1. Introduction

Vehicular incident rates have been on the rise in the U.S. and internationally. In 2020, more than 5.2 million vehicular incidents occurred, which resulted in almost 36,000 deaths [

1]. In 2021, fatalities occurring from vehicular incidents increased to over 42,000. It is estimated that injuries sustained in vehicular accidents will be the seventh leading cause of death worldwide [

2]. The occurrence of vehicular incidents involving tractor trailers has also increased [

3]. In recent years, truck volumes (both heavy-duty and medium-duty) have increased [

4] due to increases in shipping needs and the prevalence of ecommerce. Although an increase in ecommerce can result in a reduction in vehicle miles traveled (VMT) [

5] the increase in truck volume can lead to a higher occurrence of incidents involving trucks. These incidents are costly: with average health costs and property damage costs associated with truck incidents ranging from USD 300k to USD 1.2 million, depending on the number of trailers, and incidents involving fatalities costing several millions, depending on damages [

6]. These incidents are costly for businesses in terms of loss or damage of property, hindrances in efficiency, but most importantly, in terms of lives lost.

Many truck incidents are preventable: while many incidents are caused by speeding, inclement weather, or driver intoxication, the most common cause of incidents is driver fatigue [

6], thus prompting federal regulations prohibiting truck drivers from driving for more than eight consecutive hours without a break. However, another main cause cited for both U.S. and international truck incidents is vehicle maintenance [

7,

8,

9]. In the U.S., the importance of the Department of Transportation (DOT) to conduct regular and adequate vehicle inspections and pinpoint preventable maintenance is crucial in potentially reducing the number of truck incidents. However, truck drivers and fleet managers must abide by DOT guidance, especially when a vehicle is rendered out-of-service due to unaddressed maintenance issues.

The Federal Motor Carrier Safety Administration (FMCSA) of the DOT is responsible for setting guidelines and contracting qualified inspectors to perform truck inspections at designated locations across the U.S., whether at an interstate truck stop or DOT-designated truck shop. During a DOT truck inspection, the driver of the vehicle will be issued a result: no violations, non-out-of-service (Non-OOS) violation (less severe), or out-of-service (OOS) violation (more severe) [

10]. During an inspection, a driver can receive multiple violations (there are a total of 50 categories). If a driver receives one OOS violation, the driver is unable to return to operating the vehicle until the issues resulting in the OOS designation are addressed accordingly. In some cases, this can be catastrophic for the driver: with an inability to earn an income until the vehicle is serviced, inspected again, and deemed road worthy. Unfortunately, this can present opportunities for falsification of documents or illegally driving a vehicle although appropriate maintenance has not been performed. Although preventative maintenance is costly up-front, it can be an incentive for drivers and fleet managers to prevent the vehicle from being removed from the road, maintain higher freight energy efficiency, and increase overall asset availability and productivity.

The FMCSA’s Motor Carrier Management Information System (MCMIS) dataset, which is available for public download [

11], contains all truck (light-, medium-, and heavy-duty) incident and inspection data for every recorded road event in the U.S. (including Alaska, Hawaii, and Puerto Rico). The incident data provides locational and temporal attributes, as well as other attributes detailing the severity and possible causes of incidents involving commercial vehicles. Inspection data is also provided and contains details regarding the violation (if any) type and number for each event.

This paper will provide an in-depth county-level breakdown of reported truck incidents and inspections from 2016 to 2020. Prior to this study, the MCMIS dataset had never been evaluated at a national scale [

12,

13]. Previous work using the dataset has involved specific, county or state-level analyses. This paper will provide the reader with an overview of trends, anomalies, and expected key findings based on previous research. Ultimately, the purpose of this data exploration was to examine incident and inspection rates relative to locations to see where problems potentially lie to uncover future solutions for the FMCSA, inspectors, fleets, and state-level DOTs. It serves to be a resource for decision makers, namely state-level DOTs, to consider when examining incident and inspection rates, relative to losses in efficiency, and ultimately, safety improvements. This paper is structured as follows. In

Section 1, the introduction, the motivating problem, and terminology are presented. In

Section 2, this paper will present the MCMIS dataset, used in this analysis as well as justification for the categorization of results found in the analysis. In

Section 3, the results and analysis are presented, along with breakdowns at the national and county-level as well as by inspection violation category. Lastly,

Section 4 provides concluding remarks and potential directions for expanded research on the topic.

2. MCMIS Dataset

The FMCSA manages the MCMIS dataset, which contains detailed information regarding the fitness of on-road trucks, buses, and hazardous material (hazmat) shippers who must follow federal regulations regarding maintenance of these vehicles [

14]. For the purposes of this research, only the incident data files, public inspections, and inspection violation files were obtained directly from the FMCSA for the years 2016 through 2020. Although the 2021 incident data were available, 2021 inspection data were not. Thus, the 2021 data were excluded from the analyses.

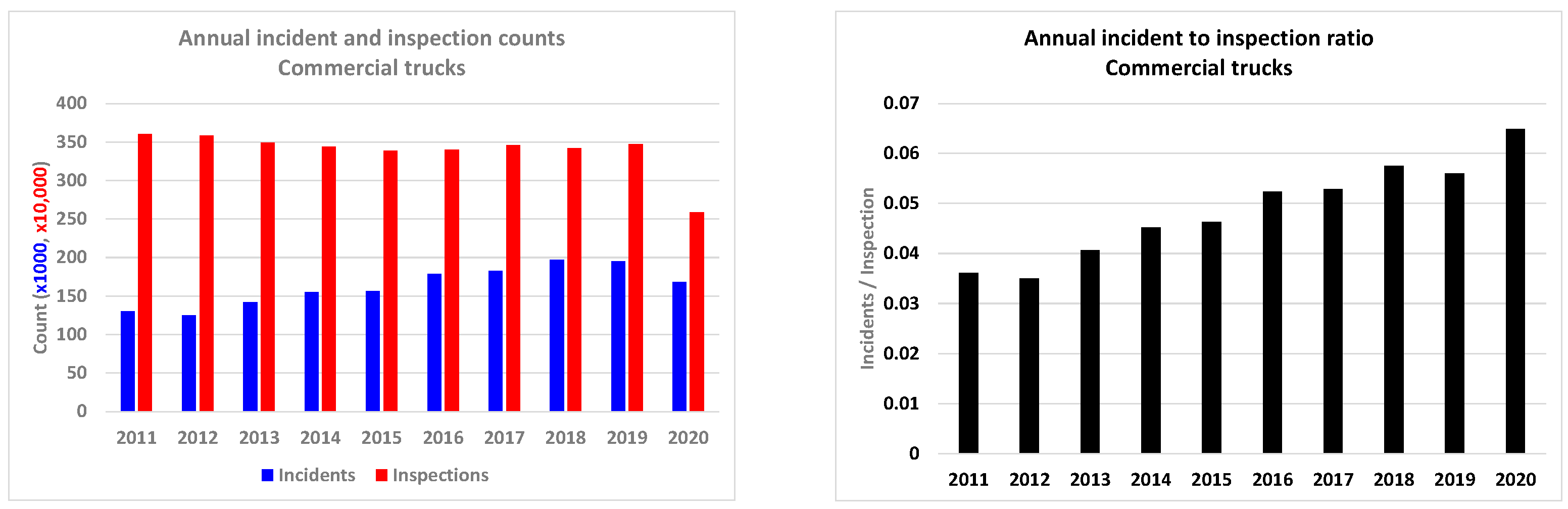

Initially, the datasets were broken down to examine total numbers of incidents and inspections per year (see

Table 1 and

Figure 1) with the assumption that total numbers would be at their lowest in 2020 due to the COVID-19 pandemic. Spatiotemporal analyses were performed to determine incident prevalence during time of day, with the assumption that most would occur during the afternoon [

14]. Other factors such as inclement weather, the presence of road construction, and road condition/presence of debris were also considered, as those are known causes of truck incidents. However, it was determined that the focus of this work would be in examining incidents relative to the top violation causes (

Table 2).

Data Processing

For each of the five years ranging from 2016 to 2020, the incident file was used to obtain the number of incidents per Federal Information Processing System (FIPS) code by U.S. county, as well as to assign a bin based on the time of the day that the incident was reported. The bins used for the assignment were: early (before 4 a.m.), morning (4 a.m. to 10 a.m.), afternoon (10 a.m. to 4 p.m.), evening (4 p.m. to 6 p.m.), and late (10 p.m. to midnight). These time bins were chosen arbitrarily but still represented the assumed distribution, namely the prevalence of incidents in the afternoon time period.

The inspection file was used to obtain the number of inspections (using an inspection ID), along with a designated time bin for each FIPS county code. The inspection violation file was then joined to the inspection file based on the unique inspection ID to obtain violation category information. Although the incident file was manageable in Microsoft Excel, the analyses involving the inspections and inspection violation files required the use of the Python Pandas library to perform the analyses. The final raw output was in csv form (see headings in

Table 3), and the total truck VMT per county per day was used to find normalized values for each variable. The VMT was found using the Freight Analysis Framework (FAF) dataset to obtain truck volumes per network link and the length of each network link (see

Figure 2) throughout each of the 3143 U.S. counties [

15]. The FAF dataset contains approximately 500,000 road segments, with segment lengths and freight flows (freight-carrying trucks) on these links provided in the attribute table. The process of finding the VMT per county involved obtaining FAF network segments per county and obtaining the product of the freight flow (volume) and total mileage. The result of this process is shown in

Figure 3. These data were fed into a Microsoft Excel macro, which processed the data and provided output tables for further analysis.

For each of the five years of data, the data were grouped into three categories, which were sorted by county: total inspections, OOS violations, and Non-OOS violations. Scatter plots were used to plot total incidents (

Figure 4), where each point represented an individual county. Additional scatter plots also showed the incident-to-inspection ratio, relative to inspections for each county. These plots were grouped into nine boxes, with designations given to each box based on the scenario description (

Table 4).

These designations were given based on several assumptions. Firstly, scenarios with low overall incidents were deemed ideal. Second, scenarios deemed less than ideal involved high inspections and moderate and high levels of incidents. The reasoning for this assumed that inspections are costly, and if inspections are high, while incidents are moderate to high, this is inefficient and not cost-effective. However, the scenario with low incidents and high inspections could also be considered ideal, as the high number of inspections could be deemed as preventative. Lastly, the scenarios deemed as not ideal involved high numbers of incidents, and a moderate number of incidents with low inspections. This last scenario was deemed not ideal due to the assumption that incidents could have been prevented with an increase in inspections.

4. Discussion

4.1. Initial Assumptions Regarding Harris, County

As assessed above, Harris County, Texas (Houston) is one of several critical incident centers in the United States. There can be several reasons for a significant number of incidents involving heavy-duty trucks in Houston. Some of the contributing factors may include the following:

High traffic volume: Houston is known for its heavy traffic, especially during peak commuting hours. The city’s population, economic activity, and extensive transportation infrastructure contribute to the congestion on its roadways. Heavy-duty trucks are often a part of this traffic, and the increased volume can lead to a higher likelihood of incidents.

Complex road system: Houston’s road system is characterized by numerous highways, interstates, and intricate urban streets. Megaregions with these complex interchange systems and multiple exits, require truck drivers to make frequent lane changes, merge with fast-moving traffic, or navigate unfamiliar routes. Maneuvering large trucks through these intricate interchanges can be challenging, leading to errors or misjudgments that contribute to incidents. As such, the complexity of the road system increases the risk of incidents involving heavy-duty trucks.

Interconnected transportation systems: Houston is part of the Texas Triangle Megaregion. This megaregion encompasses five of the largest 20 U.S. cities and is home to more than 70% of Texans—a population of nearly 21 million people. This region is formed by the state’s four main urban centers, Austin, Dallas–Fort Worth, Houston, and San Antonio, connected by Interstate 45, Interstate 10, and Interstate 35. The Texas Triangle is one of the country’s eleven megaregions, which are clusters of urban areas that share economic and cultural ties. This region experiences 306 MT of daily truck freight movement, or 5.3% of the total U.S. truck freight movement, through an average of ~35.7 k miles of daily commercial VMT (see

Figure 18). The interconnectivity of these transportation networks means that trucks are commonly involved in long-haul trips, intercity deliveries, or distribution activities. The extensive truck movement across different regions and routes can increase the exposure to potential incident risks.

Interaction with vulnerable road users: Megaregions typically have a higher concentration of pedestrians, cyclists, and other vulnerable road users. The increased interaction between trucks and these users can raise the risk of incidents, especially at intersections, crosswalks, or areas with heavy pedestrian activity.

Driver fatigue: Truck drivers often work long hours and face demanding schedules. The pressure to meet delivery deadlines can lead to fatigue and drowsiness. Fatigue impairs a driver’s cognitive abilities and reaction times, making it more difficult to maintain focus and respond effectively to changing road conditions. Fatigued truck drivers are more prone to incidents.

Weather conditions: Houston experiences a range of weather conditions, including heavy rainfall, fog, and occasional severe storms. These weather events can reduce visibility, create slippery road surfaces, and cause hydroplaning. Heavy-duty trucks, due to their size and weight, require additional stopping distance and maneuvering capabilities, making them more susceptible to incidents during adverse weather conditions.

Inadequate training: Safe operation of heavy-duty trucks requires specialized skills and knowledge. If truck drivers are not adequately trained in handling these large vehicles, understanding safety protocols, or responding to various scenarios, it can increase the risk of incidents. Insufficient training may result in errors in judgment, improper vehicle handling, or a lack of awareness of blind spots, contributing to incidents.

Maintenance and mechanical issues: Mechanical failures in heavy-duty trucks can occur due to poor maintenance practices or faulty equipment. Brake malfunctions, tire blowouts, steering problems, or engine issues can significantly impact a truck driver’s ability to control the vehicle safely. Failure to address or detect these mechanical issues in a timely manner can lead to incidents.

Unsafe driving practices: Some incidents involving heavy-duty trucks in Houston can be attributed to unsafe driving practices. Speeding, tailgating, improper lane changes, distracted driving (such as using mobile devices), or driving under the influence of alcohol or drugs are examples of behaviors that increase the risk of incidents. These unsafe practices can endanger not only the truck driver but also other road users.

Addressing these factors, especially in megaregions such as Houston, requires a comprehensive approach involving infrastructure improvements, driver education and training, improved traffic management, enhanced maintenance programs, stricter enforcement of safety regulations, and public awareness programs. By promoting safety awareness and implementing measures to mitigate these risks, it is possible to reduce the number of incidents involving heavy-duty trucks in regions such as Houston. It is important to note that the specific causes and factors contributing to incidents involving heavy-duty trucks in Houston can vary on a case-by-case basis. Detailed incident investigations, conducted by law enforcement authorities and transportation agencies, can provide more specific insights into the causes of individual incidents.

4.2. Initial Assumptions Regarding New York Boroughs

It is noteworthy that out of the top five U.S. counties with increasing truck accident rates during the 2016–2019 study period, after Harris County, Texas (Houston), the following top three counties are all New York boroughs (Kings, Queens, and the Bronx). As New York City is the most heavily populated city in the U.S. and is the most densely populated, it is not completely surprising that incidents would occur. However, it is significant that three of the five New York boroughs had upward trends in incident rates during the study period. Initially, this could be attributed to several factors, which may include the following:

Interaction with vulnerable road users: New York is the most densely populated city in the U.S. It also has one of the most expansive public transit networks in the world. Due to its sprawling network of heavy/light rail, commuter rail, and buses, many residents of New York are less car-dependent than in other U.S. city. Although this is great for many reasons, it also unfortunately provides an opportunity for more pedestrian vehicle incidents, and incidents caused by pedestrians and cyclists, especially for medium- and heavy-duty trucks.

Unsafe driving practices: New York is known for its ubiquitous taxi fleets. With the introduction of ride-hailing services such as Uber and Lyft, this introduces even more vehicles on the streets, diving in and out of parking lanes and shoulders. The presence of food delivery services (Uber Eats, GrubHub, and the like) also adds to the often-times chaotic traffic scenes, typical of New York streets.

Complex road system: A popular focus of the freight and transportation research being conducted at universities in New York (including, but not limited to Rensselaer Polytechnic Institute and the City College of New York) include the issue of a lack of on-street parking for delivery vehicles, and the occurrence of parking violations, off-hour delivery restrictions, and other means of managing the lack of curb space within the boroughs. This presents unique challenges for medium- and heavy-duty trucks.

Interconnected transportation systems: The boroughs of New York are known for their massive, multilane roadways [

19,

20,

21] (

Figure 19) and some of the country’s first parkways (Eastern Parkway, Bronx River Parkway, etc.). The notorious Cross Bronx Expressway (part of I-95) likely comes to mind, with its typical traffic jams and frequent incidents. These complicated stretches of highway are part of an interconnected network within the boroughs, and are often at a standstill during peak hours, but are also the location of many incidents due to lane changes and frequency of ingress/egress points.

Complexities due to ongoing construction: As the major thoroughfares in New York are subjected to vast amounts of vehicle traffic daily, as well as frequent and severe weather events, many of the roadways are constantly under construction. As of 2023, the Bruckner Expressway, a major thoroughfare in the Bronx, is scheduled to begin a complete revitalization, and like many of the aging roadways in the state, it is crumbling due to extreme wear and tear. This will ultimately lead to congestion and rerouting of vehicles to nearby roadways, which may result in frequent incidents, and further degradation of New York’s aging roadway network.

Weather conditions: The state of New York has experienced many severe weather events in the last few years, ranging from blizzards, Nor’Easters, hurricanes, and flash floods, all leading to traffic events, and even unforeseen damage to bridges and roadways. Unaddressed damage caused by severe weather, even something as simple as repairing potholes, can lead to significant traffic events and incidents, especially for heavy-duty trucks.

Again, these factors, as well as many others, must be addressed to uncover the underlying causes of an increase in incidents in the New York boroughs. A comprehensive approach is certainly needed to address and anticipate future infrastructure improvements and maintenance, improve and increase driver training, improve traffic management strategies, improve enforcement of safety regulations, and public education programs. As with Houston, efforts to increase safety awareness and implementing measures to mitigate these risks will make it possible to reduce the number of incidents involving heavy-duty trucks throughout New York and the New York boroughs. Additionally, as with Houston, specific causes and factors contributing to incidents involving heavy-duty trucks in the New York boroughs certainly vary on a case-by-case basis, and detailed investigations will further provide more specific insights into the causes of individual incidents.

4.3. Recommendations on Enforcement of Safety

A major goal for every fleet is to reduce the number and severity of incidents. Professional safety training is key in achieving this goal. Although safety is typically a stated goal of any fleet, demonstrating this through consistent safety training is crucial. Management of driver behavior is also important [

22], and this can be performed through the use of on-board management systems (OBMS), which monitor the driver. Understandably, there is opposition to the use of these systems, as drivers typically feel a level of discomfort in being monitored throughout their duration on the road. However, these systems have proven to be excellent in not only providing justification in legal situations, where the truck driver was falsely accused of a traffic violation, but they have also proven to be appropriate devices for teaching safe driving skills. Just as importantly, these systems provide real-time telematics data for drivers and fleet managers, which provides a means of being proactive in avoiding incidents due to imminent vehicle failures, thus increasing operator awareness [

23]. Maintaining consistency across the board, not only with training and vehicle maintenance, has been shown to reduce the number and severity of incidents. Fleets with consistent routes, scheduling, and fleet personnel, with low turnover rates, have all shown reduced numbers of incidents [

24]. Additional studies may benefit from further examination of proactive measures taken by fleet managers, which correlate with decreasing incidents.

While the aforementioned practices are strategies that fleet managers can implement, there are certainly opportunities from a regulatory perspective that can be implemented to ensure greater safety on the road. According to 49 CFR 396: Minimum Periodic Inspection Standards [

24], vehicles are required to undergo inspection at least once within a 12-month period. However, inspection requirements vary state-to-state, and obviously inspections are costly (in terms of labor and resources, as well as time lost for the carrier). Future research is needed to determine if inspections may be happening too infrequently, and whether the timeline may need to be reconsidered. Currently, a vehicle that has undergone inspection, resulting in an out-of-service (OOS) violation(s), has 15 days to complete repairs and return documentation stating that the cause(s) of the vehicle to fail inspection were addressed [

24]. Approximately two weeks may seem like an eternity for someone to be unable to work, which may necessitate the need to obtain parts and labor to address the issues outlined in the OOS report as soon as possible, but it may not be adequate time to appropriately fix the vehicle. This timeline for repairs may need to be reconsidered based on labor and part availability as well as criticality regarding further safe operation of the vehicle. According to 49 CFR 396.11, drivers must also complete and sign a post-trip form, confirming that the vehicle is in adequate condition concerning the following parts [

24]:

Appropriate and consistent training is required to ensure that this responsibility of the driver is not taken lightly. The driver (and the carrier) is also responsible for reporting if a repair required following an inspection has been addressed, and it is at their discretion to state whether they believe the repair to be unnecessary. This may allow the opportunity to forego even minor repairs that may result in major issues, perhaps even resulting in an incident later on. All of these aspects regarding the procedure(s) related to regular inspection of the vehicle and the responsibilities of the driver should be re-evaluated annually. Detailed data collection, including further driver surveys, will likely prove beneficial in potentially refining some of these safety regulations and should be considered in future studies.

5. Conclusions and Next Steps

The purpose of this work was to take an in-depth look into the FMCSA’s MCMIS dataset and attempt to uncover hints of causal variables resulting in truck incidents throughout the U.S. to increase safety and improve efficiency, both in terms of day-to-day operations and resource management, and in terms of energy usage. This data exploration is novel and has not been performed previously at this level of granularity. Previously, studies have only focused on one state or county, whereas this study provided a national-scale evaluation of the MCMIS dataset. Examining the data at the county level served to pinpoint locations of interest for further inquiry. Performing these analyses at this level of granularity allowed for a more in-depth look at specific locations, which differed from all previous studies using the MCMIS dataset. Temporal categorization of the data provided support of previous research and may also lead to support for expansion of operating hours for DOT inspections. The breakdown by OOS and Non-OOS categories provided an opportunity to examine spatio-temporal patterns within the dataset. Examination of the incident data relative to inspections at each county, and evaluation of the data using an incident-to-inspection ratio allowed for an additional level of analysis to explore relative heterogeneity within the dataset. The findings from the analyses support future expansions of this work, with the inclusion of other potential variables including, but not limited to, effects of sun angle on drivers, proximity to inspection facilities, driver characteristics, and the inclusion of improvements in technologies, namely the installation of camera-based mirror systems (CBMS) and varying levels of automation, as well as further ways to reduce fleet-level energy usage and improve energy efficiency from a systems-level perspective.