Power Quality Impact and Its Assessment: A Review and a Survey of Lithuanian Industrial Companies

Abstract

:1. Introduction

2. Literature Review

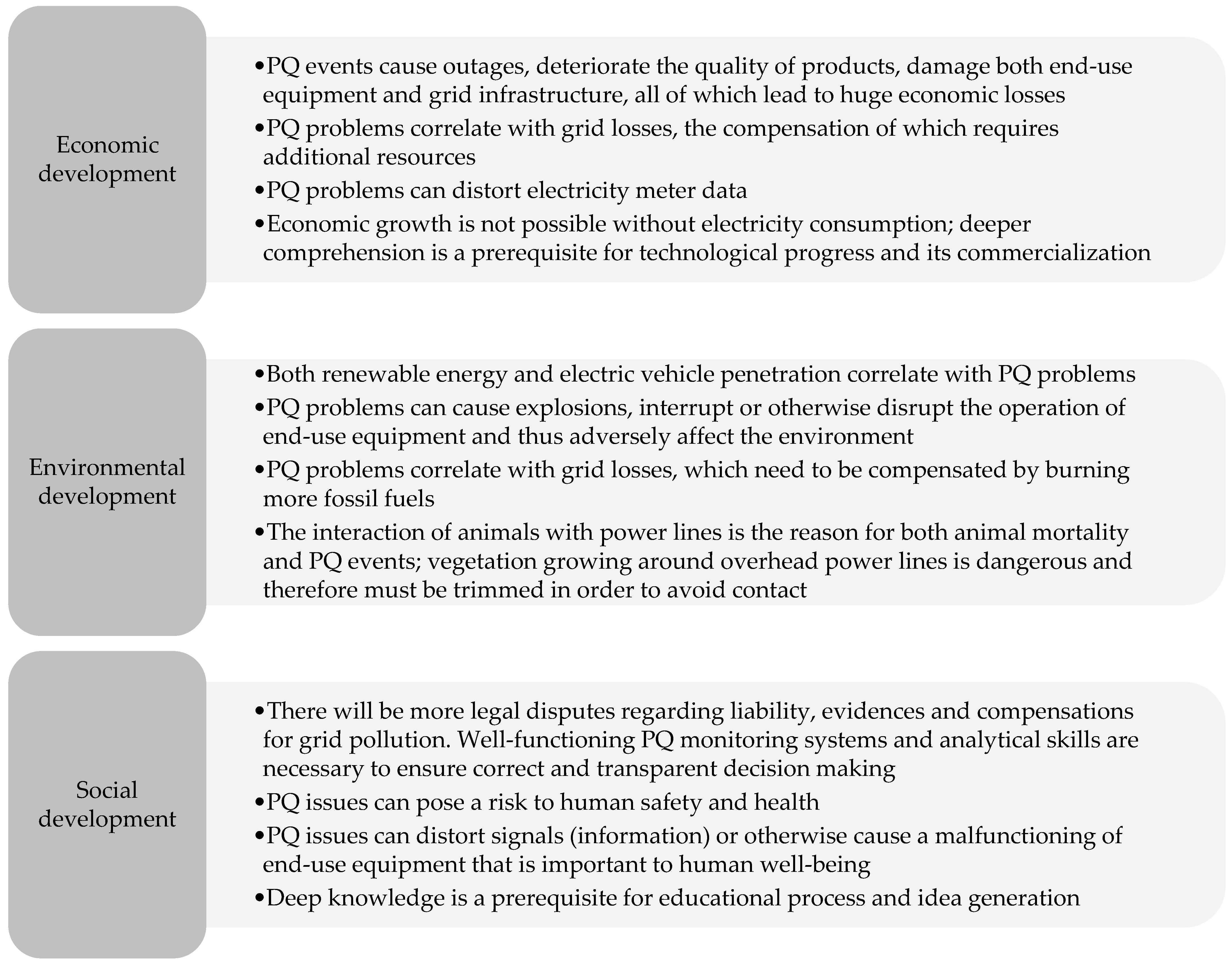

2.1. Economic Impact

2.2. Environmental Impact

- Vegetation-related faults. These faults are caused by the interaction of wires with trees and bushes. It is not a secret that among the measures to reduce the impact of vegetation are condition monitoring and surveillance of electricity grid infrastructure, vegetation clearing, as well as replacing overhead power lines with underground cables. In Lithuania, according to the statistical data of 2015–2018 provided by [2], the expected annual rate of interaction between the 10 kV grid and a tree outside the safety zone is 845, the interaction with a tree inside the safety zone—95, shrub grow-in events—117, and tree branch drop events—160. In Lithuania, according to the Law of the Republic of Lithuania on Special Conditions of Land Use [73], the safety zone of overhead power lines of up to 1 kV is 2 m in both directions, 6 kV and 10 kV—10 m, 35 kV—15 m, 110 kV—20 m, 330 kV and 400 kV—30 m, and formerly used 750 kV (between the Ignalina Nuclear Power Plant and Belarus)—40 m. Further, it is noteworthy that the safety zone of aerial power cables is 2 m in both directions, underground power cables—1 m, and submarine power cables—100 m. The formation of the safety zones results in a corridor effect—these zones, for example, can facilitate the access of both predators and hunter to ungulates, as well as hinder the movement of some ungulate species, such as the white-tailed deer (Odocoileus virginianus), when there is snow accumulation [10,74,75,76] (in addition to the already mentioned the roe deer and the European moose (Figure 5c), the following ungulate species also live in Lithuania, many of whose main enemies are grey wolves (Canis lupus) and northern lynxes (L. lynx lynx): the wild boar (Sus scrofa), the European fallow deer (Cervus dama), the red deer (Cervus elaphus), the European bison (Bison bonasus), as well as non-native and less common the northern spotted deer (Cervus nippon) (which can mate with native red deer, resulting in the hybrid offspring and thus affecting their own gene pool), the Père David’s deer (Elaphurus davidianus), and the European mouflon (Ovis ammon musimon) [77]).

- Electrical network equipment and infrastructure failures. These are electrical apparatus failures, pole and crossarm failures, and line failures [71]. The first group includes explosions of transformers, circuit breakers, and other oil-filled equipment. The most common type of insulating oil is mineral oil, which, like many other products of crude petroleum, is flammable, explosive and not environmentally friendly. The second group includes such incidents as wooden pole burning due to short circuit, and insulator contamination. In Lithuania, in contrast to, for example, Latvia, wooden poles are not used. Contamination on the surface of the insulators directly and indirectly enhances the chances of flashover by forming a conductive layer on insulator surface, accelerating the corrosion process, causing cracks, etc., and many effects can be prevented through washing: in addition to natural overgrowth with plants, lichens and algae, insulator contamination may be caused by many other factors and materials, such as salt, bird excreta and feathers, weather and its variations, cement, coal, soil, metallic particles, fertilizers, various chemicals, volcanic ash, sandstorms, smog, and smoke (e.g., see [78,79,80,81] for more information). The third group includes sparking during earthed—three-phase-to-ground, two-phase-to-ground, and single-phase—faults, when the wires fall to the ground. In the Lithuanian MV grids, after a single-phase fault, high grounding (capacitive) currents are limited with arc suppression reactors (by creating the conditions for current resonance). According to [82], it is “generally assumed that arcs extinguish by themselves when the arc current is below 5–10 A”. It is worth mentioning that under the appropriate conditions, the extinguished arc can reignite.

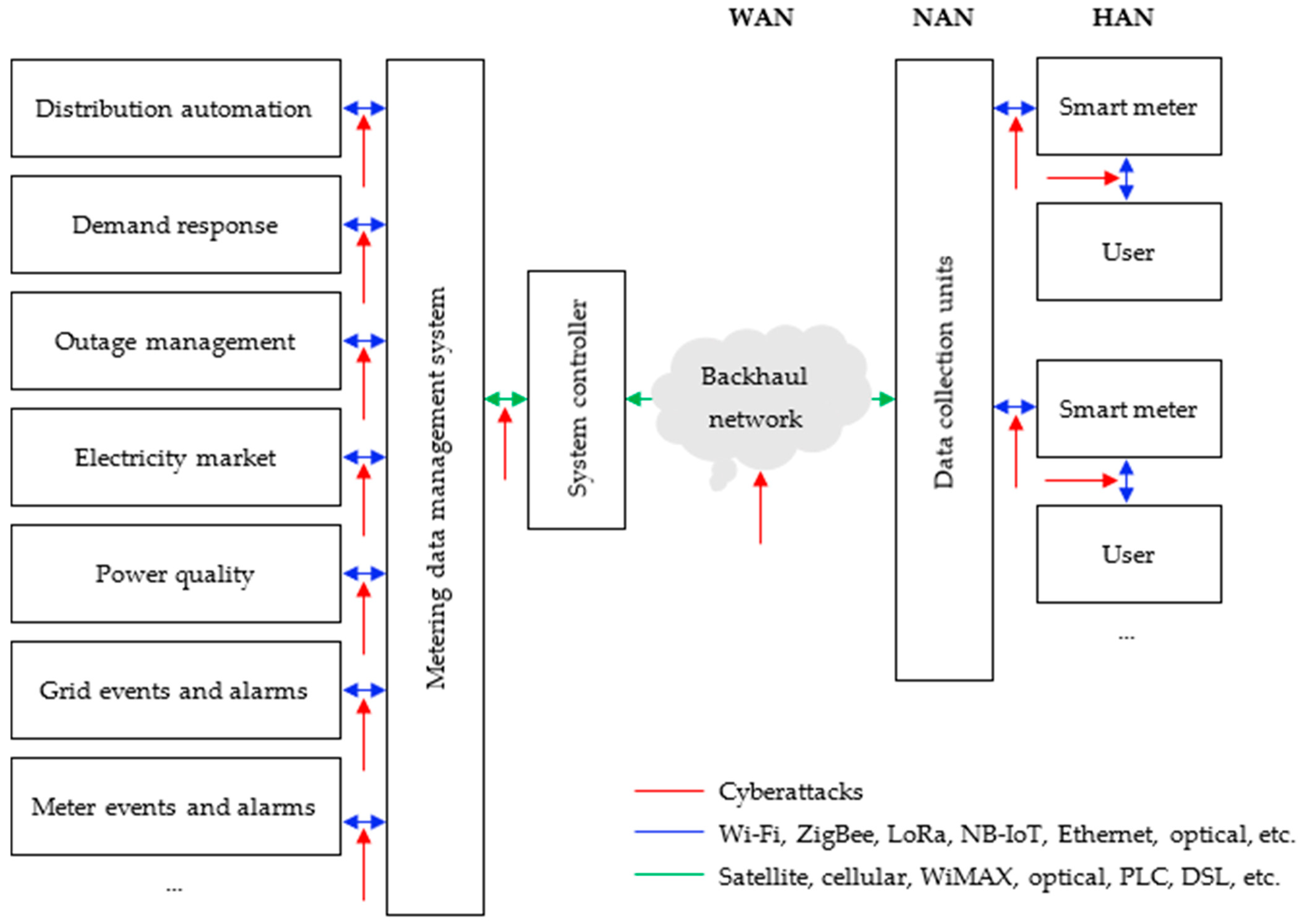

2.3. Social Impact

- EN 50160:2010 sets requirements for supply voltage and frequency in normal operation mode, flicker severity, voltage harmonics (up to the 25th, but some levels are still under consideration), voltage unbalance (only negative sequence magnitude), and mains signaling voltage (up to 100 kHz) in public electricity networks with nominal voltages up to and including 150 kV. Limits for rapid voltage changes, voltage sags, voltage swells, supply interruptions, voltage transients, and inter-harmonics are not set. The standard has many gaps which hinder the development of both artificial intelligence (AI) algorithms for PQ assessment and legal acts—some of them are already discussed in [8]. In Lithuania, as in most European countries, this standard is mentioned in the national legal acts and thus is mandatory. In accordance with the Rules for the Supply and Use of Electricity of the Republic of Lithuania [83], the operator, failing to ensure PQ in accordance with EN 50160:2010, must compensate the consumer for the damage caused, excluding the cases of natural phenomena (flood, thunderstorm, frost, sleet, storm, squall, hail, etc.), fire, war, terrorist attack, force majeure, state action, third party action, activation of accident prevention automation, circumstances of necessary action, and many other cases related to the actions or inactions of the electricity consumers.

- IEEE Std 1159-2019 and other IEEE PQ standards do not regulate PQ phenomena, except for IEEE Std 519-2022 [84] which sets limits for both voltage and current harmonics at a point of common coupling. Despite this, IEEE Std 1159-2019 is more informative than EN 50160:2010.

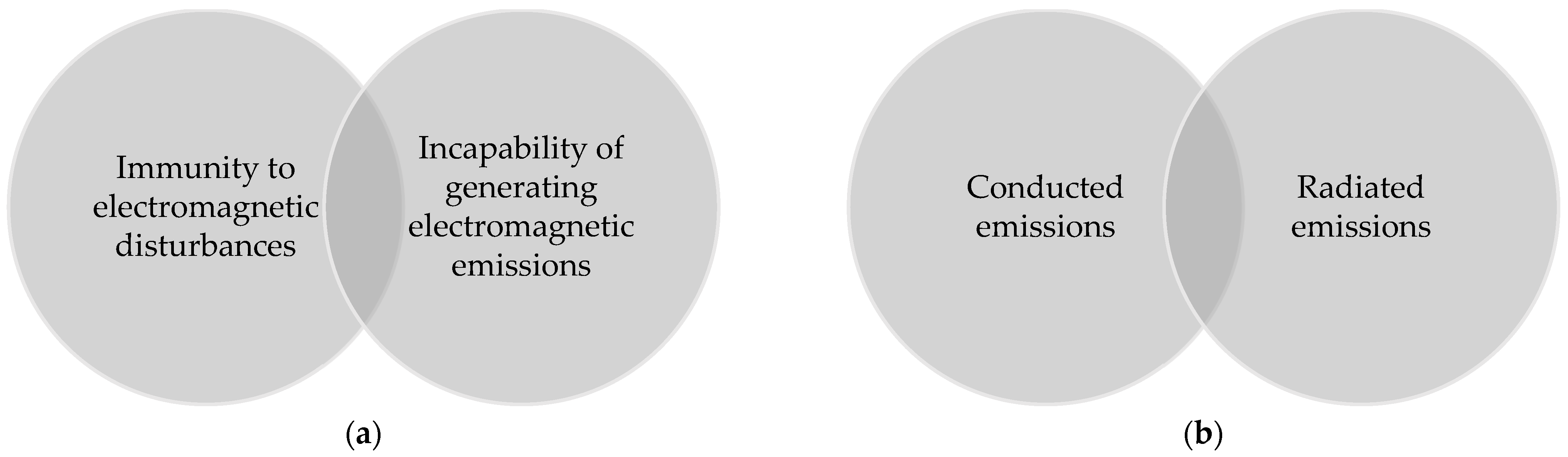

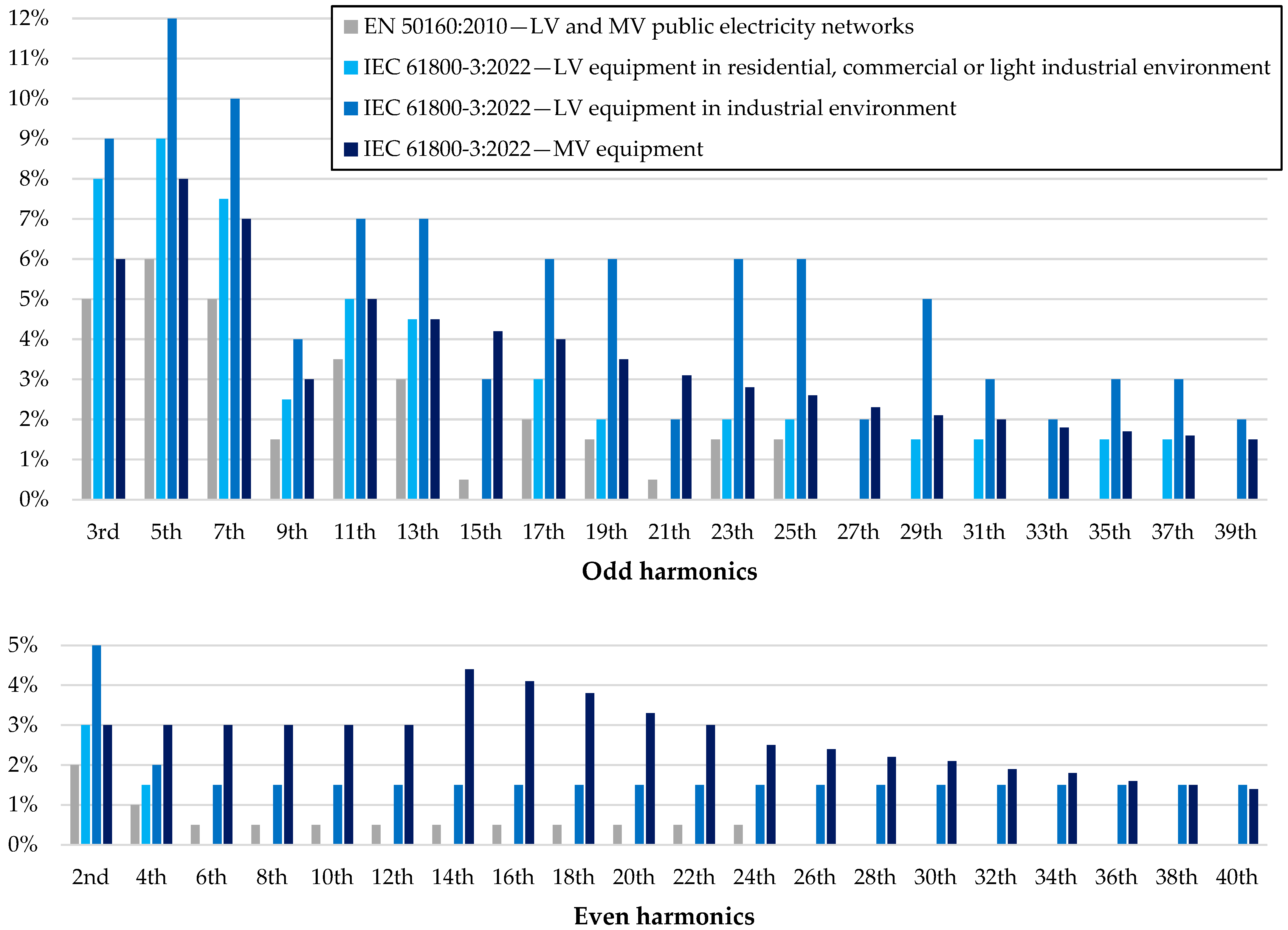

- The harmonized standards under the EMC Directive 2014/30/EU contribute to PQ regulation. IEC 61000-2-2:2002 [85] specifies PQ requirements for public LV electricity networks and supplements EN 50160:2010 by expanding the requirements for voltage harmonic levels up to the 50th, by introducing some requirements for inter-harmonics in the beat frequency range of 0.2–40 Hz (with the fundamental) based on a short-term flicker level of 1 for lamps operated at 120 V and 230 V, as well as by setting the requirements for ripple control system signals in the range of 110–3000 Hz. IEC 61000-2-4:2024 sets PQ requirements for industrial locations with a nominal voltage up to 35 kV, IEC 61800-3:2022—for current harmonic levels in networks with adjustable speed drives depending on the short-circuit power ratio at an agreed point of coupling (common or in-plant). IEC 61000-4-7:2002 [86], IEC 61000-4-15:2011 [87] and IEC 61000-4-30:2015 [88] define the methods for measurement and interpretation of PQ results and therefore play a central role in both EN 50160:2010 and IEEE PQ standards. In Lithuania, as in other European Union countries, EMC standards together with their normative references as well as IEC 61800-3:2022 are mandatory according to the principle of imperativeness of harmonized standards to ensure the compliance with the already mentioned EMC Directive 2014/30/EU.

- The increase in wind park generation during windy weather can increase flicker level. Although the flickers do not cause downtime [19], they affect occupational health.

- The increase in solar park generation during sunny weather can correlate with the level of harmonics injected into the grid.

- On request to increase consumption, the industrial company launched many electric motors, variable-frequency drives and electric arc furnaces, and its neighbors was affected by the caused voltage sags, produced harmonics and flickers (respectively).

- After increasing the consumption of an industrial company, a short circuit occurred in its internal network, which affected both the company itself and its neighbors.

- Increased consumption had need of additional staff. The lighting was switched off by a voltage sag and, as a result, an employee who worked extra hours was injured.

- The consumption was increased due to the increase in wind park generation during stormy weather, and a lightning strike (voltage transient) damaged the additionally connected end-user equipment.

3. Materials and Methods

3.1. Creating a Survey

3.2. Impact Assessment

3.3. Comparison of Two Samples

3.3.1. Statistical Hypothesis Test

3.3.2. Convolution-Based Method

- Find matrix convolution;

- Find each matrix autoconvolution;

- Find the difference between the convolution and each autoconvolution;

- Find absolute value of each element in the result matrix.

4. Results

- “The technological process is halted after each voltage sag, five technological lines are interrupted, the crushers and the conveyors become overloaded with crushed stone. The restart takes up to 2–3 h. Particularly sensitive equipment are 0.4 kV induction motors installed in the automated lines. We do not know exactly whether voltage sags are dangerous to 0.23 kV electric motors and mechanisms driven by them.”

- “The technological process is interrupted after each voltage sag, the work of both the production line equipment and eight packing lines is halted. In the production facilities, the mass prepared for pet food production becomes rigid, and needs to be re-moved and disposed. The restart takes up to 1 h. After each voltage sag, we suffer a loss of EUR 8000.”

- “Voltage variations damage technological processes and equipment, as a result of which the technological processes of water supply and domestic waste water treatment are interrupted. We do not know exactly how dangerous voltage sags are to both 0.4 kV and 0.23 kV electric motors and mechanisms driven by them.”

- “Voltage sags cause an emergency stop and sometimes a failure. The most sensitive equipment: refrigeration, product formation equipment, warehouse equipment, servers. After an emergency stop, it may take up to 2 h to start up the above-mentioned equipment, if it was not damaged during the PQ event. During this time, the temperature regime of the manufacturing premises becomes inappropriate, the products are not manufactured, and the employees experience downtimes. In the near future, we are going to install PQ analyzers, and therefore will be able to more accurately relate equipment stops and failures to the parameters of power supply.”

- “Our company has sophisticated automated technical equipment. Voltage sags and supply interruptions can have irreversible consequences for both the equipment and the production. Supply interruption during glass tempering can irreversibly damage the rollers of the glass tempering furnace. Glasses may stick to the ceramic rollers. The company experiences losses (both direct and indirect).”

- “The technological process is halted after each voltage sag, four production lines are interrupted. For the company, the most dangerous are micro-interruptions (sometimes they are multiple), which disturb the operation of our controllers. If at least one controller stops or loses the program, the controlling computer stops the production lines in an emergency manner. Then the line cannot be restarted because the products remain in it, and the products cannot be removed because the line cannot be started. This causes very long-lasting outages. There are cases of deletion of the internal parameters of the frequency converters as well as irreparable damage.”

- “In our company, the production process takes place non-stop around the clock. Voltage sags interrupt the process, and as a result up to 1–1.5 h can be lost. The technological process must be restarted. Part of the manufactured production must be disposed due to substandard processing. Electric motors, controllers, personal computers are sensitive to voltage sags.”

- “We do not have the equipment for voltage sag magnitude recording, we can admit that we are experiencing more and more disconnections. The company has many CNC machines for steel sheet, wire and pipe processing, and all of them are vulnerable. After voltage sags, very often we cannot start the equipment without service assistance.”

- “The technological process is interrupted after each voltage sag, from four to eight technological lines are halted, grains remain in the devices and need to be removed. The restart takes up to several hours. Particularly sensitive equipment are 0.4 kV induction motors installed in the automated lines, grain dryers. We do not know the exact parameters of dangerous voltage sags, because we do not have PQ monitoring equipment and experience in PQ data analysis. However, when the technological line and electric drives stop, the company experiences large economic losses.”

- “The technological process is interrupted after each voltage sag, four production lines are interrupted, plastic solidifies in the devices and needs to be removed. The restart takes up to 4 h. Particularly sensitive equipment are 0.4 kV induction motors installed in the automated lines. In the near future, the company plans to install PQ monitoring and mitigation systems. We do not know exactly whether voltage sags are dangerous to 0.23 kV electric motors and mechanisms driven by them.”

- “We do not measure the residual voltage and duration [of voltage sags], thus the completed tables would be just an improvisation. If supply interruption is longer than 3 s, important equipment stops—steam generators, air compressors, wastewater treatment facilities, packing machines, conveyor systems, robots, autoclaves for sterilization, water pumps, etc. It takes up to 0.5–1 h to restore the work.”

- “We cannot fill the tables correctly, because we do not have the accurate data. The company has a lot of automatic technological equipment that are vulnerable to voltage sags. In most cases, the processes and the equipment stop when the voltage level is below 90%. The majority of the most sensitive equipment are protected with double-conversion uninterruptible power sources (UPS). The power of the installed UPS system is about 200 kW.”

- “When the phase-to-ground voltage of the 10 kV feeder No. 1 drops below 5 kV, undervoltage protection is triggered and the power supply is disconnected. Then, the automatic transfer switch restores the supply from the feeder No. 2. Phase sequence relays installed in railway stations, GSM-Railway base stations masts and some railway level crossings also protect the equipment from voltage sags by disconnecting it when phase-to-ground voltage level drops below 90% (207 V). In stations, crossings, and substations, where automatic protection from voltage sags is not installed, the biggest problem caused by either voltage sag or supply interruption is the distortion of railway signals before the train. LED lights, metal-halide lights, various bulbs, searchlights and spotlights, heating systems of railroad switches (heating elements, magnetic starters, isolation transformers), and controllers are not very sensitive to voltage sags. Voltage, current, and earthing transformers installed in 10 kV substations are vulnerable, as well as sensitive equipment is server rooms, supervisory control and data acquisition system, teleinformation collection and transmission equipment, remote terminal units, etc.”

- “In my opinion, the impact of voltage sag must be evaluated complexly. After voltage sag, the technological process is interrupted, the equipment is disturbed, and the company suffers losses. The restart takes up to 1–4 h if there is no electronic or mechanical failure. According to monitoring data, the critical depth of voltage sag for our company is 30% of nominal phase-to-ground voltage, and the critical duration—200 ms. In case of dependent voltage sags, i.e., when two or more voltage sags occur in an interval of several seconds, the devices practically have no possibility to continue working.”

- “The technological process is interrupted after each voltage sag. Four parquet production lines are halted. Any failure of any process chain irreversibly damages unprocessed material (product). The particular sensitive part is at the end—ultraviolet coating and varnish curing. Both of these processes must be continuing. Next, voltage sags are dangerous to boiler stations. The input of biomass is inert, the forced smoke release cannot work without power supply. Moreover, the combustion continues, which poses a risk of explosion. Next, PQ impact on the grinding equipment is also dangerous because their shafts have high inertial forces. Braking is performed mechanically and electrodynamically—such facilities cannot work without power supply.”

- “The technological process is interrupted after each voltage sag, the production lines are interrupted, the restart takes up to 2 h. Particularly sensitive equipment is 0.4 kV induction motors installed in the automated lines. In the future, the company plans to install PQ monitoring equipment.”

- “Voltage sags interrupt the technological processes. Despite the fact that the appropriate protections are triggered, it does not always help, the equipment stops, and the restart is required. This generates outages, economic losses are incurred, equipment failures are caused, the quality of product suffers, production terms are prolonged.”

- “The technological process is interrupted after each voltage sag, the production lines are halted, the restart takes up to 2 h.”

- “Our company rarely experience heavy losses due to voltage sags (e.g., repair of pumps and equipment). Usually, voltage sags disrupt the process of water supply, which leads to complaints from our customers.”

- “The technological process is interrupted after each voltage sag. The equipment can be damaged. The hot water boiler stops. The restart of the equipment takes up to 2 h, sometimes longer. Moreover, the work of the network pumps is affected, and pressure fluctuations are caused. As a result, hydraulic shocks occur and the pipelines are damaged. The danger to occupational safety and health increases.”

- “When the residual voltage is equal to 0 V, the pumps and all other equipment stop. The temperature drops, the service is unavailable, the temperature schedule is not followed, direct and indirect losses are incurred, and the equipment is damaged. The likelihood of hydraulic shock increases.”

- “Particularly sensitive equipment are 0.4 kV induction motors installed in the automated lines. In the future, the company plans to install PQ monitoring equipment”.

- “We manufacture semiconductor devices. The manufacturing process is long and continuous, therefore, if any part of the chain is interrupted by voltage sag, economic losses are incurred.”

- “Voltage sags negatively affect the production of plastic and metal containers (package). When the protective relays are triggered, the plastic melting machines, metal press machines, and welding equipment stop.”

- “Voltage sags interrupt the technological process—the gas and biofuel boilers together with the electric generator stop. If the equipment is not damaged, the restoration of heat and electricity production takes 1–2 h, sometimes is longer, depending on the voltage sag depth and duration. The company suffers economic losses by not generating and not supplying both heat and electricity.”

- “The knitting and heating processes are damaged after each voltage sag. A net damaged at the knitting stage becomes waste—it cannot be sold or used for other purposes. Each time the minimum loss is EUR 600–3000 per machine (we have eight machines) plus lost time. Let us continue with the heating process—the rope stops and as a result is overheated, the impregnant is squeezed out, and the rope becomes defective. Losses—EUR 3 per meter (the length of the rope is 2000 m). In the future, the company plans to install PQ monitoring and mitigation technologies.”

- “We are a food industry company and we use modern food production equipment to produce our products. Most of the process is fully automated and is automatically stopped by the protection when voltage sag depth exceeds 10%. If at least one device is disconnected, the entire production process stops, and the production line must be cleaned before the restart. Losses depend on voltage sag magnitude, duration, location (feeder), etc., and are calculated separately in each case, but when the work efficiency is 100%, hourly losses are about EUR 22,700.”

- “We did not fill the tables for a simple reason—the voltage sags are practically undetectable without special monitoring equipment, thus only longer supply interruptions can be taken into account. The company’s losses are increasing rapidly with each passing minute. Voltage sags are particularly common in windy or adverse weather conditions. Under such conditions, the weaving looms usually cannot work.”

- “The technological process is interrupted after each voltage sag. The production lines are halted. The plastic shedders, screw loaders and centrifuges become clogged with polyethylene pieces. After each voltage sag, the plastic solidifies and must be removed from granule agglomeration units. The restart requires human resources and takes up to 4 h. Particularly sensitive equipment is the plastic film making machines. After the shutdown of the lines, a large amount of plastic waste is generated (about 4000 kg per stop). It takes up to 2–6 h to restart all the lines. It has been estimated that the company suffers a loss of EUR 5000–8000 after each dangerous voltage sag.”

- “The terminal experiences economic losses and non-material damage after voltage sag or supply interruption. After each event, the technological process is interrupted, both the operation of equipment and transport traffic are halted, and the loading process becomes unsafe and longer. The recovery takes up to several hours due to the human factor: as the person responsible for the company’s electrical sector, after a receiving a notification about the problem, I have to go to the terminal (within 4 h) and deal with the consequences outside working hours. Metal-halide lamps, which illuminate the territory, cool down and again turn on only after 30 min. Particularly sensitive equipment are computers and controllers. Some of them have UPSes. In our opinion, PQ monitoring system is not worthwhile and not cost-effective, because it only records voltage sags but does not prevent them. The monitoring, including the sharing of relevant information, must be carried out by the DSO. Most often the faults occur in the 10 kV grid, and the duration of supply interruption is equal to the automatic transfer switch time delay.”

- “The company does not have PQ analyzers or other devices; thus, we cannot provide the data about both magnitude and duration of voltage sags. Our company does not experience any significant losses due to voltage sags—the technological line is forced to stop several times a year. The restart takes up to 1 h. We do not plan to install the PQ mitigation devices as it would not be economically viable. In our opinion, more problems are caused by voltage transients. The devices are often disconnected during thunderstorms by control panels. The installed surge arresters are not efficient. In order to avoid such a problem, we stop the work by ourselves when the thunderstorm is approaching.”

- “PQ is particularly important for the production of plastic products of our company. The company has vulnerable equipment, and experiences heavy losses if the technological process is disrupted by a short circuit. There have been cases when the equipment was damaged and needed to be replaced. It usually takes two weeks from ordering new equipment parts to their replacement. Meanwhile, damaged unit is not available for use, and our company suffers heavy losses.”

- “After each voltage sag, the company suffers a loss of EUR 5000.”

- Comments about MV three-phase electric motors:

- “The technological process is interrupted after each voltage sag, the production lines are halted, fabrics freeze in the cutting machines, cutting defects may occur.”

- “The company’s electric motors and variable-frequency drives are very sensitive to voltage sags.”

- “The company’s electric motors are very sensitive to voltage sags. The company experiences losses after each dangerous voltage sag.”

- “Voltage sags that are dangerous to 6 kV electric motors triggers the emergency automation, shifting from one power source to another for continuous energy delivery.”

- Comments about LV three-phase electric motors:

- “The company’s electric motors are very sensitive to voltage sags.”

- “The company’s electric motors are very sensitive to voltage sags. After each dangerous voltage sag, the company suffers a loss of about EUR 920.”

- “No effect was observed because the motors are shut down by the automation of the control panels.”

- “Electric motors are sensitive to voltage sags. In case of a deeper voltage sag, the company’s motors are shut down by overcurrent protection of frequency converters. It also happens that the motors without frequency converters are disconnected by the thermal protection. Supply interruption halts the production process, which restoration takes up to 1.5 h.”

- “All company’s three-phase electric motors are sensitive to voltage sags. After each voltage sag, the company suffers economic and time losses, and a lot of manufacturing wastes are generated. The most affected workshops are knitting, thread and net dyeing, drying, and impregnation.”

- “Short-term voltage sags do not impact the work, motors up to 100 kW operate in self-starting mode.”

- “The company’s electric motors are very sensitive to voltage sags. After each dangerous voltage sag, the company suffers a loss of EUR 1000–11,000.”

- “Short-term voltage sags do not have a significant impact on the work.”

- “We cannot say exactly because we do not have PQ analyzers and we do not have any experience in voltage sag analysis.”

- “The motors are controlled with CNC machines, and therefore are very sensitive to voltage sags. Each time we experience losses.”

- “The electric motors of individual technological equipment are sensitive to voltage sags.”

- “[Voltage sags] are the most dangerous for refrigeration compressors. The protection turns them off.”

- “Electric motors are very sensitive; the company suffers a loss of EUR 5000–20,000 after each voltage sag.”

- “Voltage sags shorten the service life of pumps, sometimes affect the impellers”.

- “After each voltage sag (duration 200–5000 ms), the compressors disconnect and the technology stops.”

- “Voltage sags can cause the malfunctioning of railroad switches—it is possible that the switches will not switch to the right position and, as a result, the train will be delayed.”

- “The company’s electric motors are very sensitive to voltage sags. After each dangerous voltage sag, the company suffers a loss of about EUR 15,000.”

- “Electric motors and servomechanisms are very sensitive to voltage sags. After each dangerous voltage sag, the company can suffer a loss of up to EUR 28,000.”

- “The ventilation systems and pumps cease operating, resulting in production stoppage. Losses—EUR 3000 per hour.”

- Comments about LV single-phase electric motors:

- “The effect [of voltage sags] was not noticed, because the motors are disconnected by the automation of control panels.”

- “Voltage sags can cause the malfunctioning of railroad switches—it is possible that the switches will not switch to the right position and, as a result, the train will be delayed.”

- “We have a large number of units that use a variety of single-phase motors. Their reactions to voltage sags are different. Each voltage sag has an impact.”

- Comments about variable-frequency drives:

- “[Variable-frequency drives are] very sensitive [to voltage sags], because they hand or are irreparably damaged.”

- “When voltage sag occurs, the variable-frequency drives, which tries to execute the com-mand of the controller regardless of the circumstances, stop at first. The voltage drops, the current increases until it reaches the threshold limits, and the unit fails with the overload error flag. Then, the controller stops the entire technological line.”

- “The frequency converters are damaged if supply interruption is between 0.2 s and 2 s. If its duration is longer, the communication with controller is usually lost, which leads to the interruption of the technological process and product damage. The equipment can al-so be damaged: for example, if supply interruption occurs, ammonia [NH3] and carbonic acid [H2CO3] compressors working at 100% capacity damage (crush) their filters due to the pressure, which causes 1–2 h of outage.”

- “Longer voltage variations are dangerous to the equipment which has frequency converters. These devices stop in the case of inappropriate voltage parameters, and then need to be restarted. But before that, when the process stops, it is necessary to remove the unprocessed (raw) material that is no longer suitable for the production.”

- “Momentary voltage variations cause voltage transients that can damage the equipment.”

- “We cannot accurately assess the danger, because the operation of frequency converters also depends on the shape of voltage sag [e.g., single-stage or multi-stage]. The company has many frequency converters, which are sensitive to voltage sags. We suffer economic losses after each dangerous voltage sag.”

- “When voltage variations occur, the frequency converters are disturbed, and usually are disconnected by the protection thereby protecting themself from breakdown and, as a result, disconnecting the converter-fed electric motors. In more serious situations, the frequency converters break down.”

- Comment about MV three-phase generator:

- “After voltage sags, generator protections disconnect the generator from the power grid. The process of electricity generation is halted. Electricity is not sold.”

- “[Voltage sags] have an impact on mineral powder production.”

- “Voltage sags are not dangerous to heating elements.”

- “Temperature chambers are not sensitive to voltage sags.”

- “Heating elements are connected with semiconductor relays and thermoregulators. These devices are sensitive to voltage variations, which can interrupt their smooth operation and, in some cases, cause damage.”

- “All systems operating in the company have programmable controllers. Short-term voltage sags can freeze the controller or delete its settings (and time is wasted to reset them). Our processes are slow and do not require synchronization, thus the losses are minimal.”

- “The company’s heating elements are very sensitive to voltage sags.”

- “Heating elements are not sensitive to voltage sags; however, they are integral part of other equipment. Thus, the entire equipment stops after any dangerous PQ event.”

- “The factory is heated only with electricity. During 7 years of operation, three heater controllers failed due to voltage sags. Losses—about EUR 75. Perhaps this contributed to the breakdown of three air conditioners.”

- “We have 13 controllers, the work of which is highly influenced by voltage sags.”

- “The company has 62 different controllers with UPSes.”

- “All production and storage equipment of the company is controlled by more than 300 controllers, and most of the 0.4 kV electric motors have frequency converters (more than 100 units in total).”

- “The company’s controllers are very sensitive to voltage sags. After each dangerous voltage sag, petrol stations stop working. We lose customers and experience losses.”

- “Controllers of two devices (out of 17) are sensitive.”

- “Some important controllers are protected with UPS; however, many smaller devices are not protected, therefore they are more sensitive to voltage sags. After the event, our employees must restore the operation of controllers and configure their settings.”

- “Most of the company’s automation equipment and controllers are sensitive to volt-age variations. Quite a few of them have double-conversion UPS, the rest is fed directly.”

- “Voltage sags have a very big influence on controllers.”

- “The controllers are fed by pulse power (output voltage is 24 VDC). The controller switches off completely after 5 s from the moment of the voltage loss, and starts without problems when the supply is restored. Obviously, the technological process is affected [by voltage sags].”

- “Controllers with pulse power supply are sensitive to voltage sags. If power source is toroidal, such controller has the immunity. We have both. We have approximately 110 machines and all of them have programmable logic controllers.”

- “Microcontrollers and electronic devices are very sensitive to voltage sags. After each dangerous voltage sag, the company can suffer a loss of up to EUR 28,000.”

- “The controllers shut down when the voltage drops below 70% with all the consequences that follow (interruption of the production process, etc.).”

- “Some controllers are very sensitive to voltage sags. The controllers must be restarted, which takes about 10 min. The company can suffer a loss of about EUR 500.”

- “The work of heating and ventilation equipment, elevators, access control systems, and traffic management systems is interrupted. The exact duration [of voltage sag] is unknown.”

- “We have 11 programmable controllers that control the temperature of our diffusion furnaces. These controllers are very sensitive to voltage sags. Depending on the situation, losses can reach up to EUR 16,000.”

- “Shorter voltage variations are dangerous, but when supply interruption is longer than 1 s, the controller restarts correctly” (see Table 17).

- “We did not notice the effect [of voltage sags on lighting].”

- “We do not know exactly whether voltage sags have an effect on lighting.”

- “In case of a larger and longer voltage sag, indoor lighting turns off, but quickly recovers. Voltage sags have a greater effect on metal-halide lamps—the cool down period is required before switching on. To conclude, voltage sags have not a significant impact on lighting.”

- “In our company, the main source of lighting is various types of fluorescent lamps. In some cases, voltage stabilizers are used.”

- “The lighting usually recovers, but LED pulse power supplies often fail. This directly affect the manufacturing process and contributes to unexpected expenses.”

- “During loading, the switching off of the lighting of both the loading ramps and the territory (20 ha) poses a risk to occupational safety and health as well as increases loading time.”

- “LED power supplies are very sensitive to voltage sags. In our company, the share of LED lamps is 85%.”

- “The lighting remains working until the voltage drop is up to 50% of nominal value. If the voltage drop level is higher and the lighting is turned off, accidents are possible near the equipment in operation.”

- “Most lamps have power inverters. When the voltage drops below 50%, they turn off. This is dangerous for occupational safety and health—injuries are possible.”

- “[Voltage sags] may change railway signals: if the signal changes from allowing to stopping, train emergency braking and delay is possible.”

- Comments about servers:

- “We have five servers. The installed UPS can maintain the voltage up to 8 min; therefore, a longer voltage sag is not tolerated. Each time the system reset costs up to EUR 300.”

- “Micro and short-term power outages are dangerous [to servers] due to UPS switching delay.”

- “Voltage sags are very dangerous to servers and can damage their electronic components.”

- “Voltage variations disrupt our servers. They begin to conflict with each other, and their contacts may burn. Servers are very sensitive to voltage sags. The entire company’s activities are suspended while the faults are being fixed. Obviously, economic losses are experienced.”

- “The company has a server room, the work of which is greatly affected by voltage sags.”

- “The servers are protected with UPS. We are not afraid of voltage sags and supply interruptions that last up to 5–20 min.”

- “We have a server room with 6 kW UPS. We had no losses due to voltage sags, and we did not register them.”

- “Shorter voltage sags do not significantly affect the work. Our server room has UPS.”

- “If electricity is unavailable for a longer period of time, our server room may stop.”

- “The servers have UPS, but the switching cabinets and computer network is fed directly [from the mains].”

- Comments about stationary computers and telecommunications equipment:

- “After a longer voltage sag, the work of stationary computers is disrupted and unsaved data is lost.”

- “Voltage sags are very dangerous to computers, may damage electronic components.”

- “If the computers are shut down during ship loading, the process is interrupted and data can be lost. The exact duration [of voltage sag] is unknown.”

- “Administration work may be suspended due to computer shutdowns, although some of them are protected with UPS.”

- “A certain part of our equipment is controlled via Profinet network. Problems with internet connection disrupts the work of factory, although most of the equipment has UPS.”

- “Our company has about 60 welding machines, and voltage sags greatly affect welding quality.”

- “The company’s welding and soldering equipment are resistant to voltage sags. They have no influence on the work.”

5. Discussion

5.1. Research Gaps

5.2. Survey as a Scientific Method

5.2.1. Surveys Conducted on the Subject of PQ

5.2.2. Limitations

5.3. Further Analysis of the Survey Results: PQ Impact Similarity Assessment

- The similarity of “Controllers” (No. 1) with both “Servers” (No. 6) and “Variable-frequency drives” (No. 8) seems to be logical because all of them are based on printed circuit boards, but the similarity with both “LV three-phase electric motors” (No. 2) and “MV three-phase electric motors” (No. 7) cannot be explained and confirmed;

- The similarity of “LV three-phase electric motors” (No. 2) with “MV three-phase electric motors” (No. 7) and “Variable-frequency drives” (No. 8) seems very logical, but with “Servers” (No. 6) cannot be explained and confirmed;

- The similarity of “Lighting” (No. 3) with “Heating elements” (No. 4) can only be explained based on the comments of the companies, according to which voltage sags are not dangerous for both lighting and heating elements;

- The similarity of “Heating elements” (No. 4) with “Welding equipment” (No. 9) perhaps can be explained because a certain analogy can be found out in the principle of operation of these devices;

- The similarity of “LV single-phase electric motors” (No. 5) with both “Servers” (No. 6) and “Welding equipment” (No. 9) currently cannot be explained and confirmed;

- The similarity of “Servers” (No. 6) with both “MV three-phase electric motors” (No. 7) and “Variable-frequency drives” (No. 8) currently cannot be explained and confirmed;

- The similarity of “MV three-phase electric motors” (No. 7) with “Variable-frequency drives” (No. 8) seems very logical;

- The similarity of “LV single-phase electric motors” (No. 5) with “MV three-phase electric motors” (No. 7) seems very logical;

- The similarity of “LV three-phase electric motors” (No. 2) with “LV single-phase electric motors” (No. 5) seems very logical;

- The similarity of “Servers” (No. 6) with “Welding equipment” (No. 9) currently cannot be explained and confirmed;

- The similarity of “LV single-phase electric motors” (No. 5) with “Variable-frequency drives” (No. 8) currently cannot be explained and confirmed.

- The rank corresponds to the maximal number of linearly independent columns, which is equal to the maximal number of linearly independent rows. Two or more rows (columns) are called linearly independent if there is no linear expression to express their relationship with each other. The ranks of the matrices constructed from Table 6 and Table 7 is 2, and from Table 8—3. Meanwhile, the ranks of matrices given in Table 41 is 4 or 5.

- The determinant is a special number that provides a lot of useful information about the matrix. The determinant of all three matrices constructed from Table 6, Table 7 and Table 8 is equal to 0, because they all have two identical columns. Firstly, this means that the matrix does not have an inverse. Secondly, geometrically, the determinant represents the size of the region, i.e., area of parallelogram in the two-dimensional case and volume of a n-dimensional parallelotope in general case, enclosed by the vectors of matrix after a linear transformation or, in other words, linear mapping [119]: in particular, if the determinant is 0, the volume of such a parallelotope is 0, which means that it is not fully n-dimensional.

- An eigenvector is a vector with a direction that remains unchanged after a linear transformation. Such a vector is only scaled by a constant factor, which is called an eigenvalue. For instance, the matrix constructed from Table 6 has two non-zero eigenvalues—16.99 and −0.01.

5.4. Voltage Sag Tables

- Class A includes the equipment that is not specified as belonging to Class B, C or D, for example, balanced three-phase equipment, household appliances, vacuum cleaners, high pressure cleaners, non-portable tools, independent phase control dimmers, audio equipment, professional luminaries for stage lighting and studios;

- Class B includes portable tools and non-professional arc welding equipment;

- Class C includes lighting equipment;

- Class D includes the following types of devices if their specified power is less than or equal to 600 W: personal computers and their monitors, television receivers, and refrigerators and freezers having one or more variable-speed drives to control compressor motor(s).

6. Conclusions

- Currently, there is a lack of information about the impact of PQ on end-use equipment, as well as its quantification, which, for example, is essential in anticipation of predictive maintenance. In order to explore the topic, more than 60 Lithuanian industrial companies were surveyed. Although the impact can be divided into two components (equipment damage and downtime), they were not separated in the survey. The mathematical analysis of the data, the preparation of which was based on both EN 50160:2010 and IEEE Std 1564-2014, revealed the similarities between various types of equipment, but not all of them can be reasoned. Although the responses are more empirical than rational, they perfectly deepen current knowledge and lay the foundation for further research. It is not a secret that, in general, a larger and more diverse sample size can minimize survey bias and provide more representative results.

- PQ impact similarity assessment or, in the general case, comparison of datasets can be qualitative and quantitative. Applied hypothesis testing is a qualitative method. For the quantitative assessment, the convolution-based method was obtained from [2] and expanded for matrix analysis (discrete case). The qualitative method outputs the answer whether the comparative samples are similar or not, while the qualitative method does not provide such a binary response but outputs an estimate of similarity—in this way, both methods used in the ensemble perfectly complement each other. At the moment, this convolution-based method has not yet been tested with (adapted for) negative functions, oscillations, zero-crossing functions, functions with discontinuities, complex functions, multivariate functions, etc.—these cases remain for further studies.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | - | 1.645 1.645 1.645 | 1.645 1.645 1.645 | 1.645 1.645 1.645 | 1.687 1.690 1.690 | 1.721 1.721 1.721 | 1.782 1.796 1.782 | 1.812 1.796 1.796 | 1.943 1.943 1.973 |

| 2 | 1.645 1.645 1.645 | - | 1.645 1.645 1.645 | 1.645 1.645 1.645 | 1.681 1.682 1.682 | 1.711 1.711 1.711 | 1.771 1.771 1.771 | 1.782 1.771 1.771 | 1.943 1.943 1.943 |

| 3 | 1.645 1.645 1.645 | 1.645 1.645 1.645 | - | 1.645 1.645 1.645 | 1.674 1.673 1.673 | 1.697 1.688 1.688 | 1.740 1.725 1.725 | 1.746 1.711 1.714 | 1.895 1.860 1.860 |

| 4 | 1.645 1.645 1.645 | 1.645 1.645 1.645 | 1.645 1.645 1.645 | - | 1.674 1.674 1.674 | 1.692 1.687 1.687 | 1.725 1.721 1.721 | 1.729 1.711 1.711 | 1.860 1.860 1.860 |

| 5 | 1.687 1.690 1.690 | 1.681 1.682 1.682 | 1.674 1.673 1.673 | 1.674 1.674 1.674 | - | 1.691 1.688 1.688 | 1.721 1.725 1.721 | 1.725 1.711 1.711 | 1.860 1.860 1.860 |

| 6 | 1.721 1.721 1.721 | 1.711 1.711 1.711 | 1.697 1.688 1.688 | 1.692 1.687 1.687 | 1.691 1.688 1.688 | - | 1.711 1.714 1.714 | 1.714 1.711 1.711 | 1.833 1.833 1.833 |

| 7 | 1.782 1.796 1.782 | 1.771 1.771 1.771 | 1.740 1.725 1.725 | 1.725 1.721 1.721 | 1.721 1.725 1.721 | 1.711 1.714 1.714 | - | 1.740 1.740 1.740 | 1.812 1.812 1.812 |

| 8 | 1.812 1.796 1.796 | 1.782 1.771 1.771 | 1.746 1.711 1.714 | 1.729 1.711 1.711 | 1.725 1.711 1.711 | 1.714 1.711 1.711 | 1.740 1.740 1.740 | - | 1.833 1.860 1.860 |

| 9 | 1.943 1.943 1.973 | 1.943 1.943 1.943 | 1.895 1.860 1.860 | 1.860 1.860 1.860 | 1.860 1.860 1.860 | 1.833 1.833 1.833 | 1.812 1.812 1.812 | 1.833 1.860 1.860 | - |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | - | 1.280 1.280 1.280 | 1.280 1.280 1.280 | 1.280 1.280 1.280 | 1.305 1.306 1.306 | 1.323 1.323 1.323 | 1.356 1.363 1.356 | 1.372 1.363 1.363 | 1.440 1.440 1.440 |

| 2 | 1.280 1.280 1.280 | - | 1.280 1.280 1.280 | 1.280 1.280 1.280 | 1.302 1.302 1.302 | 1.318 1.318 1.318 | 1.350 1.350 1.350 | 1.356 1.350 1.350 | 1.440 1.440 1.440 |

| 3 | 1.280 1.280 1.280 | 1.280 1.280 1.280 | - | 1.280 1.280 1.280 | 1.298 1.297 1.297 | 1.310 1.306 1.306 | 1.333 1.325 1.325 | 1.337 1.318 1.319 | 1.415 1.397 1.397 |

| 4 | 1.280 1.280 1.280 | 1.280 1.280 1.280 | 1.280 1.280 1.280 | - | 1.297 1.297 1.297 | 1.308 1.305 1.305 | 1.325 1.323 1.323 | 1.328 1.318 1.318 | 1.397 1.397 1.397 |

| 5 | 1.305 1.306 1.306 | 1.302 1.302 1.302 | 1.298 1.297 1.297 | 1.297 1.297 1.297 | - | 1.307 1.306 1.306 | 1.323 1.325 1.323 | 1.325 1.318 1.318 | 1.397 1.397 1.397 |

| 6 | 1.323 1.323 1.323 | 1.318 1.318 1.318 | 1.310 1.306 1.306 | 1.308 1.305 1.305 | 1.307 1.306 1.306 | - | 1.318 1.319 1.319 | 1.319 1.318 1.318 | 1.383 1.383 1.383 |

| 7 | 1.356 1.363 1.356 | 1.350 1.350 1.350 | 1.333 1.325 1.325 | 1.325 1.323 1.323 | 1.323 1.325 1.323 | 1.318 1.319 1.319 | - | 1.333 1.333 1.333 | 1.372 1.372 1.372 |

| 8 | 1.372 1.363 1.363 | 1.356 1.350 1.350 | 1.337 1.318 1.319 | 1.328 1.318 1.318 | 1.325 1.318 1.318 | 1.319 1.318 1.318 | 1.333 1.333 1.333 | - | 1.383 1.397 1.397 |

| 9 | 1.440 1.440 1.440 | 1.440 1.440 1.440 | 1.415 1.397 1.397 | 1.397 1.397 1.397 | 1.397 1.397 1.397 | 1.383 1.383 1.383 | 1.372 1.372 1.372 | 1.383 1.397 1.397 | - |

References

- Liubčuk, V.; Radziukynas, V.; Naujokaitis, D.; Kairaitis, G. Grid Nodes Selection Strategies for Power Quality Monitoring. Appl. Sci. 2023, 13, 6048. [Google Scholar] [CrossRef]

- Liubčuk, V.; Radziukynas, V.; Kairaitis, G.; Naujokaitis, D. Power Quality Monitors Displacement Based on Voltage Sags Propagation Mechanism and Grid Reliability Indexes. Appl. Sci. 2023, 13, 11778. [Google Scholar] [CrossRef]

- EN 50160:2010; Voltage Characteristics of Electricity Supplied by Public Electricity Networks. CENELEC: Brussels, Belgium, 2010.

- IEEE Std 1159-2019; IEEE Recommended Practice for Monitoring Electric Power Quality. IEEE: New York, NY, USA, 2019.

- European Union. Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014 on the Harmonisation of the Laws of the Member States Relating to Electromagnetic Compatibility. Off. J. Eur. Union 2014, 57, 79–105. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32014L0030 (accessed on 13 September 2024).

- Communications Regulatory Authority of the Republic of Lithuania. Order of the RRT Director on the Approval of the Technical Regulation of Electromagnetic Compatibility. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/TAIS.289383/asr (accessed on 15 September 2024).

- Troubleshooting Power Quality Issues in Critical Medical Diagnostic Equipment. Available online: https://www.fluke.com/en/learn/blog/power-quality/case-study-when-power-quality-is-life-or-death (accessed on 28 August 2024).

- Liubčuk, V.; Kairaitis, G.; Radziukynas, V.; Naujokaitis, D. IIR Shelving Filter, Support Vector Machine and k-Nearest Neighbors Algorithm Application for Voltage Transients and Short-Duration RMS Variations Analysis. Inventions 2024, 9, 12. [Google Scholar] [CrossRef]

- Lithuanian National Radio and Television. Residents of Širvintos Oppose the Wind Park: May Exterminate the Local Bird Fauna. Available online: https://www.lrt.lt/naujienos/verslas/4/2272903/sirvintiskiai-priesinasi-vejo-jegainiu-parkui-gali-isnaikinti-vietine-pauksciu-fauna (accessed on 9 September 2024).

- Biasotto, L.D.; Kindel, A. Power Lines and Impacts on Biodiversity: A Systematic Review. Environ. Impact Assess. Rev. 2018, 71, 110–119. [Google Scholar] [CrossRef]

- Hunters’ Thoughts on Wind Farms. Available online: https://www.medzioklezurnalas.lt/medziotoju-mintys-apie-vejo-jegainiu-parkus (accessed on 9 September 2024).

- Bosch-Capblanch, X.; Esu, E.; Oringanje, C.M.; Dongus, S.; Jalilian, H.; Eyers, J.; Auer, C.; Meremikwu, M.; Röösli, M. The Effects of Radiofrequency Electromagnetic Fields Exposure on Human Self-Reported Symptoms: A Systematic Review of Human Experimental Studies. Environ. Int. 2024, 187, 108612. [Google Scholar]

- World Health Organization. Radiation: Electromagnetic Fields. Available online: https://www.who.int/news-room/questions-and-answers/item/radiation-electromagnetic-fields (accessed on 16 January 2025).

- European Communities. Council Recommendation of 12 July 1999 on the Limitation of Exposure of the General Public to Electromagnetic Fields (0 Hz to 300 GHz). Off. J. Eur. Communities 1999, 42, 59–70. Available online: https://eur-lex.europa.eu/eli/reco/1999/519/oj/eng (accessed on 16 January 2025).

- LST EN IEC 61000-6-3:2021; Electromagnetic Compatibility (EMC)—Part 6-3: Generic Standards—Emission Standard for Equipment in Residential Environments (IEC 61000-6-3:2020). Lithuanian Standards Board: Vilnius, Lithuania, 2021.

- LST EN IEC 61000-6-4:2019; Electromagnetic Compatibility (EMC)—Part 6-4: Generic Standards—Emission Standard for Industrial Environments (IEC 61000-6-4:2019). Lithuanian Standards Board: Vilnius, Lithuania, 2019.

- Kivrak, E.G.; Yurt, K.K.; Kaplan, A.A.; Alkan, I.; Altun, G. Effects of Electromagnetic Fields Exposure on the Antioxidant Defense System. J. Microsc. Ultrastruct. 2017, 5, 167–176. [Google Scholar] [CrossRef]

- Kaliatka, A. (Lithuanian Energy Institute, Kaunas, Lithuania). Personal communication, 2021.

- Sharma, A.; Rajpurohit, B.S.; Singh, S.N. A Review on Economics of Power Quality: Impact, Assessment and Mitigation. Renew. Sustain. Energy Rev. 2018, 88, 363–372. [Google Scholar]

- Koskolos, N.C.; Megaloconomos, S.M.; Dialynas, E.N. Assessment of Power Interruption Costs for the Industrial Customers in Greece. In Proceedings of the 8th ICHQP, Athens, Greece, 14–16 October 1998. [Google Scholar]

- Elphick, S.; Ciufo, V.S.; Perera, S. Summary of the Economic Impacts of Power Quality on Consumers. In Proceedings of the 2015 AUPEC, Wollongong, Australia, 27–30 September 2015. [Google Scholar]

- Kerin, U.; Dermelj, A.; Papic, I. Consequences of Inadequate Power Quality for Industrial Consumers in Slovenia. In Proceedings of the 19th CIRED, Vienna, Austria, 21–24 May 2007. [Google Scholar]

- Avendaño, M.; Milanović, J.V.; Madrigal, M. Assessment of Financial Losses Due to Voltage Sags Using Optimal Monitoring Schemes. In Proceedings of the ICREPQ’12, Santiago de Compostela, Spain, 28–30 March 2012. [Google Scholar]

- Perera, S.; Elphick, S. Impact and Management of Power System Voltage Sags. In Applied Power Quality; Elsevier Science: Amsterdam, The Netherlands, 2022; pp. 147–183. [Google Scholar]

- Macangus-Gerrard, G. (Ed.) Harmonics. In Offshore Electrical Engineering Manual, 2nd ed.; Gulf Professional Publishing: Cambridge, MA, USA, 2018; pp. 273–276. [Google Scholar]

- Fiorillo, F. Measurement and Characterisation of Magnetic Materials; Academic Press: Cambridge, MA, USA, 2004; p. 31. [Google Scholar]

- Shokrollahi, H.; Janghorban, K. Soft Magnetic Composite Materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Singh, P.K.; Hasan, V. Effect of Voltage Sag of Induction Motor. Int. J. Eng. Sci. Res. Technol. 2018, 7, 11–23. [Google Scholar]

- Shareef, H.; Mohamed, A.; Marzuki, N. Analysis of Personal Computer Ride Through Capability During Voltage Sags. Electr. Power Syst. Res. 2009, 79, 1615–1624. [Google Scholar] [CrossRef]

- Hardi, S.; Daut, I. Sensitivity of Low Voltage Consumer Equipment to Voltage Sags. In Proceedings of the 4th PEOCO, Shah Alam, Malaysia, 23–24 June 2010. [Google Scholar]

- Wang, Y.; Dong, Y. Evaluation of Voltage Sag Severity Based on Multisource Causative Attribute. In Proceedings of the 2019 IEEE iSPEC, Beijing, China, 21–23 November 2019. [Google Scholar]

- IEEE Std 1564-2014; IEEE Guide for Voltage Sag Indices. IEEE: New York, NY, USA, 2014.

- SEMI F47. Available online: https://voltage-disturbance.com/voltage-quality/semi-f47-voltage-sag-immunity-standard (accessed on 7 October 2024).

- Alshareef, S.M. Voltage Sag Assessment, Detection, and Classification in Distribution Systems Embedded with Fast Charging Stations. IEEE Access 2023, 11, 89864–89880. [Google Scholar] [CrossRef]

- Arias-Guzman, S.; Farfan-Ustariz, A.J.; Plata, E.A.C.; Jimenez-Salazar, A.F. Implementation of IEEE Std 1564-2014 for Voltage Sag Severity Analysis on a Medium Voltage Substation. In Proceedings of the 2015 IEEE Workshop on PEPQA, Bogota, Colombia, 2–4 June 2015. [Google Scholar]

- Ruuskanen, V.; Koponen, J.; Kosonen, A.; Hehemann, M.; Keller, R.; Niemelä, M.; Ahola, J. Power Quality Estimation of Water Electrolyzers Based on Current and Voltage Measurements. J. Power Sources 2020, 450, 227603. [Google Scholar] [CrossRef]

- Florkowski, M.; Kuniewski, M.; Mikrut, P. Effect of Voltage Harmonics on Dielectric Losses and Dissipation Factor Interpretation in High-Voltage Insulating Materials. Electr. Power Syst. Res. 2024, 226, 109973. [Google Scholar]

- LST EN IEC 61800-3:2023; Adjustable Speed Electrical Power Drive Systems—Part 3: EMC Requirements and Specific Test Methods for PDS and Machine Tools. Lithuanian Standards Board: Vilnius, Lithuania, 2023.

- LST EN IEC 61000-2-4:2024; Electromagnetic Compatibility (EMC)—Part 2-4: Environment—Compatibility Levels in Power Distribution Systems in Industrial Locations for Low-Frequency Conducted Disturbances. Lithuanian Standards Board: Vilnius, Lithuania, 2024.

- Boльдeк, A.И. Элeктpичecкиe Maшины, 3rd ed.; Toлвинcкaя, E.B., Ed.; «Энepгия»: Leningrad, Russia, 1978. [Google Scholar]

- Kemabonta, T.; Mowry, G. A Syncretistic Approach to Grid Reliability and Resilience: Investigations from Minnesota. Energy Strat. Rev. 2021, 38, 100726. [Google Scholar] [CrossRef]

- Kenward, A.; Raja, U. Blackout: Extreme Weather, Climate Change and Power Outages; Climate Central: Princeton, NJ, USA, 2014; Available online: http://assets.climatecentral.org/pdfs/PowerOutages.pdf (accessed on 7 February 2025).

- Potts, J.; Tiedmann, H.R.; Stephens, K.K.; Faust, K.M.; Castellanos, S. Enhancing Power System Resilience to Extreme Weather Events: A Qualitative Assessment of Winter Storm Uri. Int. J. Disaster Risk Reduct. 2024, 103, 104309. [Google Scholar] [CrossRef]

- Harness, R.E.; Juvvadi, P.R.; Dwyer, J.F. Avian Electrocutions in Western Rajasthan, India. J. Raptor Res. 2023, 47, 352–364. [Google Scholar] [CrossRef]

- Harness, R.; Gombobaatar, S.; Yosef, R. Mongolian Distribution Power Lines and Raptor Electrocutions. In Proceedings of the 2008 IEEE Rural Electric Power Conference, Charleston, SC, USA, 27–29 April 2008. [Google Scholar]

- Galis, M.; Nad’o, L.; Hapl, E.; Šmídt, J.; Deutschová, L.; Chavko, J. Comprehensive Analysis of Bird Mortality along Power Distribution Lines in Slovakia. Raptor J. 2019, 13, 1–25. [Google Scholar] [CrossRef]

- Hamal, S.; Sharma, H.P.; Gautam, R.; Katuwal, H.B. Drivers of Power Line Collisions and Electrocutions of Birds in Nepal. Ecol. Evol. 2023, 13, 10080. [Google Scholar] [CrossRef]

- Raptor Protection of Slovakia. Electrocutions & Collisions of Birds in EU Countries: The Negative Impact & Best Practices for Mitigation—An Overview of Previous Efforts and Up-to-Date Knowledge of Electrocutions and Collisions of Birds Across 27 EU Member States; Raptor Protection of Slovakia: Bratislava, Slovakia, 2021; Available online: https://www.birdlife.org/wp-content/uploads/2022/10/Electrocutions-Collisions-Birds-Best-Mitigation-Practices-NABU.pdf (accessed on 9 February 2025).

- Bald Eagle Comes to Chicago, Gets Electrocuted on a Power Line. Available online: https://www.dnainfo.com/chicago/20160303/midway/chicago-bald-eagle-that-got-electrocuted-on-southwest-side-power-line (accessed on 11 September 2024).

- Bald Eagle Electrocuted in Power Line Crash, 145 Residents Lose Power. Available online: https://mynorthwest.com/3945731/bald-eagle-electrocuted-power-line-crash-145-residents-lose-power (accessed on 11 September 2024).

- YouTube. Leopard Climbs Electric Pole, Gets Electrocuted [Video]. Available online: https://www.youtube.com/watch?v=5iRbqKfh3TY (accessed on 11 September 2024).

- The Guardian. Elephants Electrocuted by Sagging Power Lines. Available online: https://www.theguardian.com/environment/india-untamed/2015/sep/15/elephants-electrocuted-by-sagging-power-lines (accessed on 11 September 2024).

- The Hindu. Wild Elephant Electrocuted After Power Line Falls on it Near Coimbatore. Available online: https://www.thehindu.com/news/cities/Coimbatore/wild-elephant-electrocuted-dies-after-power-line-falls-on-it-near-coimbatore/article66660290.ece (accessed on 11 September 2024).

- The Telegraph. High-Tension Wire Kills Python. Available online: https://www.telegraphindia.com/west-bengal/high-tension-wire-kills-python/cid/1572066 (accessed on 11 September 2024).

- Hernández-Matías, A.; Real, J.; Parés, F.; Pradel, R. Electrocution Threatens the Viability of Populations of the Endangered Bonelli’s Eagle (Aquila fasciata) in Southern Europe. Biol. Conserv. 2015, 191, 110–116. [Google Scholar] [CrossRef]

- Installation of the Bird Protection Measures on the High Voltage Electricity Transmission Grid in Lithuania. Final Report. 2019. Available online: http://www.birds-electrogrid.lt/news/159/208/European-Commission-has-approved-the-final-LIFE-Birds-on-Electrogrid-report/d,detalus-en (accessed on 14 February 2025).

- Installation of Bird Collision Mitigation Measures in Bird Staging Areas. Available online: http://www.birds-electrogrid.lt/en/conservation-actions/installation-of-bird-collision-mitigation-measures-in-bird-staging-areas-c1 (accessed on 14 February 2025).

- Installation of Line Markers in the Most Sensitive Areas. Available online: http://www.birds-electrogrid.lt/en/conservation-actions/installation-of-line-markers-in-the-most-sensitive-areas-c2 (accessed on 14 February 2025).

- Installation of Bird Protection Measures on the Utility Poles. Available online: http://www.birds-electrogrid.lt/en/conservation-actions/installation-of-bird-protection-measures-on-the-utility-poles-c3 (accessed on 14 February 2025).

- Erecting of Nest-Boxes for Falcons. Available online: http://www.birds-electrogrid.lt/en/conservation-actions/erecting-of-nest-boxes-for-falcons-c4 (accessed on 14 February 2025).

- Ex Ante and Post Ante Monitoring on the Effectiveness of the Project Conservation Actions (2014–2015). Activity Report. 2016. Available online: http://www.birds-electrogrid.lt/news/55/187/The-report-on-D2-acivity-Ex-ante-and-post-ante-monitoring-on-the-effectiveness-of-the-project-conservation-actions-was-prepared/d,detalus-en (accessed on 14 February 2025).

- Infante, O.; Peris, S. Bird Nesting on Electric Power Supports in Northwestern Spain. Ecol. Eng. 2003, 20, 321–326. [Google Scholar] [CrossRef]

- Barauskas, R.; Karlonas, M. Lietuvos Paukščiai: Perinčios ir Kasmet Aptinkamos Rūšys, 2nd ed.; Lututė: Kaunas, Lithuania, 2023. [Google Scholar]

- Komsomolskaya Pravda. A Bear and a Fox were Killed by a Powerful Electric Shock in the Taiga in Kolyma. Available online: https://www.hab.kp.ru/daily/28302.5/4442350 (accessed on 11 September 2024).

- BBC. Kruger National Park Electrocution Kills Six Big Animals. Available online: https://www.bbc.com/news/world-africa-47047889 (accessed on 11 September 2024).

- Foxes Die on Power Lines. Impact of the War in Ukraine. Available online: https://www.medzioklezurnalas.lt/lapes-mirsta-ant-elektros-liniju-karo-poveikis-ukrainoje (accessed on 12 September 2024).

- EKO-Inform [Facebook Page]. Not for the Weak Nerves [Video]. Available online: https://www.facebook.com/reel/430597682687105 (accessed on 12 September 2024).

- Marxen, T. New Technology to Cut Victoria’s Powerline Fire Risk. In Proceedings of the Arboriculture Australia National Conference 2016, Melbourne, Australia, 23 February 2016. [Google Scholar]

- Babrauskas, V. Electricity-Caused Wildland Fires: Costs, Social Fairness, and Proposed Solution. Fire 2024, 7, 442. [Google Scholar] [CrossRef]

- Kandanaarachchi, S.; Anantharama, N.; Muñoz, M.A. Early Detection of Vegetation Ignition Due to Powerline Faults. IEEE Trans. Power Deliv. 2020, 36, 1324–1334. [Google Scholar] [CrossRef]

- Bandara, S.; Rajeev, P.; Gad, E. Power Distribution System Faults and Wildfires: Mechanisms and Prevention. Forests 2023, 14, 1146. [Google Scholar] [CrossRef]

- Coldham, D.; Czerwinski, A.; Marxsen, T. Probability of Bushfire Ignition from Electric Arc Faults; HRL Technology: Melbourne, Australia, 2011. [Google Scholar]

- Seimas of the Republic of Lithuania. Law of the Republic of Lithuania on Special Conditions of Land Use. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/46c841f290cf11e98a8298567570d639/asr (accessed on 9 February 2025).

- Smith, M.B.; Aborn, D.A.; Gaudin, T.J.; Tucker, J.C. Mammalian Predator Distribution Around a Transmission Line. Southeast. Nat. 2008, 7, 289–300. [Google Scholar]

- Rieucau, G.; Vickery, W.L.; Doucet, G.J. A Patch Use Model to Separate Effects of Foraging Costs on Giving-up Densities: An Experiment with White-Tailed Deer (Odocoileus virginianus). Behav. Ecol. Sociobiol. 2009, 63, 891–897. [Google Scholar]

- Bartzke, G.; May, R.F.; Bevanger, K.M.; Stokke, S.; Røskaft, E. The Effects of Power Lines on Ungulates and Implications for Power Line Routing and Rights-of-Way Management. Int. J. Biodivers. Conserv. 2014, 6, 647–662. [Google Scholar]

- Barauskas, R.; Babelis, D. Lietuvos Žinduoliai: Išvaizda, Paplitimas, Buveinės, Gyvenimo Būdas, Veiklos Žymės; Lututė: Kaunas, Lithuania, 2025. [Google Scholar]

- Hernanz, J.A.R.; Martín, J.J.C.; Gogeascoechea, J.C.; Belver, I.Z. Insulator Pollution in Transmission Lines. REPQJ 2006, 4, 124–130. [Google Scholar]

- Hadipour, M.; Shiran, M.A. Various Pollutions of Power Lines Insulators. Majlesi J. Energy Manag. 2017, 6, 29–38. [Google Scholar]

- Gençoğlu, M.T.; Cebeci, M. Investigation of Pollution Flashover on High Voltage Insulators Using Artificial Neural Network. Expert Syst. Appl. 2009, 36, 7338–7345. [Google Scholar] [CrossRef]

- Mao, X.; Ye, J.; Tian, Z.; Hu, K.; Wang, J.; Tan, F. Study on the Flashover Mechanism of Bird Droppings in the Transmission Line. AIP Adv. 2023, 13, 105204. [Google Scholar] [CrossRef]

- Electrical Engineering Portal. How Arc Suppression Reactors (Earth Fault Neutralizers or Petersen-Coils) Work? Available online: https://electrical-engineering-portal.com/arc-suppression-reactors (accessed on 10 March 2025).

- Ministry of Energy of the Republic of Lithuania. Order of the Minister of Energy of the Republic of Lithuania on the Approval of the Rules for the Supply and Use of Electricity. Available online: https://e-seimas.lrs.lt/portal/legalAct/lt/TAD/TAIS.365540/asr (accessed on 4 February 2025).

- IEEE Std 519-2022; IEEE Standard for Harmonic Control in Electric Power Systems. IEEE: New York, NY, USA, 2022.

- LST EN 61000-2-2:2003; Electromagnetic Compatibility (EMC)—Part 2-2: Environment—Compatibility Levels for Low-Frequency Conducted Disturbances and Signaling in Public Low-Voltage Power Supply Systems. Lithuanian Standards Board: Vilnius, Lithuania, 2003.

- LST EN 61000-4-7:2004; Electromagnetic Compatibility (EMC)—Part 4-7: Testing and Measurement Techniques—General Guide on Harmonics and Interharmonics Measurements and Instrumentation, for Power Supply Systems and Equipment Connected Thereto. Lithuanian Standards Board: Vilnius, Lithuania, 2004.

- LST EN 61000-4-15:2011; Electromagnetic Compatibility (EMC)—Part 4-15: Testing and Measurement Techniques—Flickermeter—Functional and Design Specifications. Lithuanian Standards Board: Vilnius, Lithuania, 2011.

- LST EN 61000-4-30:2015; Electromagnetic Compatibility (EMC)—Part 4-30: Testing and Measurement Techniques—PQ Measurement Methods. Lithuanian Standards Board: Vilnius, Lithuania, 2016.

- Council of European Energy Regulators. 5th CEER Benchmarking Report on the Quality of Electricity and Gas Supply; CEER: Brussels, Belgium, 2011. [Google Scholar]

- Ström, L.; Bollen, M.H.J.; Kolessar, R. Voltage Quality Regulation in Sweden. In Proceedings of the 21th CIRED, Frankfurt, Germany, 6–9 June 2011. [Google Scholar]

- Torkzadeh, R.; Waes, J.; Ćuk, V.; Cobben, S. Model Validation for Voltage Dip Assessment in Future Networks. Electr. Power Syst. Res. 2023, 217, 109099. [Google Scholar] [CrossRef]

- Council of European Energy Regulators. 7th CEER Benchmarking Report on the Quality of Electricity and Gas Supply; CEER: Brussels, Belgium, 2022. [Google Scholar]

- ANSI C84.1-2016; Electric Power Systems and Equipment—Voltage Ratings (60 Hertz). ANSI: Washington, DC, USA, 2016.

- Voltage Fluctuations, Flicker and Power Quality. Available online: https://www.fluke.com/en/learn/blog/power-quality/voltage-fluctuations-flicker (accessed on 12 September 2024).

- Why Is Good Power Quality Crucial in Data Centers? Available online: https://meruspower.com/blog/good-power-quality-crucial-data-centers (accessed on 9 September 2024).

- Siostrzonek, T.; Wójcik, J.; Dutka, M.; Siostrzonek, W. Impact of Power Quality on the Efficiency of the Mining Process. Energies 2024, 17, 5675. [Google Scholar] [CrossRef]

- Bhattacharyya, S.; Cobben, S. Consequences of Poor Power Quality—An Overview. In Power Quality; Eberhard, A., Ed.; IntechOpen: London, UK, 2011; pp. 3–24. [Google Scholar]

- Manson, J.; Targosz, R. Leonardo ENERGY—European Power Quality Survey Report; International Copper Association Europe: Brussels, Belgium, 2008; Available online: https://www.slideshare.net/slideshow/european-power-quality-survey-report/149087013 (accessed on 21 February 2025).

- Hartungi, R.; Jiang, L. Investigation of Power Quality in Health Care Facility. In Proceedings of the ICREPQ’10, Granada, Spain, 23–25 March 2010. [Google Scholar]

- The Critical Role of Power Supply in Medical Imaging and Diagnostic Equipment. Available online: https://www.horizon-pss.com/news-events/blog-the-critical-role-of-power-supply-in-medical-imaging-and-diagnostic-equipment (accessed on 19 February 2025).

- Ramos, M.C.G.; Tahan, C.M.V. An Assessment of the Electric Power Quality and Electrical Installation Impacts on Medical Electrical Equipment Operations at Health Care Facilities. Am. J. Appl. Sci. 2009, 6, 638–645. [Google Scholar] [CrossRef]

- Rao, U.; Singh, S.N.; Thakur, C.K. Power Quality Issues with Medical Electronics Equipment in Hospitals. In Proceedings of the 2010 International Conference on Industrial Electronics, Control and Robotics, Rourkela, India, 27–29 December 2010. [Google Scholar]

- Moreira, A.C.; Silva, L.C.P.; Paredes, H.K.M. Electrical Modelling and Power Quality Analysis of Three-Phase X-Ray Apparatus. In Proceedings of the SPEEDAM 2014, Ischia, Italy, 18–20 June 2014. [Google Scholar]

- Takla, G.M.S.; Petre, J.H.; Doyle, D.J.; Horibe, M.; Gopakumaran, B. The Problem of Artifacts in Patient Monitor Data During Surgery: A Clinical and Methodological Review. Anesth. Analg. 2006, 103, 1196–1204. [Google Scholar] [CrossRef]

- Buzdugan, M.I.; Bălan, H.; Mureşan, D.T. An Electrical Power Quality Problem in an Emergency Unit from a Hospital—Case Study. In Proceedings of the SPEEDAM 2010, Pisa, Italy, 14–16 June 2010. [Google Scholar]

- Hanada, E.; Itoga, S.; Takano, K.; Kudou, T. Investigations of the Quality of Hospital Electric Power Supply and the Tolerance of Medical Electric Devices to Voltage Dips. J. Med. Syst. 2007, 31, 219–233. [Google Scholar] [CrossRef]

- Hanada, E.; Kudou, T. Electromagnetic Noise in the Clinical Environment. In Proceedings of the ISMICT2009, Montreal, QC, Canada, 24–26 February 2009. [Google Scholar]

- Neves Neto, J.C.; Almeida, C.F.M.; Delbone, E.; Starosta, J. Investigation of Harmonic Resonance from Reactive Compensation in Hospital Electrical Installations with Magnetic Resonance Imaging (MRI). In Proceedings of the 20th ICHQP, Naples, Italy, 29 May–1 June 2022. [Google Scholar]

- Özdemirci, E.; Yatak, M.Ö.; Duran, F.; Canal, M.R. Reliability Assessment of Infant Incubator and the Analyzer. Gazi Univ. J. Sci. 2014, 27, 1169–1175. [Google Scholar]

- Ishida, K.; Hirose, M.; Hanada, E. Investigation of Interference with Medical Devices by Power Line Communication to Promote its Safe Introduction to the Clinical Setting. In Proceedings of the 2016 International Symposium on Electromagnetic Compatibility—EMC Europe, Wroclaw, Poland, 5–9 September 2016. [Google Scholar]

- Mariappan, P.M.; Raghavan, D.R.; Aleem, S.H.E.A.; Zobaa, A.F. Effects on Electromagnetic Interference on the Functional Usage of Medical Equipment by 2G/3G/4G Cellular Phones: A Review. J. Adv. Res. 2016, 7, 727–738. [Google Scholar] [CrossRef]

- Radvilė, E.; Urbonas, R. Digital Transformation in Energy Systems: A Comprehensive Review of AI, IoT, Blockchain, and Decentralised Energy Models. Energetika 2025, 71, 1–22. [Google Scholar] [CrossRef]

- Faheem, M.; Shah, S.; Bytt, R.; Raza, B.; Anwar, M.; Ashraf, M.; Ngadi, M.; Gungor, V. Smart Grid Communication and Information Technologies in the Perspective of Industry 4.0: Opportunities and Challenges. Comput. Sci. Rev. 2018, 30, 1–30. [Google Scholar]

- Stanelytė, D.; Radziukynienė, N.; Radziukynas, V. Overview of Demand-Response Services: A Review. Energies 2022, 15, 1659. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Runger, G.C. Applied Statistics and Probability for Engineers, 5th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- IEC TR 63222-100:2023; Power Quality Management—Part 100: Impact of Power Quality Issues on Electrical Equipment and Power System. IEC: Geneva, Switzerland, 2023.

- IEC TS 60601-4-2:2024; Medical Electrical Equipment—Part 4-2: Guidance and Interpretation—Electromagnetic Immunity: Performance of Medical Electrical Equipment and Medical Electrical Systems. IEC: Geneva, Switzerland, 2024.

- Milanovic, J.V.; Meyer, J.; Ball, R.F.; Howe, W.; Preece, R.; Bollen, M.H.J.; Elphick, S.; Cukalevski, N. International Industry Practice on Power Quality Monitoring. IEEE Trans. Power Deliv. 2014, 29, 934–941. [Google Scholar]

- YouTube. The Determinant [Video]. Available online: https://www.youtube.com/watch?v=Ip3X9LOh2dk&list=PLZHQObOWTQDPD3MizzM2xVFitgF8hE_ab&index=7 (accessed on 4 November 2024).

- Svinkūnas, G.; Navickas, A. Elektros Energetikos Pagrindai, 2nd ed.; Kaunas University of Technology—Publishing House “Technologija”: Kaunas, Lithuania, 2013. [Google Scholar]

- De Santis, M.; Di Stasio, L.; Noce, C.; Varilone, P.; Verde, P. Indices of Intermittence to Improve the Forecasting of the Voltage Sags Measured in Real Systems. IEEE Trans. Power Deliv. 2021, 37, 1252–1263. [Google Scholar]

- LST EN IEC 61000-3-2:2019; Electromagnetic Compatibility (EMC)—Part 3-2: Limits—Limits for Harmonic Current Emissions (Equipment Input Current ≤ 16 A per Phase). Lithuanian Standards Board: Vilnius, Lithuania, 2020.

| Species 1,2,3 | AT | BE | BG | HR | CY | CZ | DK | EE | FI | FR | DE | GR | HU | IE | IT | LV | LT | LU | MT | NL | PL | PT | RO | SK | SI | ES | SE |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A. adalberti | e | ||||||||||||||||||||||||||

| A. albifrons | ○ 4 | c | |||||||||||||||||||||||||

| A. anser | c | ○ 4 | c | ||||||||||||||||||||||||

| A. chrysaetos | e 5 | e | |||||||||||||||||||||||||

| A. cinerea | c | ○ 6 | c | c | |||||||||||||||||||||||

| A. fasciata | e | ||||||||||||||||||||||||||

| A. gentilis | ○ 5 | e | |||||||||||||||||||||||||

| A. platyrhynchos | c | c | c 7 | c | c | ||||||||||||||||||||||

| B. bubo | e | e | e | e | ○ 8 | e | e | ||||||||||||||||||||

| B. buteo | c/e | e | e | e | e | e | e | e 5 | e | e | e | e | e | ||||||||||||||

| B. ibis | c | ||||||||||||||||||||||||||

| C. ciconia | e | e | c/e | e | e | c/e | e | e | e | e 9 | c/e | e | c/e | e | e | e | c | ||||||||||

| C. corax | c | e | ○10 | ||||||||||||||||||||||||

| C. cornix | ○10 | e | |||||||||||||||||||||||||

| C. corone | e | e | e | e | |||||||||||||||||||||||

| C. coturnix | c | ○11 | |||||||||||||||||||||||||

| C. cygnus | c | c | ○12 | ||||||||||||||||||||||||

| C. livia | c | c | ○13 | c | |||||||||||||||||||||||

| C. olor | c | c | c | c | c | c | c 12 | c | c | c | c | ||||||||||||||||

| C. palumbus | c | ○13 | c | ||||||||||||||||||||||||

| C. ridibundus | c | c | ○14 | c | |||||||||||||||||||||||

| C. undulata | c | ||||||||||||||||||||||||||

| E. alba | ○ 6 | c | |||||||||||||||||||||||||

| F. atra | c | ○15 | c | ||||||||||||||||||||||||

| F. eleonorae | e | ||||||||||||||||||||||||||

| F. tinnunculus | e | e | e | e | e | ○16 | e | e | |||||||||||||||||||

| G. grus | c | ○17 | c | ||||||||||||||||||||||||

| L. muta | c | ||||||||||||||||||||||||||

| L. tetrix | c | ○11 | |||||||||||||||||||||||||

| M. migrans | e | ○ 5 | |||||||||||||||||||||||||

| M. milvus | e | ○ 5 | e | ||||||||||||||||||||||||

| O. tarda | c | c | c | ||||||||||||||||||||||||

| P. apricaria | c 18 | ||||||||||||||||||||||||||

| P. crispus | c | c | |||||||||||||||||||||||||

| P. haliaetus | e | ○19 | |||||||||||||||||||||||||

| P. pica | e | e | ○10 | e | e | e | |||||||||||||||||||||

| P. roseus | c | c | |||||||||||||||||||||||||

| S. aluco | e | ○ 8 | e | ||||||||||||||||||||||||

| S. uralensis | e | ○ 8 | e | ||||||||||||||||||||||||

| T. merula | c | ○20 | |||||||||||||||||||||||||

| T. philomelos | c | ○20 | |||||||||||||||||||||||||

| T. tetrax | c |

| Voltage, p.u. | Duration, s | |||||||

|---|---|---|---|---|---|---|---|---|

| 0 ≤ t ≤ 0.1 | 0.1 < t ≤ 0.15 | 0.15 < t ≤ 0.2 | 0.2 < t ≤ 0.5 | 0.5 < t ≤ 0.6 | 0.6 < t ≤ 1 | 1 < t ≤ 5 | 5 < t ≤ 60 | |

| Networks above 45 kV | ||||||||

| 0.9 > U ≥ 0.8 | A | A | B | B | B | B | B | B |

| 0.8 > U ≥ 0.7 | A | A | B | B | B | C | C | C |

| 0.7 > U ≥ 0.4 | A | B | B | B | B | C | C | C |

| 0.4 > U ≥ 0.05 | A | B | B | B | B | C | C | C |

| U < 0.05 | A | B | B | B | B | C | C | C |

| Networks up to and including 45 kV | ||||||||

| 0.9 > U ≥ 0.8 | A | A | A | A | B | B | B | B |

| 0.8 > U ≥ 0.7 | A | A | A | A | B | B | B | B |

| 0.7 > U ≥ 0.4 | A | A | A | B | B | B | B | C |

| 0.4 > U ≥ 0.05 | B | B | B | B | B | B | C | C |

| U < 0.05 | B | B | B | B | B | B | C | C |

| Voltage, p.u. | Duration, s | |||

|---|---|---|---|---|

| 0.01 ≤ t ≤ 0.2 | 0.2 < t ≤ 0.5 | 0.5 < t ≤ 1 | 1 < t ≤ 5 | |

| 0.9 > U ≥ 0.8 | A | A | A | A |

| 0.8 > U ≥ 0.7 | A | A | C | C |

| 0.7 > U ≥ 0.4 | A | B2 | C | C |

| 0.4 > U ≥ 0.05 | B1 | B2 | C | C |

| U < 0.05 | B1 | B2 | C | C |

| Equipment | General Information | Effects 1 |

|---|---|---|

| Computer tomography scanner | Operates using a rotating X-ray tube 2 and a number of detectors placed in a circular structure known as the gantry to measure X-ray attenuations by different tissues inside the body. The multiple measurements taken from different angles are then processed on a computer to produce a series of cross-sectional images of the body. Multiplanar and three-dimensional reconstructions are also performed 3,4 | Any inconsistency in the power supply can cause image blurring, artifacts or otherwise affect its quality, and thus compromise diagnostic accuracy and potentially affect patient care [100]. In [101,102], the measurement results of the current peaks during the operation are presented, which can cause voltage sags in the network |

| Projectional radiography machine | Uses X-ray radiation 2 to produce two-dimensional images. X-ray imaging is a quick, non-invasive and relatively inexpensive technique, particularly useful for visualizing bones, detecting fractures, joint abnormalities, certain lung conditions, as well as dental problems 3 | PQ is critical to produce sharp images as well as to avoid interruptions during the imaging sessions [100]. X-ray equipment has two—continuous and momentary—operating modes, during which it can cause a voltage sag (due to a high demand for electrical power or, in other words, current peaks) as well as voltage fluctuations (flickers) and current distortions [101,102,103] |