Research and Simulation on the Development of a Hydraulic Prop Support System of Powered Roof Support to Increase Work Safety

Abstract

1. Introduction

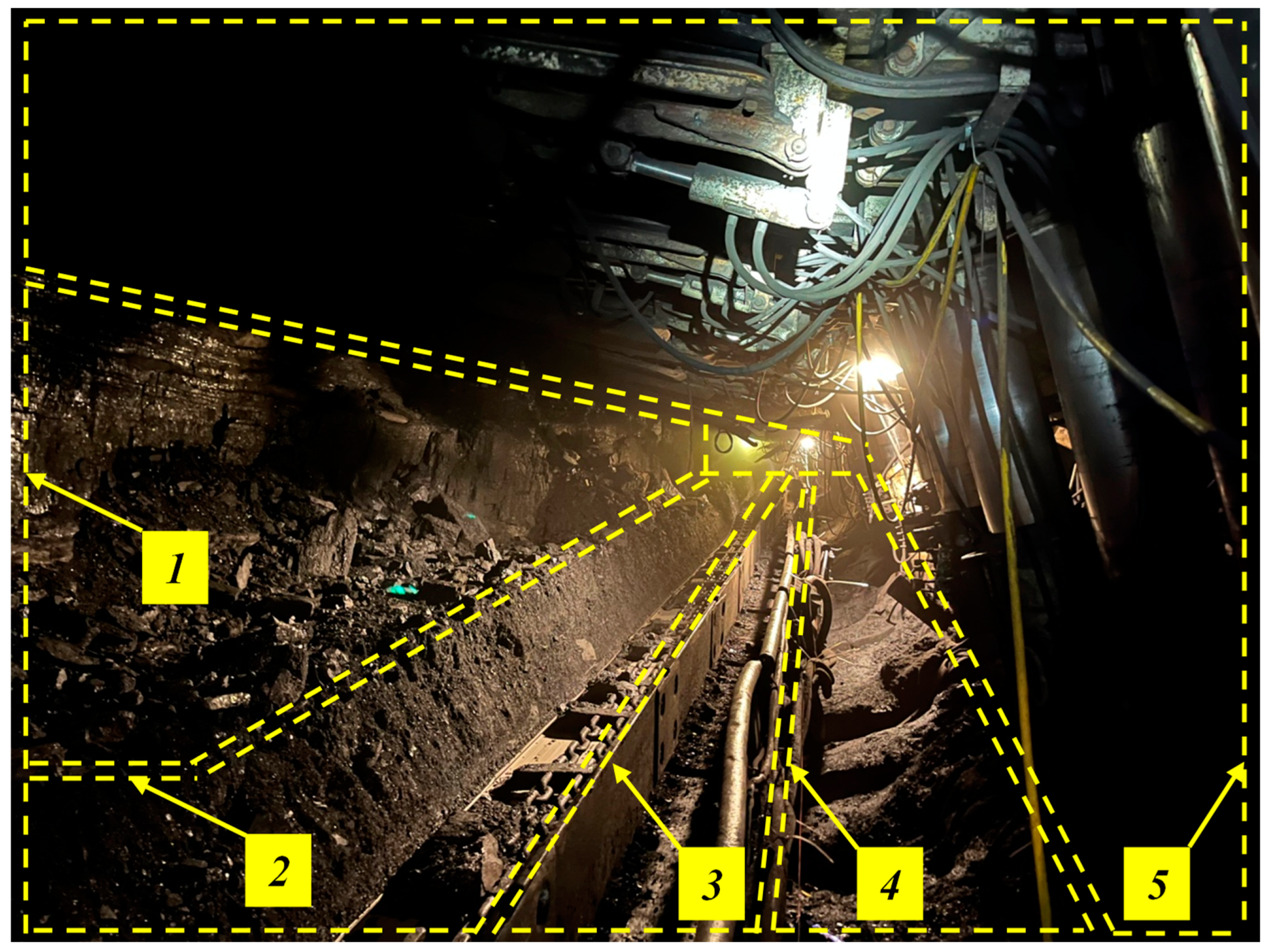

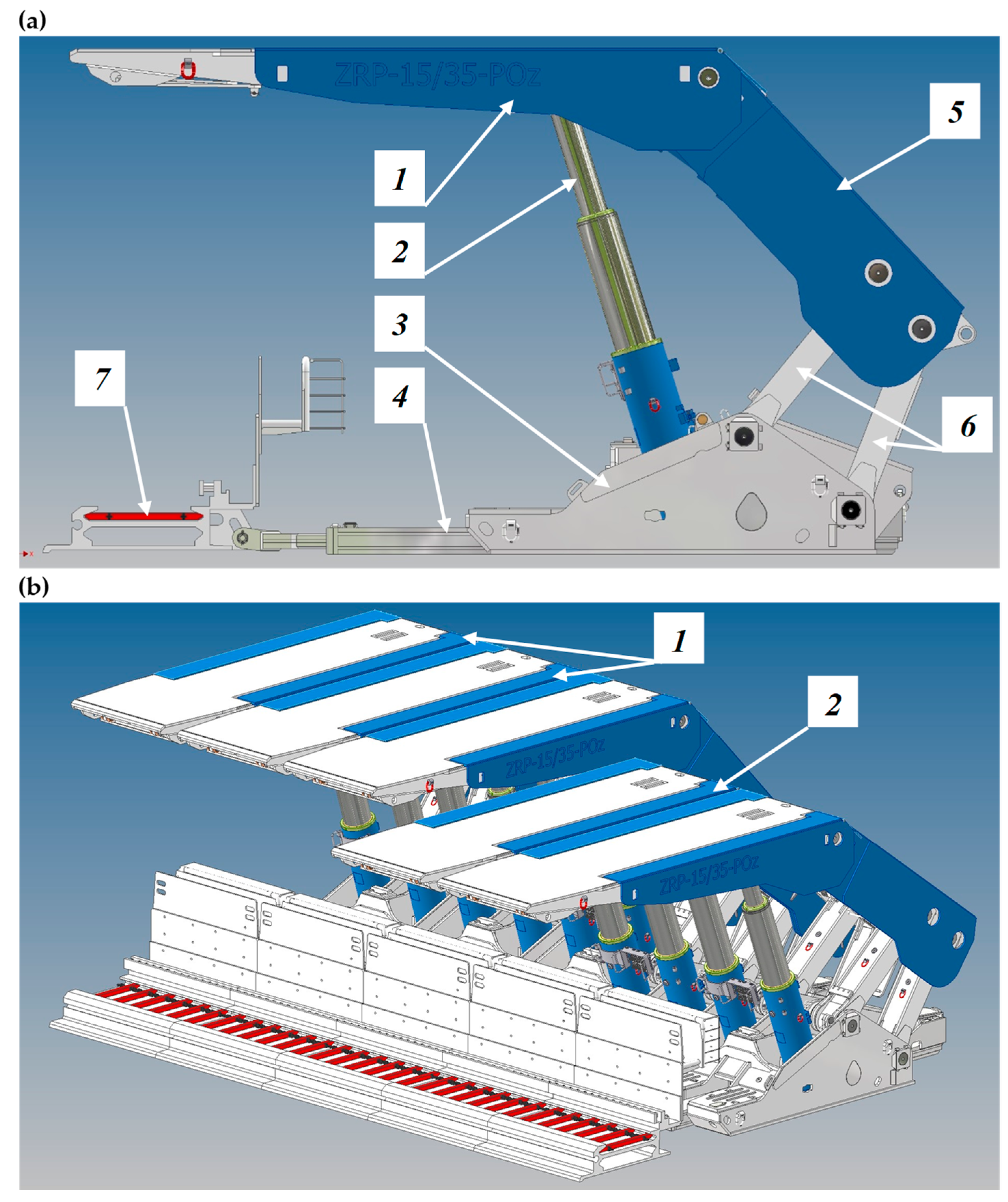

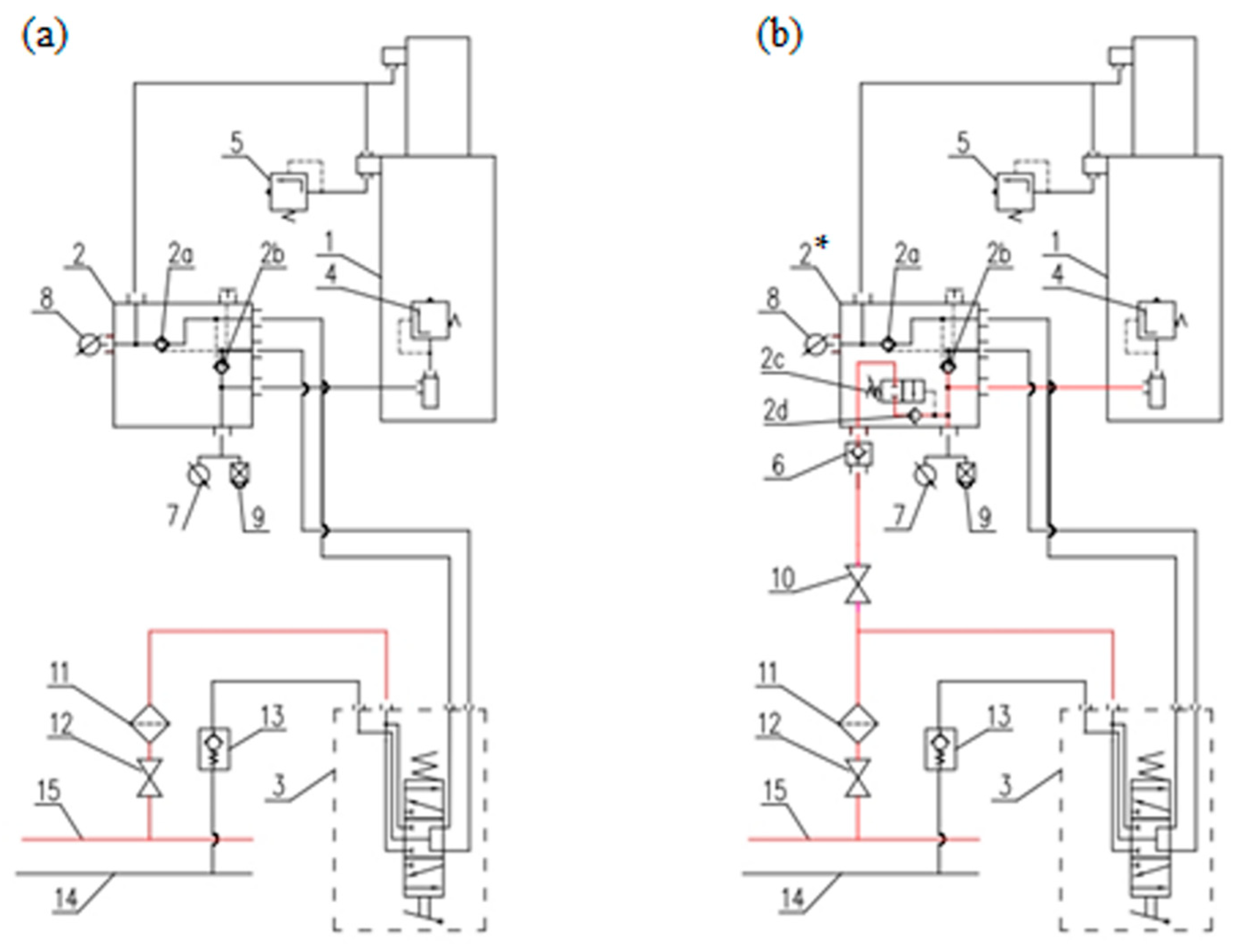

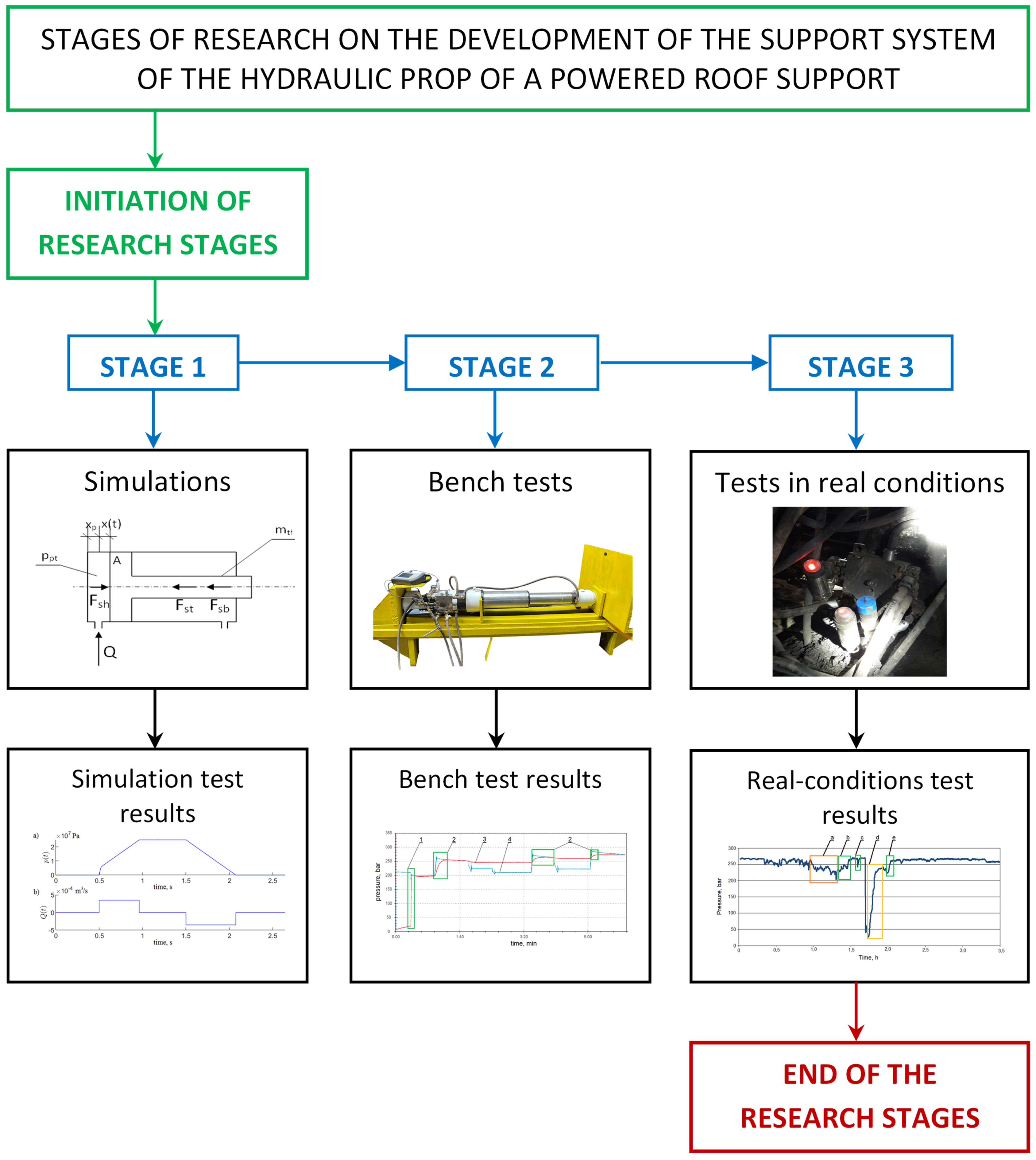

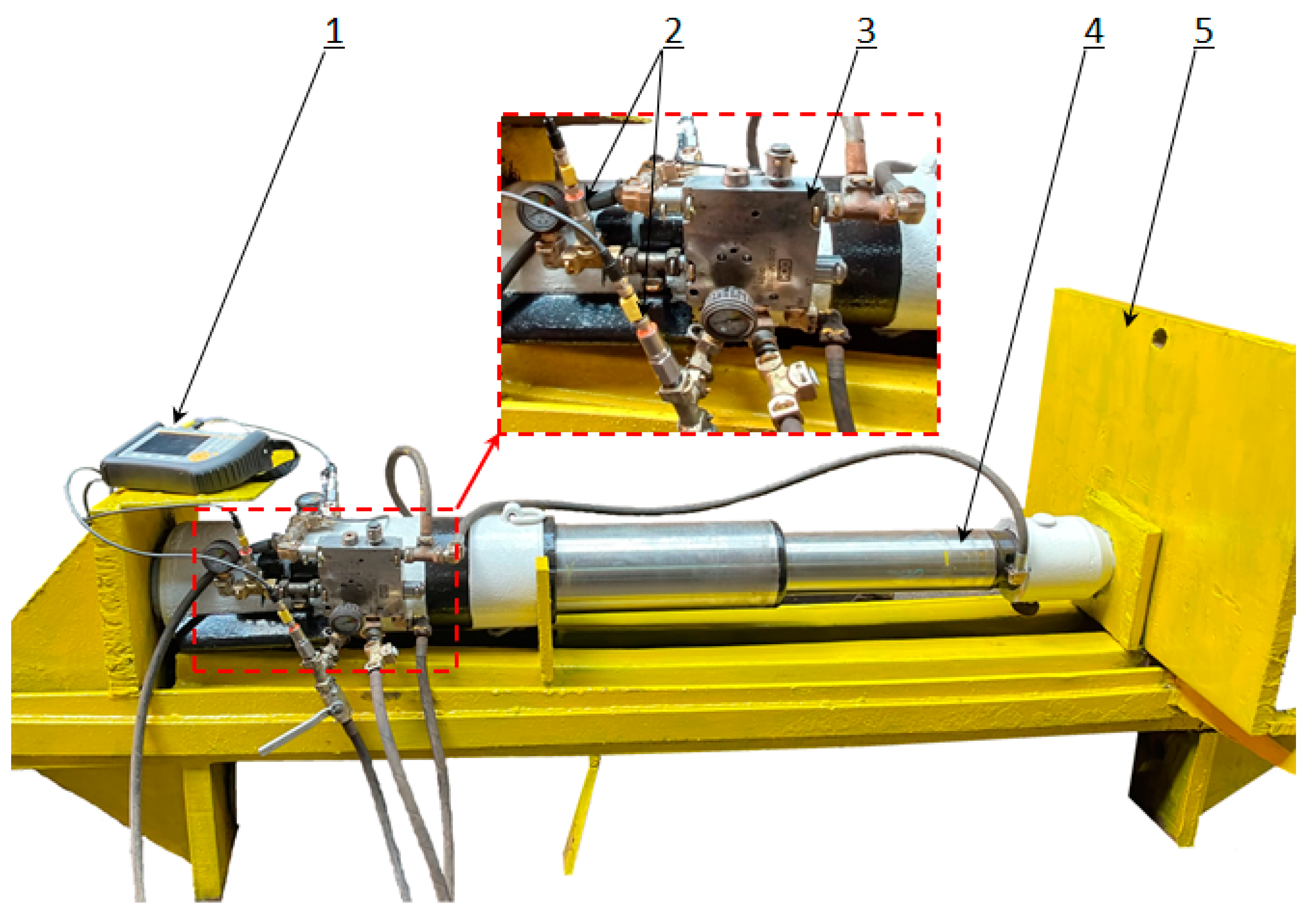

2. Materials and Methods

2.1. Proposed Change in Hydraulic Prop Support System

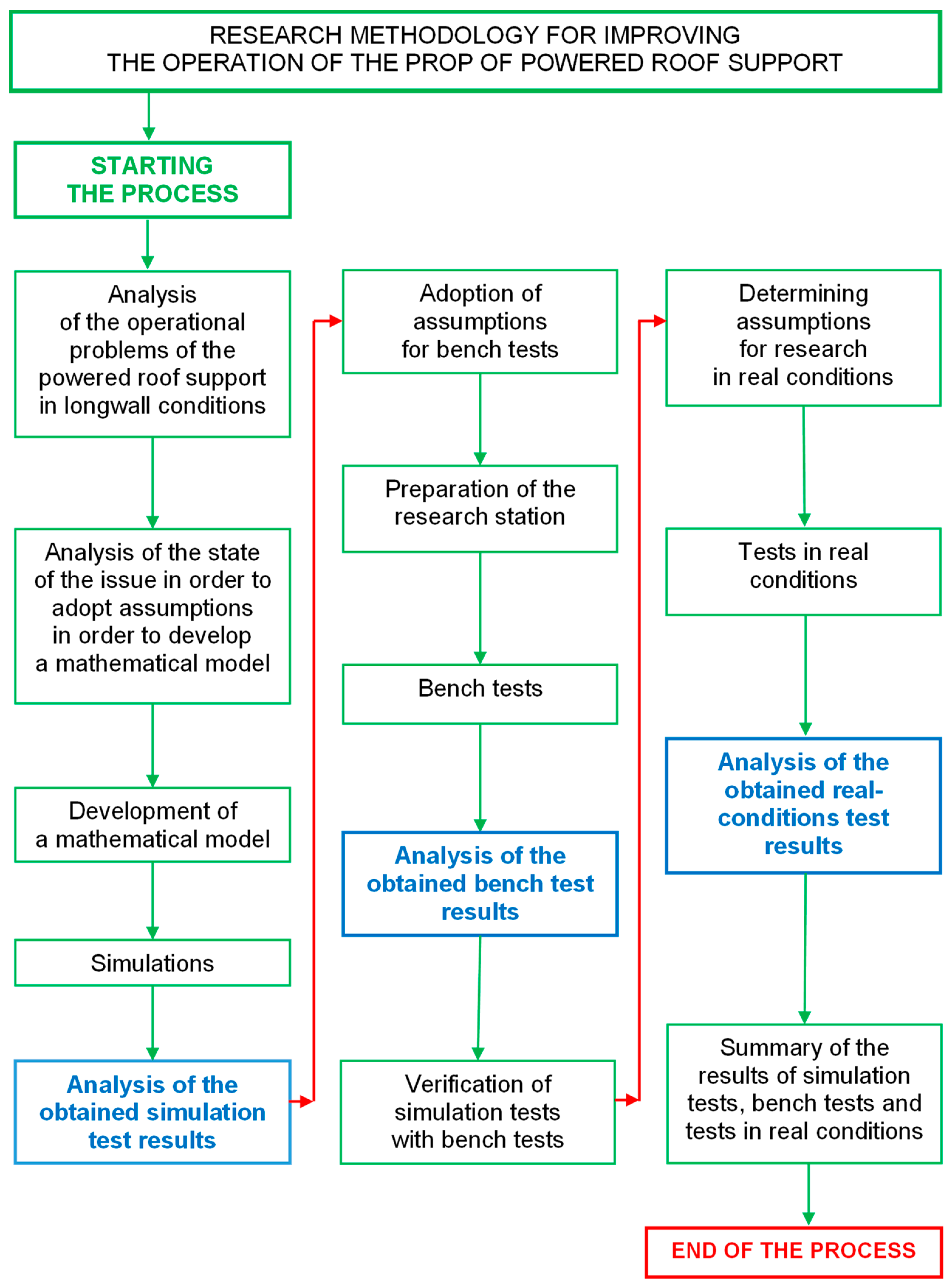

2.2. Research Methodology

3. Results

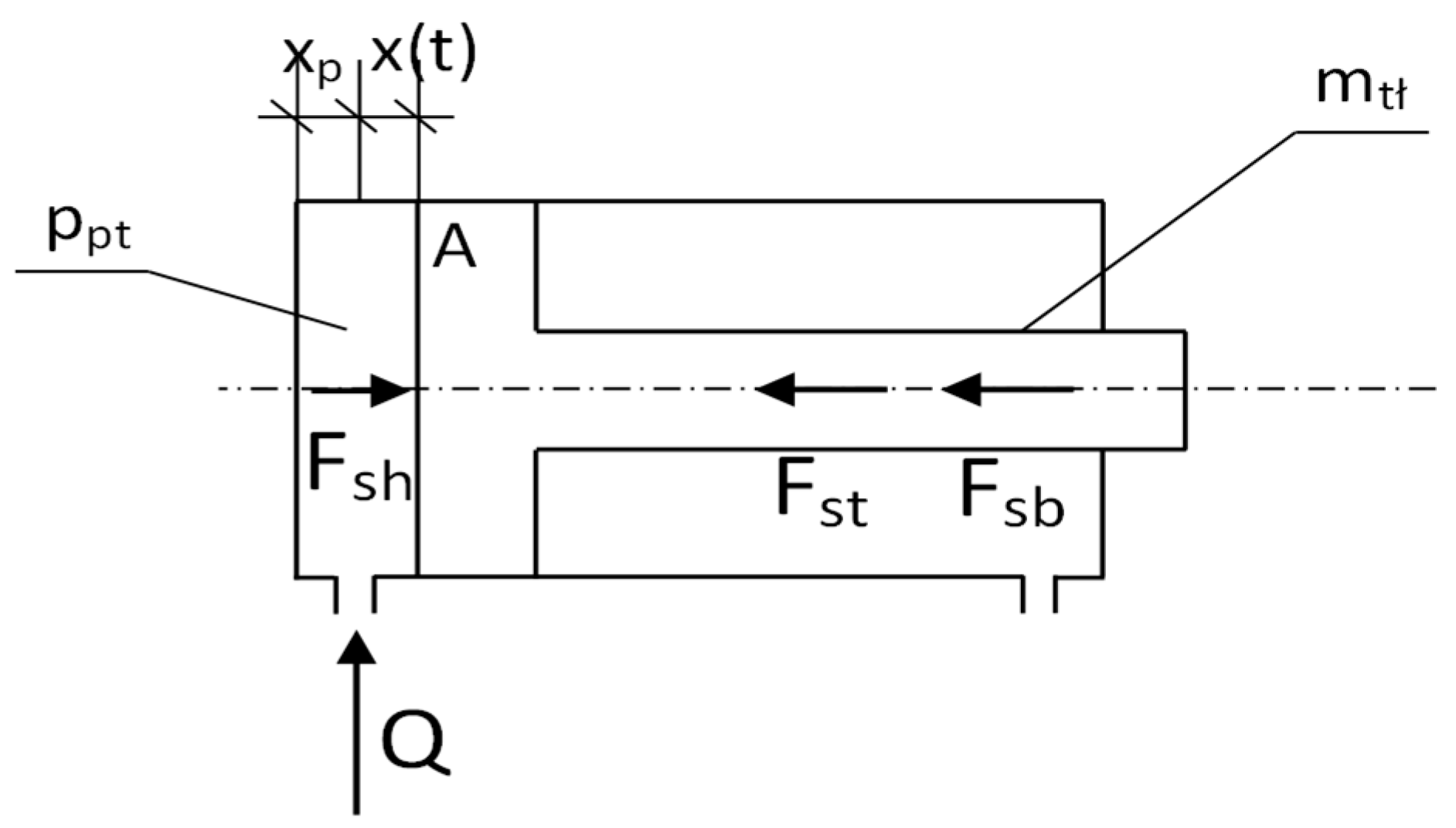

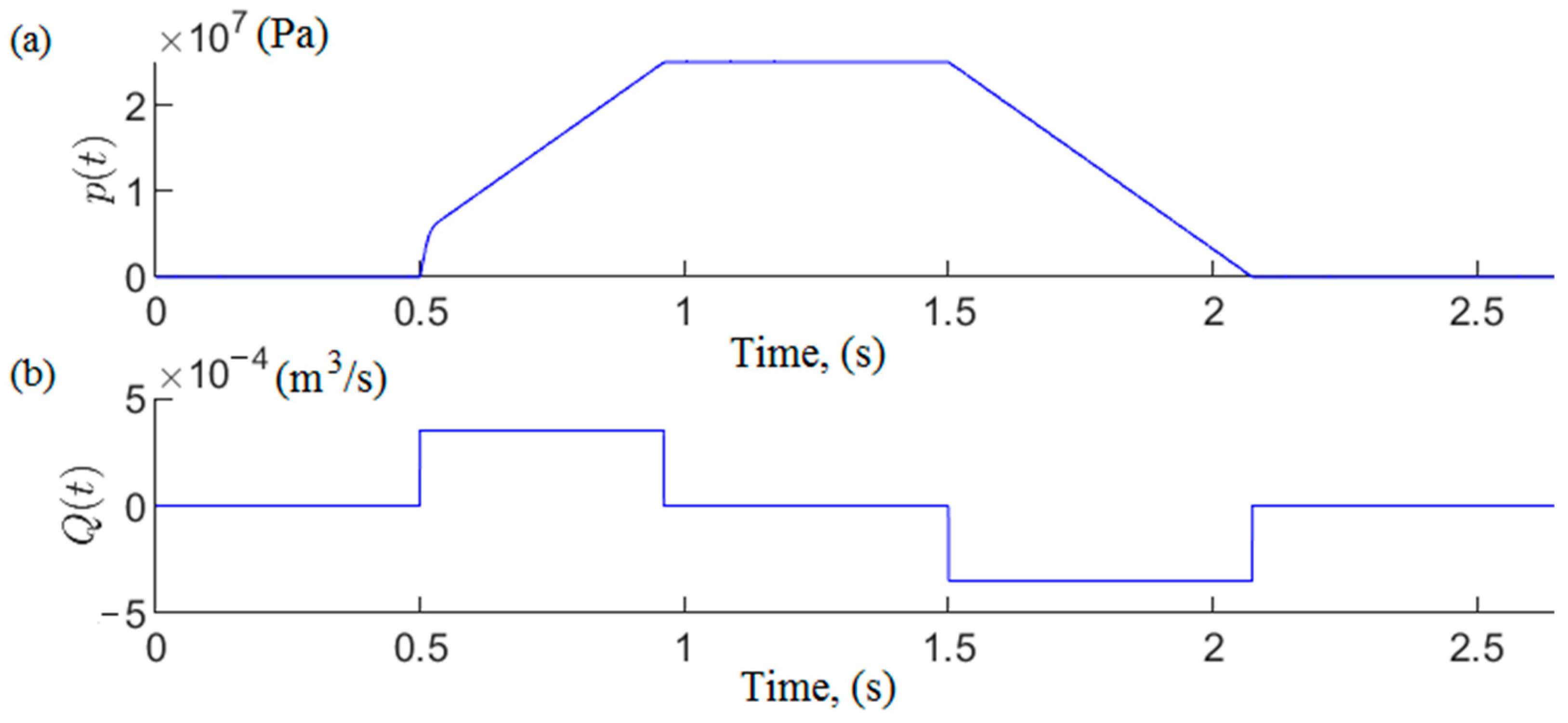

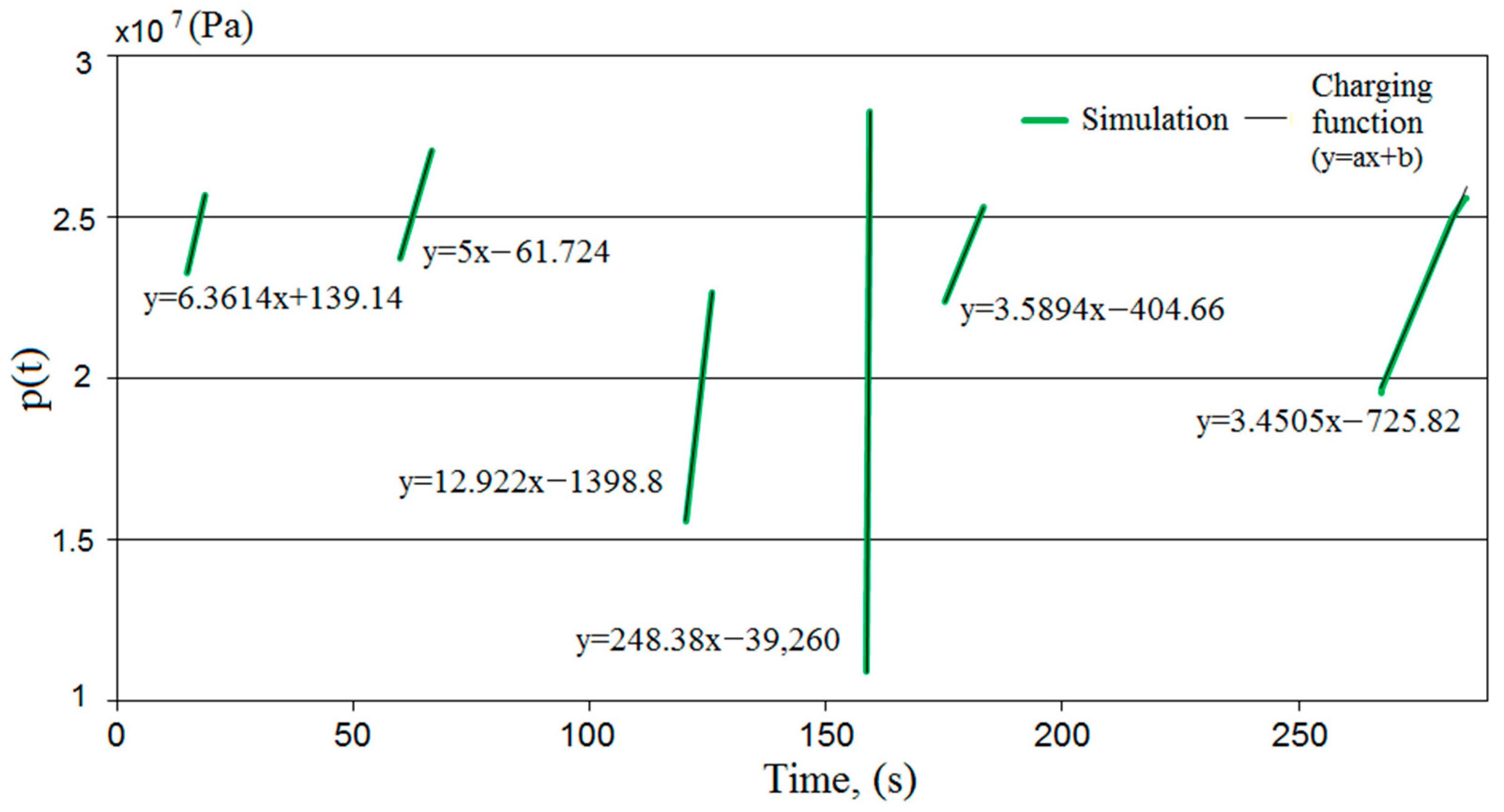

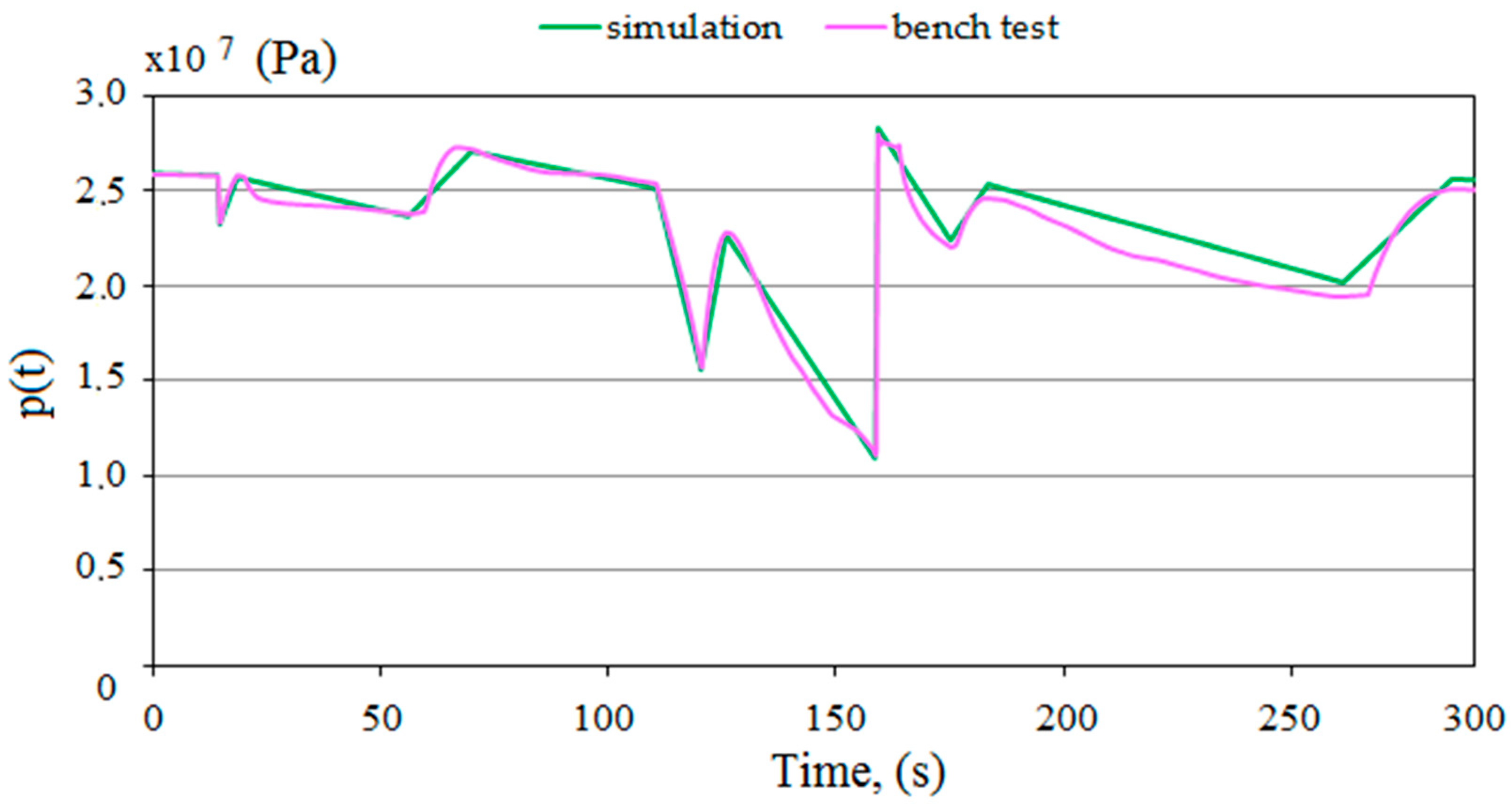

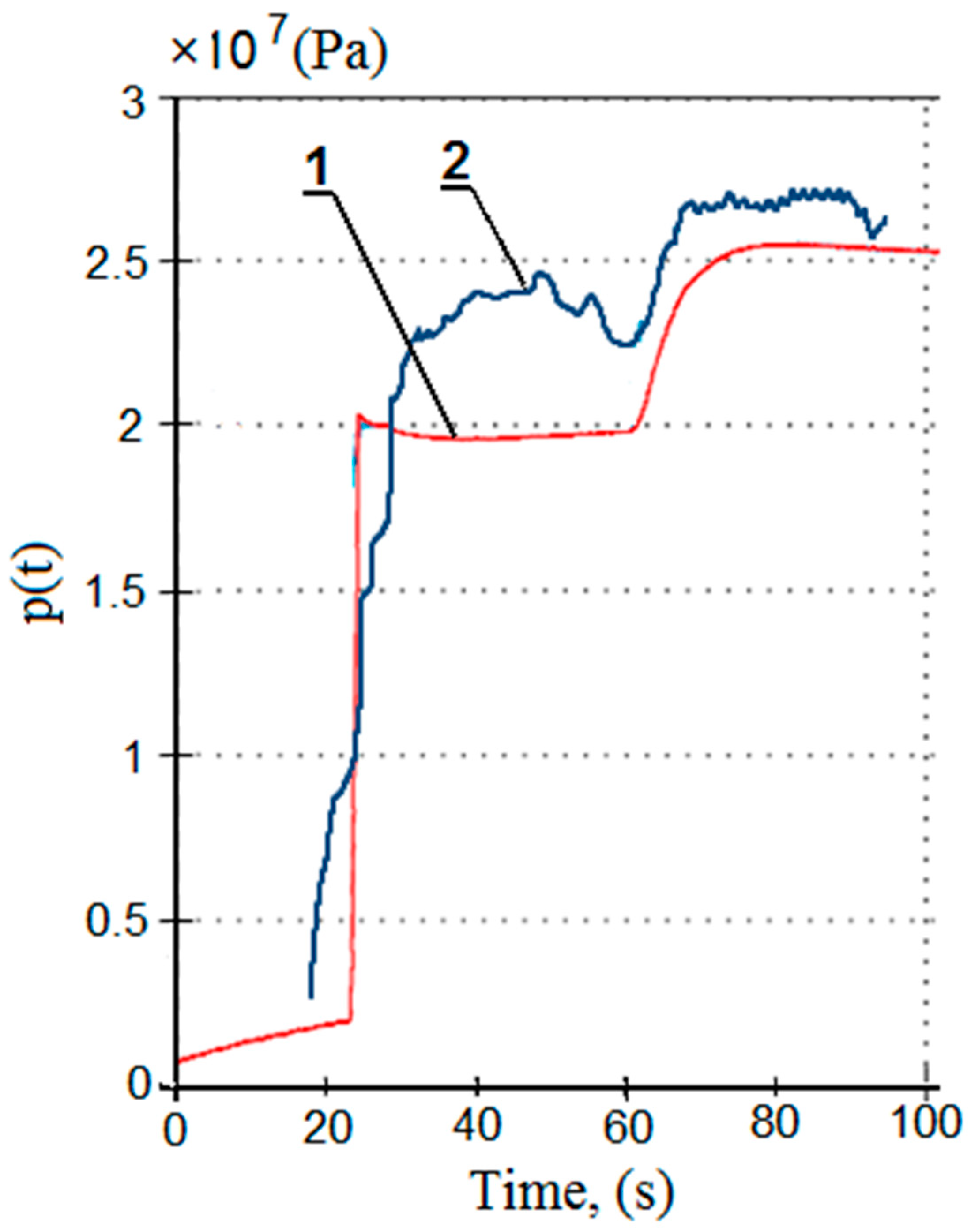

3.1. Simulation Studies

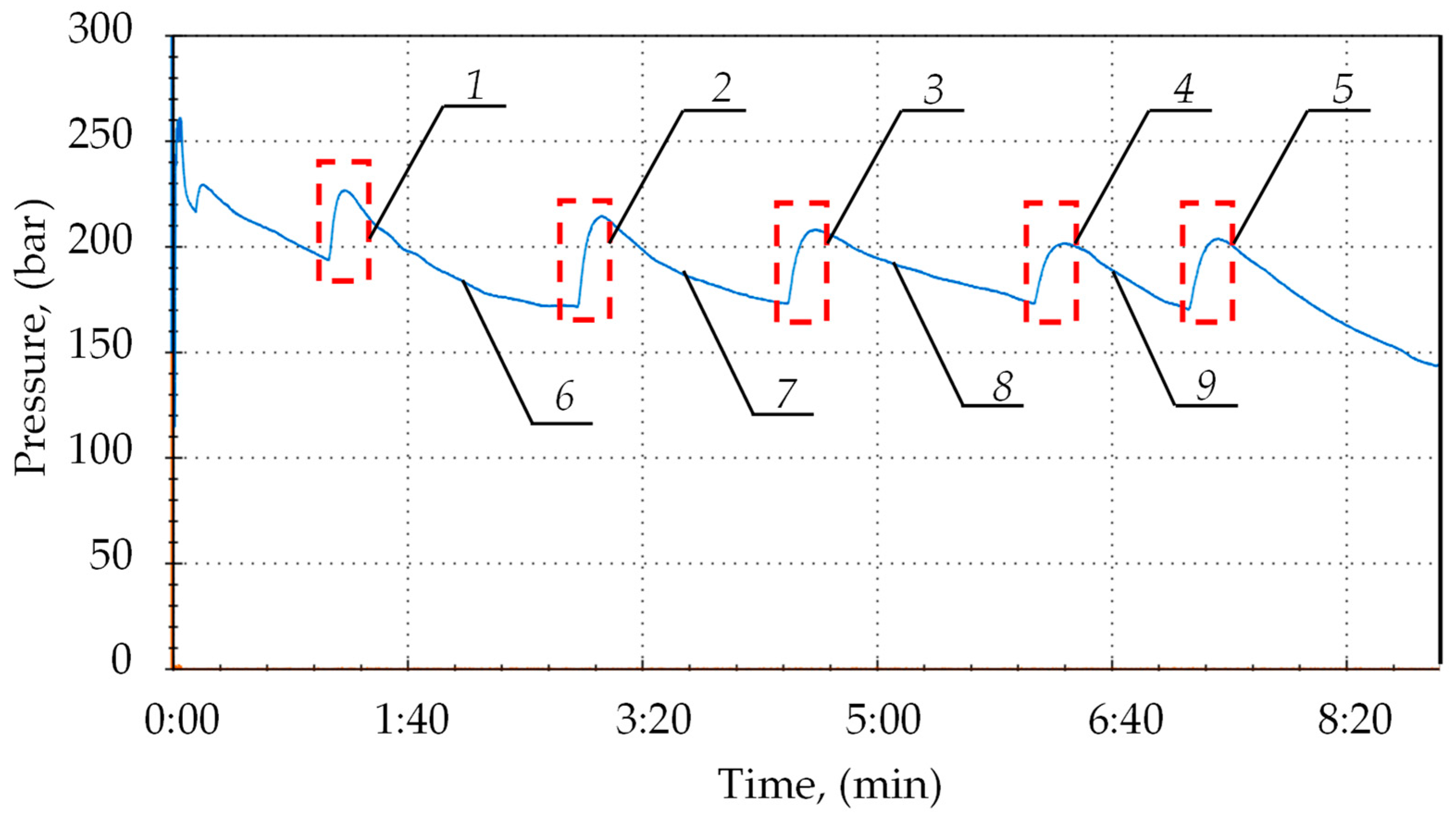

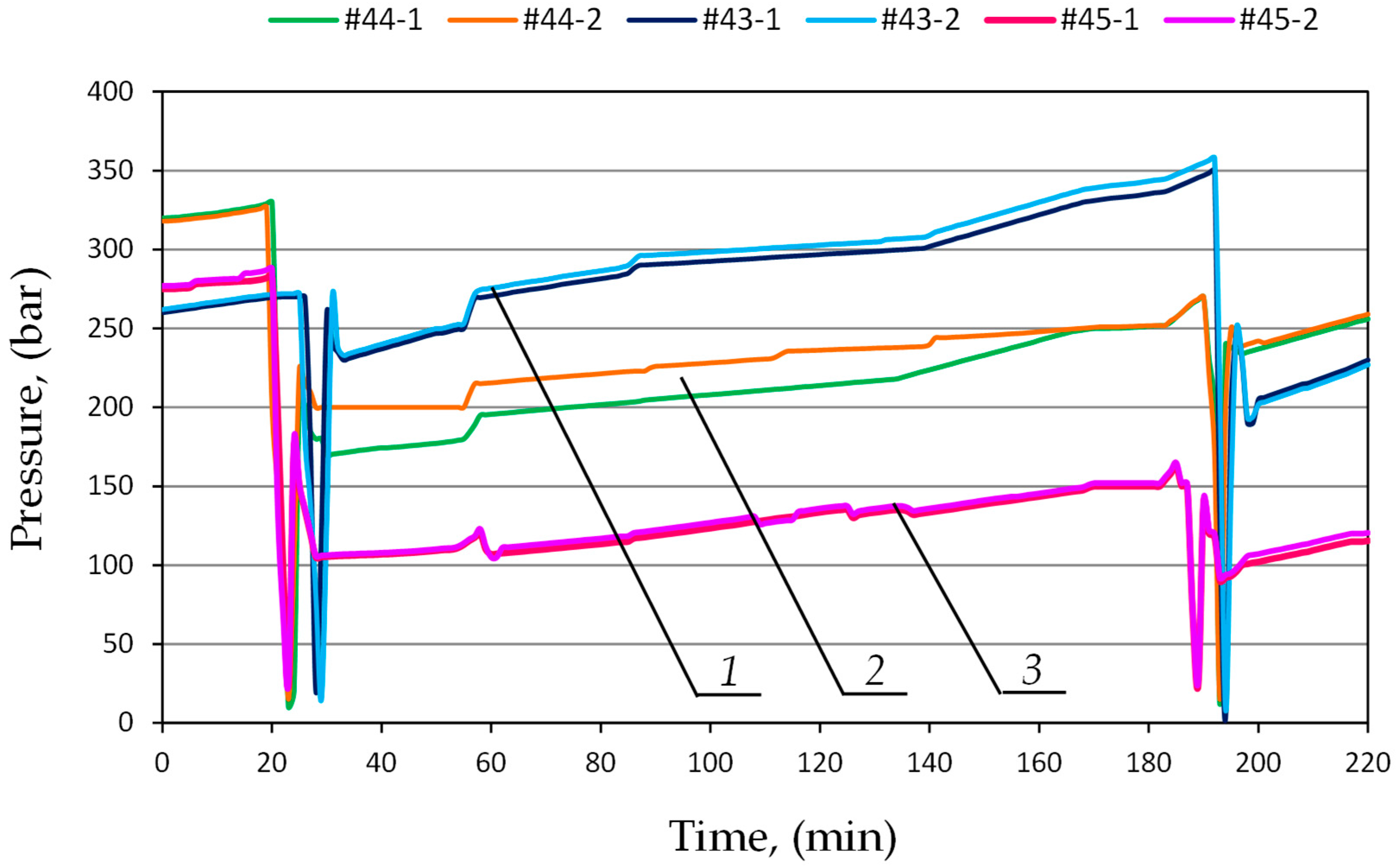

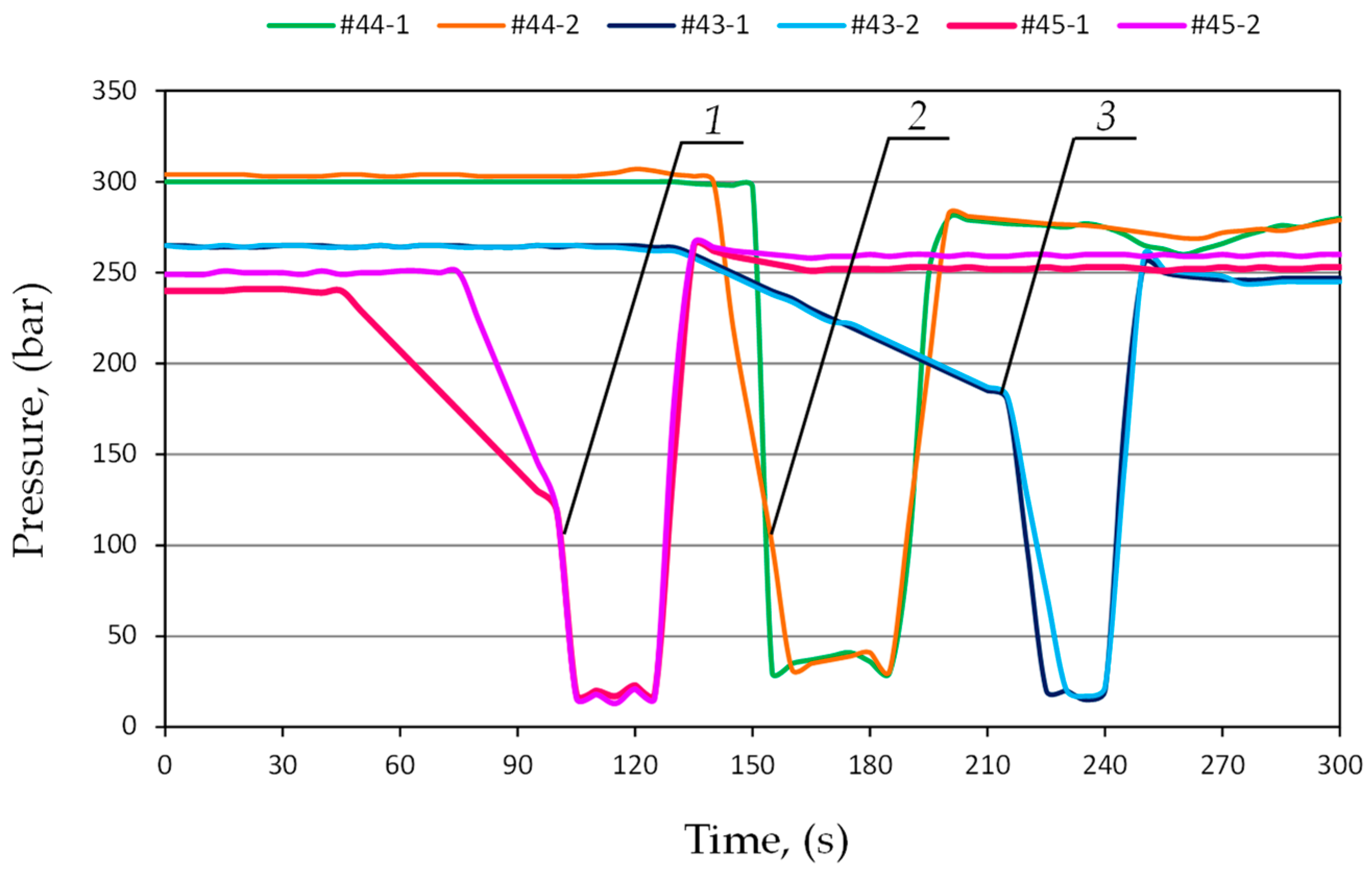

3.2. Bench Tests

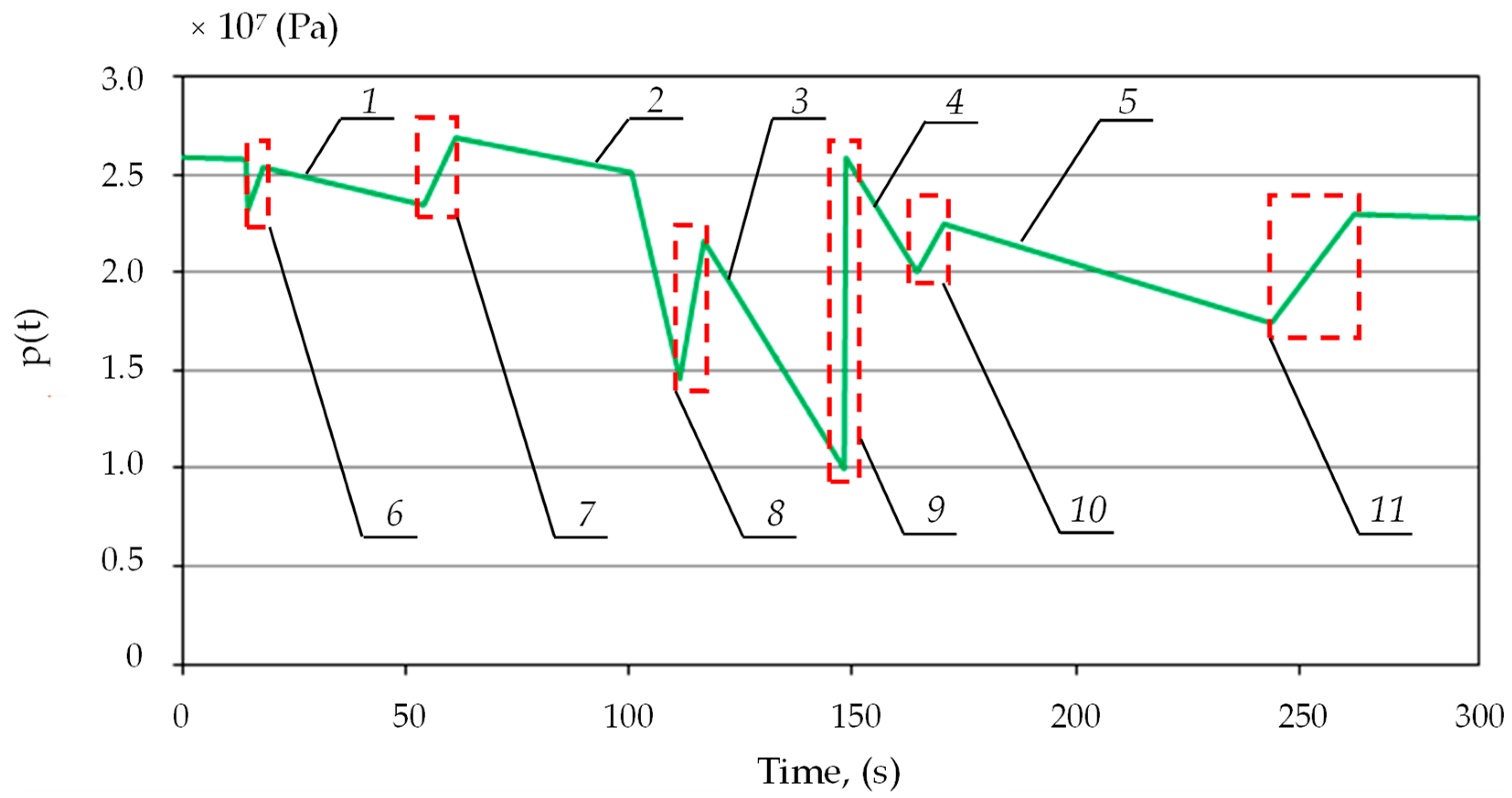

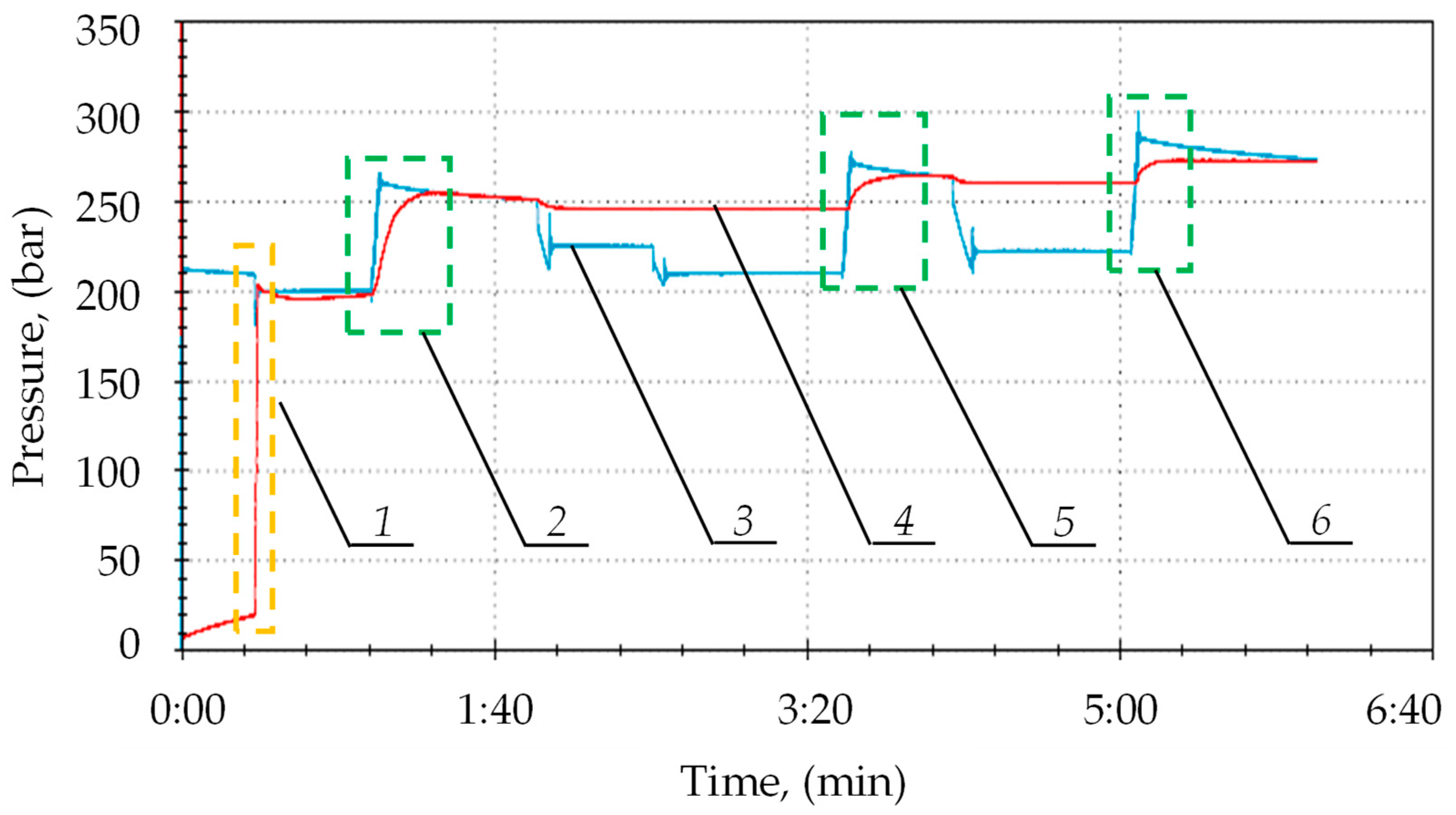

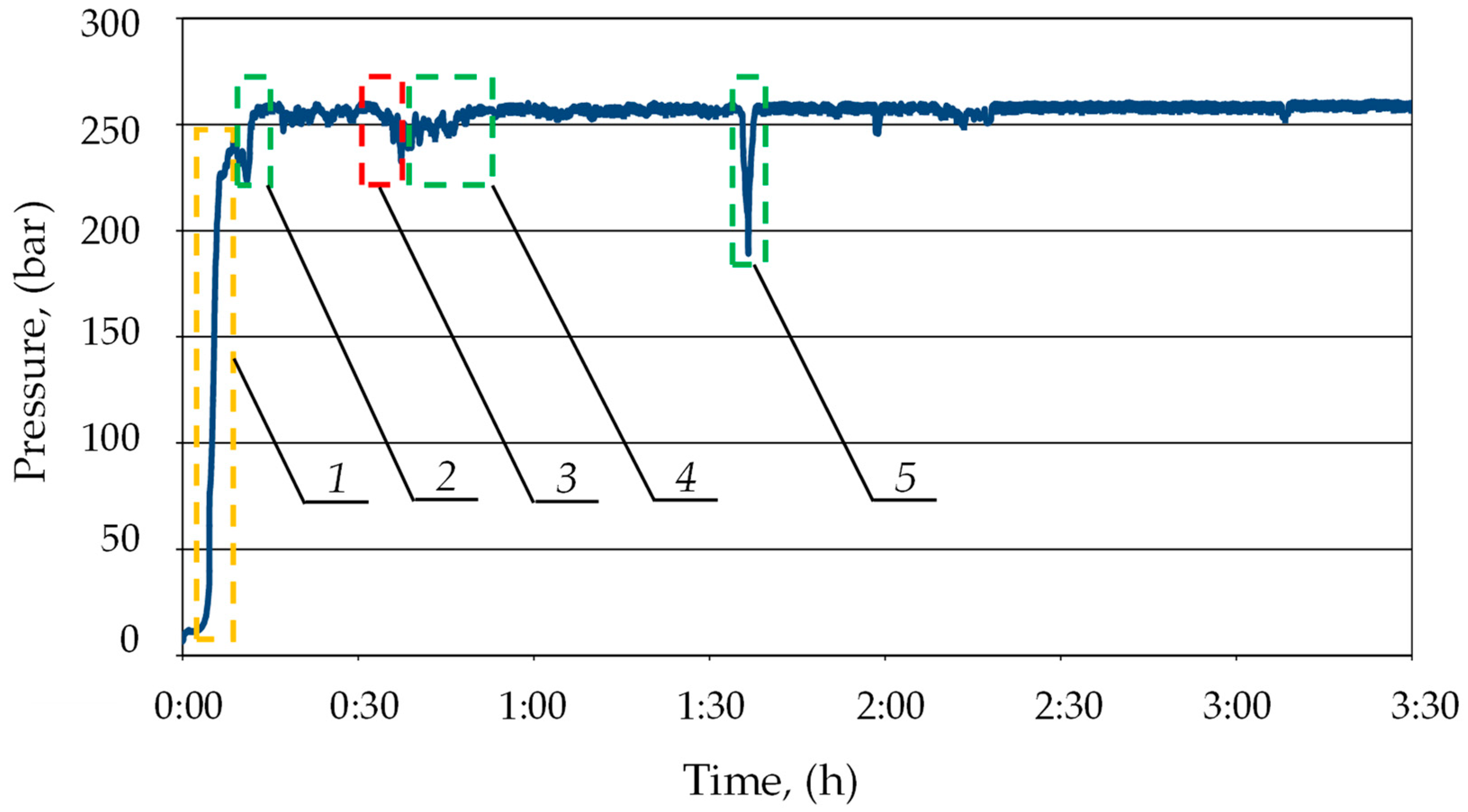

3.3. Tests in Real Conditions

4. Discussion

5. Conclusions

- (1)

- At the stage of creating the new prototype, mathematical modeling and simulation studies allowed us to determine its performance characteristics. The mathematical model and the simulation studies made it possible to quickly verify the correctness of the assumptions. Studies have shown that the proposed pressure charging function meets the accepted assumptions.

- (2)

- During the bench tests, no problems were found in implementing the charging function. Using a double block with automatic pressure charging ensured that the required pressure value was maintained in the sub-piston space of the prop. Studies have shown that the double block should achieve the required operating parameters under real conditions.

- (3)

- The results of the tests under real conditions confirmed the correctness of the proposed changes for introducing a double block with charging into the hydraulic system of the powered roof support. The prototype block performed its functions correctly under real conditions, minimizing the effects of internal leaks and ensuring that the required load-carrying capacity was reached and maintained.

- (4)

- Comparing the work of the standard block with the prototype block, the authors’ solution ensures uniform work of the powered roof support. Powered roof support sections operate at similar pressures. After using the prototype block, the sections achieved the required initial and working load-carrying capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiaozhen, W.; Jialin, X.; Weibing, Z.; Yingchun, L. Roof pre-blasting to prevent support crushing and water inrush accidents. Int. J. Min. Sci. Tech. 2012, 22, 379–384. [Google Scholar]

- Buyalich, G.; Buyalich, K.; Byakov, M. Factors Determining the Size of Sealing Clearance in Hydraulic Legs of Powered Supports. E3S Web Conf. 2017, 21, 3018. [Google Scholar] [CrossRef]

- Korbiel, T.; Stepien, B.; Batko, W.; Pawlik, P.; Blaut, J. Recognition of the 24-hour Noise Exposure of a Human. Arch. Acoust. 2017, 42, 601–607. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, A.K.; Mishra, A.K.; Singh, R. Underground mining of thick coal seams. Int. J. Min. Sci. Tech. 2015, 25, 885–896. [Google Scholar] [CrossRef]

- Oravec, M.; Lipovský, P.; Šmelko, M.; Adamčík, P.; Witoś, M.; Kwaśniewski, J. Low-Frequency Magnetic Fields in Diagnostics of Low-Speed Electrical and Mechanical Systems. Sustainability 2021, 13, 9197. [Google Scholar] [CrossRef]

- Burdzik, R. Impact and Assessment of Suspension Stiffness on Vibration Propagation into Vehicle. Sensors 2023, 23, 1930. [Google Scholar] [CrossRef] [PubMed]

- Dąbek, P.; Wróblewski, A.; Wodecki, J.; Bortnowski, P.; Ozdoba, M.; Król, R.; Zimroz, R. Application of the Methods of Monitoring and Detecting the Belt Mistracking in Laboratory Conditions. Appl. Sci. 2023, 13, 2111. [Google Scholar] [CrossRef]

- Zinchenko, A.; Baiul, K.; Krot, P.; Khudyakov, A.; Vashchenko, S.; Banasiewicz, A.; Wróblewski, A. Materials Selection and Design Options Analysis for a Centrifugal Fan Impeller in a Horizontal Conveyor Dryer. Materials 2021, 14, 6696. [Google Scholar] [CrossRef]

- Bortnowski, P.; Król, R.; Suchorab-Matuszewska, N.; Ozdoba, M.; Szczerbakowicz, M. Optimizing Retention Bunkers in Copper Mines with Numerical Methods and Gradient Descent. Appl. Sci. 2024, 14, 2612. [Google Scholar] [CrossRef]

- Uth, F.; Polnik, B.; Kurpiel, W.; Baltes, R.; Kriegsch, P.; Clause, E. An innovative person detection system based on thermal imaging cameras dedicate for underground belt conveyors. Min. Sci. 2019, 26, 263–276. [Google Scholar] [CrossRef]

- Ji, Y.; Ren, T.; Wynne, P.; Wan, Z.; Zhaoyang, M.; Wang, Z. A comparative study of dust control practices in Chinese and Australian longwall coal mines. Int. J. Min. Sci. Tech. 2016, 25, 687–706. [Google Scholar] [CrossRef]

- Hebda-Sobkowicz, J.; Gola, S.; Zimroz, R.; Wyłomańska, A. Identification and Statistical Analysis of Impulse-Like Patterns of Carbon Monoxide Variation in Deep Underground Mines Associated with the Blasting Procedure. Sensors 2019, 19, 2757. [Google Scholar] [CrossRef] [PubMed]

- Prostański, D. Empirical Models of Zones Protecting Against Coal Dust Explosion. Arch. Min. Sci. 2017, 62, 611–619. [Google Scholar] [CrossRef][Green Version]

- Peng, S.S.; Feng, D.; Cheng, J.; Yang, L. Automation in U.S. longwall coal mining: A state-of-the-art review. Int. J. Min. Sci. Tech. 2019, 29, 151–159. [Google Scholar] [CrossRef]

- Ralston, J.C.; Reid, D.C.; Dunn, M.T.; Hainsworth, D.W. Longwall automation: Delivering enabling technology to achieve safer and more productive underground mining. Int. J. Min. Sci. Tech. 2015, 25, 865–876. [Google Scholar] [CrossRef]

- Bartoszek, S.; Stankiewicz, K.; Kost, G.; Ćwikła, G.; Dyczko, A. Research on Ultrasonic Transducers to Accurately Determine Distances in a Coal Mine Conditions. Energies 2021, 14, 2532. [Google Scholar] [CrossRef]

- Bortnowski, P.; Gładysiewicz, L.; Król, R.; Ozdoba, M. Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems. Energies 2021, 14, 1786. [Google Scholar] [CrossRef]

- Khayrutdinov, M.M.; Golik, V.I.; Aleksakhin, A.V.; Trushina, E.V.; Lazareva, N.V.; Aleksakhina, Y.V. Proposal of an Algorithm for Choice of a Development System for Operational and Environmental Safety in Mining. Resources 2022, 11, 88. [Google Scholar] [CrossRef]

- Kawalec, W.; Błażej, R.; Konieczna, M.; Król, R. Laboratory Tests on e-pellets effectiveness for ore tracking. Min. Sci. 2018, 25, 7–18. [Google Scholar] [CrossRef]

- Oggeri, C.; Oreste, P. Tunnel Static Behavior Assessed by a Probabilistic Approach to the Back-Analysis. Am. J. Appl. Sci. 2012, 9, 1137–1144. [Google Scholar]

- Lalik, K.; Dominik, I.; Skrzypkowski, K.; Korzeniowski, W.; Zagórski, K. Self-Excited Acoustical Measurement System for Rock Mass Stress Mapping. Sensors 2021, 21, 6749. [Google Scholar] [CrossRef] [PubMed]

- Baiul, K.; Khudyakov, A.; Vashchenko, S.; Krot, P.V.; Solodka, N. The experimental study of compaction parameters and elastic after-effect of fine fraction raw materials. Min. Sci. 2020, 27, 7–18. [Google Scholar] [CrossRef]

- Wajs, J.; Trybała, P.; Górniak-Zimroz, J.; Krupa-Kurzynowska, J.; Kasza, D. Modern Solution for Fast and Accurate Inventorization of Open-Pit Mines by the Active Remote Sensing Technique-Case Study of Mikoszów Granite Mine (Lower Silesia, SW Poland). Energies 2021, 14, 6853. [Google Scholar] [CrossRef]

- Rajwa, S.; Tomasz Janoszek, T.; Stanisław Prusek, S. Influence of canopy ratio of powered roof support on longwall working stability—A case study. Int. J. Min. Sci. Tech. 2019, 29, 591–598. [Google Scholar] [CrossRef]

- Juganda, A.; Strebinger, C.; Brune, J.F.; Bogin, G.E. Discrete modeling of a longwall coal mine gob for CFD simulation. Int. J. Min. Sci. Tech. 2020, 30, 463–469. [Google Scholar] [CrossRef]

- Adach-Pawelus, K.; Pawelus, D. Influence of Driving Direction on the Stability of a Group of Headings Located in a Field of High Horizontal Stresses in the Polish Underground Copper Mines. Energies 2021, 14, 5955. [Google Scholar] [CrossRef]

- Qiao, S.; Zhang, Z.; Zhu, Z.; Zhang, K. Influence of cutting angle on mechanical properties of rock cutting by conical pick based on finite element analysis. J. Min. Sci. 2021, 28, 161–173. [Google Scholar] [CrossRef]

- Krauze, K.; Klempka, R.; Mucha, K.; Wydro, T. Computer-aided selection of the stabilizing system parameters of the mobile transport and assembly manipulator in mining excavations. Arch. Min. Sci. 2023, 68, 3–18. [Google Scholar] [CrossRef]

- Bardzinski, P.; Jurdziak, L.; Kawalec, W.; Król, R. Copper ore quality tracking in a belt conveyor system using simulation tools. Nat. Resour. Res. 2020, 29, 1031–1040. [Google Scholar] [CrossRef]

- Hargrave, C.O.; James, C.A.; Ralston, J.C. Infrastructure-based localization of automated coal mining equipment. Int. J. Coal Sci. Technol. 2017, 4, 252–261. [Google Scholar] [CrossRef]

- Hu, S.; Ma, L.; Guo, J.; Yang, P. Support-surrounding rock relationship and top-coal movement laws in large dip angle fully-mechanized caving face. Int. J. Min. Sci. Tech. 2018, 28, 533–539. [Google Scholar]

- Ralston, J.C.; Hargrave, C.O.; Dunn, M.T. Longwall automation: Trends, challenges and opportunities. Int. J. Min. Sci. Tech. 2017, 27, 733–739. [Google Scholar] [CrossRef]

- Gładysiewicz, L.; Król, R.; Kisielewski, W.; Kaszuba, D. Experimental determination of belt conveyors artificial friction coefficient. Acta Montan. Slovaca 2017, 22, 206–214. [Google Scholar]

- Woźniak, D.; Hardygóra, M. Method for laboratory testing rubber penetration of steel cords in conveyor belts. Min. Sci. 2020, 27, 105–117. [Google Scholar] [CrossRef]

- Babyr, N.V.; Korolev, A.I.; Neupokoeva, T.V. Enhancement of powered cleaning equipment with the view of mining and geological conditions. IOP Conf. Series Earth Environ. Sci. 2018, 194, 32004. [Google Scholar] [CrossRef]

- Buevich, V.V.; Gabov, V.V.; Zadkov, D.A.; Vasileva, P.A. Adaptation of the mechanized roof support to changeable rock pressure. Eurasian Min. 2015, 2, 11–14. [Google Scholar] [CrossRef]

- Klishin, V.I.; Klishin, S.V. Coal Extraction from Thick Flat and Steep Beds. J. Min. Sci. 2010, 46, 149–159. [Google Scholar] [CrossRef]

- Jixiong, Z.; Spearing, A.J.S.; Xiexing, M.; Shuai, G.; Qiang, S. Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int. J. Min. Sci. Tech. 2017, 27, 17–27. [Google Scholar]

- Gabov, V.V.; Zadkov, D.A.; Stebnev, A.V. Evaluation of structure and variables within performance rating of hydraulically powered roof sup-port legs with smooth roof control. Eurasian Min. 2016, 2, 37–40. [Google Scholar]

- Wang, J.; Wang, Z. Systematic principles of surrounding rock control in longwall mining within thick coal seams. Int. J. Min. Sci. Tech. 2019, 29, 591–598. [Google Scholar] [CrossRef]

- Ji, Y.; Zhang, Y.; Huang, Z.; Shao, Z.; Gao, Y. Theoretical analysis of support stability in large dip angle coal seam mined with fully-mechanized top coal caving. Min. Sci. 2020, 27, 73–87. [Google Scholar]

- Babyr, N.; Babyr, K. To improve the contact adaptability of mechanical roof support. E3S Web Conf. 2021, 266, 3015. [Google Scholar] [CrossRef]

- Gabov, V.V.; Zadkov, D.A.; Babyr, N.V.; Xie, F. Nonimpact rock pressure regulation with energy recovery into the hydraulic system of the longwall powered support. Eurasian Min. 2021, 36, 55–59. [Google Scholar] [CrossRef]

- Ren, H.; Zhang, D.; Gong, S.; Zhou, K.; Xi, C.; He, M.; Li, T. Dynamic impact experiment and response characteristics analysis for 1:2 reduced-scale model of hydraulic support. Int. J. Min. Sci. Technol. 2021, 31, 347–356. [Google Scholar] [CrossRef]

- Buyalich, G.; Byakov, M.; Buyalich, K.; Shtenin, E. Development of Powered Support Hydraulic Legs with Improved Performance. E3S Web Conf. 2019, 105, 3025. [Google Scholar] [CrossRef]

- Frith, R.C. A holistic examination of the load rating design of longwall shields after more than half a century of mechanised longwall mining. Int. J. Min. Sci. Tech. 2015, 26, 199–208. [Google Scholar] [CrossRef]

- Zhao, X.; Li, F.; Li, Y.; Fan, Y. Fatigue Behavior of a Box-Type Welded Structure of Hydraulic Support Used in Coal Mine. Materials 2015, 8, 6609–6622. [Google Scholar] [CrossRef] [PubMed]

- Rudzki, P.; Krot, P. Dynamics control of powered hydraulic roof supports in the underground longwall mining complex. IOP Conf. Ser. Earth Environ. Sci. 2021, 942, 12014. [Google Scholar] [CrossRef]

- Zeng, Q.; Xu, P.; Meng, Z.; Ma, C.; Lei, X. Posture and Dynamics Analysis of Hydraulic Support with Joint Clearance under Impact Load. Machines 2023, 11, 159. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.; Gao, K.; Zeng, Q.; Meng, F.; Cheng, J. Research on Intelligent Control System of Hydraulic Support Based on Position and Posture Detection. Machines 2023, 11, 33. [Google Scholar] [CrossRef]

- Xing, K.; Cheng, J.; Wan, Z.; Sun, X.; Yan, W.; Lv, J.; Xue, M. Extraction and Application of Hydraulic Support Safety Valve Characteristic Parameters Based on Roof Pressure Data. Sensors 2023, 23, 8853. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Lu, D.; Xing, H.; Ding, H.; Luo, J.; Liu, H.; Kong, X.; Xu, F. Recent Progress in MEMS Fiber-Optic Fabry–Perot Pressure Sensors. Sensors 2024, 24, 1079. [Google Scholar] [CrossRef] [PubMed]

- Duan, B.; Hai, Z.; Guo, M.; Zheng, Y.; Chen, J.; Bai, J.; Su, Z.; Liang, R.; Zhu, H.; Zhang, Q.; et al. A Large-Range and High-Sensitivity Fiber-Optic Fabry–Perot Pressure Sensor Based on a Membrane-Hole-Base Structure. Micromachines 2024, 15, 174. [Google Scholar] [CrossRef] [PubMed]

- Santos, J.P.; Bierlich, J.; Kobelke, J.; Ferreira, M.S. A Silica Capillary-Based Sensor with Access Channels for the Simultaneous Measurement of Pressure and Temperature. Photonics 2023, 10, 1029. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, F.; Zhang, M.; Zhang, K.; Zhang, Y.; Wang, G.; Hu, Z.; Deng, Q. FP Interferometric Optic Fiber Humidity Sensor Based on Acrylate AB Adhesive Film. Photonics 2023, 10, 873. [Google Scholar] [CrossRef]

- Atkinson, K.; Han, W.; Stewart, D.E. Numerical Solution of Ordinary Differential Equations; Wiley Series in Pure and Applied Mathematics; Wiley: Hoboken, NJ, USA, 2009. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borska, B.; Szurgacz, D. Research and Simulation on the Development of a Hydraulic Prop Support System of Powered Roof Support to Increase Work Safety. Methods Protoc. 2024, 7, 33. https://doi.org/10.3390/mps7020033

Borska B, Szurgacz D. Research and Simulation on the Development of a Hydraulic Prop Support System of Powered Roof Support to Increase Work Safety. Methods and Protocols. 2024; 7(2):33. https://doi.org/10.3390/mps7020033

Chicago/Turabian StyleBorska, Beata, and Dawid Szurgacz. 2024. "Research and Simulation on the Development of a Hydraulic Prop Support System of Powered Roof Support to Increase Work Safety" Methods and Protocols 7, no. 2: 33. https://doi.org/10.3390/mps7020033

APA StyleBorska, B., & Szurgacz, D. (2024). Research and Simulation on the Development of a Hydraulic Prop Support System of Powered Roof Support to Increase Work Safety. Methods and Protocols, 7(2), 33. https://doi.org/10.3390/mps7020033