Biofloc Application Using Aquaponics and Vertical Aquaculture Technology in Aquaculture: Review

Abstract

:1. Introduction

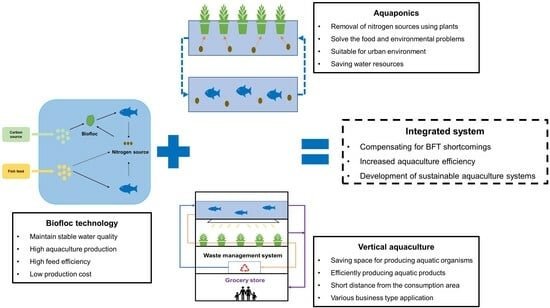

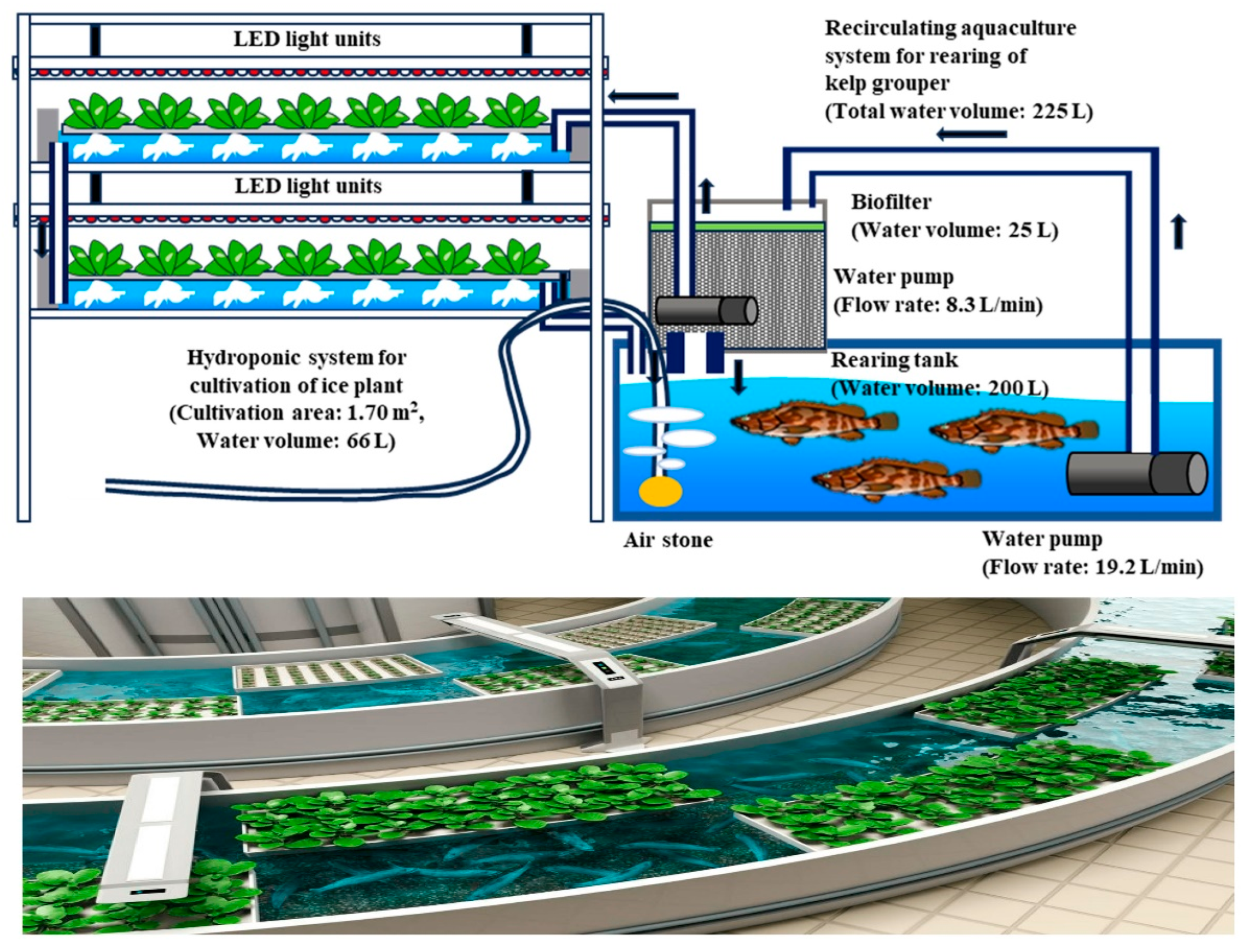

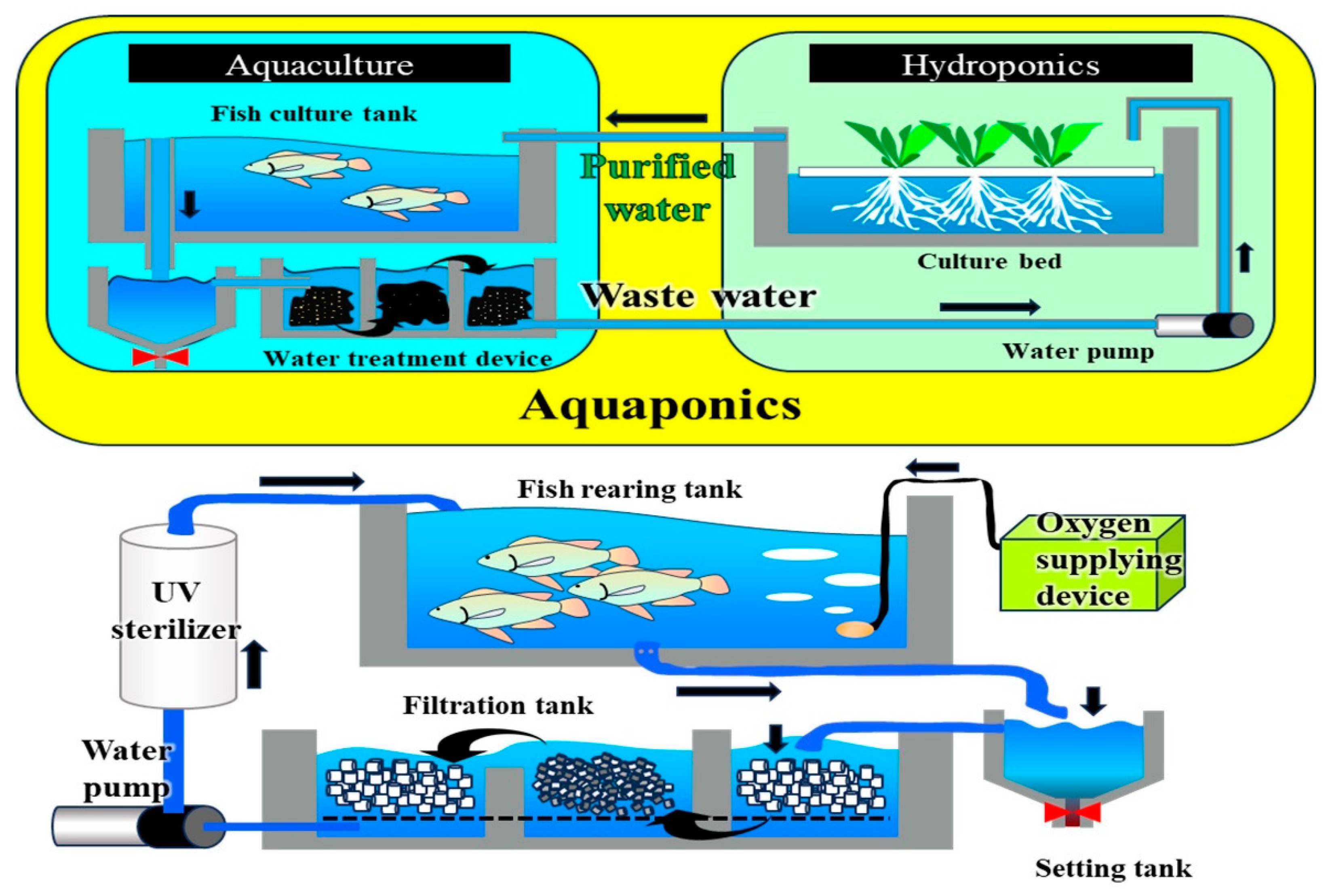

2. Aquaponics with BFT

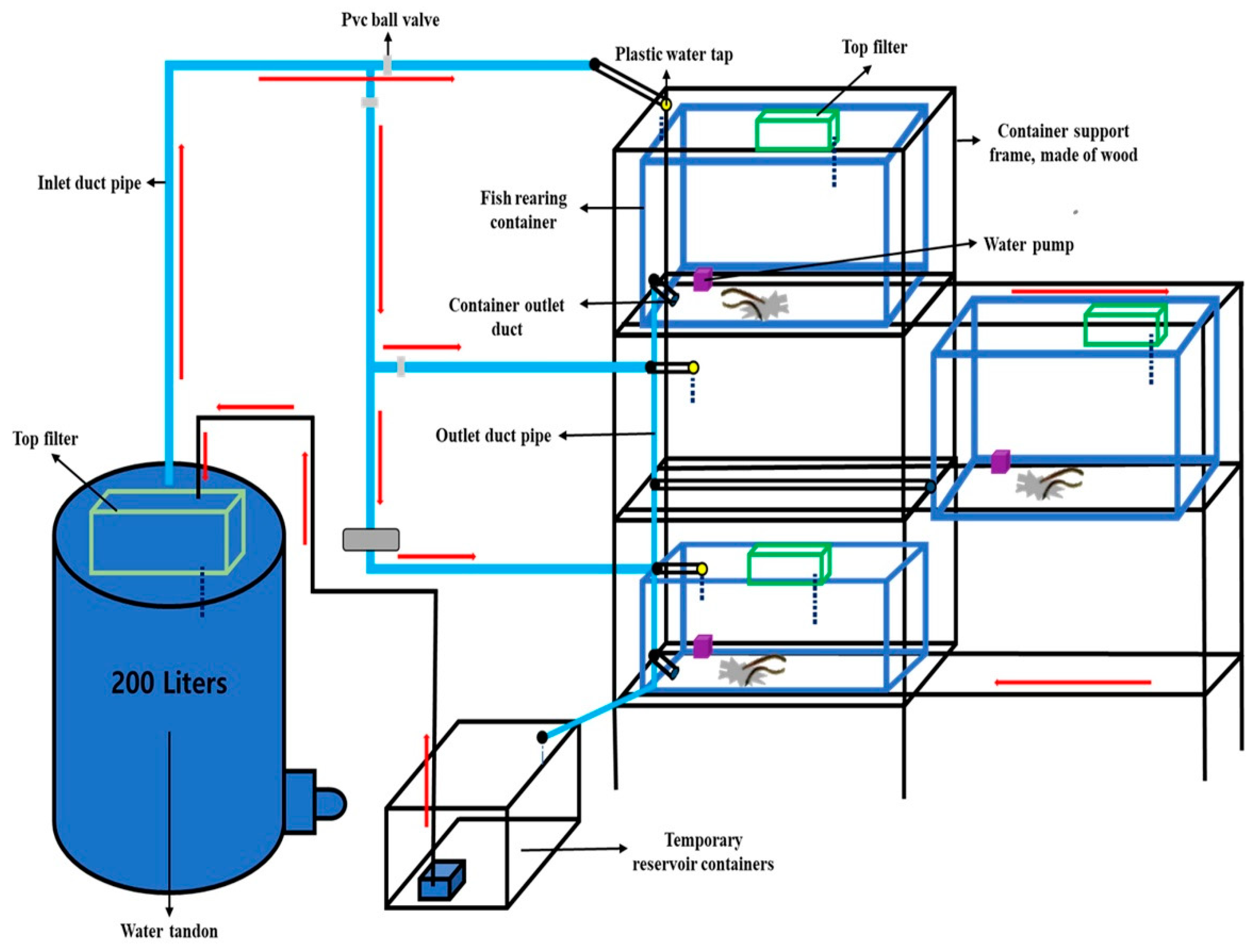

3. Vertical Aquaculture Technology with BFT

4. Conclusions and Future Direction

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Poli, M.A.; Legarda, E.C.; de Lorenzo, M.A.; Martins, M.A.; do Nascimento Vieira, F. Pacific white shrimp and Nile tilapia integrated in a biofloc system under different fish-stocking densities. Aquaculture 2019, 498, 83–89. [Google Scholar] [CrossRef]

- Pinho, S.M.; de Lima, J.P.; David, L.H.; Emerenciano, M.G.; Goddek, S.; Verdegem, M.C.; Keesman, K.J.; Portella, M.C. FLOCponics: The integration of biofloc technology with plant production. Rev. Aquac. 2022, 14, 647–675. [Google Scholar] [CrossRef]

- Hoang, M.N.; Nguyen, P.N.; Bossier, P. Water quality, animal performance, nutrient budgets and microbial community in the biofloc-based polyculture system of white shrimp, Litopenaeus vannamei and gray mullet, Mugil cephalus. Aquaculture 2020, 515, 734610. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.K.; Kim, J.H. Bio-floc technology application in flatfish Paralichthys olivaceus culture: Effects on water quality, growth, hematological parameters, and immune responses. Aquaculture 2018, 495, 703–709. [Google Scholar] [CrossRef]

- Kim, J.H.; Sohn, S.; Kim, S.K.; Kim, S.R.; Kim, S.K.; Kim, S.M.; Kim, N.Y.; Hur, Y.B. Effects on the survival rates, hematological parameters, and neurotransmitters in olive flounders, Paralichthys olivaceus, reared in bio-floc and seawater by Streptococcus iniae challenge. Fish Shellfish Immunol. 2021, 113, 79–85. [Google Scholar] [CrossRef]

- Ahmed, N.; Thompson, S.; Glaser, M. Global aquaculture productivity, environmental sustainability, and climate change adaptability. Environ. Manag. 2019, 63, 159–172. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.B.; Choi, J.H.; Lee, J.H.; Jo, A.H.; Lee, K.M.; Kim, J.H. Biofloc Technology in Fish Aquaculture: A Review. Antioxidants 2023, 12, 398. [Google Scholar] [CrossRef]

- Abakari, G.; Wu, X.; He, X.; Fan, L.; Luo, G. Bacteria in biofloc technology aquaculture systems: Roles and mediating factors. Rev. Aquac. 2022, 14, 1260–1284. [Google Scholar] [CrossRef]

- Robles-Porchas, G.R.; Gollas-Galván, T.; Martínez-Porchas, M.; Martínez-Cordova, L.R.; Miranda-Baeza, A.; Vargas-Albores, F. The nitrification process for nitrogen removal in biofloc system aquaculture. Rev. Aquac. 2020, 12, 2228–2249. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Mohammadi, A.; Emerenciano, M.G.C. Microorganisms in biofloc aquaculture system. Aquac. Rep. 2022, 26, 101300. [Google Scholar] [CrossRef]

- Abakari, G.; Luo, G.; Kombat, E.O. Dynamics of nitrogenous compounds and their control in biofloc technology (BFT) systems: A review. Aquac. Fish. 2021, 6, 441–447. [Google Scholar] [CrossRef]

- Chen, S.; Sun, X.; Tian, X.; Jiang, W.; Dong, X.; Li, L. Influence of ammonia nitrogen management strategies on microbial communities in biofloc-based aquaculture systems. Sci. Total Environ. 2023, 903, 166159. [Google Scholar] [CrossRef] [PubMed]

- Ogello, E.O.; Outa, N.O.; Obiero, K.O.; Kyule, D.N.; Munguti, J.M. The prospects of biofloc technology (BFT) for sustainable aquaculture development. Sci. Afr. 2021, 14, e01053. [Google Scholar] [CrossRef]

- Panigrahi, A.; Saranya, C.; Sundaram, M.; Kannan, S.V.; Das, R.R.; Kumar, R.S.; Rajesh, P.; Otta, S.K. Carbon: Nitrogen (C: N) ratio level variation influences microbial community of the system and growth as well as immunity of shrimp (Litopenaeus vannamei) in biofloc based culture system. Fish Shellfish Immunol. 2018, 81, 329–337. [Google Scholar] [CrossRef]

- Najdegerami, E.H.; Tukmechi, A. Poly-β-hydroxybutyrate concentration, microbial enzymes activity, and nutritional value in biofloc system using different carbon sources and C/N ratios in common carp, Cyprinus carpio culture. J. World Aquac. Soc. 2023, 54, 844–860. [Google Scholar] [CrossRef]

- Khatoon, H.; Banerjee, S.; Yuan, G.T.G.; Haris, N.; Ikhwanuddin, M.; Ambak, M.A.; Endut, A. Biofloc as a potential natural feed for shrimp postlarvae. Int. Biodeterior. Biodegrad. 2016, 113, 304–309. [Google Scholar] [CrossRef]

- Nisar, U.; Peng, D.; Mu, Y.; Sun, Y. A solution for sustainable utilization of aquaculture waste: A comprehensive review of biofloc technology and aquamimicry. Front. Nutr. 2022, 8, 791738. [Google Scholar] [CrossRef]

- Ekasari, J.; Angela, D.; Waluyo, S.H.; Bachtiar, T.; Surawidjaja, E.H.; Bossier, P.; De Schryver, P. The size of biofloc determines the nutritional composition and the nitrogen recovery by aquaculture animals. Aquaculture 2014, 426, 105–111. [Google Scholar] [CrossRef]

- Ekasari, J.; Suprayudi, M.A.; Wiyoto, W.; Hazanah, R.F.; Lenggara, G.S.; Sulistiani, R.; Muhammad, A.; Zairin, M., Jr. Biofloc technology application in African catfish fingerling production: The effects on the reproductive performance of broodstock and the quality of eggs and larvae. Aquaculture 2016, 464, 349–356. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Mozanzadeh, M.T.; Sharifinia, M.; Emerenciano, M.G.C. Biofloc: A sustainable dietary supplement, nutritional value and functional properties. Aquaculture 2023, 562, 738757. [Google Scholar] [CrossRef]

- Kumar, V.; Roy, S.; Behera, B.K.; Swain, H.S.; Das, B.K. Biofloc microbiome with bioremediation and health benefits. Front. Microbiol. 2021, 12, 741164. [Google Scholar] [CrossRef]

- Sgnaulin, T.; de Mello, G.L.; Thomas, M.C.; Garcia, J.R.E.; de Oca, G.A.R.M.; Emerenciano, M.G.C. Biofloc technology (BFT): An alternative aquaculture system for piracanjuba Brycon orbignyanus? Aquaculture 2018, 485, 119–123. [Google Scholar] [CrossRef]

- Elayaraja, S.; Mabrok, M.; Algammal, A.; Sabitha, E.; Rajeswari, M.V.; Zágoršek, K.; Ye, Z.; Zhu, S.; Rodkhum, C. Potential influence of jaggery-based biofloc technology at different C: N ratios on water quality, growth performance, innate immunity, immune-related genes expression profiles, and disease resistance against Aeromonas hydrophila in Nile tilapia (Oreochromis niloticus). Fish Shellfish Immunol. 2020, 107, 118–128. [Google Scholar] [CrossRef]

- Khanjani, M.H.; Sharifinia, M.; Emerenciano, M.G.C. A detailed look at the impacts of biofloc on immunological and hematological parameters and improving resistance to diseases. Fish Shellfish. Immunol. 2023, 137, 108796. [Google Scholar] [CrossRef] [PubMed]

- Ulloa Walker, D.A.; Morales Suazo, M.C.; Emerenciano, M.G.C. Biofloc technology: Principles focused on potential species and the case study of Chilean river shrimp Cryphiops caementarius. Rev. Aquac. 2020, 12, 1759–1782. [Google Scholar] [CrossRef]

- Ahmad, I.; Babitha Rani, A.M.; Verma, A.K.; Maqsood, M. Biofloc technology: An emerging avenue in aquatic animal healthcare and nutrition. Aquac. Int. 2017, 25, 1215–1226. [Google Scholar] [CrossRef]

- Xu, W.; Wen, G.; Su, H.; Xu, Y.; Hu, X.; Cao, Y. Effect of input C/N ratio on bacterial community of water biofloc and shrimp gut in a commercial zero-exchange system with intensive production of Penaeus vannamei. Microorganisms 2022, 10, 1060. [Google Scholar] [CrossRef]

- Thong, P.Y. Biofloc technology in shrimp farming: Success and failure. Aquac Asia Pac. 2014, 4, 13–16. [Google Scholar]

- Jamal, M.T.; Broom, M.; Al-Mur, B.A.; Al Harbi, M.; Ghandourah, M.; Al Otaibi, A.; Haque, M.F. Biofloc technology: Emerging microbial biotechnology for the improvement of aquaculture productivity. Pol. J. Microbiol. 2020, 69, 401–409. [Google Scholar] [CrossRef]

- Ray, A.J.; Lotz, J.M. Shrimp (Litopenaeus vannamei) production and stable isotope dynamics in clear-water recirculating aquaculture systems versus biofloc systems. Aquac. Res. 2017, 48, 4390–4398. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Liu, J.; Gao, Q.; Dong, S.; Zhou, C. Deep learning for smart fish farming: Applications, opportunities and challenges. Rev. Aquac. 2021, 13, 66–90. [Google Scholar] [CrossRef]

- Rakocy, J.E. Aquaponics—Integrating Fish and Plant Culture. In Aquaculture Production Systems; Wiley: Hoboken, NJ, USA, 2012; pp. 344–386. [Google Scholar] [CrossRef]

- Pinheiro, I.; Arantes, R.; do Espírito Santo, C.M.; do Nascimento Vieira, F.; Lapa, K.R.; Gonzaga, L.V.; Fett, R.; Barcelos-Oliveira, J.L.; Seiffert, W.Q. Production of the halophyte Sarcocornia ambigua and Pacific white shrimp in an aquaponic system with biofloc technology. Ecol. Eng. 2017, 100, 261–267. [Google Scholar] [CrossRef]

- Pinho, S.M.; Molinari, D.; de Mello, G.L.; Fitzsimmons, K.M.; Emerenciano, M.G.C. Effluent from a biofloc technology (BFT) tilapia culture on the aquaponics production of different lettuce varieties. Ecol. Eng. 2017, 103, 146–153. [Google Scholar] [CrossRef]

- Saseendran, S.; Dube, K.; Chandrakant, M.H.; Rani, A.B. Enhanced growth response and stress mitigation of genetically improved farmed Tilapia in a biofloc integrated aquaponic system with bell pepper. Aquaculture 2021, 533, 736200. [Google Scholar] [CrossRef]

- Yang, T.; Kim, H.J. Comparisons of nitrogen and phosphorus mass balance for tomato-, basil-, and lettuce-based aquaponic and hydroponic systems. J. Clean. Prod. 2020, 274, 122619. [Google Scholar] [CrossRef]

- König, B.; Janker, J.; Reinhardt, T.; Villarroel, M.; Junge, R. Analysis of aquaponics as an emerging technological innovation system. J. Clean. Prod. 2018, 180, 232–243. [Google Scholar] [CrossRef]

- Shumet, A. Aquaponics: A Sustainable Solution for Health, Economy, and Society—A Comprehensive Review. Aquaponics 2021, 1, 1–22. [Google Scholar]

- Shabeer, M.S.; Nagar, S.; Uppal, H. Isolation and characterization bacteria related to aquaponics for testing its bio potential. B. Tech. Biotechnol. Nat. Inst. Technol. 2016, 60. [Google Scholar]

- Okomoda, V.T.; Oladimeji, S.A.; Solomon, S.G.; Olufeagba, S.O.; Ogah, S.I.; Ikhwanuddin, M. Aquaponics production system: A review of historical perspective, opportunities, and challenges of its adoption. Food Sci. Nutr. 2023, 11, 1157–1165. [Google Scholar] [CrossRef]

- Pinho, S.M.; Flores, R.M.V.; David, L.H.; Emerenciano, M.G.; Quagrainie, K.K.; Portella, M.C. Economic comparison between conventional aquaponics and FLOCponics systems. Aquaculture 2022, 552, 737987. [Google Scholar] [CrossRef]

- Goddek, S.; Delaide, B.; Mankasingh, U.; Ragnarsdottir, K.V.; Jijakli, H.; Thorarinsdottir, R. Challenges of sustainable and commercial aquaponics. Sustainability 2015, 7, 4199–4224. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Li, S.; Ke, Z.; Zhao, H.; Yang, J.; Li, D.; Wang, L.; Yang, W.; Zhang, Z. Investigation on environment monitoring system for a combination of hydroponics and aquaculture in greenhouse. Inf. Process. Agric. 2022, 9, 123–134. [Google Scholar] [CrossRef]

- Turnsek, M.; Joly, A.; Thorarinsdottir, R.; Junge, R. Challenges of commercial aquaponics in Europe: Beyond the hype. Water 2020, 12, 306. [Google Scholar] [CrossRef]

- Yanes, A.R.; Martinez, P.; Ahmad, R. Towards automated aquaponics: A review on monitoring, IoT, and smart systems. J. Clean. Prod. 2020, 263, 121571. [Google Scholar] [CrossRef]

- Calone, R.; Pennisi, G.; Morgenstern, R.; Sanyé-Mengual, E.; Lorleberg, W.; Dapprich, P.; Winkler, P.; Orsini, F.; Gianquinto, G. Improving water management in European catfish recirculating aquaculture systems through catfish-lettuce aquaponics. Sci. Total Environ. 2019, 687, 759–767. [Google Scholar] [CrossRef] [PubMed]

- Su, M.H.; Azwar, E.; Yang, Y.; Sonne, C.; Yek, P.N.Y.; Liew, R.K.; Cheng, C.K.; Show, P.L.; Lam, S.S. Simultaneous removal of toxic ammonia and lettuce cultivation in aquaponic system using microwave pyrolysis biochar. J. Hazard. Mater. 2020, 396, 122610. [Google Scholar] [CrossRef] [PubMed]

- Junge, R.; König, B.; Villarroel, M.; Komives, T.; Jijakli, M.H. Strategic points in aquaponics. Water 2017, 9, 182. [Google Scholar] [CrossRef]

- Taha, M.F.; ElMasry, G.; Gouda, M.; Zhou, L.; Liang, N.; Abdalla, A.; Rousseau, D.; Qiu, Z. Recent Advances of Smart Systems and Internet of Things (IoT) for Aquaponics Automation: A Comprehensive Overview. Chemosensors 2022, 10, 303. [Google Scholar] [CrossRef]

- Tokunaga, K.; Tamaru, C.; Ako, H.; Leung, P. Economics of small-scale commercial aquaponics in Hawai ‘i. J. World Aquac. Soc. 2015, 46, 20–32. [Google Scholar] [CrossRef]

- Quagrainie, K.K.; Flores, R.M.V.; Kim, H.J.; McClain, V. Economic analysis of aquaponics and hydroponics production in the US Midwest. J. Appl. Aquac. 2018, 30, 1–14. [Google Scholar] [CrossRef]

- Shreejana, K.; Thapa, R.; Lamsal, A.; Ghimire, S.; Kurunju, K.; Shrestha, P. Aquaponics a modern approach for integrated farming and wise utilization of components for sustainability of food security: A review. Arch. Agric. Environ. Sci. 2022, 7, 121–126. [Google Scholar] [CrossRef]

- Meng, L.J.; Hu, X.; Wen, B.; Liu, Y.H.; Luo, G.Z.; Gao, J.Z.; Chen, Z.Z. Microplastics inhibit biofloc formation and alter microbial community composition and nitrogen transformation function in aquaculture. Sci. Total Environ. 2023, 866, 161362. [Google Scholar] [CrossRef] [PubMed]

- Said, M.M.; Ahmed, O.M. Carbohydrate supplement impact on growth performance, bacterial community, and bacterial food quality of Whiteleg shrimp (Litopenaeus vannamei) under biofloc system. Aquac. Nutr. 2022, 2022, 8964714. [Google Scholar] [CrossRef]

- Buhmann, A.K.; Waller, U.; Wecker, B.; Papenbrock, J. Optimization of culturing conditions and selection of species for the use of halophytes as biofilter for nutrient-rich saline water. Agric. Water Manag. 2015, 149, 102–114. [Google Scholar] [CrossRef]

- Krummenauer, D.; Samocha, T.; Poersch, L.; Lara, G.; Wasielesky Jr, W. The reuse of water on the culture of Pacific white shrimp, Litopenaeus vannamei, in BFT system. J. World Aquac. Soc. 2014, 45, 3–14. [Google Scholar] [CrossRef]

- Emerenciano, M.; Gaxiola, G.; Cuzon, G. Biofloc technology (BFT): A review for aquaculture application and animal food industry. Biomass Now Cultiv. Util. 2013, 12, 301–328. [Google Scholar]

- Gao, X.; Zhang, H.; Xu, Y.; Ni, Q.; Zhang, Y.; Tan, H.; Gu, C. Effects of humic acid on the nitrogen utilization efficiency and microbial communities in aquaponic systems. Aquaculture 2022, 547, 737475. [Google Scholar] [CrossRef]

- Da Rocha, A.; Biazzetti Filho, M.; Stech, M.; Paz da Silva, R. Lettuce production in aquaponic and biofloc systems with silver catfish Rhamdia quelen. Bol. Inst. Pesca 2017, 43, 64. [Google Scholar]

- Lee, D.H.; Kim, J.Y.; Lim, S.R.; Kim, D.Y.; Kim, J.M.; Shin, S.J.; Kim, J.D. Effect of dietary monobasic potassium phosphate levels on water quality and the growth of far eastern catfish Silurus asotus and four leafy vegetables in a hybrid biofloc technology aquaponic system. Korean J. Fish. Aquat. Sci. 2019, 52, 159–172. [Google Scholar] [CrossRef]

- Tetra, O.N.; Yusuf, Y.; Dewi, P.; Pardi, H. Application of FLOCponics to improve water quality (phosphate, sulphate, calcium, potassium). Aquac. Aquar. Conserv. Legis. 2023, 16, 483–495. Available online: https://www.proquest.com/docview/2784020232?pq-origsite=gscholar&fromopenview=true (accessed on 15 February 2023).

- da Silva, H.V.; Martins, M.A.; do Espírito Santo, C.M.; do Nascimento Vieira, F.; Rezende, P.C.; Gonzaga, L.V.; Fett, R.; Seiffert, W.Q. Aquaponic production of sea asparagus and Pacific white shrimp using biofloc technology: Different irrigation regimes affect plant production of bioactive compounds and antioxidant capacity. Aquac. Res. 2022, 53, 1001–1010. [Google Scholar] [CrossRef]

- Pinheiro, I.; Carneiro, R.F.S.; do Nascimento Vieira, F.; Gonzaga, L.V.; Fett, R.; de Oliveira Costa, A.C.; Magallón-Barajas, F.J.; Seiffert, W.Q. Aquaponic production of Sarcocornia ambigua and Pacific white shrimp in biofloc system at different salinities. Aquaculture 2020, 519, 734918. [Google Scholar] [CrossRef]

- Barbosa, P.T.L.; Povh, J.A.; Farias, K.N.N.; da Silva, T.V.; Teodoro, G.C.; Ribeiro, J.S.; Stringhetta, G.R.; dos Santos Fernandes, C.E.; Corrêa Filho, R.A.C. Nile tilapia production in polyculture with freshwater shrimp using an aquaponic system and biofloc technology. Aquaculture 2022, 551, 737916. [Google Scholar] [CrossRef]

- Buhmann, A.; Papenbrock, J. Biofiltering of aquaculture effluents by halophytic plants: Basic principles, current uses and future perspectives. Environ. Exp. Bot. 2013, 92, 122–133. [Google Scholar] [CrossRef]

- Fimbres-Acedo, Y.E.; Servín-Villegas, R.; Garza-Torres, R.; Endo, M.; Fitzsimmons, K.M.; Emerenciano, M.G.; Magallón-Servín, P.; López-Vela, M.; Magallón-Barajas, F.J. Hydroponic horticulture using residual waters from Oreochromis niloticus aquaculture with biofloc technology in photoautotrophic conditions with Chlorella microalgae. Aquac. Res. 2020, 51, 4340–4360. [Google Scholar] [CrossRef]

- Goddek, S.; Joyce, A.; Wuertz, S.; Körner, O.; Bläser, I.; Reuter, M.; Keesman, K.J. Decoupled aquaponics systems. In Aquaponics Food Production Systems; Springer: Cham, Switzerland, 2019; Volume 10. [Google Scholar] [CrossRef]

- Endo, M. Aquaponics in plant factory. In Plant Factory Using Artificial Light; Elsevier, 2019; pp. 339–352. Available online: https://www.sciencedirect.com/science/article/abs/pii/B9780128139738000324?via%3Dihub (accessed on 20 October 2023). [CrossRef]

- Danish, M.S.S.; Senjyu, T.; Sabory, N.R.; Khosravy, M.; Grilli, M.L.; Mikhaylov, A.; Majidi, H. A forefront framework for sustainable aquaponics modeling and design. Sustainability 2021, 13, 9313. [Google Scholar] [CrossRef]

- Harianto, E.; Supriyono, E.; Budiardi, T.; Affandi, R.; Hadiroseyani, Y. The effect of water level in vertical aquaculture systems on production performance, biochemistry, hematology, and histology of Anguilla bicolor bicolor. Sci. Rep. 2021, 11, 11318. [Google Scholar] [CrossRef]

- Huh, J.H. PLC-based design of monitoring system for ICT-integrated vertical fish farm. Hum. Centric Comput. Inf. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Imsland, A.K.; Gunnarsson, S.; Foss, A.; Sparboe, L.O.; ØIestad, V.; Sigurðsson, S. Comparison of juvenile spotted wolffish, Anarhichas minor, growth in shallow raceways and circular tanks. J. World Aquac. Soc. 2007, 38, 154–160. [Google Scholar] [CrossRef]

- Khandaker, M.; Kotzen, B. The potential for combining living wall and vertical farming systems with aquaponics with special emphasis on substrates. Aquac. Res. 2018, 49, 1454–1468. [Google Scholar] [CrossRef]

- Damery, D.; Webb, J.; Danylchuk, A.; Hoque, S. Natural systems in building integrated aquaculture design. WIT Trans. Ecol. Environ. 2012, 160, 87–93. [Google Scholar]

- Nair, A.G.; Chacko, A.; Mohan, G.; Francis, T.K. Smart vertical farming using hydroponics. J. Electr. Electron. Eng. 2015, 1, 14–17. [Google Scholar]

- Birkby, J. Vertical Farming. In ATTRA Sustainable Agriculture; National Center for Appropriate Technology: Jackson, MS, USA, 2016; Volume 2, pp. 1–12. Available online: https://attra.ncat.org/product/vertical-farming/ (accessed on 15 January 2016).

- Kalantari, F.; Mohd Tahir, O.; Mahmoudi Lahijani, A.; Kalantari, S. A review of vertical farming technology: A guide for implementation of building integrated agriculture in cities. In Advanced Engineering Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2017. [Google Scholar] [CrossRef]

- Möller Voss, P. Vertical Farming: An Agricultural Revolution on the Rise. 2013. Available online: https://www.diva-portal.org/smash/record.jsf?pid=diva2%3A628988&dswid=62 (accessed on 15 October 2017).

- Perez, V.M. Study of the Sustainability Issues of Food Production Using Vertical Farm Methods in an Urban Environment within the State of Indiana; Purdue University: West Lafayette, IN, USA, 2014; Available online: https://www.proquest.com/dissertations-theses/study-sustainability-issues-food-production-using/docview/1617518785/se-2?accountid=13358 (accessed on 15 April 2014).

- Gustavsen, G.W.; Berglann, H.; Jenssen, E.; Kårstad, S.; Rodriguez, D.G.P. The Value of Urban Farming in Oslo, Norway: Community Gardens, Aquaponics and Vertical Farming. Int. J. Food Syst. Dyn. 2022, 13, 17–29. [Google Scholar] [CrossRef]

- Ellis, J. Agricultural Transparency: Reconnecting Urban Centres with Food Production. 2012. Available online: http://hdl.handle.net/10222/14577 (accessed on 15 April 2012).

- Qin, H.; Dong, Y.; Guo, L.; Man, L.; Chai, S. An intelligent control system for building aquaculture based on model-free adaptive control. Ferroelectrics 2023, 609, 87–96. [Google Scholar] [CrossRef]

- Banerjee, C.; Adenaeuer, L. Up, up and away! The economics of vertical farming. J. Agric. Stud. 2014, 2, 40–60. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Y.-B.; Choi, J.-H.; Lee, J.-H.; Jo, A.-H.; Han, S.W.; Han, S.-H.; Choi, H.J.; Choi, C.Y.; Kang, J.-C.; Min, E.; et al. Biofloc Application Using Aquaponics and Vertical Aquaculture Technology in Aquaculture: Review. Fishes 2023, 8, 543. https://doi.org/10.3390/fishes8110543

Yu Y-B, Choi J-H, Lee J-H, Jo A-H, Han SW, Han S-H, Choi HJ, Choi CY, Kang J-C, Min E, et al. Biofloc Application Using Aquaponics and Vertical Aquaculture Technology in Aquaculture: Review. Fishes. 2023; 8(11):543. https://doi.org/10.3390/fishes8110543

Chicago/Turabian StyleYu, Young-Bin, Jae-Ho Choi, Ju-Hyeong Lee, A-Hyun Jo, Sung Won Han, Song-Hun Han, Hee Jae Choi, Cheol Young Choi, Ju-Chan Kang, EunYoung Min, and et al. 2023. "Biofloc Application Using Aquaponics and Vertical Aquaculture Technology in Aquaculture: Review" Fishes 8, no. 11: 543. https://doi.org/10.3390/fishes8110543

APA StyleYu, Y.-B., Choi, J.-H., Lee, J.-H., Jo, A.-H., Han, S. W., Han, S.-H., Choi, H. J., Choi, C. Y., Kang, J.-C., Min, E., & Kim, J.-H. (2023). Biofloc Application Using Aquaponics and Vertical Aquaculture Technology in Aquaculture: Review. Fishes, 8(11), 543. https://doi.org/10.3390/fishes8110543