Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System

Abstract

:1. Introduction

2. Materials and Methods

2.1. Calculation of the Ventilation System

2.2. Existing Ventilation System on the Reference Vessel

2.3. Minimum Combustion Air Flow and Cooling Power Needed

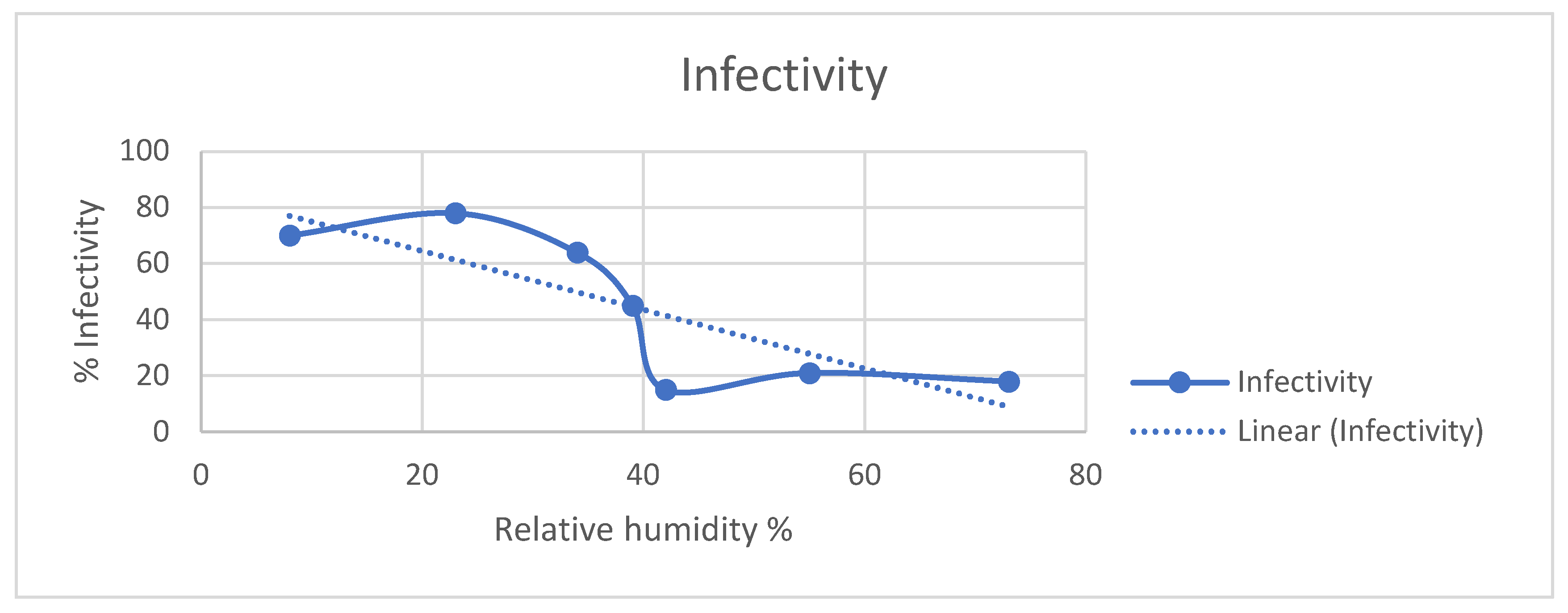

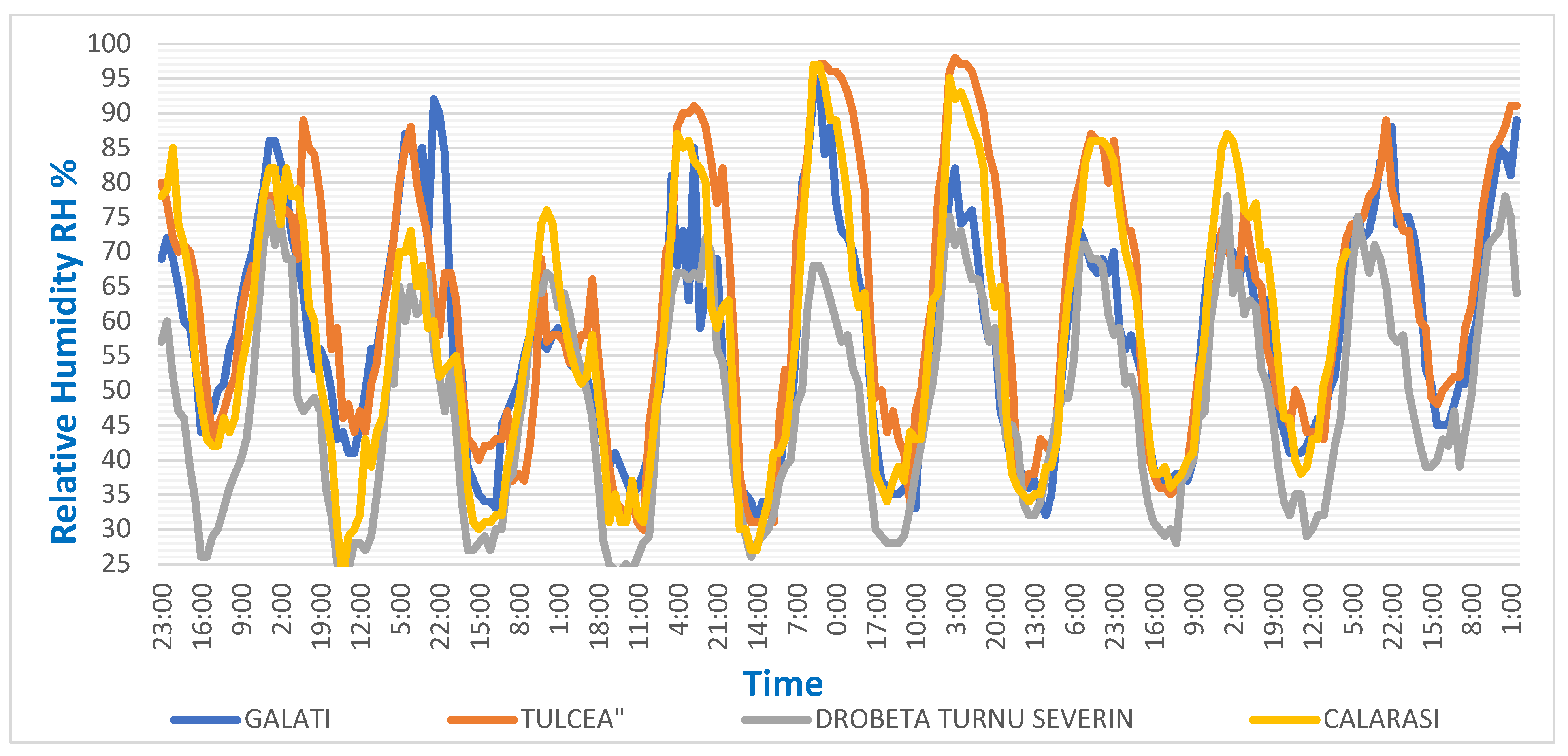

2.4. The Main Aspects and Constrains of Ventilation Systems Related to Relative Humidity

2.5. Adiabatic Cooling–General Overview

2.6. The Main Constrains for Direct Adiabatic Cooling

- -

- To use clean water;

- -

- To purge the system after using it to avoid water stagnation into the system;

- -

- The water to be kept for less than one day in the water tank after cleaning.

Potable Water Quality and Hardness at Local Suppliers

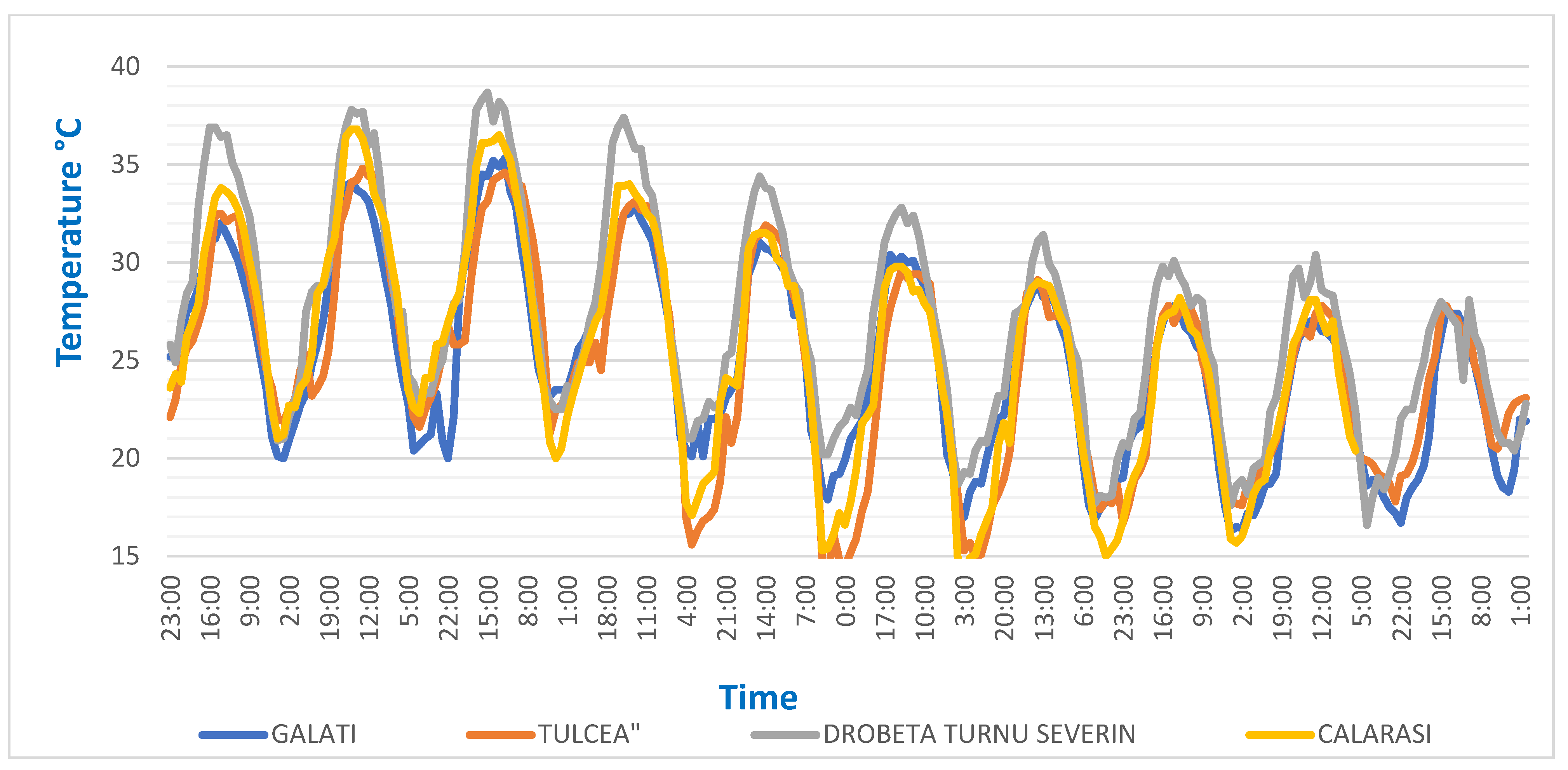

2.7. Environmental Conditions in the Danube Area

3. Results and Discussions

4. Conclusions

- -

- A small decrease in the efficiency of the combustion is expected, but this will not affect the power while the engine is designed to work at 45 °C and 60%RH.

- -

- High humidity can generate condensation in the air cooler due to the high pressure after the turbocharger and dropping down the temperature inside the cooler, but only if the combustion air is part of direct adiabatic cooling.

- -

- The comfort of the crew inside the engine room will be reduced by increasing the temperature humidity comfort index.

- -

- The air flow can be substantially reduced, which means reducing the power consumption and pressure drop across the ventilation ducts and louvers, which will also reduce the noise from the ventilation system.

- -

- Reducing temperature and increasing humidity will have a positive effect by substantially reducing pollution (NOx).

- -

- Reducing the air flow will reduce the air velocity inside the engine room, which should reduce the heat dissipation to the air from the engines. More energy will be removed by the internal water cooling system of the engines.

- -

- Regarding the airborne spreading of viruses, increasing the relative humidity will reduce the degree of infectivity.

5. Index of Notations and Abbreviations

| Acronym | Meaning |

| DCF | Dry exhaust and turbo manifold correction factor |

| Ter | Ambient Engine Room temperature |

| Qa/Qb | The air flow needed for cooling and for combustion (alternative a/b) |

| qh | The air flow needed for cooling |

| qc | The air flow needed for combustion |

| qha | The air flow of ventilation system without combustion air |

| P | The engine power |

| The air density | |

| c | The specific heat capacity of the air |

| ΔT | Increasing of the air temperature in engine room (according to ISO) |

| ΔTcs | Difference of temperature between outside air and inside air |

| Δh | The difference of air mixture (air &water vapor) enthalpy |

| ΣΦ | The sum of heat radiation of equipment inside engine room |

| Φm | Cooling power for minimum requested air flow |

| Φc | Cooling power for combustion air flow |

| Φcs | Sensible cooling power of cooling air |

| Φl | The cooling capacity of water spraying (latent heat exchange) |

| Φt | The total cooling capacity (latent & sensible heat exchange) |

| qw | The water flow for adiabatic cooling |

| The water density | |

| Hva | The heat of vaporization of water |

| THI | The temperature humidity index |

| T | The air temperature |

| U | The Relative humidity |

| ppm | Parts per million |

| UV | Ultraviolet |

| HP | Horsepower |

| IACS | International Association of Classification Societies |

| ISO | International Organization for Standardization |

| CFD | Computational Fluid Dynamics |

| CIMAC | International Council on Combustion Engines |

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- SR ISO 8861; Shipbuilding—Engine Room Ventilation in Diesel-Engined Ships—Design Requirements and Basis of Calculations. Romanian Standardization Association: Bucharest, Romania, 2002.

- Mihai, V.; Rusu, L.; Presura, A. Ventilation of Engine Rooms in Diesel Engines Ship; The Annals of “Dunarea de Jos” University of Galati Fascicle xi—Shipbuilding. I: Galati, Romania, 2020; Volume 43, pp. 69–78. [Google Scholar] [CrossRef]

- Hendri, N.S.; Adi, A.; Suharyo, O.S.; Susanto, A.D. The Air Flow Analysis in Engine Rooms at Frigate Class Ship with CFD Approach (Computational Fluids Dynamics). Int. J. Recent Eng. Sci. 2018, 5, 11–18. [Google Scholar] [CrossRef]

- Rietschel, H.; Raiss, W. Tehnica Incalzirii si Ventilarii; Ghitescu, D., Klodnischi, L., Eds.; Editura Tehnica Bucuresti: Bucharest, Romania, 1967. [Google Scholar]

- Navrom. “Romanian River Shipping Company Navrom”. Available online: https://www.navrom.ro/index.php/en/ (accessed on 28 May 2022).

- Caterpillar. “Marine Propulsion 3512C- Marine Engine Performance”. 2009. Available online: https://www.teknoxgroup.com/fileadmin/user_upload/3512C_IMO-MARINE_2.pdf (accessed on 25 July 2022).

- Caterpillar. Performance Data 3512C 4369623; Technical data sheet; Caterpillar: Deerfield, IL, USA, 2021. [Google Scholar]

- VOLVO PENTA. D5A-A T HE 1500 rpm, Document Number 21939859; Technical data sheet; AB Volvo Penta: Göteborg, Sweden, 2005. [Google Scholar]

- VOLVO PENTA. Volvo Penta Marine Genset D5A-T; Maker Technical data sheet; AB Volvo Penta: Göteborg, Sweden, 2005. [Google Scholar]

- Caterpillar. LEBW4971-06 Application & Installation Guide Engine Room Ventilation. 2015. Available online: https://www.cat.com/en_US/by-industry/marine/marine-engine-applicationandinstallationguides.html (accessed on 28 May 2022).

- International Association of Classification—IACS. UR-M40, Ambient Conditions—Temperatures. 1986. Available online: https://www.iacs.org.uk/publications/unified-requirements/ur-m/?page=2 (accessed on 25 July 2022).

- International Association of Classification—IACS. UR-M28 Requirements Concerning Machinery Installations—Ambient Reference Conditions. 1978. Available online: https://www.iacs.org.uk/media/3773/ur_m_pdf2793.pdf (accessed on 25 July 2022).

- Taşdemir, C.; Bayraktar, S. CFD Analysis of Ventilation System for an ENGINE ROOM. In Proceedings of the 1st International Ship and Marine Technology Congress (SHIP-MAR 2016), Istanbul, Turkey, 8 December 2016; Available online: https://www.researchgate.net/publication/312289286_cfd_analysis_of_ventilation_system_for_an_engine_room (accessed on 25 July 2022).

- Bohmanova, J.; Misztal, I.; Cole, J.B. Temperature-Humidity Indices as Indicators of Milk Production Losses due to Heat Stress. J. Dairy Sci. 2007, 90, 1947–1956. [Google Scholar] [CrossRef] [PubMed]

- Termotecnica. Temperature Humidity Index: What You Need to Know About it. 2018. Available online: https://www.pericoli.com/EN/news/120/Temperature-Humidity-Index-what-you-need-to-know-about-it.html (accessed on 25 July 2022).

- Vlăduţ, A. Temperature—Humidity Index (THI) within the Oltenia Plain between 2000 and 2009. Forum Geogr. 2011, X, 149–156. [Google Scholar] [CrossRef]

- Teodoreanu, E. Thermal Comfort Index. Present Environ. Sustain. Dev. 2016, 10, 105–118. [Google Scholar] [CrossRef]

- Orosa, J.A.; Costa, Á.M.; Pérez, J.A. A new modelling procedure of the engine room ventilation system for work risk prevention and energy saving. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2017, 231, 863–870. [Google Scholar] [CrossRef]

- Rakopoulos, C.D. Influence of Ambient temperature and humidity on the performance and emissions of nitric oxide and smoke of high speed diesel engines in the athens/greece region. Energy Convers. Manag. 1991, 31, 447–458. [Google Scholar] [CrossRef]

- Kahandagamage, G. Analysis of the effect of charge air temperature and humidity on the combustion process of diesel engines at Heladhanavi Power Plant, Puttalam, Sri Lanka. Eng. Phys. 2014. Available online: https://www.semanticscholar.org/paper/Analysis-of-the-effect-of-charge-air-temperature-on-Kahandagamage/6f08767c39dd78a6af6566002c80cb29e50e0a38 (accessed on 25 July 2022).

- International Council on Combustion Engines. About the Influence of Ambient Conditions on Performance of Gas Engines. 2009. Available online: https://www.cimac.com/cms/upload/workinggroups/WG17/CIMAC_GE_8th_meet_Dessau_Position_Paper_Ambients_Final_20090325.pdf (accessed on 25 July 2022).

- Hathaway, B. Hopes of pandemic respite this spring may depend upon what happens indoors. 2020. Available online: https://news.yale.edu/2020/03/30/hopes-pandemic-respite-spring-may-depend-upon-what-happens-indoors (accessed on 25 July 2022).

- Reinders, R. Ventilation and Humidity Crucial against Viruses, even after Corona. Oxycom—Natural Air Conditioning. 2020. Available online: https://www.oxy-com.com/blog-news/ventilation-and-humidity-covid-19 (accessed on 25 July 2022).

- ToolBox, E. Water—Heat of Vaporization vs. Temperature. Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/water-properties-d_1573.html (accessed on 25 July 2022).

- Rasmussen, L. High Pressure Water Misting System for Adiabatic Outdoor Cooling in Hot and Dry Areas—Combined with Shading Systems. Available online: https://www.condair.com/m/0/water-misting-system-for-adiabatic-outdoor-cooling-in-hot-and-dry-areas-general.pdf (accessed on 25 July 2022).

- Apa Canal SA Galati. RAPORT ANUAL 2019, Galati. 2019. Available online: https://www.apa-canal.ro/rapoarte-activitate/2019.pdf (accessed on 25 July 2022).

- Apa Canal SA Galati. RAPORT ANUAL 2020, Galati. 2020. Available online: https://www.apa-canal.ro/rapoarte-activitate/2020.pdf (accessed on 25 July 2022).

- Ministerul Sanatatii—Directia de Sanatate Publica Giurgiu. Buletin de Analiza Apa. Giurgiu. 2021. Available online: https://apagiurgiu.ro/wp-content/uploads/2022/01/Buletin-de-analiza-13.12.2021-Giurgiu.pdf (accessed on 25 July 2022).

- Ministerul Sanatatii—Directia de Sanatate Publica Giurgiu. Buletin de Analiza Apa. Giurgiu. 2022. Available online: https://apagiurgiu.ro/wp-content/uploads/2022/02/Buletin-de-analiza-12.01.2022-Giurgiu.pdf (accessed on 25 July 2022).

- Universitatea Transilvania Brasov. Apa. Duritatea Apei. Dedurizarea şi Demineralizarea Apei. 2015, pp. 1–23. Available online: https://www.academia.edu/12231281/Curs_4, (accessed on 25 July 2022).

- Monarch Water Ltd. Hardness Conversion Table. Available online: https://www.magmaweld.com/hardness-conversion-table/i/79 (accessed on 25 July 2022).

- Waterhardness Calculator. Available online: https://www.waterhardness.net/calculator/show?calculator (accessed on 25 July 2022).

- OGIMET. METEOSTAT. 2021. Available online: https://ogimet.com/cgi-bin/gsynres?ind=15460&decoded=yes&ndays=2&ano=2021&mes=09&day=214&hora=23 (accessed on 25 July 2022).

- Air in Motion. Mollier Diagram Calculator. 2022. Available online: https://afim-dehumidifier.com/en/mollier-chart-air-calculator/ (accessed on 25 July 2022).

- Caterpillar. “Air Intake Systems”. 2008. Available online: https://fdocuments.in/document/caterpillar-air-intake-systems.html?page=16 (accessed on 25 July 2022).

| Description | Quantity | Running | Heat Radiation | Total Heat Radiation |

|---|---|---|---|---|

| kW | ||||

| Main engines | 2 pcs | 2 pcs | 101 kW/pc | 202 |

| Diesel generators | 2 pcs | 1 pc | 6.4 kW/pc | 6.4 |

| Exhaust pipe Main engine ND350 | 4 m | 4 m | 0.3 kW/m | 1.2 |

| Exhaust pipe Diesel generator ND125 | 6 m | 3 m | 0.15 kW/m | 0.45 |

| Electrical equipment | 6.0 | |||

| Total Heat Radiated Inside the Engine Room | Abt. 216 kW | |||

| Description | Quantity | Running | Combustion Air Flow | Total Heat Radiation |

|---|---|---|---|---|

| m3/h/engine | m3/h | |||

| Main engines | 2 pcs | 2 pcs | 6650 | 13,300 |

| Diesel generators | 2 pcs | 1 pc | 350 | 350 |

| Total Combustion Air Flow m3/h | 13,650 | |||

| Description | Qh—Cooling Air Flow | qc—Combustion Air Flow | Q—Requested Air Flow |

|---|---|---|---|

| m3/h | m3/h | m3/h | |

| Qa = qh + qc | 54,520 | 13,650 | 62,710 |

| Qb = 1.5 × qc | 13,650 | 20,475 | |

| Requested Air Flow m3/h | 62,710 | ||

| Temperature | [kJ/kg] | [Wh/kg] |

|---|---|---|

| 0 °C | 2500 | 695 |

| 20 °C | 2453 | 682 |

| 25 °C | 2442 | 678 |

| 30 °C | 2430 | 675 |

| 35 °C | 2418 | 672 |

| Parameter | Quality Requested by Actual Laws | Average Values in 2019 | Average Values in 2020 |

|---|---|---|---|

| Microbiological parameters–bacteria (pcs/100 mL) | 0 | 0 | 0 |

| Water hardness (Ca & Mg) [°G] | Minim 5 | 11–19 | 19–37 |

| Sulphates [mg/L] | 250 | 39–106 | 10–20 |

| Chlorides [mg/L] | 250 | 27–106 | 40–102 |

| Others have small quantity and are not considered | 0 | 0 | 0 |

| Relative Humidity | All | RH < 40% | 40% ≥ RH ≤ 50% | 50% > RH < 60% | RH ≥ 60% | ||

|---|---|---|---|---|---|---|---|

| Temperature | ≥25 °C | <30 °C | ≥30 °C | <30 °C ≥30 °C | <30 °C ≥30 °C | <30 °C | ≥30 °C |

| June [hours] (Average temp. & RH) | 164 - | 1 (28 °C, 38%RH) | 1 (33 °C, 39%RH) | 27 29 (30 °C, 45%RH) | 36 22 (30 °C, 55%RH) | 45 | 3 |

| July [hours] (Average temp. & RH) | 337 - | 22 (28 °C, 37%RH) | 64 (34 °C, 35%RH) | 47 66 (30 °C, 45%RH) | 73 21 (28 °C, 55%RH) | 44 | 0 |

| August [hours] (Average temp. & RH) | 342 - | 62 (28 °C, 37%RH) | 63 (33 °C, 35%RH) | 54 39 (30 °C, 45%RH) | 49 11 (27 °C, 54%RH) | 62 | 2 |

| September [hours] (Average temp. & RH) | 100 - | 74 (28 °C, 35%RH) | 6 (31 °C, 35%RH) | 16 0 (27 °C, 43%RH) | 4 0 (26 °C, 54%RH) | 0 | 0 |

| TOTAL [hours] | 943 | 159 | 134 | 278 | 216 | 151 | 5 |

| 16.9% | 14.2% | 29.5% | 22.9% | 16.0% | 0.5% | ||

| 293 | 278 | 216 | 156 | ||||

| 31.1% | 29.5% | 22.9% | 16.5% | ||||

| Nr. Crt. | Fans Running | Total Air Flow m3/h | % Load of vent System | Combustion Air m3/h | Cooling Air m3/h |

|---|---|---|---|---|---|

| 1. | 1 × 8000 m3/h + 1 × 13,000 m3/h | 21.000 | 31% | 13,650 | 7.350 |

| 2. | 2 × 13,000 m3/h | 26.000 | 38% | 13,650 | 12.350 |

| Outside Air | Cooling Power | Inside Air | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hours | Temperature | RH | THI—Temp Humidity Index | Absolute Moisture | Enthalpy | Sensible Cooling Power | Adiabatic Cooling (Latent Heat) | Water Flow | Moisture Added | Absolute Moisture After Direct Adiabatic Cooling | RH | THI—Temp Humidity Index |

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 | 11 | 12 | 13 |

| [°C] | (%) | (g/kg) | (kJ/kg) | [kw] | [kw] | [L/h] | (g/kg) | (g/kg) | (%) | (%) | ||

| 1 | 28 | 38 | 74.1 | 8.9 | 49.9 | 40 | 159 | 236 | 28.4 | 37.4 | 60 | 100.8 |

| 84 | 28 | 37 | 73.9 | 8.7 | 49.3 | 40 | 159 | 236 | 28.4 | 37.1 | 60 | 100.7 |

| 74 | 28 | 35 | 73.7 | 8.2 | 48.2 | 40 | 159 | 236 | 28.4 | 36.7 | 59 | 100.6 |

| 1 | 33 | 39 | 80.2 | 12.3 | 62.8 | 28 | 171 | 253 | 30.5 | 42.8 | 68 | 103.3 |

| 64 | 34 | 35 | 80.6 | 11.6 | 62.3 | 26 | 173 | 257 | 30.9 | 42.6 | 68 | 103.3 |

| 63 | 33 | 35 | 79.5 | 11.0 | 59.8 | 28 | 171 | 253 | 30.5 | 41.5 | 66 | 102.8 |

| 6 | 31 | 35 | 77.1 | 9.8 | 54.9 | 33 | 166 | 246 | 29.7 | 39.5 | 63 | 101.9 |

| 262 | 30 | 45 | 77.5 | 11.9 | 59.1 | 35 | 164 | 243 | 29.3 | 41.2 | 66 | 102.6 |

| 16 | 27 | 43 | 73.5 | 9.6 | 50.4 | 42 | 157 | 233 | 28.0 | 37.6 | 60 | 101.0 |

| 58 | 30 | 55 | 79.1 | 14.7 | 65.5 | 35 | 164 | 243 | 29.3 | 43.9 | 70 | 103.8 |

| 94 | 28 | 55 | 76.4 | 13.0 | 59.7 | 40 | 159 | 236 | 28.4 | 41.5 | 66 | 102.8 |

| 60 | 27 | 54 | 74.9 | 12.0 | 56.3 | 42 | 157 | 233 | 28.0 | 40.1 | 64 | 102.1 |

| 4 | 26 | 54 | 73.5 | 11.3 | 53.7 | 44 | 155 | 229 | 27.6 | 38.9 | 62 | 101.6 |

| Outside Air | Cooling Power | Inside Air after Cooling | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hours | Temperature | RH | THI—Temp Humidity Index | Absolute MOISTURE | Enthalpy | Sensible Cooling Power | Adiabatic Cooling (Latent Heat) | Water Flow | Absolute Moisture After Direct Adiabatic Cooling | RH | THI—Temp Humidity Index |

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 11 | 12 | 13 |

| [°C] | (%) | (g/kg) | (kJ/kg) | [kw] | [kw] | [L/h] | (g/kg) | (%) | |||

| 1 | 28 | 38 | 74.1 | 8.9 | 49.9 | 67 | 132 | 196 | 23 | 38 | 94.2 |

| 84 | 28 | 37 | 73.9 | 8.7 | 49.3 | 67 | 132 | 196 | 23 | 38 | 94.2 |

| 74 | 28 | 35 | 73.7 | 8.2 | 48.2 | 67 | 132 | 196 | 22 | 36 | 93.7 |

| 1 | 33 | 39 | 80.2 | 12.3 | 62.8 | 47 | 152 | 225 | 28 | 46 | 96.5 |

| 64 | 34 | 35 | 80.6 | 11.6 | 62.3 | 43 | 156 | 231 | 28 | 46 | 96.5 |

| 63 | 33 | 35 | 79.5 | 11.0 | 59.8 | 47 | 152 | 225 | 27 | 44 | 96.0 |

| 6 | 31 | 35 | 77.1 | 9.8 | 54.9 | 55 | 144 | 214 | 25 | 41 | 95.1 |

| 262 | 30 | 45 | 77.5 | 11.9 | 59.1 | 59 | 140 | 208 | 27 | 44 | 96.0 |

| 16 | 27 | 43 | 73.5 | 9.6 | 50.4 | 70 | 129 | 190 | 23 | 38 | 94.2 |

| 58 | 30 | 55 | 79.1 | 14.7 | 65.5 | 59 | 140 | 208 | 30 | 35 | 93.2 |

| 94 | 28 | 55 | 76.4 | 13.0 | 59.7 | 67 | 132 | 196 | 27 | 44 | 96.0 |

| 60 | 27 | 54 | 74.9 | 12.0 | 56.3 | 70 | 129 | 190 | 26 | 42 | 95.6 |

| 4 | 26 | 54 | 73.5 | 11.3 | 53.7 | 74 | 125 | 185 | 25 | 41 | 95.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihai, V.; Rusu, L. Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System. Inventions 2022, 7, 78. https://doi.org/10.3390/inventions7030078

Mihai V, Rusu L. Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System. Inventions. 2022; 7(3):78. https://doi.org/10.3390/inventions7030078

Chicago/Turabian StyleMihai, Victor, and Liliana Rusu. 2022. "Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System" Inventions 7, no. 3: 78. https://doi.org/10.3390/inventions7030078

APA StyleMihai, V., & Rusu, L. (2022). Improving the Ventilation of Machinery Spaces with Direct Adiabatic Cooling System. Inventions, 7(3), 78. https://doi.org/10.3390/inventions7030078