Biomimetic Innovations: Exploring Bubble-Trapping Organisms for Manufacturing Breakthroughs

Abstract

1. Introduction

2. The Theoretical Basis for the Stability of Underwater Air-Layers

2.1. Wettability and the Contact Angle

2.2. Hydraulic Pressure

2.3. Buoyancy

2.4. Surface Structure

2.5. Advanced Stabilization Mechanisms in Biological Systems

2.6. Design Principles

| Design Objective | Underlying Principle | Key Design Parameters | Biomimetic Example | Target Application | Refs |

|---|---|---|---|---|---|

| Maximize air entrapment | Achieve and maintain Cassie–Baxter state | Contact angle; | Lotus leaf micro/nanopapillae | Superhydrophobicity, self-cleaning | [33] |

| Solid fraction; | |||||

| Hierarchical roughness | |||||

| Enhance stability under underwater pressure | Salvinia Effect, dual Cassie–Baxter state | Number and size of head filaments | Foliar hair structure of Salvinia molesta | Underwater equipment, low-energy transportation | [34] |

| Anchor the air–water interface | The lotus effect, low surface energy | Micro/nano composite structure; | The lotus microstructure | Stable plastron for antifouling | [35] |

| High contact angle, low sliding angle | |||||

| Enable dynamic response | Utilize structural elasticity | Low modulus; | Elastic hairs of Salvinia | Energy absorbing material | [36] |

| High elasticity | |||||

| Active gas injection | Superhydrophobic surface | Porous nested structure | Lotus leaf, water strider leg | Anti-icing, drag reduction | [37] |

3. Natural Structures

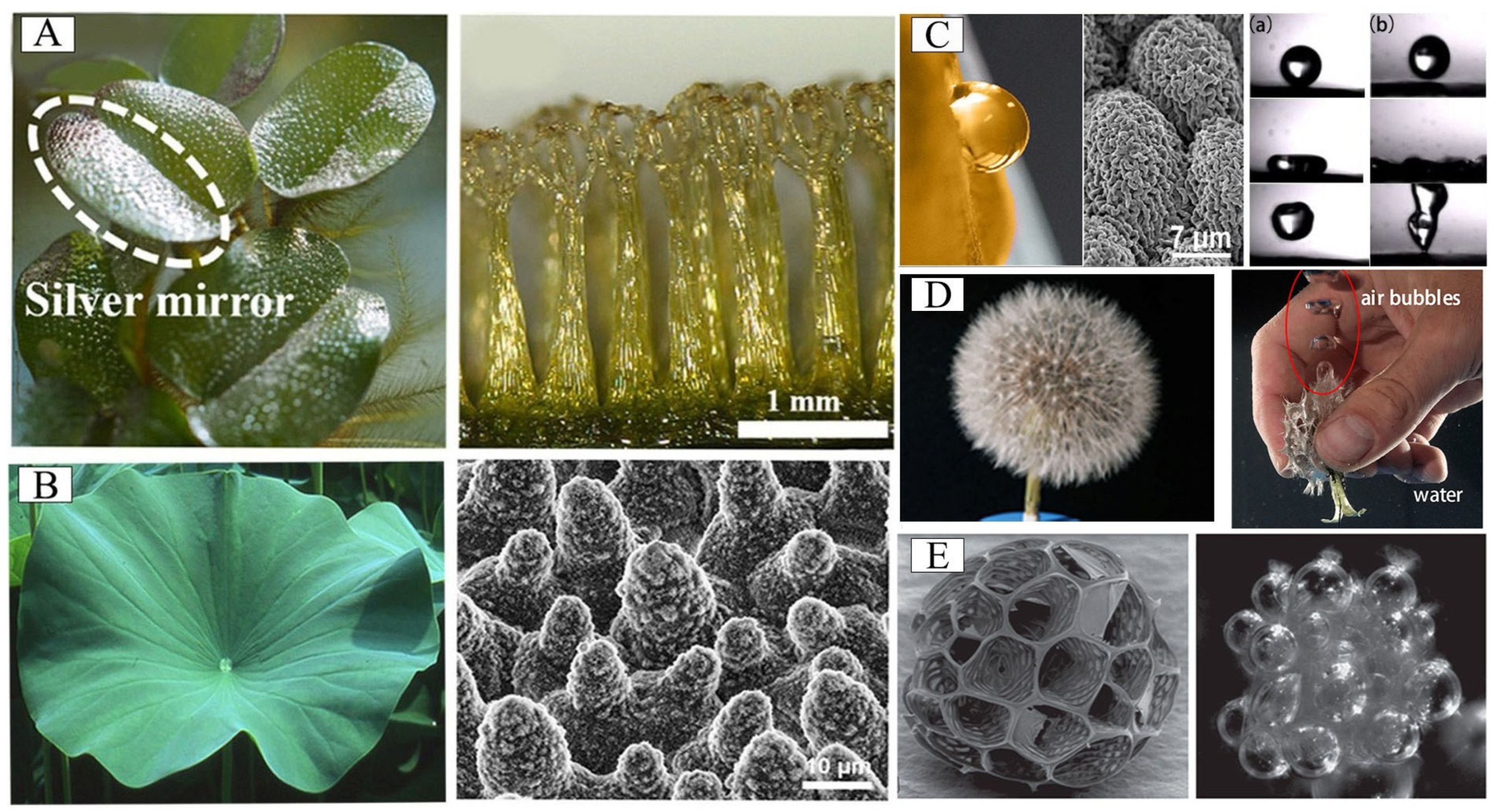

3.1. Plant Structures

3.1.1. Salvinia molesta

3.1.2. Lotus Leaf

3.1.3. Rose Petals

3.1.4. Dandelion Ripe Seed Heads

3.1.5. Aeginetia indica Seed

3.2. Natural Animal

3.2.1. Water Spider

3.2.2. Water Boatman

3.2.3. Diving Beetle

3.2.4. Water Strider

3.2.5. Basilisk lizards

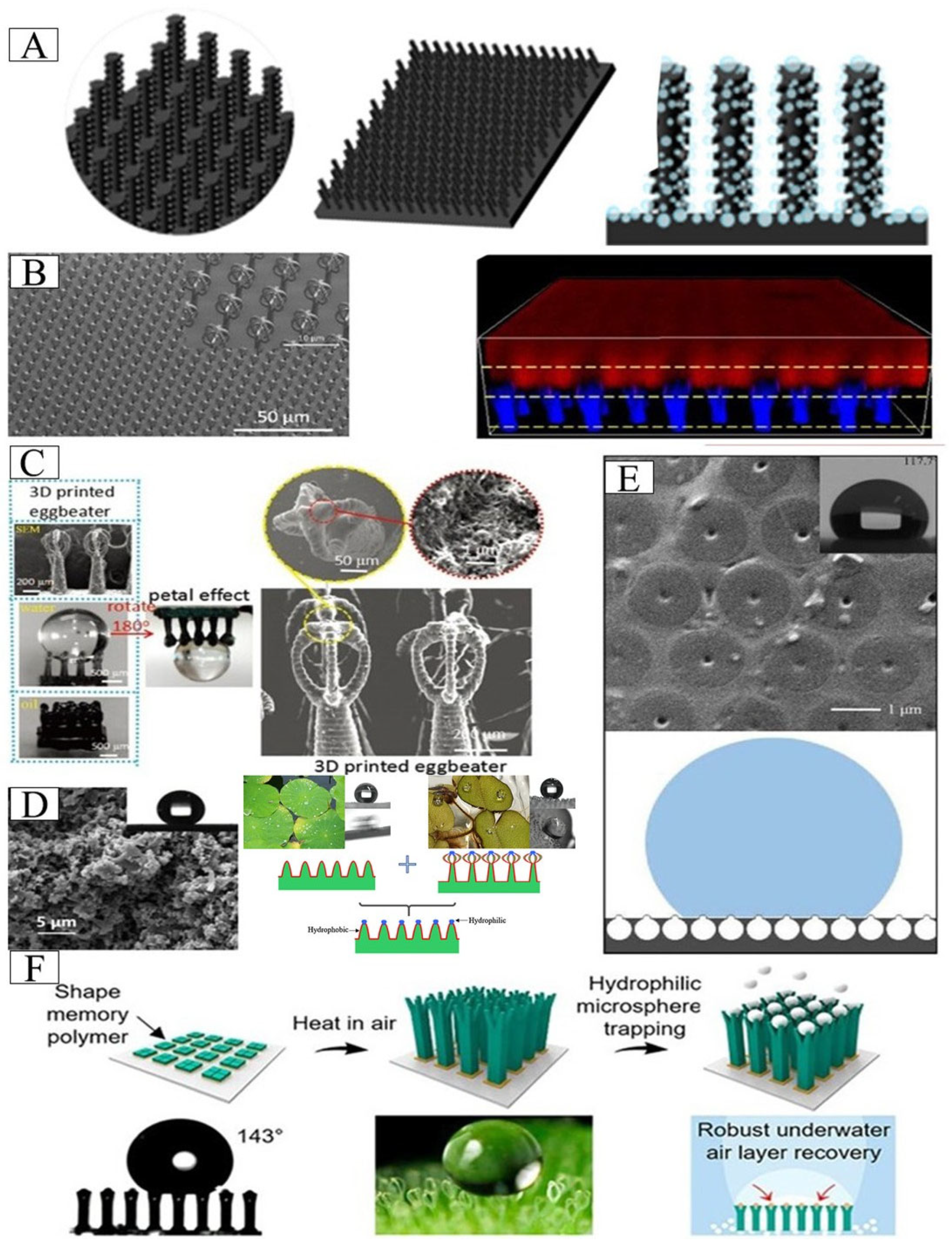

4. Artificial Biomimetic Air Layer Structure

| Biological Prototype | Key Biological Feature | Biomimetic Design Principle | Example Applications | Refs. |

|---|---|---|---|---|

| Salvinia molesta | Egg-beater-shaped hairs with hydrophilic tips | Imitate microstructure to stabilize air layer | Antifouling coatings | [2] |

| Water spider | Micron diameter, conical structure | Utilizing Laplace pressure difference, directional transport of driving gas | Drag reduction, anti-corrosion, physical gills equipment. | [85] |

| Lotus leaf | Microstructure of papillae of lotus leaf | Bionic structure, chemical modification | Self-cleaning, anti-icing | [86] |

| Water bug | Micron bristle array on the surface of insect wings | High contact angle, low sliding angle and high hydrostatic pressure resistance. | Extreme environmental protection | [87] |

| Diving beetle | The superhydrophobic abdomen of insects can capture and hold bubbles stably. | Morphological control strategy | Capture, fix and spread ozone bubbles | [88] |

| Water strider | Micron bristle diameter and nano groove depth | Nanometer roughness follows Cassie–Baxter model. | Bioinspired cargo carriers, oil/water separation | [89] |

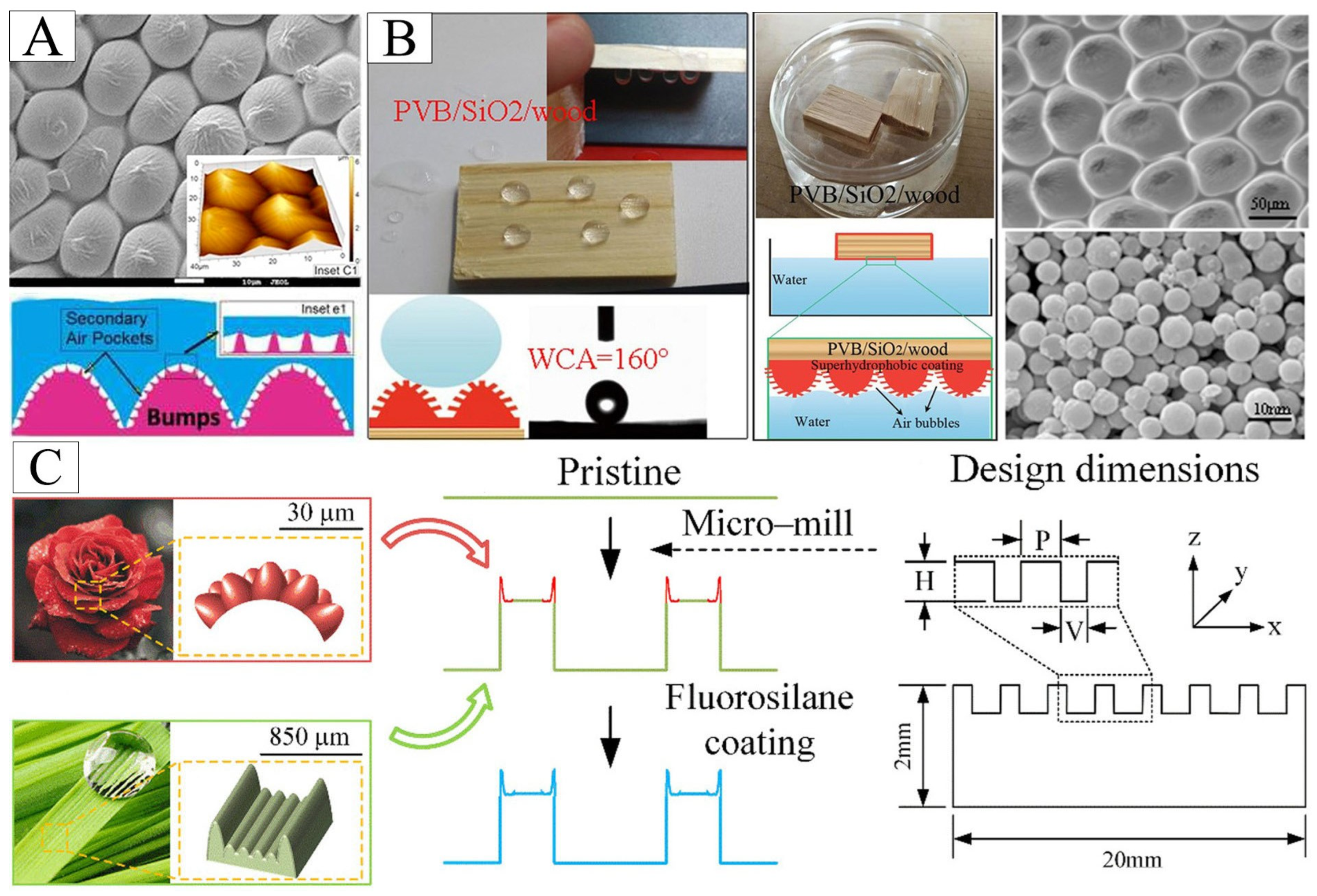

| Rose petal | Micropillars with nanofolds (“petal effect”) | Adjust the ratio of Cassie state (low adhesion) and Wenzel state (high adhesion). | Directional diffusion | [90] |

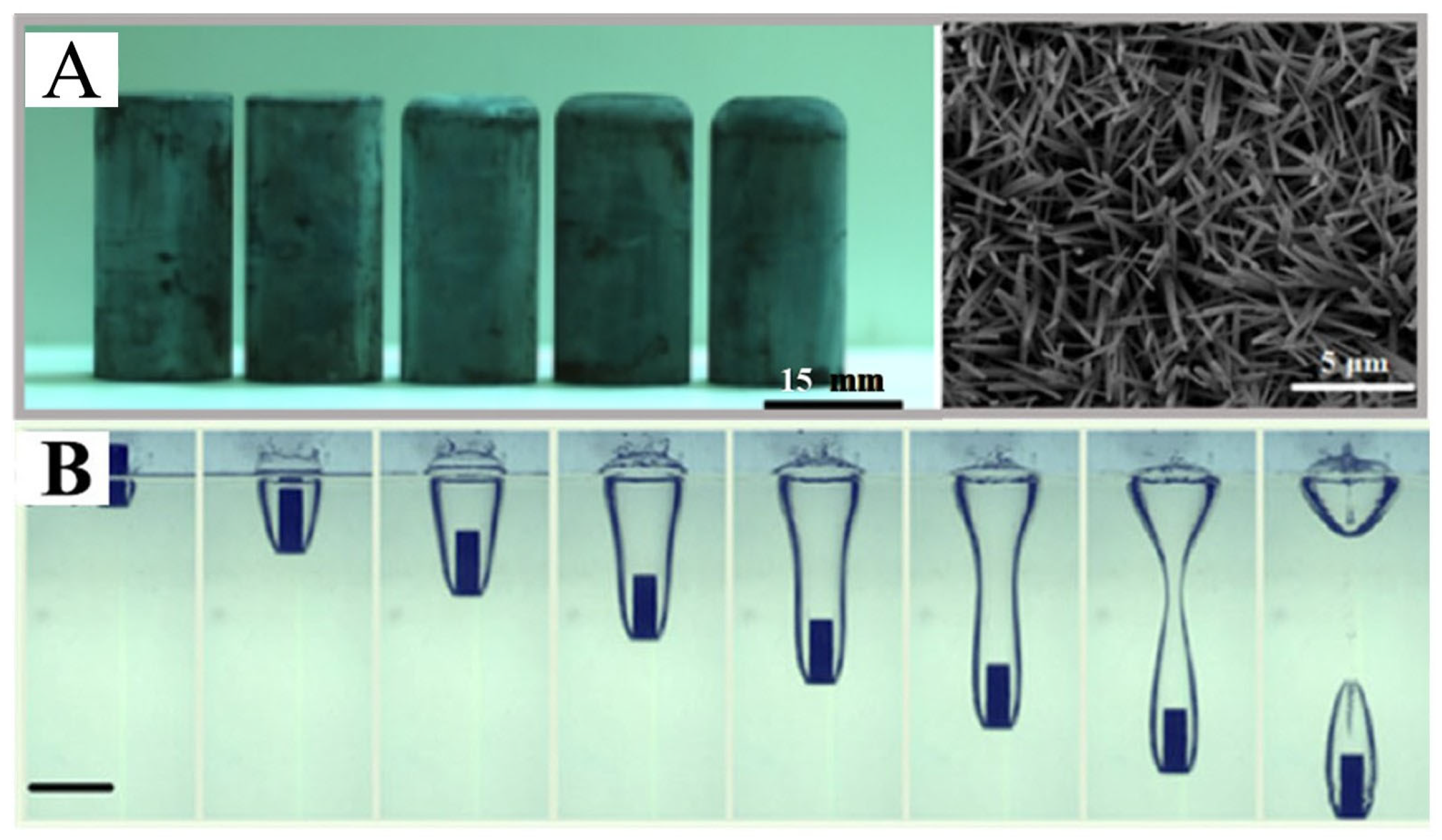

| Basilisk lizard | Hit water to form a cavity, reduce contact area and reduce friction resistance. | Cavity capture and drag reduction | Drag reduction, deep diving | [84] |

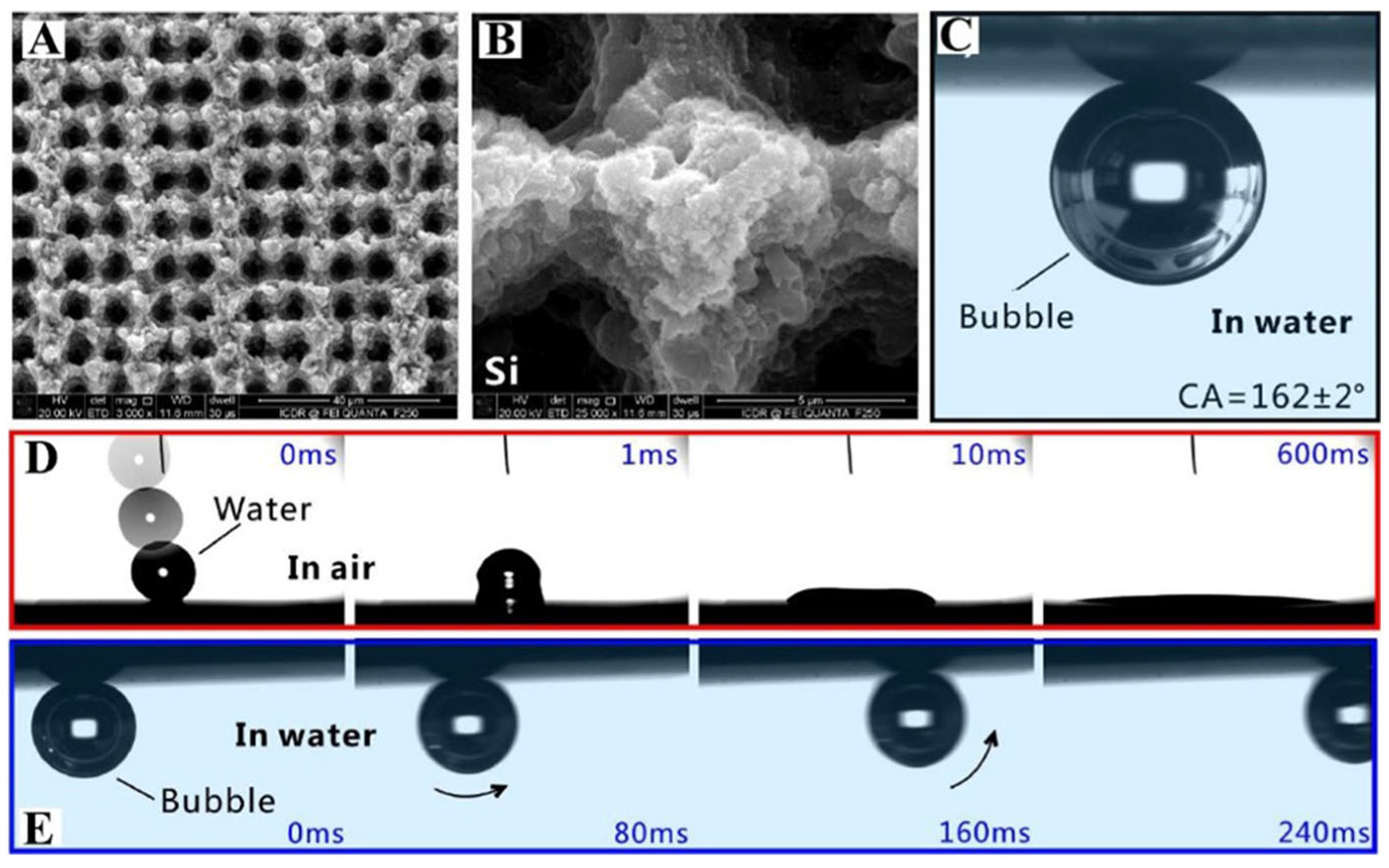

| Carp scale | Orderly arranged micro/nano papillae | Super hydrophilic surface, water will completely soak its rough structure. | Intercept and collect bubbles | [55] |

4.1. Salvinia molesta-Inspired Air Layer Surface

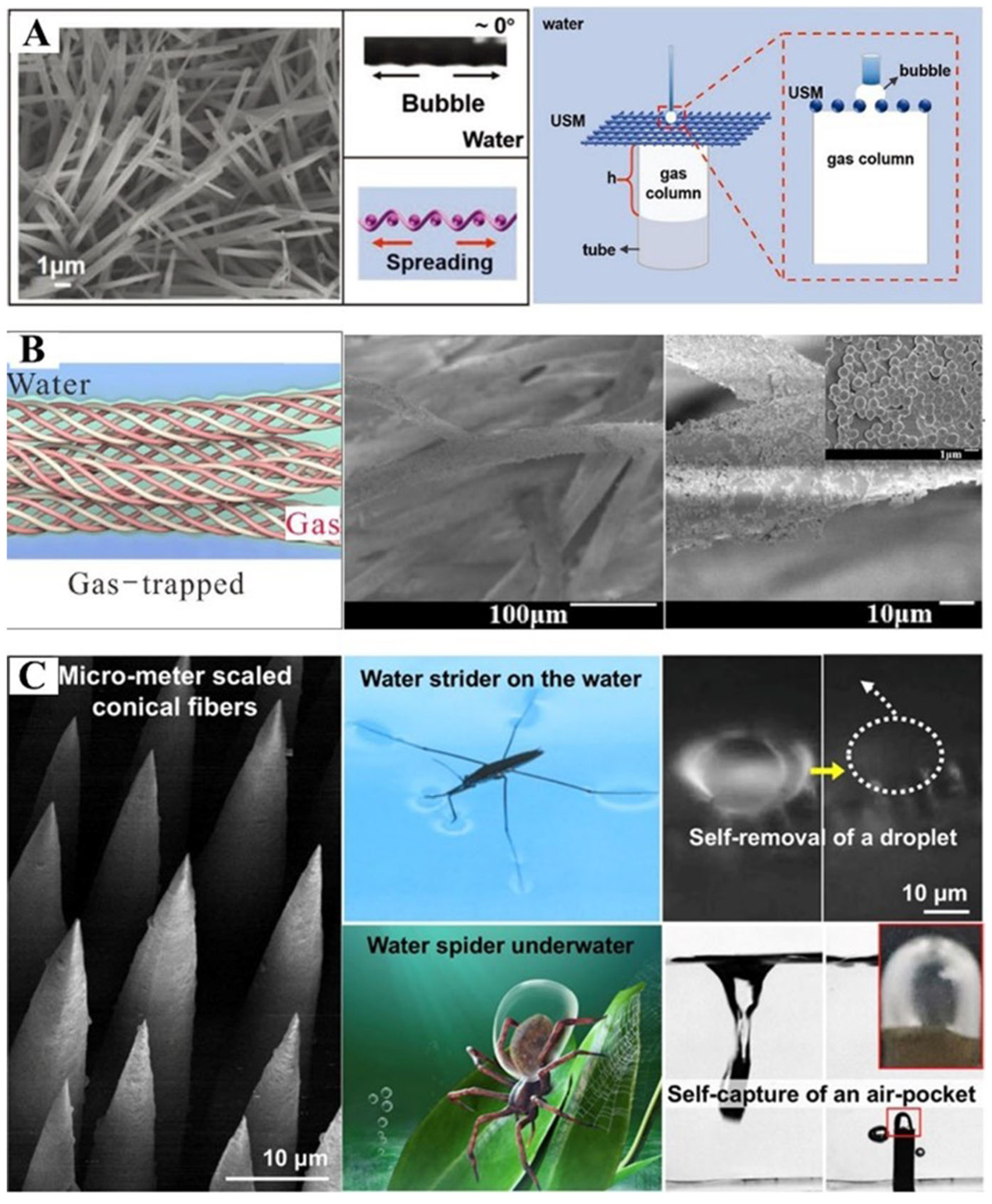

4.2. Water Spider-Inspired Air Layer Surface

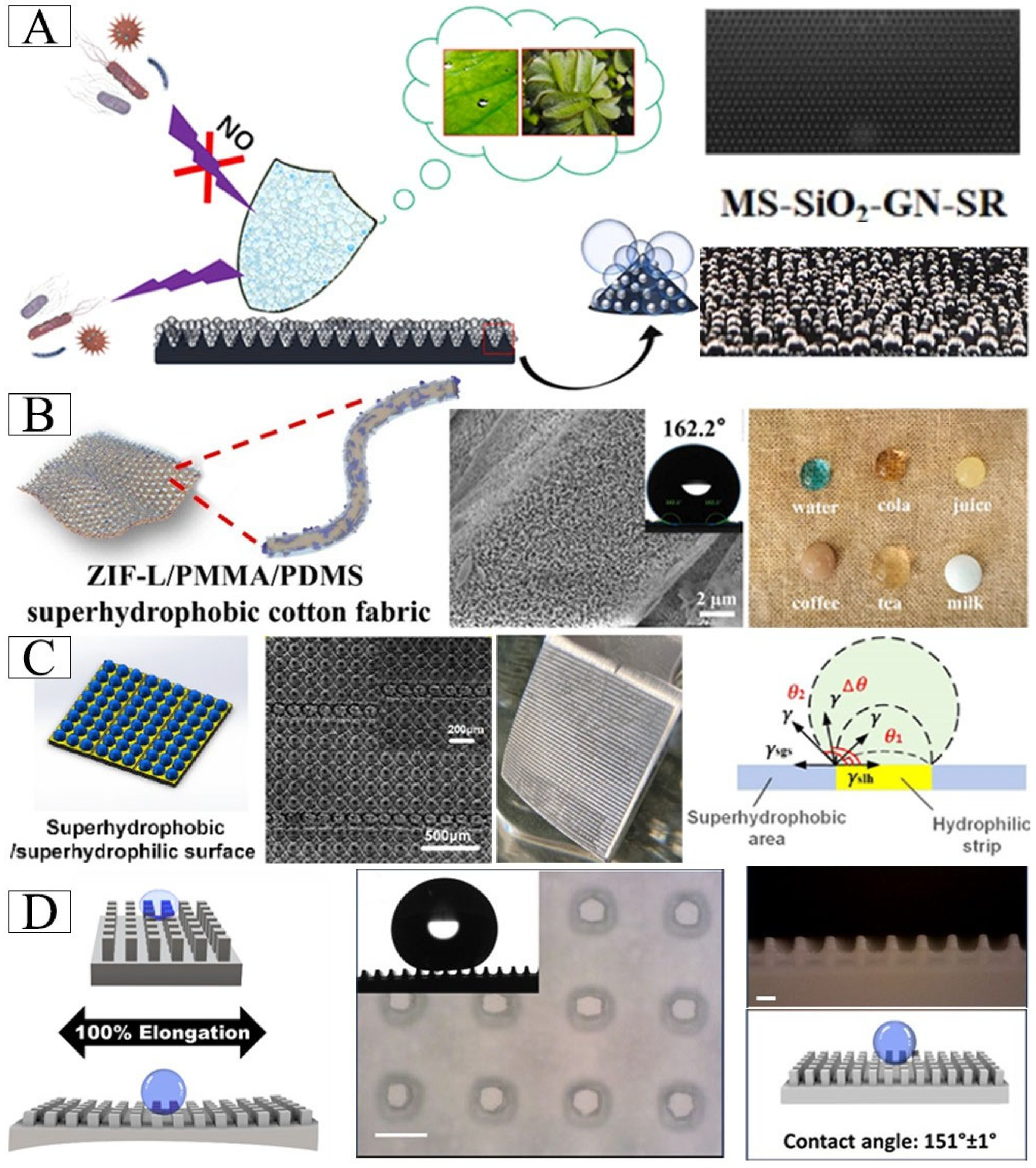

4.3. Lotus Leaf-Inspired Air Layer Surface

4.4. Water Bug Notonecta glauca-Inspired Air Layer Surface

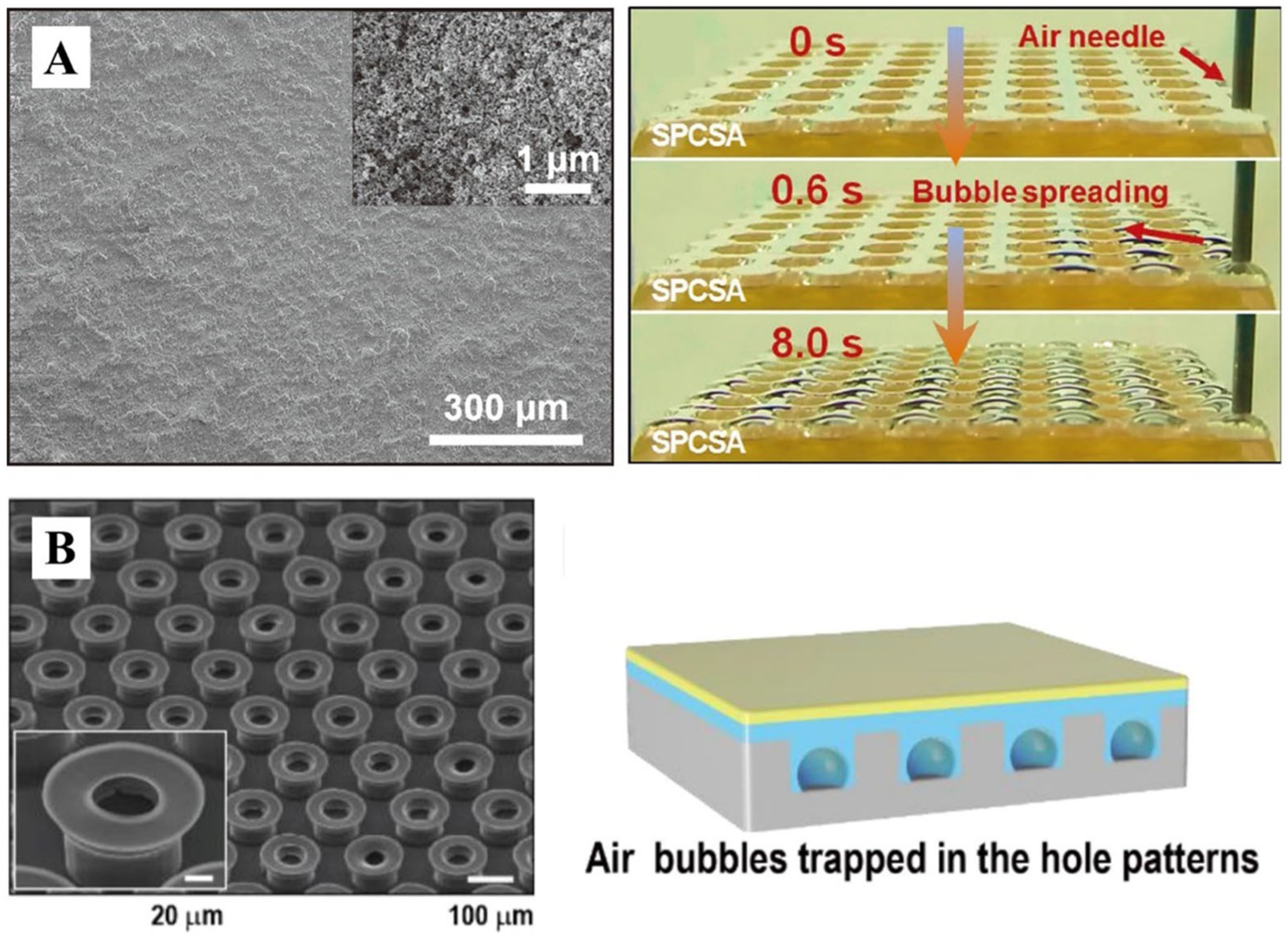

4.5. Diving Beetle-Inspired Air Layer Surface

4.6. Water Strider-Inspired Air Layer Surface

4.7. Rose Petals-Inspired Air Layer Surface

4.8. Basilisk lizards-Inspired Air Layer Surface

4.9. Scales-of-Carp-Inspired Air Layer Surface

5. Application of Air Layer Structure

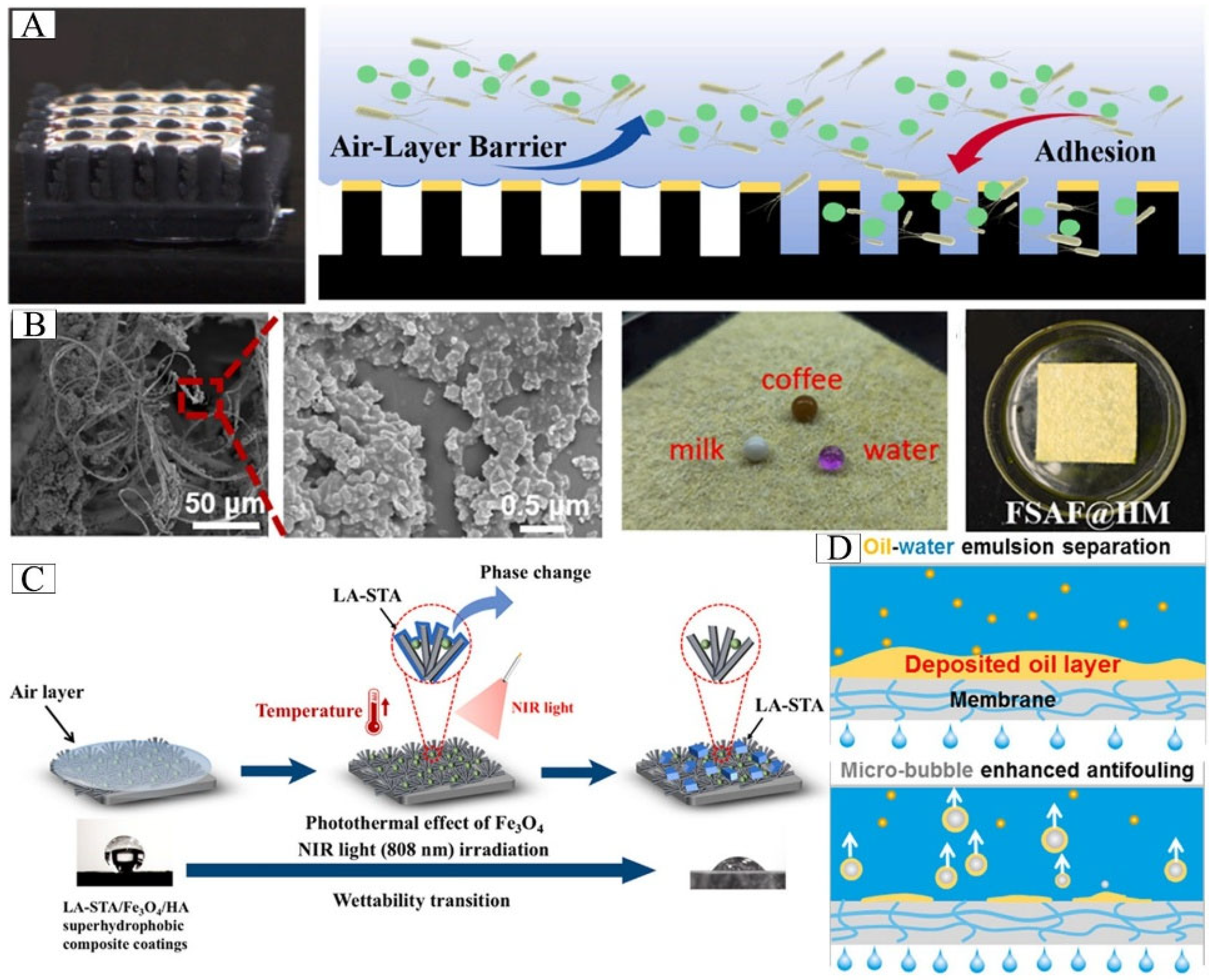

5.1. Air Layer in Antifouling Treatment

5.1.1. Antifouling Mechanisms

5.1.2. Factor Affecting Antifouling of Air Layer

5.1.3. Antifouling Application

5.2. Air Layer in Drag Reduction

5.2.1. Drag Reduction Mechanisms

5.2.2. Factor Affecting Drag Reduction of Air Layer

5.2.3. Drag Reduction Application

5.3. Other Applications of Air Layers

5.3.1. Thermal Insulation and Anti-Freezing

5.3.2. Electrochemical Energy Conversion

6. Conclusions and Outlook

6.1. Scalability and Cost-Effective Manufacturing

6.2. Long-Term Stability

6.3. Dynamic and Responsive Systems

6.4. Multifunctional Integrated Design

6.5. Quantitative Prediction and Inverse Design

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, J.; Yang, J.; Zhang, G.; Mahfoudi, W.; Lian, J. Investigation on Air Drag Reduction and Stabilisation of Bionic Multiscale Wetting Gradient Surfaces. Lubr. Sci. 2025, 37, 34–44. [Google Scholar] [CrossRef]

- Wang, H.; Fu, H.; Tian, L.; Bing, W. Salvinia-inspired biomimetic antifouling film with bubble shielding function. Prog. Org. Coat. 2024, 186, 107941. [Google Scholar] [CrossRef]

- Ji, X.; Zhong, W.; Liu, K.; Jiang, Y.; Chen, H.; Zhao, W.; Zang, D. Extraordinary stability of surfactant-free bubbles suspended in ultrasound. Droplet 2024, 3, e119. [Google Scholar] [CrossRef]

- Garcia-Gonzalez, D.; Corrales, T.P.; Dacunzi, M.; Kappl, M. Squeezing Drops: Force Measurements of the Cassie-to-Wenzel Transition. Langmuir 2022, 38, 14666–14672. [Google Scholar] [CrossRef] [PubMed]

- Qiao, S.; Cai, C.; Pan, C.; Liu, Y.; Zhang, Q. Study on the Performance of a Surface with Coupled Wettability Difference and Convex-Stripe Array for Improved Air Layer Stability. Langmuir 2024, 40, 4940–4952. [Google Scholar] [CrossRef]

- Gandyra, D.; Walheim, S.; Gorb, S.; Ditsche, P.; Barthlott, W.; Schimmel, T. Air Retention under Water by the Floating Fern Salvinia: The Crucial Role of a Trapped Air Layer as a Pneumatic Spring. Small 2020, 16, 2003425. [Google Scholar] [CrossRef]

- Wu, Y.; Zhi, W.; Jia, Q.; Zhou, B.; Shao, W.; Guo, X.; Zhou, Z.; He, D. Lotus leaf inspired hierarchical micro-nano structure on NdYbZr2O7 ceramic pellet with enhanced volcanic ash repellence. Ceram. Int. 2024, 50, 27563–27572. [Google Scholar] [CrossRef]

- Speichermann-Jägel, L.; Dullenkopf-Beck, S.; Droll, R.; Gandyra, D.; Barczewski, M.; Walheim, S.; Schimmel, T. Stable Air Retention under Water on Artificial Salvinia Surfaces Enabled by the Air Spring Effect: The Importance of Geometrical and Surface-Energy Barriers, and of the Air Spring Height. Adv. Mater. Interfaces 2024, 11, 2400400. [Google Scholar] [CrossRef]

- Sun, H.; Zhu, Y.; Bing, W. Research on underwater air layer retention and antifouling ability of Salvinia-inspired biomimetic materials. Colloid Surf. B. 2025, 253, 114728. [Google Scholar] [CrossRef] [PubMed]

- Schaber, C.F.; Grawe, I.; Gorb, S.N. Attachment discs of the diving bell spider Argyroneta aquatica. Commun. Biol. 2023, 6, 1232. [Google Scholar] [CrossRef]

- De Nicola, F.; Castrucci, P.; Scarselli, M.; Nanni, F.; Cacciotti, I.; De Crescenzi, M. Super-hydrophobic multi-walled carbon nanotube coatings for stainless steel. Nanotechnology 2015, 26, 145701. [Google Scholar] [CrossRef]

- Hunt, J.; Bhushan, B. Nanoscale biomimetics studies of Salvinia molesta for micropattern fabrication. J. Colloid Interface Sci. 2011, 363, 187–192. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zheng, X.; Chen, Z.; Zhou, Q.; Chen, Y. 3D-Printed Biomimetic Super-Hydrophobic Structure for Microdroplet Manipulation and Oil/Water Separation. Adv. Mater. 2018, 30, 1704912. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Huang, S.; Huang, T.-Y.; Dong, A.; Cao, D.; Li, H.; Xue, Y.; Lv, P.; Duan, H. Superrepellency of underwater hierarchical structures on Salvinia leaf. Proc. Natl. Acad. Sci. USA 2020, 117, 2282–2287. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhou, X.; Xing, Z.; Tu, T. Fabrication of a superhydrophobic surface with underwater air-retaining properties by electrostatic flocking. Rsc. Adv. 2018, 8, 10719–10726. [Google Scholar] [CrossRef]

- Huo, J.; Yong, J.; Chen, F.; Yang, Q.; Fang, Y.; Hou, X. Trapped Air-Induced Reversible Transition between Underwater Superaerophilicity and Superaerophobicity on the Femtosecond Laser-Ablated Superhydrophobic PTFE Surfaces. Adv. Mater. Interfaces 2019, 6, 1900262. [Google Scholar] [CrossRef]

- Young, T., III. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. Res. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Ishida, N.; Sakamoto, M.; Miyahara, M.; Higashitani, K. Optical Observation of Gas Bridging between Hydrophobic Surfaces in Water. J. Colloid Interface Sci. 2002, 253, 112–116. [Google Scholar] [CrossRef]

- Sheng, X.; Zhang, J. Air layer on superhydrophobic surface underwater. Colloid Surf. 2011, 377, 374–378. [Google Scholar] [CrossRef]

- Cai, Y.; Bing, W.; Chen, C.; Chen, Z. Gaseous Plastron on Natural and Biomimetic Surfaces for Resisting Marine Biofouling. Molecules 2021, 26, 2592. [Google Scholar] [CrossRef]

- Ling, W.Y.L.; Lu, G.; Ng, T.W. Increased Stability and Size of a Bubble on a Superhydrophobic Surface. Langmuir 2011, 27, 3233–3237. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Nie, F.-Q.; Zhai, J.; Jiang, L. Air Bubble Bursting Effect of Lotus Leaf. Langmuir 2009, 25, 14129–14134. [Google Scholar] [CrossRef]

- Tsori, Y. Discontinuous Liquid Rise in Capillaries with Varying Cross-Sections. Langmuir 2006, 22, 8860–8863. [Google Scholar] [CrossRef]

- Kwon, Y.; Patankar, N.; Choi, J.; Lee, J. Design of Surface Hierarchy for Extreme Hydrophobicity. Langmuir 2009, 25, 6129–6136. [Google Scholar] [CrossRef] [PubMed]

- Hemeda, A.A.; Gad-el-Hak, M.; Tafreshi, H.V. Effects of hierarchical features on longevity of submerged superhydrophobic surfaces with parallel grooves. Phys. Fluids 2014, 26, 082103. [Google Scholar] [CrossRef]

- Liu, T.L.; Kim, C.-J.C. Turning a surface superrepellent even to completely wetting liquids. Science 2014, 346, 1096–1100. [Google Scholar] [CrossRef] [PubMed]

- Hensel, R.; Helbig, R.; Aland, S.; Braun, H.-G.; Voigt, A.; Neinhuis, C.; Werner, C. Wetting Resistance at Its Topographical Limit: The Benefit of Mushroom and Serif T Structures. Langmuir 2013, 29, 1100–1112. [Google Scholar] [CrossRef]

- Tuteja, A.; Choi, W.; Mabry, J.M.; McKinley, G.H.; Cohen, R.E. Robust omniphobic surfaces. Proc. Natl. Acad. Sci. USA 2008, 105, 18200–18205. [Google Scholar] [CrossRef]

- Chen, Y.; Ao, J.; Zhang, J.; Gao, J.; Hao, L.; Jiang, R.; Zhang, Z.; Liu, Z.; Zhao, J.; Ren, L. Bioinspired superhydrophobic surfaces, inhibiting or promoting microbial contamination? Mater. Today 2023, 67, 468–494. [Google Scholar] [CrossRef]

- Gonzalez-Avila, S.R.; Nguyen, D.M.; Arunachalam, S.; Domingues, E.M.; Mishra, H.; Ohl, C.-D. Mitigating cavitation erosion using biomimetic gas-entrapping microtextured surfaces (GEMS). Sci. Adv. 2020, 6, eaax6192. [Google Scholar] [CrossRef]

- Krishnan, P.S.; Rowthu, S.; Kalpathy, S.K. Durable Bio-Based Hydrophobic Recrystallized Wax Coatings. ACS Appl. Bio Mater. 2025, 8, 1437–1450. [Google Scholar] [CrossRef]

- Tricinci, O.; Pignatelli, F.; Mattoli, V. 3D Micropatterned Functional Surface Inspired by Salvinia Molesta via Direct Laser Lithography for Air Retention and Drag Reduction. Adv. Funct. Mater. 2023, 33, 2206946. [Google Scholar] [CrossRef]

- Li, J.; Wang, G.; Meng, Q.; Ding, C.; Jiang, H.; Fang, Y. A biomimetic nano hybrid coating based on the lotus effect and its anti-biofouling behaviors. Appl. Surf. Sci. 2014, 315, 407–414. [Google Scholar] [CrossRef]

- Konrad, W.; Roth-Nebelsick, A.; Kessel, B.; Miranda, T.; Ebner, M.; Schott, R.; Nebelsick, J.H. The impact of raindrops on Salvinia molesta leaves: Effects of trichomes and elasticity. J. R. Soc. Interface 2021, 18, 20210676. [Google Scholar] [CrossRef] [PubMed]

- Zhu, D.; Wang, M.; Liu, Q.; Liu, G.; He, X.; Wang, R.; Zhang, L.; Song, Z.; Li, Q.; Li, Q.; et al. A strategy for anti-icing and drag reduction in marine applications via in situ gas injection. Chem. Eng. J. 2025, 503, 158689. [Google Scholar] [CrossRef]

- Seymour, R.S.; Hetz, S.K. The diving bell and the spider: The physical gill of Argyroneta aquatica. J. Exp. Biol. 2011, 214, 2175–2181. [Google Scholar] [CrossRef] [PubMed]

- Moosmann, M.; Schimmel, T.; Barthlott, W.; Mail, M. Air-water interface of submerged superhydrophobic surfaces imaged by atomic force microscopy. Beilstein J. Nanotechnol. 2017, 8, 1671–1679. [Google Scholar] [CrossRef]

- Roy, D.; Pandey, K.; Banik, M.; Mukherjee, R.; Basu, S. Dynamics of droplet impingement on bioinspired surface: Insights into spreading, anomalous stickiness and break-up. P. Roy. Soc. A Math. Phys. Eng. Sci. 2019, 475, 20190260. [Google Scholar] [CrossRef]

- Pugno, M.C.; Misseroni, D.; Pugno, N.M. Air-encapsulating elastic mechanism of submerged Taraxacum blowballs. Mater. Today Bio. 2021, 9, 100095. [Google Scholar] [CrossRef]

- Feng, X.; Chu, J.; Tian, G.; Wang, Z.; Zhou, W.; Zhang, X.; Lian, Z. Phyllostachys Viridis-Leaf-like MLMN Surfaces Constructed by Nanosecond Laser Hybridization for Superhydrophobic Antifogging and Anti-Icing. Acs. Appl. Mater. Interfaces 2023, 15, 53159–53171. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Cai, M.; Liao, P.; Bing, W. Biomimetic gaseous plastron for blocking fouling-associated biological colonization. Colloids Surf. Physicochem. Eng. Aspects 2025, 707, 135856. [Google Scholar] [CrossRef]

- Barthlott, W.; Schimmel, T.; Wiersch, S.; Koch, K.; Brede, M.; Barczewski, M.; Walheim, S.; Weis, A.; Kaltenmaier, A.; Leder, A.; et al. The Salvinia Paradox: Superhydrophobic Surfaces with Hydrophilic Pins for Air Retention Under Water. Adv. Mater. 2010, 22, 2325–2328. [Google Scholar] [CrossRef]

- Ditsche, P.; Gorb, E.; Mayser, M.; Gorb, S.; Schimmel, T.; Barthlott, W. Elasticity of the hair cover in air-retaining Salvinia surfaces. Appl. Phys. A Mater. 2015, 121, 505–511. [Google Scholar] [CrossRef]

- Wang, G.; Guo, Z.; Liu, W. Interfacial Effects of Superhydrophobic Plant Surfaces: A Review. J. Bionic Eng. 2014, 11, 325–345. [Google Scholar] [CrossRef]

- Anitha, C.; Azim, S.S.; Mayavan, S. Salvinia inspired fluroine free superhydrophobic coatings. Appl. Surf. Sci. 2018, 449, 250–260. [Google Scholar] [CrossRef]

- Mail, M.; Walheim, S.; Schimmel, T.; Barthlott, W.; Gorb, S.N.; Heepe, L. Dry under water: Air retaining properties of large-scale elastomer foils covered with mushroom-shaped surface microstructures. Beilstein J. Nanotechnol. 2022, 13, 1370–1379. [Google Scholar] [CrossRef]

- Yamamoto, M.; Nishikawa, N.; Mayama, H.; Nonomura, Y.; Yokojima, S.; Nakamura, S.; Uchida, K. Theoretical Explanation of the Lotus Effect: Superhydrophobic Property Changes by Removal of Nanostructures from the Surface of a Lotus Leaf. Langmuir 2015, 31, 7355–7363. [Google Scholar] [CrossRef]

- Chen, C.-H.; Cheng, I.C.; Chen, J.-Z. Facile method to convert petal effect surface to lotus effect surface for superhydrophobic polydimethylsiloxane. Surf. Interfaces 2022, 30, 101901. [Google Scholar] [CrossRef]

- Chen, Y.-Y.; Ou, S.-F.; Chien, H.-W. Rose petal patterns with "Lotus Effect", corrosion resistance and photocatalytic bacterial inactivation. J. Ind. Eng. Chem. 2024, 137, 536–546. [Google Scholar] [CrossRef]

- Chu, F.; Hu, Z.; Feng, Y.; Lai, N.-C.; Wu, X.; Wang, R. Advanced Anti-Icing Strategies and Technologies by Macrostructured Photothermal Storage Superhydrophobic Surfaces. Adv. Mater. 2024, 36, 2402897. [Google Scholar] [CrossRef]

- Yang, S.; Ju, J.; Qiu, Y.; He, Y.; Wang, X.; Dou, S.; Liu, K.; Jiang, L. Peanut Leaf Inspired Multifunctional Surfaces. Small 2014, 10, 294–299. [Google Scholar] [CrossRef]

- Dubey, M.C.; Mohanta, D. Exceptional anisotropic superhydrophobicity of sword-lily striated leaf surface and soft lithographic biomimicking using polystyrene replica. Phys. Scr. 2024, 99, 105996. [Google Scholar] [CrossRef]

- Yong, J.; Chen, F.; Fang, Y.; Huo, J.; Yang, Q.; Zhang, J.; Bian, H.; Hou, X. Bioinspired Design of Underwater Superaerophobic and Superaerophilic Surfaces by Femtosecond Laser Ablation for Anti- or Capturing Bubbles. ACS Appl. Mater. Interfaces 2017, 9, 39863–39871. [Google Scholar] [CrossRef]

- Bandyopadhyay, S.; Shristi, A.; Kumawat, V.; Gope, A.; Mukhopadhyay, A.; Chakraborty, S.; Mukherjee, R. Droplet Impact Dynamics on Biomimetic Replica of Yellow Rose Petals: Rebound to Micropinning Transition. Langmuir 2023, 39, 6051–6060. [Google Scholar] [CrossRef]

- Neukirch, S.; Antkowiak, A.; Marigo, J.-J. The bending of an elastic beam by a liquid drop: A variational approach. P. Roy. Soc. A Math. Phys. Eng. Sci. 2013, 469, 20130066. [Google Scholar] [CrossRef]

- Bosi, F.; Misseroni, D.; Dal Corso, F.; Bigoni, D. Self-encapsulation, or the ‘dripping’ of an elastic rod. P. Roy. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20150195. [Google Scholar] [CrossRef]

- Elettro, H.; Neukirch, S.; Vollrath, F.; Antkowiak, A. In-drop capillary spooling of spider capture thread inspires hybrid fibers with mixed solid-liquid mechanical properties. Proc. Natl. Acad. Sci. USA 2016, 113, 6143–6147. [Google Scholar] [CrossRef] [PubMed]

- Barthlott, W.; Mail, M.; Neinhuis, C. Superhydrophobic hierarchically structured surfaces in biology: Evolution, structural principles and biomimetic applications. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20160191. [Google Scholar] [CrossRef]

- Ensikat, H.J.; Ditsche-Kuru, P.; Neinhuis, C.; Barthlott, W. Superhydrophobicity in perfection: The outstanding properties of the lotus leaf. Beilstein J. Nanotechnol. 2011, 2, 152–161. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Kim, H.; Ryu, H.-S. Hydroecology of Argyroneta aquatica’s Habitat in Hantangang River Geopark, South Korea. Sustainability 2022, 14, 4988. [Google Scholar] [CrossRef]

- Seymour, R.S.; Matthews, P.G.D. Physical gills in diving insects and spiders: Theory and experiment. J. Exp. Biol. 2013, 216, 164–170. [Google Scholar] [CrossRef]

- Du, G.; Sun, Y.; Qian, Y. 3D printed strain-hardening cementitious composites (3DP-SHCC) reticulated shell roof inspired by the water spider. Automat. Constr. 2024, 167, 105717. [Google Scholar] [CrossRef]

- Li, F.; Lv, Y.; Wen, Z.; Bian, C.; Zhang, X.; Guo, S.; Shi, Q.; Li, D. The complete mitochondrial genome of the intertidal spider (Desis jiaxiangi) provides novel insights into the adaptive evolution of the mitogenome and the evolution of spiders. BMC Ecol. Evol. 2021, 21, 72. [Google Scholar] [CrossRef]

- Park, Y.M.; Gang, M.; Seo, Y.H.; Kim, B.H. Artificial petal surface based on hierarchical micro- and nanostructures. Thin Solid Films 2011, 520, 362–367. [Google Scholar] [CrossRef]

- Neumann, D.; Woermann, D. Stability of the volume of air trapped on the abdomen of the water spider Argyroneta aquatica. Springerplus 2013, 2, 694. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.; Guo, Z. The wettability of gas bubbles: From macro behavior to nano structures to applications. Nanoscale 2018, 10, 19659–19672. [Google Scholar] [CrossRef]

- Hosoda, N.; Gorb, S.N. Underwater locomotion in a terrestrial beetle: Combination of surface de-wetting and capillary forces. P. Roy. Soc. B Biol. Sci. 2012, 279, 4236–4242. [Google Scholar] [CrossRef]

- Iazzolino, A.; Cerkvenik, U.; Tourtit, Y.; Ladang, A.; Compere, P.; Gileti, T. Liquid dispensing in the adhesive hairy pads of dock beetles. J. R. Soc. Interface 2020, 17, 20200024. [Google Scholar] [CrossRef]

- Matsumura, Y.; Gorb, E.V.; Gorb, S.N. The tight attachment achieved by the male discoidal setae is possibly a counter-adaptation to the grease layer on female integument surfaces in green dock beetles. J. R. Soc. Interface 2023, 20, 20230324. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, L.; Guo, Y.; Gan, Y.; Liu, G.; Zhang, D.; Chen, H. Air Bubble Bridge-Based Bioinspired Underwater Adhesion. Small 2021, 17, 2103423. [Google Scholar] [CrossRef]

- Jones, K.K.; Seymour, R.S. Gas exchange and dive behaviour in the diving beetle Platynectes decempunctatus (Coleoptera: Dytiscidae). J. Insect Physiol. 2021, 133, 104286. [Google Scholar] [CrossRef]

- Meshkani, J.; Rajabi, H.; Kovalev, A.; Gorb, S.N. Patterns of load distribution among the legs in small water striders during standing and striding. J. Zool. 2023, 320, 84–95. [Google Scholar] [CrossRef]

- Uesugi, K.; Mayama, H.; Morishima, K. Analysis of Rowing Force of the Water Strider Middle Leg by Direct Measurement Using a Bio-Appropriating Probe and by Indirect Measurement Using Image Analysis. Cyborg. Bionic Syst. 2023, 4, 0061. [Google Scholar] [CrossRef]

- Ma, J.-Z.; Lu, H.-Y.; Li, X.-S.; Tian, Y. Interfacial phenomena of water striders on water surfaces: A review from biology to biomechanics. Zool. Res. 2020, 41, 231–246. [Google Scholar] [CrossRef]

- Armisen, D.; Viala, S.; Silva Cordeiro, I.d.R.; Johan Crumiere, A.J.; Hendaoui, E.; Le Bouquin, A.; Duchemin, W.; Santos, E.; Toubiana, W.; Vargas-Lowman, A.; et al. Transcriptome-based Phylogeny of the Semi-aquatic Bugs (Hemiptera: Heteroptera: Gerromorpha) Reveals Patterns of Lineage Expansion in a Series of New Adaptive Zones. Mol. Biol. Evol. 2022, 39, msac229. [Google Scholar] [CrossRef]

- Glasheen, J.W.; McMahon, T.A. Size-dependence of water-running ability in basilisk lizards (Basiliscus basiliscus). J. Exp. Biol. 1996, 199, 2611–2618. [Google Scholar] [CrossRef]

- Cheu, A.Y.; Reed, S.A.; Mann, S.D.; Bergmann, P.J. Performance and Kinematic Differences Between Terrestrial and Aquatic Running in Anolis Sagrei. Integr. Comp. Biol. 2022, 62, 840–851. [Google Scholar] [CrossRef] [PubMed]

- Balmert, A.; Bohn, H.F.; Ditsche-Kuru, P.; Barthlott, W. Dry Under Water: Comparative Morphology and Functional Aspects of Air-Retaining Insect Surfaces. J. Morphol. 2011, 272, 442–451. [Google Scholar] [CrossRef] [PubMed]

- Ditsche-Kuru, P.; Schneider, E.S.; Melskotte, J.-E.; Brede, M.; Leder, A.; Barthlott, W. Superhydrophobic surfaces of the water bug Notonecta glauca: A model for friction reduction and air retention. Beilstein. J. Nanotechnol. 2011, 2, 137–144. [Google Scholar] [CrossRef]

- Feldmann, D.; Das, R.; Pinchasik, B.-E. How Can Interfacial Phenomena in Nature Inspire Smaller Robots. Adv. Mater. Interfaces 2021, 8, 2001300. [Google Scholar] [CrossRef]

- Wang, Q.; Yao, X.; Liu, H.; Quere, D.; Jiang, L. Self-removal of condensed water on the legs of water striders. Proc. Natl. Acad. Sci. USA 2015, 112, 9247–9252. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Zhou, Y.; Wang, J.; Jiang, L. Bioinspired Universal Approaches for Cavity Regulation during Cylinder Impact Processes for Drag Reduction in Aqueous Media: Macrogeometry Vanquishing Wettability. ACS Appl. Mater. Interfaces 2021, 13, 38808–38815. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, P.; Xu, B.; Meng, L.; Jiang, L.; Liu, H. Bioinspired Robust Water Repellency in High Humidity by Micro-meter-Scaled Conical Fibers: Toward a Long-Time Underwater Aerobic Reaction. J. Am. Chem. Soc. 2022, 144, 10950–10957. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, X.; Li, W.; Feng, L.; Wang, K.; Wang, S.; Wei, Q.; Qiao, H. Crisscross metal–organic frameworks superhydrophobic structure for high efficient emulsion separation and anti-icing. Chem. Eng. J. 2025, 509, 161228. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, H.; Zhang, X.; Wang, C.; Lv, C.; Zhu, Y. Durable and self-healing superhydrophobic surface with bistratal gas layers prepared by electrospinning and hydrothermal processes. Chem. Eng. J. 2017, 326, 578–586. [Google Scholar] [CrossRef]

- Zhang, C.; Cao, M.; Ma, H.; Yu, C.; Li, K.; Yu, C.; Jiang, L. Morphology-Control Strategy of the Superhydrophobic Poly(Methyl Methacrylate) Surface for Efficient Bubble Adhesion and Wastewater Remediation. Adv. Funct. Mater. 2017, 27, 1702020. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; Zhang, X.; Zhao, J.; Zhang, W.; Lu, C. Water repellent Ag/Ag2O@bamboo cellulose fiber membrane as bioinspired cargo carriers. Carbohydr. Polym. 2015, 133, 493–496. [Google Scholar] [CrossRef] [PubMed]

- Wan, Q.; Hu, X.; Wang, J.; Shi, H.; Yu, W.; Wang, D.; Alam, F.; Jin, Y.; Yu, T.; Guo, P.; et al. Beyond primitive bionic surfaces: Bionic structures coupled surface with superhydrophobicity and programmable directional adhesion. Phys. Fluids 2025, 37, 062115. [Google Scholar] [CrossRef]

- Tricinci, O.; Terencio, T.; Mazzolai, B.; Pugno, N.M.; Greco, F.; Mattoli, V. 3D Micropatterned Surface Inspired by Salvinia molesta via Direct Laser Lithography. ACS Appl. Mater. Interfaces 2015, 7, 25560–25567. [Google Scholar] [CrossRef]

- Tricinci, O.; Terencio, T.; Pugno, N.M.; Greco, F.; Mazzolai, B.; Mattoli, V. Air Trapping Mechanism in Artificial Salvinia-Like Micro-Hairs Fabricated via Direct Laser Lithography. Micromachines 2017, 8, 366. [Google Scholar] [CrossRef] [PubMed]

- Shi, Z.; Zhang, Z.; Huang, W.; Zeng, H.; Mandic, V.; Hu, X.; Zhao, L.; Zhang, X. Spontaneous Adsorption-Induced Salvinia-like Micropillars with High Adhesion. Langmuir 2021, 37, 6728–6735. [Google Scholar] [CrossRef]

- Zhou, K.; Li, D.; Xue, P.; Wang, P.; Zhao, Y.; Jin, M. One-step fabrication of Salvinia-inspired superhydrophobic surfaces with High adhesion. Colloids Surf. Physicochem. Eng. Aspects 2020, 590, 124517. [Google Scholar] [CrossRef]

- Smyrnakis, A.; Ioannou, D.; Ellinas, K.; Tserepi, A.; Gogolides, E. Real-Time Monitoring and Quantification of Underwater Superhydrophobicity. Adv. Mater. Interfaces 2022, 9, 2101393. [Google Scholar] [CrossRef]

- Mo, Y.; Xue, P.; Xing, J.; Liu, H.; Wang, J.; Liu, J. Conventional silicone coating improved by novel bioinspired microcavity arrays: Generating stable air bubble arrays for gas-liquid interface antifouling. Colloid Surf. 2022, 644, 128887. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Xu, B.; Fan, J.; Zhu, S.; Song, Y.; Cui, Z.; Wu, H.; Yang, Y.; Zhu, W.; et al. Robust Underwater Air Layer Retention and Restoration on Salvinia-Inspired Self-Grown Heterogeneous Architectures. ACS Nano 2022, 16, 2730–2740. [Google Scholar] [CrossRef]

- Ning, Y.; Zhang, D.; Ben, S.; Zhao, Z.; Zha, J.; Tian, D.; Liu, K.; Jiang, L. An Innovative Design by Single-Layer Superaerophobic Mesh: Continuous Underwater Bubble Antibuoyancy Collection and Transportation. Adv. Funct. Mater. 2020, 30, 1907027. [Google Scholar] [CrossRef]

- Zhang, X.; Dong, Y.; He, Z.; Gong, H.; Xu, X.; Zhao, M.; Qin, H. Efficient Gas Transportation Using Bioinspired Superhydrophobic Yarn as the Gas-Siphon Underwater. ACS Appl. Mater. Interfaces 2020, 12, 18174–18181. [Google Scholar] [CrossRef]

- Rong, W.; Zhang, H.; Mao, Z.; Chen, L.; Liu, X. Improved Stable Drag Reduction of Controllable Laser-Patterned Superwetting Surfaces Containing Bioinspired Micro/Nanostructured Arrays. ACS Omega 2022, 7, 2049–2063. [Google Scholar] [CrossRef] [PubMed]

- Trink, N.; Magdassi, S. Tunable Lotus Leaf Effect by Three-Dimensionally Printed Stretchable Objects. ACS Appl. Mater. Interfaces 2024, 16, 64276–64286. [Google Scholar] [CrossRef]

- Kavalenka, M.N.; Vuelliers, F.; Lischker, S.; Zeiger, C.; Hopf, A.; Roehrig, M.; Rapp, B.E.; Worgull, M.; Hoelscher, H. Bioinspired Air-Retaining Nanofur for Drag Reduction. ACS Appl. Mater. Interfaces 2015, 7, 10651–10655. [Google Scholar] [CrossRef]

- Vuellers, F.; Germain, Y.; Petit, L.-M.; Hoelscher, H.; Kavalenka, M.N. Pressure-Stable Air-Retaining Nanostructured Surfaces Inspired by Natural Air Plastrons. Adv. Mater. Interfaces 2018, 5, 1800125. [Google Scholar] [CrossRef]

- Song, J.H.; Baik, S.; Kim, D.W.; Yang, T.-H.; Pang, C. Wet soft bio-adhesion of insect-inspired polymeric oil-loadable perforated microcylinders. Chem. Eng. J. 2021, 423, 130194. [Google Scholar] [CrossRef]

- Yuan, C.; Huang, M.; Yu, X.; Ma, Y.; Luo, X. A simple approach to fabricate the rose petal-like hierarchical surfaces for droplet transportation. Appl. Surf. Sci. 2016, 385, 562–568. [Google Scholar] [CrossRef]

- Ghosh, U.U.; Nair, S.; Das, A.; Mukherjee, R.; DasGupta, S. Replicating and resolving wetting and adhesion characteristics of a Rose petal. Colloid Surf. 2019, 561, 9–17. [Google Scholar] [CrossRef]

- Yang, Y.; He, H.; Li, Y.; Qiu, J. Using Nanoimprint Lithography to Create Robust, Buoyant, Superhydrophobic PVB/SiO2 Coatings on wood Surfaces Inspired by Red roses petal. Sci. Rep. 2019, 9, 9961. [Google Scholar] [CrossRef]

- Zhang, X.; Dou, X.; He, Z.; Jin, H.; He, C.; Zhang, D. Fabrication of superhydrophobic cauliflower-like Cu-Co coating with anti-corrosion and anti-fouling properties on B10 copper-nickel alloy welded joint. Surf. Coat. Technol. 2023, 474, 130121. [Google Scholar] [CrossRef]

- Manderfeld, E.; Vogler, L.; Rosenhahn, A. Fouling Inhibition by Replenishable Plastrons on Microstructured, Superhydrophobic Carbon-Silicone Composite Coatings. Adv. Mater. Interfaces 2024, 11, 2300964. [Google Scholar] [CrossRef]

- Hwang, G.B.; Page, K.; Patir, A.; Nair, S.P.; Allan, E.; Parkin, I.P. The Anti-Biofouling Properties of Superhydrophobic Surfaces are Short-Lived. ACS Nano 2018, 12, 6050–6058. [Google Scholar] [CrossRef] [PubMed]

- Scardino, A.J.; Fletcher, L.E.; Lewis, J.A. Fouling control using air bubble curtains: Protection for stationary vessels. J. Mar. Eng. Technol. 2009, 8, 3–10. [Google Scholar] [CrossRef]

- Wu, A.H.F.; Nakanishi, K.; Cho, K.L.; Lamb, R. Diatom attachment inhibition: Limiting surface accessibility through air entrapment. Biointerphases 2013, 8, 5. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; He, Q.; Zheng, J.; Wang, S.; Sun, H. Underwater drag reduction and noise attenuation properties of Salvinia-inspired aramid fiber surface. Prog. Org. Coat. 2025, 208, 109451. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, S.; Zhang, H.; Ling, L.; Zuo, Y.; Yan, S.; Yang, T.; Lu, J.; He, B.; Xu, G.; et al. Near-infrared responsive superhydrophobic-hydrophilic transition coatings: A study on corrosion resistance and biological performance. Appl. Surf. Sci. 2025, 704, 163496. [Google Scholar] [CrossRef]

- Song, K.; Shim, J.; Jung, J.-Y.; Lee, C.; Nam, Y. Endowing antifouling properties on metal substrata by creating an artificial barrier layer based on scalable metal oxide nanostructures. Biofouling 2020, 36, 766–782. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Ding, Y.; Zhou, S.; Liu, F. In situ generated micro-bubbles enhanced membrane antifouling for separation of oil-in-water emulsion. J. Membr. Sci. 2021, 621, 119005. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhao, N.; Zhang, K.; Wei, W. Research on the plume stability of air bubble curtains under low transverse flow velocity environment in dredging engineering. Ocean. Eng. 2021, 232, 109133. [Google Scholar] [CrossRef]

- Ye, Q.; Ou, Y.; Xiang, G.; Chen, J. Numerical Study on the Influence of Water Depth on Air Layer Drag Reduction. Appl. Sci. 2024, 14, 431. [Google Scholar] [CrossRef]

- Ogata, S.; Shimizu, K. Drag Reduction by Hydrophobic Microstructures. J. Environ. Eng. 2011, 6, 291–301. [Google Scholar] [CrossRef]

- Bidkar, R.A.; Leblanc, L.; Kulkarni, A.J.; Bahadur, V.; Ceccio, S.L.; Perlin, M. Skin-friction drag reduction in the turbulent regime using random-textured hydrophobic surfaces. Phys. Fluids 2014, 26, 085108. [Google Scholar] [CrossRef]

- Zhu, D.; Song, Y.; Gao, F.; Dong, S.; Xu, C.; Liu, B.; Zheng, J.; Zhou, X.; Liu, Q. Achieving underwater stable drag reduction on superhydrophobic porous steel via active injection of small amounts of air. Ocean Eng. 2024, 308, 118329. [Google Scholar] [CrossRef]

- Gao, Y.; Li, J.; Shum, H.C.; Chen, H. Drag Reduction by Bubble-Covered Surfaces Found in PDMS Microchannel through Depressurization. Langmuir 2016, 32, 4815–4819. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; He, P.C.; Yang, J.H.; Liu, Y.J.; Li, S.; Qu, J.P.; Cheng, Z.J.; Mo, J.L. Bioinspired hydrophilic strip patterning on superhydrophobic spheres for stabile underwater cavities and enhanced drag reduction. Appl. Mater. Today 2025, 44, 102770. [Google Scholar] [CrossRef]

- Yao, C.; Zhang, J.; Xue, Z.; Yu, K.; Yu, X.; Yang, X.; Qu, Q.; Gan, W.; Wang, J.; Jiang, L. Bioinspired Cavity Regulation on Superhydrophobic Spheres for Drag Reduction in an Aqueous Medium. ACS Appl. Mater. Interfaces 2021, 13, 4796–4803. [Google Scholar] [CrossRef]

- Rong, W.; Zhang, H.; Mao, Z.; Chen, L.; Liu, X. Stable drag reduction of anisotropic superhydrophobic/hydrophilic surfaces containing bioinspired micro/nanostructured arrays by laser ablation. Colloid Surf. 2021, 622, 126712. [Google Scholar] [CrossRef]

- Yan, D.; Lin, J.; Zhang, B.; Zhang, S.; Ling, S.; Song, J. Drag reduction and antifouling of a spontaneous fast moving air film. J. Mater. Chem. A 2024, 12, 19268–19276. [Google Scholar] [CrossRef]

- Li, D.; Guo, H.; Wang, C.; Cao, G.; Jiang, L.; Guo, H.; Duan, J.; Chen, S. Biomimetic Gas-Trapping Electrode Toward N2 Electrofixation. Adv. Sustain. Syst. 2025, 9, 2400856. [Google Scholar] [CrossRef]

- Xiang, T.; Hou, J.; Xie, H.; Liu, X.; Gong, T.; Zhou, S. Biomimetic micro/nano structures for biomedical applications. Nano Today 2020, 35, 100980. [Google Scholar] [CrossRef]

- Yang, M.; Kotov, N.A. Quantitative biomimetics of high-performance materials. Nat. Rev. Mater. 2025, 10, 382–395. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, H.; Wang, H.; Bing, W. Biomimetic Innovations: Exploring Bubble-Trapping Organisms for Manufacturing Breakthroughs. Biomimetics 2025, 10, 641. https://doi.org/10.3390/biomimetics10100641

Yu H, Wang H, Bing W. Biomimetic Innovations: Exploring Bubble-Trapping Organisms for Manufacturing Breakthroughs. Biomimetics. 2025; 10(10):641. https://doi.org/10.3390/biomimetics10100641

Chicago/Turabian StyleYu, Haohan, He Wang, and Wei Bing. 2025. "Biomimetic Innovations: Exploring Bubble-Trapping Organisms for Manufacturing Breakthroughs" Biomimetics 10, no. 10: 641. https://doi.org/10.3390/biomimetics10100641

APA StyleYu, H., Wang, H., & Bing, W. (2025). Biomimetic Innovations: Exploring Bubble-Trapping Organisms for Manufacturing Breakthroughs. Biomimetics, 10(10), 641. https://doi.org/10.3390/biomimetics10100641