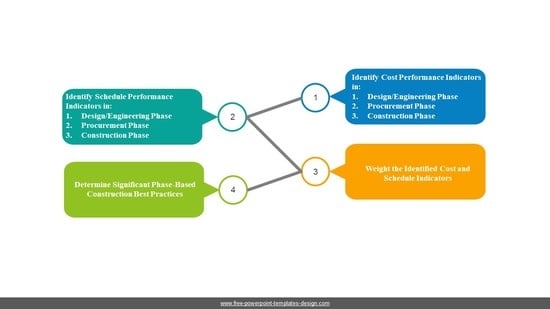

6.1. Identification of Phase-Based KPIs

The typical magnitude of delay and cost overrun in construction projects is between 5–10% of contract duration and price of the project [

46,

47]. To be conservative, we decided to classify our results into two separate groups: (1) Projects with effective performance having overrun/underrun less than 10% and (2) Projects with poor performance experiencing more than 10% deviation from the cost and schedule baseline.

The results of statistical analysis (p-values) between each KPI and construction cost and schedule performance in the engineering phase were shown in

Table 3. Each KPI has been coded with two letters, expressing the first letters of phase name (e.g., EP.1; Engineering Performance). The data analysis demonstrates that there is a significant relationship between “Change order driven by the owner”, “Communication between the design team”, “Slowness in decision making”, and engineering schedule performance, having a P-value of less than 0.05. Sometimes, due to complicated and unforeseen situations in construction, owners or engineers prefer to take a short break in order to perform the best course of action. Although this delay in decision-making may result in cost saving or quality enhancement, it can negatively affect the schedule performance of construction. Besides, since construction is among one of the information dependent industries, a lack of communication between different construction entities causes inefficient information exchange, and therefore trust and accountability decrease. Ineffective communication also creates an atmosphere that brings disagreement and conflicts, as construction participants cannot be aligned well. Subsequently, construction projects lead to having poor performance.

Further analysis revealed that “Difficulty in obtaining design approval” and “Low labor/staff productivity” are also significant within the 0.1 acceptance level in predicting engineering phase schedule performance. Most of the time multiple permits are required to start a project. Due to the submission of an application and required documents for each permit, the approval process is considered as a time-consuming one. In addition, the loss of labor productivity forces responsible entity to do the same amount of work with equal resources in a longer time. On the other hand, a statistically significant relationship was found between “Consultant & Client experience”, “Lack of frequency of reporting”, and engineering cost performance with P-values of 0.040 and 0.017, respectively. This relationship is also perceived between “Change order driven by the owner”, “Financial stability of client”, and engineering cost performance, within the 0.1 acceptance level. It is interesting to note that three of these four significant KPIs were classified in “Client & Consultant” group, indicating the decisive role of these two entities in the cost performance of the engineering phase. Moreover, a curious fact is that “Change order driven by owner” is the only indicator that can significantly affect both the schedule and cost performance of the engineering phase with the p-value of “0.001” and “0.051”, respectively. This could be described as the immense importance of design changes on the performance of the engineering phase; it can cause additional work that requires enough efforts and resources to be completed. Due to the nature of construction, changes in this industry are inevitable. Most of the time major changes require engineers to revise the drawings and send them for approval process again. Subsequently, the project management team should also devote more time to reschedule the project and update the client with the new estimation. Therefore, any change order to construction can deviate construction performance from the baseline schedule and the cost of the project.

Table 4 specifies the relationship between KPIs and construction performance in the procurement phase. According to this table, “Material quality”, “Material shortage”, “Transportation delays”, “Imported labor”, and “Slowness in decision making” were statistically proven to potentially affect the schedule of procurement phase. Among these indicators, “Material quality” and “Imported labor” were significant with a 95% confidence level. Particularly, if the quality of the material is not up to the standards, then it should be replaced or reordered, which takes time and causes delay. Moreover, due to the labor shortage in some areas, the construction industry is forced to employ imported labors, which may not be as productive as local labors. Even the hiring process of imported labor can take the time or their adoption to the new environment could be a challenge. Therefore, utilizing imported labor may impose many obstacles on the time and cost performance of projects.

Reviewing the defined group of KPIs indicates that material-related indicators have the largest portion among the significant schedule performance indicators in the procurement phase, with three significant indicators. On the other hand, equipment-related indicators comprising “Equipment shortage”, “Imported equipment”, and “Equipment quality” significantly affect the cost performance of the procurement phase. For instance, the price of equipment increases because of the bloom in the economic condition of the developing country and the number of qualified available equipment decreases. As a result, those rental-based contractors are obliged to utilize below-standard equipment and pay rent for more days to complete equipment-based activities [

35,

40]. It may be worth mentioning that “Imported labor” and “Slowness in decision making” are the only common KPIs between the two groups, which can lead a project to experience both delay and cost overrun. Due to a higher order of qualified resources, demand may exceed supply, and because of unavailability of resources, suppliers do not offer them for a long time. Therefore, even little delay in decision making for providing resources may impose severe implications to the project goals and cause delay and cost overrun.

Table 5 illustrates the relationship between potential KPIs and construction performance in the construction phase. As it is shown, since this phase includes most construction processes, it has a greater number of KPIs affecting construction schedule/cost performance when compared to that of other EPC phases. In the meanwhile, it is realized that 11 KPIs significantly influence the time completion of the construction phase. Having eight indicators (out of 11) in “Management” and “Client & Consultant” groups indicates the significance of these two groups and their KPIs on the construction performance. One of the most crucial general indicators is the lack of communication between different entities, which itself includes three significant indicators in

Table 5: “Lack of communication between prime contractor organizations”, “Lack of communication between designer & contractor”, and “Lack of communication between client & contractor”. The “Management” group also has the largest portion of the significant KPIs in the list of construction phase cost Performance Indicators, with four indicators. This might bring to mind that a substantial portion of time and cost overrun in the construction phase can be addressed if construction practitioners apply effective managerial skills during the construction phase.

Table 5 reveals that there are eight significant KPIs deviating projects from both the proposed schedule and cost in the execution stage. However, solely three of them are statistically significant, with a 95% confidence level in predicting both schedule and cost performance. These three KPIs are “Change order driven by the owner”, “Slowness in decision making”, and “Rework driven by the contractor”. Mostly rework is prompted by poor workmanship, or accident at the site and change order results from the owner’s change requirements in which are based on the condition. Each of these changes can be claimed as extra work that requires extra time and cost to be spent [

48]. According to

Table 5, contractor’s experience was statistically found to have a significant impact in completing the project on time with budgeted cost. The p-value for schedule and cost performance is 0.088 and 0.007, respectively. The contractor might face a vast range of difficulties during the construction process owing to the complex nature of the construction project. Inadequate contractor experience creates more difficulties taking longer period to be addressed, or a contractor might undertake risky actions for solving the problems.

6.2. Prioritization of Phase-Based KPIs

The results of all KPIs in different EPC phases were categorized into two different groups of effective and poor performance projects. Since the impact of each significant KPIs are different on the construction performance, a statistical effect size method was utilized to weigh the impact size of each indicator.

Table 6 shows that “Communication between design team” occupies the first position with 33% effect size on engineering phase schedule performance. It is followed by “Slowness in decision making” and “Change order driven by owner”, with 26% and 18% effect sizes, respectively. Moreover, the cost performance of engineering phase is mostly affected by the “Consultant & Client experience” and “Change order driven by the owner”, the former with 44% and the later with 40% effect size in determining the cost performance behavior. It is obvious that “Change order driven by owner” is the most significant KPIs in the engineering phase, as it is listed among the top three most significant KPIs of both the schedule and cost performance groups. Since this change order includes any modifications, additions or omissions to the scope of the work can significantly impose major changes on the construction performance and lead project to encounter major time and cost overruns.

According to

Table 6, “Slowness in decision making” has the highest impact on schedule performance of procurement phase and it is ranked as the first among the list of key schedule Performance Indicators, with 40% effect size. On the other side, “Equipment shortage” and “Imported equipment” are the primary causes of cost overrun in the procurement phase, with more than 30% effect size for each. However, the importance of “Imported labor” should not be neglected, as it was ranked third in both the schedule and cost list, with 17% and 29% effect size, respectively.

Due to participating of many entities in the construction phase, there are more indicators that can affect the construction performance of this phase. In the meantime, the lack of communication and information flow between these entities is one of the most important causes, which negatively impact the performance of the construction project and cause delay. As it is shown in

Table 6, “lack of communication between prime contractor organizations” is ranked first in the schedule list, with a 22% size effect. Moreover, “Lack of communication between designers and contractors” is also concluded that can significantly affect construction schedule and cost performance. This indicator, along with “Consultant & Client experience” and “Contractor experience”, are rated as the second most influential indicators postponing construction phase. Reviewing the list of cost Performance Indicators in

Table 6, “Contractor experience” and “Construction site layout problem” took the first and second positions, respectively, with a comparatively small difference. The first one occupies 18%, and the later one has 16% effect size on the cost performance of the construction phase. Interestingly, “Contractor experience” and “Lack of communication between designers and contractors” are the most important KPIs in the construction phase, since they are commonly in the top three ranking of both lists of cost and schedule Performance Indicators.

Table 7 illustrates the total effect size of each category in different EPC phases regarding the cost and schedule performance. As it is shown in this table, the “management” category has the largest effect size in almost all six combinations, except in the cost performance of the engineering and procurement phases. In the meantime, not only is there a zero effect size of management category on cost performance of the engineering phase, but it also has minimal effect size on the cost performance of the procurement phase. The existence of managerial indicators in almost all phases reveals that construction management should be implemented from scratch to the substantial completion of the construction phase in order to save construction professionals enough money and time.

According to

Table 7, “Client & Consultant” occupies a dominant role in the cost performance of the engineering phase, as it has 60% of total weight percent. In addition, the important role of the “Change” category in deviating schedule and cost performance should not be neglected, as it can affect the schedule and the cost performance of both the engineering and construction phases. The “Change” category impacts the cost performance of the engineering phase with the accumulated weight of 40%. Regarding the Procurement phase, as it is expected that resources groups have the highest weight percentage. In the meanwhile, “Material” and “Equipment” categories have more impact in comparison with that of other groups in the schedule and cost performance of the procurement phase, respectively. “Material” holds 43% of total weight percentage of schedule performance, followed by “Management” and “Labor” in the order that is mentioned in procurement performance. Furthermore, due to 64% effect of “Equipment” on the cost performance of the procurement phase, the responsible entity should adopt policies to minimize equipment-related issues and save money. Concerning the construction phase, it should be noted that “Management” places the first position in both schedule and cost performance of the construction phases, with 47% and 40% of total percentage weight. It is followed by “Client & Consultant” and “Contractor”, respectively, in the schedule list, with each of them having approximately one-fifth of total percentage weight.

6.3. Determine Significant Phase-Based Construction BPs

This study concentrates on the implementation of thirteen CII Best Practices, which helps construction projects to have better performance regarding their cost and schedule [

1]. These BPs consist of Constructability, Team Building, Alignment, Partnering, Front End Planning, Change Management, Material Management, Zero Accident Techniques (i.e., Safety), Planning for Start-Up, Dispute Prevention, and Resolution, Quality Management, Lessons Learned, and Project Risk Assessment. As previously mentioned, a question was designed for each BP by a seven-point Likert-scale and was provided in the survey. It should be noted that those BPs that were not applicable to a specific phase were excluded from the analysis. As a result of statistical data analysis, significant BPs improving the performance of each stage of the construction process were found and are presented in

Table 8. “Material Management” and “Planning for Start-Up” were excluded from the engineering phase, as they are related to the material and equipment that are used in the construction and procurement phases. “Zero Accident Techniques” is also not applicable to the engineering phase, since it is associated to the site safety program and project environment.

According to

Table 8, it is found that all BPs, except “Planning for Start-Up”, have a significant effect on the schedule performance of the construction phase. A few BPs were found to statistically impact the engineering and procurement phases when compared to the construction phase. Regarding the engineering phase, there are five BPs that can improve both the schedule and cost performance, including the Constructability, Alignment, Partnering, Lessons Learned, and Change Management. The implementation of Constructability as a BP would be beneficial in plan development, specifically when the project management team faces improper work experiences. Additionally, when the project team encounters difficulties while planning and designing a project, Constructability is a useful strategy to improve the cost/schedule performance. The utilization of Alignment strategy is suitable by reducing challenges among partners. Alignment effectively advances stakeholders’ communication, since this strategy adopts a common template for the collaborators while communicating. This leads them to achieve the goals of the project within its scope with less corresponding costs.

In the procurement phase, Partnering, Quality Management, Front End Planning, and Material Management were the four BPs that simultaneously enhanced the performance of schedule and cost. Quality Management implementation constitutes periodic control and evaluation of the historical data to identify and correct error and deficiencies. This strategy assists in taking the corrective actions at the appropriate time. For example, when several teams are involved in a phase of a project, Quality Management helps to reduce the number of errors, which increases the performance of the project with regard to schedule and cost. As shown in

Table 8, the Front-End Planning strategy utilization leads the project team to specify the goal and scope of the project early enough to decrease the late design and technical specification modifications. Additionally, this BP makes the schedule and cost of a project more reliable by creating a comprehensive finance strategy. In the construction phase, except for Front-End Planning and Planning for Start-Up BPs, the other ones were identified to improve the phase-based cost/schedule performance. Project Risk Assessment implementation is strongly recommended, specifically when the members of the project team do not have the required skills. In a construction project, Risk Assessment decreases the number of design changes and modifications by providing a basis to establish monitoring, training, and auditing. For instance, implementing Risk Assessment is advantageous when various localities are involved in the construction phase of a project by establishing periodic controls. Implementation of the Lesson Learned strategy improves the schedule and cost performance when laborers working in a project are multicultural.