Revolutionizing Biomass Processing: The Design and Functionality of an Innovative Extruder for Sugarcane Bagasse Milling Pretreatment

Abstract

:1. Introduction

2. Milling Pretreatment

2.1. Mechanism

- Cutting: Cutting involves the application of a force over a narrow area using a sharp cutting edge. This mechanism is used for fibrous and waxy substances and is carried out in cutter mills. For example, in pharmaceutical milling, cutting is employed to reduce the particle sizes of materials like fibrous and waxy substances using cutter mills.

- Compression: Compression occurs when the material is crushed between two surfaces by the application of pressure. This mechanism is suitable for soft materials and is carried out in roller mills. An example is the use of compression in roller mills to crush soft materials by applying pressure between two surfaces.

- Impact: Impact involves the contact of a material with a fast-moving part that imparts kinetic energy, causing internal stresses in the particle and breaking it. This mechanism is used for moderately hard and friable materials and is carried out in hammer mills and fluid energy mills. For instance, impact is utilized in hammer mills to break down materials through the forceful contact of hammers at high speeds.

- Attrition: Attrition occurs when the material is broken by rubbing it between two surfaces. This mechanism is suitable for brittle drugs and is carried out in fluid energy mills. An example is the use of attrition in fluid energy mills to break down brittle drugs by rubbing them between two surfaces.

- Shearing: Shearing involves the application of a force over a narrow area of material, resulting in shear forces that break the particles. This mechanism is used in cutting mills, where materials are cut by sharp blades. An example is the use of shearing in cutting mills to break down materials by applying shear forces over a narrow area.

2.2. Selection of Mill

2.3. Milling and Lignocellulosic Biomass

3. Screw Extruder for Milling

4. Sugarcane Bagasse

4.1. Chemical Composition

4.2. Physical Properties and Mechanical Properties

4.3. By-Products and Processes Favored by Milling

4.4. Colombian Sugarcane Bagasse Characterization

5. Design of Device and Design Details

5.1. Mathematical Model Applied

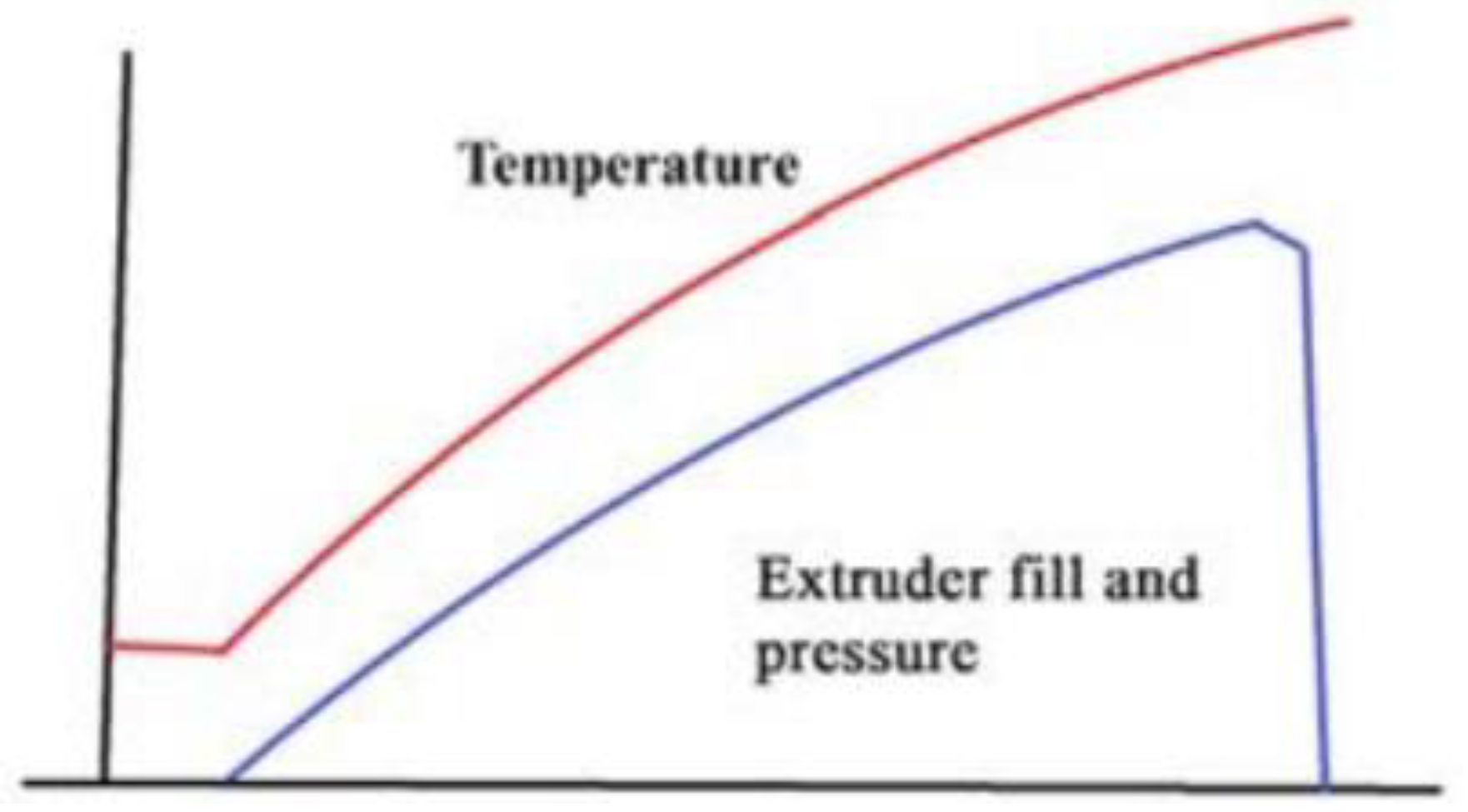

- Residence time: This illustrates the path of the biomass in the extrusion process. It is very important in the process since it defines the particle sizes obtained and the products of the thermal processes. Its magnitude corresponds to the relationship between the flow, drag, and pressure of the material and the equipment. As the screw speed increases, the residence time decreases. The average residence time value is calculated using the equation [73,74]

- Ms: material mass (kg);

- F: total feed rate (kg/min).

- Conveyance and restrictions: In this section, the screw is defined by the pitch, channel depth, number, and thickness of the helices. To establish the depth of the channel and the thickness of the propellers, it is necessary to determine the diameter of the screw and the distance of the shafts. With Equation (3), the screw pitch (SP) can be calculated, and with Equation (4), the channel width can be calculated [73,74].

- D: screw diameter;

- : flight helix angle;

- n: number of screw flights;

- e: screw flight thickness.

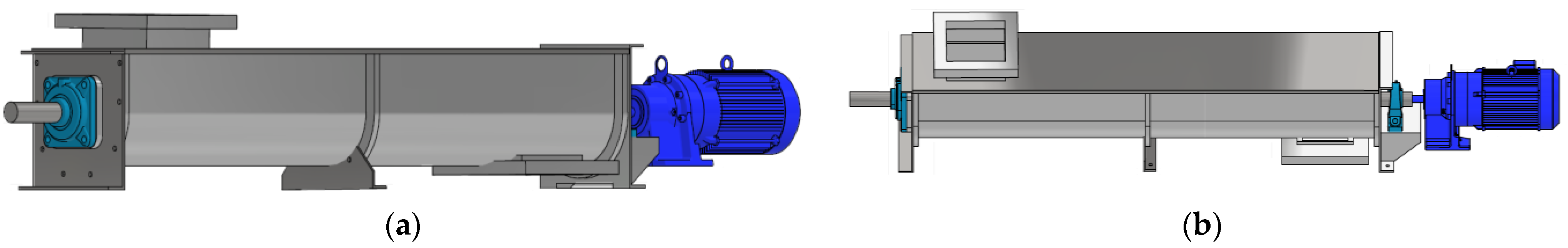

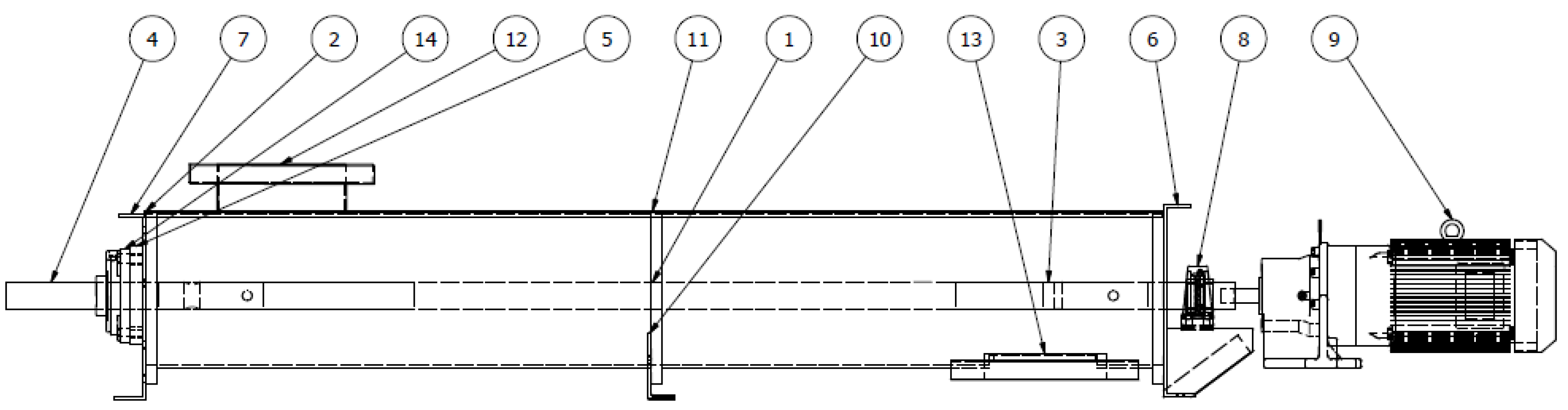

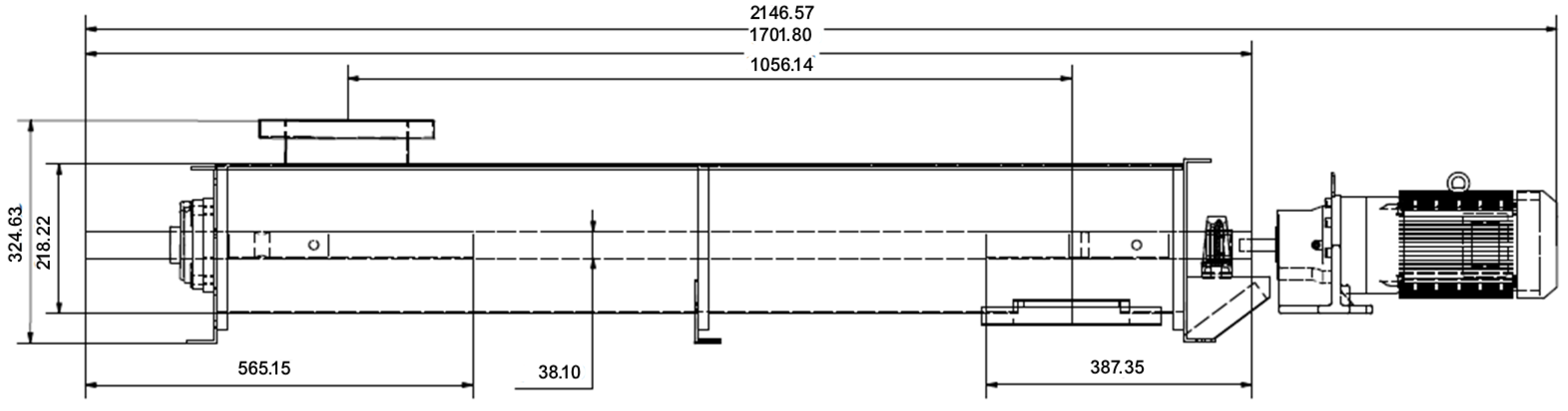

5.2. CAD Design Model

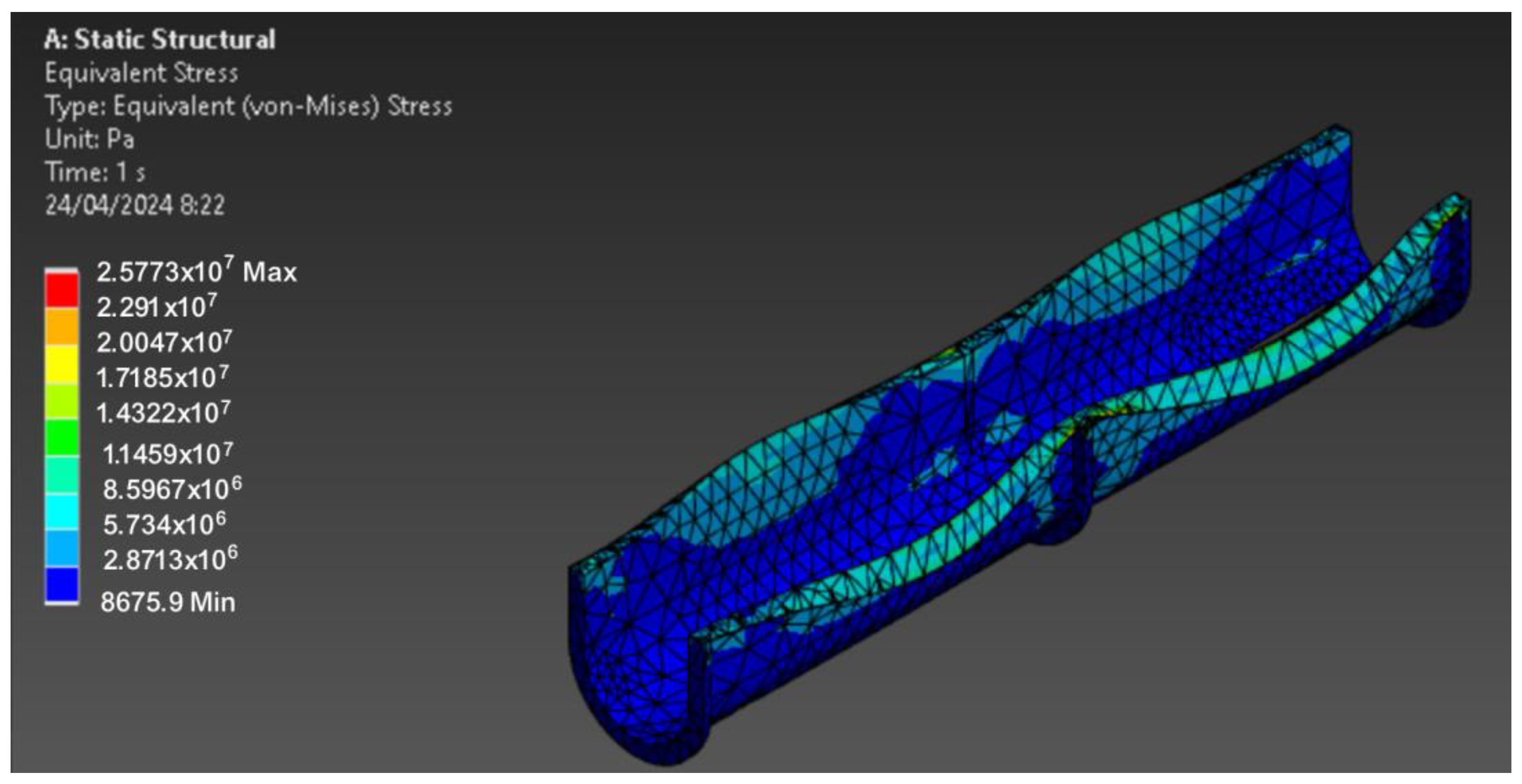

5.3. Finite Element Analysis

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0 A Global Snapshot of Solid Waste Management to 2050; World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Culaba, A.B.; Mayol, A.P.; Juan, J.L.G.S.; Vinoya, C.L.; Concepcion, R.S.; Bandala, A.A.; Vicerra, R.R.P.; Ubando, A.T.; Chen, W.-H.; Chang, J.-S. Smart sustainable biorefineries for lignocellulosic biomass. Bioresour. Technol. 2022, 344, 126215. [Google Scholar] [CrossRef] [PubMed]

- Das, S.; Chandukishore, T.; Ulaganathan, N.; Dhodduraj, K.; Gorantla, S.S.; Chandna, T.; Gupta, L.K.; Sahoo, A.; Atheena, P.; Raval, R.; et al. Sustainable biorefinery approach by utilizing xylose fraction of lignocellulosic biomass. Int. J. Biol. Macromol. 2024, 266, 131290. [Google Scholar] [CrossRef] [PubMed]

- Tsegaye, B.; Balomajumder, C.; Roy, P. Microbial delignification and hydrolysis of lignocellulosic biomass to enhance biofuel production: An overview and future prospect. Bull. Natl. Res. Cent. 2019, 43, 51. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Sarangi, P.K.; Kovalev, A.A.; Vivekanand, V. Effect of physical and thermal pretreatment of lignocellulosic biomass on biohydrogen production by thermochemical route: A critical review. Bioresour. Technol. 2023, 369, 128458. [Google Scholar] [CrossRef] [PubMed]

- Karimipour-Fard, P.; Chio, C.; Brunone, A.; Marway, H.; Thompson, M.; Abdehagh, N.; Qin, W.; Yang, T.C. Lignocellulosic biomass pretreatment: Industrial oriented high-solid twin-screw extrusion method to improve biogas production from forestry biomass resources. Bioresour. Technol. 2024, 393, 130000. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Hirata, S.; Hassan, M.A. Combined pretreatment using alkaline hydrothermal and ball milling to enhance enzymatic hydrolysis of oil palm mesocarp fiber. Bioresour. Technol. 2014, 169, 236–243. [Google Scholar] [CrossRef] [PubMed]

- Shukla, A.; Kumar, D.; Girdhar, M.; Kumar, A.; Goyal, A.; Malik, T.; Mohan, A. Strategies of pretreatment of feedstocks for optimized bioethanol production: Distinct and integrated approaches. Biotechnol. Biofuels Bioprod. 2023, 16, 44. [Google Scholar] [CrossRef]

- Kim, S.J.; Um, B.H.; Im, D.J.; Lee, J.H.; Oh, K.K. Combined Ball Milling and Ethanol Organosolv Pretreatment to Improve the Enzymatic Digestibility of Three Types of Herbaceous Biomass. Energies 2018, 11, 2457. [Google Scholar] [CrossRef]

- Kim, T.H.; Park, S.H.; Le, T.D.T.; Kim, T.H.; Oh, K.K. Effects of Colloid Milling and Hot-Water Pretreatment on Physical Properties and Enzymatic Digestibility of Oak Wood. Energies 2022, 15, 2210. [Google Scholar] [CrossRef]

- Ratnasari, A.; Syafiuddin, A.; Boopathy, R.; Malik, S.; Mehmood, M.A.; Amalia, R.; Prastyo, D.D.; Zaidi, N.S. Advances in pretreatment technology for handling the palm oil mill effluent: Challenges and prospects. Bioresour. Technol. 2022, 344, 126239. [Google Scholar] [CrossRef]

- Gallego-García, M.; Moreno, A.D.; Manzanares, P.; Negro, M.J.; Duque, A. Recent advances on physical technologies for the pretreatment of food waste and lignocellulosic residues. Bioresour. Technol. 2023, 369, 128397. [Google Scholar] [CrossRef] [PubMed]

- Tchobanoglous, G.; Theisen, H.; Vigil, S. Integrated Solid Waste Management Engineering Principles and Management Issues; McGraw Hill: New York, NY, USA, 1993. [Google Scholar]

- Arce, C.; Kratky, L. Mechanical pretreatment of lignocellulosic biomass toward enzymatic/fermentative valorization. iScience 2022, 25, 104610. [Google Scholar] [CrossRef]

- Loh, Z.H.; Samanta, A.K.; Heng, P.W.S. Overview of milling techniques for improving the solubility of poorly water-soluble drugs. Asian J. Pharm. Sci. 2015, 10, 255–274. [Google Scholar] [CrossRef]

- Carcea, M.; Turfani, V.; Narducci, V.; Melloni, S.; Galli, V.; Tullio, V. Stone Milling versus Roller Milling in Soft Wheat: Influence on Products Composition. Foods 2019, 9, 3. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhu, L.; Zhang, G.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Little, L.; Mainza, A.N.; Becker, M.; Wiese, J. Fine grinding: How mill type affects particle shape characteristics and mineral liberation. Miner. Eng. 2017, 111, 148–157. [Google Scholar] [CrossRef]

- Jung, H.; Lee, Y.J.; Yoon, W.B. Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes 2018, 6, 69. [Google Scholar] [CrossRef]

- Sarkar, A.; Fu, B.X. Impact of Quality Improvement and Milling Innovations on Durum Wheat and End Products. Foods 2022, 11, 1796. [Google Scholar] [CrossRef] [PubMed]

- Lyu, F.; Thomas, M.; Hendriks, W.; van der Poel, A. Size reduction in feed technology and methods for determining, expressing and predicting particle size: A review. Anim. Feed. Sci. Technol. 2020, 261, 114347. [Google Scholar] [CrossRef]

- Kotamarthy, L.; Metta, N.; Ramachandran, R. Understanding the Effect of Granulation and Milling Process Parameters on the Quality Attributes of Milled Granules. Processes 2020, 8, 683. [Google Scholar] [CrossRef]

- Xu, H.; Yu, G.; Mu, X.; Zhang, C.; DeRoussel, P.; Liu, C.; Li, B.; Wang, H. Effect and characterization of sodium lignosulfonate on alkali pretreatment for enhancing enzymatic saccharification of corn stover. Ind. Crop. Prod. 2015, 76, 638–646. [Google Scholar] [CrossRef]

- Da Silva, A.S.A.; Teixeira, R.S.; de Oliveira Moutta, R.; Ferreira-Leitão, V.S.; De Barros, R.D.; Ferrara, M.A.; da Silva Bon, E.P. Sugarcane and Woody Biomass Pretreatments for Ethanol Production. In Sustainable Degradation of Ligno-Cellulosic Biomass—Techniques, Applications and Commercialization; InTech: Hong Kong, China, 2013. [Google Scholar] [CrossRef]

- Zhang, M.; Song, X.; Deines, T.W.; Pei, Z.J.; Wang, D. Biofuel Manufacturing from Woody Biomass: Effects of Sieve Size Used in Biomass Size Reduction. J. Biomed. Biotechnol. 2012, 2012, 581039. [Google Scholar] [CrossRef]

- Fu, Y.; Gu, B.-J.; Wang, J.; Gao, J.; Ganjyal, G.M.; Wolcott, M.P. Novel micronized woody biomass process for production of cost-effective clean fermentable sugars. Bioresour. Technol. 2018, 260, 311–320. [Google Scholar] [CrossRef] [PubMed]

- Tsapekos, P.; Kougias, P.G.; Angelidaki, I. Mechanical pretreatment for increased biogas production from lignocellulosic biomass; predicting the methane yield from structural plant components. Waste Manag. 2018, 78, 903–910. [Google Scholar] [CrossRef] [PubMed]

- Areepak, C.; Jiradechakorn, T.; Chuetor, S.; Phalakornkule, C.; Sriariyanun, M.; Raita, M.; Champreda, V.; Laosiripojana, N. Improvement of lignocellulosic pretreatment efficiency by combined chemo—Mechanical pretreatment for energy consumption reduction and biofuel production. Renew. Energy 2022, 182, 1094–1102. [Google Scholar] [CrossRef]

- Jomnonkhaow, U.; Sittijunda, S.; Reungsang, A. Influences of size reduction, hydration, and thermal-assisted hydration pretreatment to increase the biogas production from Napier grass and Napier silage. Bioresour. Technol. 2021, 331, 125034. [Google Scholar] [CrossRef] [PubMed]

- Bai, X.; Wang, G.; Zhu, Z.; Cai, C.; Wang, Z.; Wang, D. Investigation of improving the yields and qualities of pyrolysis products with combination rod-milled and torrefaction pretreatment. Renew. Energy 2020, 151, 446–453. [Google Scholar] [CrossRef]

- Lempiäinen, H.; Lappalainen, K.; Haverinen, J.; Tuuttila, T.; Hu, T.; Jaakkola, M.; Lassi, U. The Effect of Mechanocatalytic Pretreatment on the Structure and Depolymerization of Willow. Catalysts 2020, 10, 255. [Google Scholar] [CrossRef]

- Galbe, M.; Wallberg, O. Pretreatment for biorefineries: A review of common methods for efficient utilisation of lignocellulosic materials. Biotechnol. Biofuels 2019, 12, 294. [Google Scholar] [CrossRef]

- Abolore, R.S.; Jaiswal, S.; Jaiswal, A.K. Green and Sustainable Pretreatment Methods for Cellulose Extraction from Lignocellulosic Biomass and its Applications: A Review. Carbohydr. Polym. Technol. Appl. 2023, 7, 100396. [Google Scholar] [CrossRef]

- Raud, M.; Orupõld, K.; Rocha-Meneses, L.; Rooni, V.; Träss, O.; Kikas, T. Biomass Pretreatment with the Szego Mill™ for Bioethanol and Biogas Production. Processes 2020, 8, 1327. [Google Scholar] [CrossRef]

- Liu, C.; van der Heide, E.; Wang, H.; Li, B.; Yu, G.; Mu, X. Alkaline twin-screw extrusion pretreatment for fermentable sugar production. Biotechnol. Biofuels 2013, 6, 97. [Google Scholar] [CrossRef] [PubMed]

- Ahiduzzaman, A.; Islam, A.S. Development of Biomass Stove for Heating up Die Barrel of Rice Husk Briquette Machine. Procedia Eng. 2013, 56, 777–781. [Google Scholar] [CrossRef]

- Vaish, S.; Sharma, N.K.; Kaur, G. A review on various types of densification/briquetting technologies of biomass residues. IOP Conf. Series: Mater. Sci. Eng. 2022, 1228, 012019. [Google Scholar] [CrossRef]

- Zheng, J.; Rehmann, L. Extrusion Pretreatment of Lignocellulosic Biomass: A Review. Int. J. Mol. Sci. 2014, 15, 18967–18984. [Google Scholar] [CrossRef] [PubMed]

- Chakraborty, P.; Kumar, R.; Chakrabortty, S.; Saha, S.; Chattaraj, S.; Roy, S.; Banerjee, A.; Tripathy, S.K.; Ghosh, A.K.; Jeon, B.-H. Technological advancements in the pretreatment of lignocellulosic biomass for effective valorization: A review of challenges and prospects. J. Ind. Eng. Chem. 2024, in press. [Google Scholar] [CrossRef]

- Heredia-Olea, E.; Pérez-Carrillo, E.; Montoya-Chiw, M.; Serna-Saldívar, S.O. Effects of Extrusion Pretreatment Parameters on Sweet Sorghum Bagasse Enzymatic Hydrolysis and Its Subsequent Conversion into Bioethanol. BioMed Res. Int. 2015, 2015, 325905. [Google Scholar] [CrossRef] [PubMed]

- Duque, A.; Manzanares, P.; Ballesteros, M. Extrusion as a pretreatment for lignocellulosic biomass: Fundamentals and applications. Renew. Energy 2017, 114, 1427–1441. [Google Scholar] [CrossRef]

- Han, S.-Y.; Park, C.-W.; Endo, T.; Febrianto, F.; Kim, N.-H.; Lee, S.-H. Extrusion process to enhance the pretreatment effect of ionic liquid for improving enzymatic hydrolysis of lignocellulosic biomass. Wood Sci. Technol. 2020, 54, 599–613. [Google Scholar] [CrossRef]

- Campbell, G.A.; Spalding, M.A. Single-Screw Extrusion: Introduction and Troubleshooting. In Analyzing and Troubleshooting Single-Screw Extruders; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2020; pp. 1–22. [Google Scholar] [CrossRef]

- Capolupo, L.; Faraco, V. Green methods of lignocellulose pretreatment for biorefinery development. Appl. Microbiol. Biotechnol. 2016, 100, 9451–9467. [Google Scholar] [CrossRef]

- Karunanithy, C.; Muthukumarappan, K. Optimization of alkali soaking and extrusion pretreatment of prairie cord grass for maximum sugar recovery by enzymatic hydrolysis. Biochem. Eng. J. 2011, 54, 71–82. [Google Scholar] [CrossRef]

- Lin, Z.; Liu, L.; Li, R.; Shi, J. Screw Extrusion Pretreatments to Enhance the Hydrolysis of Lignocellulosic Biomass. J. Microb. Biochem. Technol. 2013, 1, S12. [Google Scholar] [CrossRef]

- Oyedeji, O.; Gitman, P.; Qu, J.; Webb, E. Understanding the Impact of Lignocellulosic Biomass Variability on the Size Reduction Process: A Review. ACS Sustain. Chem. Eng. 2020, 8, 2327–2343. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, Y.; Hanna, M.A. Pretreatment of Corn Stover with Twin-Screw Extrusion Followed by Enzymatic Saccharification. Appl. Biochem. Biotechnol. 2012, 166, 458–469. [Google Scholar] [CrossRef] [PubMed]

- Konan, D.; Koffi, E.; Ndao, A.; Peterson, E.C.; Rodrigue, D.; Adjallé, K. An Overview of Extrusion as a Pretreatment Method of Lignocellulosic Biomass. Energies 2022, 15, 3002. [Google Scholar] [CrossRef]

- Xu, H.; Che, X.; Ding, Y.; Kong, Y.; Li, B.; Tian, W. Effect of crystallinity on pretreatment and enzymatic hydrolysis of lignocellulosic biomass based on multivariate analysis. Bioresour. Technol. 2019, 279, 271–280. [Google Scholar] [CrossRef] [PubMed]

- Zafeer, M.K.; Menezes, R.A.; Venkatachalam, H.; Bhat, K.S. Sugarcane bagasse-based biochar and its potential applications: A review. Emergent Mater. 2024, 7, 133–161. [Google Scholar] [CrossRef]

- Nasution, M.H.; Lelinasari, S.; Kelana, M.G.S. A review of sugarcane bagasse pretreatment for bioethanol production. IOP Conf. Series: Earth Environ. Sci. 2022, 963, 012014. [Google Scholar] [CrossRef]

- Mahmud, A.; Anannya, F.R. Sugarcane bagasse—A source of cellulosic fiber for diverse applications. Heliyon 2021, 7, e07771. [Google Scholar] [CrossRef]

- Shangdiar, S.; Lin, Y.-C.; Ponnusamy, V.K.; Wu, T.-Y. Pretreatment of lignocellulosic biomass from sugar bagasse under microwave assisted dilute acid hydrolysis for biobutanol production. Bioresour. Technol. 2022, 361, 127724. [Google Scholar] [CrossRef]

- Khoo, R.Z.; Chow, W.S.; Ismail, H. Sugarcane bagasse fiber and its cellulose nanocrystals for polymer reinforcement and heavy metal adsorbent: A review. Cellulose 2018, 25, 4303–4330. [Google Scholar] [CrossRef]

- Resano, D.; Guillen, O.W.; Ubillús, F.D.; Barranzuela, J.L. Caracterización fisicoquímica del bagazo de caña de azúcar industrial y artesanal como material de construcción. Inf. Tecnológica 2022, 33, 247–258. [Google Scholar] [CrossRef]

- Mkhize, T.; Mthembu, L.D.; Gupta, R.; Kaur, A.; Kuhad, R.C.; Reddy, P.; Deenadayalu, N. Enzymatic Saccharification of Acid/Alkali Pre-treated, Mill-run, and Depithed Sugarcane Bagasse. BioResources 2016, 11, 6267–6285. [Google Scholar] [CrossRef]

- Marx, S.; Laubscher, A.; Bunt, J.; Venter, R.; Uwaoma, R.; Strydom, C. Evaluation of sugar cane bagasse hydrothermal liquefaction products for co-gasification with coal as green coal pellet production. Bioresour. Technol. Rep. 2023, 22, 101503. [Google Scholar] [CrossRef]

- Machado, G.; Santos, F.; Faria, D.; de Queiroz, T.N.; Zinani, F.; de Queiroz, J.H.; Gomes, F. Characterization and Potential Evaluation of Residues from the Sugarcane Industry of Rio Grande do Sul in Biorefinery Processes. Nat. Resour. 2018, 09, 175–187. [Google Scholar] [CrossRef]

- Brodeur, G.; Yau, E.; Badal, K.; Collier, J.; Ramachandran, K.B.; Ramakrishnan, S. Chemical and Physicochemical Pretreatment of Lignocellulosic Biomass: A Review. Enzym. Res. 2011, 2011, 787532. [Google Scholar] [CrossRef] [PubMed]

- Chen, R.S.; Chai, Y.H.; Olugu, E.U.; Ahmad, S. Characterization of post-consumer HDPE/sugarcane bagasse biocomposites. Mater. Today Proc. 2022, 51, 1410–1414. [Google Scholar] [CrossRef]

- Fong, A.L.; Khandoker, N.A.N.; Debnath, S. Development and characterization of sugarcane bagasse fiber and nano-silica reinforced epoxy hybrid composites. IOP Conf. Ser. Mater. Sci. Eng. 2018, 344, 012029. [Google Scholar] [CrossRef]

- Karp, S.G.; Faraco, V.; Amore, A.; Letti, L.A.J.; Soccol, V.T.; Soccol, C.R. Statistical Optimization of Laccase Production and Delignification of Sugarcane Bagasse by Pleurotus ostreatus in Solid-State Fermentation. BioMed Res. Int. 2015, 2015, 181204. [Google Scholar] [CrossRef]

- Da Silva, A.S.; Inoue, H.; Endo, T.; Yano, S.; Bon, E.P. Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour. Technol. 2010, 101, 7402–7409. [Google Scholar] [CrossRef]

- Jamal, M.; Sujan, S.; Miah, M.; Banik, S.; Ahmed, S.; Feroza, B. Ball Milling Pretreatment of Bagasse for Ethanol Production by Enzymatic Saccharification and Fermentation. Bangladesh J. Sci. Ind. Res. 1970, 46, 353–358. [Google Scholar] [CrossRef]

- Wang, Z.; Dien, B.S.; Rausch, K.D.; Tumbleson, M.; Singh, V. Fermentation of undetoxified sugarcane bagasse hydrolyzates using a two stage hydrothermal and mechanical refining pretreatment. Bioresour. Technol. 2018, 261, 313–321. [Google Scholar] [CrossRef] [PubMed]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, J. NREL/TP-510-42621: Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples. Natl. Renew. Energy Lab. 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, J. NREL/TP-510-42622: Determination of Ash in Biomass. Natl. Renew. Energy Lab. 2005, 36, 302–305. [Google Scholar]

- ASTM E872-82; Standard Test Method for Volatile Matter in the Analysis of Particulate Wood Fuels. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D5373-21; Standard Test Methods for Determination of Carbon, Hydrogen and Nitrogen in Analysis Samples of Coal and Carbon in Analysis Samples of Coal and Coke. ASTM International: West Conshohocken, PA, USA, 2021.

- AOAC 973.18-1977; Fiber (Acid Detergent) and Lignin (H2SO4) in Animal Feed. AOAC International. AOAC International: Rockville, MD, USA, 2015.

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for Dietary Fiber, Neutral Detergent Fiber, and Nonstarch Polysaccharides in Relation to Animal Nutrition. J Dairy Sci 1991, 74, 10. [Google Scholar] [CrossRef]

- Yacu, W. Extruder screw, barrel, and die assembly: General design principles and operation. In Extrusion Cooking; Elsevier: New York, NY, USA, 2020; pp. 73–117. [Google Scholar] [CrossRef]

- Spalding, M.A.; Campbell, G.A. Extruder and Screw Design for Film Processing. In Film Processing Advances; Carl Hanser Verlag GmbH & Co. KG: München, Germany, 2014; pp. 1–26. [Google Scholar] [CrossRef]

- Huang, X.; Liu, H.; Ma, Y.; Mai, S.; Li, C. Effects of Extrusion on Starch Molecular Degradation, Order–Disorder Structural Transition and Digestibility—A Review. Foods 2022, 11, 2538. [Google Scholar] [CrossRef]

- Gallos, A.; Paës, G.; Allais, F.; Beaugrand, J. Lignocellulosic fibers: A critical review of the extrusion process for enhancement of the properties of natural fiber composites. RSC Adv. 2017, 7, 34638–34654. [Google Scholar] [CrossRef]

- Moro, M.K.; Teixeira, R.S.S.; da Silva, A.S.; Fujimoto, M.D.; Melo, P.A.; Secchi, A.R.; Bon, E.P.d.S. Continuous pretreatment of sugarcane biomass using a twin-screw extruder. Ind. Crop. Prod. 2017, 97, 509–517. [Google Scholar] [CrossRef]

- Qu, T.; Zhang, X.; Gu, X.; Han, L.; Ji, G.; Chen, X.; Xiao, W. Ball Milling for Biomass Fractionation and Pretreatment with Aqueous Hydroxide Solutions. ACS Sustain. Chem. Eng. 2017, 5, 7733–7742. [Google Scholar] [CrossRef]

- Sitotaw, Y.W.; Habtu, N.G.; Gebreyohannes, A.Y.; Nunes, S.P.; Van Gerven, T. Ball milling as an important pretreatment technique in lignocellulose biorefineries: A review. Biomass Convers. Biorefinery 2023, 13, 15593–15616. [Google Scholar] [CrossRef]

- Lan, L.; Chen, H.; Lee, D.; Xu, S.; Skillen, N.; Tedstone, A.; Robertson, P.; Garforth, A.; Daly, H.; Hardacre, C.; et al. Effect of Ball-Milling Pretreatment of Cellulose on Its Photoreforming for H2 Production. ACS Sustain. Chem. Eng. 2022, 10, 4862–4871. [Google Scholar] [CrossRef]

- Neslušan, M.; Minárik, P.; Čep, R.; Uríček, J.; Trojan, K.; Ganev, N.; Trško, L. Barkhausen noise emission of AISI 304 stainless steel originating from strain induced martensite by shot peening. J. Mater. Res. Technol. 2022, 20, 748–762. [Google Scholar] [CrossRef]

| Type of Mill | Products Obtained | ||||

|---|---|---|---|---|---|

| Type of Mill | Reduction Mechanism | Feedstock | Product/Process | Yield | Source |

| Disk refiner | Shearing, tearing | Corn stover | Sugars | 79% increase | [23] |

| Screw extruder (extrusion) | Compression, tearing, shearing | Sugarcane | Hydrolysis | 68.2% | [24] |

| Knife mill | Shearing, cutting | Wheat straw | Sugars | 24% | [25] |

| Hammer mill | Breaking | Wood chips | Sugars | 4-fold over control samples | [26] |

| Roll mill | Compression, tearing | Different types of grass | Methane | 474 mL/gVS (untreated: 33.9 mL/gVS) | [27] |

| Centrifugal mill | Cutting, breaking | Rice straw | Glucose | 94% glucose conversion | [28] |

| Ball mill | Tearing, breaking | Napier silage | Methane | 3608.6 mL CH4/L | [29] |

| Rod mill | Tearing, breaking | Wheat straw | Crystallinity index | Reduced to 11.59%, increased bio-oil yield to 46.16% | [30] |

| Component | Percentage (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cellulose | 35–55 | 23.6–35 | 20 | 40.2 | 40.88 | 36.40 | 26–47 | 52.5 |

| Hemicellulose | 16–36 | 31.3–45 | 25 | 23.8 | 25.64 | 21.60 | 19–33 | 20.6 |

| Lignin | 14–26 | 13.4–30 | 42 | 25.2 | 23.42 | 19.60 | 14–23 | 25 |

| Ash | 1–5 | 1.7–6.2 | - | - | - | - | 1–5 | 1.9 |

| Reference | [53,56] | [41] | [49] | [49] | [39] | [39] | [53] | [57] |

| Property | Result (%) | |||

|---|---|---|---|---|

| Inherent moisture | 6.3 ± 0.1 | - | - | |

| Volatile matter | 69.7 ± 0.7 | - | 74.82 | 84.54 |

| Fixed carbon | 13.1 ± 0.8 | - | 13.05 | 12.8 |

| Carbon | 49.79 | 41.67–58.14 | 43.35 | 45.57 |

| Hydrogen | 6.92 | 6.05–6.21 | 6.25 | 5.57 |

| Nitrogen | 0.42 | 0.37–0.69 | 0 | 0.305 |

| Sulfur | 0.08 | - | 0.05 | 0.04 |

| Oxygen | 42.78 | 34.57–41.33 | 45.79 | 45.135 |

| Reference | [58] | [41] | [59] | [59] |

| Physical Property | Result | Unit | Source |

|---|---|---|---|

| Tensile strength | 170–290 | MPa | [61] |

| Modulus of elasticity | 15–27.1 | GPa | [62] |

| Moisture | 7.57 ± 1.9 × 10−1 | % | [63] |

| Real density | 0.1656 ± 9.9 × 10−4 | g/cm3 | [7] |

| Feedstock | Type of Milling | Conditions | Products Obtained/Process | Source |

|---|---|---|---|---|

| Sugarcane straw | Ball milling | 90 min | Xylose/glucose: 77.6 and 56.8%. Reduction in cellulose crystallinity. | [64] |

| Sugarcane bagasse | Wet disk milling | 5% solids, 15 L water, overnight soaking | Increased fibrillation, enhanced cellulolytic enzyme accessibility. Glucose/xylose: 49.3% and 36.7%. | [24,64] |

| Sugarcane bagasse | Disk milling | 1–5% solids, passed between ceramic disks, multiple cycles | Small particle sizes, large specific surface areas, increased enzymatic hydrolysis yields. | [24] |

| Sugarcane bagasse | Ball milling/cut milling | 10–120 min—room temperature | Increase in enzymatic saccharification. | [65] |

| Sugarcane bagasse | Liquid hot water/disk milling | 140–180 °C for 10 min (20% w/w solid content) and then disk-milled | Improved glucose release: 41–177%. | [66] |

| Sugarcane bagasse | Wet disk milling | 1800 rpm, 1 kg/15 L water, overnight, 20 cycles | Glucose/xylose: 78.7% and 72.1%. | [64] |

| Sugarcane bagasse | Ball milling | 400 rpm in a 45 mL milling pot; cyclic mode of 10 min milling, followed by a 10 min rest | Glucose/xylose: 49.3% and 36.7%. | [64] |

| Property | Result (%) |

| Proximal analysis | |

| Moisture | 7.910 ± 0.07 |

| Ash | 1.555 ± 0.02 |

| Volatile matter | 80.93 ± 0.08 |

| Fixed carbon | 9.601 |

| Elemental analysis | |

| Carbon | 45.22 |

| Hydrogen | 5.94 |

| Nitrogen | 0.29 |

| Sulfur | 0 |

| Oxygen | 48.56 |

| Structural analysis | |

| Cellulose | 41.9 |

| Hemicellulose | 25.0 |

| Lignin | 8.1 |

| Characteristic | Value |

|---|---|

| Capacity | 14.7 , |

| N | 9.8 rpm |

| Motor power | 1 HP |

| Length | 4.5 ft |

| Torque | 1050 lbin |

| Screw diameter | 6 in |

| Screw pitch | Short and standard |

| Number | Name |

|---|---|

| 1 | Screw |

| 2 | Channel |

| 3 | End Shaft |

| 4 | Drive Shaft |

| 5 | Shaft Seal |

| 6 | End Plate 2 |

| 7 | End Plate 1 |

| 8 | End Bearings |

| 9 | Motor |

| 10 | Flange Foot |

| 11 | Covers |

| 12 | Inlet |

| 13 | Discharge |

| 14 | End Bearings |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramirez Cabrera, P.A.; Lozano Pérez, A.S.; Lozada Castro, J.J.; Sierra Vargas, F.E.; Guerrero Fajardo, C.A. Revolutionizing Biomass Processing: The Design and Functionality of an Innovative Extruder for Sugarcane Bagasse Milling Pretreatment. Designs 2024, 8, 85. https://doi.org/10.3390/designs8050085

Ramirez Cabrera PA, Lozano Pérez AS, Lozada Castro JJ, Sierra Vargas FE, Guerrero Fajardo CA. Revolutionizing Biomass Processing: The Design and Functionality of an Innovative Extruder for Sugarcane Bagasse Milling Pretreatment. Designs. 2024; 8(5):85. https://doi.org/10.3390/designs8050085

Chicago/Turabian StyleRamirez Cabrera, Paula Andrea, Alejandra Sophia Lozano Pérez, Juan José Lozada Castro, Fabio Emiro Sierra Vargas, and Carlos Alberto Guerrero Fajardo. 2024. "Revolutionizing Biomass Processing: The Design and Functionality of an Innovative Extruder for Sugarcane Bagasse Milling Pretreatment" Designs 8, no. 5: 85. https://doi.org/10.3390/designs8050085

APA StyleRamirez Cabrera, P. A., Lozano Pérez, A. S., Lozada Castro, J. J., Sierra Vargas, F. E., & Guerrero Fajardo, C. A. (2024). Revolutionizing Biomass Processing: The Design and Functionality of an Innovative Extruder for Sugarcane Bagasse Milling Pretreatment. Designs, 8(5), 85. https://doi.org/10.3390/designs8050085