Abstract

Accelerated curing is used for mass production in the precast concrete industry. Autogenous shrinkage and drying shrinkage occur in concrete, during and after accelerated curing. Thus, thermal cracks may occur in concrete due to both heating and cement hydration at early age, whereas drying shrinkage causes cracks after demolding. Ground granulated blast-furnace slag cement (GGBS), a byproduct in steel manufacture, has been used to improve concrete strength development during accelerated curing but poses a challenge of increased shrinkage. In this paper, two types of granulated blast-furnace slag cements were used to study mechanical and shrinkage properties of water cured and concrete subjected to accelerated curing. Limestone powder and gypsums, with two different types of fineness, were other additives used. An accelerated one day curing cycle was adopted that consisted of a 3 h delay period, heating to 65 °C, a peak temperature maintained for 3 h, and, finally, cooling. The results indicated that increment in gypsum fineness increased concrete expansion at one day for both sealed and accelerated cured concrete. In drying condition, similar shrinkage was observed. The addition of gypsum provided slightly lower shrinkage, and this may help to reduce cracking of concrete. Limestone powder improved concrete strength at early age. The difference in blast-furnace cement fineness did not have significant differences in compressive strengths, especially at 28 days.

1. Introduction

Ground granulated blast-furnace slag cement is a supplementary cementitious material (SCM) that is used in concrete, to reduce ordinary Portland cement (OPC) usage. OPC has a negative environmental impact during its production [1]. There are different GGBS types for concrete works that are distinguished either by their activity index or fineness. GGBS with fineness of about 4000 cm2/g has been used widely in the precast concrete industry. When added to concrete, it improves properties such as workability, durability, and water tightness. GGBS also improves concrete resistance to salt damage, restrained alkali–silica reaction, and so on [2,3]. Thus, its usage in concrete is generally dependent on the size and use for the concrete structure [4].

Steam curing is a widely used accelerated curing method in the precast concrete industry. In this method, it has been proven that there is a significant increase in early strength of concrete when GGBS is added [5]. Curing time plays an important role in concrete strength development as it affects the ultimate strength and other hardened concrete properties. Additionally, mineral additives such as limestone powder or gypsum are also incorporated in concrete to improve concrete workability, strength development, and durability in accelerated cured concrete [6].

During accelerated curing, concrete undergoes volume changes due to external temperature, heat of cement hydration, and autogenous shrinkage. When GGBS with 4000 cm2/g is used, high shrinkage has been observed due to its fineness. As reported by Saito et al., autogenous shrinkage of concrete may be reduced by modifying blast-furnace slag fineness used and the content of gypsum in the binder [7]. Recently, GGBS with a specific surface area of at least 2750 cm2/g and less than 3500 cm2/g was developed. This has been used for low heat slag cement as a concrete additive [8]. However, little experimental data are available on shrinkage during and after accelerated curing using this type of GGBS. Thus, this study focused on investigating mechanical and shrinkage properties of concrete, at early and later age of the newly developed GGBS cement. The results were compared with the widely used GGBS cement. The thermal properties of the new GGBS cement in semi-adiabatic condition and the effect of mineral additives on cement hydration were evaluated. Autogenous shrinkage and drying shrinkage tests were conducted in order to provide experimental data sets on concrete crack resistance at early and later age.

2. Materials and Test Methods

2.1. Concrete Materials

Table 1 provides the physical and chemical properties of binder materials used in the study. The main binders were ordinary Portland cement (“N”, hereinafter) and ground granulated blast-furnace slag cements (“S”, hereinafter). Commercially produced ordinary Portland cement conformed to the requirements of the Japanese standard JIS R 5210: 2009 Standard specifications for Portland cement [9], ASTM C150/C150M-18: 2018 Standard specification for portland cement [10]. Two different types of S cements used were classified as S3000 and S4000 based on their fineness in accordance with JIS A 6206: 2013 Ground granulated blast-furnace slag for concrete [11] and ASTM C989-06: 2006 Standard specification for ground granulated blast-furnace slag for use in concrete and mortars [12]. Limestone powder (“L”, hereinafter) and two different types of anhydrous gypsum fineness, namely, normal gypsum (“G”, hereinafter) and fine gypsum (“F.G”, hereinafter) were other additives incorporated in concrete. Six mix proportions for each type of S cement were proposed. The percentage replacement by mass of N cement and mineral admixtures contents for each concrete mix proportion are shown in Table 2. Air entraining agent (AE) and air entraining and water reducing agent (AEWR) were used to produce entrained air and improve workability.

Table 1.

Physical and chemical analysis of cementitious materials.

Table 2.

Binder content percent by mass per cubic meter of concrete.

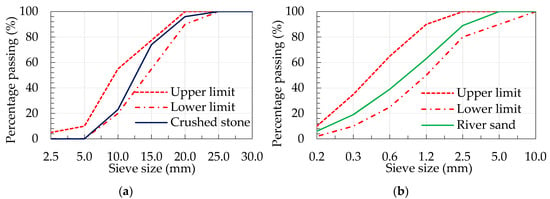

Sandstone and river sand were used as crushed coarse and fine aggregates. Figure 1a,b show the particle size distribution curves of both coarse and fine aggregates. Coarse aggregates had 20 mm maximum grain size with 2.64 g/cm3 specific gravity. River sand had 2.59 g/cm3 specific gravity, 2.55% water absorption, and 2.83 fineness modulus.

Figure 1.

Particle size distribution curve for (a) coarse and (b) fine aggregates.

2.2. Mix Proportions of Concrete

The general composition of six (6) mix proportions used in the experiments with varying mineral admixture contents are tabulated in Table 3. Target slump and air content were 12.5 to 17.5 cm and 3.5% to 5.5%, respectively.

Table 3.

Concrete mix proportions.

2.3. Test Methods

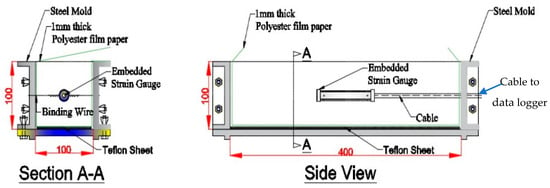

A pan type concrete mixer was used for all concrete mix proportions and batching was conducted according to the mix designs and as specified in JIS A 1119: 2014 Method of test for variability of freshly mixed concrete by measuring mortar and coarse aggregate contents [13], JIS A 1138: 2005 Method of making test sample of concrete in the laboratory [14], and ASTM C192/C192M: 2002 Standard practice for making and curing concrete test specimens in the laboratory [15]. Air entraining agent (AE) and water reducing agent (AEWR) were used in all the mix proportions. AEWR dosage was kept constant as recommended by the manufacturer, whereas AE was varied to achieve target concrete air content. Fresh concrete properties such as slump, air content, and temperature were measured just after casting, according to JIS or ASTM standards [16,17,18,19,20,21,22,23]. Transducer strain gauges and data logger were used to measure concrete strain and temperature throughout the study period. The gauges were installed in the central portion of 100 × 100 × 400 mm beam molds, as shown in Figure 2. Specimens for compressive strength tests were prepared, according to JIS A 1108: 2006 Method of test for compressive strength of concrete [24] and ASTM C39/C39M: 2005 Standard test method for compressive strength of cylindrical concrete specimens [25], using (100 mm diameter and 200 mm height) cylinder molds. Temperature rise, due to heat of cement hydration, was measured under semi-adiabatic condition in cubic molds with internal dimensions of 200 mm made of foamed polystyrene of 200 mm thick. Setting time of concrete was determined according to JIS A 1147: 2007 Method of test for setting time by penetration resistance [26] and ASTM C403/C403M: 1999 Standard test method for time of setting of concrete mixtures by penetration resistance [27].

Figure 2.

Beam concrete mold for shrinkage measurement.

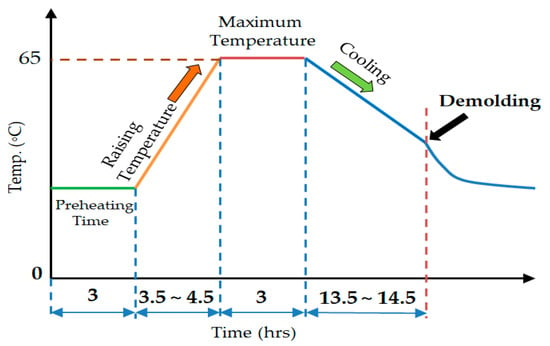

Immediately after casting, all specimens were sealed and stored in a temperature-controlled room at 20 °C and 80% relative humidity (RH) [18]. Some selected beams, together with cylinder specimens, for 1-, 7-, and 14-day compressive strength tests were then subjected to high temperature curing, 3 h after casting time. Figure 3 shows the target ambient temperature profile used in the experiments. This profile was similar to a typical steam curing process in general precast concrete factories. In this study, steam was not applied. The remaining beam and cylinder molds were kept in a temperature-controlled room at 20 °C and 80% RH; strain and temperature was measured in beam specimens as well. Accelerated curing was conducted on three mix proportions on the same day. Thus, twelve (12) mix proportions were cast and cured on four (4) different days.

Figure 3.

Target temperature history for accelerated curing.

After 24 h, all specimens were demolded. All the accelerated cured specimens were then subjected to drying condition in a different temperature-controlled room at 20 °C and RH 60%. Drying shrinkage was measured in beams specimens using data logger. Beam specimens which were stored in the temperature-controlled room at 20 °C were sealed with aluminum adhesive tape for measuring autogenous shrinkage. The storage condition for both sealed and drying condition of beam specimens are shown in Figure 4. The cylinder specimens for the 28-day compressive strength test were stored in water at 20 °C.

Figure 4.

Measurement of autogenous shrinkage (a) and drying shrinkage (b).

3. Results

3.1. Fresh Properties

Table 4 shows the results of the fresh properties for all the mix proportions. Similar results were obtained in the mix proportions.

Table 4.

Fresh concrete properties.

3.2. Setting Time

Table 5 provides the results for the concrete setting time test. As reported in previous studies, when ground granulated blast-furnace slag cement is added to concrete, the setting time of concrete is generally increased [28]. Furthermore, it has been reported that the extent of concrete setting time retardation depends on many factors such as fineness, composition, level of replacement of supplementary cementitious material used, amount and composition of the Portland cement or blended cement (particularly its alkali content), water-to-cementitious materials ratio (w/cm), and temperature of concrete [28,29]. Similarly, the results also showed a trend of longer setting times. In this study, the observed initial setting time of each mixture was used as the starting point for measuring autogenous shrinkage.

Table 5.

Setting time of concrete.

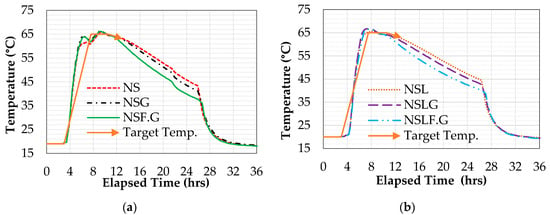

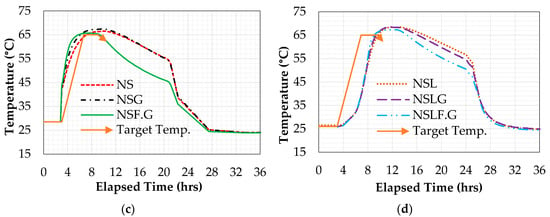

3.3. Accelerated Temperature History

Figure 5 shows the typical accelerated temperature history observed in all mix proportions with similar temperature rise of about 20 °C/h. Although the heating temperatures were not exactly the same, all the mix proportions were heated within the temperatures recommended in AC1 51 7.2R-87 [30]. During the constant maximum heating, all the mix proportions reached the target temperature of 65 °C. At the start of cooling, all the concrete specimens were kept inside a closed oven to prevent high-temperature difference in concrete and surrounding that would have led to cracking due to thermal shock. During this period, there was no automated cooling system installed in the chamber. Considering this chamber condition, cooling of concrete specimens was still achieved in a similar temperature decreasing rate of 1.8 °C/h on average. This cooling rate was also within the recommended rate in AC1 51 7.2R-87 [30] of about 2 °C/h.

Figure 5.

Temperature history for accelerated curing in S3000 (a,b) and S4000 (c,d).

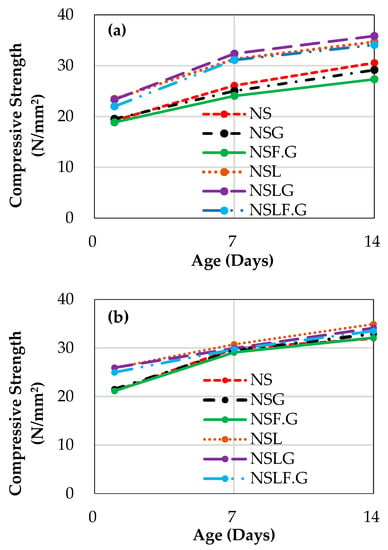

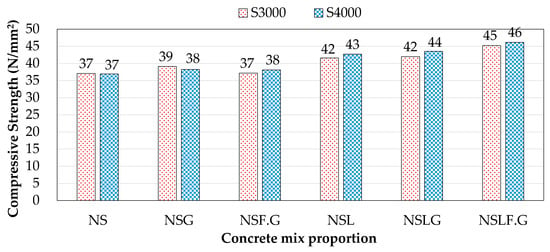

3.4. Compressive Strength

Compressive strength results for accelerated cured concrete are shown in Figure 6 and water cured compressive strength at 28 days in Figure 7. Higher one-day compressive strength for accelerated cured concrete specimens was observed for specimens containing limestone powder. The trend for strength remained, generally, the same for the 28-days compressive strength of specimens cured under water. When S3000 was used, strength development after accelerated curing was slower than S4000. This can be attributed to the difference in cement fineness that affects the rate of cement hydration. Due to the lower fineness of S3000 cement, the addition of limestone powder in S3000 had a significant effect as filler in strength improvement. Among the specimens containing limestone powder, similar strength values from one-day to 14-day results were observed in both S cement types. At 28 days, mix proportions containing NSLF.G had the highest compressive strength. In this case, fine gypsum contributed to strength development in concrete at 28 days under water. It was also observed that an increase of S cement fineness did not have a significant influence on compressive strength, especially at 28 days. Thus, S4000 may be used if early strength is needed for demolding.

Figure 6.

Compressive strength at 1 day, 7 days, and 14 days for accelerated cured S3000 (a) and S4000 (b).

Figure 7.

Compressive strength for water cured S3000 and S4000 concrete at 28 days.

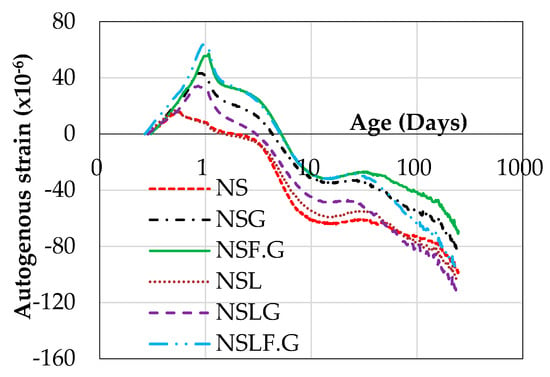

3.5. Autogenous and Drying Shrinkage, Sealed and Accelerated Cured Concrete

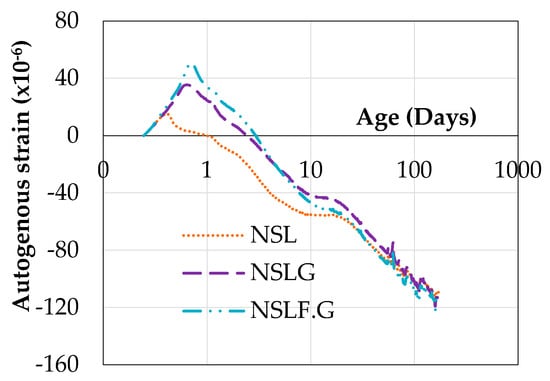

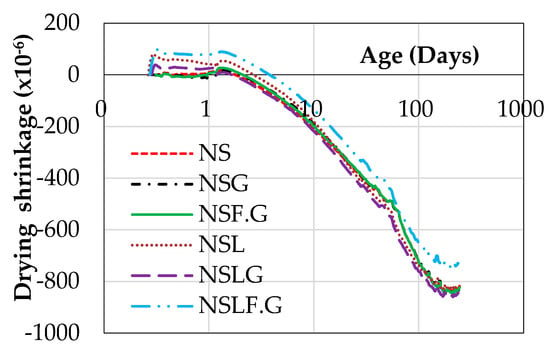

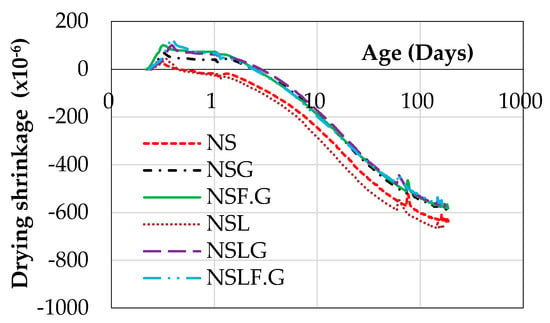

In the experiments conducted, total strain which is the sum of thermal strain and autogenous shrinkage strain, was observed. To obtain autogenous shrinkage, the coefficient of heat expansion of concrete was assumed to be 10 × 10−6/°C [31]. Thus, autogenous strain was calculated as the difference between total strain and thermal strain. The observed autogenous shrinkage in sealed concrete specimens at 20 °C containing S3000 and some for S4000 are presented in Figure 8 and Figure 9. Only mix proportions containing limestone powder for S4000 were prepared for the autogenous shrinkage measurement. Mix proportions containing gypsum showed higher expansion at early age. Additionally, increment in gypsum fineness showed more expansion. Similar shrinkage at later age in all mix proportions was observed. Figure 10 and Figure 11 show autogenous shrinkage and drying shrinkage, during and after accelerated curing. Mix proportions containing gypsum showed higher expansion during accelerated curing and slightly lower shrinkage after demolding. The addition of fine gypsum showed the highest expansion. This trend was also observed in sealed specimens, as shown in Figure 8 and Figure 9. In addition, in sealed condition, all mix proportions showed similar shrinkage values at later age. Gypsum, in this case, provided the expansive effect on concrete that compensates shrinkage.

Figure 8.

Autogenous shrinkage, S3000.

Figure 9.

Autogenous shrinkage, S4000.

Figure 10.

Drying shrinkage, S3000.

Figure 11.

Drying shrinkage, S4000.

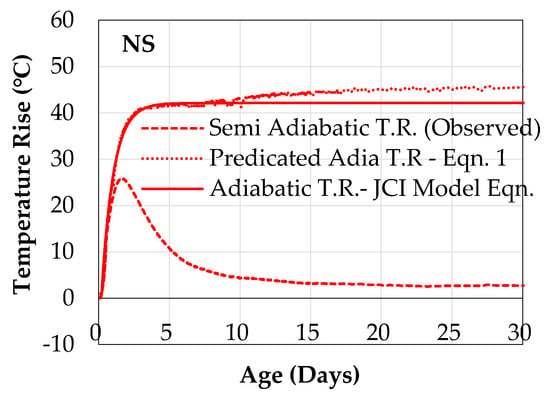

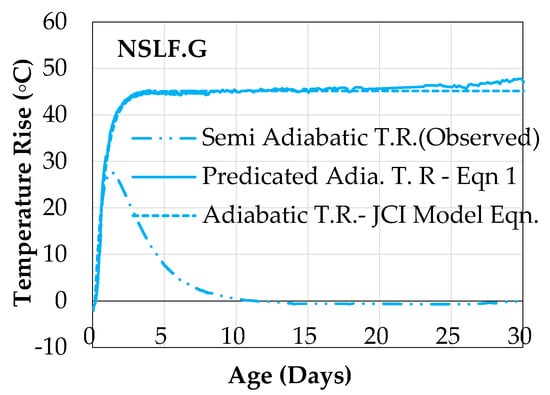

3.6. Heat of Cement Hydration of Concrete, Semi-Adiabatic Condition

Cement hydration in concrete is an exothermic reaction and causes temperature rise in concrete. This property is responsible for thermal cracking in concrete members and has an influence on shrinkage properties. Generally, there is a relationship between the extent of rise in temperature on the type and content of cementitious materials in concrete. To establish the general behavior of this concrete property, temperature rise, due to cement hydration in semi-adiabatic condition, was conducted on NS and NSLF.G containing S3000. This also enabled a check of the effect of adding limestone powder and fine gypsum on rise in concrete temperature. The results are shown in Figure 4a,b. The results were, then, used to predict adiabatic temperature rise of concrete using Equation (1). This equation is based on a simple thermal insulation test on the relationship between semi-adiabatic temperature rise and adiabatic temperature rise, proposed from previous research [32].

where ρ is the density of the sample specimen (kg/m3), C is the specific heat capacity of concrete taken as (1.05 KJ/kg °C), V is the volume of the sample specimen (m3), S is the surface area of the sample specimen (m2), h is the heat transfer coefficient (W/m2 °C), T is the temperature gradient existing between the sample specimen and ambient room temperature, and is the adiabatic temperature state.

Predicted parameters using experimental data from Equation (1) were then used to generate constants in the JCI model Equation (2), shown below, and graphs obtained are also presented in Figure 12 and Figure 13 [31]. The derived constants from Equation (2) are given in Table 6. Test results indicated that the addition of limestone powder and fine gypsum contributed to faster and higher predicted adiabatic temperature rise and ultimate temperature rise [3,33].

where t is age in days, Q(t) is adiabatic temperature rise at t (°C), is ultimate adiabatic temperature rise (°C), are parameters representing rate of adiabatic temperature rise, and is age at starting of temperature rise.

Figure 12.

Observed semi-adiabatic and predicated adiabatic temperature rise in S3000 containing NS.

Figure 13.

Observed semi-adiabatic and predicated adiabatic temperature rise in S3000 containing NSLF.G. NSLF.G—N: ordinary Portland cement; S: ground granulated blast-furnace slag cement; L: limestone powder; G: normal gypsum; F.G: fine gypsum.

Table 6.

Adiabatic temperature rise properties of S3000 concrete.

4. Discussions

Fresh concrete properties, such as slump, play various roles in precast concrete just like in other types of concrete. The slump values obtained, in this case, provided increased workability. This would make it easier to place, consolidate, and finish precast concrete units. Additionally, the setting time of concrete has been used in precast concrete to determine the start time for accelerated curing, although, generally, the delay period of two to five hours has been employed in many precast companies [34]. In this study, the setting time was used as the starting point for measuring autogenous shrinkage [31]. Three hours of preheating period were adopted, despite longer setting times observed in mix proportions. A curing cycle of one day was adopted, as it is generally effective for curing of civil engineering precast concrete products.

The main aim of accelerated curing of concrete, as mentioned earlier, is to enhance early strength. In all the mix proportions, higher concrete strength was produced at demolding time. This satisfied the minimum required strength, as recommended in published document [4,35]. On the other hand, the influence of introducing other additives, such as limestone powder, showed more effect on strength gain, especially with a decrease in blast-furnace slag cement, as observed at seven and 14 days. This may also help to have good concrete strength for dispatching of precast concrete units from precast yard to installation site that generally takes place 14 days after demolding.

During accelerated curing, more expansion was observed in the mix proportions containing limestone powder and gypsum. The increment in fineness of gypsum showed increase expansion even more. Thus, this combination may be helpful by acting as expansive agents for such mix proportions, because this effect showed a slight reduction in the drying shrinkage at later age. It was also observed that the increase in fineness of blast-furnace slag cement showed a slight reduction in the drying shrinkage which may help in cracking resistance when a concrete unit is in service, although, the difference of about 200 µm in drying shrinkage was not so significant to show major cracking tendency between the two types of cements.

Adiabatic temperature rise in concrete has been used to assess the rate of cement hydration for some purpose related to cracking. Generally, the addition of supplementary cementitious materials, such as blast-furnace slag cement, has been used to reduce rise in temperature in concrete. In this study, the rise in temperature was used to check the effect of using additives such as limestone powder and fine gypsum. The results showed a slight increased rate and rise in temperature when the two additives were used. The difference observed and other concrete properties obtained may be used in three-dimensional (3D) finite element analysis method to check the cracking tendency at early age.

5. Conclusions

This study investigated the fresh, mechanical, and shrinkage properties of concrete made with S3000 and S4000 cement as main mineral admixtures and subjected to accelerated curing by heating. On the basis of the results from the laboratory tests, conclusions were drawn and summarized as follows:

- Fine gypsum contributed to higher expansion at early age in sealed and accelerated cured concrete. A combination of limestone powder and fine gypsum had the highest expansion in concrete;

- Limestone powder contributed to compressive strength of concrete at early age whereas gypsum addition showed significant influence on concrete strength at 28 days;

- There was an insignificant difference in compressive strength, especially at 28 days, between two types of slag cements even when additives such as limestone powder and gypsum were used;

- Similar drying shrinkage was observed at later age. Concrete containing fine gypsum showed slightly lower shrinkage which may help in cracking resistance.

Author Contributions

Second author, S.M.; and third author, N.N.; actively participated in the conceptualization of research; the first author, B.A.Z.; and second author, S.M. conducted the laboratory work, analysis and interpretation of data and documentation of the study; original draft of this article was done by first author, B.A.Z.; under the supervision of the second author, S.M.

Funding

This research had no external funding except the support of the Japan International Cooperation Agency (JICA) through the Africa Business Enterprise (ABE) initiative scholarship awarded to the first author.

Acknowledgments

The authors express gratitude to the management and staff of the Civil and Environmental Engineering Department of Ashikaga University and Technical Center, DC Co. Ltd., for their infallible support on this study.

Conflicts of Interest

The authors hereby declare no conflict of interest regarding the publication of this journal.

References

- Sheikibrahim, K.; Sathish, S.; Mohammed Fahad, A.S.; Sathish Sharma, A.; Karthika, H.; Shanmuganathan, N. Ground Granulated Blast Furnace Slag (GGBS or GGBFS) and Flyash in Concrete. Int. Res. J. Eng. Technol. 2018, 5, 266–270. [Google Scholar]

- Ashish, D.K.; Singh, B.; Verma, S.K. The effect of attack of chloride and sulphate on ground granulated blast furnace slag concrete. Adv. Concr. Constr. 2016, 4, 107–121. [Google Scholar] [CrossRef]

- Suresh, D.; Nagaraju, K. Ground Granulated Blast Slag (GGBS) in Concrete—A review. IOSR J. Mech. Civ. Eng. 2015, 12, 76–82. [Google Scholar]

- Nagao, Y.; Suzuki, K. Basic properties and utilization of steam-cured concrete using Ground Granulated Blast-Furnace Slag. Nippon Steel Sumitomo Met. Tech. Rep. 2015. [Google Scholar]

- Bhanumathidas, N.; Kalidas, N. Dual role of gypsum: Set retarder and strength accelerator. Indian Concr. J. 2004, 78, 1–4. [Google Scholar]

- Esping, O. Effect of limestone filler BET (H2O)-area on the fresh and hardened properties of self-compacting concrete. Cem. Concr. Res. 2008, 38, 938–944. [Google Scholar] [CrossRef]

- Saito, S.; Ozawa, M.; Sakaguchi, Y.; Morimoto, H. Study on initial stress of precast concrete members using steam curing. In Proceedings of the Japan Concrete Institute, Osaka, Japan, 12–14 July 2011; Volume 33. [Google Scholar]

- Japan’s Concrete Technology; Japan Society of Civil Engineers: Tokyo, Japan, January 2014; Volume 131.

- Japanese Standards Association. JIS R 5210: Portland Cement; Japanese Standards Association: Tokyo, Japan, 2009. [Google Scholar]

- ASTM C150/C150M-18: Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A6206: Ground Granulated Blast-Furnace Slag for Concrete; Japanese Standards Association: Tokyo, Japan, 2013. [Google Scholar]

- ASTM C989-06: Standard Specification for Ground Granulated Blast-Furnace Slag for Use in Concrete and Mortars; ASTM International: West Conshohocken, PA, USA, 2006; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1119: Method of Test for Variability of Freshly Mixed Concrete by Measuring Mortar and Coarse Aggregate Contents; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- Japanese Standards Association. JIS A1138: Method of Making Test Sample of Concrete in the Laboratory; Japanese Standards Association: Tokyo, Japan, 2005. [Google Scholar]

- ASTM C192 /C192M-18: Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A 1101: Method of Test for Slump of Concrete; Japanese Standards Association: Tokyo, Japan, 1975. [Google Scholar]

- ASTM C143/C143M-15a: Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1115: Method of Sampling Fresh Concrete; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- ASTM C172/C172M-17: Standard Practice for Sampling Freshly Mixed Concrete; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1118: Method of Test for Air Content of Fresh Concrete by Volumetric Method; Japanese Standards Association: Tokyo, Japan, 2011. [Google Scholar]

- ASTM C231/C231M-17a: Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1156: Method of Measurement for Temperature of Fresh Concrete; Japanese Standards Association: Tokyo, Japan, 2014. [Google Scholar]

- ASTM C1064/C1064M-17: Standard Test Method for Temperature of Freshly Mixed Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2017; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1108: Method of Test for Compressive Strength of Concrete; Japanese Standards Association: Tokyo, Japan, 2006. [Google Scholar]

- ASTM C39/C39M-18: Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2018; Available online: www.astm.org (accessed on 5 October 2019).

- Japanese Standards Association. JIS A1147: Method of Test for Setting Time by Penetration Resistance; Japanese Standards Association: Tokyo, Japan, 2007. [Google Scholar]

- ASTM C403/C403M-16: Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance; ASTM International: West Conshohocken, PA, USA, 2016; Available online: www.astm.org (accessed on 5 October 2019).

- Mahmoud, N.; Mohsen, T.; Mojtaba, N. The Relationships between Setting Time and Early Age Strength of Concrete containing Silica fume, Fly ash and Slag. In Proceedings of the Third International Conference on Sustainable Construction Materials and Technologies, Kyoto Research Park, Kyoto, Japan, 18–21 August 2013; Available online: http://www.classe.info/Proceedings.htm e393.pdf (accessed on 23 April 2018).

- Sadaqat Ullah, K.; Muhammad Fadhil, N.; Tehmina, A.; Nasir, S. Effects of different mineral admixtures on the properties of fresh concrete. Sci. World J. 2014, 2014, 986567. [Google Scholar] [CrossRef]

- America Concrete Institute. ACI 517.2R Accelerated Curing of Concrete at Atmospheric Pressure-State of the Art. In ACI Manual of Concrete Practice; ACI 517.2R-87; America Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Japan Concrete Institute. Guidelines for Control. of Cracking of Mass Concrete; Japan Concrete Institute: Tokyo, Japan, 2016. [Google Scholar]

- Yasuyuki, K.; Hirotaka, K.; Hiroshi, W. A study on estimation of adiabatic temperature rise characteristics of high-strength concrete by simple adiabatic test. In Proceedings of the 57th Annual conference of the Japan Society of Civil Engineers, Sapporo, Hokkaido, Japan, 25–27 September 2002. [Google Scholar]

- Bonavetti, V.L.; Rahhal, V.F.; Irrassar, E.F. Studies on the carbolauminate formation in limestone filler blended cements. Cem. Concr. Res. 2001, 31, 853–859. [Google Scholar] [CrossRef]

- Deogekar, P.; Jain, A.; Mishra, S.; Nanthagopalan, P. Influence of Steam Curing Cycle on Compressive strength of Concrete. Int. J. Constr. Mater. Struct. 2013, 1, 18–28. [Google Scholar]

- Bernard, A.Z.; Miyazawa, S.; Nobukazu, N. Properties of blast-furnace cement concrete subjected to accelerated curing. In Proceedings of the 43rd Our World in Concrete and Structures of Premier Conference, Goodwood Park Hotel, Singapore, 29–31 August 2018; pp. 395–402. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).