Applications and Perspectives of Ultrasonic Multi-Gas Analysis with Simultaneous Flowmetry

Abstract

:1. Introduction

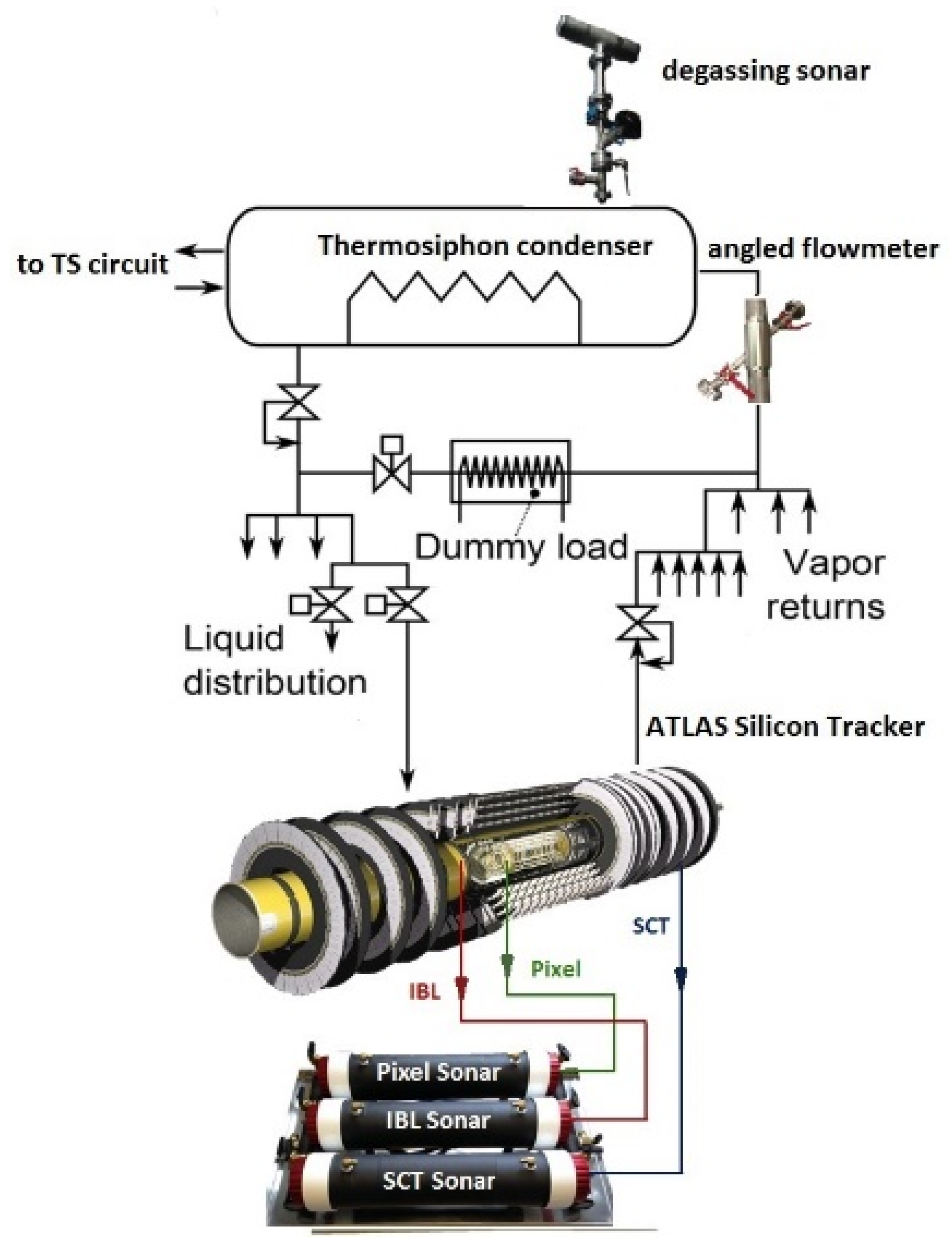

2. Materials and Methods

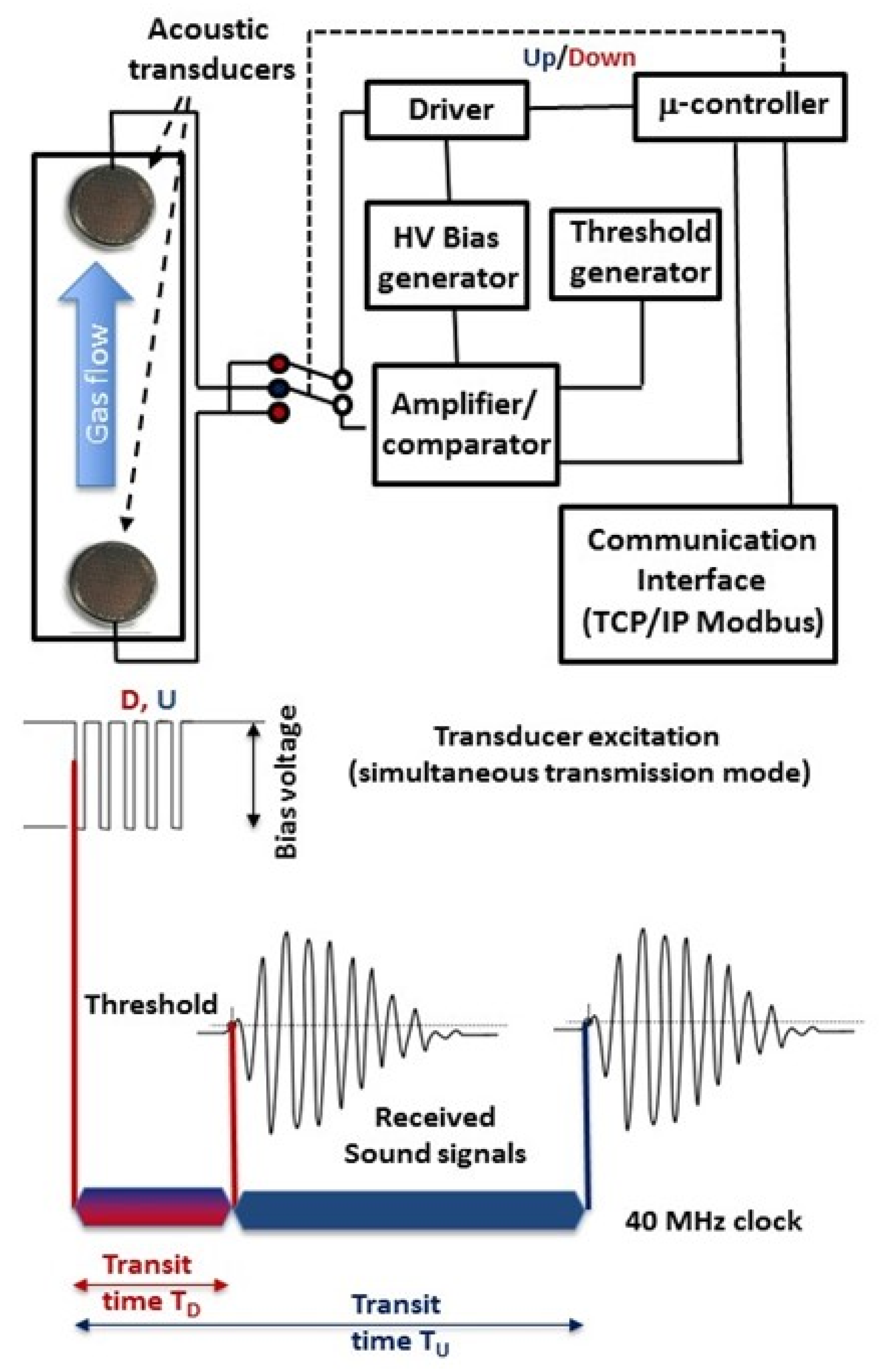

2.1. The Instrumentation and Its Operating Principle

2.2. Gas Flow and Mixture Analysis Algorithms

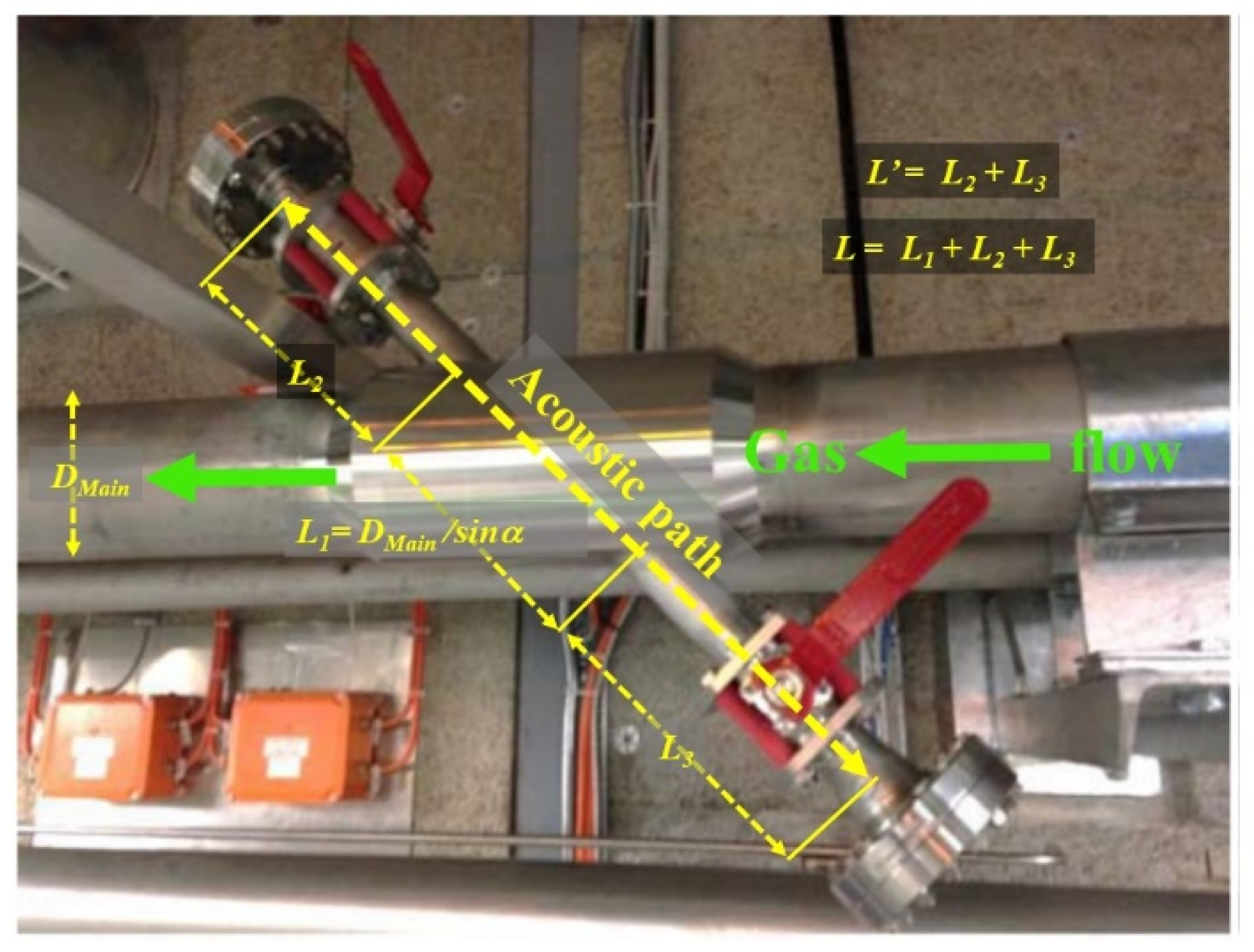

2.2.1. Physical Base for Gas Flow Measurements

2.2.2. Physical Base for Gas Mixture Analysis

2.3. Instrument Calibration

2.4. Database Operation

2.4.1. Data Generation and Storage—3-D Dataspace

2.4.2. Data Interpolation and Concentration Finding

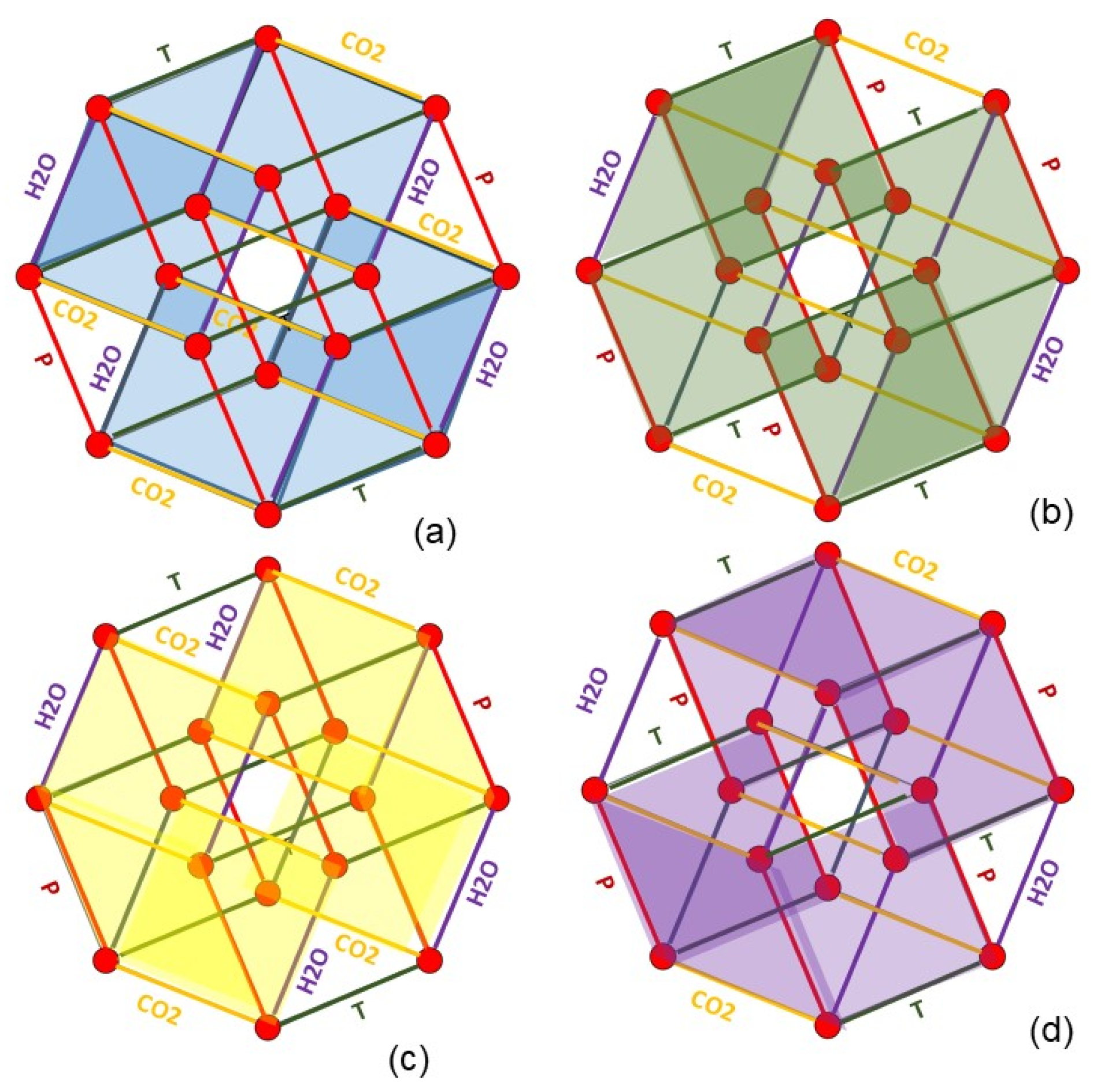

- (i)

- The {C3F8 in N2} vs. sound velocity fit parameters held in the eight cans depicted in Figure 8a are interpolated to intermediate values corresponding to Tmeas at grid pressures immediately above and below Pmeas as shown in Figure 8b, collapsing the search at the core of the grid to a 2-D search between four grid points on a square in {P, ppmCO2} space;

- (ii)

- These intermediate {C3F8 in N2} vs. sound velocity fit parameters are then interpolated along the orthogonal (P) direction to calculate new intermediate parameters corresponding to Tmeas as shown in Figure 8c, further collapsing the core search to a final interpolation between two2 adjacent grid points on a line in the {ppmCO2} direction;

- (iii)

- The final interpolation of intermediate {C3F8 in N2} vs. sound velocity fit parameters is then made along the {ppmCO2} direction obtaining the final parameters corresponding to {Pmeas,Tmeas,CO2meas}: Figure 8d.

3. Results

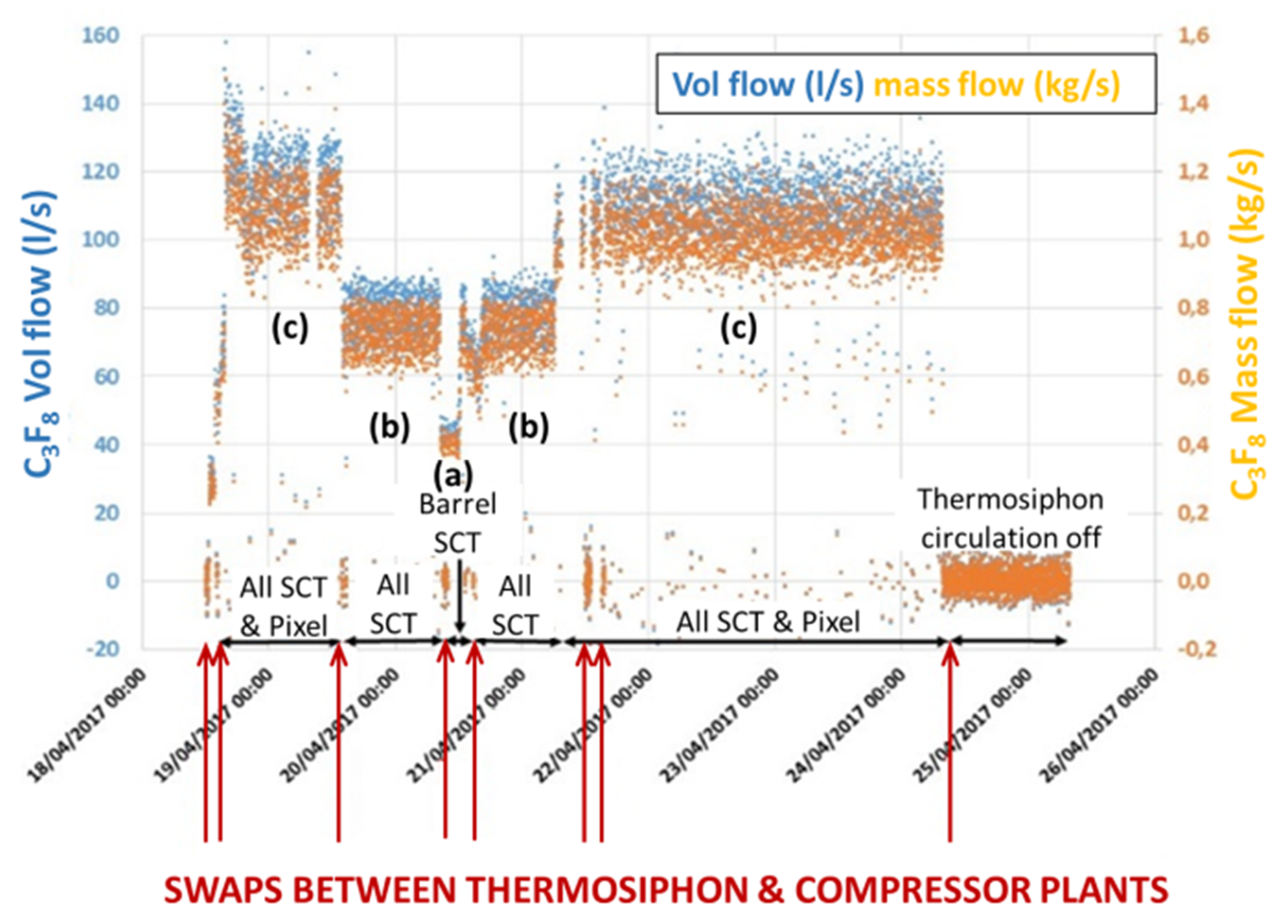

3.1. Flowmetry

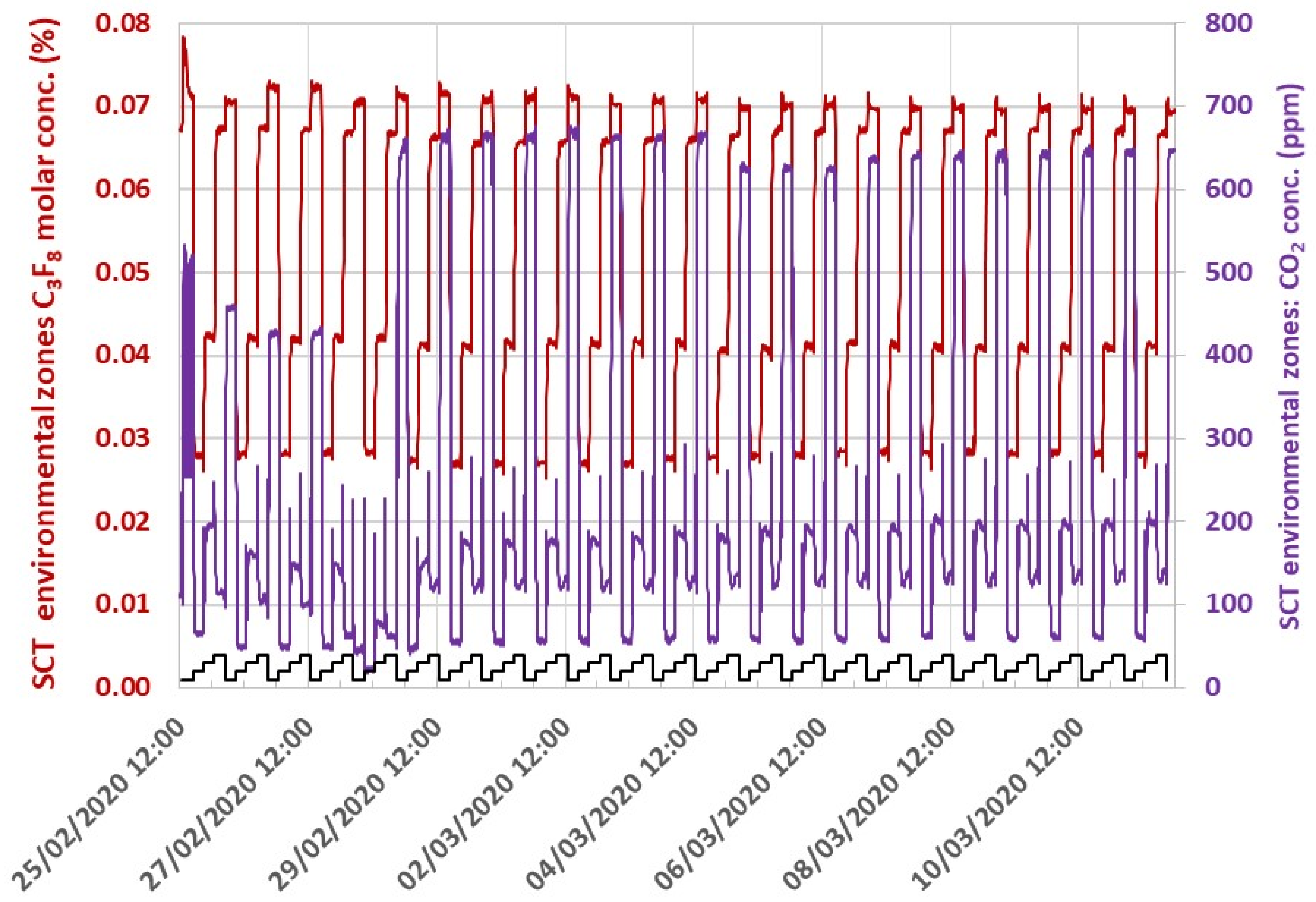

3.2. Analysis of a Pair of Gases of Primary interest in the Presence of Third-Party Gas Contamination

4. Discussion

4.1. Extensions into > 3-D Process-Spaces

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Dedication

Conflicts of Interest

References

- Bates, R.; Battistin, M.; Berry, S.; Berthoud, J.; Bitadze, A.; Bonneau, P.; Botelho-Direito, J.; Bousson, N.; Boyd, G.; Bozza, G.; et al. A combined ultrasonic flowmeter and binary vapour mixture analyzer for the ATLAS silicon tracker. J. Instrum. JINST 2013, 8, P02006. [Google Scholar] [CrossRef] [Green Version]

- Battistin, M.; Berry, S.; Bitadze, A.; Bonneau, P.; Botelho-Direito, J.; Boyd, G.; Corbaz, F.; Crespo-Lopez, O.; Da Riva, E.; DeGeorge, C.; et al. The thermosiphon cooling system of the ATLAS experiment at the CERN Large Hadron Collider. Int. J. Chem. React. Eng. 2015, 13, 511–521. [Google Scholar] [CrossRef]

- Originally by Polaroid® for Autofocus Cameras: Now Marketed as the SensComp Model 600 Transducer. Available online: http://www.senscomp.com/ultrasonic-sensors/ (accessed on 7 January 2021).

- Lemmon, E.; Huber, M.; McLinden, M. REFPROP Standard Reference Database 23, version 9.0; U.S. National Institute of Standards and Technology, Thermophysical Properties Division: Boulder, CO, USA, 2010. [Google Scholar]

- Battistin, M.; Berry, S.; Bonneau, P.; Crespo-Lopez, O.; Deterre, C.; Doubek, M.; Favre, G.; Hallewell, G.; Katunin, S.; Lombard, D.; et al. Novel ultrasonic instrumentation developments for real-time monitoring of binary gas mixtures and flow: Description and applications. Sens. Transducers 2016, 207, 4–14. Available online: https://www.sensorsportal.com/HTML/DIGEST/december_2016/Vol_207/P_2878.pdf (accessed on 7 January 2021).

- Amphenol Telaire® Infrared CO2 Monitor. Available online: https://www.amphenol-sensors.com/en/telaire (accessed on 20 November 2020).

- Siemens Simatic WINCC OA. Available online: https://new.siemens.com/global/en/products/automation/industry-software/automation-software/scada/simatic-wincc-oa.html (accessed on 20 November 2020).

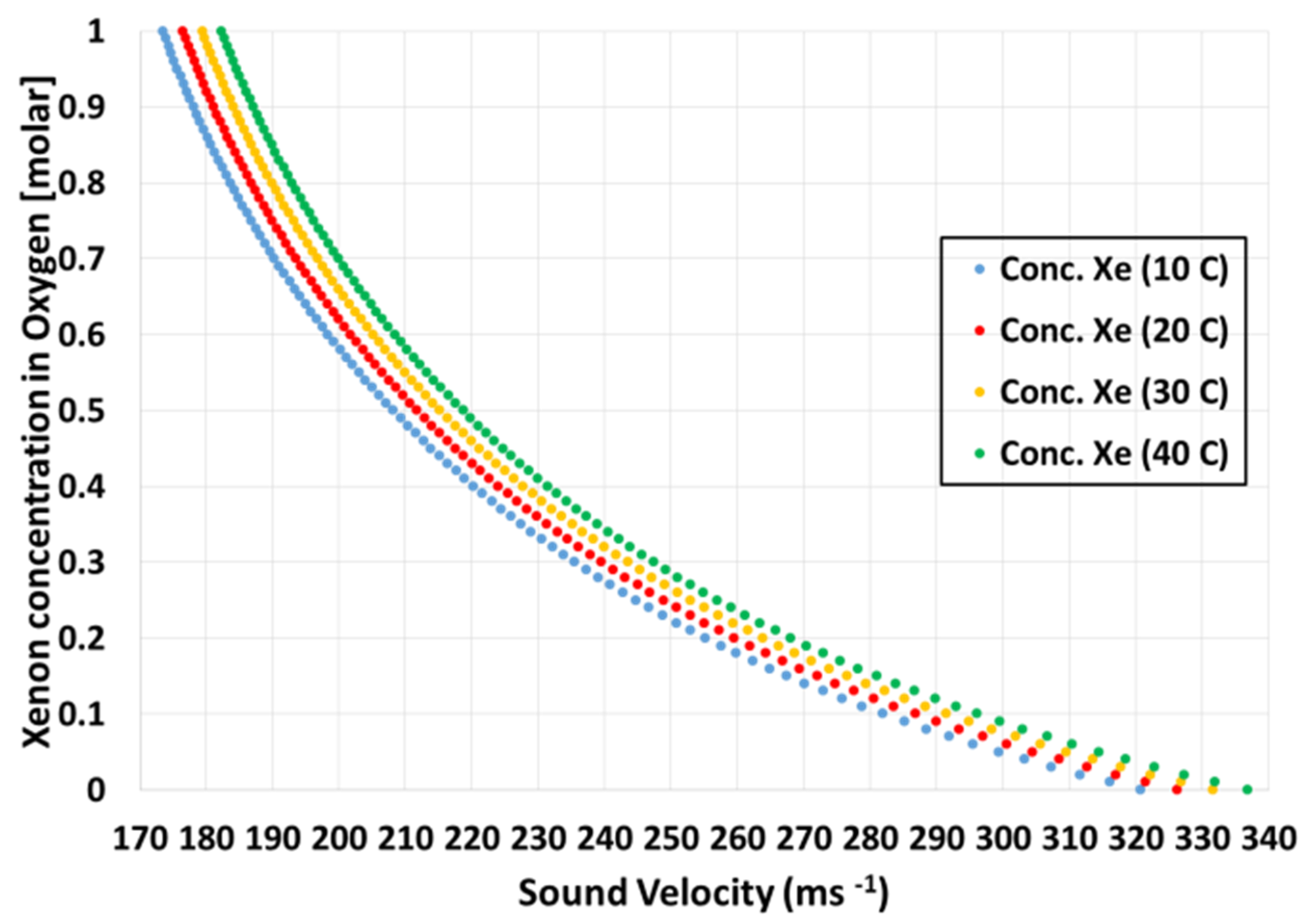

- Williams, D.; Hallewell, G.; Chakkarapani, E.; Dingley, J. Real-time measurement of Xenon in a binary gas mixture using ultrasound time-of-flight: A feasibility study. Anesth. Analg. 2019, 129, 985–990. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hallewell, G.; Lynnworth, L. A simplified formula for the analysis of binary gas containing a low concentration of a heavy vapor in a lighter carrier. In Proceedings of the 1994 IEEE Ultrasonics Symposium, Cannes, France, 31 October–3 November 1994; Volume 3, pp. 1311–1315. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hallewell, G.; Dingley, J.; Doubek, M.; Feuillassier, R.; Katunin, S.; Nagai, K.; Robinson, D.; Rozanov, A.; Williams, D.; Vacek, V. Applications and Perspectives of Ultrasonic Multi-Gas Analysis with Simultaneous Flowmetry. Instruments 2021, 5, 6. https://doi.org/10.3390/instruments5010006

Hallewell G, Dingley J, Doubek M, Feuillassier R, Katunin S, Nagai K, Robinson D, Rozanov A, Williams D, Vacek V. Applications and Perspectives of Ultrasonic Multi-Gas Analysis with Simultaneous Flowmetry. Instruments. 2021; 5(1):6. https://doi.org/10.3390/instruments5010006

Chicago/Turabian StyleHallewell, Gregory, John Dingley, Martin Doubek, Robin Feuillassier, Sergey Katunin, Koichi Nagai, David Robinson, Alexandre Rozanov, David Williams, and Vaclav Vacek. 2021. "Applications and Perspectives of Ultrasonic Multi-Gas Analysis with Simultaneous Flowmetry" Instruments 5, no. 1: 6. https://doi.org/10.3390/instruments5010006

APA StyleHallewell, G., Dingley, J., Doubek, M., Feuillassier, R., Katunin, S., Nagai, K., Robinson, D., Rozanov, A., Williams, D., & Vacek, V. (2021). Applications and Perspectives of Ultrasonic Multi-Gas Analysis with Simultaneous Flowmetry. Instruments, 5(1), 6. https://doi.org/10.3390/instruments5010006