Exploiting Low-Cost 3D Imagery for the Purposes of Detecting and Analyzing Pavement Distresses

Abstract

1. Introduction

1.1. The Need for Low-Cost Automated Pavement Distress Application

1.2. Background of Pavement Distress Detection Techniques

1.3. Using 3D Imagery to Detect and Analyze Pavement Distresses

1.4. The Use of Image Segmentation in Pavement Condition Evaluations

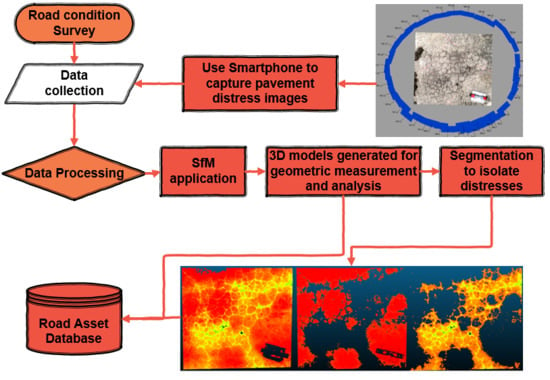

2. Materials and Methods

2.1. Structure-from-Motion Setup and Workflow

2.2. Assessment of the Accuracy of Models Generated from Mobile Phone Imagery

2.3. Application of Random Sampling Consensus (RANSAC) Segmentation Algorithm

| Algorithm 1 Extracting shapes in point Cloud Ρ |

| Ψ ← Ø {extracted shapes} C ← Ø {shape candidates} repeat C ← C ∪ new Candidates() m ← best Candidate (C) if P(|m|, |C|> pt then P ← P \Pm {remove points} Ψ ← Ψ ∪ m C ← C \ Cm {remove invalid candidates} end if until P(τ, |C|> pt return Ψ |

2.4. Application of ‘Fit’ Algorithm

3. Results and Discussion

3.1. D Pavement Distress Models

3.1.1. Pavement Section 1

3.1.2. Pavement Section 2

3.1.3. Pavement Section 3

3.2. Accuracy of 3D Models Generated by Imagery from Mobile Phones

3.2.1. Pavement Section 1

3.2.2. Pavement Section 2

3.2.3. Pavement Section 3

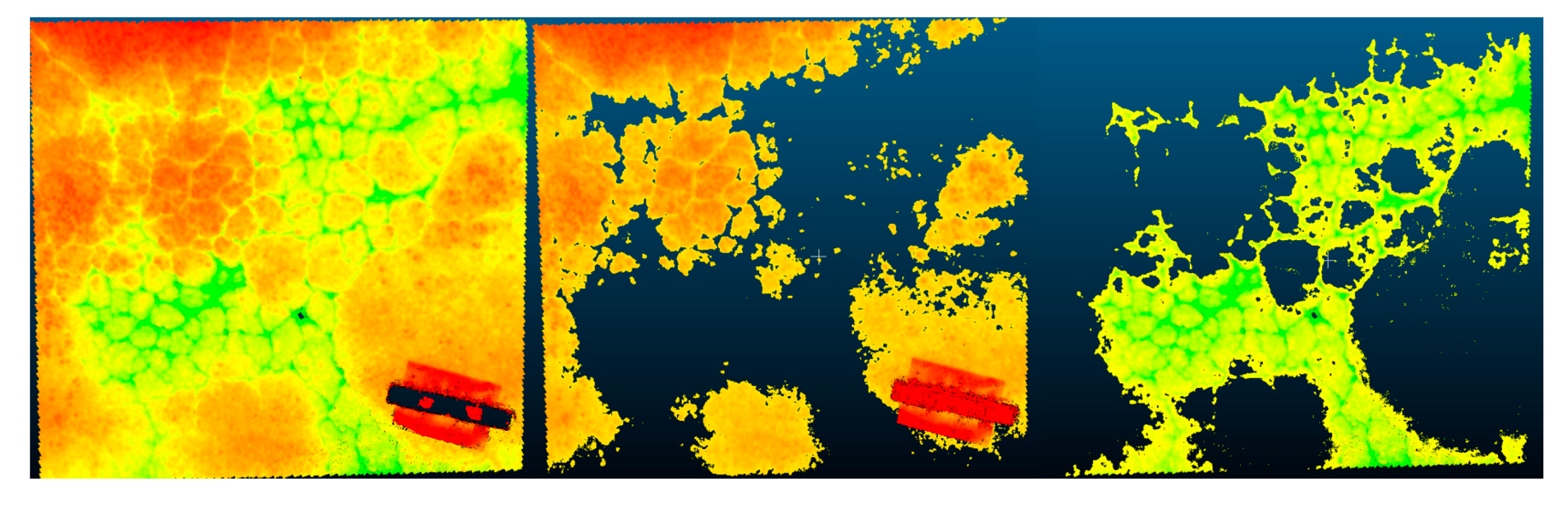

3.3. Application of RANSAC Segmentation

3.4. Application of Fit Segmentation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Vandam, T.J.; Harvey, J.T.; Muench, S.T.; Smith, K.D.; Snyder, M.B.; Al-Qadi, I.L.; Ozer, H.; Meijer, J.; Ram, P.V.; Roesier, J.R.; et al. Towards Sustainable Pavement Systems: A Reference Document FHWA-HIF-15-002; United States Federal Highway Administration: Washington, DC, USA, 2015. [Google Scholar]

- International Road Federation (IRF). IRF World Road Statistics 2018 (Data 2011–2016); International Road Federation (IRF): Brussels, Belgium, 2018. [Google Scholar]

- Mbara, T.C.; Nyarirangwe, M.; Mukwashi, T. Challenges of raising road maintenance funds in developing countries: An analysis of road tolling in Zimbabwe. J. Transp. Supply Chain Manag. 2012, 4, 151–175. [Google Scholar] [CrossRef][Green Version]

- Peterson, D. National Cooperative Highway Research Program Synthesis of Highway Practice Pavement Management Practices; Transportation Research Board: Washington, DC, USA, 1987; No. 135; ISBN 0309044197. [Google Scholar]

- Kulkarni, R.B.; Miller, R.W. Pavement Management Systems: Past, Present, and Future. Transp. Res. Rec. J. Transp. Res. Board 2003, 1853, 65–71. [Google Scholar] [CrossRef]

- Schnebele, E.; Tanyu, B.F.; Cervone, G.; Waters, N. Review of remote sensing methodologies for pavement management and assessment. Eur. Transp. Res. Rev. 2015, 7, 7. [Google Scholar] [CrossRef]

- Radopoulou, S.C.; Brilakis, I. Improving Road Asset Condition Monitoring. Transp. Res. Procedia 2016, 14, 3004–3012. [Google Scholar] [CrossRef]

- Coenen, T.B.J.; Golroo, A. A review on automated pavement distress detection methods. Cogent Eng. 2017, 4, 1374822. [Google Scholar] [CrossRef]

- Ragnoli, A.; De Blasiis, M.; Di Benedetto, A. Pavement Distress Detection Methods: A Review. Infrastructures 2018, 3, 58. [Google Scholar] [CrossRef]

- Laurent, J.; Hébert, J.F.; Lefebvre, D.; Savard, Y. Using 3D Laser Profiling Sensors for the Automated Measurement of Road Surface Conditions. In 7th RILEM International Conference on Cracking in Pavements; Scarpas, A., Kringos, N., Al-Qadi, I.A.L., Eds.; Springer: Dordrecht, The Netherlands, 2012; pp. 157–167. [Google Scholar]

- Landa, J.; Prochazka, D. Automatic Road Inventory Using LiDAR. Procedia Econ. Financ. 2014, 12, 363–370. [Google Scholar] [CrossRef]

- Sairam, N.; Nagarajan, S.; Ornitz, S. Development of Mobile Mapping System for 3D Road Asset Inventory. Sensors 2016, 16, 367. [Google Scholar] [CrossRef]

- Arhin, S.A.; Williams, L.N.; Ribbiso, A.; Anderson, M.F. Predicting Pavement Condition Index Using International Roughness Index in a Dense Urban Area. J. Civ. Eng. Res. 2015, 5, 10–17. [Google Scholar]

- Wix, R.; Leschinski, R. Cracking—A Tale of Four Systems. In Proceedings of the 25th Australian Road Research Board Conference, Perth, Australia, 23–26 September 2012; pp. 1–20. [Google Scholar]

- Oliveira, H.; Correia, P.L. Automatic road crack detection and characterization. IEEE Trans. Intell. Transp. Syst. 2013, 14, 155–168. [Google Scholar] [CrossRef]

- Wang, K.C.P.; Gong, W. Automated pavement distress survey: A review and a new direction. In Proceedings of the Pavement Evaluation Conference, Roanoke, VA, USA, 21–25 October 2002; pp. 21–25. [Google Scholar]

- Puan, O.C.; Mustaffar, M.; Ling, T.-C. Automated Pavement Imaging Program (APIP) for Pavement Cracks Classification and Quantification. Malays. J. Civ. Eng. 2007, 19, 1–16. [Google Scholar]

- Chambon, S.; Moliard, J.M. Automatic road pavement assessment with image processing: Review and Comparison. Int. J. Geophys. 2011, 2011, 989354. [Google Scholar] [CrossRef]

- Zakeri, H.; Nejad, F.M.; Fahimifar, A. Image Based Techniques for Crack Detection, Classification and Quantification in Asphalt Pavement: A Review. Arch. Comput. Methods Eng. 2017, 24, 935–977. [Google Scholar] [CrossRef]

- Inzerillo, L.; Di Mino, G.; Roberts, R. Image-based 3D reconstruction using traditional and UAV datasets for analysis of road pavement distress. Autom. Constr. 2018, 96, 457–469. [Google Scholar] [CrossRef]

- Westoby, M.J.; Brasington, J.; Glasser, N.F.; Hambrey, M.J.; Reynolds, J.M. “Structure-from-Motion” photogrammetry: A low-cost, effective tool for geoscience applications. Geomorphology 2012, 179, 300–314. [Google Scholar] [CrossRef]

- Verhoeven, G. Taking computer vision aloft -archaeological three-dimensional reconstructions from aerial photographs with photoscan. Archaeol. Prospect. 2011, 18, 67–73. [Google Scholar] [CrossRef]

- Allegra, D.; Gallo, G.; Inzerillo, L.; Lombardo, M.; Milotta, F.L.M.; Santagati, C.; Stanco, F. Low Cost Handheld 3D Scanning for Architectural Elements Acquisition. In Proceedings of the Smart Tools and Apps in Computer Graphics (STAG), Genova, Italy, 3–4 October 2016. [Google Scholar]

- Zhang, C. An UAV-based photogrammetric mapping system for road condition assessment. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2008, 37, 627–632. [Google Scholar]

- Tan, Y.; Li, Y. UAV Photogrammetry-Based 3D Road Distress Detection. ISPRS Int. J. Geo-Inf. 2019, 8, 409. [Google Scholar] [CrossRef]

- Mathavan, S.; Kamal, K.; Rahman, M. A Review of Three-Dimensional Imaging Technologies for Pavement Distress Detection and Measurements. IEEE Trans. Intell. Transp. Syst. 2015, 16, 2353–2362. [Google Scholar] [CrossRef]

- Inzerillo, L.; Inzerillo, L.; Di Mino, G.; Bressi, S.; Di Paola, F.; Noto, S. Image Based Modeling Technique for Pavement Distress surveys: A Specific Application to Rutting. Int. J. Eng. Technol. 2016, 16, 1–9. [Google Scholar]

- Andrews, D.P.; Bedford, J.; Bryan, P.G. A comparison of laser scanning and structure from motion as applied to the great barn at Harmondsworth, UK. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, 5, W2. [Google Scholar] [CrossRef]

- Wallace, L.; Lucieer, A.; Malenovskỳ, Z.; Turner, D.; Vopěnka, P. Assessment of forest structure using two UAV techniques: A comparison of airborne laser scanning and structure from motion (SfM) point clouds. Forests 2016, 7, 62. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, C.; Kwan, M.-P.; Tong, X.; Tian, S. Identifying Asphalt Pavement Distress Using UAV LiDAR Point Cloud Data and Random Forest Classification. ISPRS Int. J. Geo-Inf. 2019, 8, 39. [Google Scholar] [CrossRef]

- Chacra, D.B.A.; Zelek, J.S. Fully Automated Road Defect Detection Using Street View Images. In Proceedings of the 2017 14th Conference on Computer and Robot Vision (CRV 2017), Edmonton, AB, Canada, 16–19 May 2017; pp. 353–360. [Google Scholar]

- Zhang, D.; Zou, Q.; Lin, H.; Xu, X.; He, L.; Gui, R.; Li, Q. Automatic pavement defect detection using 3D laser profiling technology. Autom. Constr. 2018, 96, 350–365. [Google Scholar] [CrossRef]

- Gui, R.; Xu, X.; Zhang, D.; Lin, H.; Pu, F.; He, L.; Cao, M. A component decomposition model for 3D laser scanning pavement data based on high-pass filtering and sparse analysis. Sensors 2018, 18, 2294. [Google Scholar] [CrossRef]

- Li, B.; Wang, K.C.P.; Zhang, A.; Fei, Y. Automatic Segmentation and Enhancement of Pavement Cracks Based on 3D Pavement Images. J. Adv. Transp. 2019, 2019, 1813763. [Google Scholar] [CrossRef]

- Akagic, A.; Buza, E.; Omanovic, S.; Karabegovic, A. Pavement crack detection using Otsu thresholding for image segmentation. In Proceedings of the MIPRO 2018 41st International Convention on Information and Communication Technology, Electronics and Microelectronics, Opatija, Croatia, 21–25 May 2018; Croatian Society for Information and Communication Technology, Electronics and Microelectronics—MIPRO: Rijeka, Croatia, 2018; pp. 1092–1097. [Google Scholar]

- Agnisarman, S.; Lopes, S.; Chalil Madathil, K.; Piratla, K.; Gramopadhye, A. A survey of automation-enabled human-in-the-loop systems for infrastructure visual inspection. Autom. Constr. 2019, 97, 52–76. [Google Scholar] [CrossRef]

- Li, M.; Nan, L.; Smith, N.; Wonka, P. Reconstructing building mass models from UAV images. Comput. Graph. 2016, 54, 84–93. [Google Scholar] [CrossRef]

- Remondino, F.; Nocerino, E.; Toschi, I.; Menna, F. A Critical Review of Automated Photogrammetric Processing of Large Datasets. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2017, XLII-2/W5, 591–599. [Google Scholar] [CrossRef]

- Höhle, J. Oblique Aerial Images and Their Use in Cultural Heritage Documentation. ISPRS Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2013, XL-5/W2, 349–354. [Google Scholar]

- Zhang, S.; Lippitt, C.D.; Bogus, S.M.; Neville, P.R.H. Characterizing pavement surface distress conditions with hyper-spatial resolution natural color aerial photography. Remote Sens. 2016, 8, 392. [Google Scholar] [CrossRef]

- Hauser, W.; Neveu, B.; Jourdain, J.B.; Viard, C.; Guichard, F. Image quality benchmark of computational bokeh. Electron. Imaging 2018, 12, 340-1–340-10. [Google Scholar] [CrossRef]

- Loprencipe, G.; Pantuso, A. A Specified Procedure for Distress Identification and Assessment for Urban Road Surfaces Based on PCI. Coatings 2017, 7, 65. [Google Scholar] [CrossRef]

- Panagiotidis, D.; Surový, P.; Kuželka, K. Accuracy of Structure from Motion models in comparison with terrestrial laser scanner for the analysis of DBH and height influence on error behaviour. J. For. Sci. 2016, 62, 357–365. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. Comput. Graph. Forum 2007, 26, 214–226. [Google Scholar] [CrossRef]

- Arrospide, E.; Bikandi, I.; García, I.; Durana, G.; Aldabaldetreku, G.Z.J. Mechanical properties of polymer-optical fibres. In Polymer Optical Fibres; Christian-Alexander, B., Gries, T., Beckers, M., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 201–216. ISBN 978-0-08-100039-7. [Google Scholar]

- Inzerillo, L.; Roberts, R. 3D Image Based Modelling Using Google Earth Imagery for 3D Landscape Modelling. Adv. Intell. Syst. Comput. 2019, 919, 627–634. [Google Scholar]

| Device | Nikon D5200 | Huawei P20 Pro | Samsung Galaxy S9 |

|---|---|---|---|

| Camera resolution [Megapixel] | 24 | 40 | 12 |

| Image Size [pixel] | 6000 × 4000 | 3648 × 2736 | 4032 × 1960 |

| Focal length used [mm] | 24 | 3.95 | 4.3 |

| Device | Nikon D5200 | Huawei P20 Pro | Samsung Galaxy S9 |

|---|---|---|---|

| Distance from the pavement [mm] | ~1500 | ~1500 | ~1500 |

| Number of photos taken [-] | 46 | 55 | 57 |

| Ground sample distance (GSD) [mm/pixel] | 0.241 | 0.547 | 0.505 |

| Mesh faces created in SfM software [-] | 4,800,185 | 2,155,780 | 2,900,791 |

| Device | Nikon D5200 | Huawei P20 Pro | Samsung Galaxy S9 |

|---|---|---|---|

| Distance from the pavement [mm] | ~1500 | ~1500 | ~1500 |

| Number of photos taken [-] | 38 | 58 | 62 |

| Ground sample distance (GSD) [mm/pixel] | 0.322 | 0.567 | 0.485 |

| Mesh faces created in SfM software [-] | 4,615,825 | 1,912,697 | 2,022,877 |

| Device | Nikon D5200 | Huawei P20 Pro | Samsung Galaxy S9 |

|---|---|---|---|

| Distance from the pavement [mm] | ~1500 | ~1500 | ~1500 |

| Number of photos taken [-] | 42 | 42 | 58 |

| Ground sample distance (GSD) [mm/pixel] | 0.318 | 0.596 | 0.458 |

| Mesh faces created in SfM software [-] | 3,151,044 | 1,486,123 | 1,900,926 |

| Weibull Parameters | ||

|---|---|---|

| Phone | Shape (a) | Scale (b) |

| Huawei P20 Pro | 1.186156 | 0.002275 |

| Samsung Galaxy s9 | 0.981589 | 0.002794 |

| Weibull Parameters | ||

|---|---|---|

| Phone | Shape (a) | Scale (b) |

| Huawei P20 Pro | 0.941246 | 0.001772 |

| Samsung Galaxy s9 | 1.005422 | 0.001528 |

| Weibull Parameters | ||

|---|---|---|

| Phone | Shape (a) | Scale (b) |

| Huawei P20 Pro | 0.725207 | 0.002148 |

| Samsung Galaxy s9 | 1.183398 | 0.001785 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roberts, R.; Inzerillo, L.; Di Mino, G. Exploiting Low-Cost 3D Imagery for the Purposes of Detecting and Analyzing Pavement Distresses. Infrastructures 2020, 5, 6. https://doi.org/10.3390/infrastructures5010006

Roberts R, Inzerillo L, Di Mino G. Exploiting Low-Cost 3D Imagery for the Purposes of Detecting and Analyzing Pavement Distresses. Infrastructures. 2020; 5(1):6. https://doi.org/10.3390/infrastructures5010006

Chicago/Turabian StyleRoberts, Ronald, Laura Inzerillo, and Gaetano Di Mino. 2020. "Exploiting Low-Cost 3D Imagery for the Purposes of Detecting and Analyzing Pavement Distresses" Infrastructures 5, no. 1: 6. https://doi.org/10.3390/infrastructures5010006

APA StyleRoberts, R., Inzerillo, L., & Di Mino, G. (2020). Exploiting Low-Cost 3D Imagery for the Purposes of Detecting and Analyzing Pavement Distresses. Infrastructures, 5(1), 6. https://doi.org/10.3390/infrastructures5010006