An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management

Abstract

:1. Introduction

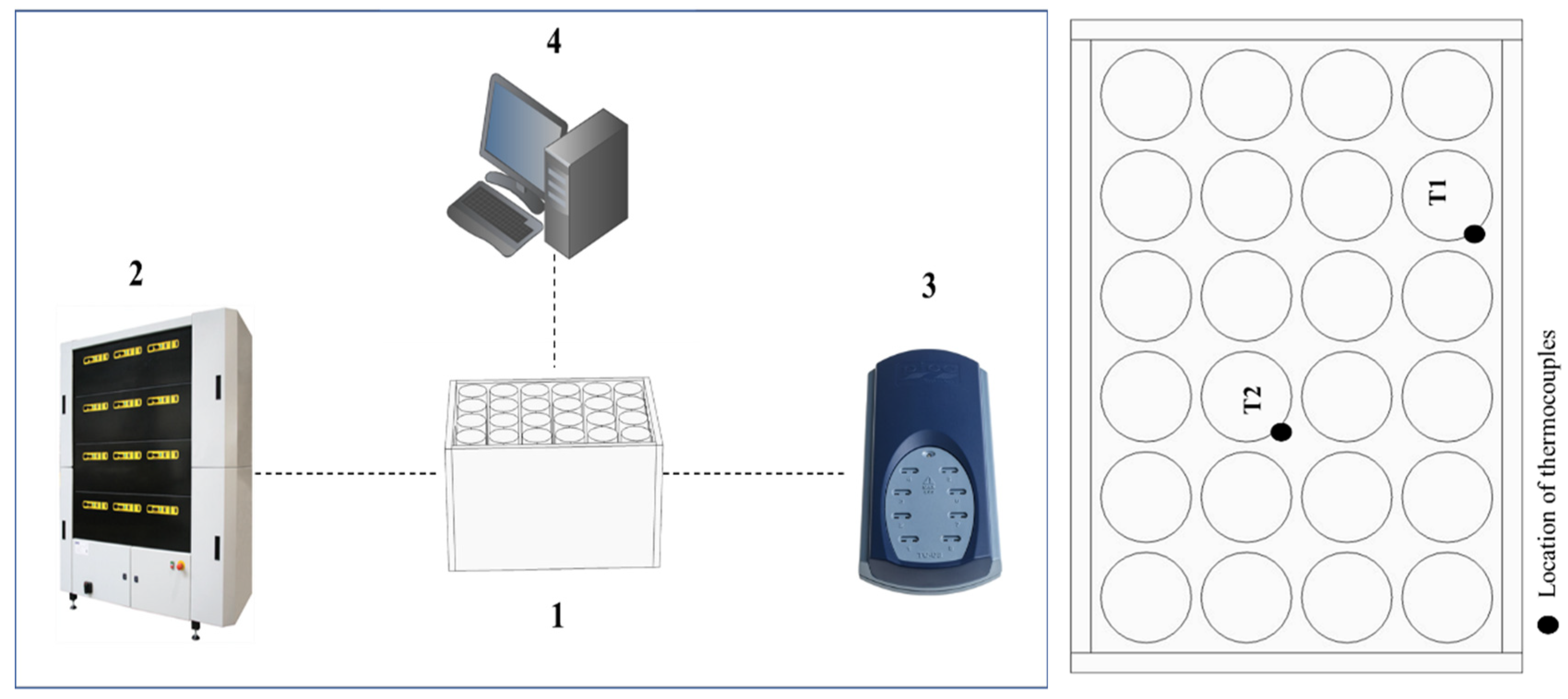

2. Experimental Test Setup

3. Experimental Results

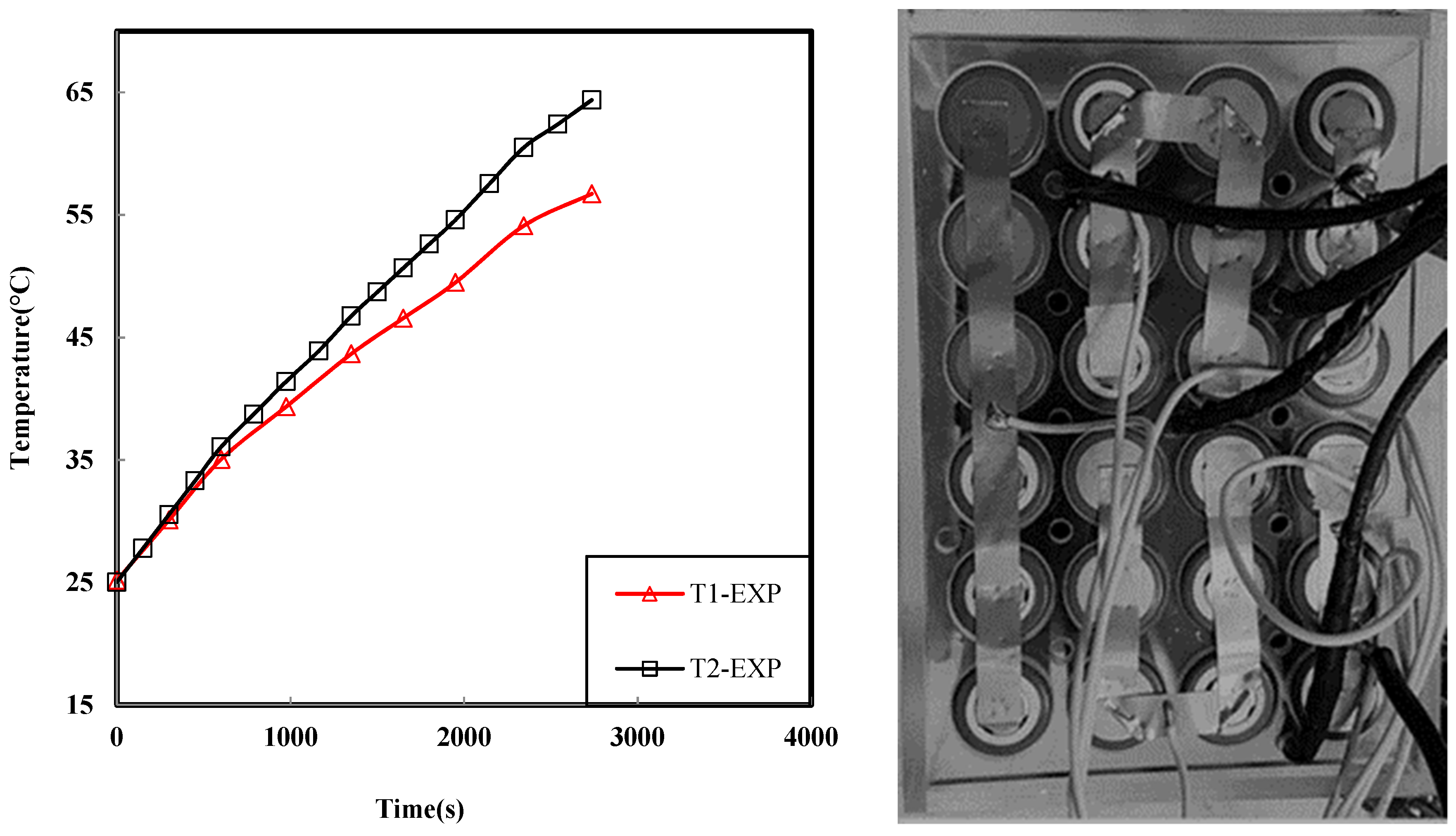

3.1. Reflection of the Natural Convection

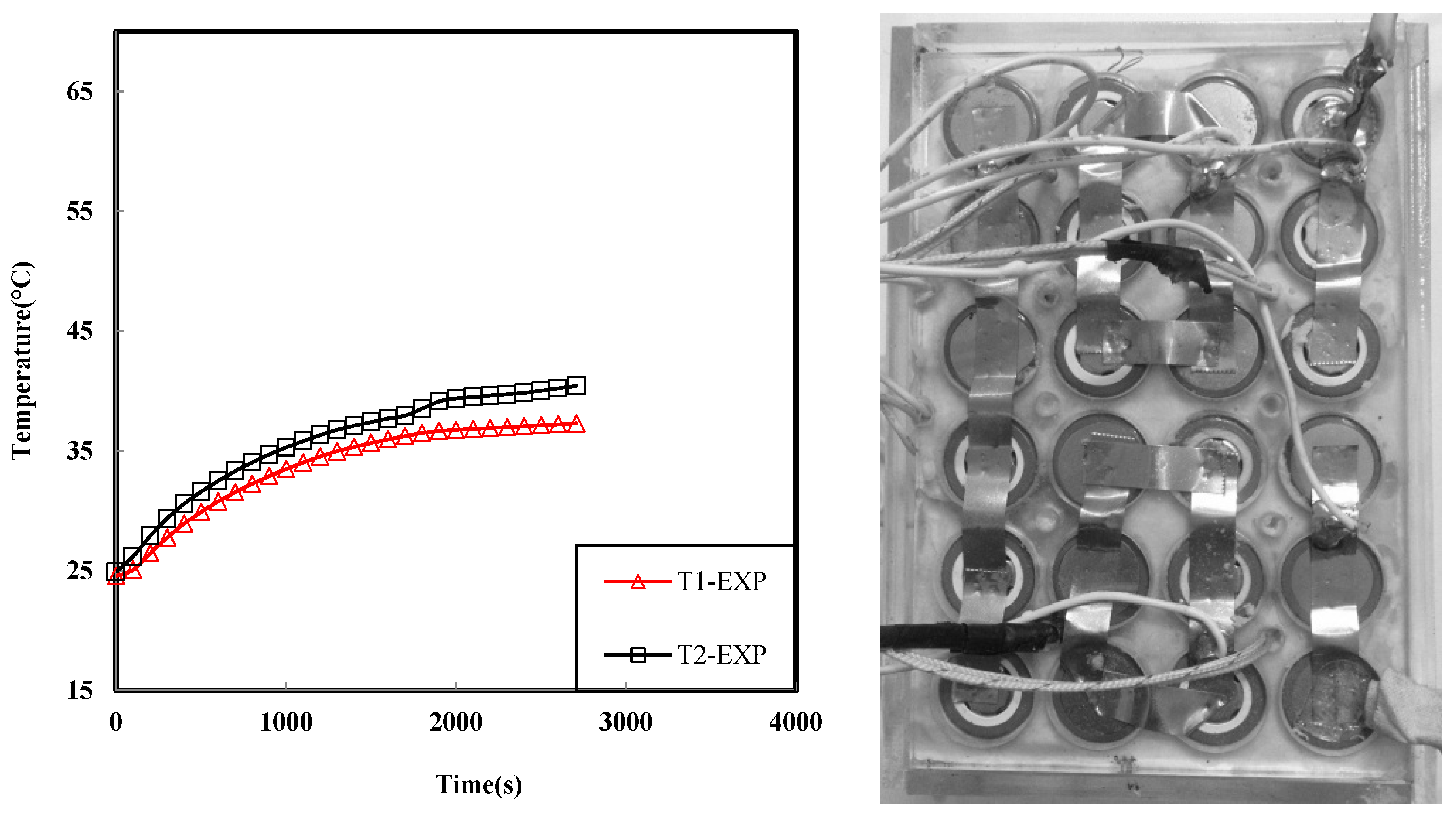

3.2. Reflection of the PCM

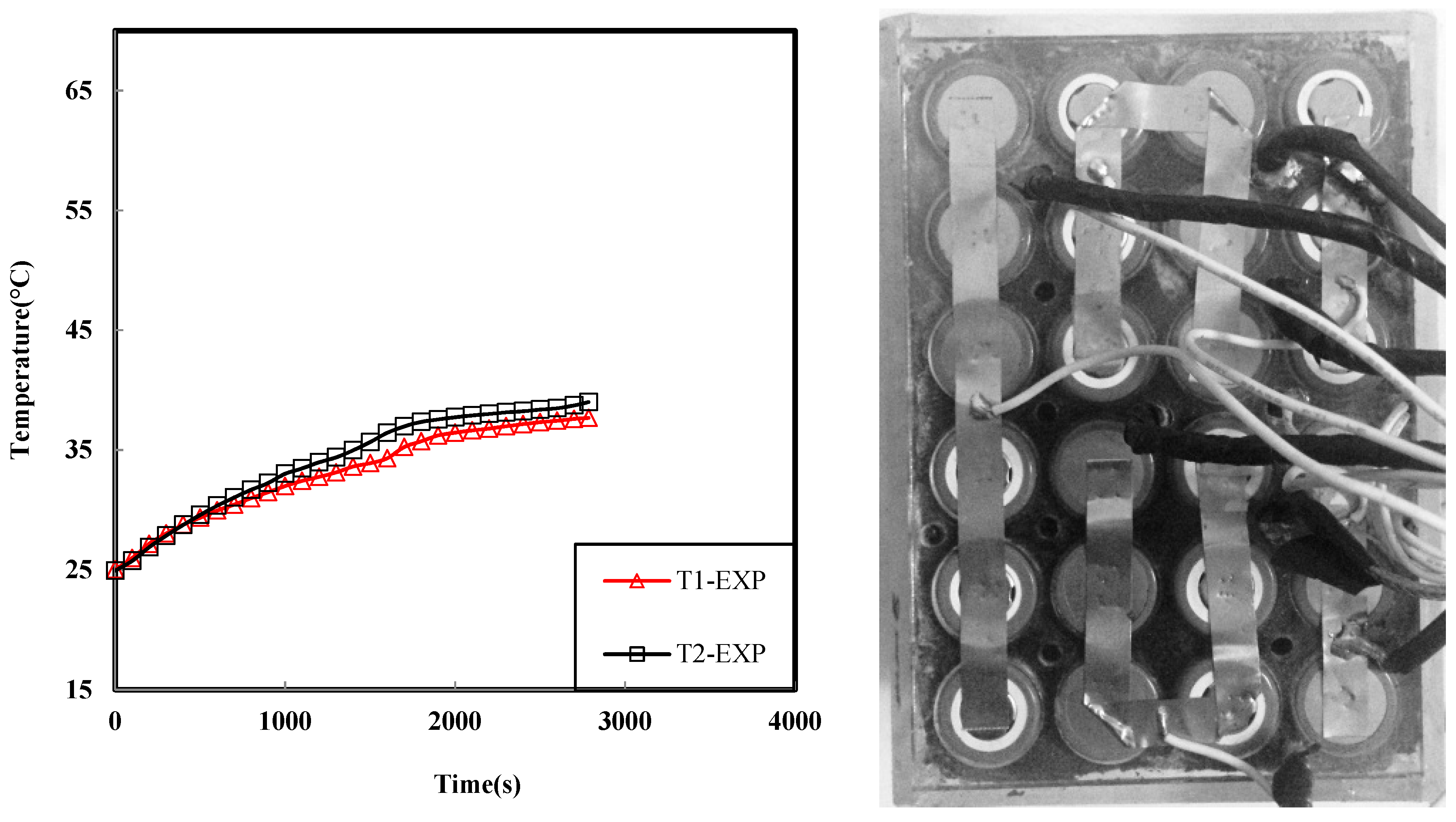

Reflection of the PCM Graphite

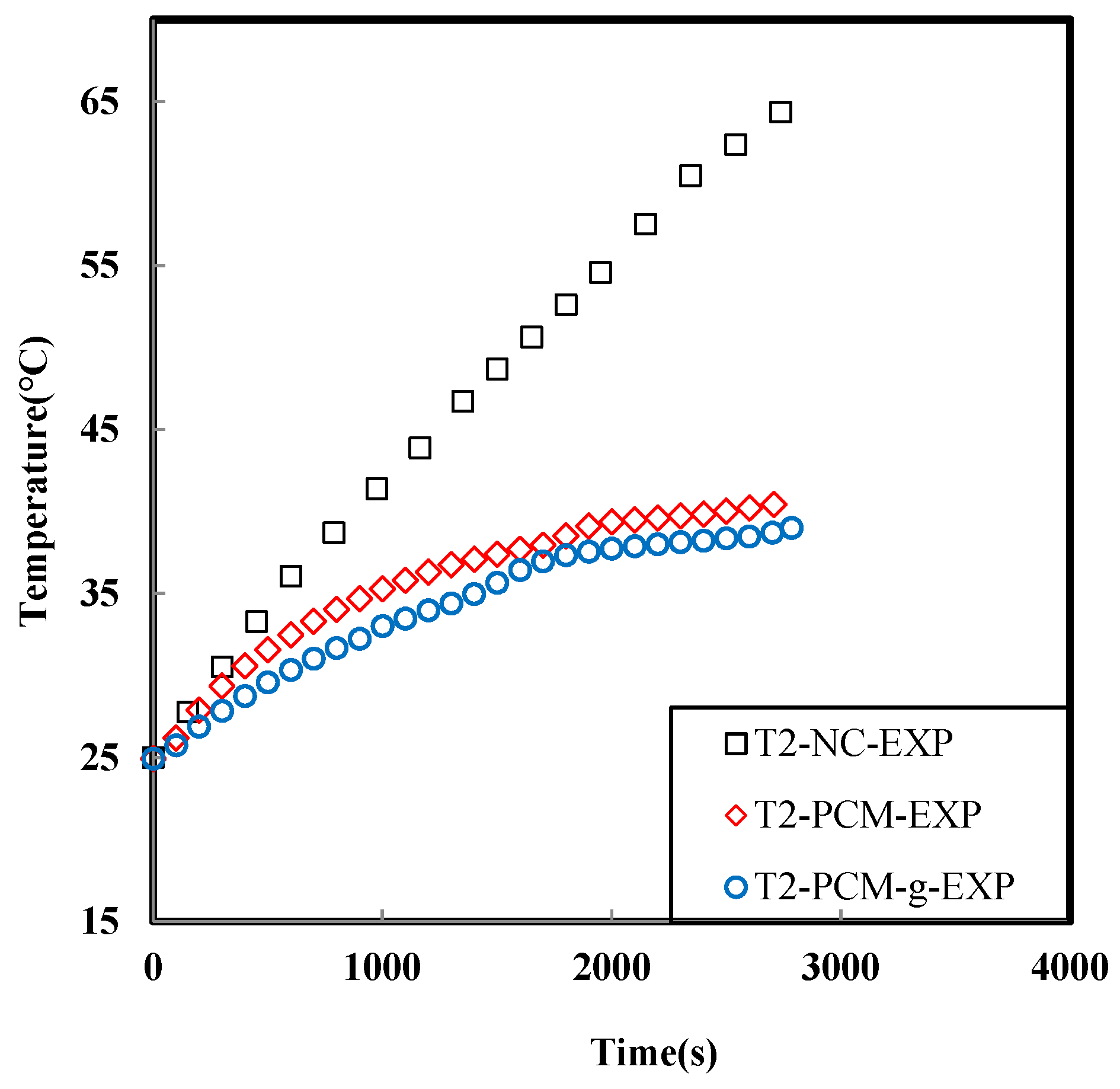

3.3. Comparison of Experimental Results

4. Simulation

4.1. Battery Thermal Model

4.2. Descriptive Equations for PCM

4.3. Validation of the Thermal Model for Natural Convection, PCM, and PCM-Graphite Cooling System

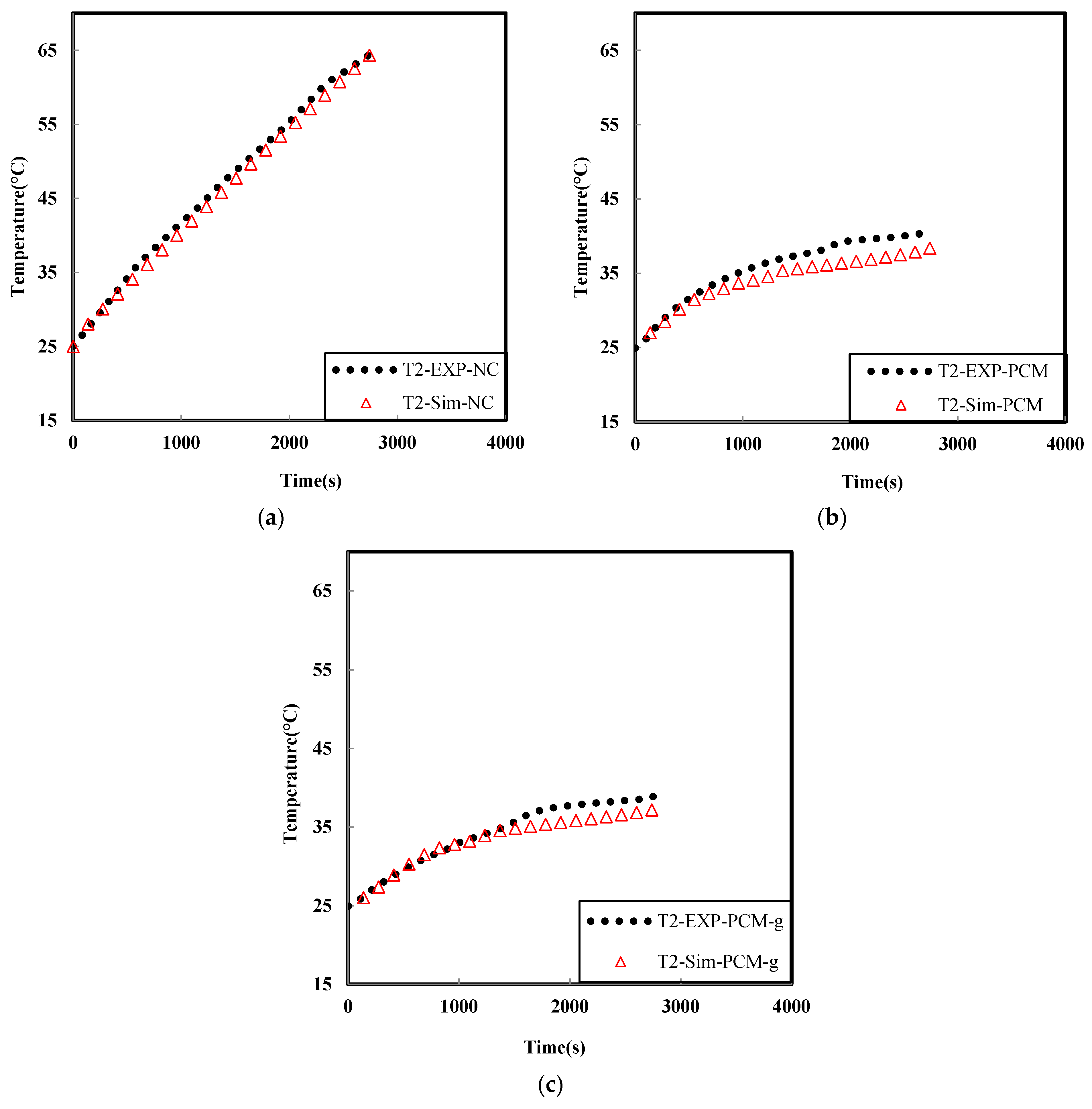

5. Simulation Results

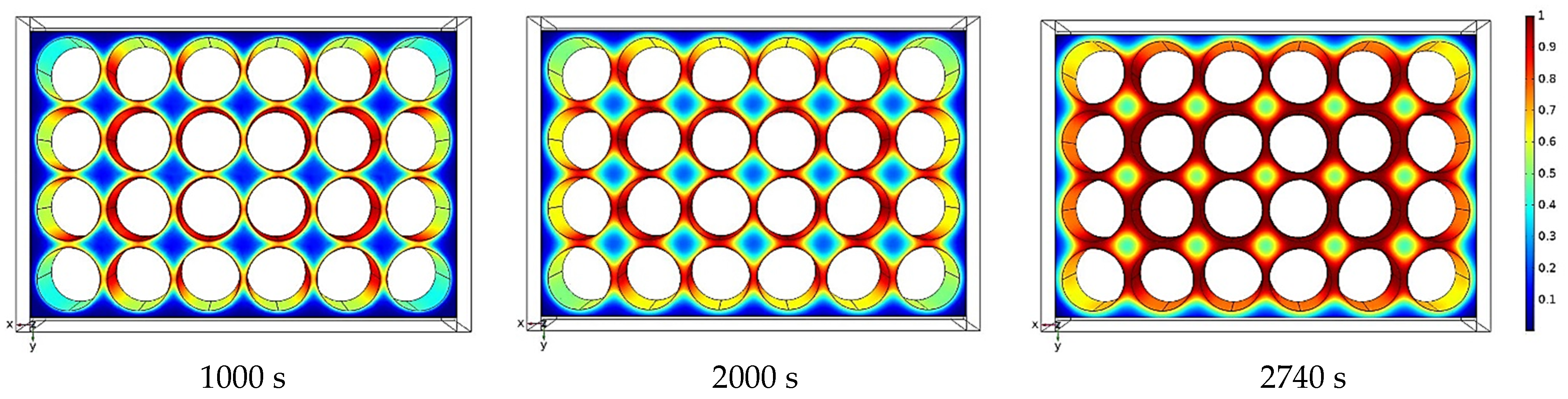

5.1. Thermal Behavior Contour of the Module in Different Cooling Methods

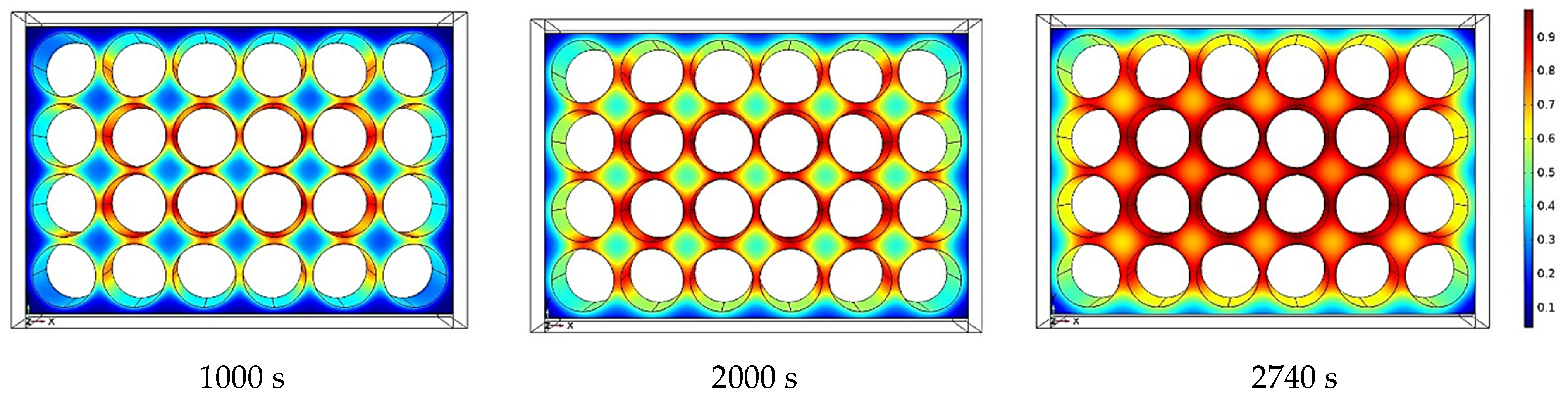

5.2. Liquid Fraction Contour of Module for PCM and PCM-Graphite Cooling Methods

6. Conclusions

- The maximum temperature of the module in the presence of natural convection for the initial temperature of 25 °C at a 1.5C discharging rate was measured. According to the measured results the maximum module temperature reached 64.38 °C, which is outside of the ideal Li-ion battery temperature;

- The PCM cooling system reduced the temperature of the module to 40.4 °C, which is a 38% reduction in the maximum module temperature. Moreover, the temperature uniformity of the module was increased by 60%;

- Using the PCM-graphite cooling system, the maximum module temperature reached 39 °C, which is a 40% reduction. Furthermore, the temperature uniformity of the module increased by 96%;

- The CFD model for different cooling strategies was validated against the experimental results and attained satisfactory agreement. The temperature contours and phase change process have been investigated at different times for PCM and PCM-graphite cooling systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Δt | Time Interval (t) |

| T | Battery Temperature (K) |

| I | Discharge Current (Ah) |

| 𝑈 | Operating Voltage (V) |

| m | Mass of the Cell (kg) |

| cp | Specific Heat Capacity (J/kg K) |

| Reversible Heat (W) | |

| Irreversible heat (W) | |

| Total Resistance of the Battery (K/W) | |

| k | Thermal Conductivity (W/m K) |

| p | Pressure (Pa) |

| S | Cross-section of the Tab and Cell (m2) |

| h | Heat Transfer Coefficient (W/m2 K) |

| Free Cooling Heat Transfer (W) | |

| QCell | Power Loss of Battery (W) |

| Density (kg/m3) | |

| Cell Heat Generation (W) | |

| Volume (m3) | |

| Height (m) | |

| Melting Temperature of the PCM (K) | |

| Velocity (m/s) | |

| Solid Phase of PCM | |

| Liquid Phase of PCM | |

| Acronyms | |

| Computational Fluid Dynamics | |

| Thermal Management System | |

| Electric Vehicle | |

| State of Charge | |

| Phase Change Material | |

| ESS | Energy storage system |

| Li-ion | Lithium-ion |

References

- Kalogiannis, T.; Akbarzadeh, M.; Hosen, S.; Behi, H.; De Sutter, L.; Jin, L.; Jaguemont, J.; Van Mierlo, J.; Berecibar, M. Effects analysis on energy density optimization and thermal efficiency enhancement of the air-cooled Li-ion battery modules. J. Energy Storage 2022, 48, 103847. [Google Scholar] [CrossRef]

- Hosen, S.; Kalogiannis, T.; Youssef, R.; Karimi, D.; Behi, H.; Jin, L.; Van Mierlo, J.; Berecibar, M. Twin-model framework development for a comprehensive battery lifetime prediction validated with a realistic driving profile. Energy Sci. Eng. 2021, 9, 2191–2201. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Akbarzadeh, M.; Khaleghi, S.; Van Mierlo, J.; Berecibar, M. Optimization of 1D/3D Electro-Thermal Model for Liquid-Cooled Lithium-Ion Capacitor Module in High Power Applications. Electricity 2021, 2, 503–523. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Akbarzadeh, M.; Van Mierlo, J.; Berecibar, M. Holistic 1D Electro-Thermal Model Coupled to 3D Thermal Model for Hybrid Passive Cooling System Analysis in Electric Vehicles. Energies 2021, 14, 5924. [Google Scholar] [CrossRef]

- Chen, F.; Huang, R.; Wang, C.; Yu, X.; Liu, H.; Wu, Q.; Qian, K.; Bhagat, R. Air and PCM cooling for battery thermal management considering battery cycle life. Appl. Therm. Eng. 2020, 173, 115154. [Google Scholar] [CrossRef]

- Hosen, S.; Karimi, D.; Kalogiannis, T.; Pirooz, A.; Jaguemont, J.; Berecibar, M.; Van Mierlo, J. Electro-aging model development of nickel-manganese-cobalt lithium-ion technology validated with light and heavy-duty real-life profiles. J. Energy Storage 2020, 28, 101265. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Van Mierlo, J.; Berecibar, M. An Experimental Study on Thermal Performance of Graphite-Based Phase-Change Materials for High-Power Batteries. Energies 2022, 15, 2515. [Google Scholar] [CrossRef]

- Khaleghi, S.; Hosen, S.; Karimi, D.; Behi, H.; Beheshti, S.H.; Van Mierlo, J.; Berecibar, M. Developing an online data-driven approach for prognostics and health management of lithium-ion batteries. Appl. Energy 2021, 308, 118348. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Akbarzadeh, M.; Van Mierlo, J.; Berecibar, M. A Novel Air-Cooled Thermal Management Approach towards High-Power Lithium-Ion Capacitor Module for Electric Vehicles. Energies 2021, 14, 7150. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Jaguemont, J.; Berecibar, M.; van Mierlo, J. A refrigerant-based thermal management system for a fast charging process for lithium-ion batteries. In Proceedings of the International Conference on Renewable Energy Systems and Environmental Engineering (IRESE2020), Brussels, Belgium, 17–18 October 2020; Global Publisher: Brussels, Belgium, 2020; pp. 1–6. [Google Scholar]

- Behi, H.; Karimi, D.; Kalogiannis, T.; He, J.; Patil, M.S.; Muller, J.-D.; Haider, A.; Van Mierlo, J.; Berecibar, M. Advanced hybrid thermal management system for LTO battery module under fast charging. Case Stud. Therm. Eng. 2022, 33, 101938. [Google Scholar] [CrossRef]

- Möller, S.; Karimi, D.; Vanegas, O.; el Baghdadi, M.; Kospach, A.; Lis, A.; Hegazy, O.; Abart, C.; Offenbach, Â.B.Â. Application considerations for Double Sided Cooled Modules in Automotive Environment. In Proceedings of the 11th International Conference on Integrated Power Electronics Systems, Berlin, Germany, 24–26 March 2020. [Google Scholar]

- Karimi, D.; Behi, H.; Van Mierlo, J.; Berecibar, M. A Comprehensive Review of Lithium-Ion Capacitor Technology: Theory, Development, Modeling, Thermal Management Systems, and Applications. Molecules 2022, 27, 3119. [Google Scholar] [CrossRef] [PubMed]

- Karimi, D.; Hosen, S.; Behi, H.; Khaleghi, S.; Akbarzadeh, M.; Van Mierlo, J.; Berecibar, M. A hybrid thermal management system for high power lithium-ion capacitors combining heat pipe with phase change materials. Heliyon 2021, 7, e07773. [Google Scholar] [CrossRef] [PubMed]

- Jaguemont, J.; Karimi, D.; Van Mierlo, J. Investigation of a Passive Thermal Management System for Lithium-Ion Capacitors. IEEE Trans. Veh. Technol. 2019, 68, 10518–10524. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Jaguemont, J.; Berecibar, M.; van Mierlo, J. Investigation of extruded heat sink assisted air cooling system for lithium-ion capacitor batteries. In Proceedings of the International Conference on Renewable Energy Systems and Environmental Engineering, Brussels, Belgium, 17–18 October 2020; Global Publisher: Brussels, Belgium, 2020; pp. 1–6. [Google Scholar]

- Behi, H.; Karimi, D.; Youssef, R.; Patil, M.S.; Van Mierlo, J.; Berecibar, M. Comprehensive Passive Thermal Management Systems for Electric Vehicles. Energies 2021, 14, 3881. [Google Scholar] [CrossRef]

- Behi, H.; Kalogiannis, T.; Patil, M.S.; Van Mierlo, J.; Berecibar, M. A New Concept of Air Cooling and Heat Pipe for Electric Vehicles in Fast Discharging. Energies 2021, 14, 6477. [Google Scholar] [CrossRef]

- Karimi, D.; Behi, H.; Jaguemont, J.; Berecibar, M.; van Mierlo, J. Optimized air-cooling thermal management system for high power lithium-ion capacitors. In Proceedings of the International Conference on Renewable Energy Systems and Environmental Engineering (IRESE2020), Brussels, Belgium, 17–18 October 2020; Volume 1. [Google Scholar]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A comparative study between air cooling and liquid cooling thermal management systems for a high-energy lithium-ion battery module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- Karimi, D.; Khaleghi, S.; Behi, H.; Beheshti, H.; Hosen, S.; Akbarzadeh, M.; Van Mierlo, J.; Berecibar, M. Lithium-Ion Capacitor Lifetime Extension through an Optimal Thermal Management System for Smart Grid Applications. Energies 2021, 14, 2907. [Google Scholar] [CrossRef]

- Gandoman, F.H.; Behi, H.; Berecibar, M.; Jaguemont, J.; Aleem, S.H.A.; Behi, M.; Van Mierlo, J. Chapter 16—Reliability evaluation of Li-ion batteries for electric vehicles applications from the thermal perspectives. In Uncertainties in Modern Power Systems; Zobaa, A.F., Abdel Aleem, S.H.E., Eds.; Academic Press: Cambridge, CA, USA, 2021; pp. 563–587. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Jaguemont, J.; Gandoman, F.H.; Khaleghi, S.; Van Mierlo, J.; Berecibar, M. Aluminum Heat Sink Assisted Air-Cooling Thermal Management System for High Current Applications in Electric Vehicles. In Proceedings of the 2020 AEIT International Conference of Electrical and Electronic Technologies for Automotive (AEIT AUTOMOTIVE), Turin, Italy, 18–20 November 2020. [Google Scholar]

- Behi, H.; Karimi, D.; Jaguemont, J.; Berecibar, M.; van Mierlo, J. Experimental study on cooling performance of flat heat pipe for lithium-ion battery at various inclination angels. Energy Perspect 2020, 1, 77–92. [Google Scholar]

- Behi, H.; Karimi, D.; Jaguemont, J.; Gandoman, F.H.; Kalogiannis, T.; Berecibar, M.; Van Mierlo, J. Novel thermal management methods to improve the performance of the Li-ion batteries in high discharge current applications. Energy 2021, 224, 120165. [Google Scholar] [CrossRef]

- Behi, H. Experimental and Numerical Study on Heat Pipe Assisted PCM Storage System. 2015. Available online: http://www.diva-portal.org/smash/get/diva2:850104/FULLTEXT01.pdf (accessed on 26 July 2022).

- Karimi, D.; Behi, H.; Van Mierlo, J.; Berecibar, M. Advanced Thermal Management Systems for High-Power Lithium-Ion Capacitors: A Comprehensive Review. Designs 2022, 6, 53. [Google Scholar] [CrossRef]

- Behi, H.; Ghanbarpour, M.; Behi, M. Investigation of PCM-assisted heat pipe for electronic cooling. Appl. Therm. Eng. 2017, 127, 1132–1142. [Google Scholar] [CrossRef]

- Behi, H.; Behi, M.; Ghanbarpour, A.; Karimi, D.; Azad, A.; Ghanbarpour, M.; Behnia, M. Enhancement of the Thermal Energy Storage Using Heat-Pipe-Assisted Phase Change Material. Energies 2021, 14, 6176. [Google Scholar] [CrossRef]

- Karimi, D.; Jaguemont, J.; Behi, H.; Berecibar, M.; van den Bossche, P.; van Mierlo, J. Passive cooling based battery thermal management using phase change materials for electric vehicles. In Proceedings of the EVS33—33nd Electric Vehicle Symposium, Portland, OR, USA, 14–17 June 2020; The Electric Drive Transportation Association (EDTA): Portland, OR, USA, 2020. [Google Scholar]

- Karimi, D.; Behi, H.; Jaguemont, J.; Sokkeh, M.A.; Kalogiannis, T.; Hosen, S.; Berecibar, M.; Van Mierlo, J. Thermal performance enhancement of phase change material using aluminum-mesh grid foil for lithium-capacitor modules. J. Energy Storage 2020, 30, 101508. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Gandoman, F.H.; Akbarzadeh, M.; Khaleghi, S.; Kalogiannis, T.; Hosen, S.; Jaguemont, J.; Van Mierlo, J.; Berecibar, M. PCM assisted heat pipe cooling system for the thermal management of an LTO cell for high-current profiles. Case Stud. Therm. Eng. 2021, 25, 100920. [Google Scholar] [CrossRef]

- Yazici, M.Y. The effect of a new design preheating unit integrated to graphite matrix composite with phase change battery thermal management in low-temperature environment: An experimental study. Therm. Sci. Eng. Prog. 2022, 29, 101244. [Google Scholar] [CrossRef]

- Siddique, A.R.M.; Mahmud, S.; Van Heyst, B. A comprehensive review on a passive (phase change materials) and an active (thermoelectric cooler) battery thermal management system and their limitations. J. Power Sources 2018, 401, 224–237. [Google Scholar] [CrossRef]

- Akula, R.; Balaji, C. Thermal management of 18650 Li-ion battery using novel fins–PCM–EG composite heat sinks. Appl. Energy 2022, 316, 119048. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Behi, M.; Ghanbarpour, M.; Jaguemont, J.; Sokkeh, M.A.; Gandoman, F.H.; Berecibar, M.; Van Mierlo, J. A new concept of thermal management system in Li-ion battery using air cooling and heat pipe for electric vehicles. Appl. Therm. Eng. 2020, 174, 115280. [Google Scholar] [CrossRef]

- Drake, S.; Wetz, D.; Ostanek, J.; Miller, S.; Heinzel, J.; Jain, A. Measurement of anisotropic thermophysical properties of cylindrical Li-ion cells. J. Power Sources 2014, 252, 298–304. [Google Scholar] [CrossRef]

- Saw, L.; Ye, Y.; Tay, A. Electrochemical–thermal analysis of 18650 Lithium Iron Phosphate cell. Energy Convers. Manag. 2013, 75, 162–174. [Google Scholar] [CrossRef]

- Spinner, N.S.; Hinnant, K.M.; Mazurick, R.; Brandon, A.; Rose-Pehrsson, S.L.; Tuttle, S.G. Novel 18650 lithium-ion battery surrogate cell design with anisotropic thermophysical properties for studying failure events. J. Power Sources 2016, 312, 1–11. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Yue, M.; Chen, J.; Zhu, H.; Deng, Y.; Zhu, Y.; Zhang, F.; Wen, M.; Zhang, B.; Kang, S. Effects of the different air cooling strategies on cooling performance of a lithium-ion battery module with baffle. Appl. Therm. Eng. 2018, 144, 231–241. [Google Scholar] [CrossRef]

- Karimi, D.; Berecibar, M.; van Mierlo, J. Modular Methodology for Developing Comprehensive Active and Passive Thermal Management Systems for Electric Vehicles. Ph.D. Thesis, Vrije Universiteit Brussel, Brussels, Belgium, 2022. [Google Scholar]

| Parameters | Value | Unit |

|---|---|---|

| Nominal capacity | 2.2 | A |

| Nominal voltage | 3.6 | V |

| Density | 2722 | Kg m−3 |

| Mass | 0.045 | kg |

| Specific heat capacity | 1200 | J kg−1 K−1 |

| Length | 65 | mm |

| Diameter | 18 | mm |

| Thermal conductivity | kr = 0.2, kz = 37.6 [37,38,39,40] | W m−1 K−1 |

| Parameters | Value | Unit |

|---|---|---|

| Melting domain | 35–42 | °C |

| Max operation temperature | 210 | °C |

| Thermal conductivity (Solid-Liquid) | 0.25–0.4 | W/m K |

| Heat storage capacity | 220 | kJ/kg |

| Density (Solid-Liquid) | 0.8–0.85 | Kg/Lit |

| Specific heat capacity | 2500 | J/kg K |

| Parameters | Value | Unit |

|---|---|---|

| Melting domain | 35–42 | °C |

| Max operation temperature | 210 | °C |

| Thermal conductivity (Solid-Liquid) | 0.5–1 | W/m K |

| Heat storage capacity | 210 | kJ/kg |

| Density (Solid-Liquid) | 0.8–0.85 | Kg/Lit |

| Specific heat capacity | 2500 | J/kg K |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Behi, H.; Karimi, D.; Behi, M.; Nargesi, N.; Aminian, M.; Ghanbarpour, A.; Mirmohseni, F.; Van Mierlo, J.; Berecibar, M. An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management. Designs 2022, 6, 70. https://doi.org/10.3390/designs6050070

Behi H, Karimi D, Behi M, Nargesi N, Aminian M, Ghanbarpour A, Mirmohseni F, Van Mierlo J, Berecibar M. An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management. Designs. 2022; 6(5):70. https://doi.org/10.3390/designs6050070

Chicago/Turabian StyleBehi, Hamidreza, Danial Karimi, Mohammadreza Behi, Niloufar Nargesi, Morteza Aminian, Ali Ghanbarpour, Farid Mirmohseni, Joeri Van Mierlo, and Maitane Berecibar. 2022. "An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management" Designs 6, no. 5: 70. https://doi.org/10.3390/designs6050070

APA StyleBehi, H., Karimi, D., Behi, M., Nargesi, N., Aminian, M., Ghanbarpour, A., Mirmohseni, F., Van Mierlo, J., & Berecibar, M. (2022). An Enhanced Phase Change Material Composite for Electrical Vehicle Thermal Management. Designs, 6(5), 70. https://doi.org/10.3390/designs6050070