Open-Source Indoor Horizontal Grow Structure Designs

Abstract

:1. Introduction

2. Materials and Methods

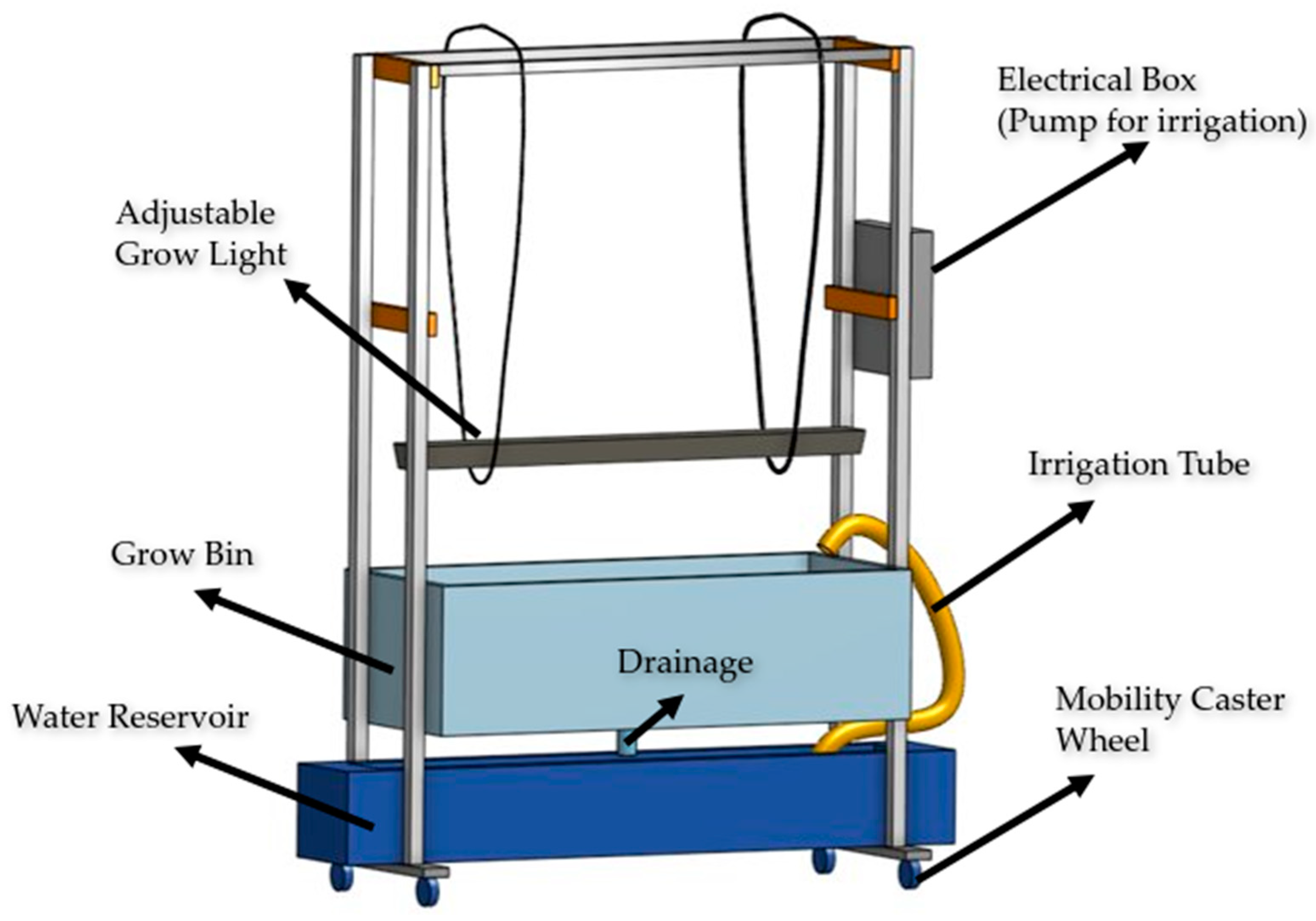

Design Criteria

- Wheels for mobility (optional);

- Water reservoir to collect drainage from grow bin;

- Drainage hole to allow excessive water to drain from grow bin;

- Grow bin to hold substrate and plants;

- The grow bins must have enough mechanical strength to hold a completely loaded grow system, including growing medium and water;

- Irrigation system to pump reclaimed water back into grow bin;

- Electrical box to control water pump;

- Structure to hold and adjust the height of the grow light as plants grow. This structure must be mechanically strong enough to hold the mass of a grow light.

3. Results

4. Discussion

4.1. Limitations

4.2. Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Components | Function | Quantity | Price (CAD) | URL |

|---|---|---|---|---|

| 2020 Aluminum Extrusion | Frame | 68ft | CAD 252.94 | https://www.amazon.ca/Aluminum-Extrusion-European-Standard-Anodized/dp/B09SF492NK |

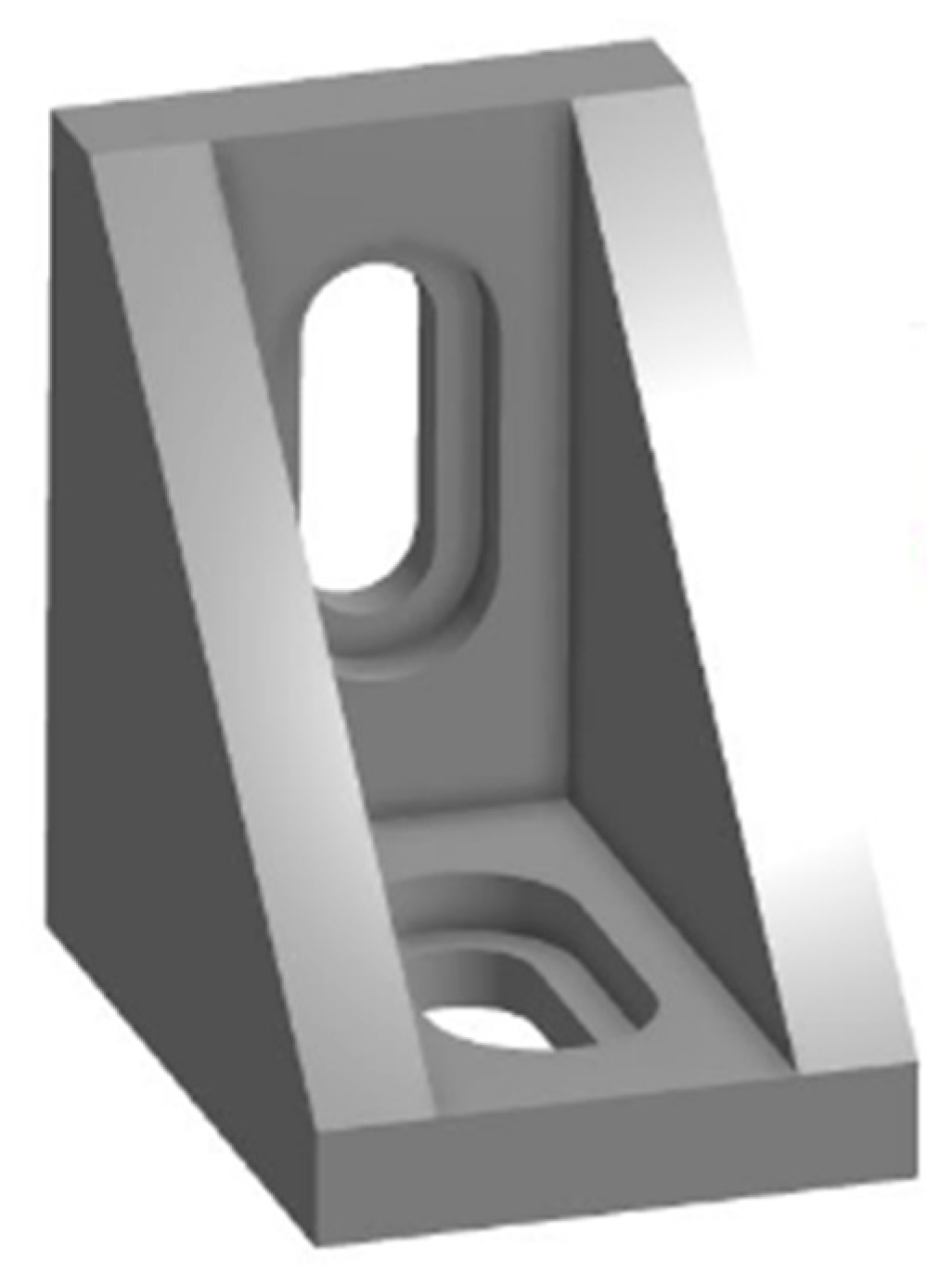

| Corner Bracket (Can be 3D printed) | Connection | 36 | CAD 18.51 | https://www.amazon.ca/Aluminum-Profile-Connector-Bracket-Accessories/dp/B0B9JVW5X8 |

| M5 0.8 × 8 mm Screws | Connection | 92 | CAD 27.18 | https://www.amazon.ca/M5-0-8-Button-Stainless-Machine-Threaded/dp/B0B7DSMN2N |

| Grow Light Rope Hanger | Light Support | 2 | CAD 5.50 | https://www.amazon.ca/VIPARSPECTRA-Adjustable-Fixtures-Gardening-Capacity/dp/B07Z613ZM2 |

| M5 Drop in Tee Nut | Connection | 92 | CAD 25.74 | https://www.amazon.ca/Boeray-Carbon-Hammer-Aluminum-Extrusion/dp/B01G7ZYHHI |

| Caster Wheels | Mobility | 6 | CAD 19.49 | https://www.princessauto.com/en/4-pk-2-in-light-duty-swivel-casters/product/PA0008937740 |

| Total Price: | CAD 349.35 | |||

| 3D-printed Corner Brackets (7.22 g PETG) | 36 | CAD 7.80 | ||

| Total Price with 3DP Replacement: | CAD 338.64 | 3.07% savings |

| Components | Function | Quantity | Price (CAD) | URL |

|---|---|---|---|---|

| Profile 4040 Aluminum Extrusion | Frame | 27ft | CAD 337.50 | https://www.amazon.ca/Aluminum-Extrusion-European-Standard-Anodized/dp/B09MWDQVB3 |

| 10 pk 1/4-20 Slide-In Centered T-Nut | Connection | 3 pack | CAD 29.97 | https://www.princessauto.com/en/10s-10-pk-1-4-20-slide-in-centred-t-nut-fbhscs-bolt-assembly/product/PA0009132473 |

| Caster Wheels | Mobility | 6 | CAD 11.99 | https://www.princessauto.com/en/4-pk-2-in-light-duty-swivel-casters/product/PA0008937740 |

| Total Price: | CAD 379.46 |

| Components | Function | Quantity | Price (CAD) | URL |

|---|---|---|---|---|

| 1/2″ PVC Pipe | Frame | 43.5ft | CAD 137.68 | https://www.amazon.ca/letsFix-Schedule-Furniture-Plumbing-Available/dp/B08KGZBGV5 |

| 2020 Aluminum Extrusion | Frame | 25ft | CAD 93.00 | https://www.amazon.ca/Aluminum-Extrusion-European-Standard-Anodized/dp/B09SF492NK |

| Caster Wheels | Mobility | 6 | CAD 19.49 | https://www.princessauto.com/en/4-pk-2-in-light-duty-swivel-casters/product/PA0008937740 |

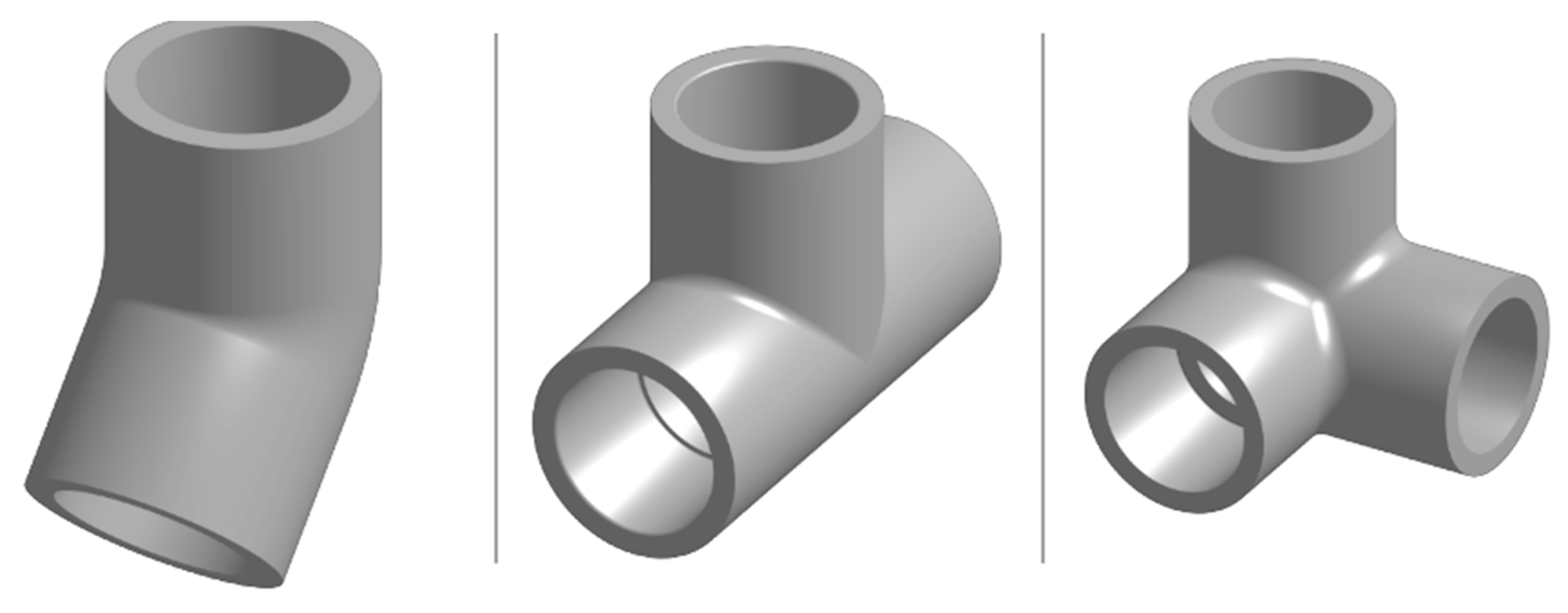

| 3 Way 1/2″ Tee PVC (Can be 3D printed) | Connection | 8 | CAD 18.32 | https://www.amazon.ca/Fittings-Connector-Furniture-Structure-Connection/dp/B0BQWJKY2Z |

| 3 way 1/2″ PVC Connector (Can be 3D printed) | Connection | 6 | CAD 11.40 | https://www.amazon.ca/Yuema-Fitting-Build-Furniture-Fittings/dp/B082NRMNLK |

| Corner Bracket (Can be 3D printed) | Connection | 16 | CAD 8.16 | https://www.amazon.ca/Bracket-Aluminum-Extrusions-Fastener-Printer/dp/B085NRPPNM |

| 1/2″ 45 Degree 2 Way Tee PVC (Can be 3D printed) | Connection | 4 | CAD 5.60 | https://www.amazon.ca/QWORK-Fitting-Furniture-Building-Structures/dp/B09DYHHTMY |

| Total Price: | CAD 293.64 | |||

| 3D-printed 3 Way 1/2″ Tee PVC (35.58 g) | 8 | CAD 8.54 | ||

| 3D-printed 3-Way PVC Connector (37.45 g) | 6 | CAD 6.74 | ||

| 3D-printed Corner Brackets (7.22 g PETG) | 16 | CAD 3.47 | ||

| 3D-printed 1/2″ 45 Degree 2-way Elbow (18.37 g) | 4 | CAD 2.20 | ||

| Total Price with 3DP Replacement: | CAD 250.16 | 14.80% savings |

| Components | Quantity | Price (CAD) | URL |

|---|---|---|---|

| Small Stackable Tote | 6 | CAD 41.94 | https://www.princessauto.com/en/product/PA0008197469 |

| 25′ × 3/4″ ID PVC Tubing | 1 | CAD 30.62 | https://www.amazon.ca/Duda-Energy-HPpvc075-025ft-Pressure-Resistant/dp/B00TMTFV3G |

| Rule Bilge Water Pump 750 GPH 12 V | 1 | CAD 23.66 | https://www.amazon.ca/Iztor-Bilge-Water-Marine-outlet/dp/B078GN8BNV |

| 64L Stackable Tote Bin | 1 | CAD 10.97 | https://www.homedepot.ca/product/hdx-64l-stackable-tough-strong-storage-tote-bin-plastic-organizer-box-black-base-yellow-snap-on-lid/1001057029 |

| Rain gutter cover | 1 | CAD 9.59 | https://www.amazon.ca/OSALADI-Attachment-Downspout-K-style-Accessories/dp/B0C7FMW59F |

| rain gutter | 1 | CAD 8.19 | https://www.rona.ca/en/product/euramax-contemporary-half-round-gutter-white-vinyl-120-in-l-x-4-in-w-t0473-0128056 |

| PVC pipe 3/4″ | 1 | CAD 5.48 | https://www.homedepot.ca/product/sharkbite-3-4-inch-x-5-feet-white-pex-pipe/1001013602 |

| Total Price: | CAD 130.45 |

References

- Godfray, H.C.J.; Beddington, J.R.; Crute, I.R.; Haddad, L.; Lawrence, D.; Muir, J.F.; Pretty, J.; Robinson, S.; Thomas, S.M.; Toulmin, C. Food Security: The Challenge of Feeding 9 Billion People. Science 2010, 327, 812–818. [Google Scholar] [CrossRef] [PubMed]

- Tirado, M.C.; Clarke, R.; Jaykus, L.A.; McQuatters-Gollop, A.; Frank, J.M. Climate Change and Food Safety: A Review. Food Res. Int. 2010, 43, 1745–1765. [Google Scholar] [CrossRef]

- Wheeler, T.; von Braun, J. Climate Change Impacts on Global Food Security. Science 2013, 341, 508–513. [Google Scholar] [CrossRef] [PubMed]

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical Farming: A Summary of Approaches to Growing Skywards. J. Hortic. Sci. Biotechnol. 2019, 94, 277–283. [Google Scholar] [CrossRef]

- Kalantari, F.; Tahir, O.M.; Joni, R.A.; Fatemi, E. Opportunities and Challenges in Sustainability of Vertical Farming: A Review. J. Landsc. Ecol. 2018, 11, 35–60. [Google Scholar] [CrossRef]

- Ayambire, R.A.; Amponsah, O.; Peprah, C.; Takyi, S.A. A Review of Practices for Sustaining Urban and Peri-Urban Agriculture: Implications for Land Use Planning in Rapidly Urbanising Ghanaian Cities. Land Use Policy 2019, 84, 260–277. [Google Scholar] [CrossRef]

- Kuusaana, E.D.; Eledi, J.A. As the City Grows, Where Do the Farmers Go? Understanding Peri-Urbanization and Food Systems in Ghana—Evidence from the Tamale Metropolis. Urban Forum 2015, 26, 443–465. [Google Scholar] [CrossRef]

- Hemerijckx, L.-M.; Nakyagaba, G.N.; Sseviiri, H.; Janusz, K.; Eichinger, M.; Lwasa, S.; May, J.; Verburg, P.H.; Van Rompaey, A. Mapping the Consumer Foodshed of the Kampala City Region Shows the Importance of Urban Agriculture. Npj Urban Sustain. 2023, 3, 11. [Google Scholar] [CrossRef]

- Blekking, J.; Waldman, K.; Davies, J.; Kaputula, M.; Nelson, E.; Robeson, S.M. Rapid Urbanization and Uneven Development of the Food Retail Environment. Geoforum 2023, 147, 103893. [Google Scholar] [CrossRef]

- Mitchell, C.A. History of Controlled Environment Horticulture: Indoor Farming and Its Key Technologies. HortScience 2022, 57, 247–256. [Google Scholar] [CrossRef]

- Niu, G.; Masabni, J. Plant Production in Controlled Environments. Horticulturae 2018, 4, 28. [Google Scholar] [CrossRef]

- Closed Systems with Lamps for Commercial Production of Transplants Using Minimal Resources. Available online: https://www.actahort.org/books/630/630_30.htm (accessed on 27 June 2024).

- Park, Y.; Gómez, C.; Runkle, E.S. Indoor Production of Ornamental Seedlings, Vegetable Transplants, and Microgreens. In Plant Factory Basics, Applications and Advances; Academic Press: Cambridge, MA, USA, 2022; pp. 351–375. [Google Scholar]

- Marzano, A. Plants, Politics and Empire in Ancient Rome; Cambridge University Press: Cambridge, UK, 2022; ISBN 978-1-00-930226-5. [Google Scholar]

- Kortright, R.; Wakefield, S. Edible Backyards: A Qualitative Study of Household Food Growing and Its Contributions to Food Security. Agric. Hum. Values 2011, 28, 39–53. [Google Scholar] [CrossRef]

- Church, A.; Mitchell, R.; Ravenscroft, N.; Stapleton, L.M. ‘Growing Your Own’: A Multi-Level Modelling Approach to Understanding Personal Food Growing Trends and Motivations in Europe. Ecol. Econ. 2015, 110, 71–80. [Google Scholar] [CrossRef]

- Algert, S.; Diekmann, L.; Renvall, M.; Gray, L. Community and Home Gardens Increase Vegetable Intake and Food Security of Residents in San Jose, California. Calif. Agric. 2016, 70, 78–82. [Google Scholar] [CrossRef]

- Galhena, D.H.; Freed, R.; Maredia, K.M. Home Gardens: A Promising Approach to Enhance Household Food Security and Wellbeing. Agric. Food Secur. 2013, 2, 8. [Google Scholar] [CrossRef]

- Understanding Food Security Issues in Remote Western Australian Indigenous Communities—Pollard—2014—Health Promotion Journal of Australia—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/full/10.1071/HE14044 (accessed on 27 June 2024).

- Pollard, C. Selecting Interventions for Food Security in Remote Indigenous Communities. In Food Security in Australia: Challenges and Prospects for the Future; Farmar-Bowers, Q., Higgins, V., Millar, J., Eds.; Springer: Boston, MA, USA, 2013; pp. 97–112. ISBN 978-1-4614-4484-8. [Google Scholar]

- Ward, P.R.; Coveney, J.; Verity, F.; Carter, P. Cost and Affordability of Healthy Food in Rural South Australia. Rural Remote Health 2012, 12, 80–89. [Google Scholar] [CrossRef]

- Booth, S.; Deen, C.; Thompson, K.; Kleve, S.; Chan, E.; McCarthy, L.; Kraft, E.; Fredericks, B.; Brimblecombe, J.; Ferguson, M. Conceptualisation, Experiences and Suggestions for Improvement of Food Security amongst Aboriginal and Torres Strait Islander Parents and Carers in Remote Australian Communities. Soc. Sci. Med. 2023, 320, 115726. [Google Scholar] [CrossRef]

- McCartney, L.; Lefsrud, M. Protected Agriculture in Extreme Environments: A Review of Controlled Environment Agriculture in Tropical, Arid, Polar, and Urban Locations. Appl. Eng. Agric. 2018, 34, 455–473. [Google Scholar] [CrossRef]

- Yakovenko, D.A.; Arkhipov, S. Agriculture in the Polar Regions: New Approaches to Historical Challenges. BIO Web Conf. 2024, 108, 25008. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Prabhjyot-Kaur; Mahajan, G.; Randhawa, R.K.; Singh, H.; Kang, M.S. Chapter Two—Global Warming and Its Possible Impact on Agriculture in India. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Cambridge, MA, USA, 2014; Volume 123, pp. 65–121. [Google Scholar]

- Bhattacharya, A. Chapter 1—Global Climate Change and Its Impact on Agriculture. In Changing Climate and Resource Use Efficiency in Plants; Bhattacharya, A., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 1–50. ISBN 978-0-12-816209-5. [Google Scholar]

- Pollard, C.M.; Landrigan, T.J.; Ellies, P.L.; Kerr, D.A.; Underwood, L.M.L.; Goodchild, S.E. Geographic Factors as Determinants of Food Security: A Western Australian Food Pricing and Quality Study. Asia Pac. J. Clin. Nutr. 2020, 23, 703–713. [Google Scholar] [CrossRef]

- Hendrickson, D.; Smith, C.; Eikenberry, N. Fruit and Vegetable Access in Four Low-Income Food Deserts Communities in Minnesota. Agric. Hum. Values 2006, 23, 371–383. [Google Scholar] [CrossRef]

- Daviron, B. Price Spikes and World Food Security. The Need for Change. Perspective 2012, 15, 1–4. [Google Scholar] [CrossRef] [PubMed]

- Kelly, N.; Vaštakaitė-Kairienė, V.; Runkle, E.S. Chapter 18—Indoor Lighting Effects on Plant Nutritional Compounds. In Plant Factory Basics, Applications and Advances; Kozai, T., Niu, G., Masabni, J., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 329–349. ISBN 978-0-323-85152-7. [Google Scholar]

- Kozai, T. Resource Use Efficiency of Closed Plant Production System with Artificial Light: Concept, Estimation and Application to Plant Factory. Proc. Jpn. Acad. Ser. B 2013, 89, 447–461. [Google Scholar] [CrossRef] [PubMed]

- Fussy, A.; Papenbrock, J. An Overview of Soil and Soilless Cultivation Techniques—Chances, Challenges and the Neglected Question of Sustainability. Plants 2022, 11, 1153. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, R.D.; Pisciotta, A.; Santamaria, P.; Scariot, V. From Soil to Soil-Less in Horticulture: Quality and Typicity. Ital. J. Agron. 2013, 8, e30. [Google Scholar] [CrossRef]

- Gruda, N.S. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Eldridge, B.M.; Manzoni, L.R.; Graham, C.A.; Rodgers, B.; Farmer, J.R.; Dodd, A.N. Getting to the Roots of Aeroponic Indoor Farming. New Phytol. 2020, 228, 1183–1192. [Google Scholar] [CrossRef]

- Solar Energy Conservation in Greenhouse: Thermal Analysis and Experimental Validation—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0960148116303810 (accessed on 17 July 2024).

- Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Tignor, M.E.; Wilson, S.B.; McMahon, M. Dynamic Modeling and Simulation of Greenhouse Environments under Several Scenarios: A Web-Based Application. Comput. Electron. Agric. 2010, 70, 105–116. [Google Scholar] [CrossRef]

- Engler, N.; Krarti, M. Review of Energy Efficiency in Controlled Environment Agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786. [Google Scholar] [CrossRef]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A Review on Hydroponics and the Technologies Associated for Medium- and Small-Scale Operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Lamsen, F.C.; Favi, J.C.; Castillo, B.H.F. Indoor Gardening with Automatic Irrigation System Using Arduino Microcontroller. ASEAN Multidiscip. Res. J. 2022, 10, 131–148. [Google Scholar]

- Benke, K.; Tomkins, B. Future Food-Production Systems: Vertical Farming and Controlled-Environment Agriculture. Sustain. Sci. Pract. Policy 2017, 13, 13–26. [Google Scholar] [CrossRef]

- Merrill, B.F.; Lu, N.; Yamaguchi, T.; Takagaki, M.; Maruo, T.; Kozai, T.; Yamori, W. Next Evolution of Agriculture: A Review of Innovations in Plant Factories. In Handbook of Photosynthesis; CRC Press: Boca Raton, FL, USA, 2016; ISBN 978-1-315-37213-6. [Google Scholar]

- Hati, A.J.; Singh, R.R. Smart Indoor Farms: Leveraging Technological Advancements to Power a Sustainable Agricultural Revolution. AgriEngineering 2021, 3, 728–767. [Google Scholar] [CrossRef]

- Kreuger, M.; Meeuws, L.; Meeuws, G. Total Indoor Farming Concepts for Large-Scale Production. In Smart Plant Factory: The Next Generation Indoor Vertical Farms; Kozai, T., Ed.; Springer: Singapore, 2018; pp. 125–135. ISBN 9789811310652. [Google Scholar]

- Mani, M. Pest Management in Horticultural Crops Under Protected Cultivation. In Trends in Horticultural Entomology; Mani, M., Ed.; Springer Nature: Singapore, 2022; pp. 387–417. ISBN 978-981-19034-3-4. [Google Scholar]

- Rajan, P.; Lada, R.R.; MacDonald, M.T. Advancement in Indoor Vertical Farming for Microgreen Production. Am. J. Plant Sci. 2019, 10, 1397. [Google Scholar] [CrossRef]

- Specht, K.; Siebert, R.; Hartmann, I.; Freisinger, U.B.; Sawicka, M.; Werner, A.; Thomaier, S.; Henckel, D.; Walk, H.; Dierich, A. Urban Agriculture of the Future: An Overview of Sustainability Aspects of Food Production in and on Buildings. Agric. Hum. Values 2014, 31, 33–51. [Google Scholar] [CrossRef]

- Wong, C.E.; Teo, Z.W.N.; Shen, L.; Yu, H. Seeing the Lights for Leafy Greens in Indoor Vertical Farming. Trends Food Sci. Technol. 2020, 106, 48–63. [Google Scholar] [CrossRef]

- Pennisi, G.; Orsini, F.; Landolfo, M.; Pistillo, A.; Crepaldi, A.; Nicola, S.; Fernández, J.A.; Marcelis, L.F.M.; Gianquinto, G. Optimal Photoperiod for Indoor Cultivation of Leafy Vegetables and Herbs. Eur. J. Hortic. Sci. 2020, 85, 329–338. [Google Scholar] [CrossRef]

- Chen, L.; Qian, L.; Zhang, X.; Li, J.; Zhang, Z.; Chen, X. Research Progress on Indoor Environment of Mushroom Factory. Int. J. Agric. Biol. Eng. 2022, 15, 25–32. [Google Scholar] [CrossRef]

- Zelkind, M.; Livingston, T.; Verlage, V. Chapter 16—Indoor Production of Tomatoes. In Plant Factory Basics, Applications and Advances; Kozai, T., Niu, G., Masabni, J., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 295–305. ISBN 978-0-323-85152-7. [Google Scholar]

- Ries, J. Improving Indoor Strawberry Production in Vertical Farming through Enhanced Lighting and Fertilization Strategies; Arizona State University: Tempe, AZ, USA, 2024. [Google Scholar]

- Du, X.; Chen, K.; Ma, Z.; Wu, C.; Zhang, G. Design, Construction, and Evaluation of a Three-Dimensional Vibratory Harvester for Tree Fruit. Appl. Eng. Agric. 2020, 36, 221–231. [Google Scholar] [CrossRef]

- Agrilyst. State of Indoor Farming. Agrilyst 2017. Available online: https://www.bayer.com/sites/default/files/stateofindoorfarming-report-2017.pdf (accessed on 19 September 2024).

- Capital, N. The Promise and Perils of Container Farming; Newbean Capital: Reno, NV, USA, 2018. [Google Scholar]

- Ahamed, M.S.; Sultan, M.; Monfet, D.; Rahman, M.S.; Zhang, Y.; Zahid, A.; Bilal, M.; Ahsan, T.M.A.; Achour, Y. A Critical Review on Efficient Thermal Environment Controls in Indoor Vertical Farming. J. Clean. Prod. 2023, 425, 138923. [Google Scholar] [CrossRef]

- Kośny, J.; Kossecka, E. Multi-Dimensional Heat Transfer through Complex Building Envelope Assemblies in Hourly Energy Simulation Programs. Energy Build. 2002, 34, 445–454. [Google Scholar] [CrossRef]

- Song, R.; Liu, D.; Pan, Y.; Cheng, Y.; Meng, C. Container Farms: Energy Modeling Considering Crop Growth and Energy-Saving Potential in Different Climates. J. Clean. Prod. 2023, 420, 138353. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Dargusch, P.; Wadley, D.; Zulkarnain, N.A.; Aziz, A.A. A Review of Research on Agrivoltaic Systems. Renew. Sustain. Energy Rev. 2022, 161, 112351. [Google Scholar] [CrossRef]

- Asgari, N.; Jamil, U.; Pearce, J.M. Net Zero Agrivoltaic Arrays for Agrotunnel Vertical Growing Systems: Energy Analysis and System Sizing. Sustainability 2024, 16, 6120. [Google Scholar] [CrossRef]

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Design and Economics of Manual Variable-Tilt Angle DIY Wood-Based Solar Photovoltaic Racking System. Designs 2022, 6, 54. [Google Scholar] [CrossRef]

- Riaz, M.H.; Imran, H.; Butt, N.Z. Optimization of PV Array Density for Fixed Tilt Bifacial Solar Panels for Efficient Agrivoltaic Systems. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; pp. 1349–1352. [Google Scholar]

- Tahir, Z.; Butt, N.Z. Implications of Spatial-Temporal Shading in Agrivoltaics under Fixed Tilt & Tracking Bifacial Photovoltaic Panels. Renew. Energy 2022, 190, 167–176. [Google Scholar] [CrossRef]

- Jamil, U.; Vandewetering, N.; Sadat, S.A.; Pearce, J.M. Wood- and Cable-Based Variable Tilt Stilt-Mounted Solar Photovoltaic Racking System. Designs 2024, 8, 6. [Google Scholar] [CrossRef]

- Krexner, T.; Bauer, A.; Gronauer, A.; Mikovits, C.; Schmidt, J.; Kral, I. Environmental Life Cycle Assessment of a Stilted and Vertical Bifacial Crop-Based Agrivoltaic Multi Land-Use System and Comparison with a Mono Land-Use of Agricultural Land. Renew. Sustain. Energy Rev. 2024, 196, 114321. [Google Scholar] [CrossRef]

- Jamil, U.; Vandewetering, N.; Pearce, J.M. Solar Photovoltaic Wood Racking Mechanical Design for Trellis-Based Agrivoltaics. PLoS ONE 2023, 18, e0294682. [Google Scholar] [CrossRef]

- Malu, P.R.; Sharma, U.S.; Pearce, J.M. Agrivoltaic Potential on Grape Farms in India. Sustain. Energy Technol. Assess. 2017, 23, 104–110. [Google Scholar] [CrossRef]

- Padilla, J.; Toledo, C.; Abad, J. Enovoltaics: Symbiotic Integration of Photovoltaics in Vineyards. Front. Energy Res. 2022, 10, 1007383. [Google Scholar] [CrossRef]

- Hayibo, K.S.; Pearce, J.M. Optimal Inverter and Wire Selection for Solar Photovoltaic Fencing Applications. Renew. Energy Focus 2022, 42, 115–128. [Google Scholar] [CrossRef]

- Masna, S.; Morse, S.M.; Hayibo, K.S.; Pearce, J.M. The Potential for Fencing to Be Used as Low-Cost Solar Photovoltaic Racking. Sol. Energy 2023, 253, 30–46. [Google Scholar] [CrossRef]

- Hwang, K.-W.; Lee, C.-Y. Estimating the Deterministic and Stochastic Levelized Cost of the Energy of Fence-Type Agrivoltaics. Energies 2024, 17, 1932. [Google Scholar] [CrossRef]

- Imran, H.; Riaz, M.H.; Butt, N.Z. Optimization of Single-Axis Tracking of Photovoltaic Modules for Agrivoltaic Systems. In Proceedings of the 2020 47th IEEE Photovoltaic Specialists Conference (PVSC), Calgary, AB, Canada, 15 June–21 August 2020; pp. 1353–1356. [Google Scholar]

- Casares de la Torre, F.J.; Varo, M.; López-Luque, R.; Ramírez-Faz, J.; Fernández-Ahumada, L.M. Design and Analysis of a Tracking/Backtracking Strategy for PV Plants with Horizontal Trackers after Their Conversion to Agrivoltaic Plants. Renew. Energy 2022, 187, 537–550. [Google Scholar] [CrossRef]

- Campana, P.E.; Stridh, B.; Amaducci, S.; Colauzzi, M. Optimisation of Vertically Mounted Agrivoltaic Systems. J. Clean. Prod. 2021, 325, 129091. [Google Scholar] [CrossRef]

- Jamil, U.; Bonnington, A.; Pearce, J.M. The Agrivoltaic Potential of Canada. Sustainability 2023, 15, 3228. [Google Scholar] [CrossRef]

- Riaz, M.H.; Imran, H.; Younas, R.; Butt, N.Z. The Optimization of Vertical Bifacial Photovoltaic Farms for Efficient Agrivoltaic Systems. Sol. Energy 2021, 230, 1004–1012. [Google Scholar] [CrossRef]

- Hayibo, K.S.; Pearce, J.M. Vertical Free-Swinging Photovoltaic Racking Energy Modeling: A Novel Approach to Agrivoltaics. Renew. Energy 2023, 218, 119343. [Google Scholar] [CrossRef]

- Vandewetering, N.; Hayibo, K.S.; Pearce, J.M. Open-Source Vertical Swinging Wood-Based Solar Photovoltaic Racking Systems. Designs 2023, 7, 34. [Google Scholar] [CrossRef]

- Hudelson, T.; Lieth, J.H. Crop Production in Partial Shade of Solar Photovoltaic Panels on Trackers; AIP Publishing: Melville, NY, USA, 2021; Volume 2361. [Google Scholar]

- Weselek, A.; Bauerle, A.; Zikeli, S.; Lewandowski, I.; Högy, P. Effects on Crop Development, Yields and Chemical Composition of Celeriac (Apium graveolens L. Var. Rapaceum) Cultivated Underneath an Agrivoltaic System. Agronomy 2021, 11, 733. [Google Scholar] [CrossRef]

- Marrou, H.; Wery, J.; Dufour, L.; Dupraz, C. Productivity and Radiation Use Efficiency of Lettuces Grown in the Partial Shade of Photovoltaic Panels. Eur. J. Agron. 2013, 44, 54–66. [Google Scholar] [CrossRef]

- Thompson, E.P.; Bombelli, E.L.; Shubham, S.; Watson, H.; Everard, A.; D’Ardes, V.; Schievano, A.; Bocchi, S.; Zand, N.; Howe, C.J.; et al. Tinted Semi-Transparent Solar Panels Allow Concurrent Production of Crops and Electricity on the Same Cropland. Adv. Energy Mater. 2020, 10, 2001189. [Google Scholar] [CrossRef]

- Barron-Gafford, G.A.; Pavao-Zuckerman, M.A.; Minor, R.L.; Sutter, L.F.; Barnett-Moreno, I.; Blackett, D.T.; Thompson, M.; Dimond, K.; Gerlak, A.K.; Nabhan, G.P.; et al. Agrivoltaics Provide Mutual Benefits across the Food–Energy–Water Nexus in Drylands. Nat. Sustain. 2019, 2, 848–855. [Google Scholar] [CrossRef]

- Edera.digital REM Tec—La Soluzione per Il Fotovoltaico Legata All’Agricoltura. Available online: https://remtec.energy/en/agrovoltaico/installations/31-castelvetro (accessed on 14 August 2024).

- Jamil, U.; Hickey, T.; Pearce, J.M. Solar Energy Modelling and Proposed Crops for Different Types of Agrivoltaics Systems. Energy 2024, 304, 132074. [Google Scholar] [CrossRef]

- Gibb, A. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers; Addison-Wesley Professional: London, UK, 2014; ISBN 978-0-13-337390-5. [Google Scholar]

- Oberloier, S.; Pearce, J.M. General Design Procedure for Free and Open-Source Hardware for Scientific Equipment. Designs 2018, 2, 2. [Google Scholar] [CrossRef]

- Smith, T.P.; Stoddard, S.; Shankle, M.; Schultheis, J. Sweetpotato Production in the United States. In The Sweetpotato; Loebenstein, G., Thottappilly, G., Eds.; Springer: Dordrecht, The Netherlands, 2009; pp. 287–323. ISBN 978-1-4020-9475-0. [Google Scholar]

- Potatoes. Available online: https://www.rhs.org.uk/vegetables/potatoes/grow-your-own (accessed on 19 August 2024).

- Greg. How Many Potatoes per Plant (Detailed Explanation). 2022. Available online: https://homesteadcrowd.com/how-many-potatoes-per-plant/ (accessed on 19 August 2024).

- Yellow Potatoes Whole Fresh, 5lb Bag. Available online: https://www.walmart.com/ip/Yellow-Potatoes-Whole-Fresh-5lb-Bag/184310759 (accessed on 19 June 2024).

- Pearce, J.M. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs; Elsevier: Amsterdam, The Netherlands, 2013; ISBN 978-0-12-410486-0. [Google Scholar]

- Chagas, A.M. Haves and Have Nots Must Find a Better Way: The Case for Open Scientific Hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Equitable Research Capacity towards the Sustainable Development Goals: The Case for Open Science Hardware. Available online: https://www.sciencepolicyjournal.org/article_1038126_jspg210202.html (accessed on 23 July 2024).

- Pearce, J.M. The Case for Open Source Appropriate Technology. Environ. Dev. Sustain. 2012, 14, 425–431. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap—The Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper: Maximizing Customizability by Breeding the Means of Production. In Handbook of Research in Mass Customization and Personalization; World Scientific Publishing Company: Singapore, 2009; pp. 568–580. ISBN 978-981-4280-25-9. [Google Scholar]

- PrusaSlicer|Original Prusa 3D Printers Directly from Josef Prusa. Available online: https://www.prusa3d.com/page/prusaslicer_424/ (accessed on 29 May 2024).

- Prusament PETG Jet Black 1kg|Original Prusa 3D Printers Directly from Josef Prusa. Available online: https://www.prusa3d.com/product/prusament-petg-jet-black-1kg/ (accessed on 29 May 2024).

- Pearce, J.M. Economic Savings for Scientific Free and Open Source Technology: A Review. HardwareX 2020, 8, e00139. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J.; Qian, J.-Y. Economic Impact of DIY Home Manufacturing of Consumer Products with Low-Cost 3D Printing from Free and Open Source Designs. Eur. J. Soc. Impact Circ. Econ. 2022, 3, 1–24. [Google Scholar] [CrossRef]

- Petersen, E.E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Woods WiOn 50050 Indoor Wi-Fi Outlet, Wireless Switch, Programmable Timer: Amazon.ca: Tools & Home Improvement. Available online: https://www.amazon.ca/Woods-50050-Indoor-Wireless-Programmable/dp/B00ZYLRQNE?th=1 (accessed on 23 August 2024).

- Goap, A.; Sharma, D.; Shukla, A.K.; Rama Krishna, C. An IoT Based Smart Irrigation Management System Using Machine Learning and Open Source Technologies. Comput. Electron. Agric. 2018, 155, 41–49. [Google Scholar] [CrossRef]

- Simionesei, L.; Ramos, T.B.; Palma, J.; Oliveira, A.R.; Neves, R. IrrigaSys: A Web-Based Irrigation Decision Support System Based on Open Source Data and Technology. Comput. Electron. Agric. 2020, 178, 105822. [Google Scholar] [CrossRef]

- Puig, F.; Rodríguez Díaz, J.A.; Soriano, M.A. Development of a Low-Cost Open-Source Platform for Smart Irrigation Systems. Agronomy 2022, 12, 2909. [Google Scholar] [CrossRef]

- Hogewoning, S.W.; Trouwborst, G.; Maljaars, H.; Poorter, H.; van Ieperen, W.; Harbinson, J. Blue Light Dose–Responses of Leaf Photosynthesis, Morphology, and Chemical Composition of Cucumis Sativus Grown under Different Combinations of Red and Blue Light. J. Exp. Bot. 2010, 61, 3107–3117. [Google Scholar] [CrossRef]

- Okamoto, K.; Yanagi, T.; Kondo, S. Growth and morphogenesis of lettuce seedlings raised under different combinations of red and blue light. Acta Hortic. 1997, 435, 149–158. [Google Scholar] [CrossRef]

- Chan, A.M.H.; Pay, M.L.; Christensen, J.; He, F.; Roden, L.C.; Ahmed, H.; Foo, M. Red, Blue or Mix: Choice of Optimal Light Qualities for Enhanced Plant Growth and Development through in Silico Analysis. Silico Plants 2024, 6, diae008. [Google Scholar] [CrossRef]

- Stark, W. The Importance of Canopy Ventilation in Controlled Environment Agriculture. In Proceedings of the 2024 ASABE Annual International Meeting. American Society of Agricultural and Biological Engineers, Omaha, Nebraska, USA, 9–12 July 2023. [Google Scholar]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design Challenges of Agricultural Greenhouses in Hot and Arid Environments. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Ruppel, S. Houseplants and the Invention of Indoor Gardening. In The Routledge History of the Domestic Sphere in Europe; Routledge: London, UK, 2020; ISBN 978-0-429-03158-8. [Google Scholar]

- He, J. Enhancing Productivity and Improving Nutritional Quality of Subtropical and Temperate Leafy Vegetables in Tropical Greenhouses and Indoor Farming Systems. Horticulturae 2024, 10, 306. [Google Scholar] [CrossRef]

- Indoor Hydroponic Gardening Systems|AeroGarden. Available online: https://aerogarden.com/gardens/all-gardens (accessed on 21 August 2024).

- The Smart Garden 9. Available online: https://ca.clickandgrow.com/products/the-smart-garden-9 (accessed on 21 August 2024).

- Hydroponic Garden for Home|Indoor Garden by Rise Gardens. Available online: https://ca.risegardens.com/ (accessed on 21 August 2024).

- Kanno, K.; Mae, T.; Makino, A. High Night Temperature Stimulates Photosynthesis, Biomass Production and Growth during the Vegetative Stage of Rice Plants. Soil Sci. Plant Nutr. 2009, 55, 124–131. [Google Scholar] [CrossRef]

- Venkatramanan, V.; Singh, S.D. Differential effects of day and night temperatures on growth of wheat crop. Ann. Agric. Res. 2009, 38, 449–454. [Google Scholar]

- Tanikella, N.G.; Wittbrodt, B.; Pearce, J.M. Tensile Strength of Commercial Polymer Materials for Fused Filament Fabrication 3D Printing. Addit. Manuf. 2017, 15, 40–47. [Google Scholar] [CrossRef]

- Botero-Valencia, J.S.; Mejia-Herrera, M.; Pearce, J.M. Design and Implementation of 3-D Printed Radiation Shields for Environmental Sensors. HardwareX 2022, 11, e00267. [Google Scholar] [CrossRef]

- Whitcomb, C.E. Plant Production in Containers II; Lacebark, Inc.: Stillwater, OK, USA, 2003; ISBN 978-0-9613109-6-7. [Google Scholar]

| Print Settings | |||

|---|---|---|---|

| Layer height | Layer height | 0.4 mm | |

| First layer height | 0.3 mm | ||

| Vertical shells | Perimeters | 2 | |

| Horizontal shells | Solid layers | Top | 4 |

| Bottom | 3 | ||

| Minimum shell thickness | Top | 1.2 mm | |

| Bottom | 0.8 mm | ||

| Infill | Infill pattern | Rectilinear | |

| Infill percentage | 100% | ||

| Top fill pattern | Monotonic lines | ||

| Bottom fill pattern | Monotonic | ||

| Skirt and brim | Skirt distance | 3 mm | |

| Brim type | Outer brim only | ||

| Brim width | 0 mm | ||

| Temperature [PETG] | Nozzle (0.6 mm) | 240 °C | |

| Bed | 85 °C | ||

| Fan | Automatic | ||

| Travel lift height | 0.2 mm | ||

| Retraction length | 1 mm | ||

| Max volumetric speed | 15 mm3/s | ||

| Inverted T | Boxed Rectangle | Single Water Reservoir | PVC | Commercial Metal | |

|---|---|---|---|---|---|

| BOM cost [CAD] | CAD 201.74 | CAD 331.14 | CAD 379.46 | CAD 293.64 | CAD 4500.00 |

| Grow volume [L] | Up to 192 | Up to 128 | Up to 106 | Up to 128 | Up to 110 |

| Water reservoir volume [L] | Up to 192 | Up to 128 | Up to 64 | Up to 128 | Up to 62 |

| Growing surface area [m2] | 0.76 | 0.51 | 0.60 | 0.51 | 0.50 |

| Cost per surface area [CAD/m2] | 265.45 | 649.29 | 632.43 | 575.76 | 9000.00 |

| Percent savings of cost per surface area [%] | 97 | 93 | 93 | 94 | NA |

| Assembly difficulty | Low | Low | Medium | Low | High |

| Rigidity | Low | Medium | Medium High | Low | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, J.-Y.; Pearce, J.M. Open-Source Indoor Horizontal Grow Structure Designs. Designs 2024, 8, 95. https://doi.org/10.3390/designs8050095

Qian J-Y, Pearce JM. Open-Source Indoor Horizontal Grow Structure Designs. Designs. 2024; 8(5):95. https://doi.org/10.3390/designs8050095

Chicago/Turabian StyleQian, Jun-Yu, and Joshua M. Pearce. 2024. "Open-Source Indoor Horizontal Grow Structure Designs" Designs 8, no. 5: 95. https://doi.org/10.3390/designs8050095

APA StyleQian, J.-Y., & Pearce, J. M. (2024). Open-Source Indoor Horizontal Grow Structure Designs. Designs, 8(5), 95. https://doi.org/10.3390/designs8050095