1. Introduction

In the business context, organizations seek a competitive advantage to survive in a globalized market. Among the possible options, it is important to have a competent staff, so that they make an effort to increase their capacities [

1]. This effort could be reduced by narrowing the gap between what new employees offer after their university studies and what the market needs [

2]. In the industrial sectors, the role of engineers (as practitioners or managers) is evolving with the addition of new responsibilities. In the last thirty years, safety and health issues in industry are increasingly considered in order to anticipate and prevent these types of potential problems [

3,

4,

5].

On the other hand, the advance of technology and its social implications, particularly in terms of the environment and health and safety, generates in academia the need to significantly rethink the way in which knowledge is generated, acquired, shared, capitalized on, transferred and applied. In order to do this, there is a need to develop activities that improve the processes to achieve a higher level of quality and sustainability, and to train highly qualified future professionals [

6].

In Spain, the list of competences that graduates must acquire after completing their university education, with a view to entering the labor market, is set out in the verified programs of university degrees. These are based on the Blank Books of the National Agency for Quality Assessment and Accreditation (ANECA) [

7] and the Royal Decree 861/2010 [

8], which ensure the basic competences contained in the Spanish Framework of Qualifications for Higher Education (MECES) regulated by the Royal Decree 1027/2011 [

9].

In Europe, educational policies, following the implementation of the European Higher Education Area (EHEA), have among their main objectives that universities promote innovative attitudes, for which they demand a cultural change (transforming the relationship between companies and society) and an increase in the skills and abilities of workers [

10]. According to the European Qualifications Framework for Lifelong Learning (EQF-MEC) [

11], demonstrating the acquisition of competences implies manifesting the capacity to use personal, social and methodological knowledge, skills and abilities in work and study situations. As a result of this definition, the personal plane cannot be dissociated from the professional one, since the components of professional competence are a combination of personal attributes (capacities, motivation, personality, aptitudes, attitudes and values) that are complemented and integrated with other elements related to work contexts (knowledge, abilities, skills, behavior and experience) [

12].

At a university level, the Tuning Project [

13] establishes that demonstrating the possession of a competence implies being able to prepare, develop, execute and control tasks with sufficiency and responsibility. The quality and performance of educational processes aimed at improving training in competences is ensured through learning, teaching and evaluation, based on the European Credit Transfer System (ECTS). In the field of engineering, the European Network for Engineering Accreditation (ENAEE) [

14] is proposed as the guarantor of engineering degrees in Europe for the promotion of student employability through the European Accredited Engineer (EUR-ACE

®) Label. This is an award that accredits engineering degree programs which satisfy the ENAEE requirements to fulfill the needs of economies and of society.

The knowledge area of Occupational Health and Safety (OHS), in accordance with the European Agency for Safety and Health at Work (EU-OSHA) in the European Union (EU), is the least likely to be systematically integrated into university courses, even in technological engineering degrees [

15], which should aim to educate and train competent engineers. However, the EU strategy on OHS also identifies education and training as key factors to prevent accidents in the workplace [

16]. In the same vein, the global Accreditation Board for Engineering and Technology (ABET) establishes safety and health criteria to be included in its accredited engineering degree programs. It can be noted that engineers play a vital role in managing risks, including those relating to health and safety [

17]. Therefore, it is essential that future engineering graduates are prepared for this role.

The paper is structured as follows:

Section 2 presents a structured literature review connecting gamification with engineering practice.

Section 3 presents the research objectives.

Section 4 relates the research method.

Section 5 describes its implementation in a case study.

Section 6 shows its major findings, discussing the results obtained.

Section 7 concludes the paper, summarizes the contributions and proposes further research continuations.

2. Background

The literature on industrial safety focuses on approaches related to its management, at a strategic [

18], organizational [

19] and operational level [

20], as well as to skills from stakeholders involved, such as communication [

21], commitment [

22], leadership [

23], or specialization [

24], among others. However, there is hardly any information on how to approach the training of OHS for future employees in the industrial sector, or how to deal with current workers.

In the Spanish context, industrial companies need the preventative figure of the “preventive resource” that must hold an adequate qualification. Industrial-technical engineers and industrial engineers can take on the role of technicians (even and/or manager experts) in occupational risk prevention (ORP) [

25], thanks to their abilities to:

Gather basic information about the technical characteristics of work (raw materials, work equipment, etc.), its organization (complexity, tasks, distribution, etc.), and the state of health of workers (illnesses, personal characteristics, etc.).

Analyze the previous information in order to identify what health hazards exist in those working conditions, and which workers are exposed to these.

Assess the existing risk, taking into account the objective criteria of assessment, existing technical knowledge and criteria agreed with the workers.

In spite of this, current legislation does not reserve any special attribution or require specific competence in ORP for the regulated profession of an industrial technical engineer (Order CIN 351:2009) [

26], and only does so generically for that of an industrial engineer (Order CIN 311:2009) [

27]. In this context, the role of universities in the promotion of occupational health and safety has been underrated [

28], so that ORP′s competences are barely included in their different habilitating grade or master degrees [

29]. In fact, the challenge confronting those who want to enhance the safety component of engineering education, is to develop effective strategies for incorporating safety and health principles into the engineering curriculum that make optimal use of available instructors and materials, and demonstrate the relevance of safety issues for traditional engineering concerns [

30]. Nevertheless, it is necessary to adapt the structures of the engineering courses to the new students [

31] in order to attract and keep them.

Teaching practice can encourage greater student participation if it motivates work that stimulates creative thinking, empowers students′ autonomy, and facilitates the learning of professional competences, both longitudinal and transversal ones [

32]. Competence development, through training, mentoring and coaching, allows for better performance in the challenges undertaken, thanks to increased motivation and better self-organization by students, and less need for central control [

33] by teachers. In this sense, gamification is a natural way of adapting basic skills and developing new ones, thanks to the inclusion of stimuli that encourage attention and overcome resistance to change [

34].

Game activities allow the acquisition of cognitive skills that, generally, are rarely stimulated by academic programs, so the application of the mechanics of gamification, integrating game dynamics as part of the training, with profiles of more purposeful thinking, introduces spaces for reflection and transcends beyond the usual activities in the classrooms [

35]. However, unlike a conventional game, gamification (by way of a serious game) aims to influence the behavior of gamers [

36], while producing and creating experiences, feelings of domination and autonomy in participants. To understand its exact meaning, the following considerations must be established [

37]:

It is a set of relevant activities and systematic processes;

It must have a purpose, to solve specific problems;

It should not be considered as such because of the mere use of the mechanics of the game;

It should be based on the characteristics of the elements of the game.

The main objective of gamification is to achieve a change of attitude without the need to use coercion or deception, using elements of the game [

38]. Thanks to this, frontiers between teachers and students are blurred, managing to surprise, entertain, attract and invite active participation, as well as increasing commitment [

39]. It is interesting to highlight the use of games specifically oriented to the development of the capacities of generation, structuring and consolidation of ideas, such as Binnakle, Gamestorming, Gamification Model Canvas, Lego

® Serious Play

®, or Wake Up Brain

®, amongst others. In addition, this can work for the development of the dynamic capacities of innovation related to the integration of clients, designing their game according to their characteristics, needs and expectations, as do multinational organizations such as AXA, Bank of America, BBVA, Google, IBM, Microsoft, Nescafé, NIKE, SAP or Volkswagen, among others.

In the educational context, there is a growing interest by the academic and scientific community in the application of gamification to various areas of knowledge, in order to motivate students in their studies, promote competitiveness among them and guide them in the learning processes. Some of the advantages are [

40]:

With regard to students, it rewards effort, penalizes lack of interest, indicates when entering the “danger” zone, rewards extra work, provides a clear measure of performance and proposes ways to improve their grades and learning curricula.

As far as teachers are concerned, it is a way of encouraging work in the classroom, makes it easier to reward those who really deserve it and allows automatic control of the state of the students, relieving them of management tasks.

For the institution, it can offer a measure of students′ performance, being a novel and effective system.

3. Objectives

This research deals with the formation and training, by means of gamification techniques and tools, of future engineers of the industrial branch, as key actors in the prevention of industrial risks, in order to improve the safety and health of their industries before events occur, such as accidents at work or occupational diseases, which affect the study of their working conditions. The universities of Cadiz and Seville choose to train their future engineers in the industrial branch with the knowledge, skills and abilities necessary to assume professional responsibilities as technicians or even as experts in ORP in industrial environments, proposing four basic objectives:

To acquire the knowledge, skills, abilities and attitudes necessary to work at a high level in industrial risk prevention (IRP).

To standardize the basic knowledge in those areas that are fundamental for the ORP in the engineering of the industrial branch.

To know the three non-medical ORP specialties (occupational health and safety, industrial hygiene and ergonomics and applied social psychology).

To apply knowledge in passive and active fire protection (PFP and AFP).

The acquisition of these skills in IRP includes the application of knowledge, transmission of ideas, interpretation of data and making judgments related to prevention planning, risk assessment, safety inspections, investigation of occupational accidents and diseases, adoption of collective and individual protection measures and signaling. This is done from the perspective of the trainer as a facilitator, counselor and promoter, leaving behind the traditional master classes, and favoring the autonomy of the students. Finally, if the results are as foreseen in this research, it is intended that these trainings are transferred to real industrial environments.

4. Methodology

This research uses the Lego® Serious Play® (LSP) methodology through its implementation in a case study. In this way, LSP offers a range of opportunities for successful application in contexts in which activities are undertaken similar to those of a project, highlighting the approach based upon the acquisition and improvement of skills of people involved in OHS, IRP, ORP, PFP and AFP.

In 1996, the company Lego

® requested the design of an executive development program in which aspects of game, constructivism and constructionism are incorporated in a natural way, encouraging the participants in the program to use company material to make and express meanings [

34]. Collaborative work leads Lego

® to develop a set of basic principles for successful projects that characterize its commitment [

41], leading to the LSP methodology:

To clarify the rules and expectations of the working groups.

To ensure that each project is mutually beneficial.

To ensure a clear dividing line between staff and users.

To develop communication tools and forums for interaction.

To be as transparent as possible.

LSP incorporates reflection into ways of learning, undertaking, teaching, training, evaluating, innovating and researching [

42]. In this way, LSP modifies the conventional means of verbal, two-dimensional and graphical texts by introducing three-dimensional models, and simultaneously contributes to both academic understanding and practical value. In this context, real themes are developed while providing fun, but with cognitive development identified as the main purpose [

43].

The elements of LSP have been used since its inception for a wide range of purposes [

44], including strategy and communication, organizational development, innovation, product design and development, change management, mergers and acquisitions, branding, team leadership and management, reform and restructuring, market entry and value chain analysis. However, examples related to ORP, IRP, PFP or AFP are scarce or directly non-existent. In spite of this lack of practical application, LSP has demonstrated that it allows several transversal competences to work at the same time, such as creativity, teamwork and decision making, although an appropriate approach is needed so that activities do not become a mere leisure exercise [

45].

In relation to creativity, LSP can support collective processes [

46] by illustrating already formed ideas, elaborating on new ideas, discovering conceptual disagreements and exploring through material representation. Concerning teamwork, LSP adds value to problem solving, from a collaborative, motivating and informative dynamic [

47]. In this way, LSP facilitates a positive interaction and allows strategies to be adapted in real-time, encourages the desire to engage, and achieves the discovery of new ideas. This allows accessing the experience, knowledge and understanding of each individual, and trusting in shared knowledge, so that greater commitment is acquired, and teams are prepared to respond optimally to the unknown. With regard to decision-making, LSP is presented as a facilitating tool, highlighting the following particularities [

48]:

New process, new content: It involves a different mode of intentionality, as well as an alternative medium in which to express strategic content, allowing all participants to generate new knowledge about their context and any problems they face.

Overcoming “yes, but...” defenses: It serves to overcome psychodynamic defenses, coming from biases and conflicts in decision-making, involving strategic decisions in three-dimensional representations, by implying emotional, social and cognitive dimensions in an interdependent and non-discrete way.

Power and decision-making: It minimizes hierarchical power, broadening and democratizing interaction and the exchange of opinions on important contextual issues among participants, making them more open and less prone to self-censorship.

Adaptive potential: It identifies and develops sources of resilience or solidity that allow the organization to be more prepared for unexpected events, thus contributing to face uncertainty when it cannot be reduced through algorithmic models or statistical analysis.

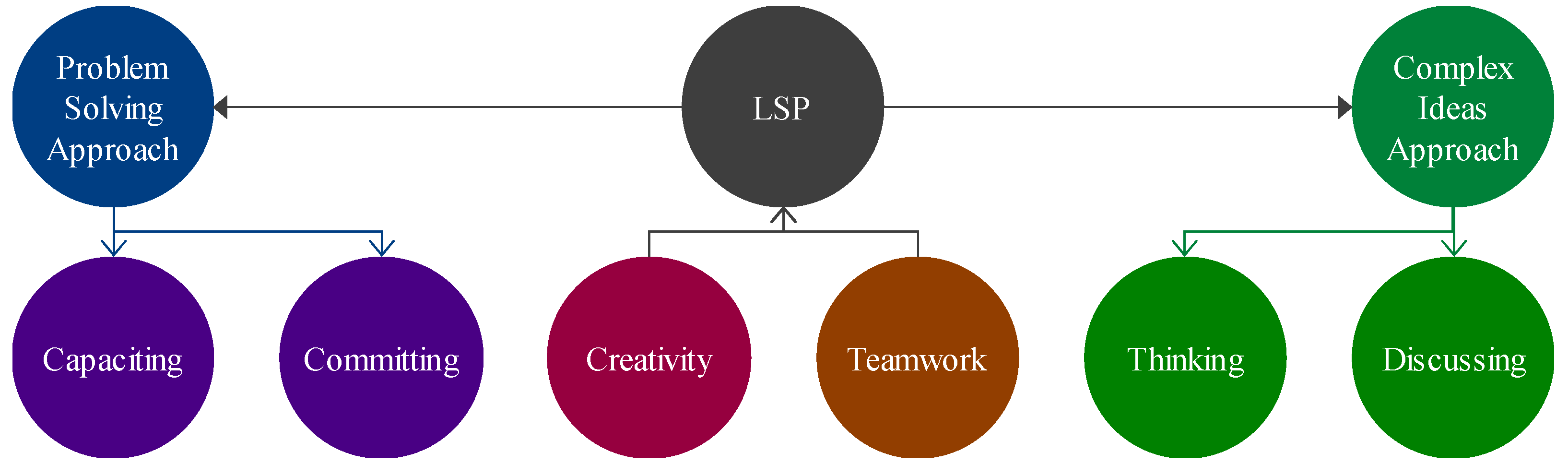

In the field of engineering, LSP helps students to think and discuss complex ideas, improving their commitment and ability to solve problems, and it is applied as a mechanism for the promotion and training of group tasks, as summarized in

Figure 1. If this is also approached in a creative way, gathering information and analyzing contents, imaginative solutions are proposed, thanks to participation, and through experimentation and prototyping [

32].

LSP has achieved satisfactory results in higher education in electronic [

49], industrial [

50], mechanical [

51] and organizational engineering [

52], as well as in civil [

53], computational [

54], design [

55], systems [

56] or software [

57] engineering, among others. In this context, conducting a practical workshop facilitates the exchange of knowledge (production, transmission and dissemination) with students and between their environment, which implies, from the outset, the development of three main strategic activities (acquiring, integrating and exploiting knowledge) [

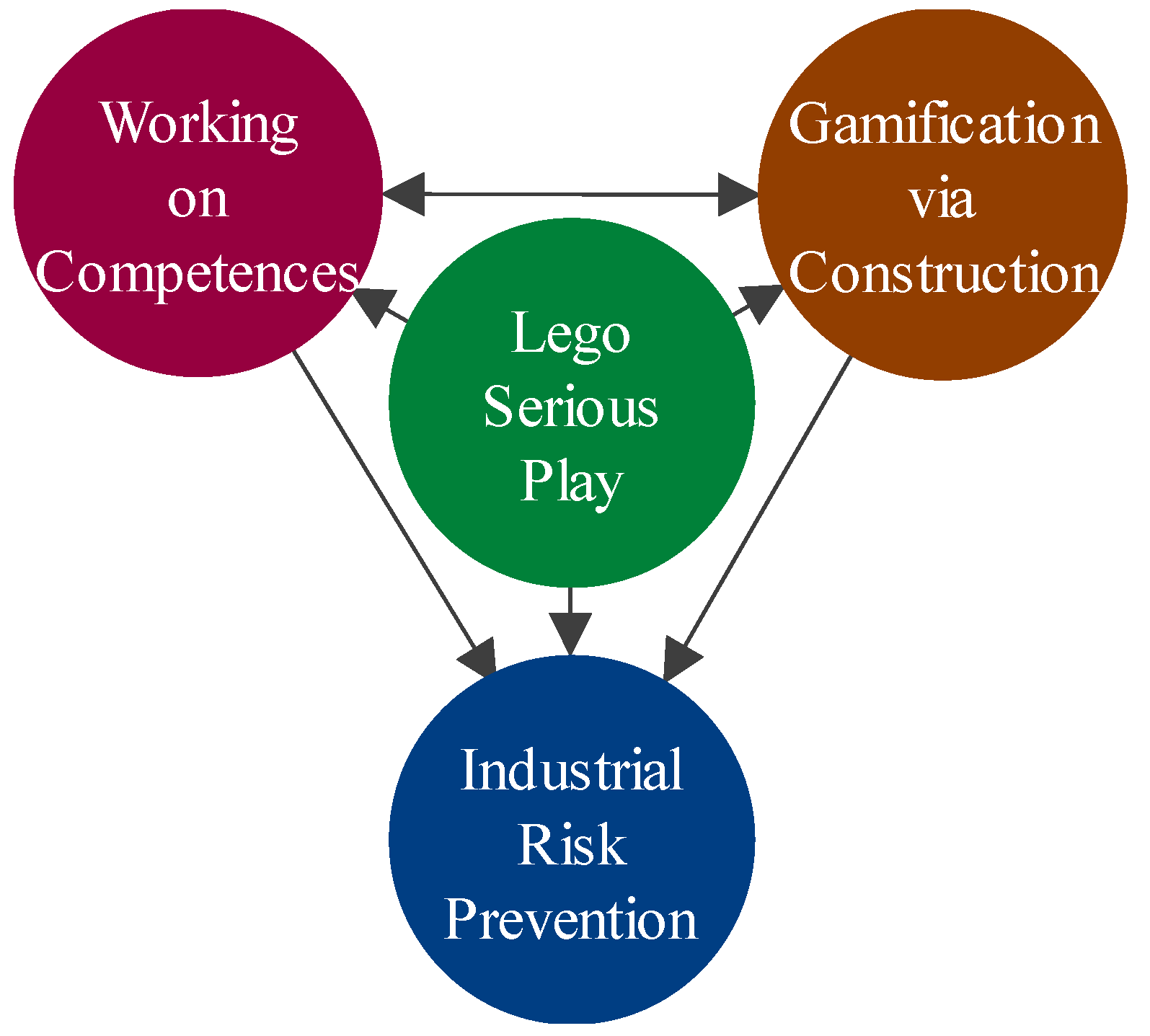

58], as presented in

Figure 2.

The LSP methodology follows a sequential process in which, by means of questions, the participants go deeper into the subject throughout the session. To this end, ideas are developed, models are suggested and scenarios are proposed through the use of Lego© construction pieces, which serve as a basis for subsequent decision-making, exchange of knowledge and experiences, as well as a group debate through sharing. The nuclear process of the LSP methodology is based on four essential steps [

59], as indicated in

Figure 3:

Based on these steps, the creators of the methodology propose seven complementary strategies for its implementation:

Construction of individual models.

Construction of shared models.

Creation of scenarios.

Identification of connections between models.

Construction of a system.

Simulation of a situation for decision making.

Development of conclusions.

5. Case Study

Although there is a significant amount of research on gamification in educational contexts, most will address business and marketing, as well as innovation and productivity. Very few studies cover other issues, such as quality, environment or safety. The design and development of IRP/ORP practices through gamification need to be further investigated, especially for future engineers of industrial sectors. Consequently, qualitative research is required to clarify the real advantages that these kinds of students can get from the use of gamification methods during their education and training. Therefore, a case study is needed, because there is hardly any previous research on the topic available, with a lack of sufficient empirical observations to turn it into a quantitative study. If only limited theoretical knowledge exists concerning the utility, relevance and/or the need to acquire and manage OHS competences by these students, an inductive research strategy leading to the theory emerging from the case can be a valuable starting point [

60].

Building theory from a case study is a research strategy that creates theoretical constructs, propositions and/or midrange theory from case-based, empirical evidence [

61]. Theoretical sampling of single cases is straightforward. They are chosen because they are ideally revelatory, extremely exemplary, or an opportunity for unusual research access [

62]. If the case study is information-rich, with empirical descriptions of a particular instance that is typically based on a variety of data sources [

62], then an accurate, interesting and testable theory is developed [

60], becoming one of the best bridges from rich qualitative evidence to mainstream deductive research. While experiments isolate the phenomena from their context, case studies emphasize the rich and real-world context in which they occur [

63], in addition to considering the views of all the people and entities involved [

64].

The area of Engineering Projects of the universities of Cadiz (UCA) and Seville (US), during the academic years 2017–2019, launched an initiative, organizing a series of practical workshops in which to apply the methodologies of LSP and Work by Competences, using Lego© material, as summarized in

Figure 4. These take place in the obligatory subjects of “Industrial Risk Prevention” in the third year of the UCA and “Occupational Risk Prevention” in the fourth year of the US, from the complementary industrial training module, for the degrees of engineering of the industrial branch (electrical, electronic, mechanical and technological engineering). In this context, these practical workshops achieve a double objective.

In this context, students are trained in a series of competences in IRP/ORP, which later have to be evaluated, based on a series of criteria that measure their degree of performance (learning outcomes). These competences are traceable with those from the Tuning Project and are inserted in the context of the EUR-ACE

® label. Currently, the University of Cadiz is initiating the process for the accreditation of its engineering programs of the industrial branch through the ENAEE, and the University of Seville already has the EUR-ACE

® Label for its mechanical and technological engineering grades.

Table 1 compiles the competences established by the Tuning Project into the EHEA and the dimensions (accreditation criteria) of the ENAEE EUR-ACE

® label.

Into the practices, several competences considered by the Tuning Project play an essential role over the course of the learning process. Students analyze the context, search information, put in practice their knowledge and synthesize their findings, as well as schedule their availability. In order to do this, students identify problems, solve them and make decisions as they go along. For that, motivation and teamwork are crucial interpersonal competences. In relation to systemic competences, sustainability and quality concerns are also taken into account.

Regarding the EUR-ACE

® Label by the ENAEE, and based on the Deming cycle (which is implicitly present in the nuclear process of the LSP methodology), questionnaires, surveys, feedback, oral presentation of practices and even 3D models, are collected. With this information, differences among examinations and other assessments are detected. In this way, when gaps appear, improvement plans can be developed, giving the necessary feedback to the students in order to proceed with their learning process. Likewise, the competences trained in the workshops are included among the competences contemplated in the verified programs of the corresponding engineering degrees (which are also aligned in turn with the ANECA Blank Books), as shown in

Table 2. A series of general, basic and transversal competences are needed to manage industry-specific ones.

In previous courses, the subject consisted of a series of classes, broken down into two thirds theoretical content and one third practical, with a weighting in the assessment of the students of 70% for theory and 30% for practice. Thanks to the introduction of the LSP methodology, the distribution is broken down into one half for theoretical classes, one quarter for LSP workshops and another quarter for practical classes, determining a new weighting in their evaluation of 40% for theory and 60% for practice.

Currently, students are involved as stakeholders in companies from their industrial field, and must intervene in the processes of defining their organization chart (assuming roles related to ORP) and laying out their main functional areas (offices, warehouses, etc.). Then, they have to plan the preventive action, undertake a risk assessment, execute a safety inspection, investigate an accident at work, and propose collective and individual protections, as well as adopt fire prevention measures.

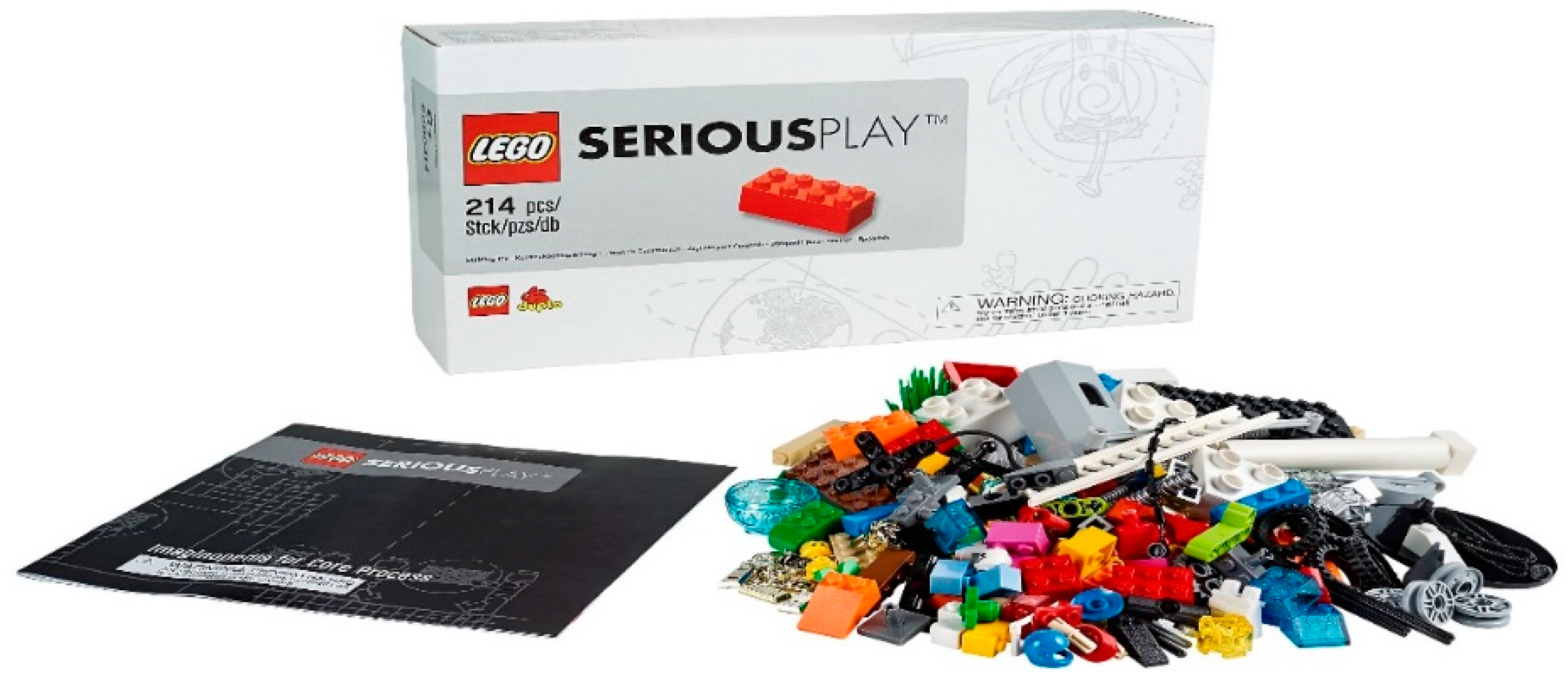

In order to develop the workshops, the same LSP material is always used: The 2000414 “Starter Bag” Lego

® kit of 214 pieces, as shown in

Figure 5. The Starter kit has the pieces needed to perform a basic session, build metaphors, create stories, or apply imagination. Although in the beginning it is oriented to group use for team activities, individual use is also possible. The kit includes a selection of basic blocks, together with some elements of the DUPLO

® series, as well as special blocks such as wheels, trees, mini-figures, bases, etc.

Practical classes last two hours, the sessions of which begin with the projection and sharing of short videos from the YouTube video repository of Alphabet, related to the corresponding subject matter. Next, classes are divided into teams of four students, which will carry out the LSP workshops, in which students work the three case studies contemplated in the program of the subject: The adaptation of a company′s policies and procedures (to the current regulation), the inspection of the industrial safety and the investigation of an occupational accident. The conclusions collected during the LSP workshops are used as a basis for the development of the practical work requested.

6. Results

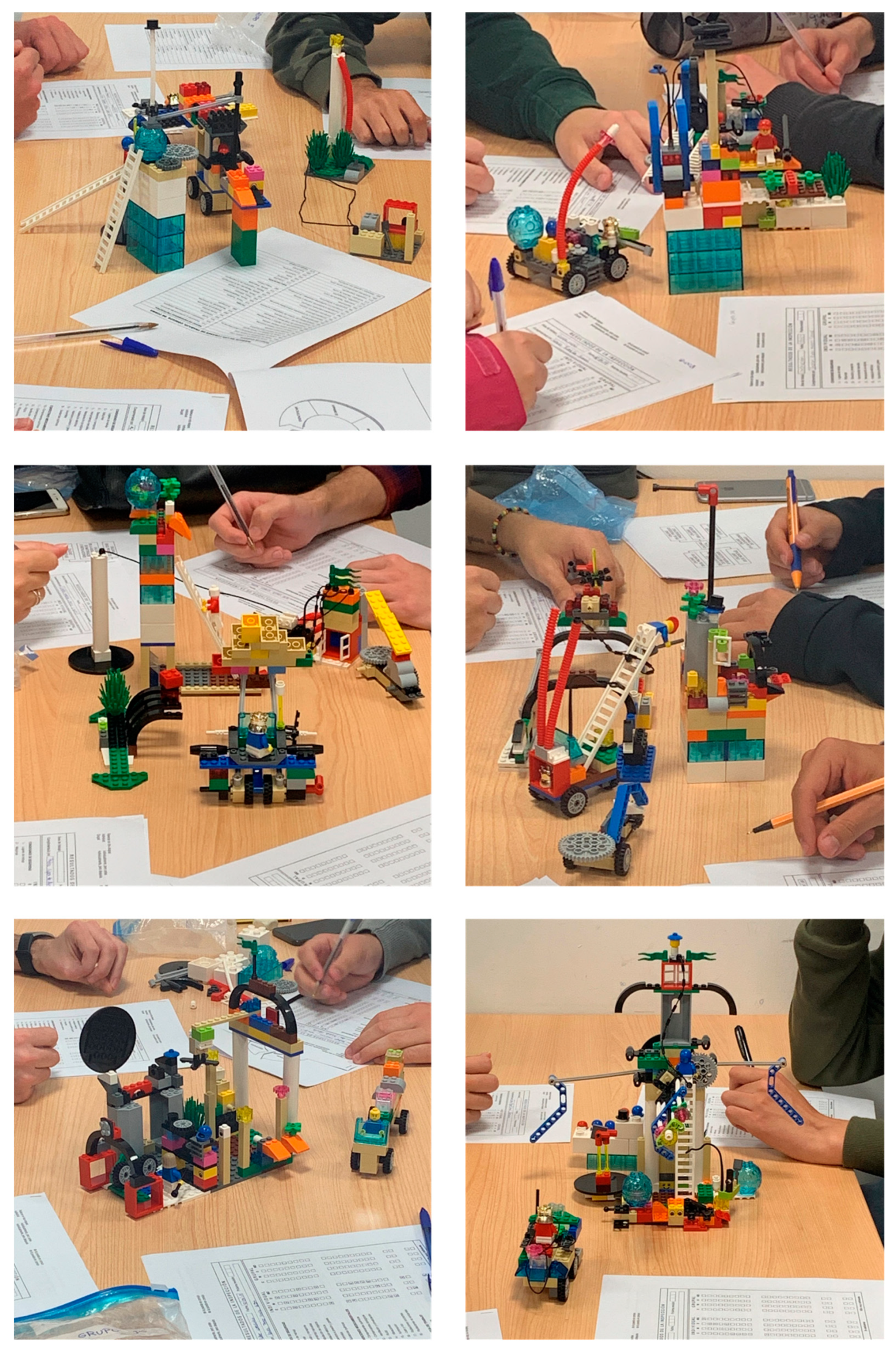

The first case consists of the adaptation of the policy and procedures of a company operating in a sector related to the industrial branch of students to the current legislation. In practice, they have to break down the functional organigram of the chosen company, up to the distribution of professional roles and jobs. The intervening processes and the areas and/or departments involved, including offices, laboratories, warehouses, and of course, production areas (as the core of the operational processes), must be declared. To this end, they have to include the distribution of the entire work center in the industrial plant, in addition to the self-protection and emergency plan. Next, they must organize the prevention resources (worker representatives, health and safety committee and prevention services), as well as carry out an initial risk assessment and plan the preventive actions derived for the current year. The first LSP workshop is used to introduce the already formed teams of students to the first case study, as shown in

Figure 6. For reasons of schedule and class size, and in order to balance its sample, the sessions are organized separately for the degrees of electrical, electronic and technological engineering, and for the degree of mechanical engineering.

In addition to the Lego

® material, students are provided with a questionnaire consisting of twenty-two material agents, on a scale of 0–10, in relation to safety conditions (nine factors), environmental conditions (nine factors), workload (two factors) and organization of work (two factors). This questionnaire serves to establish the initial conditions of each company, helping them to reflect upon the matter. The results are shown in

Figure 7.

The second case consists of carrying out a safety inspection in one of the areas of the companies already studied. Based on the application of the FINE method developed by William T. Fine [

65], an analysis of workplaces and workspaces associated is carried out, studying the degree of dangerousness of the sequences found, comparing the justification of the measures adopted and contrasting their reduction in risk. As a support, the second LSP workshop takes advantage of the experience of the previous one by knowing the group dynamics, construction material and initial conditions. Given that the students know the theory of the method, they proceed to construct their 3D models to discuss weak points and debate possible alternative solutions, as shown in

Figure 8. Likewise, the teams are supplied with a questionnaire similar to the previous one, to indicate the degree of correction/deficiency of the locations and sequences inspected, on a scale of 1–4, as summarized in

Figure 9.

Issues related to OHS, in addition to profitability, are the most important elements of management in an industrial company [

66]. The know-how and skills acquired during the training are beneficial for improving work safety through better understanding of processes, as well as potentially dangerous events [

67]. By reducing the random factors affecting processes, the probability of potentially dangerous situations affecting the safety level is also reduced.

To finish with the series of workshops, the third case consists of an investigation of an accident at work that occurred in one of the areas of the companies already studied. Based on the causal analysis [

68], an analysis of the workplaces and workspaces associated is carried out, studying the proven facts from the collection of data, interviews with the actors involved and the organization of the data collected, until the determination of the primary causes. As a support, the third LSP workshop takes advantage of the experience of the previous ones, knowing the group dynamics, construction material and initial conditions. Given that the students know the theory of the method, they proceed to construct their 3D models to discuss plausible causes and debate possible triggering events, as shown in

Figure 10. Likewise, the teams are provided with a questionnaire similar to the previous ones, to indicate the degree of deficiencies found, on a scale of 1–4, as summarized in

Figure 11.

It is necessary to emphasize that potentially dangerous situations and accidents can be taken as the measure of the safety level of a company [

66]. Students must evaluate the exposure to OHS risks associated with their companies, for which they have to take into account the physical work environment, equipment, materials and substances used, work tasks, and how they are performed, and work design and management. For that, a process, structured into four steps, is suggested:

Identify hazards.

Assess the risk.

Control the risk.

Review risk control.

Finally, when workshops are ended and in order to evaluate the achievement of the proposed objectives, a survey (anonymous) is carried out on the 172 students who participated in the study (108 from UCA and 64 from US), at two specific points during the course: At the beginning of the course and at the end of it (just before the final examination), the results of which are shown in

Table 3. This survey asks for a score of 0–10, in relation to the following questions:

USEFULNESS that you give to IRP, as part of your training to graduate in engineering.

IMPORTANCE that you give to IRP, for your future as a professional engineer.

INTEREST that you give to IRP, as part of your professional future.

COMPETENCE that you have in IRP, to start your professional career.

Statistics at the beginning of the course, through self-evaluation, places students at a certain level of “maturity”. Then, at the end of the course, their own “self-evolution” can be considered. According to

Table 3, the level of competence they think they possess at the beginning of the course is very low, but it almost triples (268%), until it reaches almost eight out of 10 on a ten-point scale. Analogously, the usefulness they give to the contents of the subject increases by 77%, the importance they attach to it increases by 72% and the interest they show rises by 89%, reaching almost nine out of 10 in the first two cases, and almost eight out of 10 in the third one.

Furthermore, in relation to the degree of competence acquired (knowledge, attitudes, aptitudes, skills, abilities, expertise, etc.), their self-evaluation can be compared with the learning outcomes from the evaluation, which are summarized in

Table 4. In addition, it can be noted that the gaps detected can be studied; therefore, the “coordinating” teaching team can propose a personal and individualized plan for the students. Nevertheless, the quasi-equality between self-evaluated competence (evolution) and the learning outcome obtained (evaluation) by the students—7.83 out of 10 versus 7.79 out of 10 (according to the results shown in

Table 3 and

Table 4)—must be stressed.

Finally, it is necessary to evaluate the learning process itself (allowing qualitative variables, such as valuations, expectations, emotions or motivations to be measured), for which a variant of the Kirkpatrick Model is chosen [

69,

70], as shown in

Table A1 in

Appendix A. The variation of the original model is based on a hierarchical decomposition of the objective of evaluation, following the question-objective metric [

71]. In turn, the motivation considers four categories: Attention, relevance, trust and satisfaction [

72]. For its part, the experience of game considers thoughts, feelings, pleasure, and other interactions [

73], and includes five dimensions: Immersion, challenge, competition, fun and interaction [

74,

75]. Finally, learning observes three components of taxonomy [

76] and two additional dimensions of short- and long-term learning [

77].

To better understand the results obtained,

Table 5 shows the combined results of this evaluation. When presented in greater detail, the results are very positive in all areas, as can be seen in

Figure 12. A large majority of the participants, above 80–90%, are quite or totally in agreement with the statements related to each of these categories.

7. Conclusions

The evaluation by competences allows for the alignment of the verified engineering degree programs of the industrial branches of the universities of Cadiz and Seville with the Tuning Project of the EHEA. This achieves a traceability that links what is taught/learned in the University with the standards of international excellence in engineering (such as the ENAEE EUR-ACE® Label), in accordance with the principles of quality, relevance, transparency, recognition and mobility contemplated in the EHEA and with the labor market (employability).

A new generation of interdisciplinary engineers is arising [

78]. In this context of technological change, new approaches to teach engineering are required. Thanks to the innovation project presented, competences related to OHS and ORP that are trained through LSP workshops are highlighted. The coordination of these practical cases is developed according to a peer-to-peer collaborative model, facilitating the exchange of information and compliance with deadlines, as well as the resolution of conflicts that occur during the process. Students′ attendance, active participation and commitment, in addition to the degree of advancement and progress in their own work, allows progress towards the objectives proposed, which are achieved according to the results obtained by this project. The acquisition and training of skills in IRP reinforces and broadens the knowledge and skills of students, which are necessary to develop for their future profession, providing a holistic and integrative vision.

The statistics of self-evaluation at the end of the course with those reported at the beginning of the course in relation to the selected competences and the learning results, according to the teachers′ evaluation, can be contrasted and interpreted. The lessons learned from this innovation project, with a view to improving students′ development, can be documented.

LSP allows teams to build models, obtaining valuable ideas on strategy, teamwork dynamics and industrial process organization, offering flexibility and transferability to them [

79]. In educational settings, LSP is a vehicle for the metaphorical exploration of the dimensions of learning associated with professional development [

80]. It also helps students to transfer meanings and models to different places and, through its three-dimensional and sensory nature, makes learning more memorable. Additionally, with the help and support of the statistical analysis performed, results presented and personal observations noted in the sessions held, it can be concluded that the following are achieved:

Receptivity to the use of LSP, demonstrating respectful behavior, involvement in the proposed exercises and enjoyment (with a relaxed and fun approach).

Creation of a playful environment that encourages participation, creativity and communication, ensuring that participants have the opportunity to express their own point of view before being influenced by the rest of the group.

Promotion of discovery, making use of multiple intelligences (visual, spatial, linguistic and kinesthetic).

Elimination of cultural or gender obstacles in the realization of the workshops.

Positive impact on the team′s assumption of responsibility, setting in motion its own collaboration and cooperation capacities.

Awareness of belonging to a group, enhancing more channels of communication.

LSP, with the right approach, allows students to develop several transversal skills: Creativity, motivation, commitment, open attitude, resilience, teamwork and effective oral communication. In addition, LSP enables students to navigate their integrated intelligence and build simple representative models as a response to “real” problems raised [

37,

81,

82,

83].

The investment in LSP is justified in the thematic areas related to the prevention of occupational risks, industrial risks and fire protection, offering them better preparation for the industrial and commercial reality. These kinds of workshops can be duplicated by other members of academia, thanks to the help of LSP, once design aspects in solving problems are ensured. To this end, the game must be taken seriously in engineering classrooms, as it has a purpose.

This paper contributes to the scientific understanding of how LSP methodology can be adopted in engineering degrees of the industrial branch. However, the qualitative nature of the paper and its reliance on a single case study may raise some issues regarding the generalizability of its results. Hopefully, this limitation is attenuated by the representativeness of the case study analyzed. Still, the present study should encourage future analyses, expanding the implementation steps of LSP in other university and industrial contexts.

This area has been lacking in recent research, but it is absolutely worth revisiting in the context of educational innovation. In addition, the application of these LSP workshops can be extended to other degrees (such as environmental sciences, marine sciences, aerospace engineering, industrial design and product development engineering, naval engineering, chemical engineering and software engineering, among others).

As a continuation of the work initiated, as shown in

Figure 13, it is proposed that the investigation be continued, extending the use of this methodology to the industry, as a basis for the training with new employees or recycled ones on risk prevention, safety inspection, or accident investigation into industrial environments. Other applications include the design of industrial facilities (manufacturing factories, wastewater treatment plants, power generation plants, etc.), the management of engineering projects, and the implementation of safety and environmental techniques, among others.

LSP can also be proposed as a tool for OHS managers and preventive resources in order to deal with special risks and the concurrence of operations. In the context in which many industry practitioners usually work in siloed environments, and system and even safety issues are overlooked, LSP can provide the means to represent possible risks from different perspectives, such as active assurance and human factors, which ends up benefiting the industry itself.

Finally, it is necessary to point out that the use of the LSP methodology in IRP can be extended easily to contexts in which competences are worked on, both academic (EHEA, ALFA, ABET, CDIO, etc.) and industrial. However, the difference in mentality and/or level of acceptance towards new approaches from other countries (especially Asian versus European and American ones) when gamification (by serious games) may be faced, is challenging. Under these circumstances, foreseeable difficulties should be anticipated when applying this method, in order to achieve success in the activities and tasks undertaken.