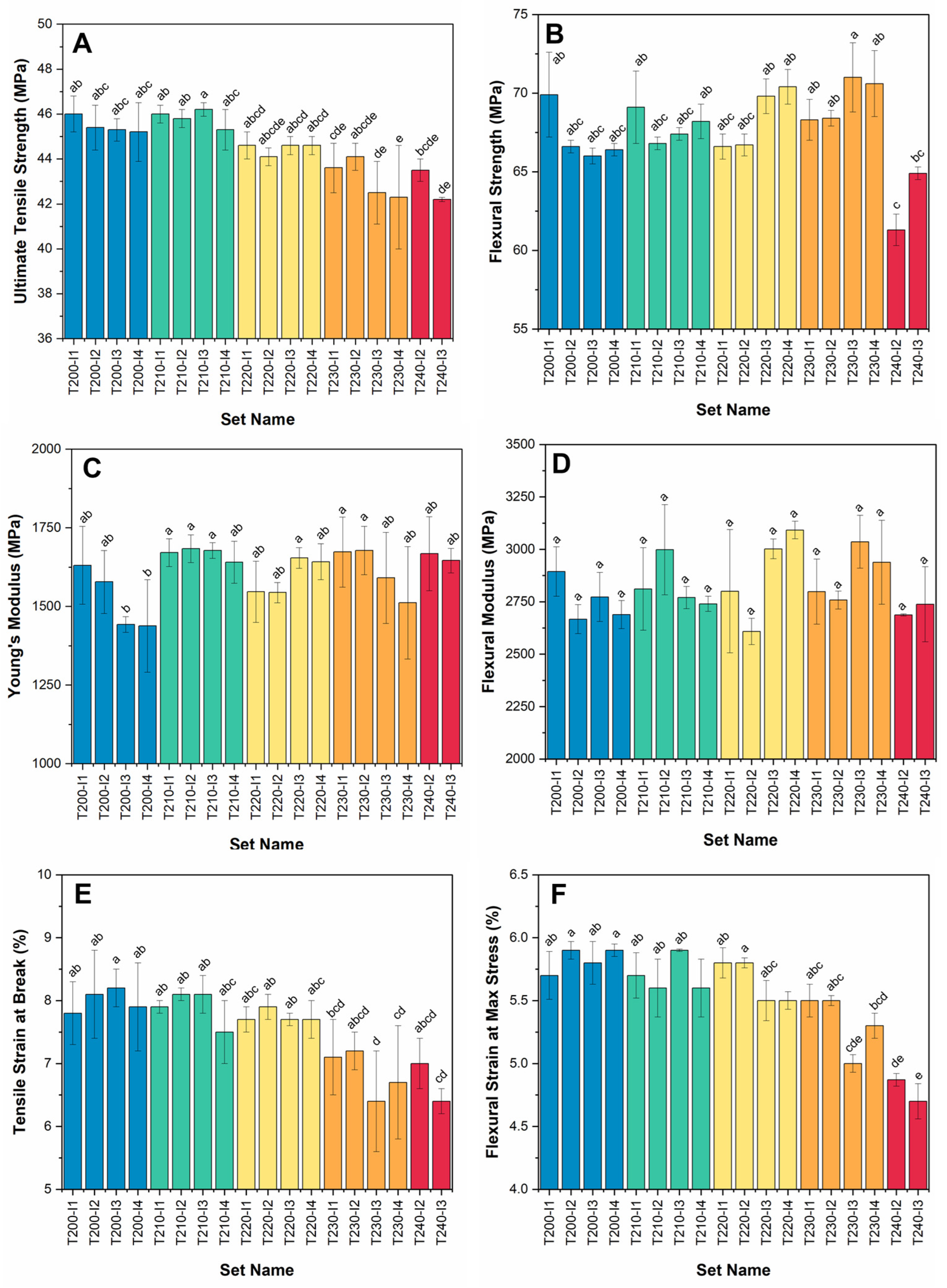

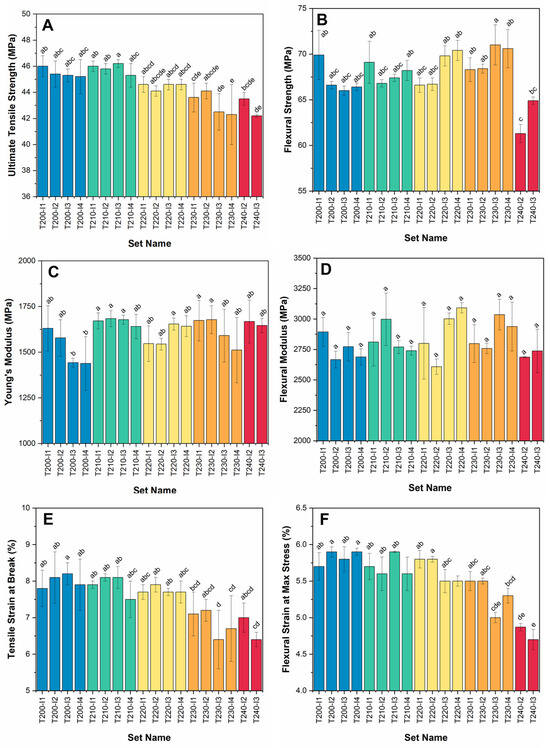

The mechanical behavior of the composites was studied using flexural and tensile analysis. For both methods, the modulus, strength, and strain at failure were recorded as these properties are critical for composite part performance in automotive applications. In particular, the moduli and strength are used as design criteria. The three measured properties are shown in Figure 4 for both tensile and flexural testing. The same method of regression analysis as previously described was used to determine the statistical significance of processing parameters. The p-values for this analysis are reported in Table 4. One-way analysis of variance (ANOVA) was used to determine statistically different pairs using the Tukey−Kramer test, the results of which are included in Figure 5.

Figure 4.

Ratio of intensities of various peaks to intensity of the C−CH3 peak at 2917 cm−1. Trends are shown only for samples molded at an injection rate of 2 in3/s, as they are representative of other injection rates.

Table 4.

p-values and correlation direction for the effects of temperature, injection rate, and their interaction on mechanical properties. Statistically significant terms are bolded for clarity (p < 0.05).

Figure 5.

Mechanical properties of injection-molded specimens: (A) ultimate tensile strength, (B) flexural strength, (C) Young’s modulus, (D) flexural modulus, (E) tensile strain at break and (F) flexural strain at maximum stress. Different letters (i.e., a, b, c, d, and e) designate statistically different data sets at p < 0.05.

Both processing temperature and injection rate were statistically significant for the tensile strength and modulus of the composites, while only temperature had a statistically significant effect on strain at break. Tensile modulus was positively correlated with temperature and negatively correlated with injection rate, while tensile strength was negatively correlated with both parameters. It should be noted that the interaction term (temperature*injection rate) was not statistically significant, which indicates that these two variables do not interact with each other in a meaningful way. Tensile strain at break was also negatively correlated with temperature, similar to ultimate tensile strength.

The increase in tensile modulus with increasing temperature can likely be attributed to the increase in crystallinity, as PP crystallinity is well known to correlate with Young’s modulus [39]. This is further corroborated by the thermal analysis data, indicating that increasing the processing temperature led to higher crystallinity. Higher crystallinity within the matrix can also explain the observed decreases in tensile strength and strain at break.

This is a direct consequence of an increased modulus for strain at break—as the composite becomes stiffer, it will also become more brittle [40]. The decrease in tensile strength with increasing temperature can also be associated with this increased crystallinity, as smaller and weaker amorphous fractions must account for most of the composite strain [41]. This ultimately leads to brittle failure at lower stress. The reduction in modulus and strength associated with an increasing injection rate can also be attributed to fiber length reduced by increased shear forces during injection molding [22,42].

The trends observed in flexural properties were somewhat different from those seen in the tensile properties of the composite material. Only flexural strain at maximum stress was correlated with a primary factor—a negative correlation with processing temperature. Neither temperature nor injection rate was directly correlated with either flexural strength or modulus; however, the interaction term was positively correlated with all three measured properties. In general, flexural strength appears to stay relatively constant with increasing temperature; however, this trend abates once we reach a processing temperature of 240 °C, at which point the flexural strength drops significantly. This indicates that flexural strength is less sensitive to the degradation that occurs until a threshold is reached, unlike tensile strength which drops off in a more linear fashion. These contrasting observations can be explained by the inherent differences between tensile and flexural testing. Tensile tests apply uniform stress throughout the cross-section of the materials, whereas flexural tests concentrate stress on the surfaces of the specimen. This also explains why flexural strengths are typically higher than tensile strengths for a given material [43]. The positive correlation between the interaction term (temp. × injection rate) is likely due to the decreased viscosity of the polymer under more intense processing conditions. The improved flow of the polymer will lead to better surface properties thereby improving flexural strength, although under very intensive processing conditions, the degradation of the fibers is more significant than these positive effects. This is likewise true for the flexural modulus; however, we do not observe a drop-off in the stiffness of the material as this is less sensitive to defects in the bulk material than the strength. Flexural strain at maximum stress experiences similar trends to tensile strain at break and can again be attributed to increasing matrix crystallinity.

The analysis of variance between the different data sets revealed that although the processing conditions have statistically significant effects on the trends of the material properties, the actual values of the mechanical properties do not change significantly throughout the processing window studied. This is particularly true for the stiffness of the material, with all the flexural moduli falling within a statistically equal range, and the tensile Young’s modulus has only a few data sets that are not statistically equivalent. From a manufacturing perspective, this suggests that the recyclate is tolerant of a wide processing window, although there is an upper limit to the temperature that it can endure.

2.5. Impact of Injeciton Molding Parameters on Composite Water Uptake Behavior

The water absorption behavior of the injection-molded samples was measured to assess their resistance to humid environments, a common challenge for natural fiber composites. The samples exhibited a low water uptake, with an average mass increase of 0.4 ± 0.2 wt.% after 24 h of submersion and 0.7 ± 0.4 wt.% after 504 h of submersion. The processing conditions had no statistically significant effect on water uptake behavior, as all the p-values were far greater than 0.05, as shown in Table 5. A significant degree of variability was observed, likely due to limitations in the resolution of the scale used for these measurements. Overall, these tests indicate that paper fibers were almost entirely encapsulated by the polypropylene matrix, thereby preventing moisture ingress into the fibers.

Table 5.

p-values and correlation direction for the effects of temperature, injection rate, and their interaction on water uptake behavior.

2.6. Correlation Between Crystallinity and Mechanical Properties

Multivariate analysis was used to analyze the relationship between crystallinity and mechanical properties to understand the underlying correlations. The Pearson’s correlation coefficients from this analysis are shown in Table 6, with associated p-values reported in the Supplementary information. Tm (2nd heat) and ΔHm (2nd heat) were not included in this analysis, as they do not correspond to the thermal history associated with processing the tested specimens. These relationships were analyzed and no correlations were observed. In general, Pearson’s correlation coefficients with an absolute value between 0.00 and 0.09 are considered to have a negligible correlation, and those from 0.10 to 0.39 are weakly correlated, 0.40 to 0.69 moderately correlated, 0.70 to 0.89 strongly correlated, and 0.90–1.00 very strongly correlated [44].

Table 6.

Pearson’s correlation coefficients from multivariate analysis, with moderate or better correlation bolded for clarity.

The majority of the correlation coefficients generated by the multivariate analysis fall in the negligible to weakly correlated range; however, there are a number of notable exceptions. Ultimate tensile strength is very strongly correlated with tensile strain at break, strongly correlated with flexural strain at maximum stress, and moderately negatively correlated with ΔHm (1st heat), Tc and ΔHc. Tensile strain at break is also strongly correlated with flexural strain at maximum stress, and moderately negatively correlated with Tc and ΔHc. Flexural modulus shows a moderate negative correlation with Tm (1st heat), while flexural strain at max stress shows a moderate positive correlation.

These correlations provide further insight into the relationship between polymer morphology and mechanical behavior. In particular, these results support the conclusion that the degree of crystallinity and type of crystal have significant impacts on material strength and brittleness. The degree of crystallinity is directly measured by both ΔTc and ΔHc. The inverse correlation between these two properties and ultimate tensile strength further confirms the previously hypothesized relationship. Likewise, the inverse correlation between tensile strain at break and both ΔTc and ΔHc further suggests that increasing polymer crystallinity cause the composites to become more brittle. The relationships between melting temperature and both flexural modulus and flexural strain at maximum stress suggest that the increase in β crystalline regions within the polypropylene matrix impacts the stiffness and brittleness of the composite. The β crystal morphology appears to have a negative impact on stiffness, while increasing the ductility of the material.

2.7. Identification of Optimal Injection Molding Processing Conditions

A set of optimal processing conditions was selected by comparing the mechanical properties (ultimate tensile strength, Young’s modulus, flexural strength, and flexural modulus) associated with different processing conditions, as well as their standard deviations. This comparison was done using objective function minimization, which aligns with our previous work. The objective function was defined as

where is the number of properties (), is the value of property for sample , is the average value of property over all samples, is the relative weight of property , and is the exponent for property , which is set to a value of . A positive value of was used for standard deviations, as it is desired to minimize the variability, while a negative value of was used for the mechanical properties studied, as we would like to maximize mechanical performance. All weights, , were set to 1 for this work, indicating that all properties were considered equally important. The samples produced at 240 °C were excluded from this analysis due to the processing challenges experienced at this temperature. The results of this optimization analysis are shown in Table 7, with the results color-coded by processing temperature to match previous figures. We also compared the mechanical properties to literature values for talc-filled polypropylene. This is a material that is commonly used for injection-molded automotive parts such as bumpers, instrument panels, door panels, and mirror housings [36,37]. We chose this as a point of comparison to determine whether our recycled material has appropriate properties for automotive applications.

Table 7.

Results of objective function analysis for injection-molded specimens with color-coding to match previous figures (i.e., Figure 1). Comparison data for talc-filled polypropylene were obtained from Kant et al. [45].

Overall, our analysis shows that 210 °C is the best temperature for injection molding of paper composite material, producing samples with the highest mechanical properties and lowest standard deviations. Higher screw speeds also appear to produce better samples overall, although this is not consistent across the study. The comparison with talc-filled polypropylene also shows that even the “worst” of the injection-molded paper composite samples are on par or better than a widely used automotive material. This suggests that even under sub-optimal processing conditions, the paper–polypropylene composite could be used in a wide variety of automotive applications.

3. Materials and Methods

3.1. Materials

The following materials were used as received: Domtar bleached hardwood kraft market pulp (MP) and MiniFibers precision cut 3 mm length, 15.3 μm diameter polypropylene (PP) fibers, isotactic PP pellets with a melt flow index (MFI) of 35, and Honeywell AC950 propylene maleic anhydride copolymer (MAPP). Market pulp fiber dimensions were measured using an L&W Fiber Tester Plus, revealing a mean fiber length of 1.004 mm and a mean fiber width of 19.9 μm. The market pulp density was estimated to be 1.53 ± 0.05 g/cm3 using a Micromeritics AccuPyc II 1340 gas pycnometer.

3.2. Recyclate Manufacturing

Recyclate was prepared for injection molding in such a way as to mimic an industrial process, aiming to achieve representative material properties. Composite laminates were produced from 60 wt.% market pulp and 40 wt.% polypropylene fiber using the method described in our previous work [13]. These laminates are meant to represent the virgin composite that would be used in automotive interior applications, such as door panels, dashboards, or interior trim parts. Following compression molding, the laminates were shredded into flakes using a Conair–Wortex granulator (model number: 933001). The flake was further reduced in size using the Thomas Model 4 Wiley Mill to obtain a low bulk density granulate.

MAPP was included in the formulation to improve compatibility between the pa-per fibers and the polypropylene matrix. Therefore, the paper composite granulate was manually blended with PP pellets and MAPP pastilles to achieve a final mixture with a composition of 4.7 wt.% MAPP, 28.6 wt.% market pulp fiber, and 66.7 wt.% polypro-pylene (nominally 30% paper fiber/70% PP). This mixture was compounded in a 27 mm Leistriz twin screw extruder and pelletized using a BT 25 Lab Series Pelletizer for use in the injection molding stage of this study. An overview of the recycling process is shown in Figure 1, and the extrusion processing parameters are shown in Table 8.

Table 8.

Extruder processing parameters used for compounding paper composite granulate with MAPP and PP.

3.3. Injection Molding

Specimens were injection- molded using a custom three-cavity mold designed to produce flexural, tensile, and rheology test specimens. A 28-ton Arburg Allrounder machine, equipped with a hot-air desiccant dryer and a mold heating/cooling device, was employed for the injection molding process. The injection rate and temperature were varied as shown in Table 9, while all other processing parameters were kept constant. Specifically, the injection pressure was set at 86.2 MPa (12,500 psi), the shot size at 19.7 cm3 (1.2 in3), the packing pressure at 75.8 MPa (11,000 psi), the packing time at 0.5 s, the holding pressure at 55.2 MPa (8000 psi), the holding time at 10 s, the cooling time at 15 s, and the mold temperature at 35 °C (95 °F). In this study, the term “injection temperature” refers to the barrel temperature at the nozzle. Detailed barrel temperature profiles can be found in the Supplementary Information in Table S1. The injection rate and temperature were selected as the main focus of this study due to the well-documented shear and temperature sensitivity of natural fibers and their associated composites [46,47,48,49].

Table 9.

Experimental conditions for different injection temperatures and speeds. Each set name represents a combination of injection temperature (°C) and injection rate (in3/s).

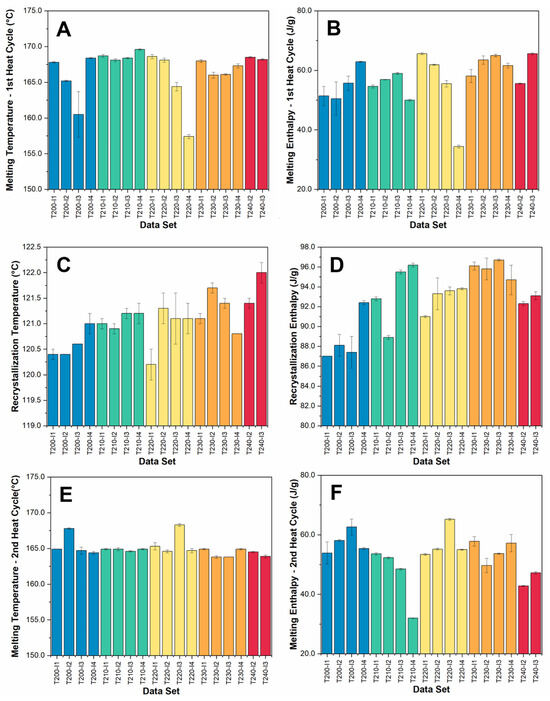

3.4. Differential Scanning Calorimetry

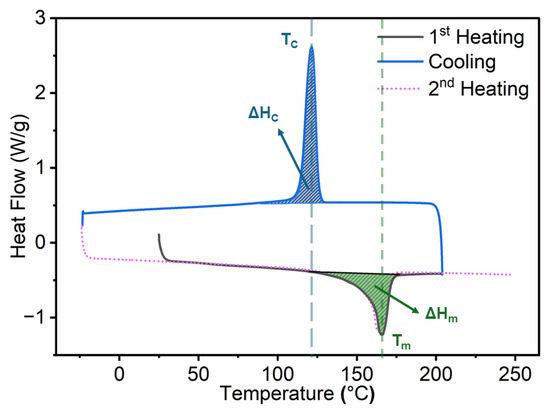

Differential scanning calorimetry was performed using a TA Q2000 to study the thermal behavior of the injection-molded samples. Samples (5–10 mg) were cut from the injection molding runner system of the injection-molded parts and subjected to a heating cycle from room temperature to 205 °C, followed by cooling to −25 °C, and a final heating cycle to 250 °C. All temperature scans were conducted at a rate of 5 °C/min under a nitrogen (N2) atmosphere. The DSC data were analyzed to obtain melt temperatures (ΔTm) and enthalpies (ΔHm) reported for both heating cycles, and crystallization temperatures (ΔTc) and enthalpies (ΔHc) reported for the sole cooling cycle. A representative DSC curve is shown below in Figure 6 to demonstrate the method by which temperatures and enthalpies were obtained.

Figure 6.

Example of DSC curve of paper-reinforced polypropylene composites to illustrate how enthalpies and temperatures were measured for each sample. The 2nd heating cycle does not show the integration enthalpy for clarity.

3.5. Thermogravimetric Analysis

Thermogravimetric analysis was performed using a TA Q50 instrument to evaluate the thermal stability of the injection-molded materials. The samples were ramped from room temperature to 600 °C at 10 °C/min under an N2 atmosphere. The sample size was approximately 10 mg for all tests. As with the DSC testing, samples were obtained from the injection molding runner system. The TGA data were analyzed to obtain the temperature at which 50% mass loss occurred (T50) and residual mass.

3.6. Fourier Transform Infrared Spectroscopy

Attenuated total reflectance–Fourier transform infrared (ATR-FTIR) spectroscopy was performed using a PerkinElmer Spectrum Two FT-IR spectrometer to investigate the chemical composition and potential degradation of the injection-molded parts. Testing was performed between 500 and 4000 cm−1 at a resolution of 4 cm−1 and 32 scans per spectrum. FTIR samples were prepared by slicing off thin pieces from the runner system using a precision utility knife.

3.7. Tensile Testing

Tensile testing was performed in accordance with ASTM D638 using Type IV specimens. The samples measured 115 mm in overall length, 6.4 mm in width in the gauge region, and 2.2 mm in thickness. They were conditioned at 25 °C and 65% relative humidity for 88 h prior to testing. Tensile testing was performed using an Instron 5567 universal testing machine equipped with self-centering wedge grips and a 30 kN load cell. The crosshead speed during testing was set to 5 mm/min and strain was measured using a clip-on extensometer.

3.8. Flexural Testing

Flexural testing was performed in accordance with ASTM D790. The samples were conditioned using the same procedure described in the tensile testing section. Flexural testing measurements were taken using an Instron 5567 universal testing machine equipped with a 3-point bend test fixture and 500 N load cell. A test span of 45 mm and a test rate of 1.125 mm/min were used. The samples were tested until a 25% strain was reached. The Instron deflectometer used to measure strain was equipped with an extensometer with a 25 mm range. Flexural sample dimensions were approximately 60 × 12 × 3 mm.

3.9. Water Uptake Testing

Water uptake measurements were conducted using a modified ASTM D570 method, in which test specimens were 14 mm in length, 14 mm in width, and 2.4 mm in thickness, rather than standardized dimensions. Prior to testing, the samples were dried overnight under vacuum at 80 °C to remove any excess moisture. Following the conditioning step, the samples were cooled in a desiccator unit and weighed using a precision analytical balance to establish an initial mass. For testing, the samples were placed into a 23 °C water bath and mass was re-measured after 24 h and 504 h of submersion.

3.10. Statistical Analysis

All statistical analysis was performed in JMP Pro 16.0.0. Regression analysis was performed using Standard Least Squares fit with Effect Leverage emphasis. The p-values were calculated from the t-statistic using a two-tailed test. A confidence level of 95% was used for all tests, corresponding to α = 0.05. One-way ANOVA was performed on the mechanical properties data to identify statistically different data sets. The Tukey–Kramer test was used as the post-hoc analysis method. Multivariate analysis was performed to determine the correlation coefficients between variable pairs.

4. Conclusions

This research investigated the feasibility of mechanically recycling paper fiber-reinforced polypropylene composites using industrially relevant methods. Paper composite laminates were size-reduced and compounded with virgin polypropylene to produce an injection molding compound. This material was then injection-molded under various processing conditions to explore the optimal processing parameter windows. The impact of these processing parameters on the thermal, mechanical, and water uptake properties of the resulting composites was studied. Our findings indicate that processing temperature has the most significant impact on the material properties. Higher processing temperatures increased crystallinity, potentially due to a decrease in polypropylene molecular weight through chain scission. Additionally, higher processing temperatures resulted in increased degradation of the paper fibers, negatively impacting the mechanical performance of the composite. The injection rate had a less significant impact on the material properties than the processing temperature; however, increasing the injection rate did appear to damage the paper fibers via shear effects. Neither the composites’ water uptake nor their thermal stability changed as a function of processing conditions. The mechanical strength of the composite decreased with increasing processing temperature. However, the mechanism was different for tensile and flexural behavior. Tensile strength decreased linearly, while flexural strength remained constant until a temperature threshold was exceeded. Neither tensile nor flexural stiffness changed significantly as a function of processing conditions. Ultimately, the results of this research demonstrate a high potential for mechanical recycling of paper fiber-reinforced polypropylene composites into an automotive-grade injection molding compound and that the material system has a wide injection molding processing window. Under the optimal conditions identified in this work, the tensile strength, flexural strength, and tensile modulus of our recyclable paper fiber-reinforced polypropylene composites were 70% to 220% higher than for the unfilled PP or talc-filled PP.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/recycling9060126/s1. Table S1: Injection molding barrel temperature profile; Table S2: Thermal analysis data summary; Table S3: Mechanical properties and water uptake data summary; Table S4: p-Values for multivariate correlation analysis; Figure S1: TGA plot for samples molded at an injection rate of 2 in3/s but different temperatures; Figure S2: TGA results (a) T50 and (b) residual mass for samples molded at different injection rate and temperatures; Figure S3: DSC analysis of JMP plots; Figure S4: TGA analysis JMP plots; Figure S5: Mechanical properties JMP of plots.

Author Contributions

Conceptualization: C.A.G., D.P.H., H.M., J.M. and M.K.; Methodology: C.A.G., D.P.H., D.J.K., J.M. and M.M.; Formal Analysis: C.A.G. and M.M.; Investigation: C.A.G., D.P.H., J.G., J.M. and M.M.; Resources: D.P.H. and J.M.; Data Curation: C.A.G. and M.M.; Writing—Original Draft Preparation: C.A.G. and M.M.; Writing—Review and Editing: D.P.H., D.J.K., H.M., J.G. and M.M.; Visualization: C.A.G. and M.M.; Supervision: D.P.H. and D.J.K.; Project Administration: D.P.H.; Funding Acquisition: D.P.H., H.M. and M.K. All authors have read and agreed to the published version of the manuscript.

Funding

The research reported in this publication was supported, in part, by Volkswagen Group of America, Inc. (VWGoA), and by the University of Tennessee’s Faculty Student Research Award.

Data Availability Statement

Data are contained within the article and Supplementary Material.

Acknowledgments

The research reported in this publication was supported, at least in part, by Volkswagen Group of America, Inc. (VWGoA). The content of this research is solely the authors’ responsibility and does not necessarily represent the official views of VWGoA. The authors would also like to thank Domtar Corporation, part of the Paper Excellence Group of companies, for donating the market pulp used in this work.

Conflicts of Interest

The authors declare the following financial interests/personal relationships which may be considered potential competing interests: David P. Harper reports financial support provided by Volkswagen Group of America, Inc. David P. Harper reports a relationship with Volkswagen Group of America, Inc., that includes funding grants. Cecile Grubb reports a relationship with Volkswagen Group of America, Inc., that includes employment. Mahshid Mokhtarnejad reports a relationship with Volkswagen Group of America that includes employment. Marton Kardos reports a relationship with Volkswagen Group of America, Inc., that includes employment. Hendrik Mainka reports a relationship with Volkswagen Group of America, Inc., that includes employment. David P. Harper has a patent pending to the University of Tennessee Research Foundation. Marton Kardos has a patent pending to Volkswagen Group of America. Hendrik Mainka has a patent pending to Volkswagen Group of America. If there are other authors, they declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Koronis, G.; Silva, A.; Fontul, M. Green Composites: A Review of Adequate Materials for Automotive Applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural Fiber Reinforced Composites: Sustainable Materials for Emerging Applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Khan, T.; Hameed Sultan, M.T.B.; Ariffin, A.H. The Challenges of Natural Fiber in Manufacturing, Material Selection, and Technology Application: A Review. J. Reinf. Plast. Compos. 2018, 37, 770–779. [Google Scholar] [CrossRef]

- Nassar, M.M.A.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and Challenges in Sustainability, Compatibility, and Production of Eco-Composites: A State-Of-Art Review. J. Appl. Polym. Sci. 2021, 138, 51284. [Google Scholar] [CrossRef]

- Haag, K.; Padovani, J.; Fita, S.; Trouvé, J.-P.; Pineau, C.; Hawkins, S.; De Jong, H.; Deyholos, M.K.; Chabbert, B.; Müssig, J.; et al. Influence of Flax Fibre Variety and Year-to-Year Variability on Composite Properties. Ind. Crop. Prod. 2017, 98, 1–9. [Google Scholar] [CrossRef]

- Naidu, A.L.; Rao, P.R. A Review on Chemical Behavior of Natural Fiber Composites. Int. J. Chem. Sci. 2016, 14, 2223–2238. [Google Scholar]

- Injection Molding of Natural Fiber Reinforced Composites. In Green Biorenewable Biocomposites; Thakur, V.K., Kessler, M.R., Eds.; Apple Academic Press: Cambridge, MA, USA, 2016; pp. 293–308. ISBN 978-0-429-17420-9. [Google Scholar] [CrossRef]

- Jahnz, A.; Dejond, C. Circular Economy: Improving Design and End-of-Life Management of Cars for More Resource-Efficient Automotive Sector 2023. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_23_3819 (accessed on 14 December 2024).

- Grubb, C.A.; Kardos, M.; Webb, C.; Mainka, H.; Keffer, D.J.; Harper, D.P. Manufacturing and Characterization of Polypropylene-Paper Composites for Automotive Applications. In Proceedings of the SAMPE 2023, Seattle, WA, USA, 17–20 April 2023; NA SAMPE. 2023. [Google Scholar]

- Dunne, R.; Desai, D.; Sadiku, R.; Jayaramudu, J. A Review of Natural Fibres, Their Sustainability and Automotive Applications. J. Reinf. Plast. Compos. 2016, 35, 1041–1050. [Google Scholar] [CrossRef]

- Bahar, K. Ince, Zeynep Cetecioglu and Orhan Ince. Pollution Prevention in the Pulp and Paper Industries. In Environmental Management in Practice; Broniewicz, E., Ed.; InTech: Houston, TX, USA, 2011; ISBN 978-953-307-358-3. [Google Scholar] [CrossRef]

- Sithole, B.B. Pulp and Paper. Anal. Chem. 1995, 67, 87R–95R. [Google Scholar] [CrossRef]

- Grubb, C.A.; Keffer, D.J.; Webb, C.D.; Kardos, M.; Mainka, H.; Harper, D.P. Paper Fiber-Reinforced Polypropylene Composites from Nonwoven Preforms: A Study on Compression Molding Optimization from a Manufacturing Perspective. Compos. Part Appl. Sci. Manuf. 2024, 185, 108339. [Google Scholar] [CrossRef]

- Zhao, X.; Copenhaver, K.; Wang, L.; Korey, M.; Gardner, D.J.; Li, K.; Lamm, M.E.; Kishore, V.; Bhagia, S.; Tajvidi, M.; et al. Recycling of Natural Fiber Composites: Challenges and Opportunities. Resour. Conserv. Recycl. 2022, 177, 105962. [Google Scholar] [CrossRef]

- Augier, L.; Sperone, G.; Vaca-Garcia, C.; Borredon, M.-E. Influence of the Wood Fibre Filler on the Internal Recycling of Poly(Vinyl Chloride)-Based Composites. Polym. Degrad. Stab. 2007, 92, 1169–1176. [Google Scholar] [CrossRef]

- Beg, M.D.H.; Pickering, K.L. Reprocessing of Wood Fibre Reinforced Polypropylene Composites. Part I: Effects on Physical and Mechanical Properties. Compos. Part Appl. Sci. Manuf. 2008, 39, 1091–1100. [Google Scholar] [CrossRef]

- Nadali, E.; Layeghi, M.; Ebrahimi, G.; Naghdi, R.; Jonoobi, M.; Khorasani, M.M.; Mirbagheri, Y. Effects of Multiple Extrusions on Structure-Property Performance of Natural Fiber High-Density Polyethylene Biocomposites. Mater. Res. 2018, 21, e20170301. [Google Scholar] [CrossRef]

- Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. Reprocessing of UV-Weathered Wood Flour Reinforced Polypropylene Composites: Study of a Natural Outdoor Exposure. Polym. Degrad. Stab. 2016, 133, 389–398. [Google Scholar] [CrossRef]

- Correa-Aguirre, J.P.; Luna-Vera, F.; Caicedo, C.; Vera-Mondragón, B.; Hidalgo-Salazar, M.A. The Effects of Reprocessing and Fiber Treatments on the Properties of Polypropylene-Sugarcane Bagasse Biocomposites. Polymers 2020, 12, 1440. [Google Scholar] [CrossRef]

- Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Hossain, M.; Haafiz, M.K.; H.P.S., A. Disposal Options of Bamboo Fabric-Reinforced Poly(Lactic) Acid Composites for Sustainable Packaging: Biodegradability and Recyclability. Polymers 2015, 7, 1476–1496. [Google Scholar] [CrossRef]

- Uitterhaegen, E.; Parinet, J.; Labonne, L.; Mérian, T.; Ballas, S.; Véronèse, T.; Merah, O.; Talou, T.; Stevens, C.V.; Chabert, F.; et al. Performance, Durability and Recycling of Thermoplastic Biocomposites Reinforced with Coriander Straw. Compos. Part Appl. Sci. Manuf. 2018, 113, 254–263. [Google Scholar] [CrossRef]

- Graupner, N.; Albrecht, K.; Ziegmann, G.; Enzler, H.; Muessig, J. Influence of Reprocessing on Fibre Length Distribution, Tensile Strength and Impact Strength of Injection Moulded Cellulose Fibre-Reinforced Polylactide (PLA) Composites. Express Polym. Lett. 2016, 10, 647–663. [Google Scholar] [CrossRef]

- Bourmaud, A.; Åkesson, D.; Beaugrand, J.; Le Duigou, A.; Skrifvars, M.; Baley, C. Recycling of L-Poly-(Lactide)-Poly-(Butylene-Succinate)-Flax Biocomposite. Polym. Degrad. Stab. 2016, 128, 77–88. [Google Scholar] [CrossRef]

- Tajvidi, M.; Takemura, A. Recycled Natural Fiber Polypropylene Composites: Water Absorption/Desorption Kinetics and Dimensional Stability. J. Polym. Environ. 2010, 18, 500–509. [Google Scholar] [CrossRef]

- Litster, J.; Ennis, B. The Science and Engineering of Granulation Processes; Particle Technology Series; Springer: Dordrecht, The Netherlands, 2004; Volume 15, ISBN 978-90-481-6533-9. [Google Scholar]

- Agassant, J.-F.; Arda, D.R.; Combeaud, C.; Merten, A.; Münstedt, H.; Mackley, M.R.; Robert, L.; Vergnes, B. Polymer Processing Extrusion Instabilities and Methods for Their Elimination or Minimisation. Int. Polym. Process. 2006, 21, 239–255. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, B.-H.; Xu, J. A Review on Polymer Crystallization Theories. Crystals 2016, 7, 4. [Google Scholar] [CrossRef]

- González-González, V.A.; Neira-Velázquez, G.; Angulo-Sánchez, J.L. Polypropylene Chain Scissions and Molecular Weight Changes in Multiple Extrusion. Polym. Degrad. Stab. 1998, 60, 33–42. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Ji, F.; Zhang, X.; Zheng, G.; Shen, C. Effects of Melt Structure on Shear-Induced β-Cylindrites of Isotactic Polypropylene. Polymer 2012, 53, 1791–1800. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, J. Effect of Nucleating Agent on the Crystallization Behavior, Crystal Form and Solar Reflectance of Polypropylene. Sol. Energy Mater. Sol. Cells 2013, 117, 577–584. [Google Scholar] [CrossRef]

- Bednarek, W.H.; Paukszta, D.; Szostak, M.; Szymańska, J. Fundamental Studies on Shear-Induced Nucleation and Beta-Phase Formation in the Isotactic Polypropylene—Effect of the Temperature. J. Polym. Res. 2021, 28, 439. [Google Scholar] [CrossRef]

- Androsch, R.; Monami, A.; Kucera, J. Effect of an Alpha-Phase Nucleating Agent on the Crystallization Kinetics of a Propylene/Ethylene Random Copolymer at Largely Different Supercooling. J. Cryst. Growth 2014, 408, 91–96. [Google Scholar] [CrossRef]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez C., V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.-J.; et al. Validation of ATR FT-IR to Identify Polymers of Plastic Marine Debris, Including Those Ingested by Marine Organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef]

- Qian, S.; Igarashi, T.; Nitta, K. Thermal Degradation Behavior of Polypropylene in the Melt State: Molecular Weight Distribution Changes and Chain Scission Mechanism. Polym. Bull. 2011, 67, 1661–1670. [Google Scholar] [CrossRef]

- Łojewska, J.; Miśkowiec, P.; Łojewski, T.; Proniewicz, L.M. Cellulose Oxidative and Hydrolytic Degradation: In Situ FTIR Approach. Polym. Degrad. Stab. 2005, 88, 512–520. [Google Scholar] [CrossRef]

- Łojewska, J.; Missori, M.; Lubańska, A.; Grimaldi, P.; Ziȩba, K.; Proniewicz, L.M.; Congiu Castellano, A. Carbonyl Groups Development on Degraded Cellulose. Correlation between Spectroscopic and Chemical Results. Appl. Phys. A 2007, 89, 883–887. [Google Scholar] [CrossRef]

- Chen, Z.; Hu, T.Q.; Jang, H.F.; Grant, E. Multivariate Analysis of Hemicelluloses in Bleached Kraft Pulp Using Infrared Spectroscopy. Appl. Spectrosc. 2016, 70, 1981–1993. [Google Scholar] [CrossRef] [PubMed]

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Li, J.; Zhu, Z.; Li, T.; Peng, X.; Jiang, S.; Turng, L. Quantification of the Young’s Modulus for Polypropylene: Influence of Initial Crystallinity and Service Temperature. J. Appl. Polym. Sci. 2020, 137, 48581. [Google Scholar] [CrossRef]

- Tsui, N.T.; Paraskos, A.J.; Torun, L.; Swager, T.M.; Thomas, E.L. Minimization of Internal Molecular Free Volume: A Mechanism for the Simultaneous Enhancement of Polymer Stiffness, Strength, and Ductility. Macromolecules 2006, 39, 3350–3358. [Google Scholar] [CrossRef]

- Schultz, J.M. Microstructural Aspects of Failure in Semicrystalline Polymers. Polym. Eng. Sci. 1984, 24, 770–785. [Google Scholar] [CrossRef]

- Nugroho, G.; Budiyantoro, C. Optimization of Fiber Factors on Flexural Properties for Carbon Fiber Reinforced Polypropylene. J. Compos. Sci. 2022, 6, 160. [Google Scholar] [CrossRef]

- Leguillon, D.; Martin, É.; Lafarie-Frenot, M.-C. Flexural vs. Tensile Strength in Brittle Materials. Comptes Rendus Mécanique 2015, 343, 275–281. [Google Scholar] [CrossRef]

- Schober, P.; Boer, C.; Schwarte, L.A. Correlation Coefficients: Appropriate Use and Interpretation. Anesth. Analg. 2018, 126, 1763–1768. [Google Scholar] [CrossRef]

- Kant, S.; Urmila; Kumar, J.; Pundir, G. Study of Talc Filled Polypropylene—A Concept for Improving Mechanical Properties of Polypropylene. Int. J. Res. Eng. Technol. 2013, 02, 411–415. [Google Scholar] [CrossRef]

- González-Sánchez, C.; Fonseca-Valero, C.; Ochoa-Mendoza, A.; Garriga-Meco, A.; Rodríguez-Hurtado, E. Rheological Behavior of Original and Recycled Cellulose–Polyolefin Composite Materials. Compos. Part Appl. Sci. Manuf. 2011, 42, 1075–1083. [Google Scholar] [CrossRef]

- Mohanty, S.; Nayak, S.K. Rheological Characterization of HDPE/Sisal Fiber Composites. Polym. Eng. Sci. 2007, 47, 1634–1642. [Google Scholar] [CrossRef]

- Le Moigne, N.; Van Den Oever, M.; Budtova, T. Dynamic and Capillary Shear Rheology of Natural Fiber-reinforced Composites. Polym. Eng. Sci. 2013, 53, 2582–2593. [Google Scholar] [CrossRef]

- Bouafif, H.; Koubaa, A.; Perre, P.; Cloutier, A. Effects of Composite Processing Methods on Wood Particle Development and Length Distribution: Consequences on Mechanical Properties of Wood–Thermoplastic Composites. WOOD FIBER Sci. 2010, 42. Available online: https://wfs.swst.org/index.php/wfs/article/view/758 (accessed on 14 December 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).