A Cause Analysis Model of Nuclear Accidents in Marine Nuclear Power Plants Based on the Perspective of a Socio-Technical System

Abstract

:1. Introduction

2. Theories

2.1. Socio-Technical System Theory

2.2. Nuclear Accident and Bayesian Network Theory

- (1)

- Nuclear accident

- (2)

- Bayesian network theory

3. Methods

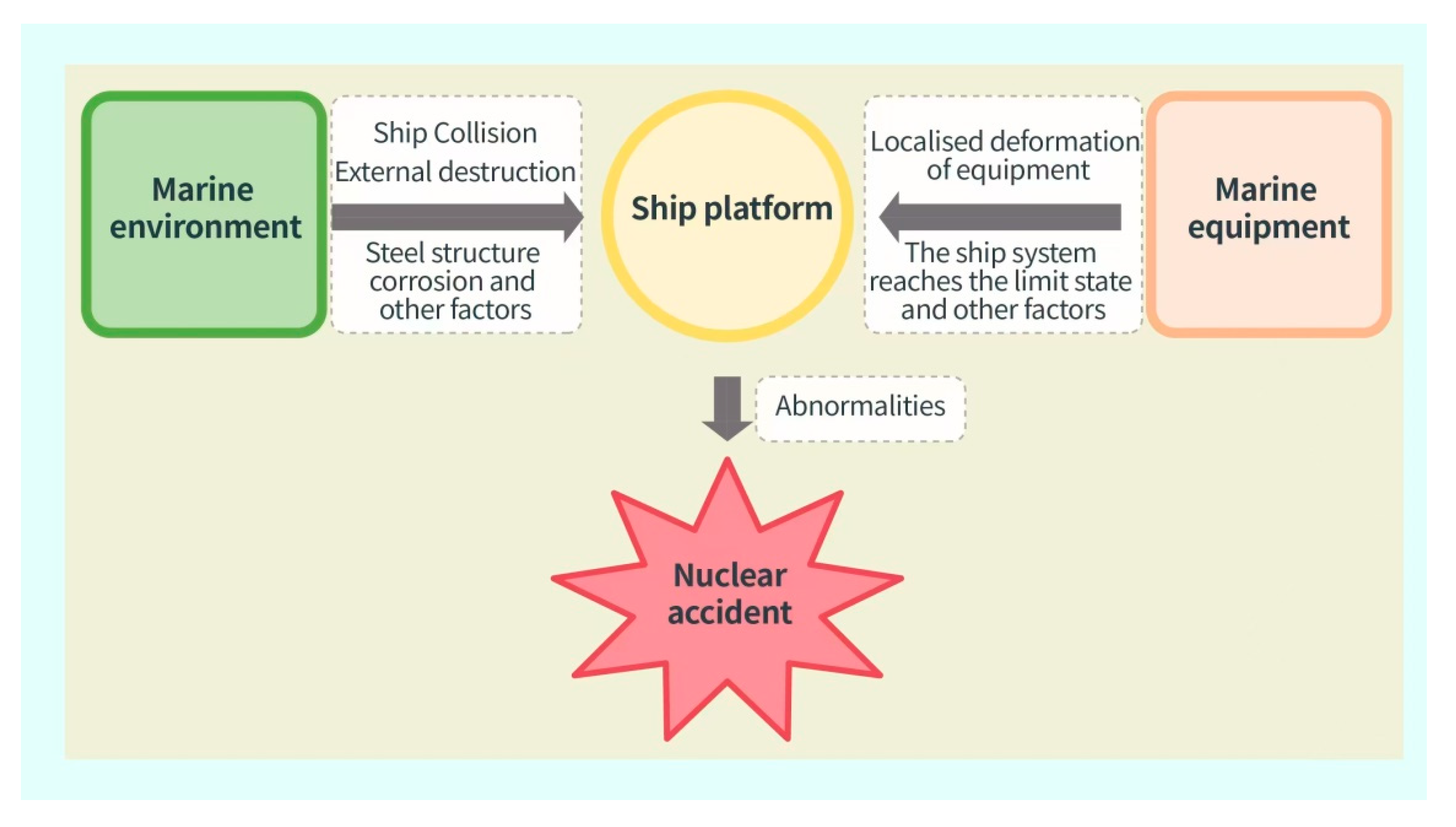

3.1. Characteristics Analysis of Marine Reactor Nuclear Accidents

3.2. Analysis of the Cause Mechanism of Marine Reactor Nuclear Accidents

3.2.1. Internal Core Cause Analysis: Technical Control

- (1)

- Factors of a nuclear technology system

- (2)

- Ship factors

- (3)

- Crew factors

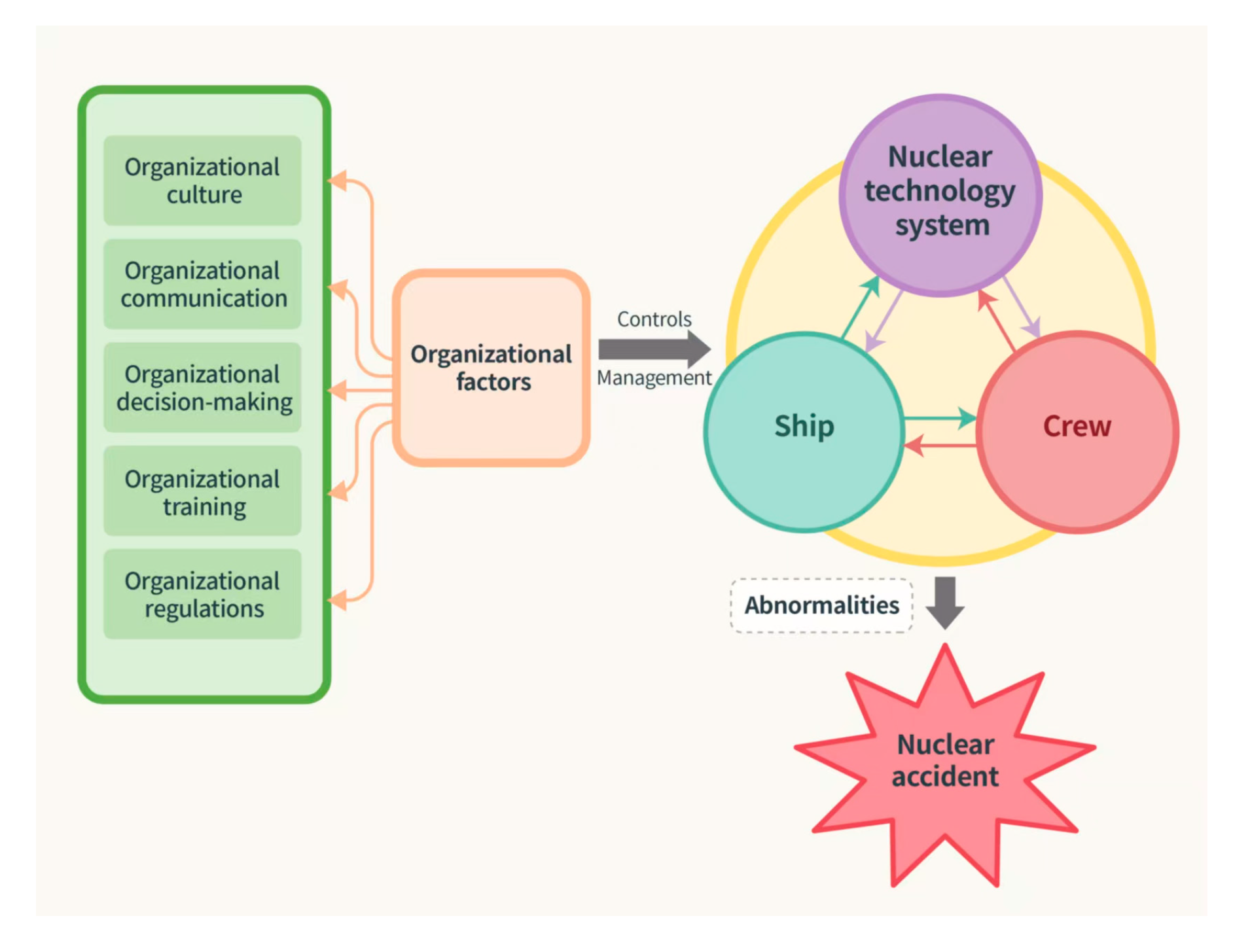

3.2.2. External Core Cause Analysis: Social Interventions

- (1)

- Intervention factors by government departments and other sectors

- (2)

- Organizational factors

- (3)

- Social factors

3.2.3. Construction of the Causal Analysis Model of Nuclear Accidents

4. Case Study

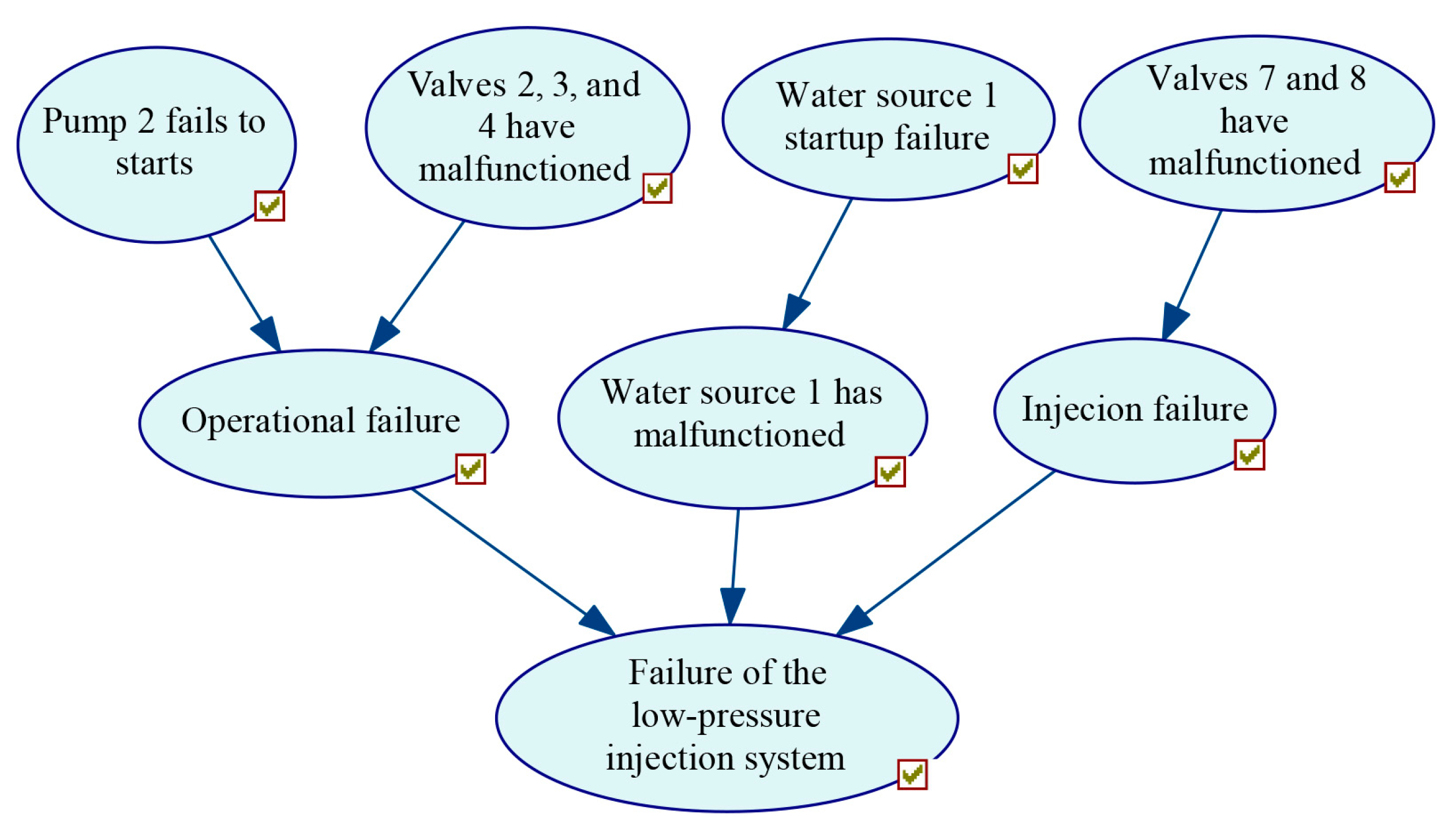

4.1. Accident Hypothesis

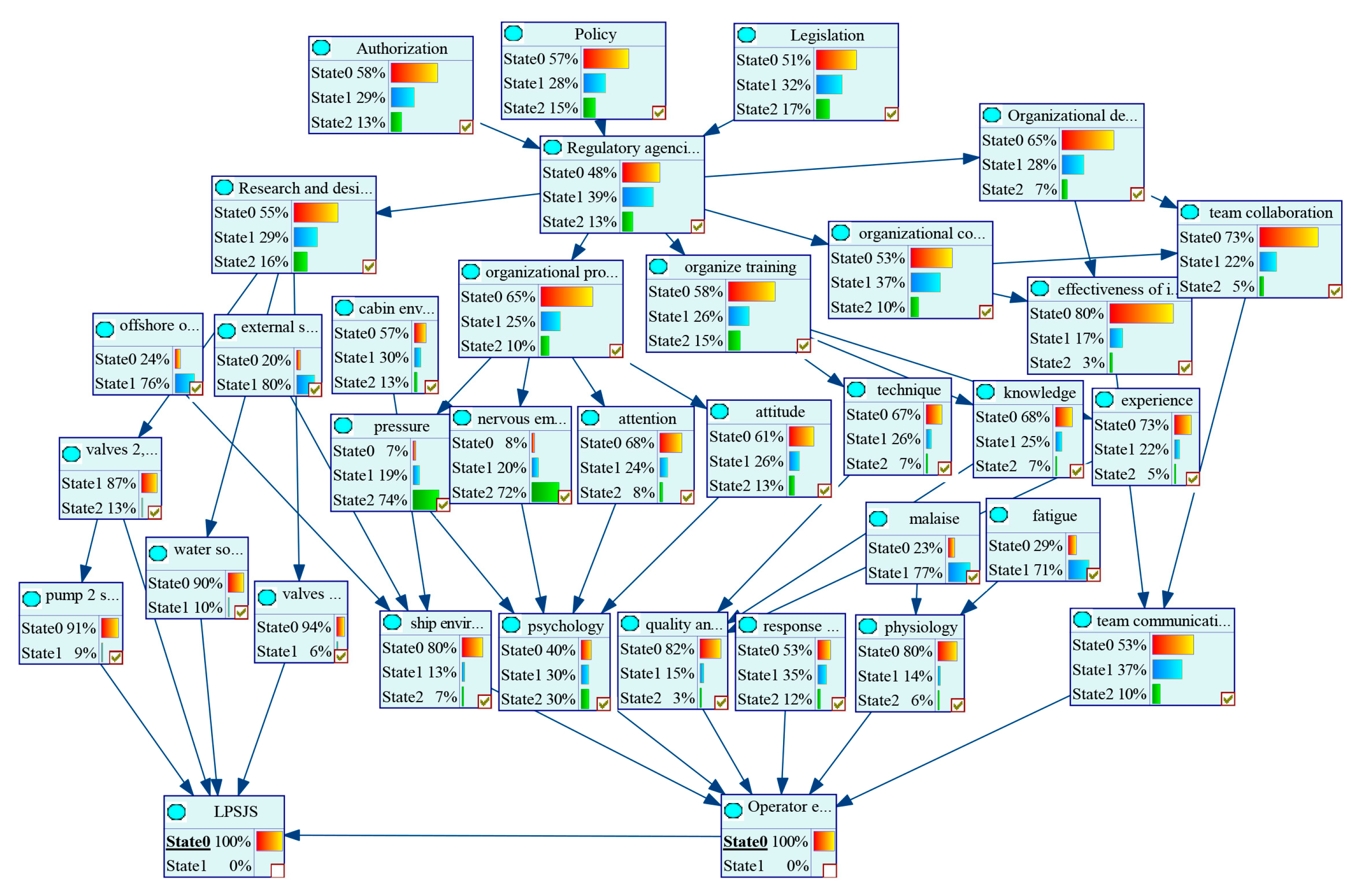

4.2. Construction of Accident Model

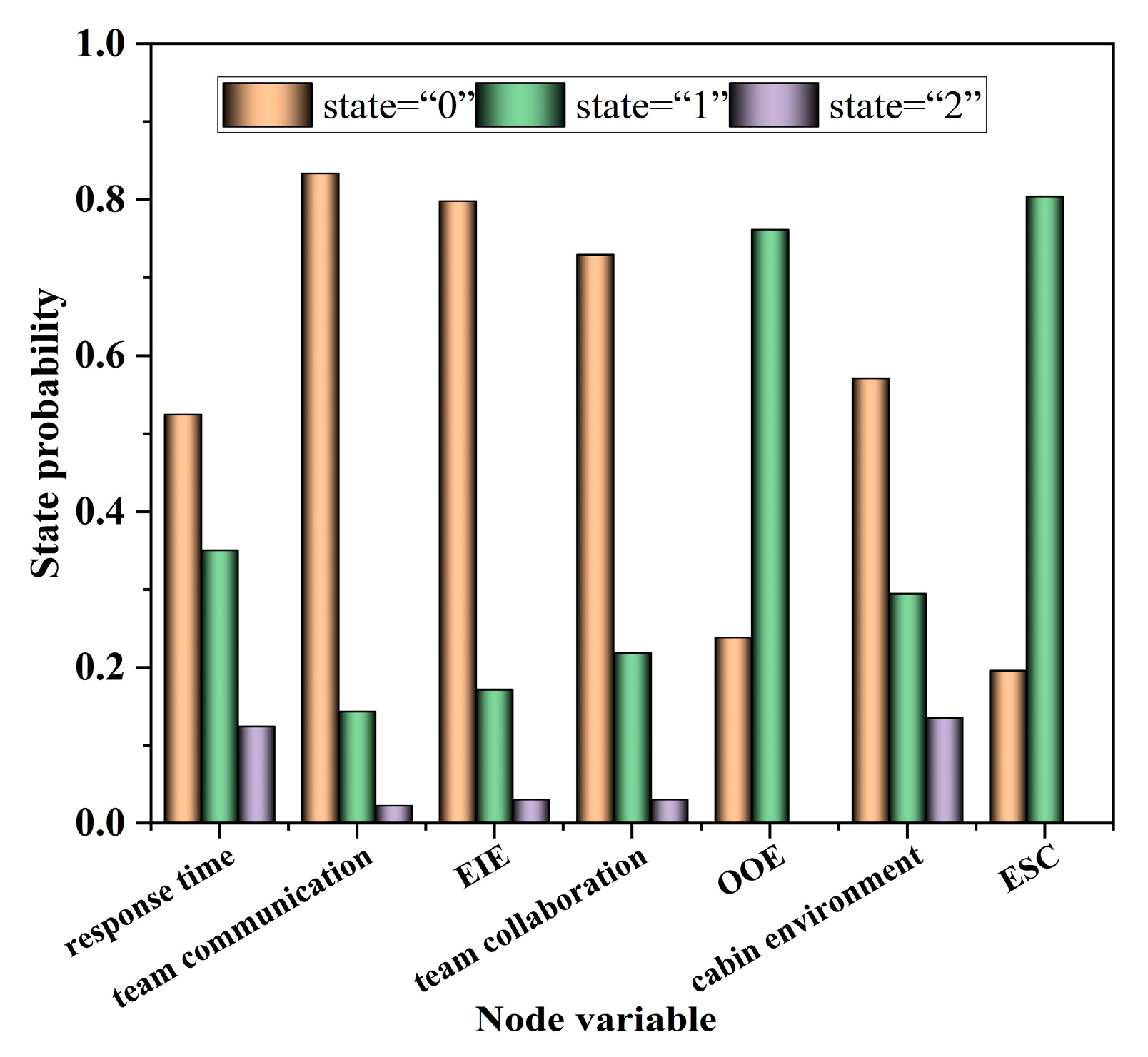

4.3. Determination of the State Probability of Node Variables

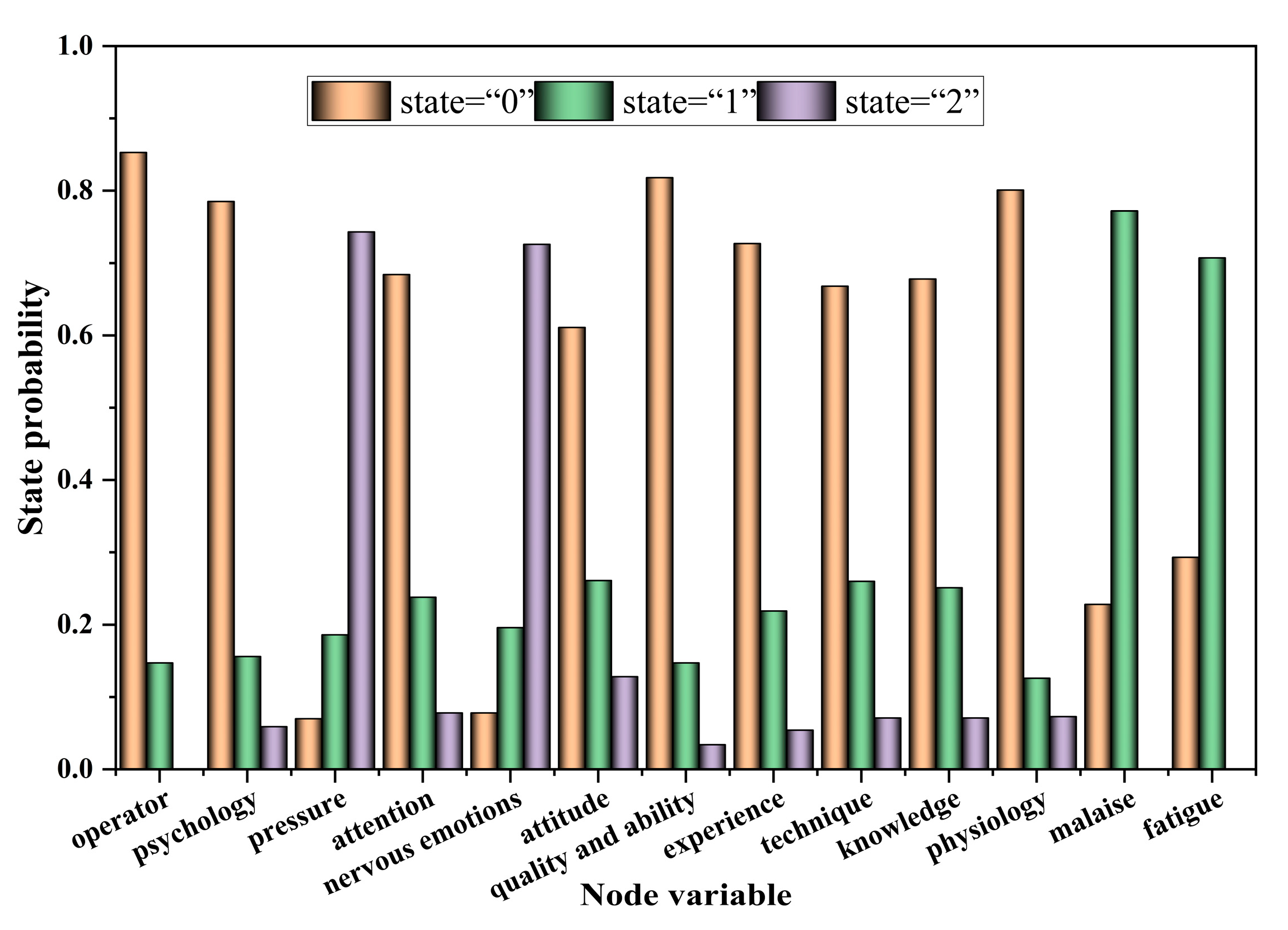

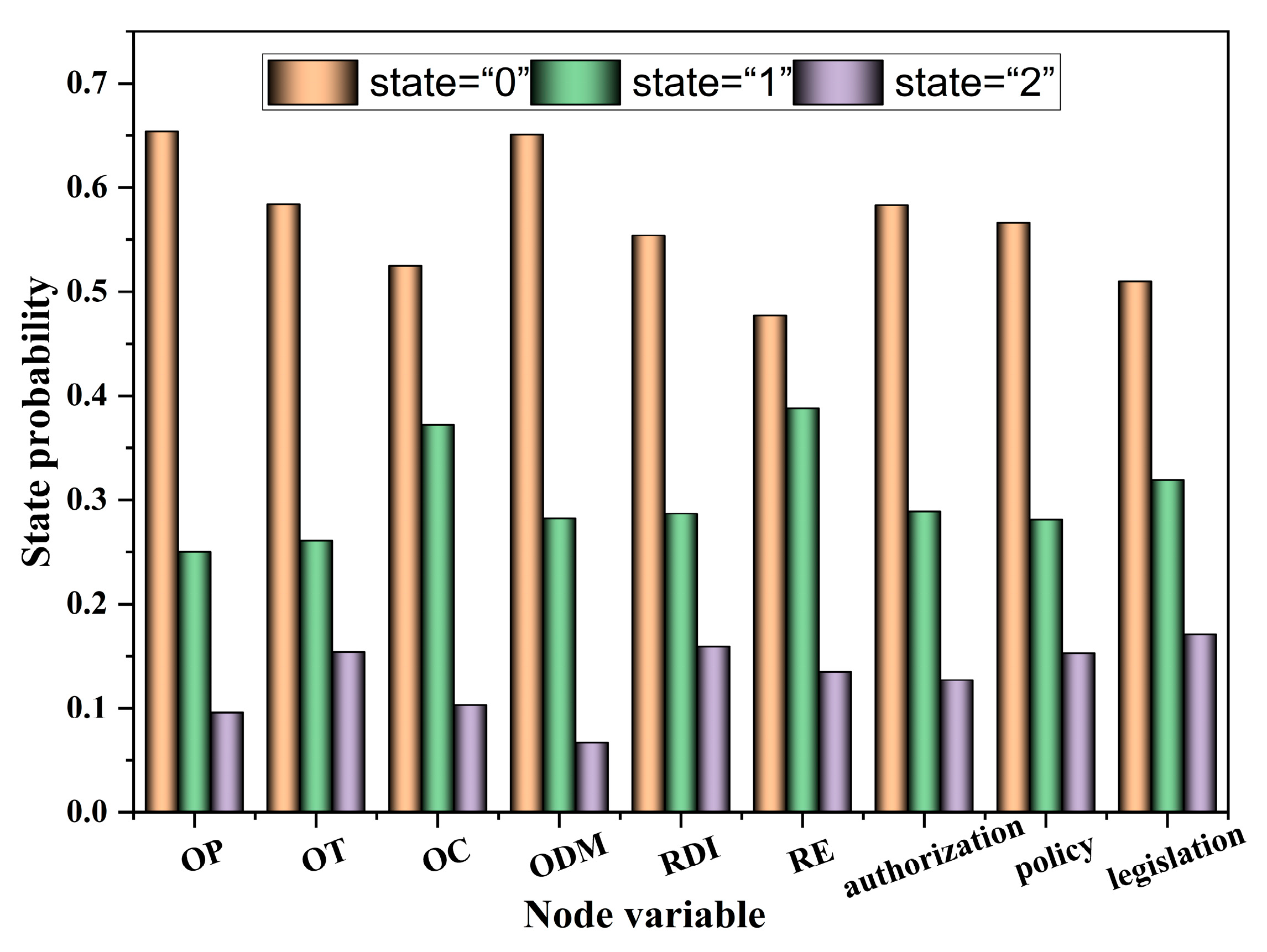

4.4. Bayesian Network Reasoning

- (1)

- Reverse inference

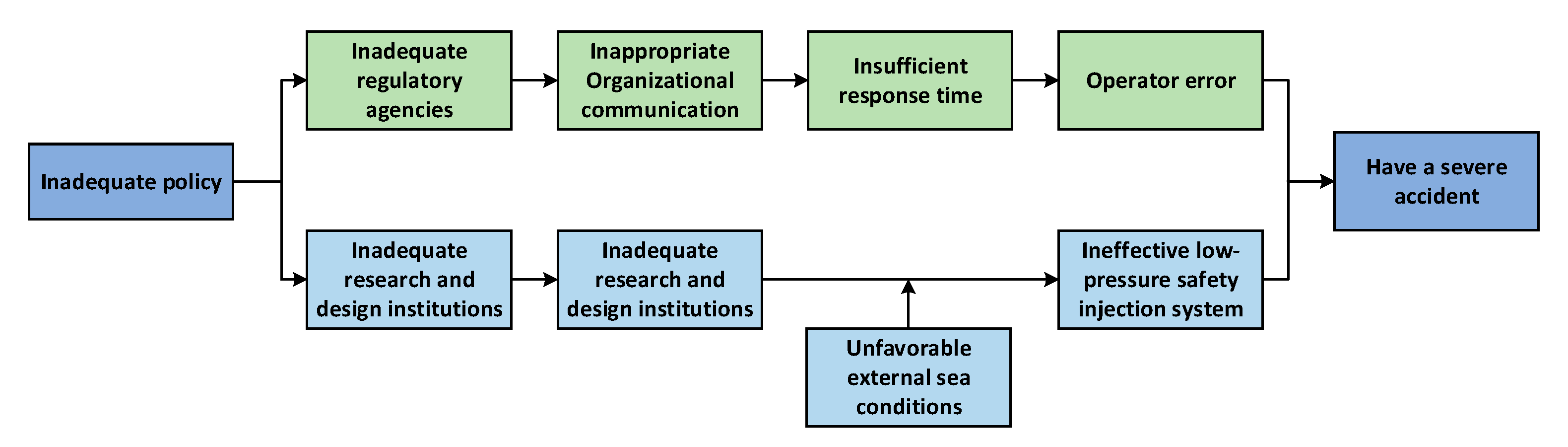

- (2)

- Analysis of the chain structure of the accident cause

5. Conclusions

6. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, L. The application prospect of small nuclear reactor power supply in the field of ocean engineering. Chin. Off. Plat. 2018, 33, 1–5. [Google Scholar]

- Zheng, J.; Yu, F.; Zhu, J.M.; Liu, C.G.; Wang, X.Y.; Zhu, Y.F. Development Status and Prospect of Marine Nuclear Power Equipment in China and Abroad. Eng. Sci. Chin. 2023, 25, 62–73. [Google Scholar] [CrossRef]

- Hjelmeland, M.; Nøland, K.J.; Backe, S.; Korpås, M. The role of nuclear energy and baseload demand in capacity expansion planning for low-carbon power systems. Appl. Energy 2025, 377, 124366. [Google Scholar] [CrossRef]

- Zheng, S.Y.; Sohail, S.; Ozturk, I.; Ullah, S.; Attar, R.W. How does geopolitical risk affect sustainable nuclear energy development? Nucl. Eng. Technol. 2024, 9, 033. [Google Scholar] [CrossRef]

- Rahman, M.M.; Ji, D.X.; Jahan, N.; Salvatores, M.; Zhao, J.Y. Design concepts of supercritical water-cooled reactor (SCWR) and nuclear marine vessel: A review. Prog. Nucl. Energy 2020, 124, 103320. [Google Scholar] [CrossRef]

- Zhida, Y.; Zhou, L.Y.; Zhou, J.; Luan, X.C.; Wang, J.L. Simulation research on passive safety injection system of marine nuclear power plant based on compressed gas. Ann. Nucl. Energy 2020, 145, 107552. [Google Scholar] [CrossRef]

- Guo, C.C.; Wu, W.H. Fuzzy dynamic Bayesian network based on a discrete aggregation method for risk assessment of marine nuclear power platform hinge joints accidents. Appl. Ocean Res. 2023, 138, 103674. [Google Scholar] [CrossRef]

- Guo, C.C.; Wu, W.H. Risk assessment of disconnect operations of MNPP using similarity aggregation method based fuzzy dynamic Bayesian networks model. Ocean Eng. 2023, 285, 115390. [Google Scholar] [CrossRef]

- Sich, A.R. The Chernobyl Nuclear Power Plant Unit-4 Accident. Encycl. Nucl. Energy 2021, 30–52. [Google Scholar] [CrossRef]

- Leslie, M. Amid Uncertainty for US Nuclear Power, Three Mile Island Shuts Down. Engineering 2020, 6, 4–5. [Google Scholar] [CrossRef]

- Akahane, K.; Yonai, S.; Fukuda, S.; Miyahara, N.; Yasuda, H.; Iwaoka, K.; Matsumoto, M.; Fukumura, A.; Akashi, M. The Fukushima Nuclear Power Plant Accident and Exposures in the Environment. Environmentalist 2012, 32, 136–143. [Google Scholar] [CrossRef]

- Kwag, S.; Oh, J. Development of Network-based Probabilistic Safety Assessment: A Tool for Risk Analyst for Nuclear Facilities. Prog. Nucl. Energy 2019, 110, 178–190. [Google Scholar] [CrossRef]

- Silva, K.; Ishiwatari, Y.; Takahara, S. Cost Per Severe Accident as an Index for Severe Accident Consequence Assessment and Its Applications. Reliab. Eng. Syst. Safe 2014, 123, 110–122. [Google Scholar] [CrossRef]

- Mohsendokht, M.; Jamshidi, M. Re-evaluation of Level 2 PSA Results of a VVER-1000 NPP with Consideration of Innovative Severe Accident Management Strategies. Ann. Nucl. Energy 2021, 151, 107966. [Google Scholar] [CrossRef]

- Lyu, X.F.; Liu, S.; Ji, K.; Feng, Y.; Wang, S.F.; Huang, Z.C. Research on Hydrogen Risk and Hydrogen Control System in Marine Nuclear Reactor. Ann. Nucl. Energy 2020, 141, 107373. [Google Scholar] [CrossRef]

- Ouyang, K.H.; Chen, W.Z.; He, Z.Y. Analysis of the Radioactive Atmospheric Dispersion Induced by Ship Nuclear Power Plant Severe Accident. Ann. Nucl. Energy 2019, 127, 395–399. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Zhang, F.; Zhao, X.W.; Zheng, Y.F. Source Term Analysis in Severe Accident Induced by Large Break Loss of Coolant Accident Coincident with Ship Blackout for Ship Reactor. At. Energy Sci. Technol. 2013, 47, 1565–1571. [Google Scholar]

- Wang, W.; Chen, L.S.; Zhang, F.; Liu, H.P. Radioactive Analysis on Accident of SG-tube Rupture Coupled with Whole Ship Blackout. At. Energy Sci. Technol. 2015, 49, 871–876. [Google Scholar]

- Wang, W.; Chen, L.S.; Zhang, F.; Cai, Q. Source Term Analysis on Blackout Accident of Marine Reactor. At. Energy Sci. Technol. 2014, 48, 1038. [Google Scholar]

- Delikhoon, M.; Habibi, E.; Zarei, E.; Valdez, O.A.V.; Faridan, M. Towards decision-making support for complex socio-technical system safety assessment: A hybrid model combining FRAM and dynamic Bayesian networks. Process Saf. Environ. 2024, 187, 776–791. [Google Scholar] [CrossRef]

- Zarei, E.; Khan, F.; Abbassi, R. A dynamic human-factor risk model to analyze safety in sociotechnical systems. Process Saf. Environ. 2022, 164, 479–498. [Google Scholar] [CrossRef]

- Rathnayaka, S.; Khan, F.; Amyotte, P. SHIPP methodology: Predictive accident modeling approach. Part I: Methodology and model description. Process Saf. Environ. 2011, 89, 151–165. [Google Scholar] [CrossRef]

- Chen, C.; Li, J.; Zhao, Y.X.; Goerlandt, F.; Reniers, G.; Liu, Y.L. Resilience assessment and management: A review on contributions on process safety and environmental protection. Process Saf. Environ. 2023, 170, 1039–1051. [Google Scholar] [CrossRef]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Zarei, E.; Yazdi, M.; Abbassi, R.; Khan, F. A hybrid model for human factor analysis in process accidents: FBN-HFACS. J. Loss Prev. Process 2019, 57, 142–155. [Google Scholar] [CrossRef]

- Zarei, E.; Khakzad, N.; Cozzani, V.; Reniers, G. Safety analysis of process systems using Fuzzy Bayesian Network (FBN). J. Loss Prev. Process 2019, 57, 7–16. [Google Scholar] [CrossRef]

- Zarei, E.; Khan, F.; Abbassi, R. An advanced approach to the system safety in sociotechnical systems. Saf. Sci. 2023, 158, 105961. [Google Scholar] [CrossRef]

- Tan, Q.L.; Chen, G.M.; Zhang, L.; Fu, J.M.; Li, Z.M. Dynamic accident modeling for high-sulfur natural gas gathering station. Process Saf. Environ. 2014, 92, 565–576. [Google Scholar] [CrossRef]

- Mahmudah, R.S.; Putri, D.I.; Abdullah, A.G.; Shafii, M.A.; Hakim, D.L.; Setiadipura, T. Developing a Multi-Criteria Decision-Making model for nuclear power plant location selection using Fuzzy Analytic Hierarchy Process and Fuzzy VIKOR methods focused on socio-economic factors. Clean. Eng. Technol. 2024, 19, 100737. [Google Scholar] [CrossRef]

- Ceylan, B.O.; Sezer, S.I.; Akyuz, E. An integrated system theoretic accident model and process (STAMP)-Bayesian network (BN) for safety analysis of water mist system on tanker ships. Appl. Ocean Res. 2025, 154, 104344. [Google Scholar] [CrossRef]

- Oettingen, M. Criticality analysis of the Louis Slotin accident. Nucl. Eng. Des. 2018, 338, 92–101. [Google Scholar] [CrossRef]

- Oettingen, M. A criticality study on the LA-1 accident using Monte Carlo methods. Nucl. Eng. Des. 2020, 359, 110467. [Google Scholar] [CrossRef]

- Antonelloa, F.; Buongiorno, J.; Zio, E. A methodology to perform dynamic risk assessment using system theory and modeling and simulation: Application to nuclear batteries. Reliab. Eng. Syst. Saf. 2022, 228, 108769. [Google Scholar] [CrossRef]

- Leveson, N.G. Engineering a Safer World: Systems Thinking Applied to Safety; MIT Press: Cambridge, MA, USA, 2011. [Google Scholar]

- Stefana, E.; Marciano, F.; Paltrinieri, N.; Cocca, P. A systematic approach to develop safety-related undesired event databases for Machine Learning analyses: Application to confined space incidents. Process Saf. Environ. 2024, 182, 279–297. [Google Scholar] [CrossRef]

- Salehi, V.; Hanson, N.; Smith, D.; McCloskey, R.; Jarrett, P. Modeling and analyzing hospital to home transition processes of frail older adults using the functional resonance analysis method (FRAM). Appl. Ergon. 2021, 93, 103392. [Google Scholar] [CrossRef]

- Ale, B.; Gulijk, C.V.; Hanea, A.; Hanea, D.; Hudson, P.; Lin, P.H. Towards BBN based risk modelling of process plants. Saf. Sci. 2014, 69, 48–56. [Google Scholar] [CrossRef]

- Patriarca, R.; Gravio, G.D.; Costantino, F. A Monte Carlo evolution of the Functional Resonance Analysis Method (FRAM) to assess performance variability in complex systems. Saf. Sci. 2017, 91, 49–60. [Google Scholar] [CrossRef]

- Zinetullina, A.; Yang, M.; Khakzad, N.; Golman, B.; Li, X.H. Quantitative resilience assessment of chemical process systems using functional resonance analysis method and Dynamic Bayesian network. Reliab. Eng. Syst. Saf. 2021, 205, 107232. [Google Scholar] [CrossRef]

- Kim, Y.C.; Yoon, W.C. Quantitative representation of the functional resonance analysis method for risk assessment. Reliab. Eng. Syst. Saf. 2021, 214, 107745. [Google Scholar] [CrossRef]

- Yang, G.S.; Chen, B.; Liu, B.X.; Shi, H.; Cai, Q. Classification method of nuclear events for marine nuclear power plants. Chin. J. Ship Res. 2015, 10, 95–100. [Google Scholar]

- Leveson, N. Safeware: System Safety and Computers; Addison-Wesley: Boston, MA, USA, 1995; Volume 30, p. 123. [Google Scholar] [CrossRef]

| Level | Radioactive Safety | Power Output | Defense in Depth |

|---|---|---|---|

| 1 | The radiation monitoring system in the cabin for a staff whose dose exceeded the dose constraint value. | In non-emergency situations, the power supply of the whole ship cannot be fully guaranteed, and the output power of the turbine generator cannot meet the emergency power demand of the whole ship | A few issues with the safety components, but defense in depth remains effective |

| 2 | ① A member of the public was exposed to a dose exceeding 10 mSv. ② The radiation monitoring system in the cabin of a staff whose dose exceeded the legal annual limit. ③ The measured value of one parameter exceeds its intervention value. ④ The exposure dose of one member of the public exceeds the legal limit. | After the MNPP loses some power in emergency, the remaining power output capacity can meet the needs of the task. | The safety measures apparently failed, but there were no real consequences. |

| 3 | ① Individuals experienced non-fatal deterministic effects. ② The effective dose to one staff exceeded 10 times the legal annual systemic dose limit. | In case of emergency, the power output capacity cannot meet the needs of the task, but the output power of the turbogenerator can meet the emergency power demand of the whole MNPP. | An accident on MNPP in which all safety measures are rendered ineffective. |

| 4 | The release of radioactive material from the core of a fatal deterministic effect on an individual exceeds 0.1% of the total amount. | The power output capacity of the MNPP is completely lost in an emergency. | |

| 5 | The equivalent of 131I with a radioactive release exceeding 1014Bq | ||

| 6 | The equivalent of 131I with a radioactive release exceeding 1015Bq | ||

| 7 | The equivalent of 131I with a radioactive release exceeding 1016Bq |

| Serial Number | Abnormal Phenomenon | Reason for Failure |

|---|---|---|

| 1 | Operational failure | Pump 2 fails to start, Valves 2, 3, and 4 have malfunctioned |

| 2 | Water source 1 has malfunctioned | Water source l startup failure |

| 3 | Injection failure | Valves 7 and 8 have malfunctioned |

| Level | Semantic Value | Probability Value |

|---|---|---|

| 1 | Very low impact | (0, 0, 0.1) |

| 2 | Low impact | (0, 0.1, 0.3) |

| 3 | Relatively low impact | (0.1, 0.3, 0.5) |

| 4 | Moderate impact | (0.3, 0.5, 0.7) |

| 5 | Relatively high impact | (0.5, 0.7, 0.9) |

| 6 | High impact | (0.7, 0.9, 1.0) |

| 7 | Very high impact | (0.9, 1.0, 1.0) |

| Node Variables | State | ||

|---|---|---|---|

| State = “0” | State = “1” | State = “2” | |

| Low-pressure safety injection system | Ineffective | Effective | |

| Water pump 2 | Ineffective | Effective | |

| Valve 2, 3, 4 | Malfunctioning | Good | |

| Valve 7, 8 | Malfunctioning | Good | |

| Source of water 1 | Ineffective | Effective | |

| Operator | Inappropriate | Acceptable | |

| Psychology | Relatively poor | General | Good |

| Pressure | Relatively low | General | Very high |

| Attention | Inadequate | General | Adequate |

| Nervous emotions | Relatively low | General | Very high |

| Attitude | Inappropriate | Acceptable | Appropriate |

| Quality and ability | Inappropriate | Acceptable | Appropriate |

| Experience | Inadequate | General | Adequate |

| Technique | Inadequate | General | Adequate |

| Knowledge | Inadequate | General | Adequate |

| Response time | Inadequate | More urgent | Adequate |

| Physiology | Relatively poor | General | Good |

| Malaise | Good | Serious | |

| Fatigue | Good | Serious | |

| Team communication | Inadequate | General | Adequate |

| Effectiveness of information exchange (EIE) | Ineffective | More effective | Very effective |

| Team collaboration | Inappropriate | Acceptable | Appropriate |

| Ship environment | Unfavorable | Acceptable | Favorable |

| Offshore operating environment (OOE) | Gentle | Severe | |

| Cabin environment | Unfavorable | Acceptable | Favorable |

| External sea conditions (ESC) | Gentle | Severe | |

| Organizational procedures | Inappropriate | Acceptable | Appropriate |

| Organizational training | Inadequate | General | Adequate |

| Organizational communication | Inappropriate | Acceptable | Appropriate |

| Organizational decision-making | Inappropriate | Acceptable | Appropriate |

| Research and design institutions | Inadequate | General | Adequate |

| Regulatory agencies | Inadequate | General | Adequate |

| Authorization | Inadequate | General | Adequate |

| Policy | Inadequate | General | Adequate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Shu, R.; Xu, S.; Zou, S. A Cause Analysis Model of Nuclear Accidents in Marine Nuclear Power Plants Based on the Perspective of a Socio-Technical System. Safety 2025, 11, 10. https://doi.org/10.3390/safety11010010

Zhao F, Shu R, Xu S, Zou S. A Cause Analysis Model of Nuclear Accidents in Marine Nuclear Power Plants Based on the Perspective of a Socio-Technical System. Safety. 2025; 11(1):10. https://doi.org/10.3390/safety11010010

Chicago/Turabian StyleZhao, Fang, Ruihua Shu, Shoulong Xu, and Shuliang Zou. 2025. "A Cause Analysis Model of Nuclear Accidents in Marine Nuclear Power Plants Based on the Perspective of a Socio-Technical System" Safety 11, no. 1: 10. https://doi.org/10.3390/safety11010010

APA StyleZhao, F., Shu, R., Xu, S., & Zou, S. (2025). A Cause Analysis Model of Nuclear Accidents in Marine Nuclear Power Plants Based on the Perspective of a Socio-Technical System. Safety, 11(1), 10. https://doi.org/10.3390/safety11010010