Model-Free Control of a Soft Pneumatic Segment

Abstract

1. Introduction

- The characterisation and implementation of three resistive sensors in a segment of the robot;

- The development of a closed-loop control loop based on feedforward neural networks that achieves very low error.

2. Related Works

2.1. Sensing

2.1.1. Capacitive Sensors

2.1.2. Resistive Sensors

2.1.3. Other Sensor Typologies

2.2. Control

2.2.1. Model-Based Control

2.2.2. Model-Free Control

2.3. PAUL Approach

3. Materials and Methods

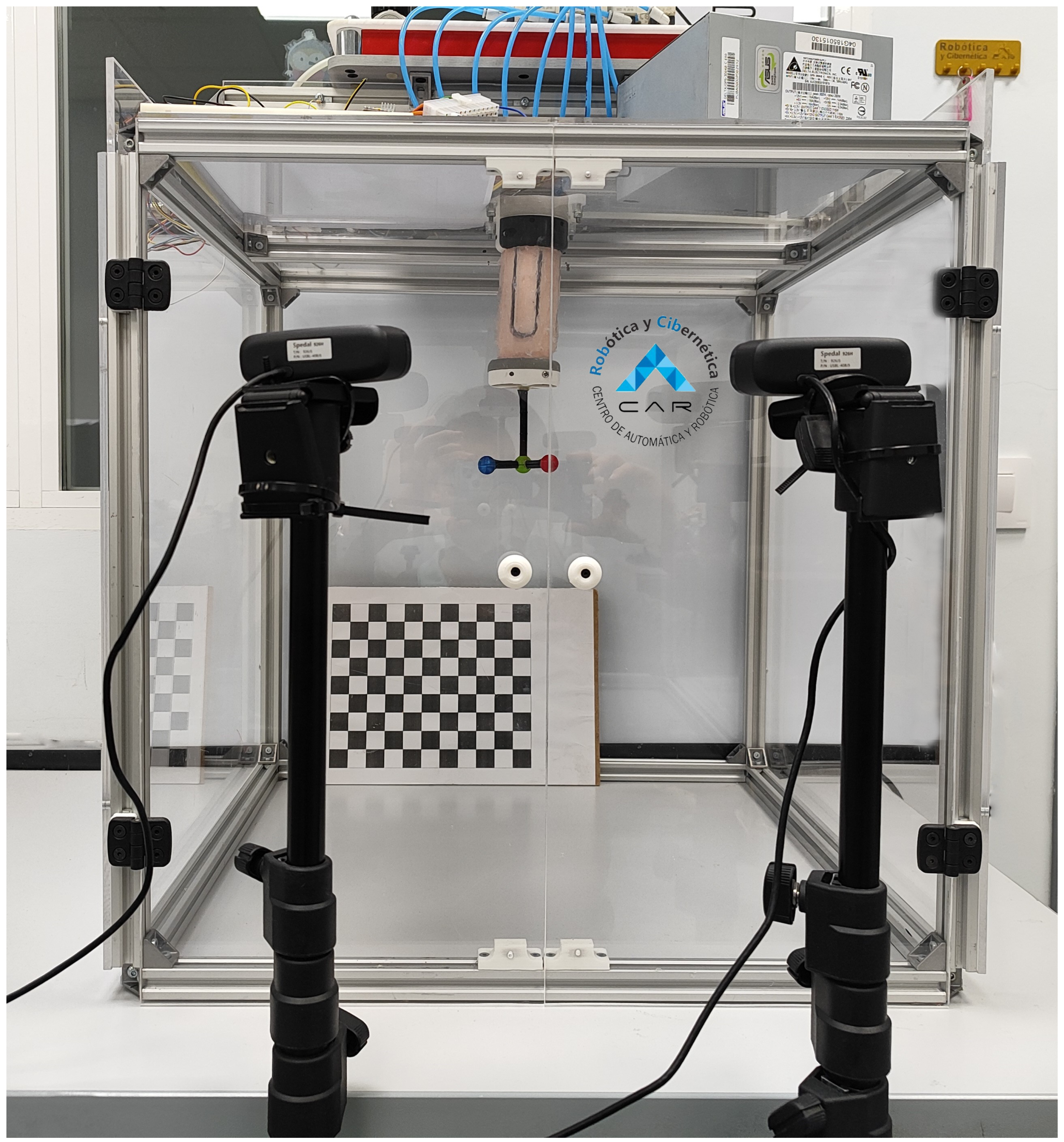

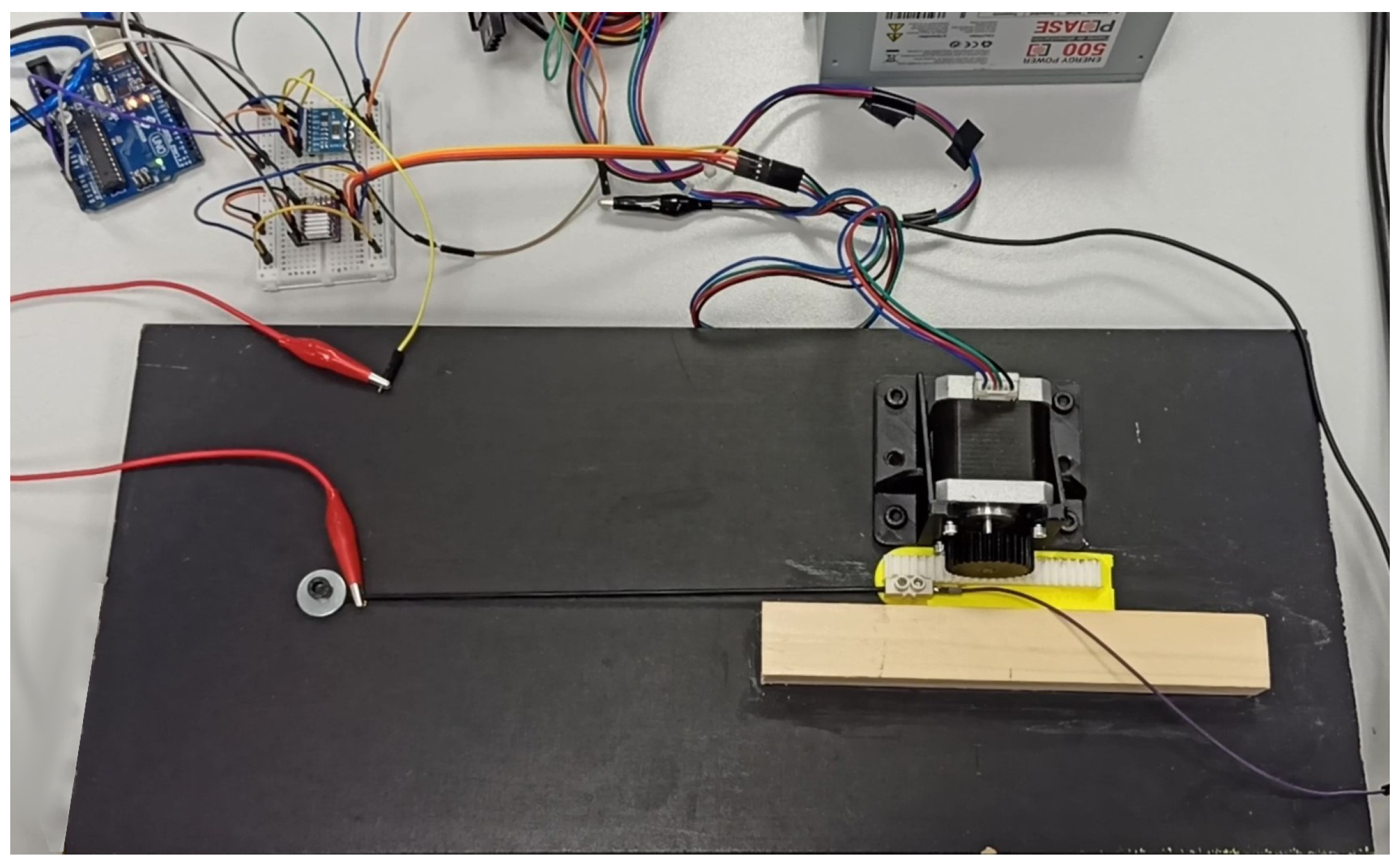

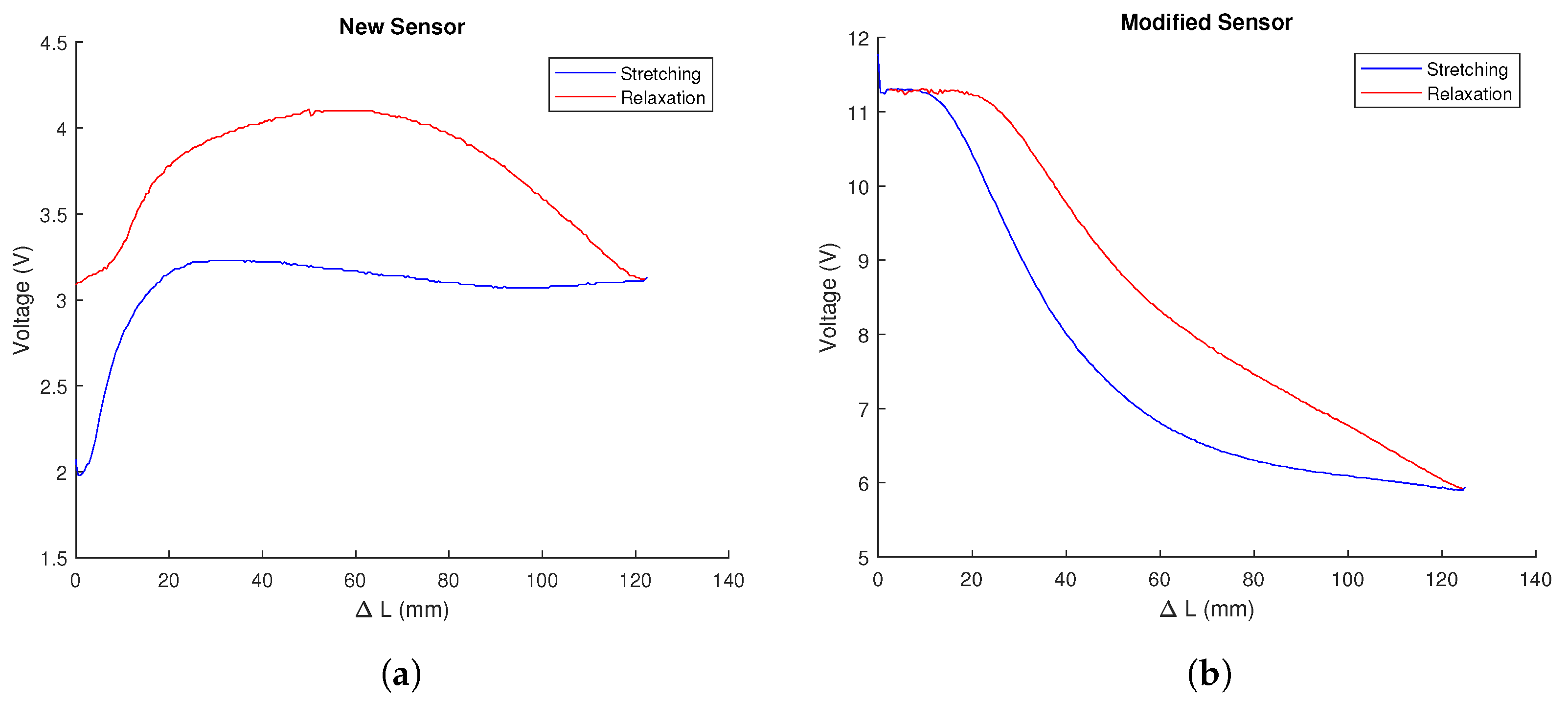

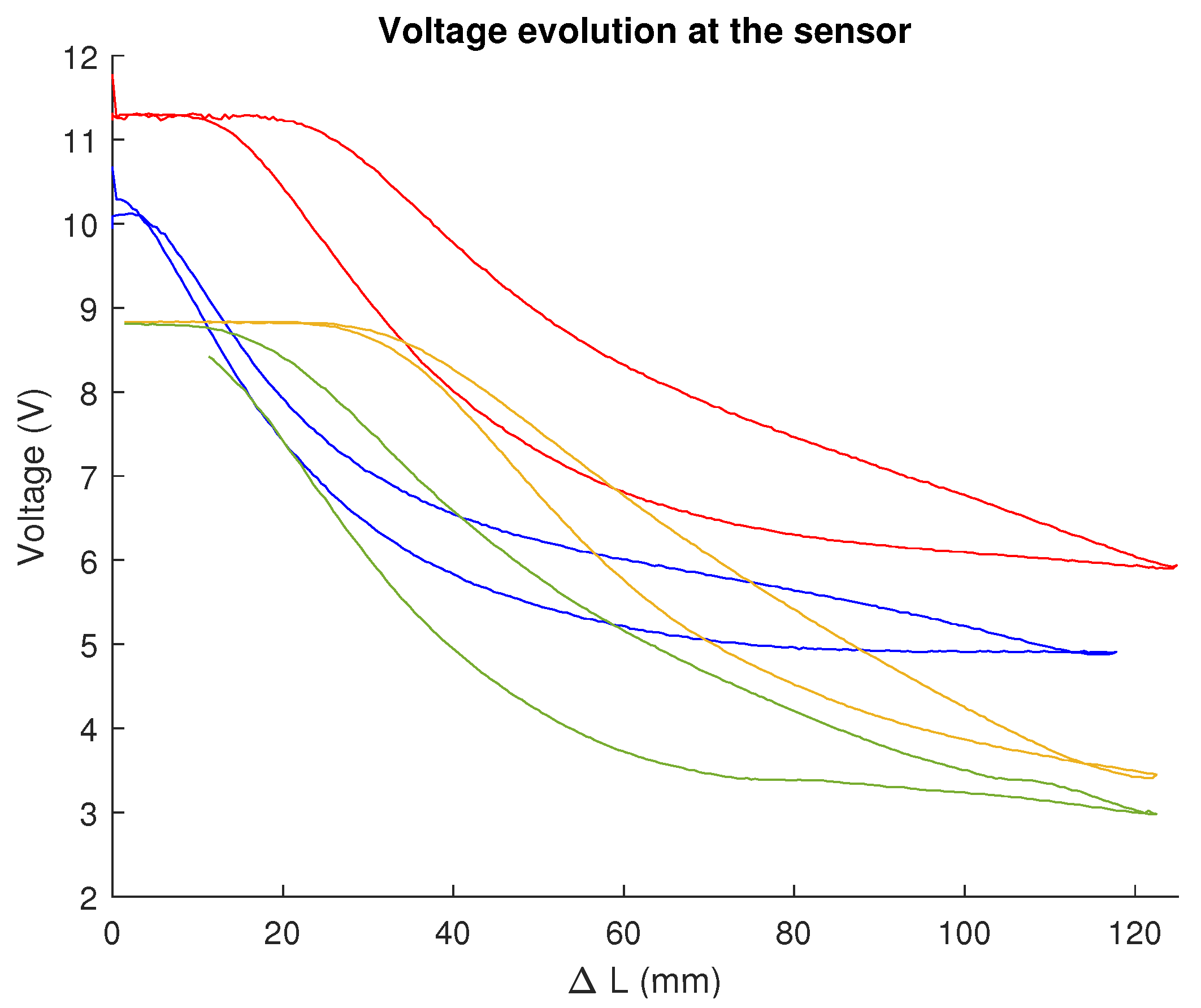

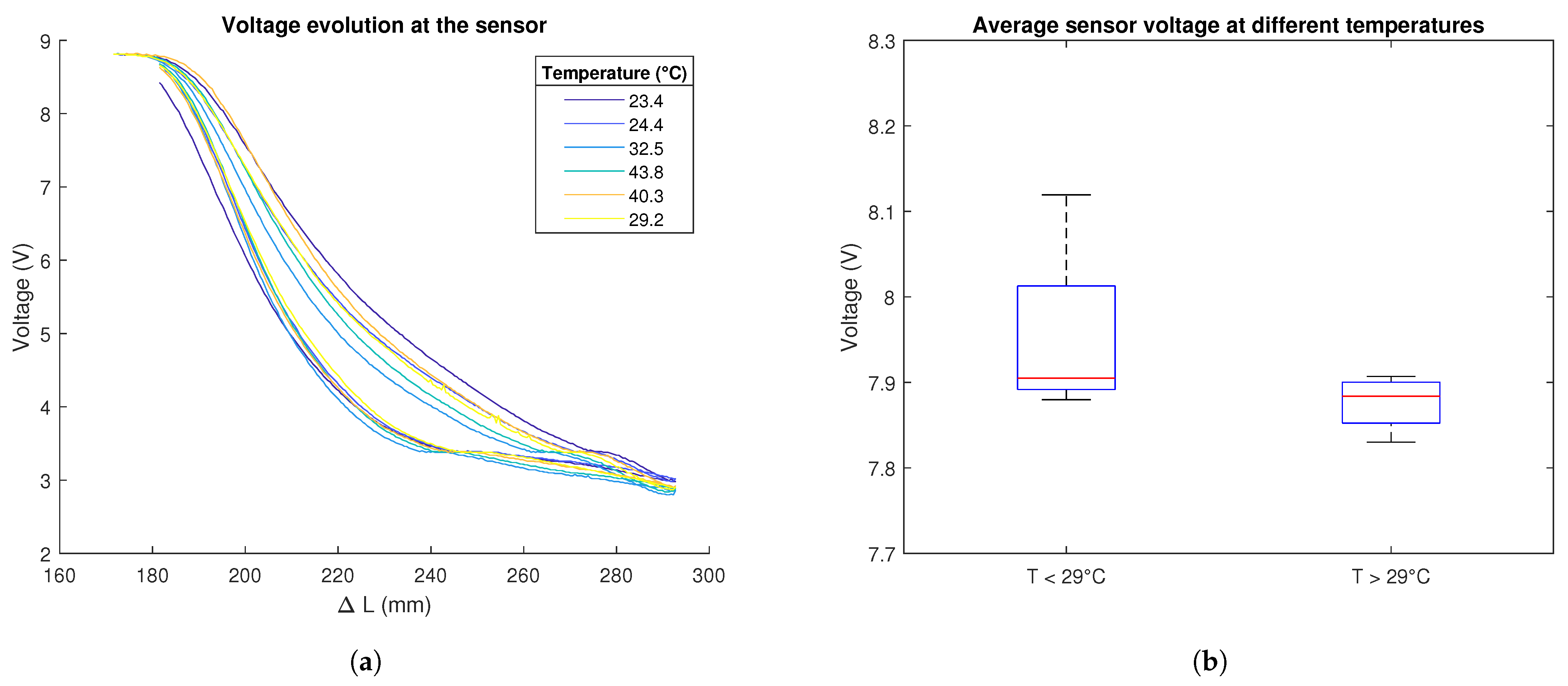

3.1. Sensor Characterisation

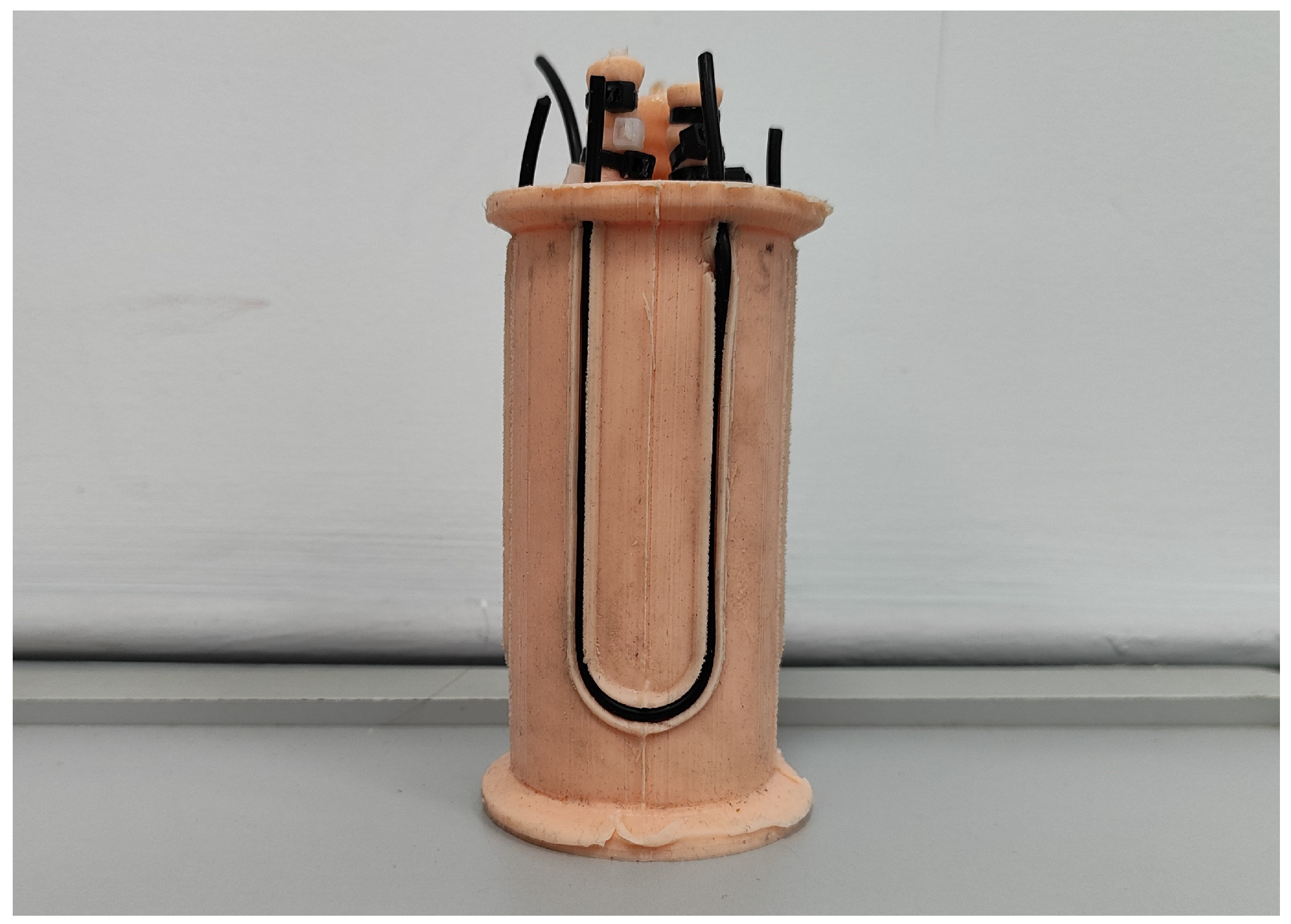

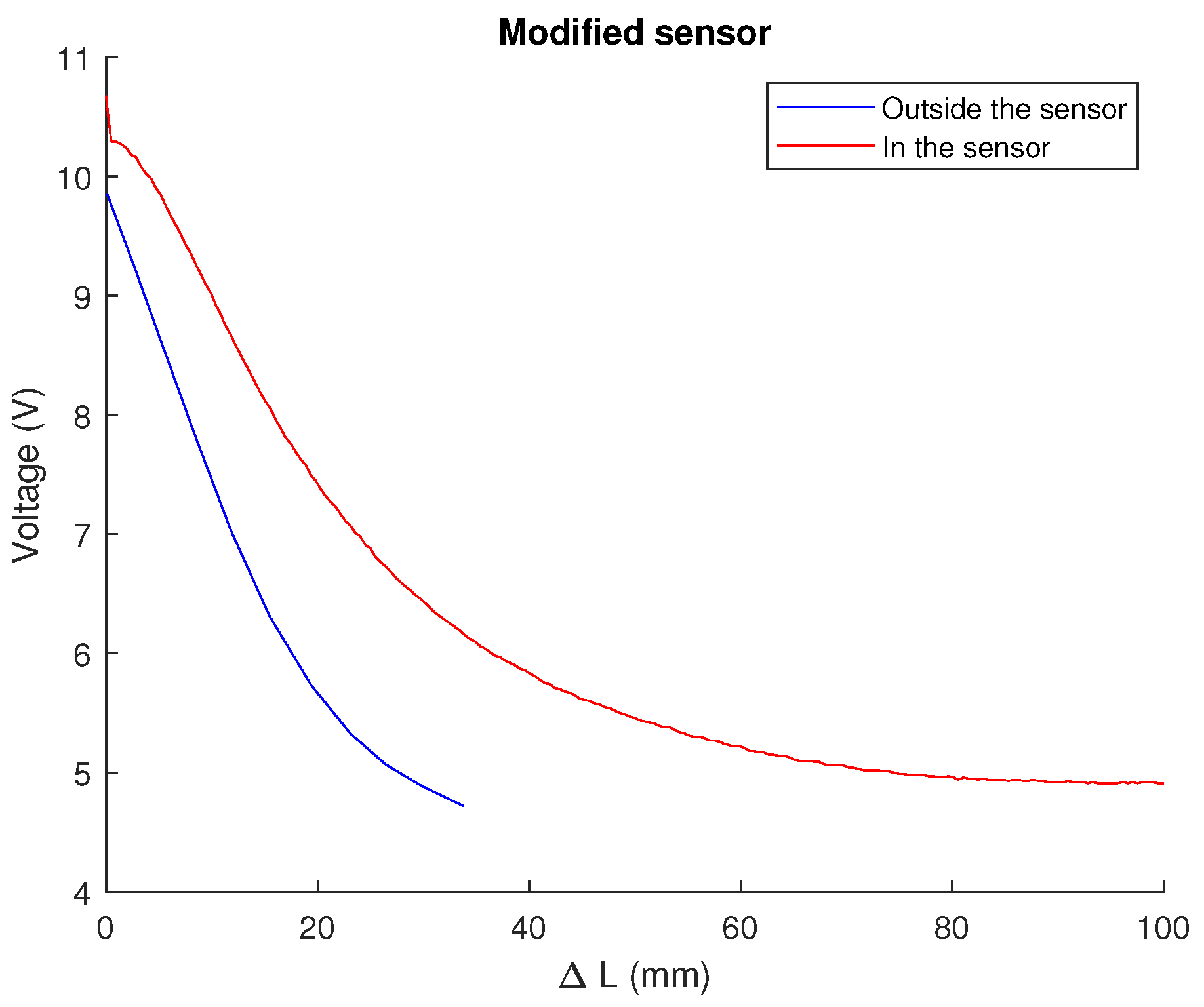

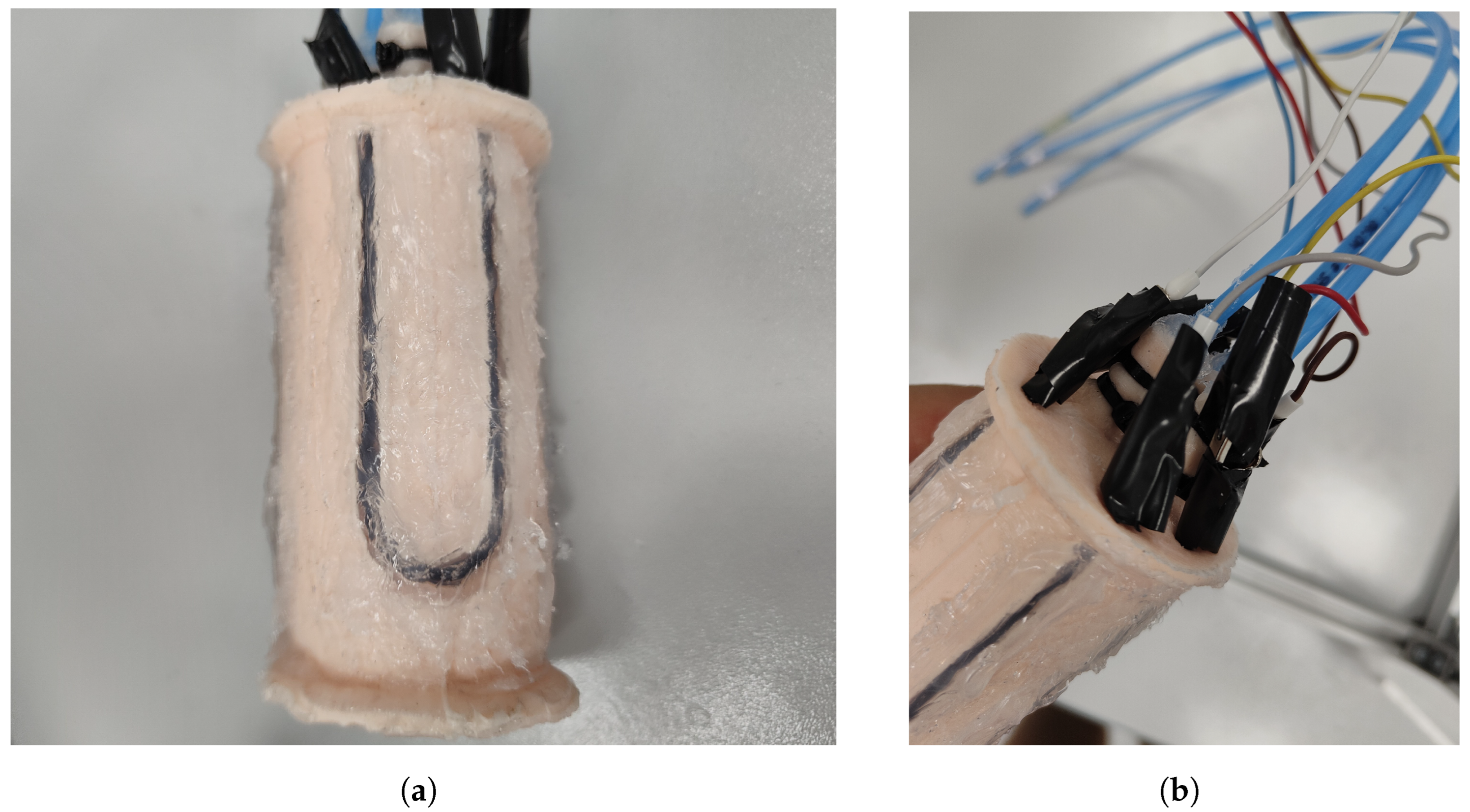

3.2. Changes to Segment Design

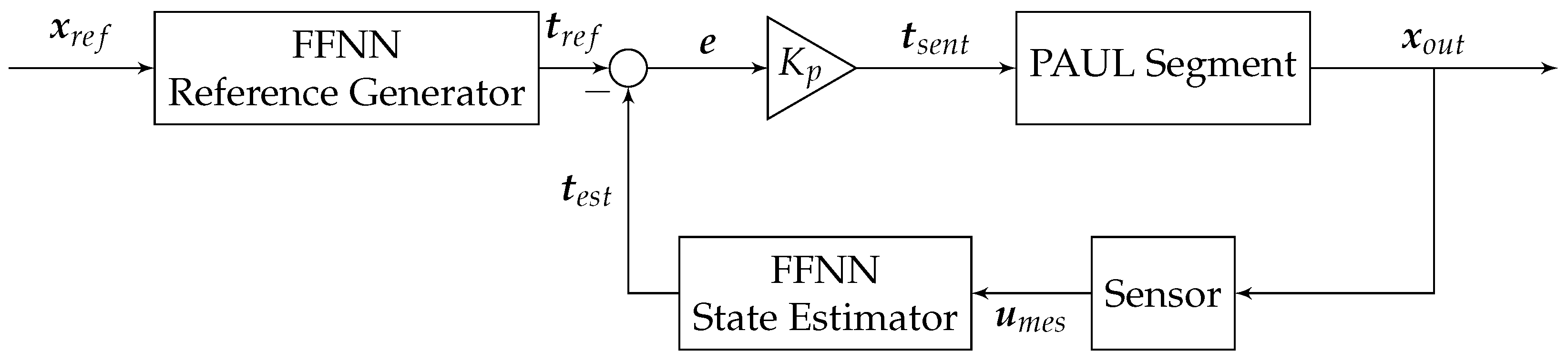

3.3. Control Loop Design

3.4. Data Acquisition and Networks Training

- A random combination of inflation times was generated. Times were chosen in the interval for safety reasons and in steps of 50 . Although that discretisation was not strictly necessary, it will be very helpful in the next step.

- It was checked that the previous combination had not been previously generated. The aim of that verification was to ensure that the training samples were evenly distributed throughout the segment’s workspace. If this was not the case, the system returned to step 1.

- PAUL was inflated based on the generated value.

- The position, voltage and inflation time were recorded.

- The segment was completely deflated to avoid hysteresis effects during the data capture process. When an LSTM net was tested, this step was not done, as previous positions were also used for training.

4. Results

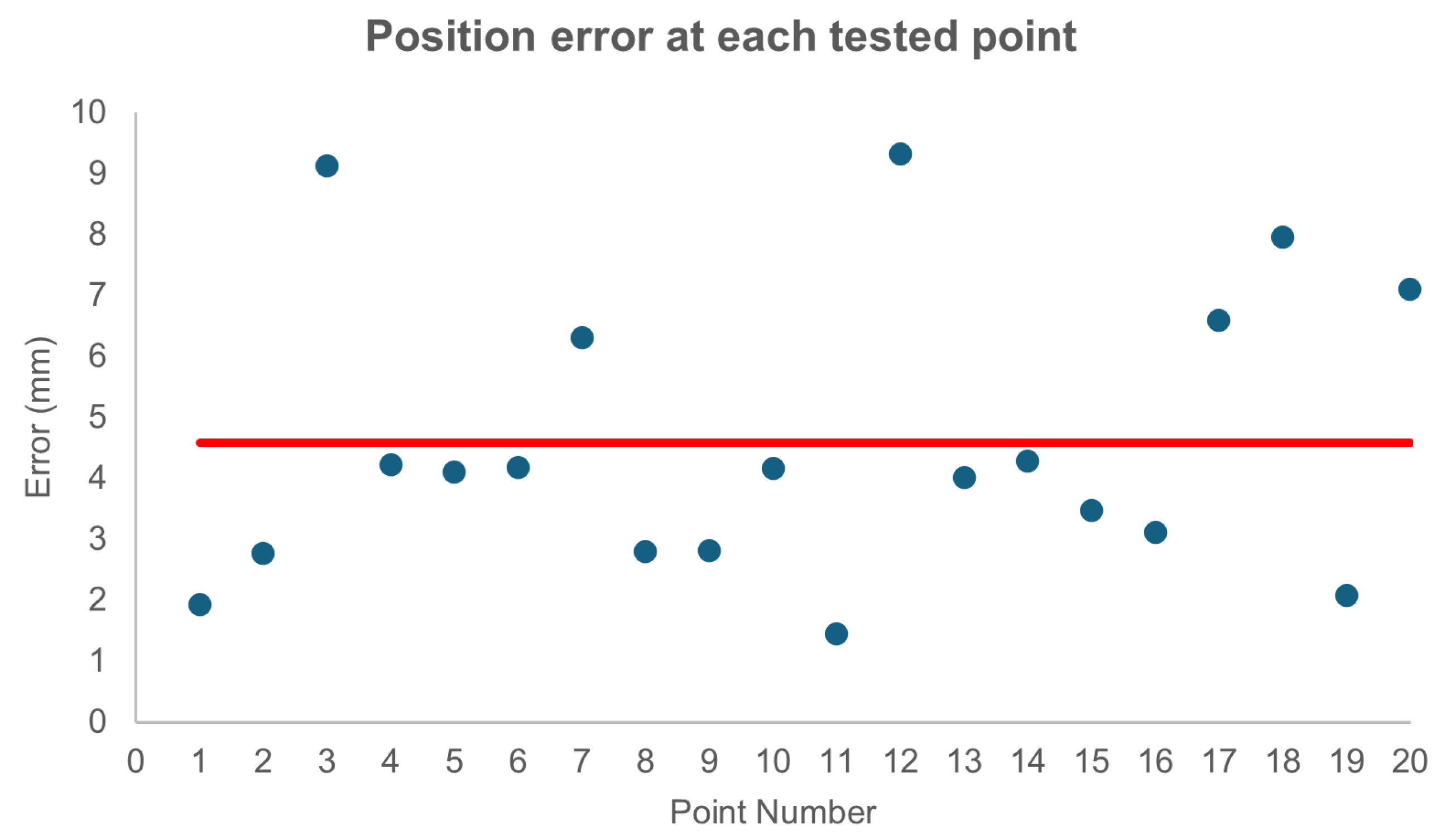

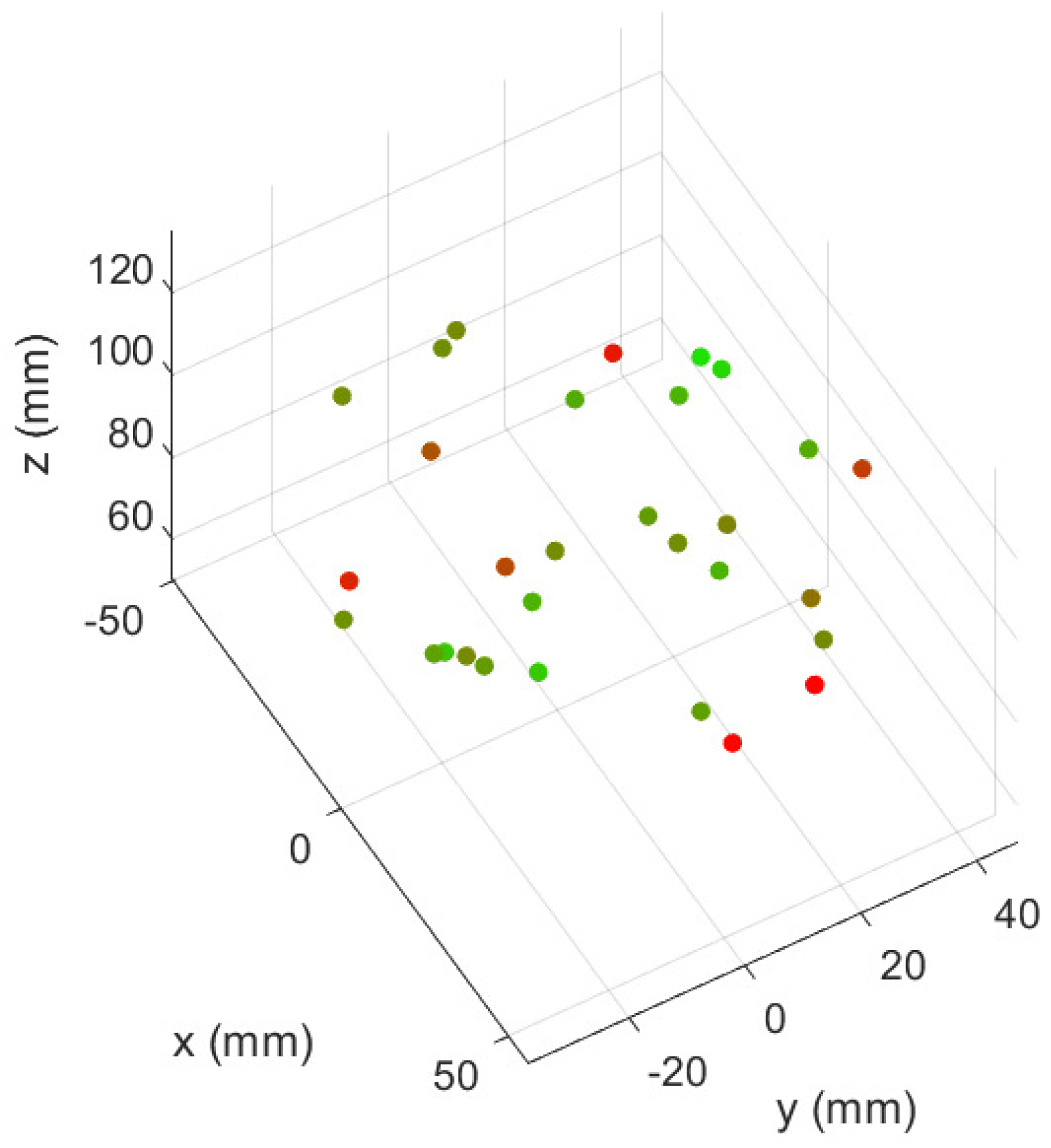

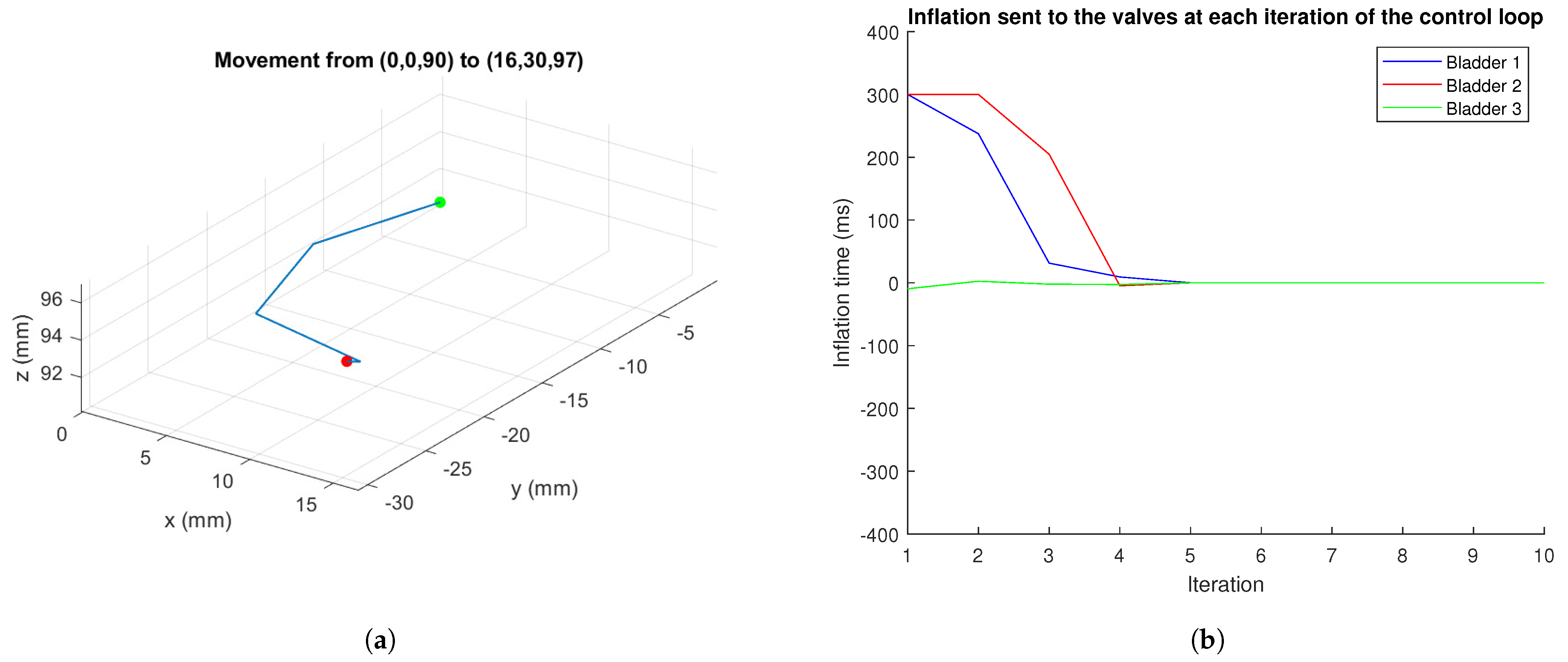

4.1. Point-to-Point Movement

4.2. Figure Drawing

4.3. Multiple Segment Tests

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CNN | Convolutional Neural Network |

| FEM | Finite Element Method |

| FFNN | Feedforward Neural Network |

| INA | Instrumentation Amplifier |

| LSTM | Long Short Term Memory |

| ML | Machine Learning |

| MPC | Model Predictive Controller |

| NARX | Nonlinear Autoregressive Network with Exogenous Inputs |

| PAUL | Pneumatic Articulated Ultrasoft Limb |

| PCC | Piecewise Constant Curvature |

| ReLU | Rectified Linear Unit |

| RL | Reinforcement Learning |

| RNN | Recurrent Neural Network |

Appendix A

- Sensor Characterisation (from 0:00 to 0:41);

- Data Acquisition (between 0:42 and 1:39);

- Closed-Loop Control (from 1:40 to the end).

References

- Manti, M.; Pratesi, A.; Falotico, E.; Cianchetti, M.; Laschi, C. Soft assistive robot for personal care of elderly people. In Proceedings of the 2016 6th IEEE International Conference on Biomedical Robotics and Biomechatronics (BioRob), Singapore, 26–29 June 2016; pp. 833–838. [Google Scholar] [CrossRef]

- Paternò, L.; Lorenzon, L. Soft robotics in wearable and implantable medical applications: Translational challenges and future outlooks. Front. Robot. AI 2023, 10, 1075634. [Google Scholar] [CrossRef]

- Li, G.; Wong, T.W.; Shih, B.; Guo, C.; Wang, L.; Liu, J.; Wang, T.; Liu, X.; Yan, J.; Wu, B.; et al. Bioinspired soft robots for deep-sea exploration. Nat. Commun. 2023, 14, 7097. [Google Scholar] [CrossRef]

- Terrile, S.; Argüelles, M.; Barrientos, A. Comparison of Different Technologies for Soft Robotics Grippers. Sensors 2021, 21, 3253. [Google Scholar] [CrossRef]

- Wang, P.; Tang, Z.; Xin, W.; Xie, Z.; Guo, S.; Laschi, C. Design and Experimental Characterization of a Push-Pull Flexible Rod-Driven Soft-Bodied Robot. IEEE Robot. Autom. Lett. 2022, 7, 8933–8940. [Google Scholar] [CrossRef]

- Polygerinos, P.; Correll, N.; Morin, S.A.; Mosadegh, B.; Onal, C.D.; Petersen, K.; Cianchetti, M.; Tolley, M.T.; Shepherd, R.F. Soft robotics: Review of fluid-driven intrinsically soft devices; manufacturing, sensing, control, and applications in human-robot interaction. Adv. Eng. Mater. 2017, 19, 1700016. [Google Scholar] [CrossRef]

- Sharma, S.; Chhetry, A.; Zhang, S.; Yoon, H.; Park, C.; Kim, H.; Sharifuzzaman, M.; Hui, X.; Park, J.Y. Hydrogen-Bond-Triggered Hybrid Nanofibrous Membrane-Based Wearable Pressure Sensor with Ultrahigh Sensitivity over a Broad Pressure Range. ACS Nano 2021, 15, 4380–4393. [Google Scholar] [CrossRef]

- Sun, W.; Akashi, N.; Kuniyoshi, Y.; Nakajima, K. Physics-Informed Recurrent Neural Networks for Soft Pneumatic Actuators. IEEE Robot. Autom. Lett. 2022, 7, 6862–6869. [Google Scholar] [CrossRef]

- Della Santina, C.; Katzschmann, R.K.; Bicchi, A.; Rus, D. Dynamic control of soft robots interacting with the environment. In Proceedings of the 2018 IEEE International Conference on Soft Robotics, RoboSoft, Livorno, Italy, 24–28 April 2018; pp. 46–53. [Google Scholar] [CrossRef]

- Wang, X.; Li, Y.; Kwok, K.W. A Survey for Machine Learning-Based Control of Continuum Robots. Front. Robot. AI 2021, 8, 730330. [Google Scholar] [CrossRef] [PubMed]

- Schegg, P.; Duriez, C. Review on generic methods for mechanical modeling, simulation and control of soft robots. PLoS ONE 2022, 17, e0251059. [Google Scholar] [CrossRef] [PubMed]

- Della Santina, C.; Duriez, C.; Rus, D. Model Based Control of Soft Robots: A Survey of the State of the Art and Open Challenges. IEEE Control Syst. Mag. 2023, 43, 30–65. [Google Scholar] [CrossRef]

- Nadizar, G.; Medvet, E.; Nichele, S.; Pontes-Filho, S. An experimental comparison of evolved neural network models for controlling simulated modular soft robots. Appl. Soft Comput. 2023, 145, 110610. [Google Scholar] [CrossRef]

- Bhagat, S.; Banerjee, H.; Tse, Z.T.H.; Ren, H. Deep reinforcement learning for soft, flexible robots: Brief review with impending challenges. Robotics 2019, 8, 4. [Google Scholar] [CrossRef]

- García-Samartín, J.F.; Rieker, A.; Barrientos, A. Design, Manufacturing, and Open-Loop Control of a Soft Pneumatic Arm. Actuators 2024, 13, 36. [Google Scholar] [CrossRef]

- Continelli, N.A.; Nagua, L.F.; Monje, C.A.; Balaguer, C. Modeling of a soft robotic neck using machine learning techniques. Rev. Iberoam. Autom. Inform. Ind. 2023, 20, 282–292. [Google Scholar] [CrossRef]

- Atalay, A.; Sanchez, V.; Atalay, O.; Vogt, D.M.; Haufe, F.; Wood, R.J.; Walsh, C.J. Batch Fabrication of Customizable Silicone-Textile Composite Capacitive Strain Sensors for Human Motion Tracking. Adv. Mater. Technol. 2017, 2, 1700136. [Google Scholar] [CrossRef]

- Kang, M.; Kim, J.; Jang, B.; Chae, Y.; Kim, J.H.; Ahn, J.H. Graphene-Based Three-Dimensional Capacitive Touch Sensor for Wearable Electronics. ACS Nano 2017, 11, 7950–7957. [Google Scholar] [CrossRef]

- Yaragalla, S.; Dussoni, S.; Zahid, M.; Maggiali, M.; Metta, G.; Athanasiou, A.; Bayer, I.S. Stretchable graphene and carbon nanofiber capacitive touch sensors for robotic skin applications. J. Ind. Eng. Chem. 2021, 101, 348–358. [Google Scholar] [CrossRef]

- Rocha, R.P.; Lopes, P.A.; De Almeida, A.T.; Tavakoli, M.; Majidi, C. Fabrication and characterization of bending and pressure sensors for a soft prosthetic hand. J. Micromech. Microeng. 2018, 28, 034001. [Google Scholar] [CrossRef]

- Yu, H.; Li, H.; Sun, X.; Pan, L. Biomimetic Flexible Sensors and Their Applications in Human Health Detection. Biomimetics 2023, 8, 293. [Google Scholar] [CrossRef]

- Shahzad, U.; Marwani, H.M.; Saeed, M.; Asiri, A.M.; Rahman, M.M. Two-dimensional MXenes as Emerging Materials: A Comprehensive Review. ChemistrySelect 2023, 8, e202300737. [Google Scholar] [CrossRef]

- Lee, S.; Bhuyan, P.; Bae, K.J.; Yu, J.; Jeon, H.; Park, S. Interdigitating Elastic Fibers with a Liquid Metal Core toward Ultrastretchable and Soft Capacitive Sensors: From 1D Fibers to 2D Electronics. ACS Appl. Electron. Mater. 2022, 4, 6275–6283. [Google Scholar] [CrossRef]

- Ji, Q.; Jansson, J.; Sjöberg, M.; Wang, X.V.; Wang, L.; Feng, L. Design and calibration of 3D printed soft deformation sensors for soft actuator control. Mechatronics 2023, 92, 102980. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and Highly Sensitive Graphene Strain Sensors for Human Motion Monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Shan, C.; Che, M.; Cholewinski, A.; Kunihiro, K.I.J.; Yim, E.K.; Su, R.; Zhao, B. Adhesive hydrogels tailored with cellulose nanofibers and ferric ions for highly sensitive strain sensors. Chem. Eng. J. 2022, 450, 138256. [Google Scholar] [CrossRef]

- Di Tocco, J.; Presti, D.L.; Rainer, A.; Schena, E.; Massaroni, C. Silicone-Textile Composite Resistive Strain Sensors for Human Motion-Related Parameters. Sensors 2022, 22, 3954. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Chen, Z.; Wang, S.; Zuo, S. Novel shape-lockable self-propelling robot with a helical mechanism and tactile sensing for inspecting the large intestine. Smart Mater. Struct. 2021, 30, 125023. [Google Scholar] [CrossRef]

- Sun, X.; Yao, F.; Li, J. Nanocomposite hydrogel-based strain and pressure sensors: A review. J. Mater. Chem. A 2020, 8, 18605–18623. [Google Scholar] [CrossRef]

- Zhang, J.; Xue, W.; Dai, Y.; Wu, C.; Li, B.; Guo, X.; Liao, B.; Zeng, W. Ultrasensitive, flexible and dual strain-temperature sensor based on ionic-conductive composite hydrogel for wearable applications. Compos. Part A Appl. Sci. Manuf. 2023, 171, 107572. [Google Scholar] [CrossRef]

- Chung, D.D. A critical review of piezoresistivity and its application in electrical-resistance-based strain sensing. J. Mater. Sci. 2020, 55, 15367–15396. [Google Scholar] [CrossRef]

- Luo, X.L.; Schubert, D.W. Experimental and Theoretical Study on Piezoresistive Behavior of Compressible Melamine Sponge Modified by Carbon-based Fillers. Chin. J. Polym. Sci. (Engl. Ed.) 2022, 40, 1503–1512. [Google Scholar] [CrossRef]

- Feng, E.; Zheng, G.; Zhang, M.; Li, X.; Feng, G.; Cao, L. Self-healing and freezing-tolerant strain sensor based on a multipurpose organohydrogel with information recording and erasing function. Colloids Surf. A Physicochem. Eng. Asp. 2023, 672, 131781. [Google Scholar] [CrossRef]

- Zhang, C.; Song, S.; Liu, M.; Wang, J.; Liu, Z.; Zhang, S.; Li, W.; Zhang, Y. Facile fabrication of silicone rubber composite foam with dual conductive networks and tunable porosity for intelligent sensing. Eur. Polym. J. 2022, 164, 110980. [Google Scholar] [CrossRef]

- Lacasse, M.A.; Duchaine, V. Characterization of the Electrical Resistance of Carbon-Black-Filled Silicone: Application to a Flexible and Stretchable Robot Skin. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010. [Google Scholar] [CrossRef]

- Dong, W.; Li, W.; Shen, L.; Sheng, D. Piezoresistive behaviours of carbon black cement-based sensors with layer-distributed conductive rubber fi bres. Mater. Des. 2019, 182, 108012. [Google Scholar] [CrossRef]

- Yang, H.; Yuan, L.; Yao, X.F.; Fang, D.N. Piezoresistive response of graphene rubber composites considering the tunneling effect. J. Mech. Phys. Solids 2020, 139, 103943. [Google Scholar] [CrossRef]

- Dong, R.; Xie, J. Stretchable strain sensor with controllable negative resistance sensitivity coefficient based on patterned carbon nanotubes/silicone rubber composites. Micromachines 2021, 12, 716. [Google Scholar] [CrossRef]

- Chen, Y.F.; Huang, M.L.; Cai, J.H.; Weng, Y.X.; Wang, M. Piezoresistive anisotropy in conductive silicon rubber/multi-walled carbon nanotube/nickel particle composites via alignment of nickel particles. Compos. Sci. Technol. 2022, 225, 109520. [Google Scholar] [CrossRef]

- Li, Y.; Liu, G.; Wang, L.; Zhang, J.; Xu, M.; Shi, S.Q. Multifunctional conductive graphite/cellulosic microfiber-natural rubber composite sponge with ultrasensitive collision-warning and fire-waring. Chem. Eng. J. 2022, 431, 134046. [Google Scholar] [CrossRef]

- Błazewicz, S.; Patalita, B.; Touzain, P. Study of piezoresistance effect in carbon fibers. Carbon 1997, 35, 1613–1618. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, G.W. Hysteresis compensation of piezoresistive carbon nanotube/polydimethylsiloxane composite-based force sensors. Sensors 2017, 17, 229. [Google Scholar] [CrossRef]

- Sixt, J.; Davoodi, E.; Salehian, A.; Toyserkani, E. Characterization and optimization of 3D-printed, flexible vibration strain sensors with triply periodic minimal surfaces. Addit. Manuf. 2023, 61, 103274. [Google Scholar] [CrossRef]

- Di Tocco, J.; Massaroni, C.; Schena, E.; Marra, F.; Tamburrano, A.; Minutillo, S.; Sarto, M.S. Feasibility assessment of a piezoresistive sensor based on graphene nanoplatelets for respiratory monitoring. In Proceedings of the 2022 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT), Trento, Italy, 7–9 June 2022; pp. 267–271. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Shih, B.; Laschi, C.; Tolley, M.T. Soft robot perception using embedded soft sensors and recurrent neural networks. Sci. Robot. 2019, 4, eaav1488. [Google Scholar] [CrossRef]

- Xing, Z.; Lin, J.; McCoul, D.; Zhang, D.; Zhao, J. Inductive Strain Sensor With High Repeatability and Ultra-Low Hysteresis Based on Mechanical Spring. IEEE Sens. J. 2020, 20, 14670–14675. [Google Scholar] [CrossRef]

- Kar, D.; George, B.; Sridharan, K. A review on flexible sensors for soft robotics. In Systems for Printed Flexible Sensors: Design and Implementation; IOP Publishing: Bristol, UK, 2022; p. 1. [Google Scholar]

- Wang, H.; Kow, J.; Raske, N.; de Boer, G.; Ghajari, M.; Hewson, R.; Alazmani, A.; Culmer, P. Robust and high-performance soft inductive tactile sensors based on the Eddy-current effect. Sens. Actuators A Phys. 2018, 271, 44–52. [Google Scholar] [CrossRef]

- Paulino, T.; Ribeiro, P.; Neto, M.; Cardoso, S.; Schmitz, A.; Santos-Victor, J.; Bernardino, A.; Jamone, L. Low-cost 3-axis soft tactile sensors for the human-friendly robot Vizzy. In Proceedings of the 2017 IEEE International Conference on Robotics and Automation (ICRA), Singapore, 29 May–3 June 2017; pp. 966–971. [Google Scholar] [CrossRef]

- Jung, J.; Park, M.; Kim, D.; Park, Y.L. Optically Sensorized Elastomer Air Chamber for Proprioceptive Sensing of Soft Pneumatic Actuators. IEEE Robot. Autom. Lett. 2020, 5, 2333–2340. [Google Scholar] [CrossRef]

- Kubus, D.; Rayyes, R.; Steil, J.J. Learning Forward and Inverse Kinematics Maps Efficiently. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; pp. 5133–5140. [Google Scholar] [CrossRef]

- Cerrillo, D.; Barrientos, A.; Del Cerro, J. Kinematic Modelling for Hyper-Redundant Robots—A Structured Guide. Mathematics 2022, 10, 2891. [Google Scholar] [CrossRef]

- Katzschmann, R.K.; Santina, C.D.; Toshimitsu, Y.; Bicchi, A.; Rus, D. Dynamic motion control of multi-segment soft robots using piecewise constant curvature matched with an augmented rigid body model. In Proceedings of the RoboSoft 2019—2019 IEEE International Conference on Soft Robotics, Seoul, Republic of Korea, 14–18 April 2019; pp. 454–461. [Google Scholar] [CrossRef]

- Trumic, M.; Della Santina, C.; Jovanovic, K.; Fagiolini, A. Adaptive Control of Soft Robots Based on an Enhanced 3D Augmented Rigid Robot Matching. In Proceedings of the American Control Conference, New Orleans, LA, USA, 25–28 May 2021; pp. 4991–4996. [Google Scholar] [CrossRef]

- Della Santina, C.; Katzschmann, R.K.; Bicchi, A.; Rus, D. Model-based dynamic feedback control of a planar soft robot: Trajectory tracking and interaction with the environment. Int. J. Robot. Res. 2020, 39, 490–513. [Google Scholar] [CrossRef]

- Pozzi, M.; Miguel, E.; Deimel, R.; Malvezzi, M.; Bickel, B.; Brock, O.; Prattichizzo, D. Efficient FEM-Based simulation of soft robots modeled as kinematic chains. In Proceedings of the IEEE International Conference on Robotics and Automation, Brisbane, QLD, Australia, 21–25 May 2018; pp. 4206–4213. [Google Scholar] [CrossRef]

- Ding, L.; Niu, L.; Su, Y.; Yang, H.; Liu, G.; Gao, H.; Deng, Z. Dynamic Finite Element Modeling and Simulation of Soft Robots. Chin. J. Mech. Eng. (Engl. Ed.) 2022, 35, 24. [Google Scholar] [CrossRef]

- Cangan, B.G.; Navarro, S.E.; Yang, B.; Zhang, Y.; Duriez, C.; Katzschmann, R.K. Model-Based Disturbance Estimation for a Fiber-Reinforced Soft Manipulator using Orientation Sensing. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Kyoto, Japan, 23–27 October 2022; pp. 9424–9430. [Google Scholar] [CrossRef]

- Martin-Barrio, A.; Terrile, S.; Diaz-Carrasco, M.; del Cerro, J.; Barrientos, A. Modelling the Soft Robot Kyma Based on Real-Time Finite Element Method. Comput. Graph. Forum 2020, 39, 289–302. [Google Scholar] [CrossRef]

- Dubied, M.; Michelis, M.Y.; Spielberg, A.; Katzschmann, R.K. Sim-to-Real for Soft Robots Using Differentiable FEM: Recipes for Meshing, Damping, and Actuation. IEEE Robot. Autom. Lett. 2022, 7, 5015–5022. [Google Scholar] [CrossRef]

- Chaillou, P.; Shi, J.; Kruszewski, A.; Fournier, I.; Wurdemann, H.A.; Duriez, C. Reduced finite element modelling and closed-loop control of pneumatic-driven soft continuum robots. In Proceedings of the 2023 IEEE International Conference on Soft Robotics, RoboSoft 2023, Singapore, 3–7 April 2023; pp. 1–8. [Google Scholar] [CrossRef]

- Bern, J.M.; Rus, D. Soft IK with stiffness control. In Proceedings of the 2021 IEEE 4th International Conference on Soft Robotics, RoboSoft 2021, New Haven, CT, USA, 12–16 April 2021; pp. 465–471. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, G. FEM-Based Nonlinear Controller for a Soft Trunk Robot. IEEE Robot. Autom. Lett. 2022, 7, 5735–5740. [Google Scholar] [CrossRef]

- Wu, K.; Zheng, G. FEM-Based Gain-Scheduling Control of a Soft Trunk Robot. IEEE Robot. Autom. Lett. 2021, 6, 3081–3088. [Google Scholar] [CrossRef]

- Zhou, Y.; Ju, M.; Zheng, G. Closed-loop control of soft robot based on machine learning. In Proceedings of the Chinese Control Conference (CCC), Guangzhou, China, 27–30 July 2019; pp. 4543–4547. [Google Scholar] [CrossRef]

- Jangid, H.; Jain, S.; Teka, B.; Raja, R.; Dutta, A. Kinematics-based end-effector path control of a mobile manipulator system on an uneven terrain using a two-stage Support Vector Machine. Robotica 2020, 38, 1415–1433. [Google Scholar] [CrossRef]

- Devi, M.A.; Jadhav, P.D.; Adhikary, N.; Hebbar, P.S.; Mohsin, M.; Shashank, S.K. Trajectory Planning and Computation of Inverse Kinematics of SCARA using Machine Learning. In Proceedings of the 2021 International Conference on Artificial Intelligence and Smart Systems (ICAIS), Coimbatore, India, 25–27 March 2021; pp. 170–176. [Google Scholar] [CrossRef]

- Cagigas-Muñiz, D. Artificial Neural Networks for inverse kinematics problem in articulated robots. Eng. Appl. Artif. Intell. 2023, 126, 107175. [Google Scholar] [CrossRef]

- García-Samartín, J.F.; Barrientos, A. Kinematic Modelling of a 3RRR Planar Parallel Robot Using Genetic Algorithms and Neural Networks. Machines 2023, 11, 952. [Google Scholar] [CrossRef]

- Terrile, S.; López, A.; Barrientos, A. Use of Finite Elements in the Training of a Neural Network for the Modeling of a Soft Robot. Biomimetics 2023, 8, 56. [Google Scholar] [CrossRef] [PubMed]

- Fang, G.; Tian, Y.; Yang, Z.X.; Geraedts, J.M.; Wang, C.C. Efficient Jacobian-Based Inverse Kinematics With Sim-to-Real Transfer of Soft Robots by Learning. IEEE/ASME Trans. Mechatron. 2022, 27, 5296–5306. [Google Scholar] [CrossRef]

- Bern, J.M.; Schnider, Y.; Banzet, P.; Kumar, N.; Coros, S. Soft Robot Control with a Learned Differentiable Model. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics, RoboSoft 2020, New Haven, CT, USA, 15 May–15 July 2020; pp. 417–423. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Hassan, T.; Falotico, E.; Ansari, Y.; Cianchetti, M.; Laschi, C. Closed loop control of a braided-structure continuum manipulator with hybrid actuation based on learning models. In Proceedings of the 2019 IEEE International Conference on Cyborg and Bionic Systems, CBS 2019, Munich, Germany, 18–20 September 2019; pp. 116–122. [Google Scholar] [CrossRef]

- Shi, L.; Liu, Z.; Karydis, K. Koopman Operators for Modeling and Control of Soft Robotics. Curr. Robot. Rep. 2023, 4, 23–31. [Google Scholar] [CrossRef]

- Bruder, D.; Gillespie, B.; David Remy, C.; Vasudevan, R. Modeling and Control of Soft Robots Using the Koopman Operator and Model Predictive Control. arXiv 2019, arXiv:1902.02827. [Google Scholar] [CrossRef]

- Almanzor, E.; Ye, F.; Shi, J.; Thuruthel, T.G.; Wurdemann, H.A.; Iida, F. Static Shape Control of Soft Continuum Robots Using Deep Visual Inverse Kinematic Models. IEEE Trans. Robot. 2023, 39, 2973–2988. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Iida, F. Multi-modal Sensor Fusion for Learning Rich Models for Interacting Soft Robots. In Proceedings of the 2023 IEEE International Conference on Soft Robotics, RoboSoft 2023, Singapore, 3–7 April 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Falotico, E.; Manti, M.; Laschi, C. Stable Open Loop Control of Soft Robotic Manipulators. IEEE Robot. Autom. Lett. 2018, 3, 1292–1298. [Google Scholar] [CrossRef]

- Thuruthel, T.G.; Falotico, E.; Renda, F.; Laschi, C. Model-Based Reinforcement Learning for Closed-Loop Dynamic Control of Soft Robotic Manipulators. IEEE Trans. Robot. 2019, 35, 127–134. [Google Scholar] [CrossRef]

- Centurelli, A.; Arleo, L.; Rizzo, A.; Tolu, S.; Laschi, C.; Falotico, E. Closed-Loop Dynamic Control of a Soft Manipulator Using Deep Reinforcement Learning. IEEE Robot. Autom. Lett. 2022, 7, 4741–4748. [Google Scholar] [CrossRef]

- Alessi, C.; Hauser, H.; Lucantonio, A.; Falotico, E. Learning a Controller for Soft Robotic Arms and Testing its Generalization to New Observations, Dynamics, and Tasks. In Proceedings of the 2023 IEEE International Conference on Soft Robotics, RoboSoft 2023, Singapore, 3–7 April 2023; Volume 2, pp. 1–7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Samartín, J.F.; Molina-Gómez, R.; Barrientos, A. Model-Free Control of a Soft Pneumatic Segment. Biomimetics 2024, 9, 127. https://doi.org/10.3390/biomimetics9030127

García-Samartín JF, Molina-Gómez R, Barrientos A. Model-Free Control of a Soft Pneumatic Segment. Biomimetics. 2024; 9(3):127. https://doi.org/10.3390/biomimetics9030127

Chicago/Turabian StyleGarcía-Samartín, Jorge Francisco, Raúl Molina-Gómez, and Antonio Barrientos. 2024. "Model-Free Control of a Soft Pneumatic Segment" Biomimetics 9, no. 3: 127. https://doi.org/10.3390/biomimetics9030127

APA StyleGarcía-Samartín, J. F., Molina-Gómez, R., & Barrientos, A. (2024). Model-Free Control of a Soft Pneumatic Segment. Biomimetics, 9(3), 127. https://doi.org/10.3390/biomimetics9030127