Testing and Improving an ISO 14119-Inspired Tool to Prevent Bypassing Safeguards on Industrial Machines

Abstract

:1. Introduction

1.1. A Review of the Importance of the Bypassing Issue in Industry

1.2. The Scope of the Paper

2. Materials and Methods

2.1. Selection and Recruitment of the Companies

2.2. Organization of Visits and Meetings with the Team of OHS Practitioners

2.3. Information Collection

2.4. Data Analysis

2.5. The Final Test Step

3. Results

4. Discussion

4.1. How the Results Improve the Tool

- The incentive with the code “I42” was revised in order to be distinguished from “I43” (see Appendix D). Since each of the manners, either ordering, tolerating, encouraging or ignoring the circumvention, is a lack of management commitment according to the authors’ points of view, this incentive (I36) would not be split, but it was revised for clarification (see Appendix D). In addition, the authors have provided exhaustive and detailed expressions for each incentive that will guide users of the tool to better understand the incentives and make an objective evaluation. Thus, the Microsoft Excel file is comprised of three sheets: (1) instructions for applying the bypassing-related assessment tool (Table 2), (2) a detailed explanation of incentives, and (3) the assessment tool.

- To address the last point of the cons, the authors reverified the existing version of the assessment tool. Therefore, users are free to use either the mouse or the keyboard when marking the cells.

- First, company A is a company that designs and manufactures the equipment (shown in Table 1) for customers (i.e., the equipment is customized,) such as baggers and robot cells. That company also has a workshop including a lathe machine, grinding machine and others that are used in manufacturing. An interesting observation stems from the application of the assessment tool, which shows that the ISO 14119-inspired tool is more user-friendly, practical and adapted for manufacturing machines or factories that have production lines, rather than for machines that are manufactured. This fact is entirely consistent with the objective of the assessment tool, which is developed for the usage phase.

- Second, a multidisciplinary team, including the OHS practitioners, operators and even management, has a significant role in identifying the existing incentives and assessing their effect levels. The companies could achieve a more objective assessment this way, rather than only the OHS practitioners, who carry out the evaluation based on their own experience. This way, the results would be subjective because the OHS practitioners do not operate the machines. The participation of relevant mainstream operators provides a realistic evaluation. This fact is fully in line with the authors’ intent. For this reason, during consultation with the companies before they applied the tool, the research team encouraged the OHS practitioners to benefit from operators’ participation during the assessment. In addition, as Haghighi, Jocelyn and Chinniah [12] have stated, the subjectivity of the results could be minimized if the assessment tool was applied by experienced OHS practitioners who are familiar with the machines. As shown in Table 1, the OHS practitioners who have more than five years of experience applied the tool; this helps mitigate subjectivity. Furthermore, a lack of workers’ involvement has been identified as one of the possible incentives (I53) in the bypassing-related assessment tool inspired by ISO 14119. Thus, workers’ participation in the process for estimating the probability level of bypassing is as important as in the other OHS issues.

- Third, the maturity of the company with regard to OHS issues has a significant impact on having a realistic assessment. The company must be committed and willing to do the assessment in order to obtain more reliable results and honest feedback. Therefore, the research team considered voluntary participation in the process of company selection. The companies selected were eager to send back real information and feedback to the research team. In addition, the research team applied the assessment to more than one case study to decrease probable errors.

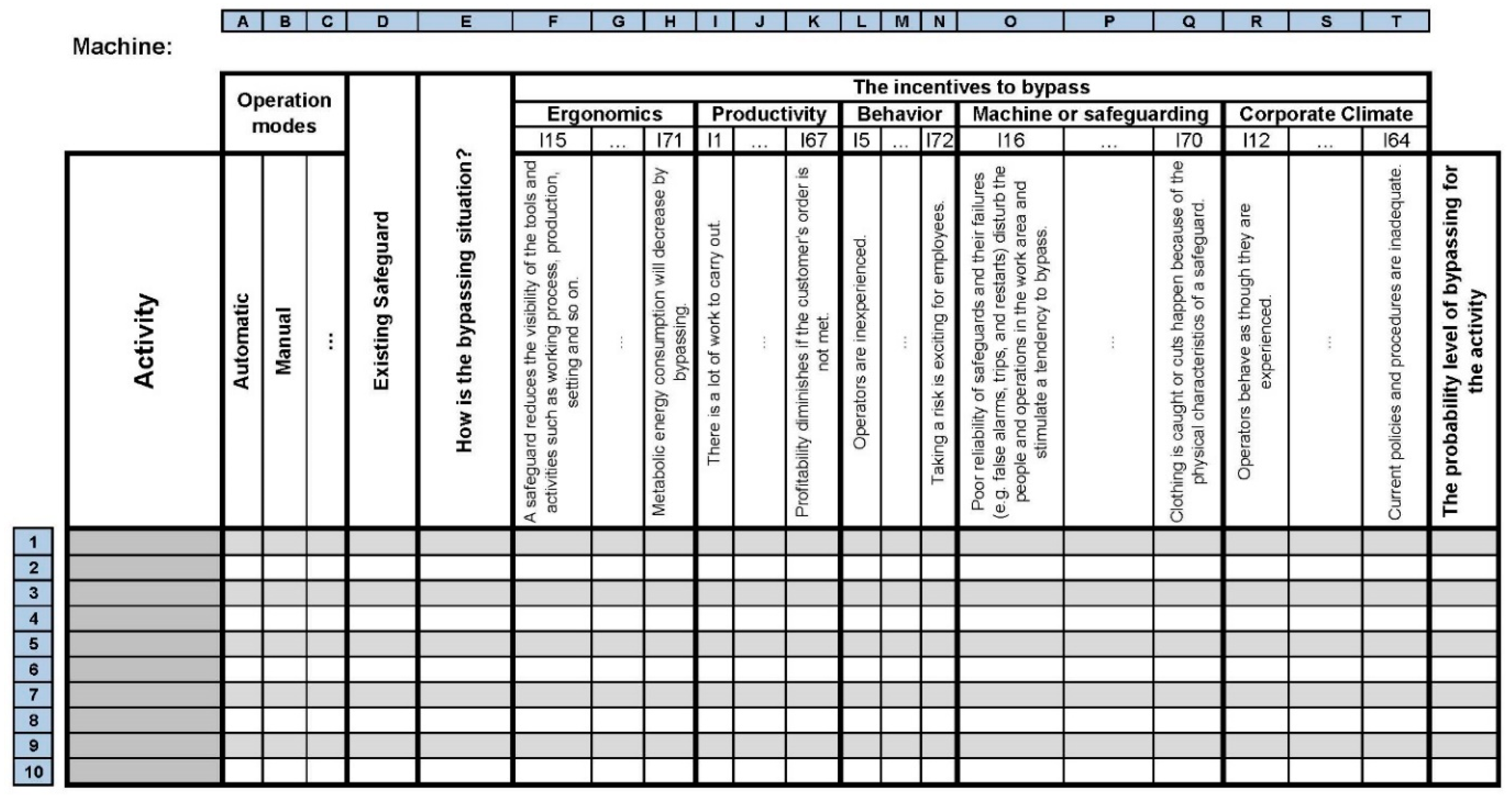

- The tool should be vertical and not horizontal. Writing the incentives vertically from bottom to top is not comfortable from an ergonomic point of view. The user may have bad posture during the application of the tool, and while entering the data. This comment was implemented in the new version of the tool (Figure 1).

- The tool seems to be very useful. It challenges the methods used to make machines safe. The results show that the incentives can enormously change from one activity to another.

- Sometimes, the incentives are not really related to the activity, thus, it was complicated in terms of how to assess the effect level of the incentive in that situation. According to [12], the authors intended to develop a holistic assessment tool comprising of a wide scope of possible incentives to bypass (as mentioned in Section 1.1). Therefore, companies with various activities could identify the existing and relevant incentives among the 72 possible incentives classified into five main categories. It is reasonable that some incentives are not applicable from one company to another.

4.2. Analyzing the Existing Incentives and the Probability Levels of Bypassing

4.2.1. Leveraging the Probability Levels to Prioritize Machines and Safeguards Where Bypassing Needs to be Tackled

- The machines that have at least one activity whose probability level of bypassing for its safeguard is “High”. Subsequently, the other machines with “Significant”, “Moderate”, and “Low” levels of bypassing probability for their safeguards would be respectively placed in the next priorities with the same process.

- For the machines whose safeguards have an identical probability level of bypassing, we consider a machine whose safeguards have more existing incentives.

- If the number of existing incentives is equal for some machines, a machine that has more incentives with a significant effect “++” would be taken into account. Next, a machine that has more incentives with a slight effect “+”.

- After prioritizing the machines and safeguards in the companies, the incentives with a significant effect “++”, and then, the incentives with a slight effect “+” are considered for defining the preventive measures in order to eliminate or reduce the incentives to bypass safeguards on each machine.

4.2.2. Suggestions for Preventive Measures

- Suggestions related to the technical factors are listed below to prevent bypassing:

- Consider the special control modes, required operating modes, or alternate safeguarding devices such as an enabling device, or a hold-to-run device required during the activities in those control modes (I19, I20, I24, I58). Reduce the speed, for instance, to a quarter of the original full speed.

- All of the safeguards and alternate safeguarding devices could be controlled by a safety smart controller. For instance, use interlocks, i.e., stopping movement, when guards are opened or removed (I17).

- “New technological advances”, “safety engineering aspects” and substantial expenses for controls could protect the safeguards against bypassing (I17, I19, I24, I43, I58).

- Passive design and configurable design could be applied in order to mitigate the incentives to bypass (I17, I19, I24). Barriers, interlocks, two-hand devices, hold-to-run controls, and presence sensing devices are examples of a passive design. For instance, movable guards could be replaced with interlocking guards with or without guard locking. As Schuster [49] stated, the configurable design allows the worker to change the behavior of safety measures when a kind of energy is required for carrying out some activities such as maintenance, unjamming, or robot teaching. In addition, a lockable system design locks the safety configuration selected and protects those configuration changes. This alternative could be used instead of lockout.

- Communication between manufacturers and companies could help find technical solutions to facilitate operations without disabling safeguards (I19, I24, I58).

- The accessibility of tools or keys for bypassing interlocks could be limited (I17, I18). For example, the interlocks or the panels containing the keys could be installed out of reach (e.g., up high) or be placed in a lockbox so that only supervisors would be able to access the keys to the controls.

- “Error messages”, “audible or visible alarms” could be applied to machines to detect when safeguards are bypassed.

- Suggestions related to organizational factors are listed below to prevent bypassing:

- Procedures could clarify that the safeguards should be in place and utilized (I46).

- The workers could be involved during machine procurement and also other OHS issues (I36, I46). This shows that management pays attention to the workers’ needs. With their participation, workers are encouraged to respect safety rules and procedures.

- An employer is liable for respecting OHS regulations and ensuring that protection devices function sufficiently. He or she would not tolerate or order manipulation (I36). The employer will suffer legal troubles because of accidents due to bypassing.

- The workers are prohibited from disabling safety measures (I46).

- Appropriate supervision results in workers avoiding manipulation (I46). Furthermore, such monitoring could show management’s commitment at all organizational levels (I36).

- Employers could provide the required training and retraining (I36). The Systematic Approach to Training (SAT) develops and organizes a training program to be in line with the “environmental and occupational hazards” faced in industry, the opinions of end-users and their training needs to meet learning objectives [71].

- Management could clarify to workers that defeating is not tolerated and pay attention to workers’ recommendations (I36).

- Managers could raise their awareness of hazards in order to improve their commitment (I36).

- New machines could be provided or existing machines could be upgraded (I17, I18, I19, I20, I24, I43, I46, I58). For instance, automatic systems are suggested, such as the CNC lathe machine with full safety enclosures or fully automatic wire drawing machines. These improvements facilitate work, might change the workers’ old habits, and they would not easily disable advanced safety measures.

- Safety signs, images, and videos at toolbox talks could raise awareness (I46).

- Clear and detailed guides could change workers’ beliefs (I46).

- Suggestions related to the individual factors are listed below to prevent bypassing:

- Workers are responsible for using safeguards (I46).

- Workers could promote an awareness of bypassing (I46).

4.3. Impact and Further Research

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Questionnaire-OHS Practitioner’s Opinions | ||

|---|---|---|

| Company Information | ||

| Company Name: | Sector: | |

| Number of employees: | Type of production/services: | |

| Address: | ||

| Contact person (OHS practitioner) | ||

| Name: | Position: | |

| Experience in the position (year): | Date of completion: | |

| While using the tool | 1- Is the list of incentives in the tool satisfying?

⬜Yes

⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | |

| 2- Is the tool easy to use (user-friendly)?

⬜Yes

⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | ||

| 3- Is the tool useful to identify the incentives to bypass in the company? ⬜Yes ⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | ||

| The results of the tool | 1- Is the tool appropriate to estimate the probability of bypassing in the company?

⬜Yes

⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | |

| 2- Are the probability levels of bypassing accurate based on the work environment of the company?

⬜Yes

⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | ||

| 3- Is the tool useful to prevent bypassing?

⬜Yes

⬜No Explain:………………………………………………………………………………. ………………………………………………………………………………………... | ||

| Limitations of the tool: | ||

| Other comments: | ||

| Signature ---------------------------------------------------- Date --------------------------- | ||

Appendix C

| Company | Machine | Activity | Operation Modes 1 | Existing Safeguard | Answer to Question | The Incentives to BYPASS 2,3 | The Probability Level of Bypassing for the Activity |

|---|---|---|---|---|---|---|---|

| A | Bagger | Adjustment of the conveyor speed | Man. | Interlocking access gate | A | I24- I40- I41- I43- I58- I2- I3- I4- I19- I38- I44- I50- I61- I67- I46- I18- I36- I64 | High |

| Robot cell | Teach programming of the robot in the manual mode | Auto | Emergency stop safety function triggered by enclosure opening or E-stop button | A | I24- I1- I3- I4- I25- I32- I33- I44- I50- I61- I67- I46- I17- I18- I36- I52 | High | |

| Drill press | Machining | Auto | Chuck guard | B | I15- I21- I20- I50- I5- I18- I12- I27- I52 | Moderate | |

| Conventional lathe machine | Machining | Man. | Interlocking removable guard (protection against projection: protection against fluid and falling metals) | A | I15- I24- I34- I47- I1- I19- I20- I22- I25- I50- I18- I23 | Significant | |

| Interlocking movable chuck guard | B | I24- I47- I1- I19- I20- I50- I18 | Moderate | ||||

| Protective curtain (screw bearing protection) | B | I18 | Moderate | ||||

| Interlocking movable guard (protection of the other team members against projection of fluid or falling of metals) | C | - | Low | ||||

| Cleaning | Man. | Interlocking removable access guard (access to the back of the machine) | B | I18 | Moderate | ||

| Grinding machine | Grinding | Man. | Removable guard (protection against sparks) | B | I15- I43- I47- I1- I20- I17- I18- I57 | Moderate | |

| Brushing | Man. | Movable guard (protection against projection) | B | I43- I47- I1- I20- I17- I18- I57 | Moderate | ||

| B | Wire drawing machine | Pulling a new wire from the crown to the finishing block or replacing the matrices (dye) | Auto | Interlocking guard | B | I24- I31- I58- I3- I4- I14- I19- I20- I25- I33- I50- I5- I6- I7- I8- I9- I10- I49- I18- I29- I55- I70- I12- I51- I52- I53- I54- I60- I64 | Moderate |

| Inspecting the wire being drawn | Auto | Interlocking guard | B | I15- I24- I40- I42- I71- I3- I19- I20- I50- I5- I6- I8- I10- I49- I62- I17- I18- I29- I12- I36- I37- I51- I52- I53 | Moderate | ||

| Welding and grinding the wire ends of the 2 crowns while the wire drawing machine is running | Man. | Interlocking guard | B | I15- I40- I47- I3-I50- I5- I6- I8- I10- I13- I49- I62- I17- I18- I12- I36- I37- I51- I52- I53 | Moderate | ||

| Disassembly, adjustment or cleaning of the wire drawing machine in interlocking guard sections | Man. | Interlocking guard | A | I15- I21- I71- I2- I3- I14- I19- I20- I25- I33- I44- I50- I6- I8- I10- I49- I62- I17- I18- I28- I29- I55- I69- I12- I36- I37- I51- I52- I53 | Significant | ||

| Galvanizing lead bath | Passing the wire in the lead bath | Man. | Removable guard | A | I24- I31- I35- I42-I43- I58- I71- I2- I3- I14- I19- I20- I25- I33- I44- I65- I67- I6- I7- I8- I46- I49- I62- I17- I30- I55- I12- I27- I36- I37- I54 | Significant | |

| Strander | Monitoring from outside the enclosure while the equipment is running | Auto | Interlocking guard | C | - | Low | |

| Hydraulic press | Pressing the parts | Man. | Protection rods | A | I15- I24- I43- I58- I71- I3- I19- I22- I44- I67- I6- I7- I8- I9- I10- I46- I62- I17- I18- I23- I36- I37- I51- I60 | Significant | |

| C | Discharge conveyor | Unjamming | Auto or Man. | Enclosure with interlocking key in the control panel | A | I15- I24- I31- I34- I40- I42- I43- I58- I71- I1- I2- I3- I4- I14- I22- I25- I32- I33- I44- I50- I65- I67- I6- I7- I8- I46- I49- I62- I17- I18- I26- I28- I55- I66- I69- I70- I12- I27- I36- I37- I51- I52- I60 - I63- I64 | High |

| Preventive maintenance | Man. | Enclosure with interlocking key in the control panel | B | I15- I31- I34- I39- I42- I58- I71- I1- I3- I19- I38- I67- I7- I8- I62- I17- I18- I57- I69- I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||

| Weekly cleaning | Man. | Enclosure with interlocking key in the control panel | B | I34- I58- I1- I2- I3- I25- I33- I5- I7- I8- I62- I17- I18- I57- I69- I12- I36- I37- I51- I52- I63- I64 | Moderate | ||

| Megabale press | Access on the top of the machine for inspection/troubleshooting in operation | Auto or Man. | Interlocking key in the control panel | A | I15- I24- I31- I34- I39- I40- I42- I43- I58- I71- I1- I2- I3- I4- I14- I19- I20- I25- I32- I33- I38- I44- I50- I67- I6- I7- I8- I46- I49- I62- I17- I18- I26- I28- I55- I57- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | High | |

| Fence | B | I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||||

| Operation | Auto or Semi | Light curtain to avoid entering the area where the operator must put the bags | B | I15- I71- I2- I3- I14- I20- I32- I33- I67- I7- I62- I17- I57- I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||

| Preventive maintenance | Auto or Man. or Semi | Light curtain to avoid entering the area where the operator must put the bags | B | I15- I24- I31- I39- I58- I71- I2- I3- I4- I19- I20- I25- I32- I33- I38- I44- I6- I7- I8- I46- I49- I62- I17- I18- I26- I28- I45- I55- I57- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Interlocking key in the control panel | B | I15- I24- I31- I39- I58- I71- I2- I3- I4- I19- I20- I25- I32- I33- I38- I44- I6- I7- I8- I46- I49- I62- I17- I18- I26- I28- I45- I55- I57- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||||

| Fence | B | I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||||

| Floor conveyor | Recycling good product from rejected bags | Auto | Interlocking enclosure | A | I15- I24- I31- I34- I35- I40- I42- I43- I58- I71- I1- I2- I3- I4- I14- I22- I25- I33- I44- I67- I6- I7- I8- I46- I62- I17- I18- I26- I28- I55- I57- I12- I36- I37- I51- I52- I53- I60- I63- I64 | High | |

| Continuous operation | Auto or Man. | Fence | B | I15- I24- I31- I40- I42- I43- I71- I3- I44- I67- I7- I8- I46- I49- I62- I17- I18- I57- I12- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Preventive maintenance | Man. | Guard | A | I15- I24- I34- I35- I58- I3- I19- I20- I38- I44- I67- I8- I46- I49- I62- I17- I18- I26- I57- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Significant | ||

| Wrapping machine | Wrapping two bags with plastic | Auto or Man. | Light curtain | A | I15- I24- I31- I35- I42- I43- I58- I71- I1- I2- I3- I14- I19- I20- I25- I32- I33- I38- I44- I67- I6- I7- I8- I46- I62- I17- I18- I26- I28- I29- I57- I69- I12- I36- I37- I51- I52- I53- I60- I63- I64 | High | |

| Cleaning | Man. | Light curtain | B | I5- I6- I7- I8- I11- I46- I49- I62- I17- I18- I57- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Preventive maintenance | Man. | Light curtain | B | I31- I58- I2- I19- I20- I38- I8- I46- I49- I62- I17- I18- I57- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Small bag press | Troubleshooting of pneumatic system | Man. | Gate with Interlocking key in the control panel | A | I15- I24- I39- I42- I43- I58- I71- I1- I2- I3- I4- I14- I19- I20- I25- I32- I33- I38- I44- I67- I6- I7- I8- I46- I62- I17- I18- I26- I28- I29- I57- I69- I70- I12- I36- I37- I51- I52- I53- I60- I63- I64 | High | |

| Fence | B | I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||||

| Daily maintenance (door greasing, minor adjustments, changing Teflon on the sealer) | Auto or Man. or Semi | Gate with Interlocking key in the control panel | B | I24- I31- I39- I40- I58- I1- I2- I3- I14- I25- I32- I38- I44- I67- I8- I46- I49- I62- I17- I18- I56- I57- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Fence | B | I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||||

| Normal operation | Auto | Gate with Interlocking key in the control panel | B | I58- I2- I3- I20- I22- I32- I67- I49- I62- I17- I18- I29- I56- I69- I12- I27- I36- I37- I51- I52- I53- I60- I63- I64 | Moderate | ||

| Fence | B | I12- I27- I36- I37- I51- I52- I60- I63- I64 | Moderate | ||||

| D | Coater #1 | Adjustment of dyes | Man. | Movable guard | A | I15- I19- I22- I25- I32- I46- I17 | Significant |

| Troubleshooting of gas flame and camera | Man. | Fixed guard | A | I24- I19 | Significant | ||

| Troubleshooting of control box | Auto | Fixed guard | A | I24- I19 | Significant | ||

| Coater #2 | Adjustment | Man. | Fixed guard | A | I24- I19 | Significant | |

| Checking the belt | Man. | Fixed guard | A | I24- I19 | Significant | ||

| Fitting the switch | Man. | Fixed guard | A | I24- I19 | Significant | ||

| Winder | Adjustment of control valve | Man. | Fixed guard | A | I24- I19 | Significant | |

| Lathe machine | Tool adjustment | Man. | Movable guard | A | I15- I24- I58- I19 | Significant |

Appendix D

| Code of Incentives | Definition |

|---|---|

| I1. | There is a lot of work to carry out. |

| I2. | Reaching into a hazardous zone several times to do the work. |

| I3. | Using safeguards is extra work. |

| I4. | Using safeguards is time-consuming. |

| I5. | Operators are inexperienced. |

| I6. | Operators feel machines are safe without safeguards, and using them is unnecessary. |

| I7. | There is a lack of knowledge on the hazards, the severity of consequences or the risks due to the defeating of safeguards. |

| I8. | The risk of bypassing is underestimated or overlooked. |

| I9. | Operators do not know that using a safeguard is required. |

| I10. | Operators forget to use the safeguard. |

| I11. | Operators think that they used the safeguard. |

| I12. | Operators behave as though they are experienced. |

| I13. | Operators cannot explain why they do not use a safeguard. |

| I14. | Safeguards disturb the work process and production. |

| I15. | A safeguard reduces the visibility of the tools and activities such as working process, production, setting and so on. |

| I16. | Poor reliability of safeguards and their failures (e.g., false alarms, trips, and restarts) disturb the people and operations in the work area and stimulate a tendency to bypass. |

| I17. | Safeguards can be disabled easily and with little effort. |

| I18. | The required tools or keys for defeating are accessible in enterprises. |

| I19. | Safeguard removal is necessary to perform activities such as adjustments, troubleshooting, maintenance, and installation (no specific operation modes exist for performing them). |

| I20. | Coping with faults would be more efficient with safeguard circumvention. |

| I21. | Removing and installing safeguards frequently for lubrication is tedious. |

| I22. | Acting quickly to remove products that fall off without interrupting production. |

| I23. | Producing unusual pieces of work requires a safeguard defeat. |

| I24. | Bypassing provides convenience and facilitates work. |

| I25. | Safeguards in place slow down the work process and production. |

| I26. | Safeguards are difficult to use because they are impractical. |

| I27. | Other individuals are involved, not just operators. |

| I28. | An unsuitable safeguard has been selected at the design phase, which is unacceptable for the operator. |

| I29. | Easy access to software and switches make safeguards possible to defeat. |

| I30. | Safeguards are not maintained correctly to ensure complete protection. |

| I31. | A safeguard limits the adequate lighting in a workplace. |

| I32. | Bypassing increases downtime due to production disturbances. |

| I33. | A safeguard is an obstruction to quickening the pace of work and enhancing productivity. |

| I34. | Machinery and safeguards are not user friendly and have poor ergonomics. |

| I35. | There is not enough workspace when using a safeguard. |

| I36. | There is a lack of management commitment and managers either ordered, tolerated, encouraged or ignored circumvention. |

| I37. | There are no enforcement or disciplinary actions for those who bypass safeguards. |

| I38. | A safeguard is bypassed to obtain greater precision. |

| I39. | Safeguard is bypassed to have better audibility. |

| I40. | Safeguard is bypassed to require less physical effort. |

| I41. | Safeguard is bypassed to reduce the rate of travel. |

| I42. | Safeguard is bypassed to facilitate the freedom of movement. |

| I43. | Safeguard is bypassed to improve the flow of movement. |

| I44. | Safeguards are bypassed to save time carrying out the operations. |

| I45. | There is an unsuitable machine to work with. |

| I46. | Bypassing is a habit. |

| I47. | Safeguard is bypassed because of stress. |

| I48. | A safeguard vibrates or rattles. |

| I49. | Bypassing occurs with experienced operators because they think that they are less at risk than others. |

| I50. | There is time pressure to perform the job or to meet expectations. |

| I51. | There is a lack of adequate training and awareness about manipulation. |

| I52. | Bypassing a safeguard is not detectable; they are usually restored or bosses cannot detect it. |

| I53. | Employee involvement is ignored when procuring machines or other OHS issues. |

| I54. | Experienced operators force others to bypass, or defeating is carried out with peers. |

| I55. | The machine design is poor. |

| I56. | There is a lack of flexibility in programming (e.g., a program that goes back to the beginning when the machine was stopped for swarf removal, etc., and it cannot be restarted mid-cycle or when the safeguard has to be enabled all the time or just during CNC mode.) |

| I57. | The regulatory requirements do not clarify whether safeguards should be operated all the time or just when operating in CNC mode. |

| I58. | There is impaired accessibility to the job and the tools. |

| I59. | Bypassing occurs to achieve encouragement and performance bonuses from bosses. |

| I60. | There is no supervision that monitors if a safeguard is enabled. |

| I61. | Bypassing occurs because of financial pressures. |

| I62. | Safeguards are not checked before operating the machine to ensure that they are in place. |

| I63. | The issue of defeating is not integrated into a culture of safety. |

| I64. | Current policies and procedures are inadequate. |

| I65. | The time costs due to a program restart are reduced. |

| I66. | Machines are produced by manufacturers with poor quality safeguards. |

| I67. | Profitability diminishes if the customer’s order is not met. |

| I68. | Moving the heavy safeguard is difficult. |

| I69. | The safeguard’s size makes it difficult to access areas around it. |

| I70. | Clothing is caught or cuts happen because of the physical characteristics of a safeguard. |

| I71. | Metabolic energy consumption will decrease by bypassing. |

| I72. | Taking a risk is exciting for employees. |

References

- Pagell, M.; Johnston, D.; Veltri, A.; Klassen, R.; Biehl, M. Is safe production an oxymoron? Prod. Oper. Manag. 2014, 23, 1161–1175. [Google Scholar] [CrossRef]

- Lo, C.K.Y.; Pagell, M.; Fan, D.; Wiengarten, F.; Yeung, A.C.L. OHSAS 18001 certification and operating performance: The role of complexity and coupling. J. Oper. Manag. 2014, 32, 268–280. [Google Scholar] [CrossRef]

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Relation between occupational safety management and firm performance. Saf. Sci. 2009, 47, 980–991. [Google Scholar] [CrossRef]

- Smallman, C.; John, G. British directors perspectives on the impact of health and safety on corporate performance. Saf. Sci. 2001, 38, 227–239. [Google Scholar] [CrossRef]

- Loeppke, R.; Taitel, M.; Richling, D.; Parry, T.; Kessler, R.C.; Hymel, P.; Konicki, D. Health and productivity as a business strategy. J. Occup. Environ. Med. 2007, 49, 712–721. [Google Scholar] [CrossRef]

- Hesapro. The Link between Productivity and Health and Safety at Work—Background Research Paper. Available online: https://docplayer.net/7790585-The-link-between-productivity-and-health-and-safety-at-work.html (accessed on 10 August 2020).

- Dabbagh, R.; Yousefi, S. A hybrid decision-making approach based on FCM and MOORA for occupational health and safety risk analysis. J. Saf. Res. 2019, 71, 111–123. [Google Scholar] [CrossRef]

- Apfeld, R.; Huelke, M.; Lüken, K.; Schaefer, M.; Paridon, H.; Windemuth, D.; Zieschang, H.; Preuße, C.; Umbreit, M.; Hüning, A.; et al. Bypassing of Protective Devices on Machinery (HVBG Report); Hauptverband der gewerblichen Berufsgenossenschaften (HVBG): Sankt Augustin, Germany, 2006. [Google Scholar]

- Apfeld, R. Stop defeating the safeguards of machines. In Proceedings of the 6th International Conference Safety of Industrial Automated Systems, Tampere, Finland, 14–15 June 2010; p. 15. [Google Scholar]

- Zimmermann, A. SuvaPro-STOP à la manipulation des dispositifs de protection. Benefit 2007, 3, 9–10. [Google Scholar]

- ISO 14119. Interlocking Devices Associated with Guards—Principles for Design and Selection; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- Haghighi, A.; Jocelyn, S.; Chinniah, Y. A holistic assessment tool to estimate the probability of bypassing safeguards on machinery. Saf. Sci. 2019, 120, 561–574. [Google Scholar] [CrossRef]

- Fan, D.; Lo, C.K.Y.; Ching, V.; Kan, C.W. Occupational health and safety issues in operations management: A systematic and citation network analysis review. Int. J. Prod. Econ. 2014, 158, 334–344. [Google Scholar] [CrossRef]

- Colquitt, J.A.; LePine, J.A.; Zapata, C.P.; Wild, R.E. Trust in typical and high-reliability contexts: Building and reacting to trust among firefighters. Acad. Manag. J. 2011, 54, 999–1015. [Google Scholar] [CrossRef] [Green Version]

- Das, A.; Pagell, M.; Behm, M.; Veltri, A. Toward a theory of the linkages between safety and quality. J. Oper. Manag. 2008, 26, 521–535. [Google Scholar] [CrossRef]

- Amponsah-Tawiah, K.; Mensah, J. Occupational health and safety and organizational commitment: Evidence from the Ghanaian mining industry. Saf. Health Work 2016, 7, 225–230. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Johnston, D.; Pagell, M.; Veltri, A.; Klassen, R. Values-in-action that support safe production. J. Saf. Res. 2020, 72, 75–91. [Google Scholar] [CrossRef] [PubMed]

- Vautrin, J.; Dei-Svaldi, D. Accidents du travail sur sites automatisés. Évaluation d’une prévention technique. Cah. Notes Doc. 1989, 136, 445–453. [Google Scholar]

- Järvinen, J.; Karwowski, W. A questionnaire study of accidents in advanced manufacturing systems. Proc. Human Fact. Ergon. Soc. Ann. Meet. 1993, 37, 1004–1008. [Google Scholar] [CrossRef]

- Backström, T.; Döös, M. Problems with machine safeguards in automated installations. Int. J. Ind. Ergon. 2000, 25, 573–585. [Google Scholar] [CrossRef]

- Shaw, S. Machinery accidents–Contributory factors. In Proceedings of the 6th International Conference Safety of Industrial Automated Systems, Tampere, Finland, 14–15 June 2010; p. 15. [Google Scholar]

- Charpentier, P. Safety of machinery: Experience feedback on automated accidents from the EPICEA database. In Proceedings of the 4th International Conference on Safety of Industrial Automated Systems, Chicago, IL, USA, 26–28 September 2005. [Google Scholar]

- Dźwiarek, M. An analysis of accidents caused by improper functioning of machine control systems. Int. J. Occup. Saf. Ergonom. 2004, 10, 129–136. [Google Scholar] [CrossRef]

- Mattila, M.; Tallberg, T.; Vannas, V.; Kivistö-Rahnasto, J. Fatalities at advanced machines and dangerous incidents at FMS implementations. Int. J. Hum. Factors Manuf. 1995, 5, 237–250. [Google Scholar] [CrossRef]

- Gardner, D.; Cross, J.; Fonteyn, P.; Carlopio, J.; Shikdar, A. Mechanical equipment injuries in small manufacturing businesses. Saf. Sci. 1999, 33, 1–12. [Google Scholar] [CrossRef]

- Chinniah, Y.; Bourbonniere, R. Automation safety. Prof. Saf. 2006, 51, 26–33. [Google Scholar]

- KANbrief. Bypassing of Protective Devices—A Need for Action by Standardization Bodies? KANBrief-Kommission Arbeitsschutz und Normung: Sankt Augustin, Germany, 2003. [Google Scholar]

- Charpentier, P.; Sghaier, A. Industrial Robotic: Accident analysis and Human-Robot Coactivity. In Proceedings of the 7th International Conference Safety of Industrial Automated Systems, Montreal, QC, Canada, 11–12 October 2012; pp. 170–175. [Google Scholar]

- Chinniah, Y.; Paques, J.-J.; Champoux, M. Risk Assessment & Reduction. Prof. Saf. 2007, 52, 49–56. [Google Scholar]

- Huelke, M.; Stollewerk, R.; Lüken, K.; Post, M. Safety from the Testing of Ergonomic Machinery Design; International Syposium: Nice, France, 1–3 March 2006. [Google Scholar]

- Hopkinson, J.; Lekka, C. Identifying the Human Factors Associated with the Defeating of Interlocks on Computer Numerical Control (CNC) Machines; RR974 Research Report; Health and Safety Laboratory: Buxton, UK, 2013. [Google Scholar]

- Parker, D.L.; Brosseau, L.M.; Samant, Y.; Xi, M.; Pan, W.; Haugan, D.; The Study Advisory, B. A Randomized, Controlled Intervention of Machine Guarding and Related Safety Programs in Small Metal-Fabrication Businesses. Publ. Health Rep. 2009, 124, 90–100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Samant, Y.; Parker, D.; Brosseau, L.; Pan, W.; Xi, M.; Haugan, D. Profile of machine safety in small metal fabrication businesses. Am. J. Ind. Med. 2006, 49, 352–359. [Google Scholar] [CrossRef] [PubMed]

- Chinniah, Y. Machine safety: Commonly observed problems in the manufacturing sector in Quebec. J. Occup. Health Saf. Aust. N. Z. 2009, 25, 405–410. [Google Scholar]

- Chinniah, Y. Analysis and prevention of serious and fatal accidents related to moving parts of machinery. Saf. Sci. 2015, 75, 163–173. [Google Scholar] [CrossRef]

- Pratt, S.; Hard, D. Injury Risk Factors Associated with AgriculturalWorkplace Fatalities. J. Agricult. Saf. Health 1998, 4, 29–38. [Google Scholar] [CrossRef]

- CSAZ432. Safeguarding of Machinery; Canadian Standards Association: Toronto, ON, Canada, 2016. [Google Scholar]

- Le Parlement Européen. EURO Directive 2006/42/CE du Parlement Européen et du Conseil du 17 Mai 2006 Relative aux; Machines et Modifiant la Directive 95/16/CE (Refonte). Available online: http://www.ilo.org/dyn/natlex/natlex4.detail?p_lang=fr&p_isn=73786 (accessed on 10 August 2020).

- ISO 13855. Safety of Machinery—Positioning of Safeguards with Respect to the Approach Speeds of Parts of the Human Body; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- ISO 13851. Safety of Machinery—Two-Hand Control Devices—Functional Aspects and Design Principles; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- ISO 12100. Safety of Machinery—General Principles for Design—Risk Assessment and Risk Reduction; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- IFA. The Incentive to Bypass Protective Devices on Machinery. 2011. Available online: http://www.dguv.de/medien/ifa/en/pra/manipulation/explanations.pdf (accessed on 9 August 2020).

- Caputo, A.C.; Pelagagge, P.M.; Salini, P. AHP-based methodology for selecting safety devices of industrial machinery. Saf. Sci. 2013, 53, 202–218. [Google Scholar] [CrossRef]

- Racz, S.G.; Breaz, R.E.; Cioca, L.I. Evaluating Safety Systems for Machine Tools with Computer Numerical Control using Analytic Hierarchy Process. Safety 2019, 5, 14. [Google Scholar] [CrossRef] [Green Version]

- Tochio, M.; Nakayama, K.; Arai, T.; Nonoaka, S.; Shiomi, M.; Knamaru, H.; Toyama, H.; Fujita, T.; Takaoka, H.; Mukaidono, M. The Improvement of Industrial Safety achieved by the Introduction of Safety Assessor/Safety Basic Assessor Qualification System and its International Operations. In Proceedings of the 7th International Conference Safety of Industrial Automated Systems, Montreal, QC, Canada, 11–12 October 2012; pp. 255–260. [Google Scholar]

- Lüken, K.; Pardon, H.; Windemuth, D. Bypassing and defeating protective devices of machines—A multidimensional problem. INRS Hyg. Secur. Trav. 2006, 4, 55–58. [Google Scholar]

- Adams, P.S. Using human factors to understand and improve machine safeguarding. In Applied Ergonomics; CRC Press: Boca Raton, FL, USA, 2001; pp. 69–75. [Google Scholar]

- Johnson, L.F. The luxury of machine guarding. Occup. Health Saf. 1999, 68, 26–29. [Google Scholar]

- Schuster, G. Improving Manufacturing Performance. Prof. Saf. 2012, 57, 62–64. [Google Scholar]

- Freedman, S. Issues in System Design. Occup. Health Saf. 2004, 73, 126. [Google Scholar] [PubMed]

- Chinniah, Y. Causes of fatal and serious accidents involving machinery in Quebec. In Proceedings of the 8th International Conference Safety of Industrial Automated Systems, Königswinter, Germany, 18–20 November 2015; pp. 170–179. [Google Scholar]

- Neudörfer, A. Designing Machines for Safety; Hazards-Safety Precautions. K.A. Schmersal GmbH. 2012. Available online: http://www.schmersal.com (accessed on 1 September 2020).

- Roudebush, C. Machine safeguarding: A process for determining tolerable risk. Prof. Saf. 2005, 50, 20–24. [Google Scholar]

- McConnell, S.M. Machine safeguarding: Building a successful program. Prof. Saf. 2004, 49, 18–27. [Google Scholar]

- Sherrard, L. Things everyone should know about machine guarding. Occup. Health Saf. 2007, 76, 112–113. [Google Scholar]

- Haghighi, A.; Chinniah, Y.; Jocelyn, S. Literature review on the incentives and solutions for the bypassing of guards and protective devices on machinery. Saf. Sci. 2019, 111, 188–204. [Google Scholar] [CrossRef]

- Dźwiarek, M. Prevention of Defeating Interlocking Devices Associated with Guards. J. KONBiN 2019, 49, 451–470. [Google Scholar] [CrossRef] [Green Version]

- DGUV. Checklist Machinery Purchase. Available online: https://stop-defeating.org/en/fuer-betreiber/ (accessed on 10 August 2020). (In German).

- Suvapro. Liste de Contrôle: STOP à la Manipulation des Dispositifs de Protection. 2007. Available online: https://extra.suva.ch/webshop/56/56A6469AB0342C70E10080010A63035B.pdf (accessed on 10 August 2020).

- Gauthier, F.; Lambert, S.; Chinniah, Y. Experimental analysis of 31 risk estimation tools applied to safety of machinery. Int. J. Occup. Saf. Ergon. 2012, 18, 245–265. [Google Scholar] [CrossRef]

- Chinniah, Y.; Gauthier, F.; Lambert, S.; Moulet, F. Experimental Analysis of Tools Used for Estimating Risk Associated with Industrial Machines; Report R-684; IRSST Research Institute Robert-Sauvé Health and Safety: Montreal, QC, Canada, 2011; p. 77. [Google Scholar]

- Chinniah, Y.; Gauthier, F.; Aucourt, B.; Burlet-Vienney, D. Validation of the impact of architectural flaws in six machine risk estimation tools. Saf. Sci. 2018, 101, 248–259. [Google Scholar] [CrossRef]

- Hancock, D.R.; Algozzine, B. Doing Case Study Research: A Practical Guide for Beginning Researchers; Teachers College Press: New York, NY, USA, 2016. [Google Scholar]

- Perry, C. Processes of a case study methodology for postgraduate research in marketing. Eur. J. Mark. 1998, 32, 785–802. [Google Scholar] [CrossRef]

- Eisenhardt, K.M. Building theories from case study research. Acad. Manag. Rev. 1989, 14, 532–550. [Google Scholar] [CrossRef]

- Leung, D.; Rispoli, L.; Chan, R. Small, Medium-Sized, and Large Businesses in the Canadian Economy: Measuring their Contribution to Gross Domestic Product from 2001 to 2008; Statistics Canada: Ottawa, ON, Canada, 2012.

- Bell, J. Doing Your Research Project: A Guide for First-Time Researchers; McGraw-Hill Education: London, UK, 2014. [Google Scholar]

- Giraud, L. Machine Safety-Prevention of Mechanical Hazards: Fixed Guards and Safety Distances; Guide RG-597; IRSST: Montréal, QC, Canada, 2009. [Google Scholar]

- ISO 45001. Occupational Health and Safety Management Systems—Requirements with Guidance for Use; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- Kim, Y.; Park, J.; Park, M. Creating a culture of prevention in occupational safety and health practice. Saf. Health Work 2016, 7, 89–96. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lagerstrom, E.; Magzamen, S.; Brazile, W.; Stallones, L.; Ayers, P.; Rosecrance, J. A Case Study in the Application of the Systematic Approach to Training in the Logging Industry. Safety 2019, 5, 43. [Google Scholar] [CrossRef] [Green Version]

- Jocelyn, S.; Baudoin, J.; Chinniah, Y.; Charpentier, P. Feasibility study and uncertainties in the validation of an existing safety-related control circuit with the ISO 13849-1: 2006 design standard. Reliab. Eng. Syst. Saf. 2014, 121, 104–112. [Google Scholar] [CrossRef]

| Company | Type of Production/Services | Number of OHS Practitioners Who Were Involved | Number of Employees | OHS Practitioner’s Years of Experience (years) | Number of Machines Selected | Number of Activities Performed for Testing |

|---|---|---|---|---|---|---|

| A | Equipment design and manufacturing | 2 | 625 | 5 and 20 years | 5 | 7 |

| B | Iron and steel | 1 | 125 | 16 years | 4 | 7 |

| C | Horticulture and agriculture | 1 | 700 | 10 years | 5 | 15 |

| D | Pulp and paper | 1 | 60 | 12 years | 4 | 8 |

| Total | 5 | 18 | 37 |

| Instructions for Applying the Bypassing-Related Assessment Tool | ||

|---|---|---|

| This tool has been designed for OHS practitioners. It helps them identify existing incentives to bypass and estimate the probability of bypassing. | ||

| 1- | Write the name of the machine. | |

| 2- | List the activities implemented on the machine in order to have as precise of an assessment as possible (OHS practitioners can adapt the activity list with the participation of operators). | |

| 3- | The modes of operation can be selected with an asterisk as manual, automatic or something else for each activity (if there are other modes of operation, you can add a new column). | |

| 4- | The existing bypassed safeguards for each activity would be written (the OHS practitioner can assign more than one safeguard to an activity and write other safeguards in the next rows). | |

| 5- | Answer the “How is the bypassing situation?” question by selecting one of the following entries for each safeguard: | |

| A | The safeguard is bypassed and the OHS practitioner in the enterprise notices actual incentives to take corrective measure. | |

| B | The safeguard is not bypassed, but the OHS practitioner in the enterprise observes some potential incentives. That may cause bypassing in the future. | |

| C | There are no incentives to bypass. | |

| 6- | Identify the existing incentives to bypass (potential or actual) among the possible incentives classified in the tool per the five categories that are available: (1) ergonomics, (2) productivity, (3) behavior, (4) machine or safeguarding, and (5) corporate climate. Three levels are considered to estimate the impact of the incentives on the probability of bypassing. Select one of the following effect levels based on your judgment: | |

| 0 | No effect due to the nonexistence of an incentive. | |

| + | Slight effect of an incentive on the probability of bypassing. | |

| ++ | Significant effect of an incentive on the probability of bypassing. | |

| 7- | The probability of bypassing is automatically calculated by Excel functions. Four levels are considered for the probability of bypassing to attain adequate results for prioritization. | |

| High | The corresponding answer to the question from step 5 is A and half or more than half of the incentives identified for the activity have a significant effect (++) on the probability of bypassing. | |

| Significant | The corresponding answer to the question from step 5 is A and fewer than half of the incentives identified for the activity have a significant effect (++) on the probability of bypassing. | |

| Moderate | The corresponding answer to the question from step 5 is B and there is at least one incentive identified for the activity that has a slight effect (+) or significant effect (++) on the probability of bypassing. | |

| Low | The corresponding answer to the question from step 5 is C and there is no reasonably foreseeable incentive for the activity (0). | |

| Questions | Companies | ||||

|---|---|---|---|---|---|

| A | B | C | D | ||

| While using the tool | 1. Is the list of incentives in the tool satisfying? | No | Yes | Yes | Yes |

| 2. Is the tool easy to use (user-friendly)? | Yes | No | Yes | Yes | |

| 3. Is the tool useful to identify the incentives to bypass in the company? | No | Yes | Yes | Yes | |

| The results of the tool | 1. Is the tool appropriate to estimate the probability of bypassing in the company? | Yes | - | Yes | No |

| 2. Are the probability levels of bypassing accurate based on the work environment of the company? | Yes | Yes | Yes | Yes | |

| 3. Is the tool useful to prevent bypassing? | Yes | - | Yes | Yes | |

| Phase | Pros | Cons |

|---|---|---|

| While using the tool |

|

|

| The results of the tool |

|

|

| NO. | Category 1 | The Actual Incentives to Bypass (with Slight or Significant Effects) | N |

|---|---|---|---|

| 1 | E | Bypassing provides convenience and facilitates work (I24). | 18 |

| 2 | P | Safeguard removal is necessary to perform activities such as adjustments, troubleshooting, maintenance, and installation (no specific operation modes exist for performing them) (I19). | 17 |

| 3 | P | Using safeguards is extra work (I3). | 11 |

| 4 | E | A safeguard reduces the visibility of the tools and activities such as working process, production, setting and so on (I15). | 11 |

| 5 | Mach. | Safeguards can be disabled easily and with little effort (I17). | 11 |

| 6 | Mach. | The required tools or keys for defeating are accessible in enterprises (I18). | 11 |

| 7 | Co | There is a lack of management commitment and managers either ordered, tolerated, encouraged or ignored circumvention (I36). | 11 |

| 8 | P | Safeguards are bypassed to save time carrying out the operations (I44). | 11 |

| 9 | B | Bypassing is a habit (I46). | 11 |

| 10 | P | Safeguards in place slow down the work process and production (I25). | 10 |

| 11 | E | There is impaired accessibility to the job and the tools (I58) | 10 |

| 12 | P | Profitability diminishes if the customer’s order is not met (I67). | 10 |

| 13 | Beh. | The risk of bypassing is underestimated or overlooked (I8). | 9 |

| 14 | Co | There are no enforcement or disciplinary actions for those who bypass safeguards (I37). | 9 |

| 15 | Beh. | Safeguards are not checked before operating the machine to ensure that they are in place (I62). | 9 |

| Company | Prioritization of Machine 1 | Prioritization of Safeguards 1 | ||

|---|---|---|---|---|

| A | 1. Bagger | H | 1. Interlocking access gate | H |

| 2. Robot cell | H | 1. Emergency stop safety function triggered by enclosure opening or E-stop button | H | |

| 3. Conventional lathe machine | S | 1. Interlocking removable guard (protection against projection: protection against fluid and falling metals) | S | |

| 2. Interlocking movable chuck guard | M | |||

| 3. Protective curtain (screw bearing protection)—Interlocking removable access guard (access to the back of the machine | M | |||

| 4. Interlocking movable guard (protection of the other team members against projection of fluid or falling of metals) | L | |||

| 4. Grinding machine | M | 1. Removable guard (protection against sparks) | M | |

| 2. Movable guard (protection against projection) | M | |||

| 5. Drill press | M | 1. Chuck guard | M | |

| B | 1. Galvanizing lead bath | S | 1. Removable guard | S |

| 2. Wire drawing machine | S | 1. Interlocking guard | S | |

| 3. Hydraulic press | S | 1. Protection rods | S | |

| 4. Strander | L | 1. Interlocking guard | L | |

| C | 1. Floor conveyor | H | 1. Interlocking enclosure | H |

| 2. Guard | S | |||

| 3. Fence | M | |||

| 2. Megabale press | H | 1. Interlocking key in the control panel | H | |

| 2. Light curtain to avoid entering the area where the operator must put the bags | M | |||

| 3. Fence | M | |||

| 3. Discharge conveyor | H | 1. Enclosure with interlocking key in the control panel | H | |

| 4. Small bag press | H | 1. Gate with interlocking key in the control panel | H | |

| 2. Fence | M | |||

| 5. Wrapping machine | H | 1. Light curtain | H | |

| D | 1. Coater #1 | S | 1. Movable guard | S |

| 2. Fixed guard | S | |||

| 2. Lathe machine | S | 1. Movable guard | S | |

| 3. Coater #2 and Winder | S | 1. Fixed guard | S | |

| Actual Incentives with Significant Effects | Category 1 |

|---|---|

| Safeguards can be disabled easily and with little effort (I17). | Mach. |

| The required tools or keys for defeating are accessible in enterprises (I18). | Mach. |

| Safeguard removal is necessary to perform activities such as adjustments, troubleshooting, maintenance, and installation (no specific operation modes exist for performing them) (I19). | P |

| Coping with faults would be more efficient with safeguard circumvention (I20). | P |

| Bypassing provides convenience and facilitates work (I24). | E |

| There is a lack of management commitment and managers either ordered, tolerated, encouraged or ignored circumvention (I36). | Co |

| Safeguard is bypassed to improve the flow of movement (I43). | E |

| Bypassing is a habit (I46). | Beh. |

| There is impaired accessibility to the job and the tools (I58). | E |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haghighi, A.; Jocelyn, S.; Chinniah, Y. Testing and Improving an ISO 14119-Inspired Tool to Prevent Bypassing Safeguards on Industrial Machines. Safety 2020, 6, 42. https://doi.org/10.3390/safety6030042

Haghighi A, Jocelyn S, Chinniah Y. Testing and Improving an ISO 14119-Inspired Tool to Prevent Bypassing Safeguards on Industrial Machines. Safety. 2020; 6(3):42. https://doi.org/10.3390/safety6030042

Chicago/Turabian StyleHaghighi, Aida, Sabrina Jocelyn, and Yuvin Chinniah. 2020. "Testing and Improving an ISO 14119-Inspired Tool to Prevent Bypassing Safeguards on Industrial Machines" Safety 6, no. 3: 42. https://doi.org/10.3390/safety6030042

APA StyleHaghighi, A., Jocelyn, S., & Chinniah, Y. (2020). Testing and Improving an ISO 14119-Inspired Tool to Prevent Bypassing Safeguards on Industrial Machines. Safety, 6(3), 42. https://doi.org/10.3390/safety6030042