Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction

Abstract

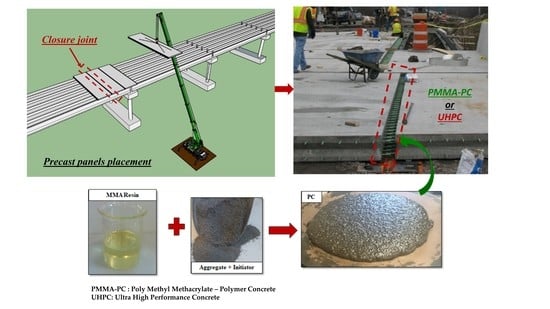

1. Introduction

2. Material and Methods

2.1. Materials

2.2. Pull-Out Test

2.3. Lap Splice Test

2.4. Shear Test

3. Experimental Results

3.1. Pull-Out Test Results

3.2. Lap Splice Test Results

3.3. Shear Strength Test Results

4. Discussion

5. Closure Joint Design Example

6. Conclusions and Findings

- The minimum development length required for steel bars embedded in PMMA-PC was found to range between 3.6 and 4.1 times the reinforcing bar diameter. This development length is almost one-half of the minimum development length of UHPC and is one-fifth that required by AASHTO for normal concrete.

- The minimum lap splice length required for uncoated steel bars in PMMA-PC with concrete cover of 3 times the reinforcing bar diameter to achieve yield in the rebar was found to be 4.1 times the reinforcing bar diameter. Comparing to UHPC, 4.5 times the reinforcing bar diameter is enough lap splice length to observe yielding in the rebar. The splice length is also 40% of what required by AASHTO for normal concrete.

- PMMA-PC has shear strength of 7.57 MPa, significantly higher than both normal concrete (+344%) and UHPC (+190%) and much higher than the shear strength expected by AASHTO.

- It is obvious that PMMA-PC provides an excellent opportunity for making a relatively small closure joint compared with all other alternative concretes. Testing of PMMA-PC and a practical design example show that PMMA-PC is an excellent alternative for bridge deck closure joints and requires significantly narrower precast gap spacing compared with UHPC associated with direct and indirect cost saving.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Culmo, M.P. Accelerated Bridge Construction-Experience in Design, Fabrication and Erection of Prefabricated Bridge Elements and Systems; Report No. FHWA-HIF-12-013; USDOT FHWA: Washington, DC, USA, 2011.

- ACI (American Concrete Institute). Building Code Requirements for Structural Concrete; ACI 318-14; ACI: Farmington Hills, MI, USA, 2014. [Google Scholar]

- AASHTO (American Association of State Highway and Transportation Officials). AAHSTO LRFD Bridge Design Specifications, 7th ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2014. [Google Scholar]

- Graybeal, B. Ultra-High Performance Concrete; Report No. FHWA-HRT-11-038; USDOT FHWA: Washington, DC, USA, 2011; p. 8.

- Yuan, J.; Graybeal, B.A. Bond Behavior of Reinforcing Steel in Ultra-High Performance Concrete; Report No. FHWA-HRT-14-090; USDOT: Washington, DC, USA, 2014.

- Graybeal, B. Design and Construction of Field-Cast UHPC Connections; Report No. FHWA-HRT-14-084; USDOT FHWA: Washington, DC, USA, 2014.

- Reda, M.M.; Shrive, N.G.; Gillott, J.E. Microstructural investigation of innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Optimum silica fume content and its mode of action on concrete. ACI Mater. J. 2003, 100, 407–412. [Google Scholar]

- Schießl, P.; Mazanec, O.; Lowke, D. SCC and UHPC—Effect of mixing technology on fresh concrete properties. In Advances in Construction Materials; Springer: Berlin/Heidelberg, Germany, 2007; pp. 513–522. [Google Scholar]

- ACI (American Concrete Institute). Guide for the Use of Polymers in Concrete; ACI 548.1R-09; ACI: Farmington Hills, MI, USA, 2009. [Google Scholar]

- Rebeiz, K.S.; Serhal, S.P.; Craft, A.P. Properties of polymer concrete using fly ash. J. Mater. Civ. Eng. 2004, 16, 15–19. [Google Scholar] [CrossRef]

- Gorninski, J.P.; Dal Molin, D.C.; Kazmierczak, C.S. Comparative assessment of isophtalic and orthophtalic polyester polymer concrete: Different costs, similar mechanical properties and durability. Constr. Build. Mater. 2007, 21, 546–555. [Google Scholar] [CrossRef]

- Czarnecki, L.; Chmielewska, B. The influence of coupling agent on the properties of vinylester mortar. In Proceedings of the II International RILEM Symposium on Adhesion between Polymers and Concrete; RILEM: Paris, France, 1999; Volume 99, pp. 57–66. [Google Scholar]

- Wheat, D.L.; Fowler, D.W.; Al-Negheimish, A.I. Thermal and fatigue behavior of polymer concrete overlaid beams. J. Mater. Civ. Eng. 1993, 5, 460–477. [Google Scholar] [CrossRef]

- Whitney, D.P.; Fowler, D.W. New applications for polymer overlays. Adv. Mater. Res. 2015, 1129, 277–282. [Google Scholar] [CrossRef]

- ASTM C39-17b. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39-17b; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM C496-17. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM C496-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Graybeal, B. Bond Behavior of Reinforcing Steel in Ultra-High Performance Concrete; Report No. FHWA-HRT-14-089; USDOT FHWA: Washington, DC, USA, 2014.

- Esfahani, M.R.; Rangan, B.V. Bond between normal strength and high-strength concrete (HSC) and reinforcing bars in splices in beams. Struct. J. 1998, 95, 272–280. [Google Scholar]

- Shuraim, A.B. A novel approach for evaluating the concrete shear strength in reinforced concrete beams. Lat. Am. J. Solids Struct. 2014, 11, 93–112. [Google Scholar] [CrossRef]

- Saleem, M.A.; Mirmiran, A.; Xia, J.; Mackie, K. Development length of high-strength steel rebar in ultrahigh performance concrete. J. Mater. Civ. Eng. 2012, 25, 991–998. [Google Scholar] [CrossRef]

| PMMA-PC | Properties | |

|---|---|---|

| Mixture | MMA Polymer | 159.5 |

| Aggregate | 2224.6 | |

| Compressive strength | 72.6 ±2.1 | |

| Split tensile strength | 6.6 ± 0.6 |

| Cement | 1029 |

| Water | 227.5 |

| Aggregate (Clean Medium Sand) | 910 |

| Silica Fume | 306.6 |

| Superplasticizer (Glenium 3030 NS) | 26.7 |

| Development Length | Average Load (kN) at Failure | Average Failure Stress (MPa) in rebar | ||

|---|---|---|---|---|

| Bar #13 (12.7 mm) | Bar #16 (15.9 mm) | Bar #13 (12.7 mm) | Bar #16 (15.9 mm) | |

| 4db | 51.3 ± 1.8 | 93.0 ± 1.0 | 404.8 ± 14.1 | 469.8 ± 4.9 |

| 6db | 76.4 ± 8.9 | 98.1 ± 10.8 | 602.9 ± 70.0 | 495.8 ± 54.5 |

| 8db | 84.6 ± 9.2 | 7.0 ± 5.3 | 667.6 ± 72.4 | 490.1 ± 27.0 |

| 10db | 78.3 ± 9.9 | 97.4 ± 10.1 | 618.4 ± 77.8 | 491.9 ± 50.8 |

| Design Parameter | UHPC | PMMA-PC |

|---|---|---|

| Panel Dimension (m) | 2.44 width | 2.44 width |

| 11.9 length | 11.9 length | |

| Link Slab Dimension (m) | 2.84 width | 3.36 width |

| 11.9 length | 11.9 length | |

| Top Longitudinal Reinforcement for Panels | #13 (12.7 mm) | #13 (12.7 mm) |

| Bottom Longitudinal Reinforcement for Panels | #16 (15.9 mm) | #16 (15.9 mm) |

| Top Longitudinal Reinforcement for Link Slab | #16 (15.9 mm) | #16 (15.9 mm) |

| Bottom Longitudinal Reinforcement for Link Slab | #16 (15.9 mm) | #16 (15.9 mm) |

| Closure Joint Width | 101.6 mm | 76.2 mm |

| Embedment Length | 95.3 mm | 70 mm |

| Lap Splice Length | 76.2 mm | 70 mm |

| Volume of Closure Joint Material | 5.60 m3 | 4.40 m3 |

| Unit Cost of Closure Joint Material | $5230/m3 | $2615/m3 |

| Cost of Closure Joint Material | $29,280 | $11,500 (saving $17,780) |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mantawy, I.; Chennareddy, R.; Genedy, M.; Taha, M.R. Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction. Infrastructures 2019, 4, 31. https://doi.org/10.3390/infrastructures4020031

Mantawy I, Chennareddy R, Genedy M, Taha MR. Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction. Infrastructures. 2019; 4(2):31. https://doi.org/10.3390/infrastructures4020031

Chicago/Turabian StyleMantawy, Islam, Rahulreddy Chennareddy, Moneeb Genedy, and Mahmoud Reda Taha. 2019. "Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction" Infrastructures 4, no. 2: 31. https://doi.org/10.3390/infrastructures4020031

APA StyleMantawy, I., Chennareddy, R., Genedy, M., & Taha, M. R. (2019). Polymer Concrete for Bridge Deck Closure Joints in Accelerated Bridge Construction. Infrastructures, 4(2), 31. https://doi.org/10.3390/infrastructures4020031