Electric Bike Product Conception and Styling According to Design Trends

Abstract

:1. Introduction

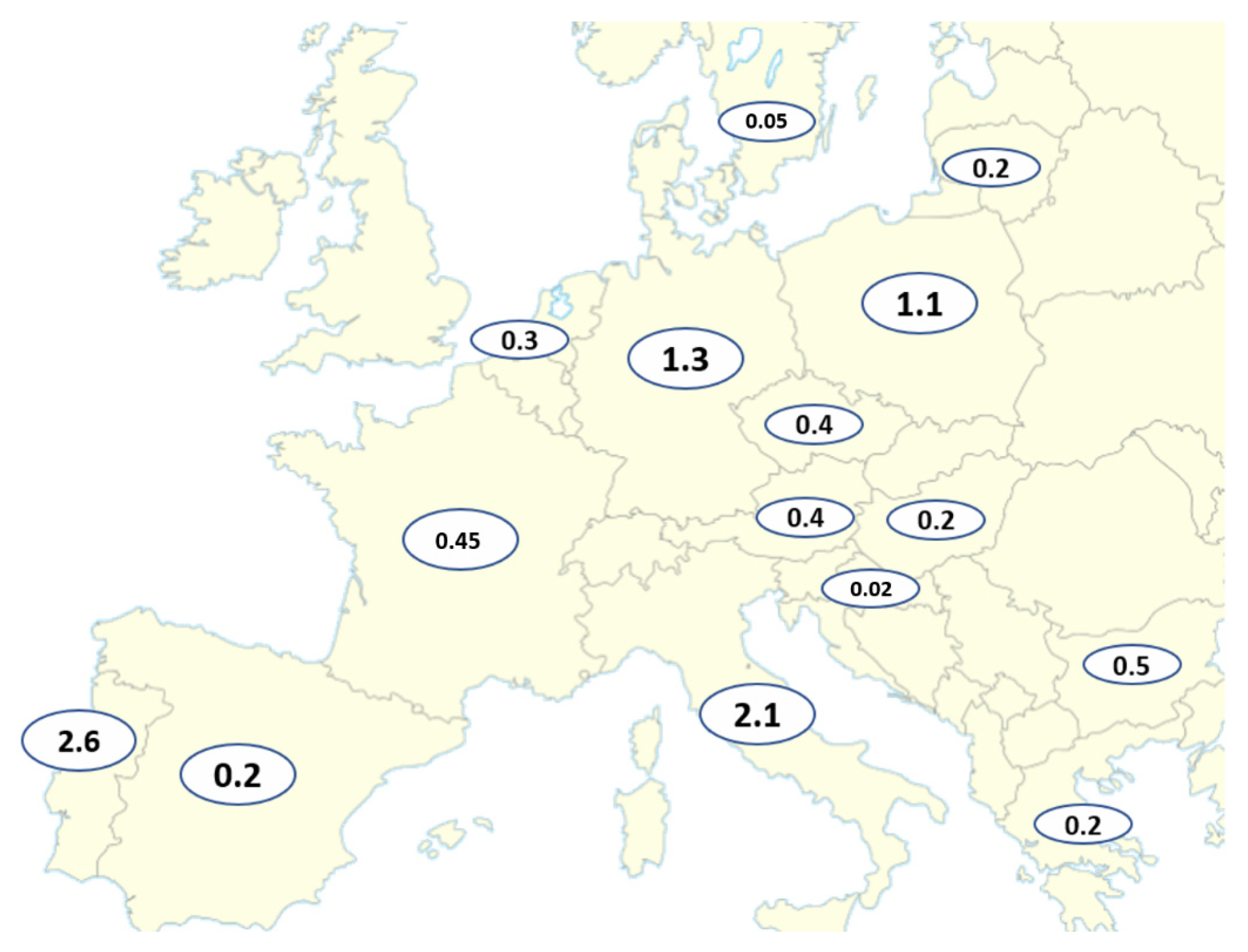

1.1. Environment Analysis

1.2. Analysis of the E-Bike Market

2. Materials and Methods

2.1. Market Feasibility Assessment

2.1.1. Tool: Quality Function Deployment (QFD)

2.1.2. Requirements Obtained

2.1.3. Independence Matrix

2.1.4. Importance Matrix

2.1.5. What-How Matrix

2.2. Benchmarking Analysis

3. Description of the Case Study

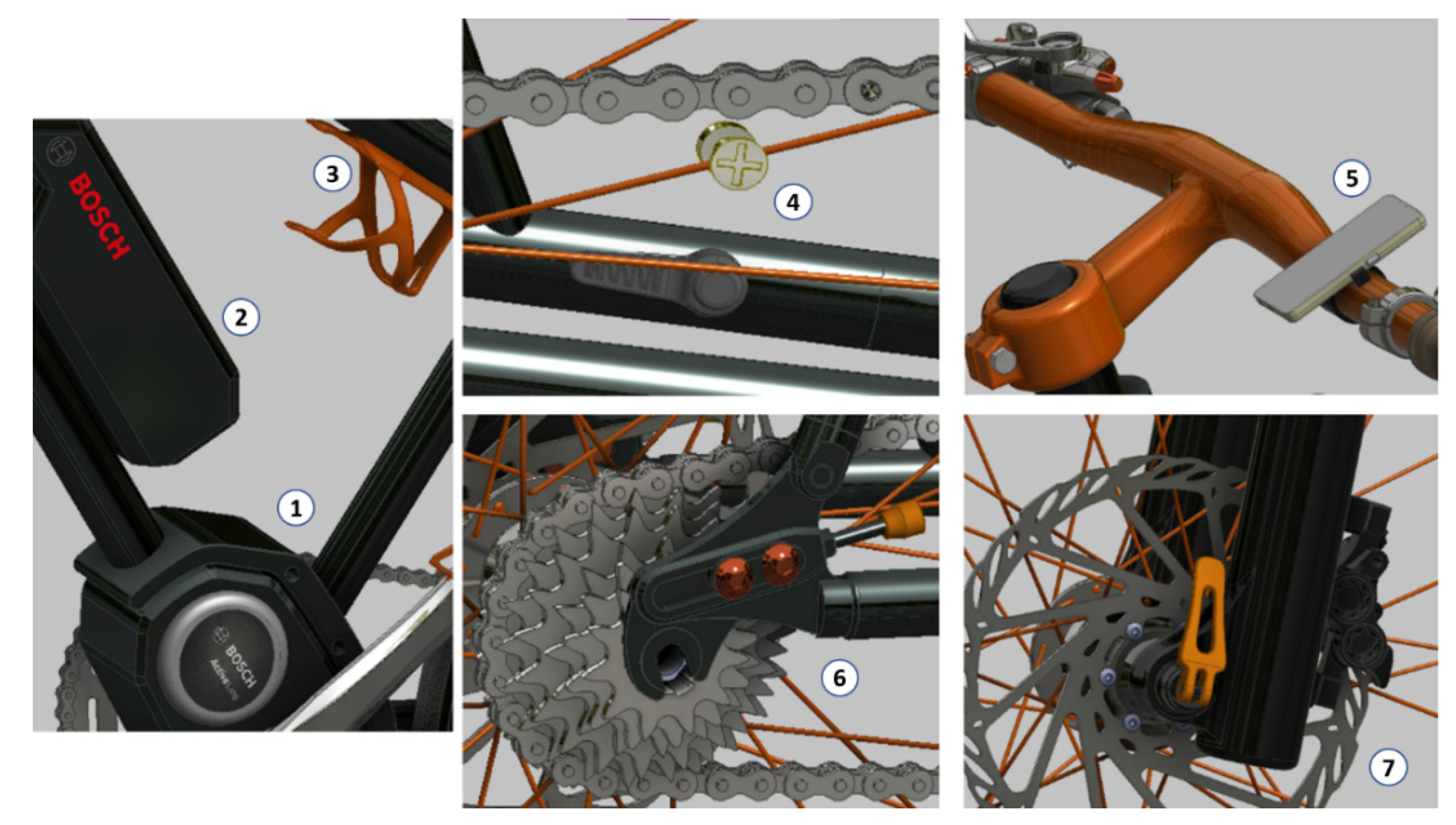

3.1. Product Architecture

3.2. Innovation

3.3. Sketching

4. Results

5. Future Developments

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Dou, J.; Han, X. How does the industry mobility affect pollution industry transfer in China: Empirical test on Pollution Haven Hypothesis and Porter Hypothesis. J. Clean. Prod. 2019, 217, 105–115. [Google Scholar] [CrossRef]

- Schmitz, K.; Hoppe, W.-D. The Future of Automotive Mobility. Available online: https://www.adlittle.ch/sites/default/files/viewpoints/adl_future_of_automotive_mobility_short.pdf (accessed on 21 January 2020).

- Trombin, M.; Pinna, R.; Musso, M.; Magnaghi, E.; Marco, M. De Mobility management: From traditional to people-centric approach in the smart city. In Emerging Technologies for Connected Internet of Vehicles and Intelligent Transportation System Networks; Springer: Cham, Germany, 2020; pp. 165–182. [Google Scholar]

- Rich, J.; Jensen, A.F.; Pilegaard, N.; Hallberg, M. Cost-benefit of bicycle infrastructure with e-bikes and cycle superhighways. Case Stud. Transp. Policy 2021, 9, 608–615. [Google Scholar] [CrossRef]

- Giménez-Nadal, J.I.; Molina, J.A.; Velilla, J. Trends in commuting time of European workers: A cross-country analysis. Transp. Policy 2022, 116, 327–342. [Google Scholar] [CrossRef]

- Breed, A.K.; Speth, D.; Plötz, P. CO2 fleet regulation and the future market diffusion of zero-emission trucks in Europe. Energy Policy 2021, 159, 112640. [Google Scholar] [CrossRef]

- McQueen, M.; MacArthur, J.; Cherry, C. The E-Bike Potential: Estimating regional e-bike impacts on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2020, 87, 102482. [Google Scholar] [CrossRef]

- Hoj, T.H.; Bramwell, J.J.; Lister, C.; Grant, E.; Crookston, B.T.; Hall, C.; West, J.H. Increasing active transportation through e-bike use: Pilot study comparing the health benefits, attitudes, and beliefs surrounding e-bikes and conventional bikes. JMIR Public Health Surveill. 2018, 4, e10461. [Google Scholar] [CrossRef] [PubMed]

- Rérat, P. The rise of the e-bike: Towards an extension of the practice of cycling? Mobilities 2021, 16, 423–439. [Google Scholar] [CrossRef]

- Trichinopoly Krishna, S.; Roberts, S.; Dardis, R. Electrically assisted pedal cycles: Is new legislation required to mitigate increased head injury risk? Br. J. Neurosurg. 2021, 35, 629–632. [Google Scholar] [CrossRef] [PubMed]

- Galatoulas, N.-F.; Genikomsakis, K.N.; Ioakimidis, C.S. Spatio-temporal trends of e-bike sharing system deployment: A review in Europe, North America and Asia. Sustainability 2020, 12, 4611. [Google Scholar] [CrossRef]

- Gu, T.; Kim, I.; Currie, G. The two-wheeled renaissance in China—An empirical review of bicycle, E-bike, and motorbike development. Int. J. Sustain. Transp. 2021, 15, 239–258. [Google Scholar] [CrossRef]

- Cherry, C.R.; Fishman, E. E-bikes in Europe and North America. In Cycling for Sustainable Cities; MIT Press: Cambridge, MA, USA, 2021. [Google Scholar]

- Newson, C.; Sloman, L. The Case for a UK Incentive for E-Bikes; Bicycle Association: London, UK, 2019. [Google Scholar]

- Sundfør, H.B.; Fyhri, A.; Bjørnarå, H.B. E-bikes—Good for public health? In Advances in Transportation and Health; Elsevier: Amsterdam, The Netherlands, 2020; pp. 251–266. [Google Scholar]

- Sun, Q.; Feng, T.; Kemperman, A.; Spahn, A. Modal shift implications of e-bike use in the Netherlands: Moving towards sustainability? Transp. Res. Part D Transp. Environ. 2020, 78, 102202. [Google Scholar] [CrossRef]

- Shital, M.; Anjali, G.; Suraj, D.; Pankaj, W. A Review: Design, Analysis & Optimization of E-Bike. Int. Res. J. Eng. Technol. 2019, 6, 1597–1599. [Google Scholar]

- Wulandari, I.P.; Pan, M.-C. Internal Resistance Based Assessment Model for the Degradation of Li-Ion Battery Pack. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, American Society of Mechanical Engineers, Online, 16–19 November 2020; Volume 84560, p. 008. [Google Scholar]

- Erdil, N.O.; Arani, O.M. Quality function deployment: More than a design tool. Int. J. Qual. Serv. Sci. 2019, 11, 142–166. [Google Scholar] [CrossRef]

- Giacobone, G.A.; Mincolelli, G. Human-Centered Design for Automotive Styling Design: Conceptualizing a Car from QFD to ViP. In International Conference on Intelligent Human Systems Integration; Springer: Cham, Germany, 2020; pp. 59–65. [Google Scholar]

- Gandara, G.S.; Muri, R.; Purba, H.H. Increase service selling of formaldehyde products by implementing Quality Function Deployment (QFD). J. Appl. Res. Ind. Eng. 2019, 6, 219–231. [Google Scholar]

- Vanany, I.; Maarif, G.A.; Soon, J.M. Application of multi-based quality function deployment (QFD) model to improve halal meat industry. J. Islam. Mark. 2018, 10, 97–124. [Google Scholar] [CrossRef]

- Ping, Y.-J.; Liu, R.; Lin, W.; Liu, H.-C. A new integrated approach for engineering characteristic prioritization in quality function deployment. Adv. Eng. Inform. 2020, 45, 101099. [Google Scholar] [CrossRef]

- Pandey, M.M. Evaluating the strategic design parameters of airports in Thailand to meet service expectations of Low-Cost Airlines using the Fuzzy-based QFD method. J. Air Transp. Manag. 2020, 82, 101738. [Google Scholar] [CrossRef]

- Adiandari, A.M.; Winata, H.; Fitriandari, M.; Hariguna, T. Improving the quality of Internet banking services: An implementation of the quality function deployment (QFD) concept. Manag. Sci. Lett. 2020, 10, 1121–1128. [Google Scholar] [CrossRef]

- Hasibuan, A.; Parinduri, L.; Sulaiman, O.K.; Suleman, A.R.; Harahap, A.K.Z.; Hasibuan, M.; Rupilele, F.G.J.; Simarmata, J.; Kurniasih, N.; Daengs, G.S.A. Service quality improvement by using the quality function deployment (QFD) method at the government general hospital. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; Volume 1363, p. 012095. [Google Scholar]

- Frizziero, L.; Santi, G.M.; Donnici, G.; Leon-Cardenas, C.; Ferretti, P.; Liverani, A.; Neri, M. An Innovative Ford Sedan with Enhanced Stylistic Design Engineering (SDE) via Augmented Reality and Additive Manufacturing. Designs 2021, 5, 46. [Google Scholar] [CrossRef]

- Dabir, A.; Solkar, R.; Kumbhar, M.; Narayanan, G. GPS and IOT equipped smart walking stick. In Proceedings of the 2018 International Conference on Communication and Signal Processing (ICCSP), Chennai, India, 3–5 April 2018; pp. 0322–0326. [Google Scholar]

- Lin, C.-C.; Lai, Y.-C.; Wang, C.-C.; Tsai, L.; Wang, J.-W. Development and Implementation of Solar-Assisted Electric Bicycle with GPS Tracking Service over Cloud. In Proceedings of the 2019 IEEE International Conference on Consumer Electronics-Taiwan (ICCE-TW), Yilan, Taiwan, 20–22 May 2019; pp. 1–2. [Google Scholar]

- Robert Bosch GmbH Batteria Bosch Power Pack 300 Wh|Mobilita Elettrica. Available online: https://www.bosch-ebike.com/en/products/batteries (accessed on 25 February 2022).

- Fortes, I.; Pinto, D.; Vieira, J.; Pessoa, R.; José, R. The perspective of cyclists on current practices with digital tools and envisioned services for urban cycling. In World Conference on Information Systems and Technologies; Springer: Cham, Germany, 2021; pp. 313–322. [Google Scholar]

| Power/Speed | Weight | Safety | Appealing Design | Comfort | Ergonomics | Price | Custom | Smart | Recharge | Space-Saving | Easy to Use | Total | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power/Speed | 9 | 9 | 3 | 9 | 9 | 39 | |||||||

| Weight | 9 | 3 | 3 | 9 | 3 | 9 | 9 | 3 | 48 | ||||

| Safety | 9 | 3 | 9 | 9 | 9 | 39 | |||||||

| Appealing Design | 9 | 3 | 3 | 3 | 3 | 9 | 3 | 3 | 36 | ||||

| Comfort | 3 | 3 | 9 | 9 | 9 | 3 | 9 | 9 | 9 | 63 | |||

| Ergonomics | 9 | 9 | 9 | 3 | 3 | 33 | |||||||

| Price | 9 | 9 | 1 | 3 | 3 | 3 | 1 | 1 | 9 | 39 | |||

| Custom | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 33 | |

| Smart | 1 | 9 | 3 | 3 | 3 | 1 | 3 | 23 | |||||

| Recharge | 9 | 9 | 3 | 21 | |||||||||

| Space-Saving | 3 | 9 | 9 | 9 | 1 | 3 | 9 | 43 | |||||

| Easy to Use | 9 | 9 | 9 | 3 | 9 | 39 | |||||||

| Total | 36 | 61 | 37 | 24 | 48 | 39 | 35 | 46 | 22 | 39 | 42 | 27 |

| Requirements | Power/Speed | Weight | Safety | Appealing Design | Comfort | Ergonomics | Price | Custom | Smart | Recharge | Space-Saving | Easy to Use | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power/Speed | 1 | 1 | 0 | 2 | 0 | 0 | 1 | 1 | 2 | 1 | 1 | 1 | 11 |

| Weight | 1 | 1 | 0 | 2 | 1 | 0 | 0 | 1 | 2 | 1 | 1 | 1 | 11 |

| Safety | 2 | 2 | 1 | 2 | 1 | 1 | 0 | 2 | 2 | 1 | 1 | 1 | 16 |

| Appealing Design | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 4 |

| Comfort | 2 | 1 | 1 | 2 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 17 |

| Ergonomics | 2 | 2 | 1 | 2 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 18 |

| Price | 1 | 2 | 2 | 2 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 18 |

| Custom | 1 | 1 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 7 |

| Smart | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 0 | 4 |

| Recharge | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 2 | 2 | 1 | 2 | 1 | 16 |

| Space-Saving | 1 | 1 | 1 | 1 | 0 | 0 | 0 | 1 | 1 | 0 | 1 | 1 | 8 |

| Easy to Use | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 1 | 2 | 1 | 1 | 1 | 14 |

| Price | Motor Torque | Wattage | Watt Hours | Charge Time | Distance Eco Mode | Distance Sport Mode | Frame | Suspension | Brakes Type | Weight | Maximum Speed | TOTAL | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Appealing design | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 9 | 3 | 3 | 0 | 0 | 18 |

| Comfort | 3 | 0 | 0 | 0 | 3 | 0 | 0 | 9 | 9 | 3 | 9 | 0 | 27 |

| Ergonomics | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 9 | 3 | 3 | 9 | 0 | 27 |

| Price | 9 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 42 |

| Custom | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 1 | 1 | 1 | 0 | 9 |

| Smart | 9 | 0 | 0 | 0 | 3 | 3 | 3 | 3 | 0 | 0 | 0 | 3 | 24 |

| Recharge | 3 | 0 | 3 | 9 | 9 | 3 | 3 | 0 | 0 | 0 | 3 | 0 | 33 |

| Space-saving | 3 | 0 | 0 | 0 | 0 | 0 | 0 | 9 | 3 | 1 | 3 | 0 | 19 |

| Total | 46 | 13 | 16 | 24 | 27 | 24 | 24 | 66 | 37 | 29 | 52 | 24 |

| Brand | CUBE | CUBE | iGO Electric | Orbea | Rad Power Bikes | Ride1Up | Riese & Müller | Stromer | Super73 | Yamaha | Innovation Column |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | Kathmandu Hybrid Pro 625 Unisex | Town Hybrid One 400 | Core Extreme 3.0 | GAIN D50 | RadRover Step-Thru 1 | Core-5 | Delite GT Touring | ST1 X | Z1 | Cross Core | |

| Price ($) | 3999 | 2599 | 1899 | 2999 | 1699 | 1195 | 7479 | 4199 | 1395 | 2399 | 1195 |

| Torque (Nm) | 85 | 50 | 80 | 40 | 80 | 60 | 75 | 35 | 35 | 70 | 85 |

| Wattage (W) | 250 | 250 | 750 | 250 | 750 | 500 | 250 | 800 | 500 | 250 | 800 |

| Watt hours (Wh) | 625 | 400 | 624 | 250 | 672 | 624 | 500 | 618 | 556.8 | 500 | 672 |

| Charge time (h) | 11 | 4 | 5 | 3.5 | 6 | 4 | 4.5 | 4 | 4 | 4 | 3.5 |

| Distance in eco mode (Km) | 153 | 145 | 80 | 161 | 72 | 64 | 129 | 121 | 32 | 129 | 161 |

| Distance in sport mode (Km) | 48 | 64 | 48 | 42 | 40 | 32 | 56 | 64 | 24 | 48 | 64 |

| Frame | Unisex | Unisex | Crossbar | Crossbar | Unisex | Crossbar | Crossbar | Crossbar | Crossbar | Crossbar | / |

| Suspension | Front | Front | Front | Carbon fiber | Front | None | Full | None | None | None | / |

| Brakes type | Hydr | Hydr | Mech | Mech | Mech | Mech | Hydr | Hydr | Mech | Mech | / |

| Weight (kg) | 26.4 | 24.7 | 33.5 | 11.3 | 32.4 | 22.2 | 28.5 | 26.7 | 31.7 | 19.7 | 11.3 |

| Maximum speed (kph) | 32 | 25 | 43 | 25 | 32 | 45 | 32 | 45 | 32 | 32 | 45 |

| Top | 1 | 1 | 0 | 3 | 1 | 1 | 0 | 3 | 0 | 0 | |

| Flop | 2 | 2 | 1 | 3 | 0 | 0 | 2 | 1 | 3 | 1 | |

| Delta | −1 | −1 | −1 | 0 | 1 | 1 | −2 | 2 | −3 | −1 |

| Model | Material | Distance Saddle-Handlebar | Wheel Diameter | Wheelbase | Max Rider Weight | Max Speed | Weight | Range per Charge |

|---|---|---|---|---|---|---|---|---|

| E-motion | Aluminum | 48 cm | 69 cm | 122 cm | 150 kg | 25 km/h | 13 kg | 40–100 km |

| Battery | Capacity | Charge Time | Motor | Power | RPM | Weight | Torque | Speed |

| Lithium-ion | 300 Wh | 2.5 h | Brushless | 500 W | 105 | 3.2 kg | 50 Nm | 25 km/h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frizziero, L.; Freddi, M.; Bucchi, G.; Coltelli, L.; Leon-Cardenas, C. Electric Bike Product Conception and Styling According to Design Trends. Designs 2022, 6, 42. https://doi.org/10.3390/designs6030042

Frizziero L, Freddi M, Bucchi G, Coltelli L, Leon-Cardenas C. Electric Bike Product Conception and Styling According to Design Trends. Designs. 2022; 6(3):42. https://doi.org/10.3390/designs6030042

Chicago/Turabian StyleFrizziero, Leonardo, Marco Freddi, Gabriele Bucchi, Lorenzo Coltelli, and Christian Leon-Cardenas. 2022. "Electric Bike Product Conception and Styling According to Design Trends" Designs 6, no. 3: 42. https://doi.org/10.3390/designs6030042

APA StyleFrizziero, L., Freddi, M., Bucchi, G., Coltelli, L., & Leon-Cardenas, C. (2022). Electric Bike Product Conception and Styling According to Design Trends. Designs, 6(3), 42. https://doi.org/10.3390/designs6030042