K-mer Frequency Encoding Model for Cable Defect Identification: A Combination of Non-Destructive Testing Approach with Artificial Intelligence

Abstract

:1. Introduction

2. Material and Methods

2.1. Metal Cable Fault Detection

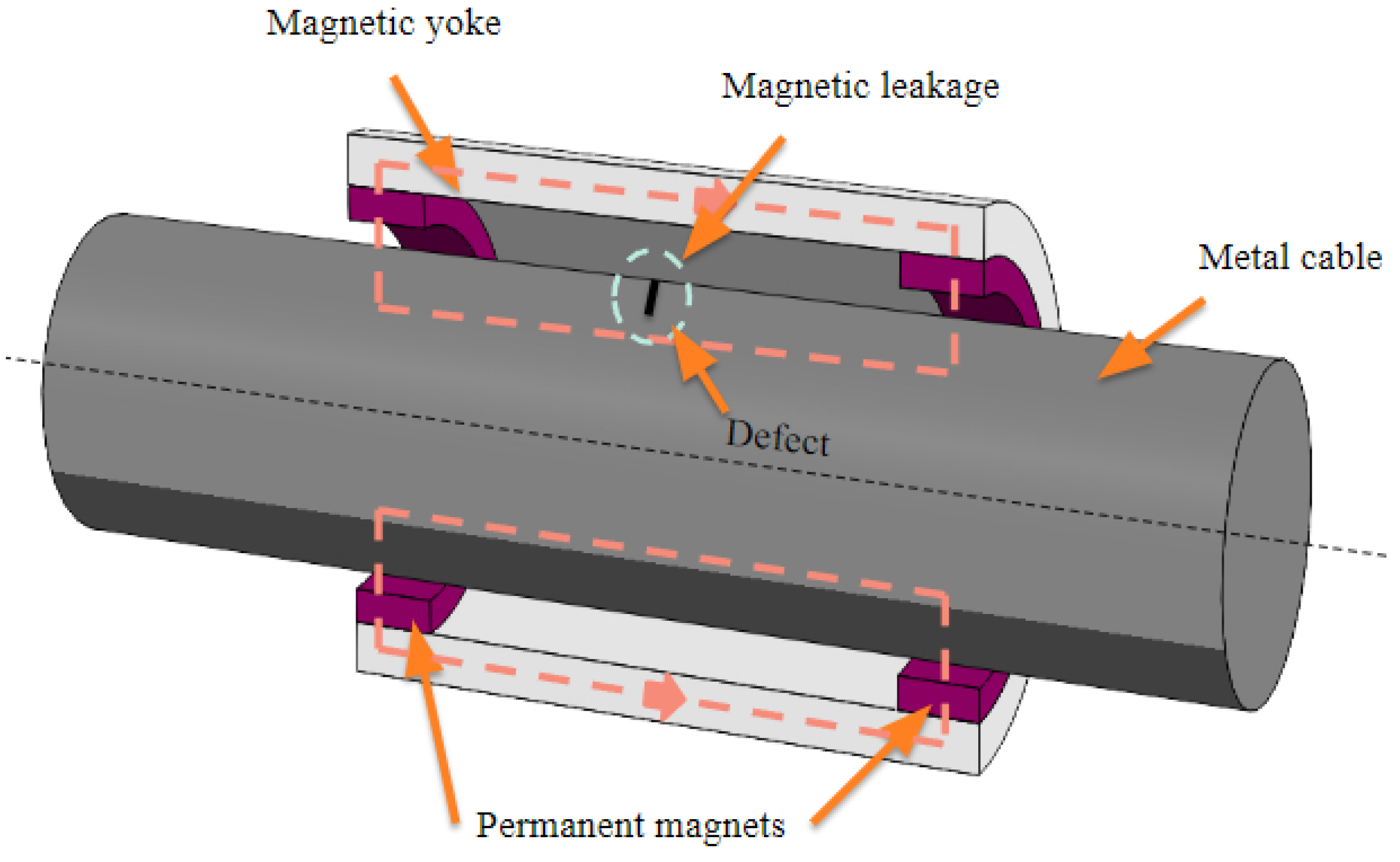

2.1.1. Metal Cable Fault Detection Using Magnetic Flux Leakage

2.1.2. Metal Cable Fault Data Acquisition Using Magnetic Flux Leakage Equipment

2.2. K-mer Frequency Encoding Method

3. Results

3.1. Comparative Analysis of Cable Defect Identification Data Using K-mer Frequency Encoding Method

3.2. Comparative Analysis of Repeated Sampling Data

3.3. Comparative Analysis of K-mer Frequency

3.4. Comparision of the K-mer Frequency Encoding Method with the Classical Method

4. Discussion and Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, I.; Jeon, G.; Piccialli, F. From artificial intelligence to explainable artificial intelligence in industry 4.0: A survey on what, how, and where. IEEE Trans. Ind. Inform. 2022, 18, 5031–5042. [Google Scholar] [CrossRef]

- Xu, Z.; Saleh, J.H. Machine learning for reliability engineering and safety applications: Review of current status and future opportunities. Reliab. Eng. Syst. Saf. 2021, 211, 107530. [Google Scholar] [CrossRef]

- Liu, Z.; Xie, K.; Li, L.; Chen, Y. A paradigm of safety management in industry 4.0. Syst. Res. Behav. Sci. 2020, 37, 632–645. [Google Scholar] [CrossRef]

- Lee, J.; Phillips, I.; Lynch, Z. Causes and prevention of mobile crane-related accidents in South Korea. Int. J. Occup. Saf. Ergon. 2022, 28, 469–478. [Google Scholar] [CrossRef]

- Chang, X.; Chen, X.; Dong, Y.; Lu, H.; Tang, W.; Zhang, Q.; Huang, K. Friction and Wear Behavior between Crane Wire Rope and Pulley under Different Contact Loads. Lubricants 2022, 10, 337. [Google Scholar] [CrossRef]

- Čereška, A.; Zavadskas, E.K.; Bucinskas, V.; Podvezko, V.; Sutinys, E. Analysis of steel wire rope diagnostic data applying multi-criteria methods. Appl. Sci. 2018, 8, 260. [Google Scholar] [CrossRef]

- Yousri, M.; Jacobs, G.; Neumann, S. Impact of fiber versus steel ropes on the lifetime of crane winches. MIC J. 2020, 41, 129–139. [Google Scholar] [CrossRef]

- Tan, J. Principle and Technology of Steel Wire Rope Safety Detection; Science Press: Beijing, China, 2009. [Google Scholar]

- GELAN, T.M. Convolutional Neural Networks for Defect Detection on LV cables. J. Appl. Artif. Intell. 2022, 3, 39–46. [Google Scholar] [CrossRef]

- Zhang, J.; Tan, X.; Zheng, P. Non-destructive detection of wire rope discontinuities from residual magnetic field images using the Hilbert-Huang transform and compressed sensing. Sensors 2017, 17, 608. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, C.; Li, R.; Cai, M.; Jia, G. Theory and application of magnetic flux leakage pipeline detection. Sensors 2015, 15, 31036–31055. [Google Scholar] [CrossRef]

- ISO 4309:2017; Cranes—Wire Ropes—Care and Maintenance, Inspection and Discard. International Organization for Standardization: Geneva, Switzerland, 2017.

- Park, S.; Kim, J.-W.; Lee, C.; Lee, J.-J. Magnetic flux leakage sensing-based steel cable NDE technique. Shock Vib. 2014, 2014, 929341. [Google Scholar] [CrossRef]

- Tse, P.W.; Rostami, J. Advanced signal processing methods applied to guided waves for wire rope defect detection. In Proceedings of the 42nd Annual Review of Progress in Quantitative Nondestructive Evaluation: Incorporating the 6th European-American Workshop on Reliability of NDE, Minneapolis, MN, USA, 26–31 July 2015. [Google Scholar]

- Jie, T.; Hong-Yao, W.; Bilen, S.; Xinli, W.; Guo-Ying, M. Application of a morphological non-sampling wavelet method to the online detection signal processing of coal mine wire rope. Insight-Non-Destr. Test. Cond. Monit. 2019, 61, 521–527. [Google Scholar] [CrossRef]

- Benaissa, B.; Khatir, S.; Jouini, M.S.; Riahi, M.K. Optimal Axial-Probe Design for Foucault-Current Tomography: A Global Optimization Approach Based on Linear Sampling Method. Energies 2023, 16, 2448. [Google Scholar] [CrossRef]

- Amidu, M.A.; Addad, Y.; Riahi, M. A hybrid multiphase flow model for the prediction of both low and high void fraction nucleate boiling regimes. Appl. Therm. Eng. 2020, 178, 115625. [Google Scholar] [CrossRef]

- Riahi, M.K. A new approach to improve ill-conditioned parabolic optimal control problem via time domain decomposition. Numer. Algorithms 2016, 72, 635–666. [Google Scholar] [CrossRef]

- Agrawal, D.; Bernstein, P.; Bertino, E.; Davidson, S.; Dayal, U.; Franklin, M.; Gehrke, J.; Haas, L.; Halevy, A.; Han, J. Challenges and Opportunities with Big Data 2011-1; Cyber Center Technical Reports; Purdue University Press Open Access: Collections, IN, USA, 2011. [Google Scholar]

- Tsai, C.-W.; Lai, C.-F.; Chao, H.-C.; Vasilakos, A.V. Big data analytics: A survey. J. Big Data 2015, 2, 21. [Google Scholar] [CrossRef]

- Zhang, C.; Patras, P.; Haddadi, H. Deep learning in mobile and wireless networking: A survey. IEEE Commun. Surv. Tutor. 2019, 21, 2224–2287. [Google Scholar] [CrossRef]

- Fan, J.; Han, F.; Liu, H. Challenges of big data analysis. Natl. Sci. Rev. 2014, 1, 293–314. [Google Scholar] [CrossRef]

- Sivarajah, U.; Kamal, M.M.; Irani, Z.; Weerakkody, V. Critical analysis of Big Data challenges and analytical methods. J. Bus. Res. 2017, 70, 263–286. [Google Scholar] [CrossRef]

- Mao, Q.; Ma, H.; Zhang, X.; Zhang, G. An improved skewness decision tree svm algorithm for the classification of steel cord conveyor belt defects. Appl. Sci. 2018, 8, 2574. [Google Scholar] [CrossRef]

- Shirazi, M.I.; Khatir, S.; Benaissa, B.; Mirjalili, S.; Wahab, M.A. Damage assessment in laminated composite plates using modal Strain Energy and YUKI-ANN algorithm. Compos. Struct. 2023, 303, 116272. [Google Scholar] [CrossRef]

- Ghandourah, E.; Khatir, S.; Banoqitah, E.M.; Alhawsawi, A.M.; Benaissa, B.; Wahab, M.A. Enhanced ANN Predictive Model for Composite Pipes Subjected to Low-Velocity Impact Loads. Buildings 2023, 13, 973. [Google Scholar] [CrossRef]

- Amoura, N.; Benaissa, B.; Al Ali, M.; Khatir, S. Deep Neural Network and YUKI Algorithm for Inner Damage Characterization Based on Elastic Boundary Displacement. In Proceedings of the International Conference of Steel and Composite for Engineering Structures, Ancona, Italy, 12–13 September 2022; pp. 220–233. [Google Scholar]

- Aloysius, N.; Geetha, M. A review on deep convolutional neural networks. In Proceedings of the 2017 international conference on communication and signal processing (ICCSP), Chennai, India, 6–8 April 2017; pp. 0588–0592. [Google Scholar]

- Pyakillya, B.; Kazachenko, N.; Mikhailovsky, N. Deep learning for ECG classification. J. Phys. Conf. Ser. 2017, 913, 012004. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Zhu, Z.; Tang, C.; He, Z.; Li, W.; Jiang, F. Health monitoring for balancing tail ropes of a hoisting system using a convolutional neural network. Appl. Sci. 2018, 8, 1346. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Z.; Zhang, X.; Kang, J.; Zhang, M.; Guo, Y. Surface damage detection for steel wire ropes using deep learning and computer vision techniques. Measurement 2020, 161, 107843. [Google Scholar] [CrossRef]

- Liu, S.; Chen, M. Wire Rope Defect Recognition Method Based on MFL Signal Analysis and 1D-CNNs. Sensors 2023, 23, 3366. [Google Scholar] [CrossRef]

- Breitwieser, F.P.; Baker, D.N.; Salzberg, S.L. KrakenUniq: Confident and fast metagenomics classification using unique k-mer counts. Genome Biol. 2018, 19, 198. [Google Scholar] [CrossRef]

- Sun, H.; Ding, J.; Piednoël, M.; Schneeberger, K. findGSE: Estimating genome size variation within human and Arabidopsis using k-mer frequencies. Bioinformatics 2018, 34, 550–557. [Google Scholar] [CrossRef]

- Mapleson, D.; Garcia Accinelli, G.; Kettleborough, G.; Wright, J.; Clavijo, B.J. KAT: A K-mer analysis toolkit to quality control NGS datasets and genome assemblies. Bioinformatics 2017, 33, 574–576. [Google Scholar] [CrossRef]

- ValizadehAslani, T.; Zhao, Z.; Sokhansanj, B.A.; Rosen, G.L. Amino acid K-mer feature extraction for quantitative antimicrobial resistance (AMR) prediction by machine learning and model interpretation for biological insights. Biology 2020, 9, 365. [Google Scholar] [CrossRef]

- Yao, Y.-T.; Wu, Y.-W.; Lin, P.T. A Two-Stage Multi-Fidelity Design Optimization for K-mer-Based Pattern Recognition (KPR) in Image Processing. In Proceedings of the ASME 2020 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Virtual, 17–19 August 2020. [Google Scholar]

- Subburaj, S.; Yeh, C.-H.; Patel, B.; Huang, T.-H.; Hung, W.-S.; Chang, C.-Y.; Wu, Y.-W.; Lin, P.T. K-mer-Based Human Gesture Recognition (KHGR) Using Curved Piezoelectric Sensor. Electronics 2023, 12, 210. [Google Scholar] [CrossRef]

- Akkaya, U.M.; Kalkan, H. Classification of DNA Sequences with k-mers Based Vector Representations. In Proceedings of the 2021 Innovations in Intelligent Systems and Applications Conference (ASYU), Elazig, Turkey, 6–8 October 2021; pp. 1–5. [Google Scholar]

- Li, X.; Gao, C.; Guo, Y.; He, F.; Shao, Y. Cable surface damage detection in cable-stayed bridges using optical techniques and image mosaicking. Opt. Laser Technol. 2019, 110, 36–43. [Google Scholar] [CrossRef]

- Zhou, P.; Zhou, G.; Zhu, Z.; He, Z.; Ding, X.; Tang, C. A review of non-destructive damage detection methods for steel wire ropes. Appl. Sci. 2019, 9, 2771. [Google Scholar] [CrossRef]

- Halaki, M.; Ginn, K. Normalization of EMG signals: To normalize or not to normalize and what to normalize to. Comput. Intell. Electromyogr. Anal. A Perspect. Curr. Appl. Future Chall. 2012, 10, 49957. [Google Scholar]

- Chen, X.; Kingma, D.P.; Salimans, T.; Duan, Y.; Dhariwal, P.; Schulman, J.; Sutskever, I.; Abbeel, P. Variational lossy autoencoder. arXiv 2016, arXiv:1611.02731. [Google Scholar]

- An, J.; Cho, S. Variational autoencoder based anomaly detection using reconstruction probability. Spec. Lect. IE 2015, 2, 1–18. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Patel, B.; Huang, Z.F.; Yeh, C.-H.; Shih, Y.-R.; Lin, P.T. K-mer Frequency Encoding Model for Cable Defect Identification: A Combination of Non-Destructive Testing Approach with Artificial Intelligence. Inventions 2023, 8, 132. https://doi.org/10.3390/inventions8060132

Patel B, Huang ZF, Yeh C-H, Shih Y-R, Lin PT. K-mer Frequency Encoding Model for Cable Defect Identification: A Combination of Non-Destructive Testing Approach with Artificial Intelligence. Inventions. 2023; 8(6):132. https://doi.org/10.3390/inventions8060132

Chicago/Turabian StylePatel, Brijesh, Zih Fong Huang, Chih-Ho Yeh, Yen-Ru Shih, and Po Ting Lin. 2023. "K-mer Frequency Encoding Model for Cable Defect Identification: A Combination of Non-Destructive Testing Approach with Artificial Intelligence" Inventions 8, no. 6: 132. https://doi.org/10.3390/inventions8060132

APA StylePatel, B., Huang, Z. F., Yeh, C. -H., Shih, Y. -R., & Lin, P. T. (2023). K-mer Frequency Encoding Model for Cable Defect Identification: A Combination of Non-Destructive Testing Approach with Artificial Intelligence. Inventions, 8(6), 132. https://doi.org/10.3390/inventions8060132