Kinetic Model of Fluorescein Release through Bioprinted Polylactic Acid Membrane

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Spectrofluorimetric and Spectrophotometric Measurements

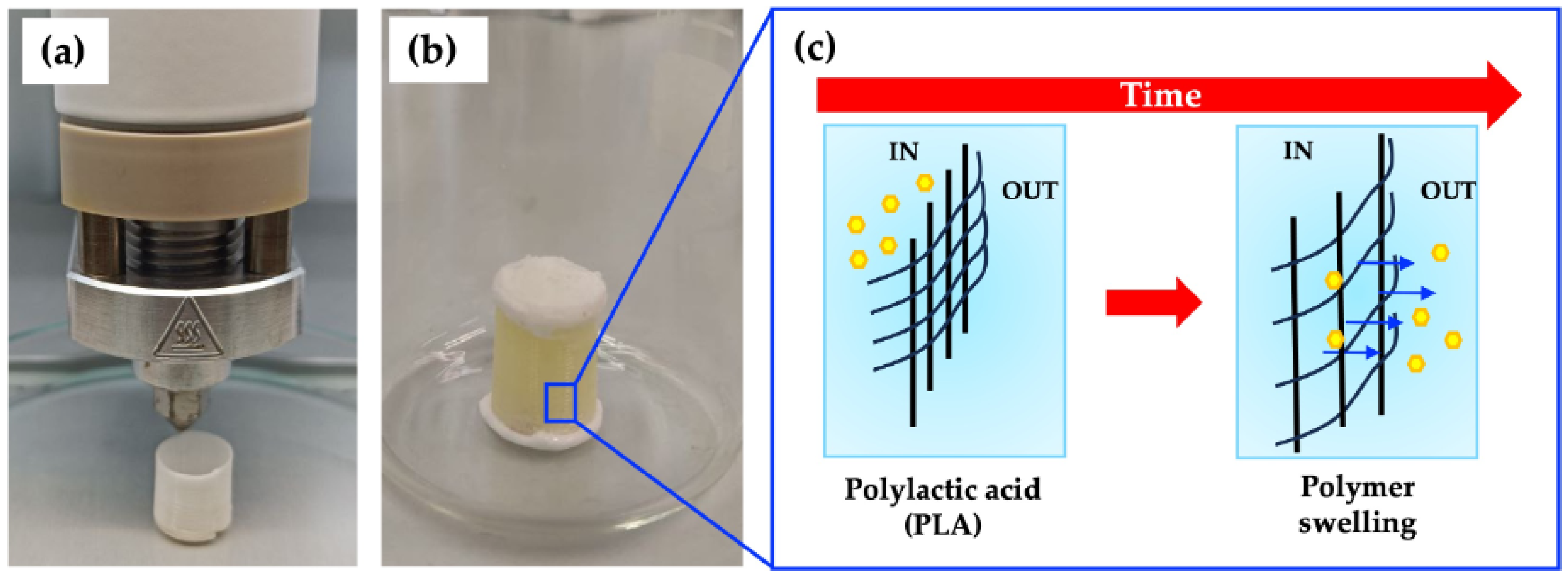

2.3. Manufacturing of PLA Membrane

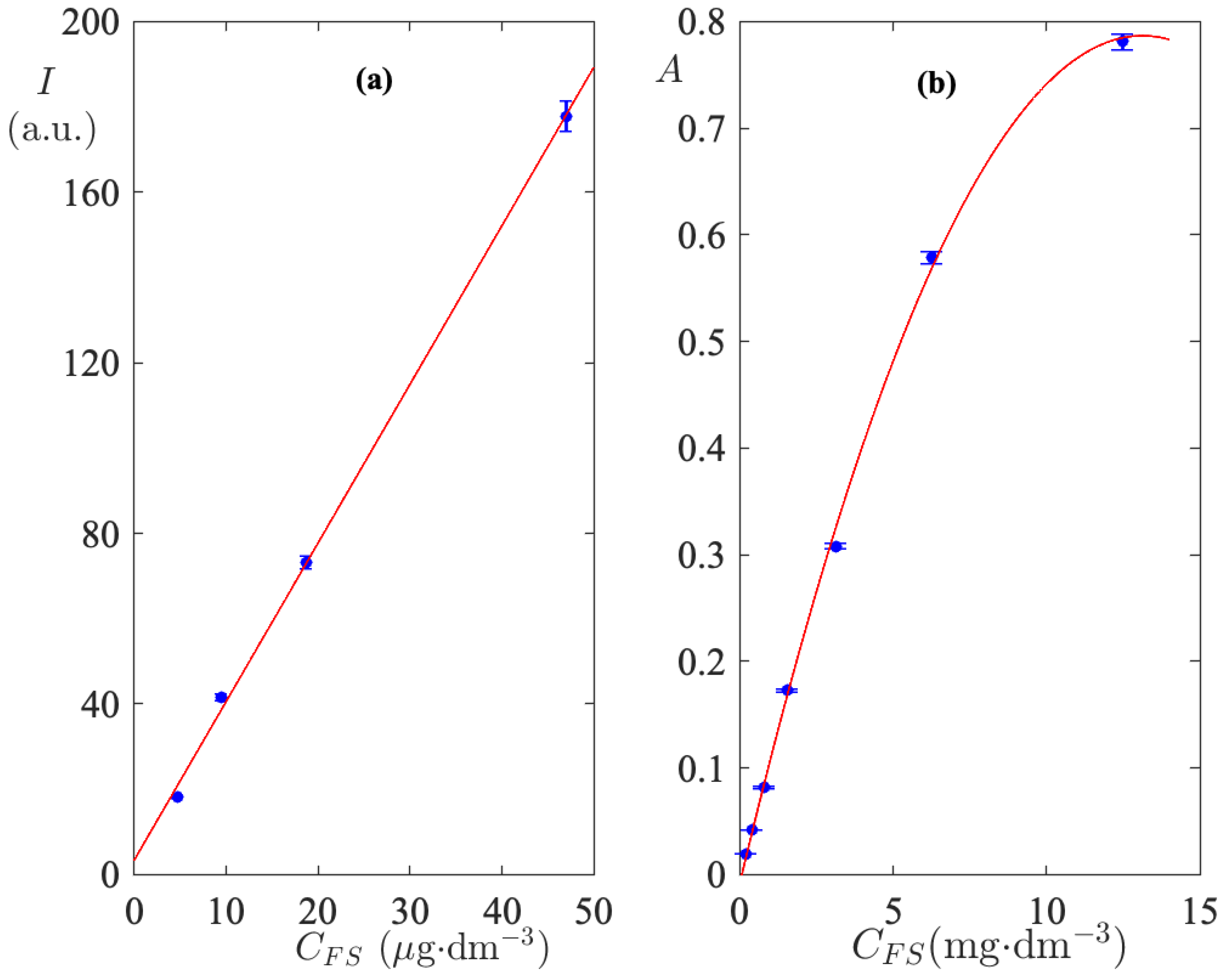

2.4. Calibration Curves

2.5. Kinetics Measurements

3. Results and Discussion

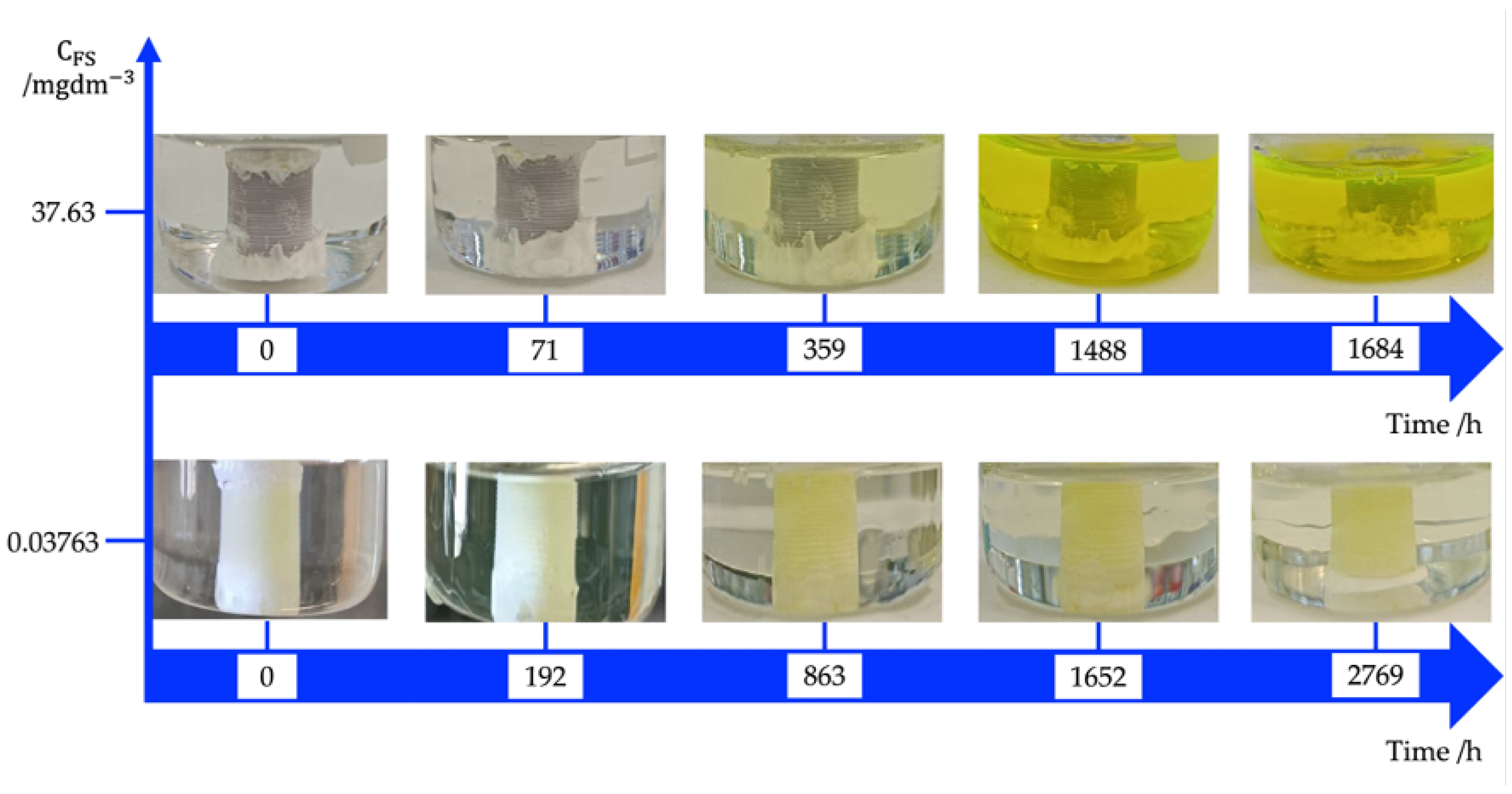

3.1. Osmotic Swelling

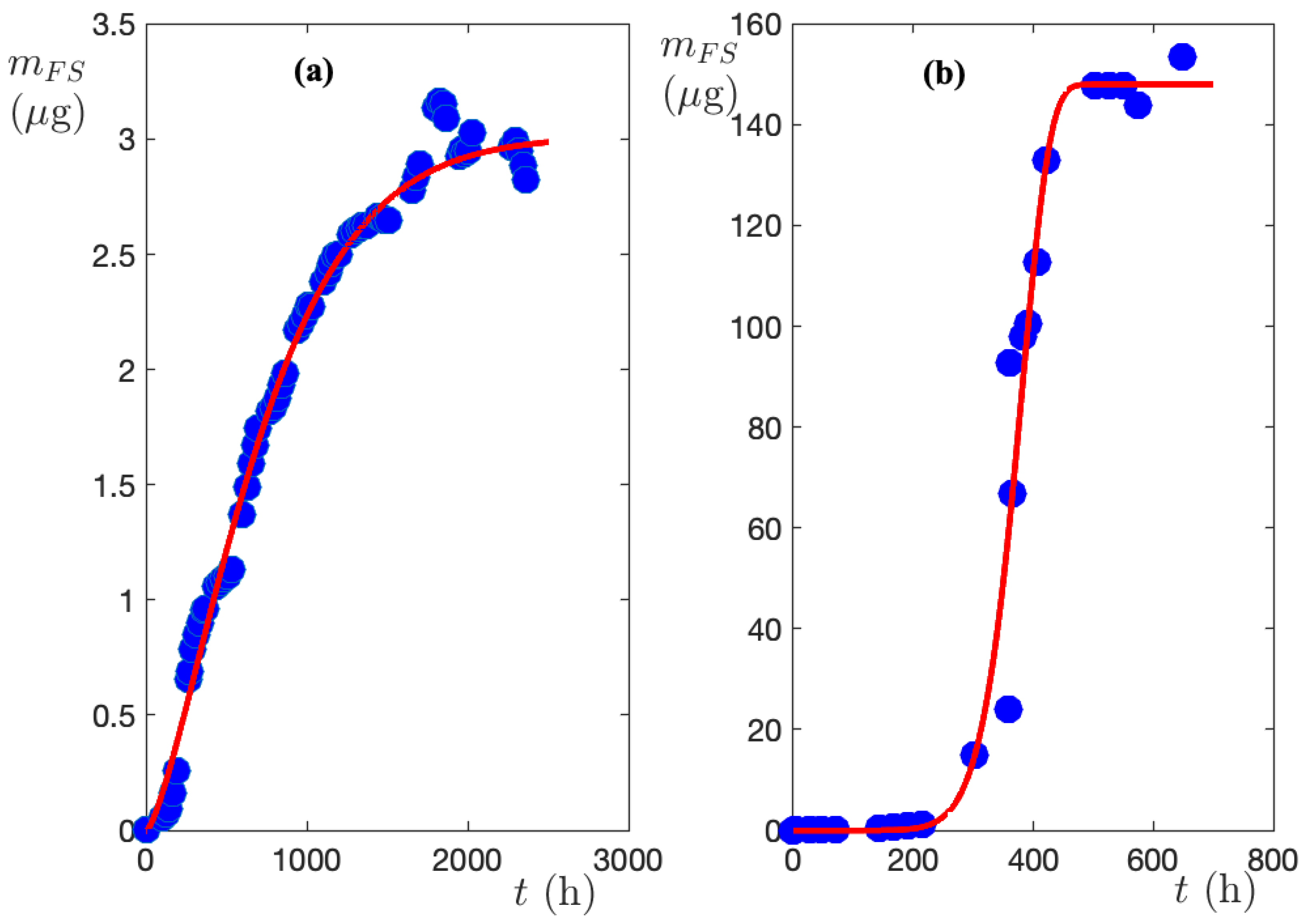

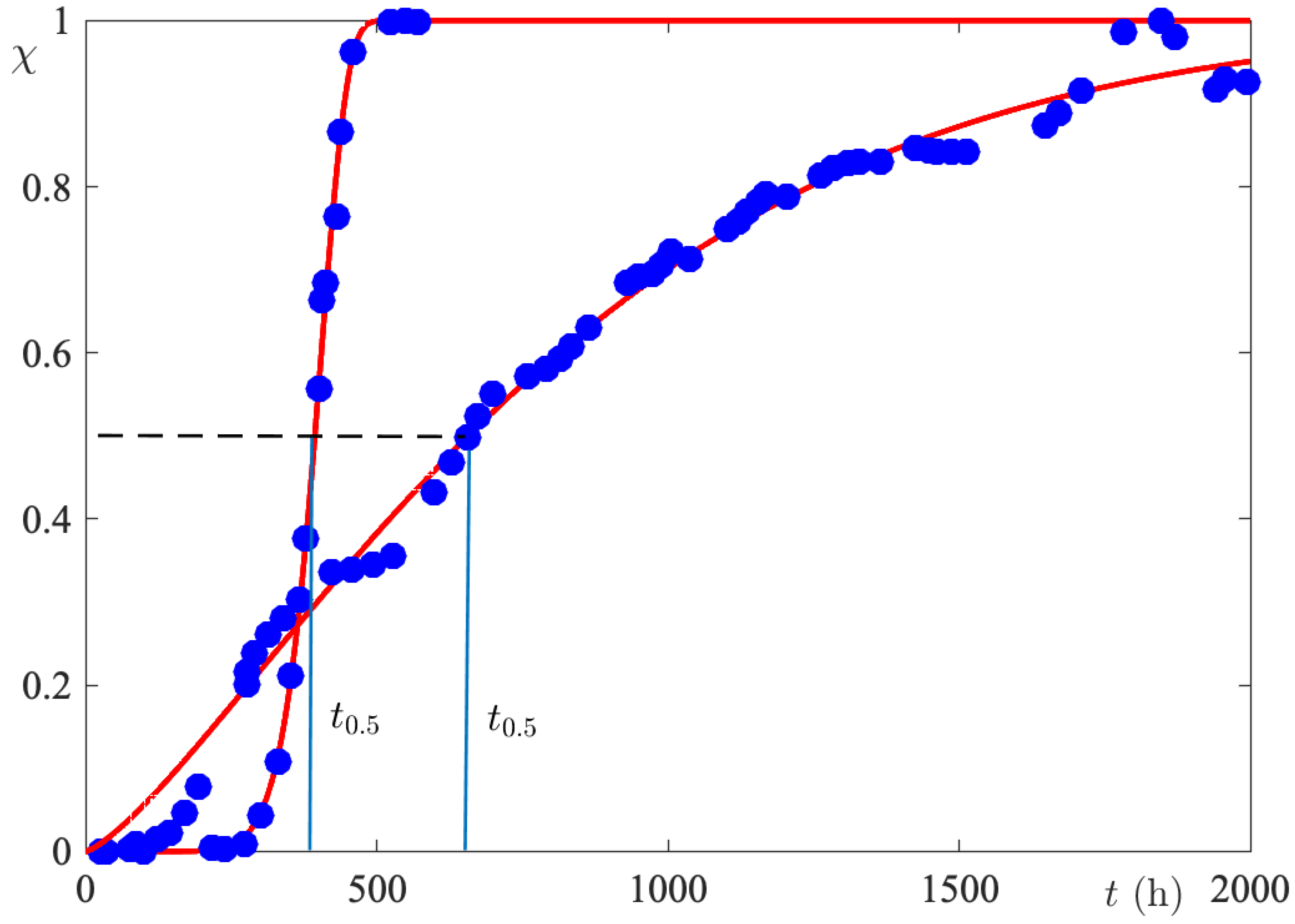

3.2. Kinetic Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FS | fluorescein sodium salt |

| PLA | polylactic acid |

| UPW | ultra pure water |

| root mean square error | |

| LOD | limit of determination |

| LOQ | limit of quantification |

References

- Fink, J.K. A Concise Introduction to Additives for Thermoplastic Polymers; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Peppas, N.A.; Hilt, J.Z.; Khademhosseini, A.; Langer, R. Hydrogels in biology and medicine: From molecular principles to bionanotechnology. Adv. Mater. 2006, 11, 1345–1360. [Google Scholar] [CrossRef]

- Xiao, L.; Wang, B.; Yang, G.; Gauthier, M. Poly (lactic acid)-based biomaterials: Synthesis, modification and applications. Biomed. Sci. Eng. Technol. 2012, 11, 247–282. [Google Scholar]

- Jürger, G.; Richter, W.; Gbureck, T.; Fischer, H.M.; Jüngst, T. Current advances in 3D printing in tissue engineering and regenerative medicine. Curr. Opin. Biotechnol. 2016, 40, 45–51. [Google Scholar]

- Qi, F.; Liao, R.; Shuai, Y.; Pan, H.; Qian, G.; Peng, S.; Shuai, C. A conductive network enhances nerve cell response. Addit. Manuf. 2022, 52, 102694. [Google Scholar] [CrossRef]

- Hölzl, K.; Shengmao, L.; Tytgat, L.; Van Vlierberghe, S.; Gu, L.; Ovsianikov, A. Bioink properties before, during and after 3D bioprinting. Biofabrication 2016, 3, 032002. [Google Scholar] [CrossRef]

- Mandrycky, C.; Wang, Z.; Kim, K.; Kim, D.H. 3D bioprinting for engineering complex tissues. Biotechnol. Adv. 2016, 34, 422–434. [Google Scholar] [CrossRef]

- Hsu, C.-Y.; Rheima, A.M.; Kadhim, M.M.; Ahmed, N.N.; Mohammed, S.H.; Abbas, F.H.; Abed, Z.T.; Mahdi, Z.M.; Abbas, Z.S.; Hachim, S.K.; et al. An overview of nanoparticles in drug delivery: Properties and applications. South Afr. J. Chem. Eng. 2023, 46, 233–270. [Google Scholar] [CrossRef]

- Minó, A.; Lopez, F.; Barbaro, R.; Barile, M.; Ambrosone, L.; Colella, M. Effects of Anionic Liposome Delivery of All–Trans–Retinoic Acid on Neuroblastoma Cell Differentiation. Biomimetics 2024, 9, 257. [Google Scholar] [CrossRef]

- Minó, A.; Cinelli, G.; Paventi, G.; Testa, G.; Passaro, F.; Lopez, F.; Ambrosone, L. Poly (Lactic-co-glycolic) Acid and Phospholipids Hybrid Nanoparticles for Regeneration of Biological Tissue. ChemEngineering 2022, 6, 10. [Google Scholar] [CrossRef]

- Capuana, E.; Lopresti, B.; Yang, F.; Ceraulo, M.; La Carrubba, V. Poly-L-lactic acid (PLLA)-based biomaterials for regenerative medicine: A review on processing and applications. Polymers 2022, 14, 1153. [Google Scholar] [CrossRef]

- Vasconcelos, A.; Freddi, G.; Cavaco-Paulo, A. Biodegradable materials based on silk fibroin and keratin. Biomacromolecules 2008, 9, 1299–1305. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, S.; Eblagon, K.M.; Miranda, F.; Pereira, M.F.R.; Figueiredo, J.L. Towards controlled degradation of poly (lactic) acid in technical applications. Carbon Circ. Econ. 2021, 7, 42. [Google Scholar] [CrossRef]

- DeStefano, V.; Khan, S.; Tabada, A. Applications of PLA in modern medicine. Eng. Regen. 2000, 1, 76–87. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, D.; Kaduri, M.; Poley, M.; Adir, O.; Krinsky, N.; Shainsky-Roitman, J.; Schroeder, A. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem. Eng. J. 2018, 340, 9–14. [Google Scholar] [CrossRef] [PubMed]

- Vlachopoulos, A.; Karlioti, G.; Balla, E.; Daniilidis, V.; Kalamas, T.; Stefanidou, M.; Bikiaris, N.D.; Christodoulou, E.; Koumentakou, I.; Karavas, E.; et al. Poly(Lactic Acid)-Based Microparticles for Drug Delivery Applications: An Overview of Recent Advances Pharmaceutics 2022, 359, 359. Pharmaceutics 2022, 359, 359. [Google Scholar]

- Al-Araji, D.D.; Al-Ani, F.H.; Alsalhy, Q.F. The permeation and separation characteristics of polymeric membranes incorporated with nanoparticles for dye removal and interaction mechanisms between polymer and nanoparticles: A mini review. Eng. Technol. J. 2022, 40, 1399–1411. [Google Scholar] [CrossRef]

- Campaña, F.; Uquillas, J.; Villamarín, E.; Jácome, G.Y.; Estévez, D.R.; Pilaquinga, F. Potencial uso de nanomateriales combinados con ácido poliláctico (pla) en prótesis ortopédicas: Una revisión. infoANALÍTICA 2022, 10, 15–41. [Google Scholar] [CrossRef]

- Cuomo, F.; Palazzo, G.; Ceglie, A.; Lopez, F. Quenching efficiency of pyrene fluorescence by nucleotide monophosphates in cationic micelles. J. Photochem. Photobiol. A Chem. 2009, 202, 21–27. [Google Scholar] [CrossRef]

- Bose, A.; Thomas, I.; Abraham, E. Fluorescence spectroscopy and its applications: A Review. Int. J. Adv. Pharm. Res 2018, 8, 1–8. [Google Scholar]

- Schramm, S.; Weiss, D. Fluorescent heterocycles: Recent trends and new developments. Adv. Heterocycl. Chem. 2019, 128, 103–179. [Google Scholar]

- Yan, F.; Fan, K.; Bai, Z.; Zhang, R.; Zu, F.; Xu, J.; Li, X. Fluorescein applications as fluorescent probes for the detection of analytes. TrAC Trends Anal. Chem. 2017, 97, 15–35. [Google Scholar] [CrossRef]

- Thapa, P.; Bhatt, S.; Mishra, D.; Mehta, D.S. Effect of fluorescein dye concentration in oral cancer tissue: Statistical and spectroscopic analysis. Photodiagnosis Photodyn. Ther. 2023, 44, 103889. [Google Scholar] [CrossRef]

- Ramtohul, P.; Freund, K.B.; Lee, W.K. Diagnostic and Therapeutic Challenges. Retina 2021, 41, 1786–1789. [Google Scholar] [CrossRef] [PubMed]

- Johonson, R.N.; McDonald, H.R.; Schatz, H. Rash, fever, and chills after intravenous fluorescein angiography. Am. J. Ophthalmol. 1998, 126, 837–838. [Google Scholar] [CrossRef] [PubMed]

- Di Nezza, F.; Zeppa, L.; Costagliola, C.; Bufalo, G.; Ambrosone, L. A physicochemical study of ophthalmological vital dyes: From dimerization equilibrium in buffer solution to their liposomal dispersions. Dyes Pigment. 2019, 162, 680–687. [Google Scholar] [CrossRef]

- Takayama, T.; Wanibuchi, Y.; Suma, H.; Terada, Y.; Saito, T.; Fukuda, S.; Furuta, S. Intraoperative coronary angiography using fluorescein: Basic studies and clinical application. Vasc. Surg. 1992, 26, 193–199. [Google Scholar] [CrossRef]

- Jhanji, V.; Young, A.L.; Mehta, J.S.; Sharma, N.; Agarwal, T.; Vajpayee, R.B. Management of corneal perforation. Surv. Ophthalmol. 2011, 56, 522–538. [Google Scholar] [CrossRef]

- Berginc, K.; Žakelj, S.; Levstik, L.; Uršič, D.; Kristl, A. Fluorescein transport properties across artificial lipid membranes, Caco-2 cell monolayers and rat jejunum. Eur. J. Pharm. Biopharm. 2007, 66, 281–285. [Google Scholar] [CrossRef]

- Barletta, M.; Moretti, P.; Pizzi, E.; Puopolo, M.; Tagliaferri, V.; Vesco, S. Engineering of Poly Lactic Acids (PLAs) for melt processing: Material structure and thermal properties. J. Appl. Polym. Sci. 2017, 134, 44504. [Google Scholar] [CrossRef]

- Chung, C.I. Extrusion of Polymers: Theory & Practice; Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2019. [Google Scholar]

- Gupta, A.P.; Kumar, V. New emerging trends in synthetic biodegradable polymers–Polylactide: A critique. Eur. Polym. J. 2007, 43, 4054–4074. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, X.F.; Gao, G.; Yonezawa, T.; Cui, X. 3D bioprinting and the current applications in tissue engineering. Biotechnol. J. 2017, 12, 1000734. [Google Scholar]

- Huang, Y.; Li, X.; Poudel, A.J.; Zhang, W.; Xiao, L. Hydrogel-based bioinks for 3D bioprinting articular cartilage: A comprehensive review with focus on mechanical reinforcement. Appl. Mater. Today 2022, 129, 101668. [Google Scholar] [CrossRef]

- Guideline, I.H. Validation of analytical procedures: Text and methodology. Q2 (R1) 2005, 1, 5. [Google Scholar]

- Minó, A.; Zeppa, L.; Ambrosone, L. Excess Absorbance as a Novel Approach for Studying the Self-Aggregation of Vital Dyes in Liquid Solution. Int. J. Mol. Sci. 2023, 24, 1645. [Google Scholar] [CrossRef]

- Minó, A.; Cinelli, G.; Lopez, F.; Ambrosone, L. Optical behavior of nile red in organic and aqueous media environments. Appl. Sci. 2023, 13, 638. [Google Scholar] [CrossRef]

- Sakai, T. Swelling and deswelling. Phys. Polym. Gels 2020, 77–107. [Google Scholar]

- Lu, W.; Park, T.G. Protein release from poly (lactic-co-glycolic acid) microspheres: Protein stability problems. PDA J. Pharm. Sci. Technol. 1995, 49, 13–19. [Google Scholar]

- Jonnalagadda, S.; Robinson, D.H. A bioresorbable, polylactide reservoir for diffusional and osmotically controlled drug delivery. AAPS PharmSciTech 2000, 1, 29–37. [Google Scholar] [CrossRef]

- Bufalo, G.; Ambrosone, L. Method for Determining the Activation Energy Distribution Function of Complex Reactions by Sieving and Thermogravimetric Measurements. J. Phys. Chem. B 2016, 120, 244–249. [Google Scholar] [CrossRef]

- Aravkin, A.Y.; Baraldi, R.; Orban, D. A Levenberg-Marquardt method for nonsmooth regularized least squares. arXiv 2023, arXiv:2301.02347. [Google Scholar]

- Silori, Y.; De, A.K. Tuning effect of local environment to control mechanism of fluorescence depolarization: Rotational diffusion and resonance energy transfer within homo-aggregates of xanthenes. J. Photochem. Photobiol. A Chem. 2019, 377, 198–206. [Google Scholar] [CrossRef]

- Lakowicz, J.R. Principles of Fluorescence Spectroscopy; Springer: Boston, MA, USA, 2006. [Google Scholar]

- Tümer, E.H.; Erbil, H.Y. Extrusion-based 3D printing applications of PLA composites: A review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

| Dye Initial Concentration 0.03763 gdm−3 | Dye Initial Concentration 37.63 gdm−3 | |

|---|---|---|

| 3.0 ± 0.2 | 147 ± 6 | |

| 808 ± 4 | 385 ± 6 | |

| 1.37 ± 0.09 | 9 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Nigris, A.; Minó, A.; Cinelli, G.; Colella, M.; Lopez, F.; Ambrosone, L. Kinetic Model of Fluorescein Release through Bioprinted Polylactic Acid Membrane. Biomimetics 2024, 9, 342. https://doi.org/10.3390/biomimetics9060342

de Nigris A, Minó A, Cinelli G, Colella M, Lopez F, Ambrosone L. Kinetic Model of Fluorescein Release through Bioprinted Polylactic Acid Membrane. Biomimetics. 2024; 9(6):342. https://doi.org/10.3390/biomimetics9060342

Chicago/Turabian Stylede Nigris, Antonio, Antonio Minó, Giuseppe Cinelli, Matilde Colella, Francesco Lopez, and Luigi Ambrosone. 2024. "Kinetic Model of Fluorescein Release through Bioprinted Polylactic Acid Membrane" Biomimetics 9, no. 6: 342. https://doi.org/10.3390/biomimetics9060342

APA Stylede Nigris, A., Minó, A., Cinelli, G., Colella, M., Lopez, F., & Ambrosone, L. (2024). Kinetic Model of Fluorescein Release through Bioprinted Polylactic Acid Membrane. Biomimetics, 9(6), 342. https://doi.org/10.3390/biomimetics9060342