Diagnostic Reliability in the Assessment of Degradation in Precast Concrete Elements

Abstract

:1. Introduction

Research Aim

2. Concrete Bridge Failures and Collapses Due to Corrosion

3. Guidelines for Assessing the Concrete Degradation in Prestressed Elements

4. Causes of RC Structures Deterioration

4.1. Some Divergencies between Past and Present on RC Durability

4.2. Considerations on the Reliability of Nondestructive Techniques for Corrosion Measurement in Concrete-Embedded Steel Bars

5. Materials and Methods

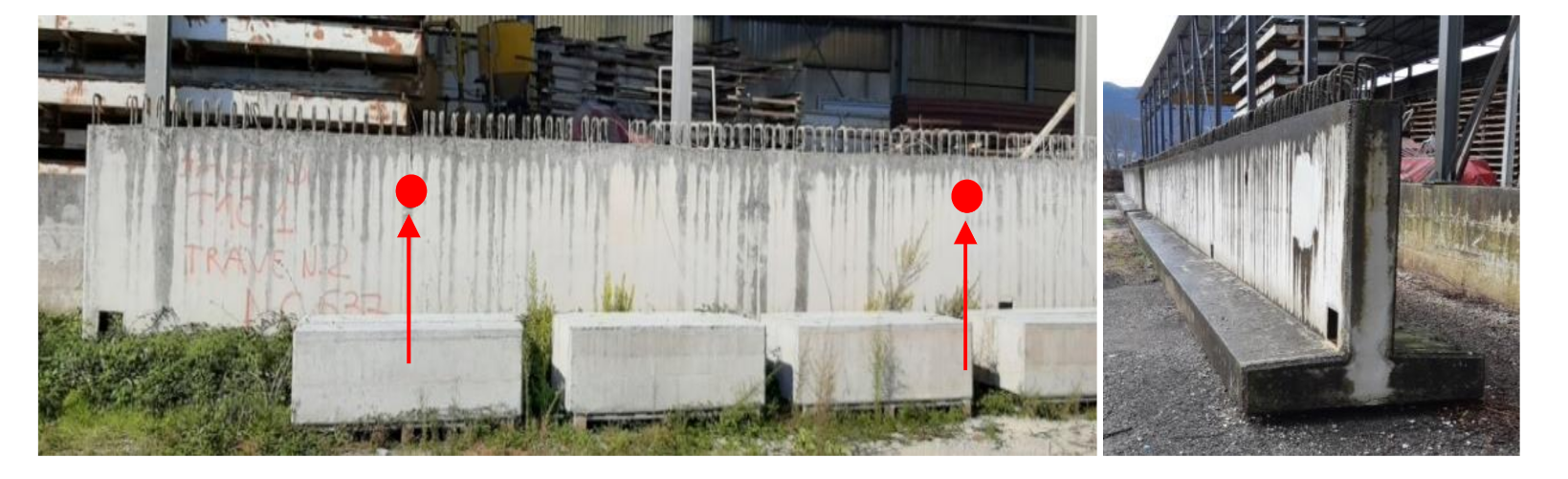

5.1. Tested Elements

5.2. Site Environmental Conditions

5.3. Testing Methods

- visual inspection of the elements, with an appraisal of concrete cover depths;

- assessment of the deterioration of concrete and steel;

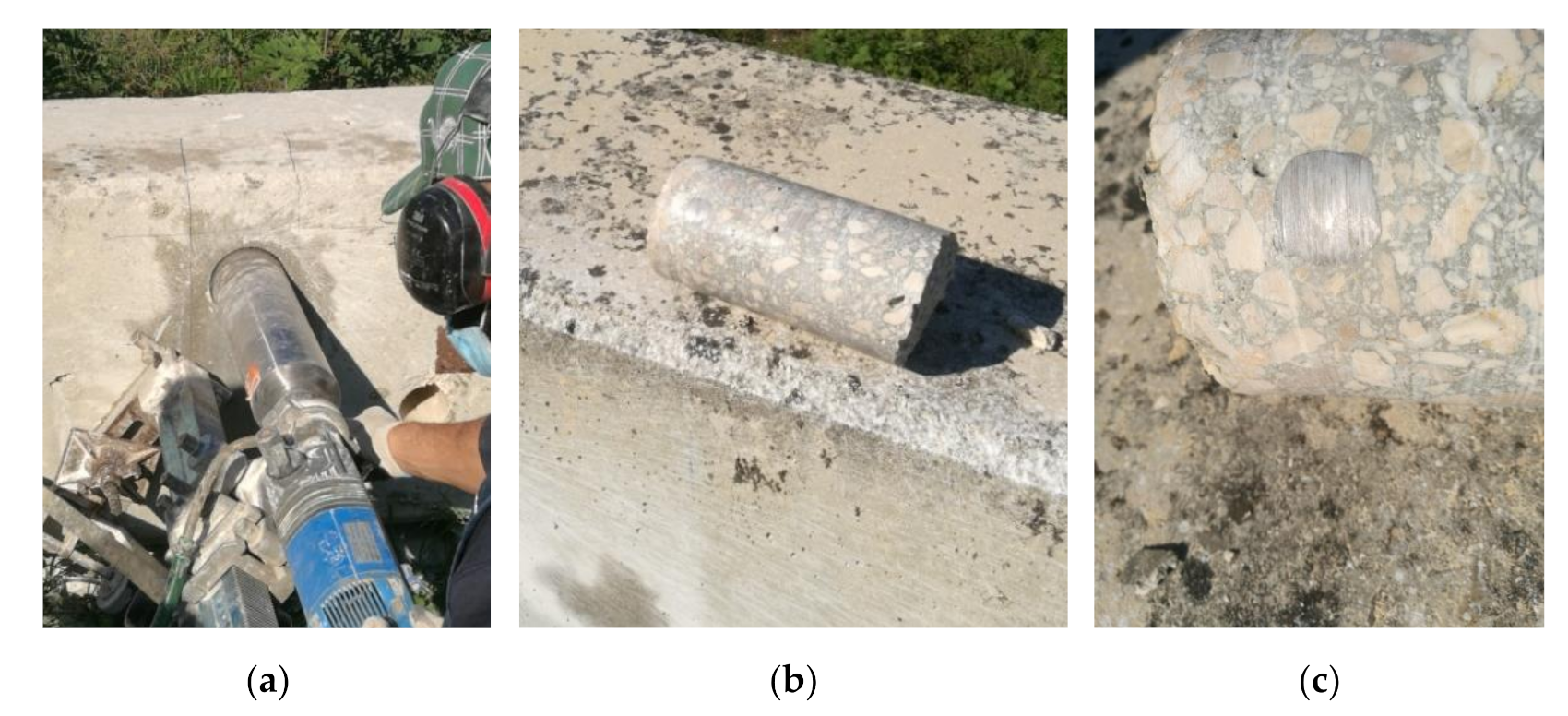

- extraction of concrete core samples, according to [43];

- visual inspection of the drilled surfaces;

- visual inspection of the core samples and possible oxidation evidence;

6. Tests and Results

6.1. Visual Inspections

6.2. Core Sampling

6.3. Mechanical Tests

6.4. Carbonation Tests

- −

- the storage area of the beams is located near the bank of the Volturno river and is a considerably humid site; therefore, since the higher the humidity, the slower the transport of gaseous CO2, due to the saturation of the pores by water [64], humidity may have slowed the penetration of CO2 through the concrete cover [65].

- −

- although beam B1 is younger, it could have been cast with a concrete composition that may have favored carbonation.

6.5. Corrosion Potential Mapping

7. Discussion

7.1. Reliability Hierarchy of Testing and Inspection Activities

7.2. Service Life: Past and Present

8. Conclusions

- −

- A close visual inspection of the structural elements showed what could be expected for prefabricated structures of twenty years of age. Only the steel surfaces directly exposed to the atmosphere showed generalized superficial corrosion. The same corrosion was detected in limited superficial regions with an insufficient thickness of concrete, or where cracks were present. As reported, a conservative upper bound of the percentage of surface extension of these degraded regions over the total area of the visible exposed surfaces can be reasonably set to 2%, while an upper bound of the thickness of the delaminated cover in these regions (see Figure 4b) can be set to 1.5 cm.

- −

- The concrete surfaces of the cores showed a well-sorted grain size distribution and adequate concrete compaction, demonstrating evidence of the good quality of the concrete manufacturing, coherent with the higher quality in prefabricated concretes.

- −

- No visually detectable corrosion was found in any of the sampled bar segments.

- −

- Altogether, the neutralization assays showed that the pH 9.2 threshold is far below the concrete cover thickness, so that the condition of pH lowering, deemed to be a necessary condition for bar corrosion, is not achieved. Such evidence is coherent with the big picture that came from the direct visual inspection of exposed concrete and bar surfaces.

- −

- The high compressive strength of the concrete can be considered indicative of an adequate design of the concrete mix and of the adoption of a sufficiently low water/cement ratio, capable of granting low porosity and, consequently, water tightness. For beam B2, the concrete compressive strengths were 21% lower than the design value that was retrievable from the available technical documentation. Even in this beam of presumably lower concrete quality, however, no evidence of oxidation was found across the sampled steel bars.

- −

- Half-cell measurements led to estimating the absence of interior zones where the corrosion process may be initiated. The measured potentials were affected by variations in the concrete cover thickness. The existence of some arbitrariness was recognized in interpreting these measures.

- −

- Neutralization assays of drilling powders have proven to be a much less invasive alternative when compared to neutralization assays performed on sampled cores. The importance of calibrating suitable corrective correlation factors, to avoid the overestimation of neutralization depths, was shown. Such a calibration was made possible by the availability of sampled cores.

- −

- Core sampling with a visual inspection of embedded bars can be assumed to be a diriment golden standard for the diagnosis of degradation in concrete and steel reinforcement. None of the non-destructive methods is reliable enough for corrosion estimation.

- −

- Altogether, the performed experimental research confirms a considerable amount of pre-1980 knowledge: adequate design and manufacturing of concrete cover and concrete mixture ordinarily lead to concrete infrastructures able to fulfill a design engineering service life conventionally established in 75 years.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Moore, G.; Klodt, D.T.; Hensen, R.D. Protection of Steel in Prestressed Concrete Bridges; Report 90; National Cooperative Highway Research Program (NCHRP): Washington, DC, USA, 1970. [Google Scholar]

- Manning, G. Durability of Prestressed Concrete Highway Structures; Report 140; National Cooperative Highway Research Program (NCHRP): Washington, DC, USA, 1988. [Google Scholar]

- Shirole, A.M.; Holt, R.C. Planning for a comprehensive bridge safety assurance program. Transportation Research Record, No. 1290. In Proceedings of the Third Bridge Engineering Conference, Denver, CO, USA, 10–13 March 1991; Volume 1. [Google Scholar]

- Lee, G.C.; Mohan, S.B.; Huang, C.; Fard, B.N. A Study of US Bridge Failures (1980–2012). Technical Report MCEER-13-0008. 2013. Available online: https://ubir.buffalo.edu/xmlui/handle/10477/29474 (accessed on 8 November 2021).

- Wardhana, K.; Hadipriono, F.C. Analysis of Recent Bridge Failures in the United States. J. Perform. Constr. Facil. 2003, 17, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Ravasini, S.; Scalvenzi, M.; Parisi, F.; Belletti, B.; Gasperi, A. Role of structural details in progressive collapse of precast RC structures. In Proceedings of the Italian Concrete Days, Naples, Italy, 14–16 April 2021. [Google Scholar]

- Kusenberger, F.N.; Barton, J.R. Detection of Flaws in Reinforcing Steel in Prestressed Concrete Bridge Members; Report No. FHWA/RD-81/087; Southwest Research Institute Division of Instrumentation; Federal Highway Administration: Washington, DC, USA, 1981. [Google Scholar]

- American Concrete Institute ACI 562-16. Code Requirements for Assessment, Repair, and Rehabilitation of Existing Concrete Structures and Commentary. 2018. Available online: www.concrete.org (accessed on 8 November 2021).

- ASTM C42/C42M-20, Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C823/C823M-12(2017), Standard Practice for Examination and Sampling of Hardened Concrete in Constructions; ASTM International: West Conshohocken, PA, USA, 2017.

- American Concrete Institute 222.2R-14. Report on Corrosion of Prestressing Steels; ACI Committee: Farmington Hills, MI, USA, 2014; Available online: http://civilwares.free.fr/ACI/MCP04/2222r_01.pdf (accessed on 8 November 2021).

- American Concrete Institute ACI 364.1R-07. Guide for Evaluation of Concrete Structures before Rehabilitation; ACI Committee: Farmington Hills, MI, USA, 2007; Available online: http://civilwares.free.fr/ACI/MCP04/3641r_94.pdf (accessed on 8 November 2021).

- CEN European Committee for Standardization. Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. EN 1998-3; The European Union: Brussels, Belgium, 2005. [Google Scholar]

- ANAS—National Autonomous Company of Roads. Valutazione delle Caratteristiche Meccaniche del Calcestruzzo. Quaderni Tecnici per la Salvaguardia delle Strutture, 1. (In Italian). Available online: https://www.stradeanas.it/it/lazienda/attivit%C3%A0/documenti-tecnici (accessed on 8 November 2021).

- MIT Ministero delle Infrastrutture e dei Trasporti. Norme Tecniche Italiane per le Costruzioni, (2018). Gazzetta Ufficiale della Repubblica Italiana n. 42 del 20/02/2018. 2018. (In Italian). Available online: https://www.gazzettaufficiale.it/eli/gu/2018/02/20/42/so/8/sg/pdf (accessed on 8 November 2021).

- UNI EN 12390-8:2019. Prove sul Calcestruzzo Indurito—Parte 8: Profondità di Penetrazione dell’acqua sotto Pressione. 2019. (In Italian). Available online: http://store.uni.com›catalogo›uni-en-12390-8-2019 (accessed on 8 November 2021).

- Servizio Tecnico Centrale del Consiglio Superiore dei Lavori Pubblici della Repubblica Italiana. Linee Guida per la Valutazione delle Caratteristiche del Calcestruzzo in Opera. 2017; (In Italian). Available online: https://trasparenza.mit.gov.it/pagina782_linee-guida-per-la-valutazione.html (accessed on 8 November 2021).

- Cowan, H. A history of masonry and concrete domes in building construction. Build. Environ. 1977, 12, 1–24. [Google Scholar] [CrossRef]

- Atkinson, A.; Goult, D.J.; Hearne, J.A. An Assessment of the Long-Term Durability of Concrete in Radioactive Waste Repositories. Materials Research Society, Symposium STOCKHOLM—Scientific Basis for Nuclear Waste Management IX, 239, MRS Online Proceedings Library (OPL). 1985, Volume 50, pp. 239–246. Available online: https://www.researchgate.net/publication/231768748 (accessed on 8 November 2021).

- Clifton, J.R.; Knab, L.I. Service Life of Concrete. No. NUREG/CR—5466; Prepared for United States Nuclear Regulatory Commission. Div. of Engineering; National Technical Information Service: Springfield, VA, USA, 1989. Available online: https://www.nrc.gov/docs/ML0614/ML061430380.pdf (accessed on 8 November 2021).

- Mozer, J.D.; Bianchini, A.C.; Kesler, C.E. Corrosion of Reinfocing Bars in Concrete. J. Am. Concr. Inst. 1965, 62, 909–932. [Google Scholar]

- Houston, J.T.; Atimtay, E.; Ferguson, P.M. Corrosion of Reinforcing Steel Embedded in Structural Concrete; Research Report No. 112-1F; Research Project Number 3-5-68-112; Conducted for Texas Highway Department, Center for Highway Research, The University of Texas at Austin: Austin, TX, USA, 1972; Available online: https://www.researchgate.net/publication/271613669_Corrosion_behavior_of_reinforcing_steel_embedded_in_chloride_contaminated_concretes_with_and_without_metakaolin (accessed on 8 November 2021).

- Santarella, L. Il Cemento Armato. Volume I. La Tecnica e la Statica. 19a Edizione; Hoepli: Milan, Italy, 1975. [Google Scholar]

- Campus, F. Emploi du béton pour les ouvrages à la mer. Commission Belge du Béton Armé. Association Belge pour l’Etude l’Essai et l’Emploi des Materiaux ABEM. Publ. ABEM 1973, 398, 25–37. Available online: https://orbi.uliege.be/bitstream/2268/216030/1/ST_CAMPUS_169.pdf (accessed on 8 November 2021).

- Ferraro, E.; Fantilli, A. La Resistenza dei Calcestruzzi Confezionati nella prima metà del ’900 Ingenio-Web. 2020. Available online: https://www.ingenio-web.it/24328-la-resistenza-dei-calcestruzzi-confezionati-nella-prima-meta-del-900 (accessed on 8 November 2021).

- Rostam, S.; Bakker, R.F.M.; Beeby, A.W.; Hartl, G.; Van Neuwenburg, D.; Schiessl, P.; Sentler, L.; van Vugt, A.P.; CEB. Durable Concrete Structures. Bulletin d’information 183. Comité Européen du Béton. 1992. Available online: https://books.google.it/books?id=jB_wNOHAIR4C&printsec=frontcover#v=onepage&q&f=false (accessed on 8 November 2021).

- Beeby, A.W.; Hartl, G.; van Nieuwenburg, D.; Schiessl, P.; van Vugt, A.P.; CEB. Durability of Concrete Structures. CEB, Paris, State of the art Report, Bulletin Information 148. Comité Européen du Béton. 1982. Available online: https://books.google.it/books?id=qJOgDwAAQBAJ&pg=PP2#v=onepage&q&f=false (accessed on 8 November 2021).

- Tuutti, K. Corrosion of Steel in Concrete. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 1982. [Google Scholar]

- Basile, A.; Frunzio, G.; Mattiello, G. Diagnosis of the critical state of concrete. In Proceedings of the XIII International Forum Le vie dei Mercanti-Heritage and Technology-Mind Knowledge Experience, Capri, Napoli, Italy, 11–13 June 2015; Scuola Pitagora Editore: Napoli, Italy, 2015; pp. 1783–1791. [Google Scholar]

- Biondi, E.; Frunzio, G. Analysis of Degradations for the Conservation of Reinforced Concrete; World Heritage and Legacy, Atti XVII Forum Gangemi Editore: Roma, Italy, 2019; pp. 943–952. [Google Scholar]

- Biondi, E.; Frunzio, G. Degradation of Concrete Resistance: Analysis of a Homogeneous Area. The City of Caserta. Lect. Notes Civ. Eng. 2021, 110, 31–48. [Google Scholar] [CrossRef]

- Bossio, A.; Lignola, G.P.; Prota, A. An overview of assessment and retrofit of corroded reinforced concrete structures. Procedia Struct. Integr. 2018, 11, 394–401. [Google Scholar] [CrossRef]

- Bossio, A.; Imperatore, S.; Kioumarsi, M. Ultimate Flexural Capacity of Reinforced Concrete Elements Damaged by Corrosion. Buildings 2019, 9, 160. [Google Scholar] [CrossRef] [Green Version]

- Imperatore, S.; Rinaldi, Z.; Spagnuolo, S. Experimental investigations on the effects of the steel rebar corrosion at structural level. Struct. Concr. 2019, 20, 2230–2241. [Google Scholar] [CrossRef]

- Tang, S.; Yao, Y.; Andrade, C.; Li, Z. Recent durability studies on concrete structure. Cem. Concr. Res. 2015, 78, 143–154. [Google Scholar] [CrossRef]

- Kioumarsi, M.; Benenato, A.; Ferracuti, B.; Imperatore, S. Residual Flexural Capacity of Corroded Prestressed Reinforced Concrete Beams. Metals 2021, 11, 442. [Google Scholar] [CrossRef]

- Collepardi, M.; Fratesi, R.; Moriconi, G.; Branca, C.; Simoncini, S. The Influence of Carbonation on the Steel Corrosion in Reinforced Concrete. Atti del Convegno AICAP’89, Napoli 4–6 Maggio 1989. Available online: https://www.encosrl.it/OLDSITE/pubblicazioni-scientifiche/armature.html (accessed on 8 November 2021).

- Elsener, B.; Andrade, C.; Gulikers, J.; Polder, R.; Raupach, M. RILEM TC 154 EMC: Electrochemical Techniques for Measuring Metallic Corrosion Half Cell Potential Measurements—Potential Mapping on Reinforced Concrete Structures. Mater. Struct. 2003, 36, 461–471. [Google Scholar] [CrossRef]

- Ebell, G.; Burkert, A.; Mietz, J. Detection of Reinforcement Corrosion in Reinforced Concrete Structures by Potential Mapping: Theory and Practice. Int. J. Corros. 2018, 2018, 1–6. [Google Scholar] [CrossRef]

- Andrade, C. Electrochemical methods for on-site corrosion detection. Struct. Concr. 2020, 21, 1385–1395. [Google Scholar] [CrossRef]

- Indig, M.E.; Groot, C. Some Limitations of the Linear Polarization Techniques in Evaluating Corrosion Behavior. Corrosion 1969, 25, 455–461. [Google Scholar] [CrossRef]

- CEN European Committee for Standardization. Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; EN 1992-1-1; The European Union: Brussels, Belgium, 2004. [Google Scholar]

- UNI EN 12504-1/2002 Prove sul Calcestruzzo Nelle Strutture-Carote-Prelievo, Esame e Prova di Compressione. 2002. (In Italian). Available online: http://store.uni.com/catalogo/uni-en-12504-1-2002 (accessed on 8 November 2021).

- UNI 9944/1992 Corrosione e Protezione dell’armatura del Calcestruzzo. Determinazione della Profondità di Carbonatazione e del profilo di Penetrazione degli ioni Cloruro nel Calcestruzzo. 1992. (In Italian). Available online: http://store.uni.com/catalogo/uni-9944-1992 (accessed on 8 November 2021).

- UNI EN 14630:2007. Products and Systems for the Protection and Repair of Concrete Structures-Test Methods—Determination of Carbonation Depth in Hardened Concrete by the Phenolphthalein Method; BSI: London, UK, 2007. [Google Scholar]

- Felicetti, R. Strumenti inediti per l’analisi del degrado nelle strutture in calcestruzzo armato. In Proceedings of the 17th Italian Congress CTE (Collegio dei Tecnici della Industrializzazione Edilizia), Roma, Italy, 5–8 November 2008; Volume 1, p. 675. [Google Scholar]

- Felicetti, R. Analysis of sorted powder samples for the assessment of deteriorated concrete. In Proceedings of the 6th International Conference on Concrete under Severe Conditions: Environment and Loading (CONSEC’10), Merida, Yucatan, Mexico, 7–9 June 2010; Pedro Castro-Borges; Taylor & Francis: London, UK, 2010; pp. 1123–1129. [Google Scholar]

- Felicetti, R. Assessment of Deteriorated Concrete Cover by Combined While-Drilling Techniques. ASCE J. Infrastruct. Syst. 2012, 18, 25–33. [Google Scholar] [CrossRef]

- UNI EN 12390-1/2012 Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. 2012. Available online: http://store.uni.com/catalogo/uni-en-12390-1-2012 (accessed on 8 November 2021).

- UNI EN 12390-3/2019 Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. 2019. Available online: http://store.uni.com/catalogo/uni-en-12390-3-2019 (accessed on 8 November 2021).

- ASTM, C 876-15. Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete. 2015. Available online: https://www.astm.org/Standards/C876.htm (accessed on 8 November 2021).

- UNI 10174:2020 Istruzioni per l’ispezione Delle Strutture di Calcestruzzo Armato Esposte ad Ambienti Aggressivi Mediante Mappatura di Potenziale. 2020. (In Italian). Available online: http://store.uni.com/catalogo/uni-10174-2020 (accessed on 8 November 2021).

- British Standard EN 12504-1:2009. Testing Concrete in Structures. Cored Specimens. Taking, Examining, and Testing in Compression; BSI: London, UK, 2009. [Google Scholar]

- American Concrete Institute ACI 214. Obtaining Cores and Interpreting Compressive Strength Results; American Concrete Institute: Farmington Hills, MI, USA, 2010; Available online: https://www.concrete.org/portals/0/files/pdf/previews/214.4r-10web.pdf (accessed on 8 November 2021).

- UNI EN 13791:2007. Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components. 2007. Available online: http://store.uni.com/catalogo/en-13791-2007 (accessed on 8 November 2021).

- Concrete Society. Concrete Core Testing for Strength; Technical Report No. 11; The Concrete Society: London, UK, 1987; pp. 1–44. [Google Scholar]

- Soroka, I. On compressive strength variation in concrete. Mater. Struct. 1971, 4, 155–161. [Google Scholar] [CrossRef]

- Arioz, O.; Ramyar, K.; Tuncan, M.; Tuncan, A. Effect of Length-to-Diameter Ratio of Core Sample on Concrete Core Strength—Another Look. J. Test. Eval. 2008, 36, 1–4. [Google Scholar] [CrossRef]

- Khoury, S.; Aliabdo, A.A.-H.; Ghazy, A. Reliability of core test—Critical assessment and proposed new approach. Alex. Eng. J. 2014, 53, 169–184. [Google Scholar] [CrossRef] [Green Version]

- Bartlett, F.M.; MacGregor, J.G. Effect of Core Diameter on Concrete Core Strengths. ACI Mater. J. 1994, 91, 460–469. [Google Scholar]

- Bažant, Z.P.; Planas, J. Fracture and Size Effect in Concrete and Other Quasibrittle Materials; CRC Press: Boca Raton, FL, USA, 1997; Volume 16. [Google Scholar]

- Meininger, R.C. Effect of Core Diameter on Measured Concrete Strength. J. Mater. 1968, 3, 320–336. [Google Scholar]

- Lewis, R.K. Effect of Core Diameter on the Observed Strength of Concrete Cores; Commonwealth Scientific and Industrial Research Organization; Division of Building Research: Melbourne, Australia, 1976; No. 50, 13. [Google Scholar]

- Talukdar, S.; Banthia, N.; Grace, J. Carbonation in concrete infrastructure in the context of global climate change—Part 1: Experimental results and model development. Cem. Concr. Compos. 2012, 34, 924–930. [Google Scholar] [CrossRef]

- Coppola, L. Concretum; McGraw Hill: Milano, Italy, 2007; ISBN 978-88-386-6465-6. [Google Scholar]

- Tremper, B.; Benton, J.L.; Stratfull, R.F. Corrosion of reinforcing steel and repair of concrete in a marine environment, Part II: Fundamental factors causing corrosion. Highw. Res. Board Bull. 1958, 182, 18–41. [Google Scholar]

- NCHRP 101: Callahan, J.P.; Siess, C.P.; Kesler, C.E. Effect of Stress on Freeze-Thaw Durability of Concrete Bridge Decks, National Cooperative Highway Research Program Report 101; HBR Press: Washington, DC, USA, 1970. [Google Scholar]

- Beaton, J.L.; Stratfull, R.F. Environmental influence on corrosion of reinforcing in concrete bridge substructures. Highw. Res. Rec. 1963, 14, 60–78. [Google Scholar]

| Element Code | Element Description | Year of Casting | Design Rc (MPa) |

|---|---|---|---|

| C | Precast RC Column | 2000 | 45 |

| B1 | Prestressed RC Omega beam | 2006 | 45 |

| B2 | Prestressed RC T-beam | 2004 | 45 |

| Specimen | ϕ mm | H mm | ρ kg/m3 | Breaking Load kN |

|---|---|---|---|---|

| C1 | 104 | 104 | 2275 | 326.49 |

| C2 | 104 | 104 | 2259 | 386.50 |

| B1_1 | 70 | 70 | 2487 | 150.87 |

| B1_2 | 70 | 70 | 2613 | 179.01 |

| B2_1 | 104 | 104 | 2279 | 302.10 |

| B2_2 | 104 | 104 | 2257 | 253.75 |

| Specimen | fcore | BS [53] | NTC [15] | ACI [54] | UNI EN [55] | CS [56] |

|---|---|---|---|---|---|---|

| C1 | 38.43 | 42.60 | 40.74 | 43.38 | 45.22 | 37.05 |

| C2 | 45.50 | 50.43 | 48.23 | 51.53 | 53.53 | 43.85 |

| B1_1 | 39.20 | 43.45 | 41.56 | 45.79 | 46.12 | 37.79 |

| B1_2 | 46.52 | 51.56 | 49.31 | 54.52 | 54.72 | 44.83 |

| B2_1 | 35.56 | 39.42 | 37.70 | 40.08 | 41.84 | 34.28 |

| B2_2 | 29.87 | 33.11 | 31.66 | 33.58 | 35.14 | 28.79 |

| Structural Element | Mean Cubic Strength from Cores MPa | Design Cubic Strength MPa | δ % |

|---|---|---|---|

| C | 45.65 | 45 | +1.44 |

| B1 | 46.96 | 45 | +4.36 |

| B2 | 35.56 | 45 | −20.98 |

| Test Tube | |||||

|---|---|---|---|---|---|

| 1 | 40 | 30 | 17 | 283% | 378% |

| 2 | 35 | 25 | 15 | 250% | 350% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bossio, A.; Faella, G.; Frunzio, G.; Guadagnuolo, M.; Serpieri, R. Diagnostic Reliability in the Assessment of Degradation in Precast Concrete Elements. Infrastructures 2021, 6, 164. https://doi.org/10.3390/infrastructures6110164

Bossio A, Faella G, Frunzio G, Guadagnuolo M, Serpieri R. Diagnostic Reliability in the Assessment of Degradation in Precast Concrete Elements. Infrastructures. 2021; 6(11):164. https://doi.org/10.3390/infrastructures6110164

Chicago/Turabian StyleBossio, Antonio, Giuseppe Faella, Giorgio Frunzio, Mariateresa Guadagnuolo, and Roberto Serpieri. 2021. "Diagnostic Reliability in the Assessment of Degradation in Precast Concrete Elements" Infrastructures 6, no. 11: 164. https://doi.org/10.3390/infrastructures6110164

APA StyleBossio, A., Faella, G., Frunzio, G., Guadagnuolo, M., & Serpieri, R. (2021). Diagnostic Reliability in the Assessment of Degradation in Precast Concrete Elements. Infrastructures, 6(11), 164. https://doi.org/10.3390/infrastructures6110164