Catastrophic Failure Analysis of a Wind Turbine Gearbox by the Finite Element Method and Fracture Analysis

Abstract

1. Introduction

2. Materials and Methods

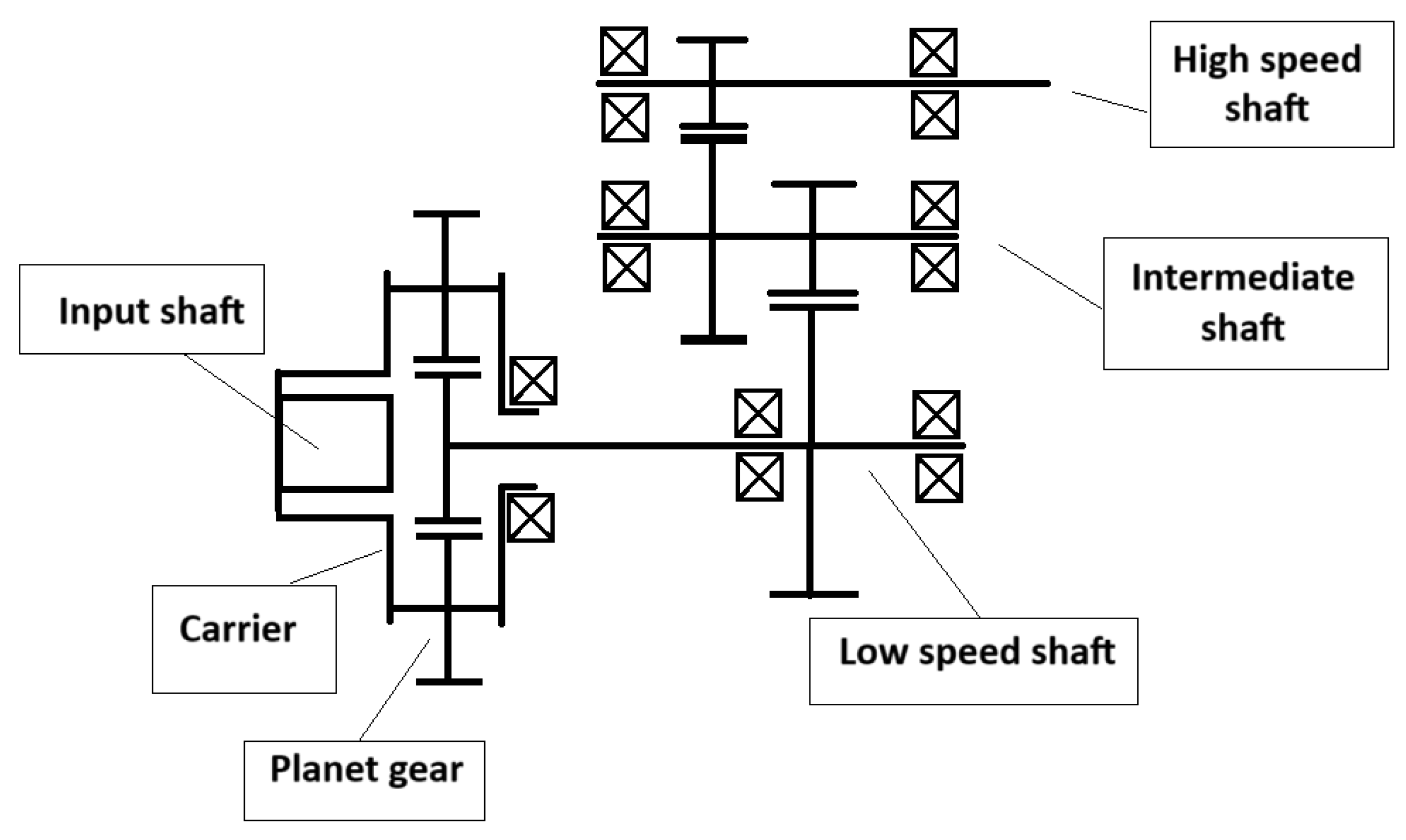

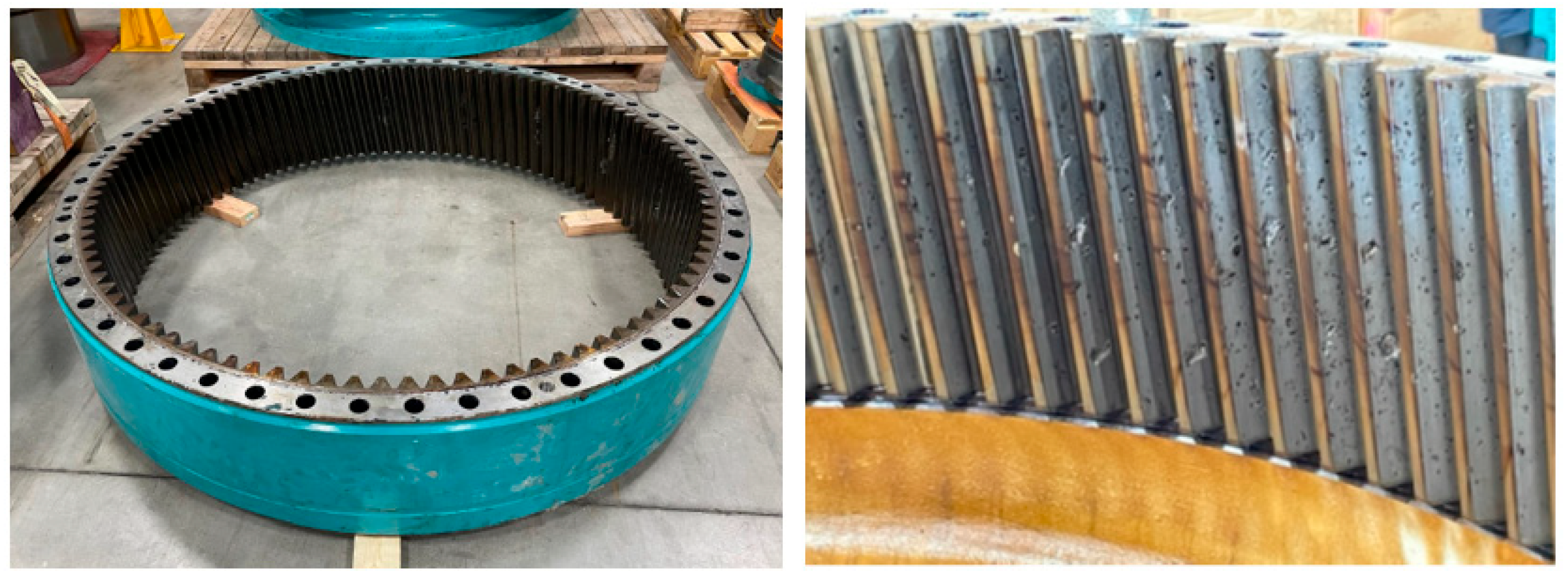

2.1. Gearbox Anatomy

2.2. Power and Analysis of the Torque at the Planet Stage

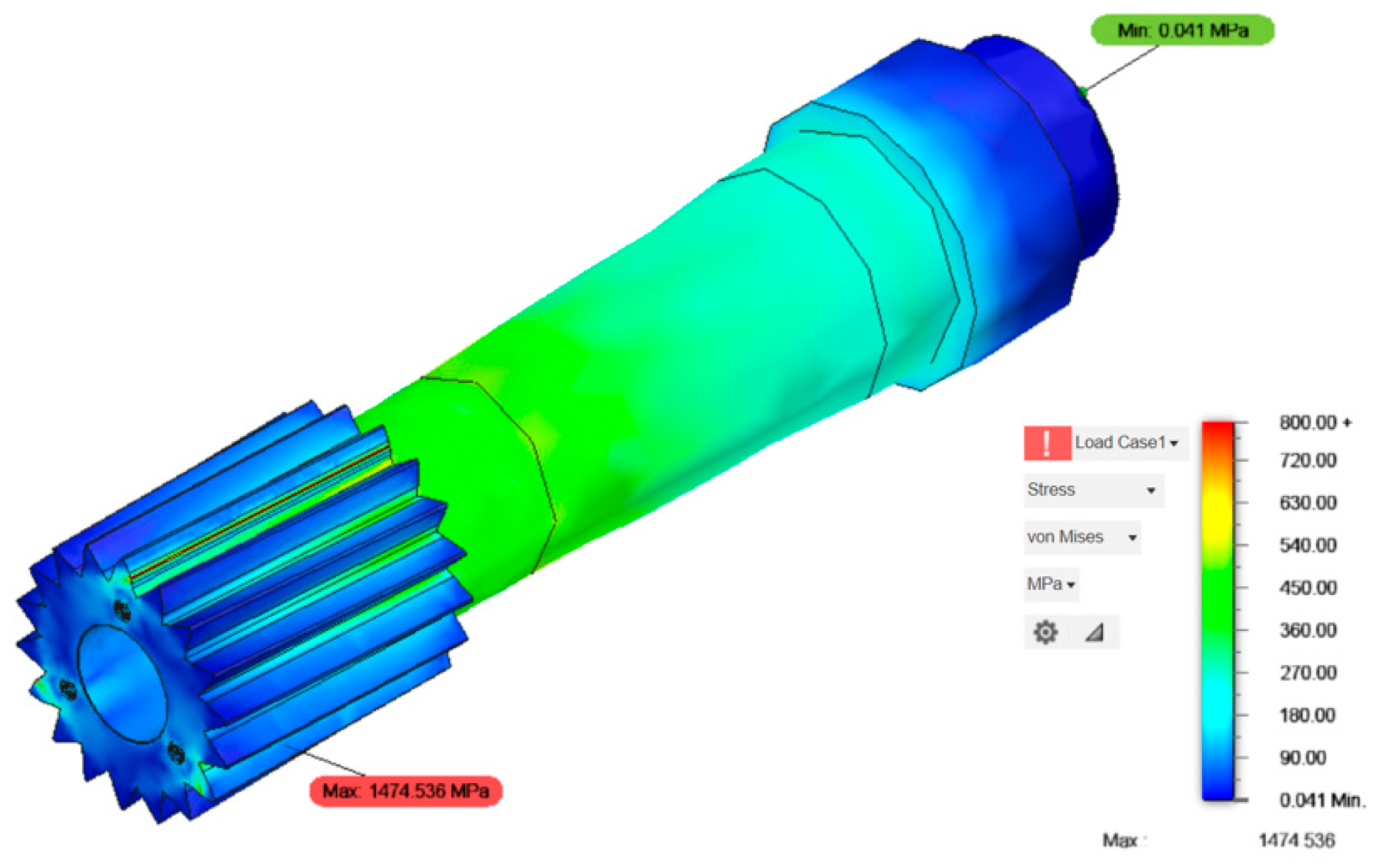

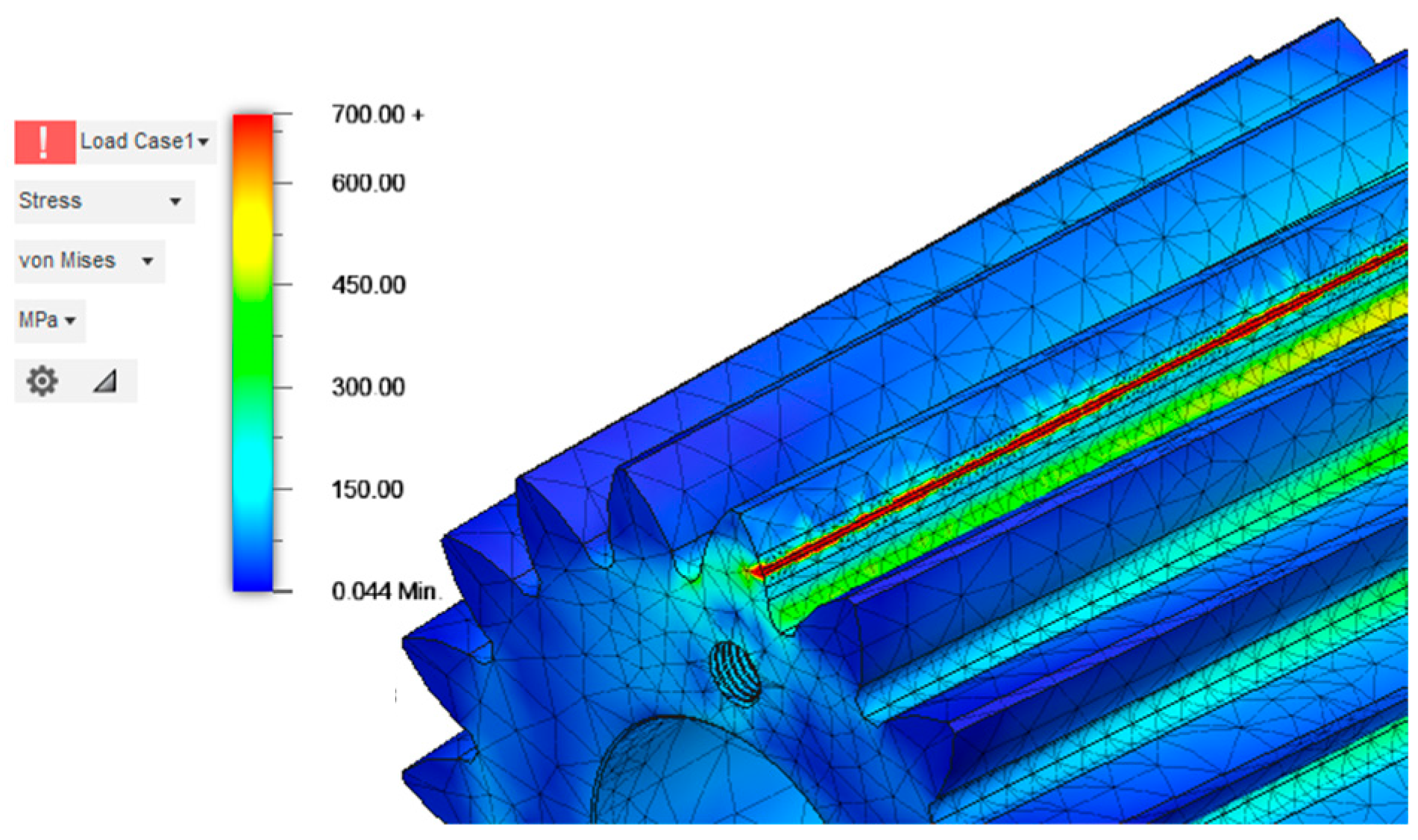

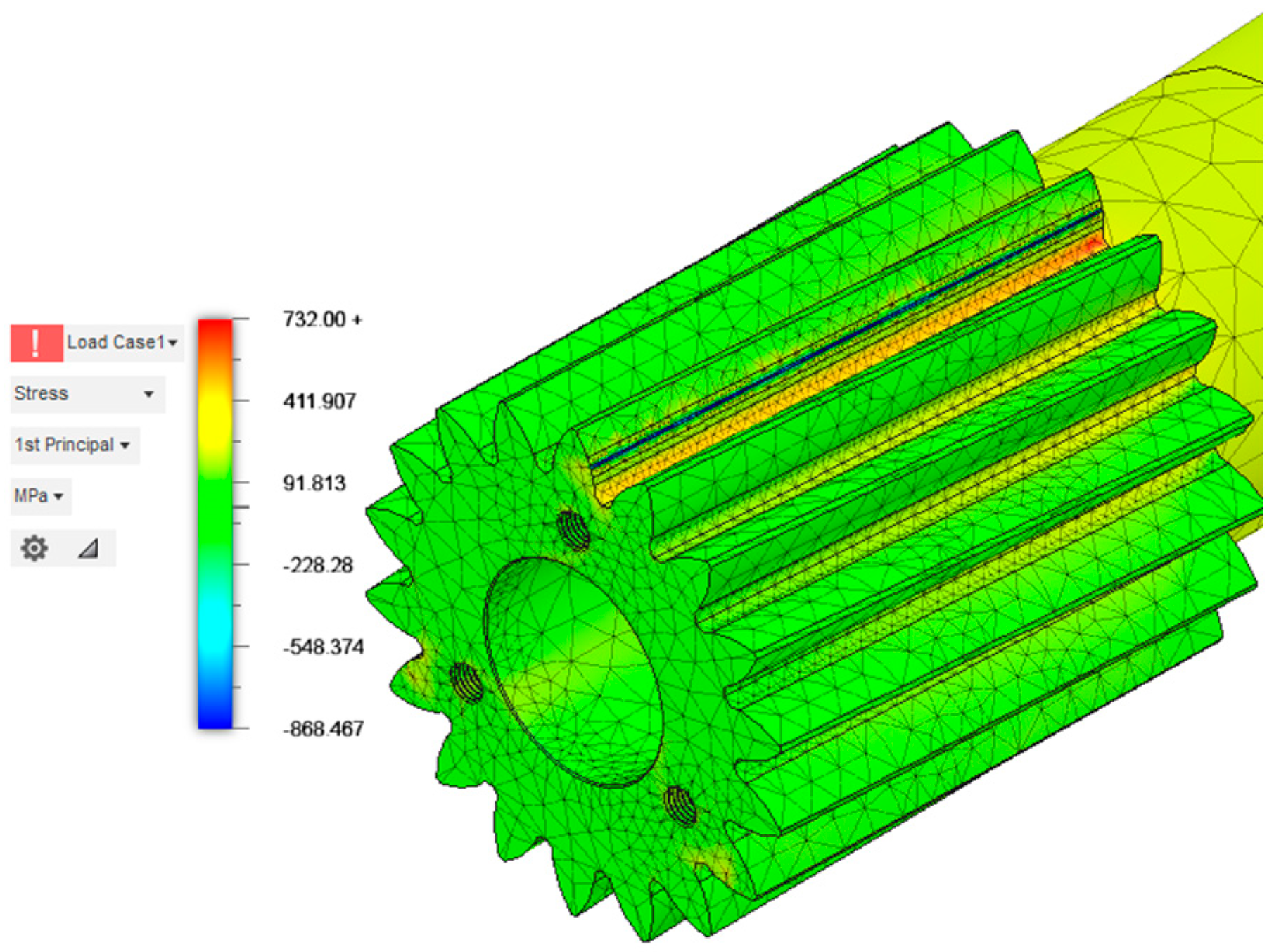

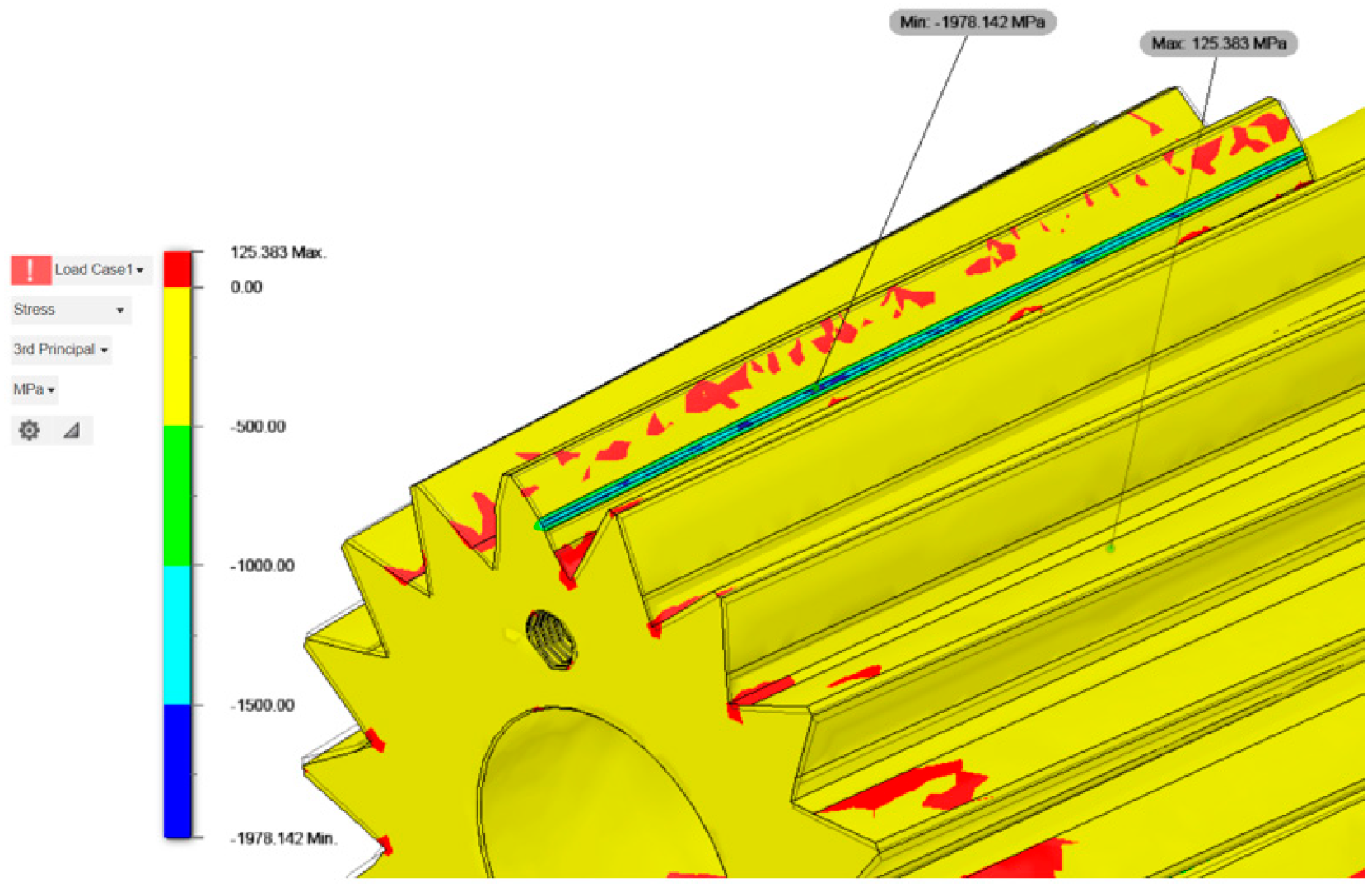

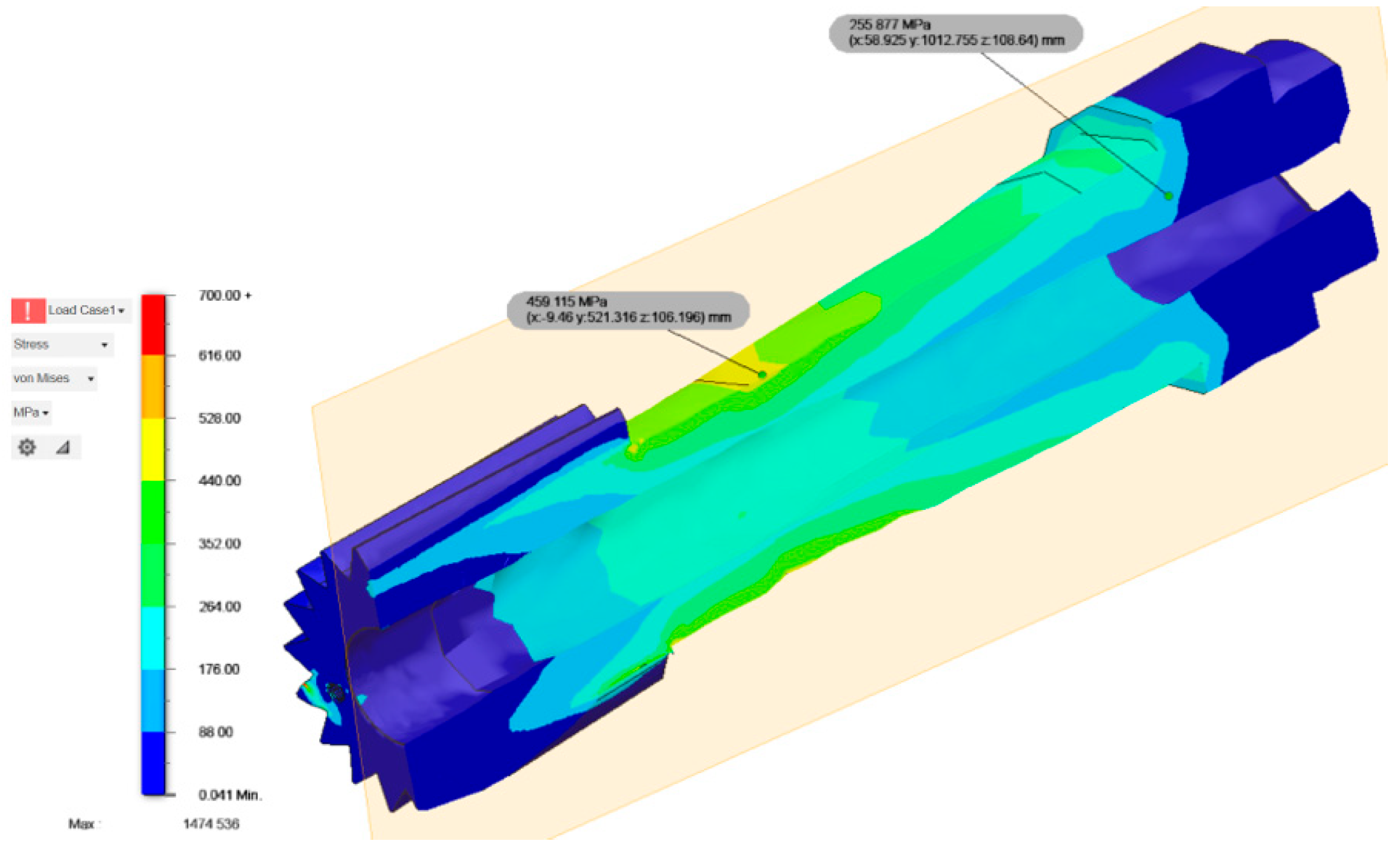

2.3. Numerical Simulation (Finite Element Method) and Hertz Contact

2.4. Torque at the Planetary Stage

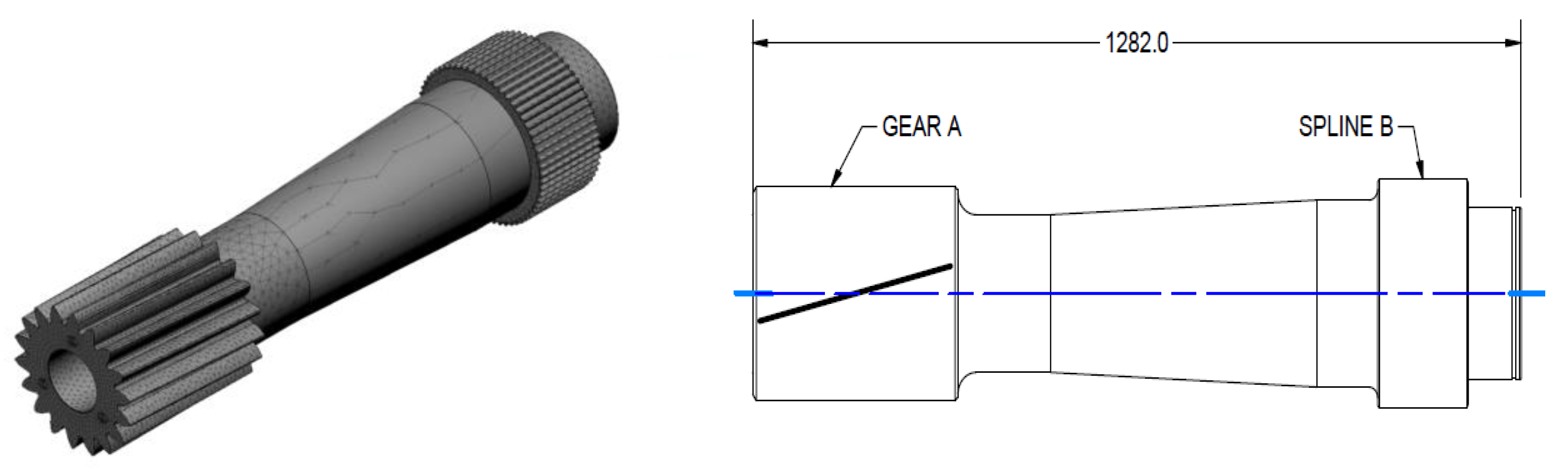

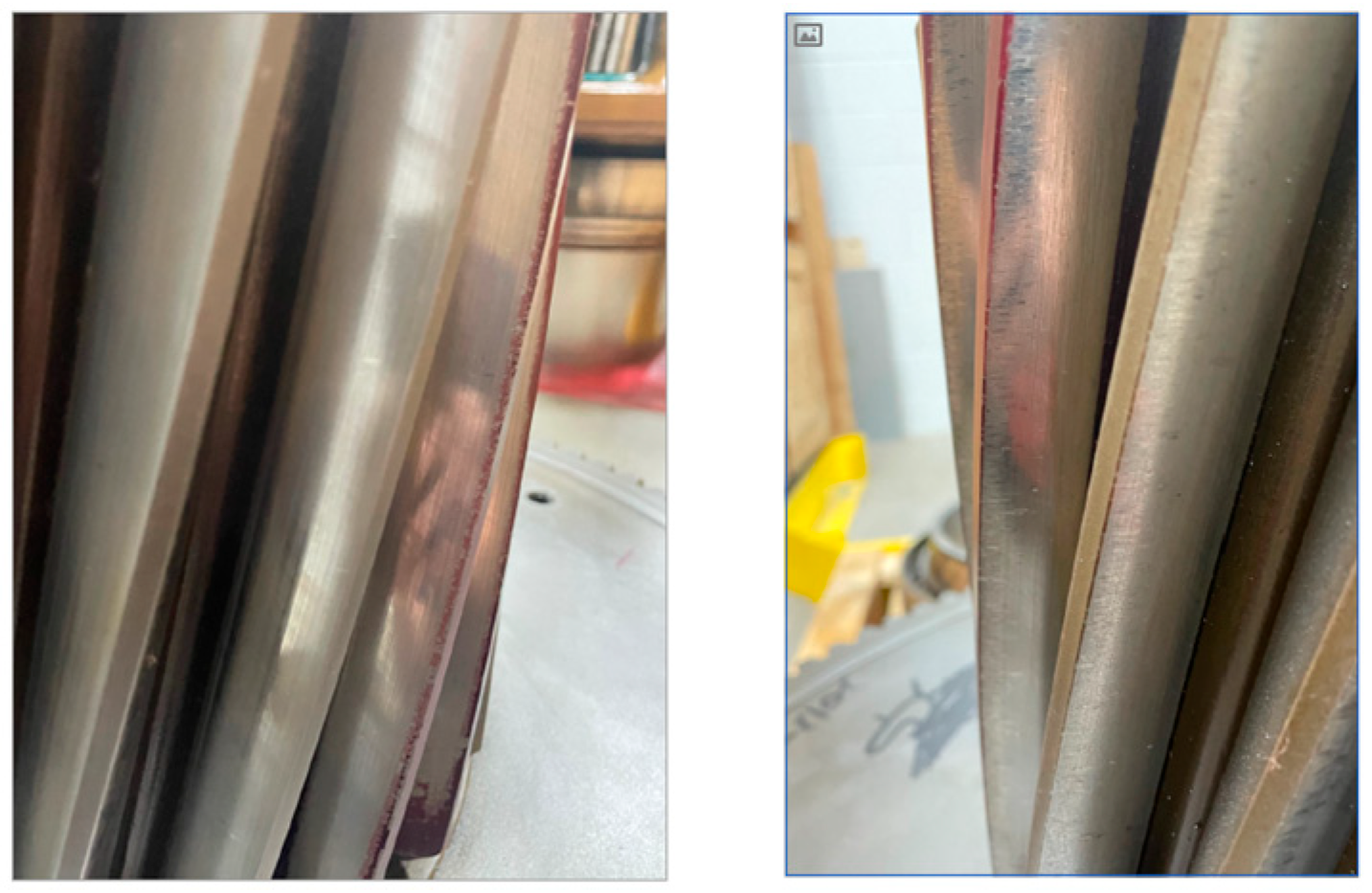

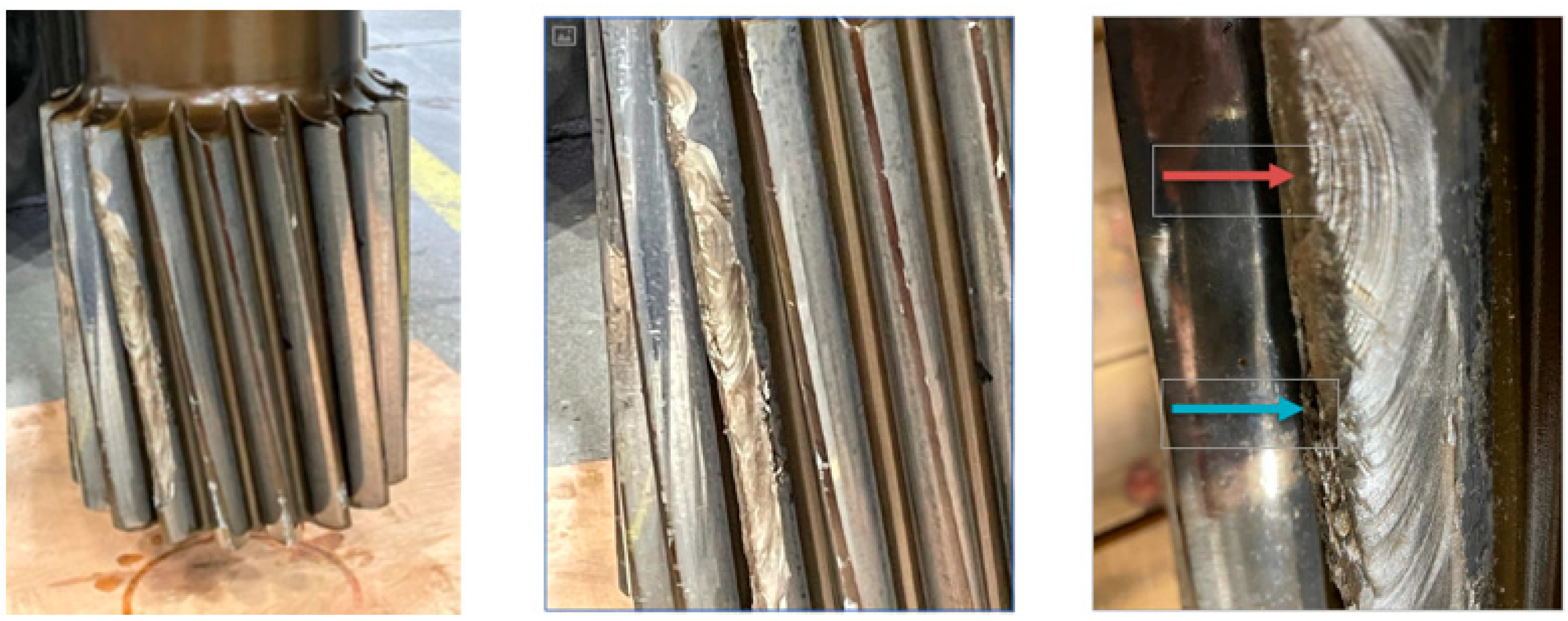

2.5. Investigation of the Main Components of the Gearbox

3. Results and Remarks

3.1. Torque at the Planetary Stage and Numerical Simulation (FEA)

3.2. Peripherical Components

3.3. Shafts, Gears, and Bearings

4. Conclusions

5. Recommendations

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lauha Fried, S.S. Chapter 26—Growth Trends and the Future of Wind Energy. In Wind Energy Engineering; Academic Press: Cambridge, MA, USA, 2017; pp. 559–586. [Google Scholar]

- Akhmedovich, M.A.; Fazliddin, A. Current State of Wind Power Industry. Am. J. Eng. Technol. 2020, 32–36. [Google Scholar] [CrossRef]

- Balat, M. A Review of Modern Wind Turbine Technology. Energy Sources Part A Recover. Util. Environ. Eff. 2009, 31, 1561–1572. [Google Scholar] [CrossRef]

- Şahin, A.D. Progress and recent trends in wind energy. Prog. Energy Combust. Sci. 2004, 30, 501–543. [Google Scholar] [CrossRef]

- Grogg, K. Harvesting the Wind: The Physics of Wind Turbines. Physics and Astronomy Comps Papers. 2005. Available online: https://www.semanticscholar.org/paper/Harvesting-the-Wind%3A-The-Physics-of-Wind-Turbines-Grogg/222b04606e2c401b64eb67b53f86293848e0606d (accessed on 19 November 2024).

- Jayathilake, K.G.; Wijetunga, P.G. Design of Wind Turbine. Semester Project; Faculty of Engineering and Science, University of Agder: Kristiansand City, Norway, 2015. [Google Scholar]

- Sankar, S.; Nataraj, M.; Prabhu Raja, V. Failure Analysis of Bearing in Wind Turbine Generator Gearbox. J. Inf. Syst. Commun. 2012, 3, 302–309. [Google Scholar]

- Bruce, T. Analysis of the Premature Failure of Wind Turbine Gearbox Bearings; University of Sheffield: Sheffield, UK, 2016. [Google Scholar]

- Evans, M.-H. An updated review: White etching cracks (WECs) and axial cracks in wind turbine gearbox bearings. Mater. Sci. Technol. 2016, 32, 1133–1169. [Google Scholar] [CrossRef]

- Singh, D.K.; Kurien, J.; Villayamore, A. Study and analysis of wind turbine gearbox lubrication failure and its mitigation process. Mater. Today: Proc. 2020, 44, 3976–3983. [Google Scholar] [CrossRef]

- Rajinikanth, V.; Soni, M.K.; Mahato, B.; Rao, M.A. Microstructural investigation of rolling contact fatigue (RCF) on a failed planetary gear of a windmill gearbox. Eng. Fail. Anal. 2020, 121, 105167. [Google Scholar] [CrossRef]

- Wang, Q.; Zhu, Y.; Zhang, Z.; Fu, C.; Dong, C.; Su, H. Partial Load: A Key Factor Resulting in the Failure of Gear in the Wind Turbine Gearbox. J. Fail. Anal. Prev. 2015, 16, 109–122. [Google Scholar] [CrossRef]

- Bai, H.; Zhu, C.; Zhou, Y.; Chen, X.; Feng, H.; Ye, W. Study on Tooth Interior Fatigue Fracture Failure of Wind Turbine Gears. Metals 2020, 10, 1497. [Google Scholar] [CrossRef]

- Chen, D.; Hu, M.; Ye, J.; Gao, X.; Lin, Q.; Zhou, Q.; Zhao, D.; Wu, M. Failure analysis of planetary gear in wind turbine gearbox. IET Conf. Proc. 2023, 2023, 217–224. [Google Scholar] [CrossRef]

- Wang, C. Study on dynamic performance and optimal design for differential gear train in wind turbine gearbox. Renew. Energy 2023, 221, 119776. [Google Scholar] [CrossRef]

- Qiao, Z.; Chen, K.; Zhou, C.; Ma, H. An improved fault model of wind turbine gear drive under multi-stage cracks. Simul. Model. Pract. Theory 2022, 122, 102679. [Google Scholar] [CrossRef]

- Paik, C.; Chung, Y.; Kim, Y.J. Power Curve Modeling of Wind Turbines through Clustering-Based Outlier Elimination. Appl. Syst. Innov. 2023, 6, 41. [Google Scholar] [CrossRef]

- Vaz, J.R.; Wood, D.H. Performance analysis of wind turbines at low tip-speed ratio using the Betz-Goldstein model. Energy Convers. Manag. 2016, 126, 662–672. [Google Scholar] [CrossRef]

- Shigley, J.E.; Mitchell, L.D.; Saunders, H. Mechanical Engineering Design (4th Ed.). J. Mech. Des. 1985, 107, 145. [Google Scholar] [CrossRef]

- Tazi, N.; Chatelet, E.; Bouzidi, Y. Wear Analysis of Wind Turbine Bearings. Int. J. Renew. Energy Res. 2017, 7, 2120–2129. [Google Scholar]

- Provenza, F. Projetista de Máquinas; Provenza: São Paulo, Brazil, 1996. (In Portuguese) [Google Scholar]

- ANSYS. Fluent Users’ Guide—Ansys 2024 (R2). Available online: https://ansyshelp.ansys.com/public/Views/Secured/corp/v242/en/flu_ug/flu_ug.html (accessed on 20 December 2024).

- Verma, G. Autodesk Fusion 360, 2nd ed.; Cadcamcae Works: Eastman, GA, USA, 2018. [Google Scholar]

- Sarin, V.K. Comprehensive Hard Materials; College of Engineering, Boston University: Boston, MA, USA, 2014; ISBN 978-0-08-096528-4. [Google Scholar]

- Errichello, R.; Milburn, A. Optimum Carburized and Hardened Case Depth; American Gear Manufacturer Association: Alexandria, VA, USA, 2020. [Google Scholar]

- Parrish, G. Carburizing Microstructure and Properties; ASM International: Almere, The Netherlands, 1999. [Google Scholar]

- AGMA. Appearance of Gear Teeth—Terminology of Wear and Failure, AINSI/AGMA 1010-F14. 2014. Available online: https://members.agma.org/MyAGMA/MyAGMA/Store/Item_Detail.aspx?iProductCode=1010_F14&Category=STANDARDS (accessed on 18 October 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, J.A.; Romão, E.C. Catastrophic Failure Analysis of a Wind Turbine Gearbox by the Finite Element Method and Fracture Analysis. Designs 2025, 9, 4. https://doi.org/10.3390/designs9010004

Martins JA, Romão EC. Catastrophic Failure Analysis of a Wind Turbine Gearbox by the Finite Element Method and Fracture Analysis. Designs. 2025; 9(1):4. https://doi.org/10.3390/designs9010004

Chicago/Turabian StyleMartins, Jairo Aparecido, and Estaner Claro Romão. 2025. "Catastrophic Failure Analysis of a Wind Turbine Gearbox by the Finite Element Method and Fracture Analysis" Designs 9, no. 1: 4. https://doi.org/10.3390/designs9010004

APA StyleMartins, J. A., & Romão, E. C. (2025). Catastrophic Failure Analysis of a Wind Turbine Gearbox by the Finite Element Method and Fracture Analysis. Designs, 9(1), 4. https://doi.org/10.3390/designs9010004