Design, Fabrication and Performance Evaluation of an Inter-Row Cultivator for Sugarcane Fields

Abstract

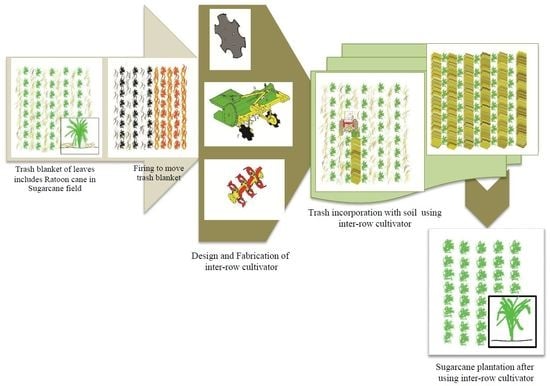

:1. Introduction

2. Materials and Methods

2.1. Design of the Inter-Row Cultivator

- (1)

- PTO shaft: The speed of the PTO shaft of each tractor that was suitable for the inter-row cultivator was approximately 540 rpm.

- (2)

- Gearbox: The gearbox (41.03 kW) was suitable for the requirements of the rotavator (speed ratio 1:1) and for attachment to 25.3- and 37.3-kW tractors. The gear box was used as the transmission system of this machine. It relayed the power of the tractor via the PTO shaft to the chain box to move the rotor blade.

- (3)

- Rotor: The inter-row cultivator was designed with a consistent working width of 80 cm. Inter-row cultivators are mostly available with a working width of 80–90 cm, which is suitable for tractors with a 25-kW or higher power rating [9,10]. The blades attached to each flange were arranged in a spiral form, which allows only one blade to make contact with the ground at the time of rotation. This enables the inter-row cultivator to consume less fuel. The rotor shaft had three flanges, each of which was fitted with six European C-shaped blades spaced 20 degrees apart in a spiral arrangement.

- (4)

- Chain box: The chain box consisted of 13 upper sprockets and 14 lower sprockets, all driven by a chain.

- (5)

- Blades: European C-shaped blades (Manufacturer: Cumar, Valencia, Spain) were selected because of their thickness (8 mm), and the lack of a hooking problem caused by plant residues [9]. Such blades are commonly used in Thailand due to their reasonable efficiency and price. The size of each blade was 140 mm × 198 mm × 8 mm. The shape of the blades is shown in Figure 4.

- (6)

- Notch-cutting discs: There were two notch-cutting discs (Manufacturer: Siam implement, Phitsanulok, Thailand) with a 40-cm diameter in front of the inter-row cultivator. The discs were used for cutting and pressing the sugarcane leaves into smaller sizes before being chopped and mixed by the inter-row cultivator. The working angle of the cutting discs is parallel to the axis of tractor advancement. Clearly, the notch-cutting discs separated the cultivated field from the non-cultivated field, and reduced the possibility of blocking as a result of long leaves.

2.2. Field Evaluation

- (a)

- The length of the sugarcane leaves was measured before and after the cultivator pass based on sample collection from a 1 m × 1 m area, and the length of the sugarcane leaves was measured before and after the cultivator pass (Figure 5).

- (b)

- The weight of the residue left on the soil surface per area (kg·ha−1) was measured based on the leaves and the sugarcane residue in the 1 m × 1 m sampling area (Figure 5), which was then converted to total area (ha).

- (c)

- Soil inversion (SI) was quantitatively expressed as the ratio of the weight of the residue remaining on the soil surface after the cultivator pass relative to that before the cultivator pass (Equation (1)).where Wp is the residue weight per unit area before the cultivator pass, and We is the residue weight per unit area after the cultivator pass.

- (d)

- Effective field efficiency (EFC), theoretical field capacity (TFC), and field efficiency (FE) are shown in Equations (2), (3), and (4), respectively.where We is the effective working width, Ve is the effective operation speed, Tp is the productive time (h) (time for operating the machine in the testing area), Wt is the theoretical working width, Vt is the theoretical operation speed, and Tl is non-productive time (h) (time lost for turning, loading and adjustment, excluding refuelling and machine trouble).

- (e)

- Operating speed: Two poles spaced 20 m apart were placed approximately in the middle of the test run. On the opposite side, another two poles were placed in a similar position, also 20 m apart. The four poles formed the corners of a rectangle that was parallel to at least one long side of the test plot to measure the operating speed of the tractor.

- (f)

- The working width was defined as the distance between the middle of the sugarcane row to the middle of the next sugarcane row (Figure 5).

- (g)

- Fuel consumption: The tank was filled to capacity before and after the test. The amount of fuel required after the test was considered as the fuel consumed during the test.

2.3. Economic Analysis of the Machinery

2.3.1. Tractor and Inter-Row Cultivator Cost

2.3.2. Fixed Cost

2.3.3. Variable Cost

2.3.4. Net Income

3. Results and Discussion

3.1. Inter-Row Cultivator Attached to the 25.3-kW Tractor

3.2. Inter-Row Cultivator Attached to the 37.3-kW Tractor

3.3. Inter-Row Cultivator Attached to the 25.3-kW Tractor at Different Thicknesses of the Trash Blanket

3.4. Inter-Row Cultivator Attached to the 37.3-kW Tractor at Different Thicknesses of the Trash Blanket

3.5. Economic Analysis of the Machinery

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Illovo Sugar. International Sugar Statistics. Available online: https://www.illovosugarafrica.com/home (accessed on 20 August 2017).

- Srisink, S. Sugarcane Management; The Plant Protection Research and Development office, The Department of Agriculture: Bangkok, Thailand, 2015. [Google Scholar]

- Singh, G.; Pathak, B.K. A decision support system for mechanical harvesting and transportation of sugarcane in Thailand. Comput. Electron. Agric. 1994, 11, 173–182. [Google Scholar] [CrossRef]

- Office of Agricultural Economics. Agricultural Production. Sugarcane; Office of Agricultural Economics, Agricultural Statistics, Ministry of Agriculture and Cooperatives: Bangkok, Thailand, 2015.

- Boontrum, A.; Tangpremsri, T.; Prammanee, P.; Lairungreang, C. A Use of an Inter-Row Cultivator to Solve a Problem of Sugarcane Leave Burning after Harvesting; The Institute of Field Crop Research, The Department of Agriculture: Bangkok, Thailand, 1997. [Google Scholar]

- Chainarong, T. Development of a Rotary Tiller for Mixing Sugarcane Residues. Master’s Thesis, Asian Institute of Technology, Bangkok, Thailand, 2002. [Google Scholar]

- Sangla, L.; Suppadit, T. The impacts of sugarcane leaf burning and solving methods. Thai J. Environ. Manag. Nida Thail. 2005, 2, 85–102. [Google Scholar]

- Jenjariyakosoln, S.; Gheewala, H.S.; Sajjakulnukit, B.; Garivait, S. Energy and GHG emission reduction potential of power generation from sugarcane residues in Thailand. Energy Sustain. Dev. 2014, 23, 32–45. [Google Scholar] [CrossRef]

- Sngiamphongse, S.; Senanarong, A.; Khaehanchanpong, Y.; Wannaronk, K. A Research and Development of an Inter-Row Cultivator for Incorporating Sugarcane Leaves between Sugarcane Planting Plots; Research Registration Number 09-01-42-0101; Agricultural Engineering Research Institute: Bangkok, Thailand, 2005. [Google Scholar]

- Sngiamphongse, S. Design and Development of Rotary Tiller for Small Four Wheel Tractor; Agricultural Engineering Research Institute: Bangkok, Thailand, 2000. [Google Scholar]

- Regional Network for Agricultural Machinery (RNAM). Test Code & Procedures for Farm Machinery, 2nd ed.; RNAM: Bangkok, Thailand, 1995. [Google Scholar]

- Hunt, D. Farm Power and Machinery Management; Iowa State University: Ames, IA, USA, 1995. [Google Scholar]

| Description | Tractor 25.3 kW | Tractor 37.3 kW |

|---|---|---|

| Engine capacity (CC) | 1647 | 2434 |

| Bore × Stroke (mm) | 87 × 92.4 | 87 × 102.4 |

| Horsepower/rpm | 34.7/2700 | 50/2700 |

| Gear combination (km·h−1) | 1.8–22.2 | 2.5–29.7 |

| Forward speed | 8 speed | 8 speed |

| PTO speed | 540 | 540 |

| 3-point hitch | Category I | Category I/II |

| Front wheel size | 8–16 | 8.3–24 |

| Rear wheel size | 12.2–24 | 14.9–28 |

| Wheel base (mm) | 1610 | 2000 |

| Weight (kg) | 1115 | 1800 |

| Description | Trash Left Through | t-Test | |

|---|---|---|---|

| Harvesting by Hand | Harvesting Using the Sugarcane Harvester | ||

| Field Test Condition | |||

| Thickness of the trash blanket (cm) | 10 | 10 | |

| A length before cultivation (cm) | 132.0 | 119.3 | −5.939 ** |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 6500 | 6600 | 0.615 ns |

| Results after Using the Inter-Row Cultivator | |||

| Forward speed (m·s−1) | 0.57 | 0.57 | – |

| Theoretical field capacity (ha·h−1) | 0.33 | 0.33 | – |

| Effective field capacity (ha·h−1) | 0.30 | 0.31 | 1.236 ns |

| Field efficiency (%) | 90.91 | 93.94 | 4.044 ** |

| Fuel consumption (L·ha−1) | 19.50 | 18.40 | 3.627 ** |

| A length after cultivation (cm) | 32.60 | 19.30 | 20.822 ** |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 494.7 | 372.9 | −3.247 * |

| Soil inversion (%) | 92.39 | 94.35 | 0.587 * |

| Description | Trash Left Through | t-Test | |

|---|---|---|---|

| Harvesting by Hand | Harvesting Using the Sugarcane Harvester | ||

| Field Test Condition | |||

| Thickness of the trash blanket, cm | 18 | 18 | |

| Leaf length before cultivation (cm) | 119.2 | 112.5 | 2.43 * |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 6780 | 6871 | −0.610 ns |

| Results after Using the Inter-Row Cultivator | |||

| Forward speed (m·s−1) | 0.57 | 0.58 | 1 ns |

| Theoretical field capacity (ha·h−1) | 0.33 | 0.33 | - |

| Effective field capacity (ha·h−1) | 0.30 | 0.31 | 1.12 ns |

| Field efficiency (%) | 90.91 | 93.94 | 4.047 ** |

| Fuel consumption (L·ha−1) | 20.31 | 19.12 | 3.65 ** |

| Leaf length after cultivation (cm) | 27.7 | 15.50 | 19.87 ** |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 352.95 | 244.86 | 5.24 ** |

| Soil inversion (%) | 94.79 | 96.44 | −1.25 * |

| Description | Trash Thickness Level | t-Test | |

|---|---|---|---|

| Thickness of Trash Blanket (10 cm) | Thickness of Trash Blanket (18 cm) | ||

| Field Test Condition | |||

| Leaf length before cultivation (cm) | 114.2 | 116.8 | 2.047 ns |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 5760 | 6480 | 10.126 ** |

| Results after Using the Inter-Row Cultivator | |||

| Forward speed (m·s−1) | 0.56 | 0.56 | - |

| Theory field capacity (ha·h−1) | 0.32 | 0.32 | - |

| Effective field capacity (ha·h−1) | 0.31 | 0.30 | 1.213 ** |

| Field efficiency (%) | 96.88 | 93.75 | −4.784 ** |

| Fuel consumption (L·ha−1) | 16.62 | 19.48 | 4.792 ** |

| Leaf length after cultivation (cm) | 19.17 | 31.78 | 29.748 ** |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 374.40 | 482.60 | 18.17 ns |

| Soil inversion (%) | 93.50 | 92.55 | 2.17 ns |

| Description | Trash Thickness Level | t-Test | |

|---|---|---|---|

| Thickness of the Trash Blanket (10 cm) | Thickness of the Trash Blanket (18 cm) | ||

| Field Test Condition | |||

| Leaf length before cultivation (cm) | 114.5 | 118.0 | 2.152 ns |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 5620 | 6600 | 12.126 ** |

| Results after Using the Inter-Row Cultivator | |||

| Forward speed (m·s−1) | 0.58 | 0.58 | – |

| Theoretical field capacity (ha·h−1) | 0.33 | 0.33 | – |

| Effective field capacity (ha·h−1) | 0.32 | 0.30 | 1.454 ** |

| Field efficiency (%) | 96.97 | 90.91 | −5.409 ** |

| Fuel consumption (L·ha−1) | 17.79 | 19.88 | 2.778 ** |

| Leaf length after cultivation (cm) | 15.50 | 36.40 | 53.964 ** |

| Weight of the residue left on the soil surface per area (kg·ha−1) | 243.35 | 325.74 | 21.59 ns |

| Soil inversion (%) | 95.67 | 95.06 | 1.82 ns |

| Description | 25.3-kW Tractor | 37.3-kW Tractor | Inter-Row Cultivator |

|---|---|---|---|

| Fixed Costs | |||

| Purchase price (P, $) | 13,333.33 | 26,666.66 | 2166.66 |

| Economic life (years) | 7 | 7 | 7 |

| Salvage (10% P, $) | 1333.33 | 2666.66 | 216.66 |

| Annual interest rate (%) | 10 | 10 | 10 |

| Variable Costs | |||

| Fuel consumption (L·ha−1) | 19.50 | 19.88 | – |

| Price of oil ($·L−1) | 0.83 | 0.83 | – |

| Field capacity (ha·h1) | 0.32 | 0.33 | – |

| Fuel cost ($·h−1) | 5.18 | 5.45 | – |

| Lubricant ($·h−1) | 0.47 | 0.59 | – |

| Maintenance ($·h−1) | 6.66 | 13.33 | 1.08 |

| Labor ($·h−1) | 0.83 | 0.83 | – |

| Break-even point (ha) | 48.15 | 101.81 | – |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khaehanchanpong, Y.; Ahamed, T.; Takigawa, T. Design, Fabrication and Performance Evaluation of an Inter-Row Cultivator for Sugarcane Fields. Inventions 2017, 2, 25. https://doi.org/10.3390/inventions2030025

Khaehanchanpong Y, Ahamed T, Takigawa T. Design, Fabrication and Performance Evaluation of an Inter-Row Cultivator for Sugarcane Fields. Inventions. 2017; 2(3):25. https://doi.org/10.3390/inventions2030025

Chicago/Turabian StyleKhaehanchanpong, Yuttana, Tofael Ahamed, and Tomohiro Takigawa. 2017. "Design, Fabrication and Performance Evaluation of an Inter-Row Cultivator for Sugarcane Fields" Inventions 2, no. 3: 25. https://doi.org/10.3390/inventions2030025

APA StyleKhaehanchanpong, Y., Ahamed, T., & Takigawa, T. (2017). Design, Fabrication and Performance Evaluation of an Inter-Row Cultivator for Sugarcane Fields. Inventions, 2(3), 25. https://doi.org/10.3390/inventions2030025