Axial Load Behavior of Ultrahigh Strength Concrete-Filled Steel Tube Columns of Various Geometric and Reinforcement Configurations

Abstract

:1. Introduction

2. Experimental Program

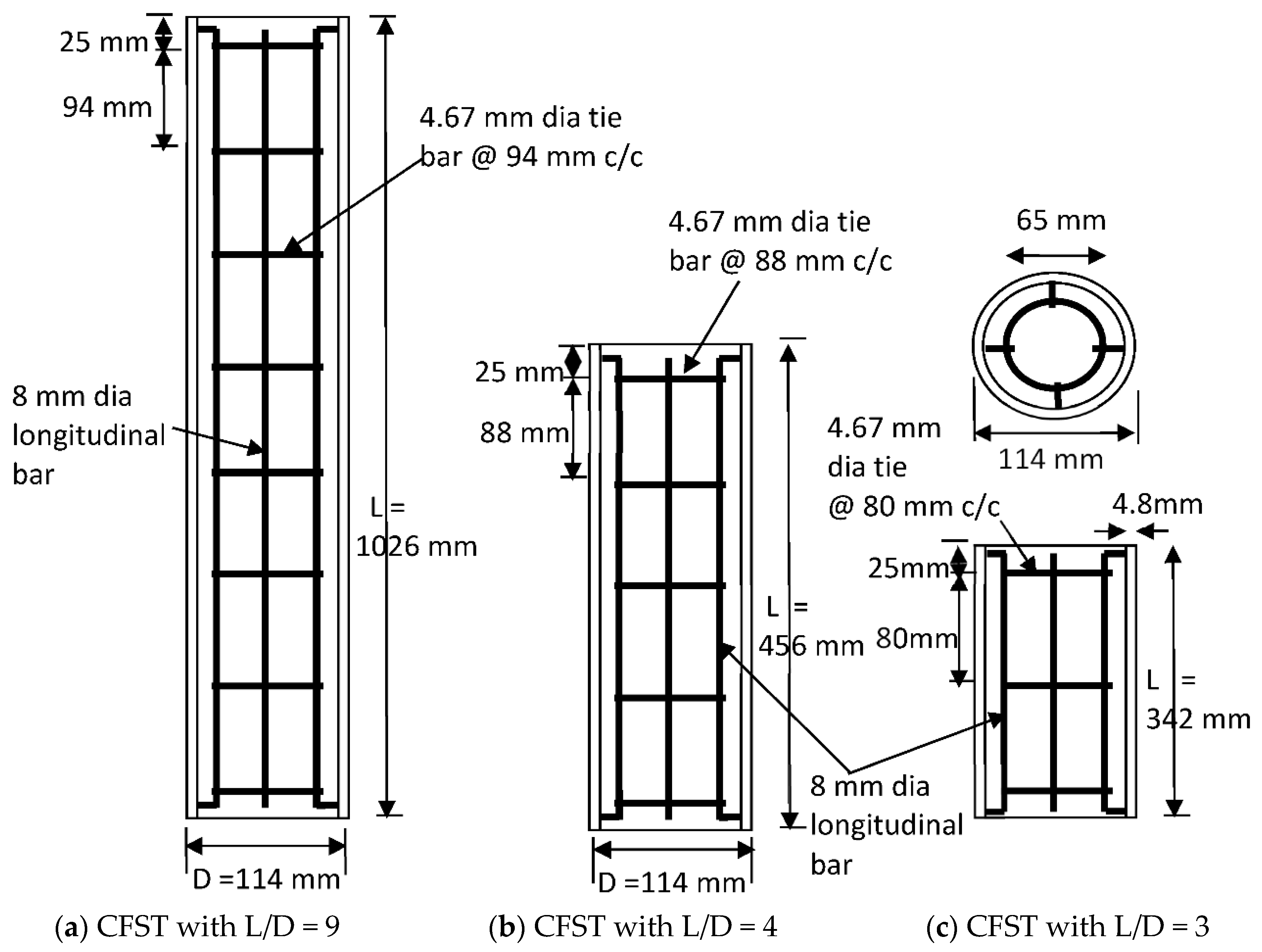

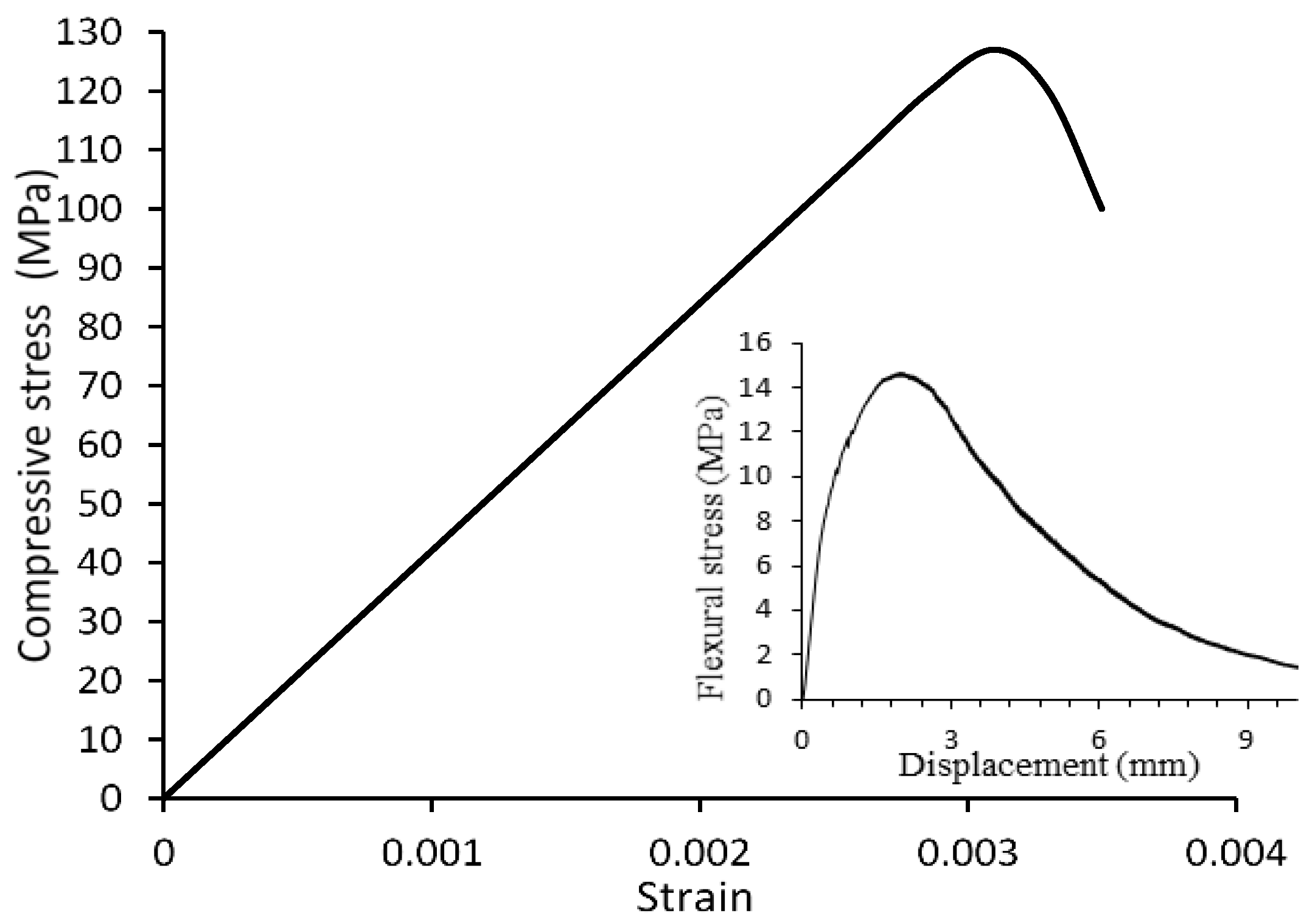

2.1. Column Sample Specifications

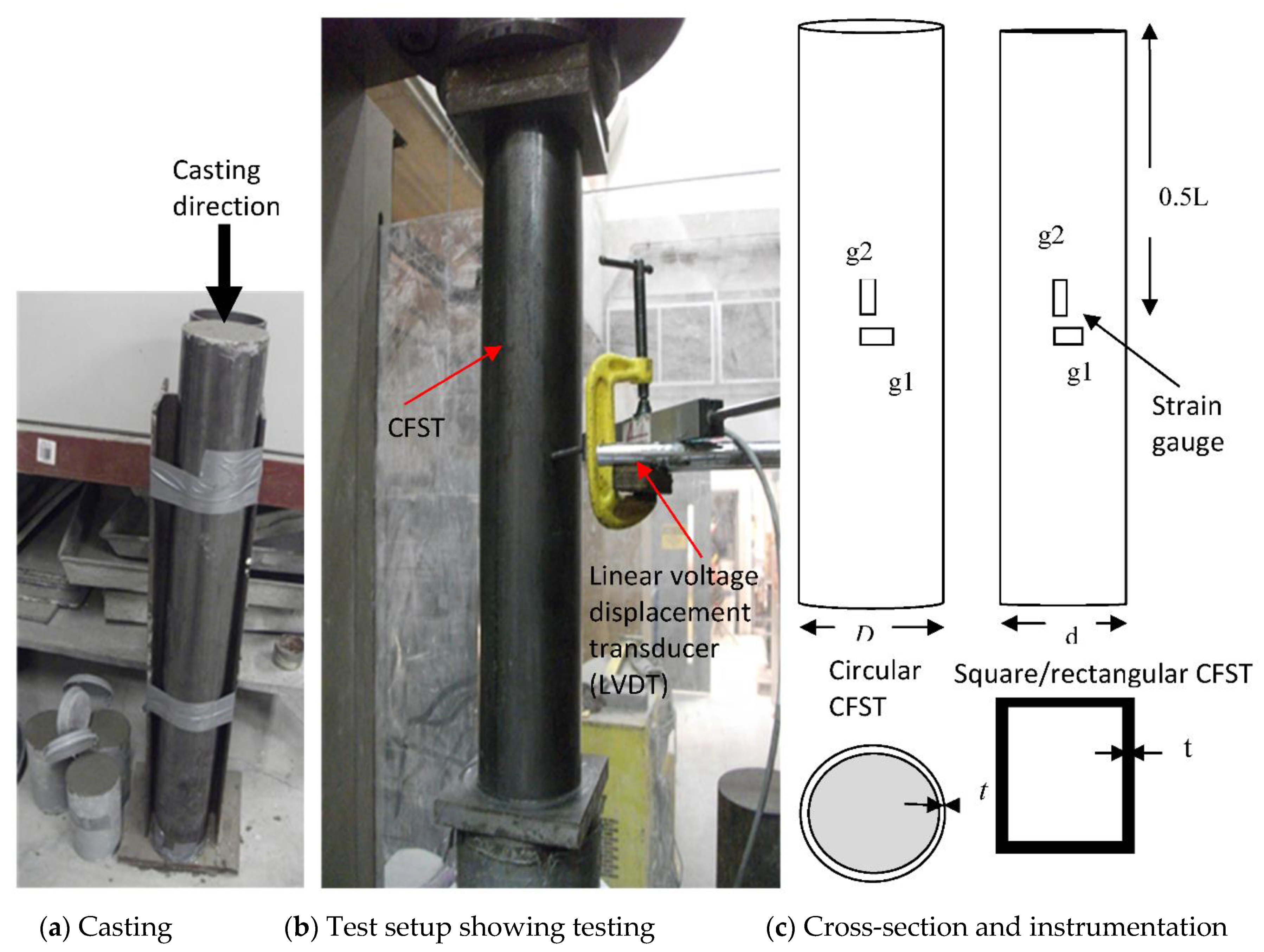

2.2. Specimen Casting, Curing, Instrumentation, and Testing

3. Results and Discussion

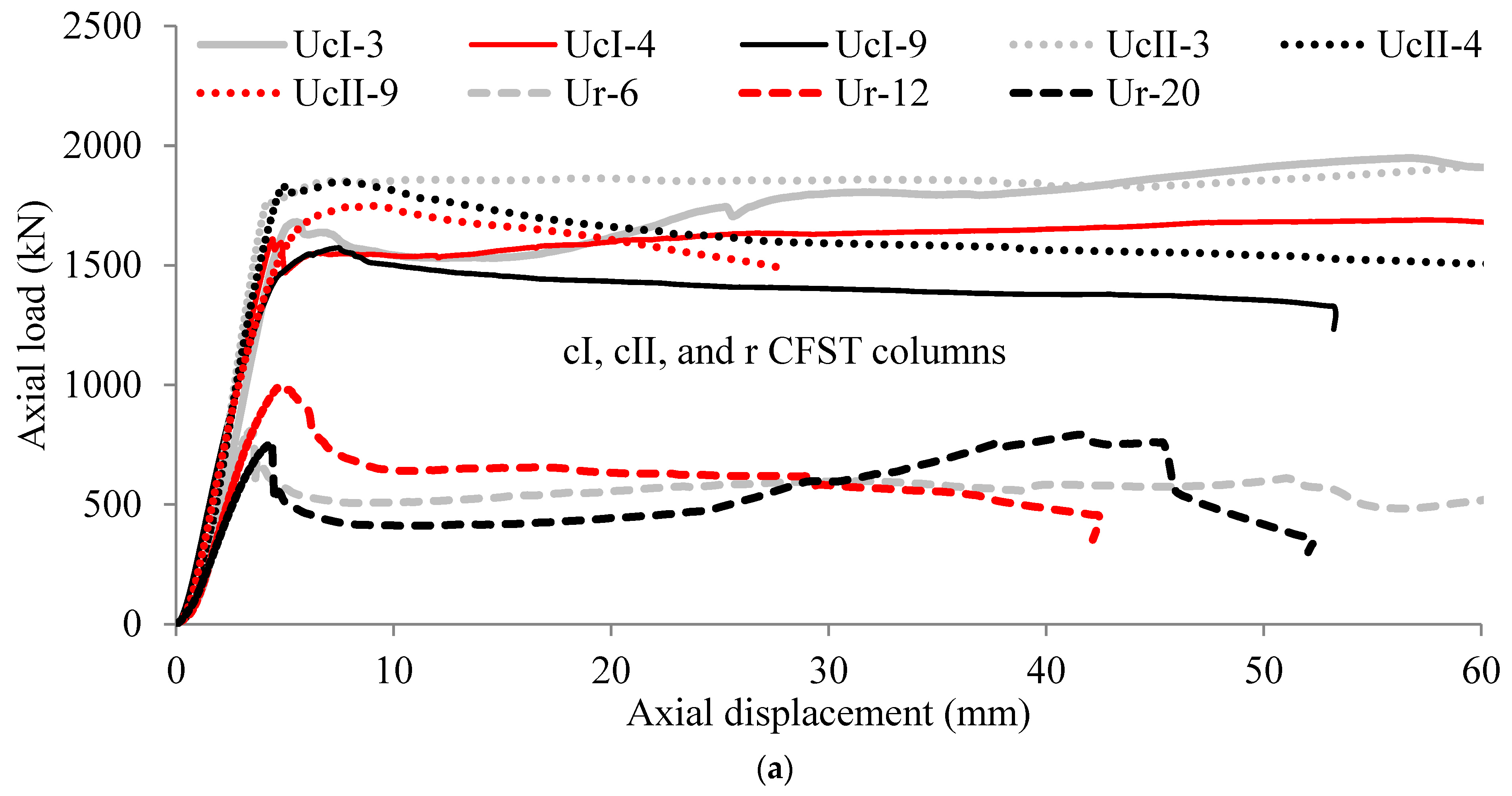

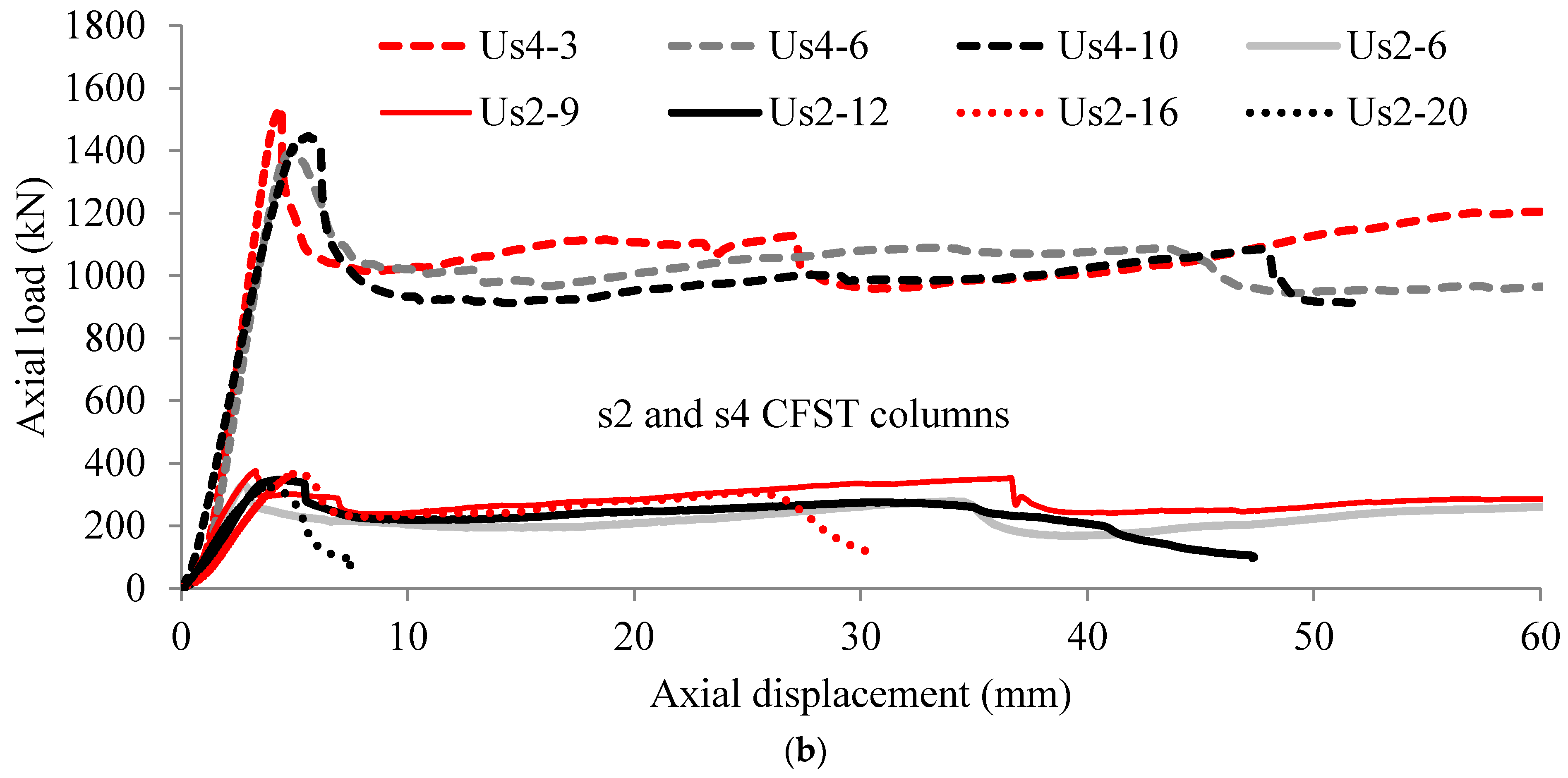

3.1. Load-Displacement Responses and Failure Modes of CFST Columns

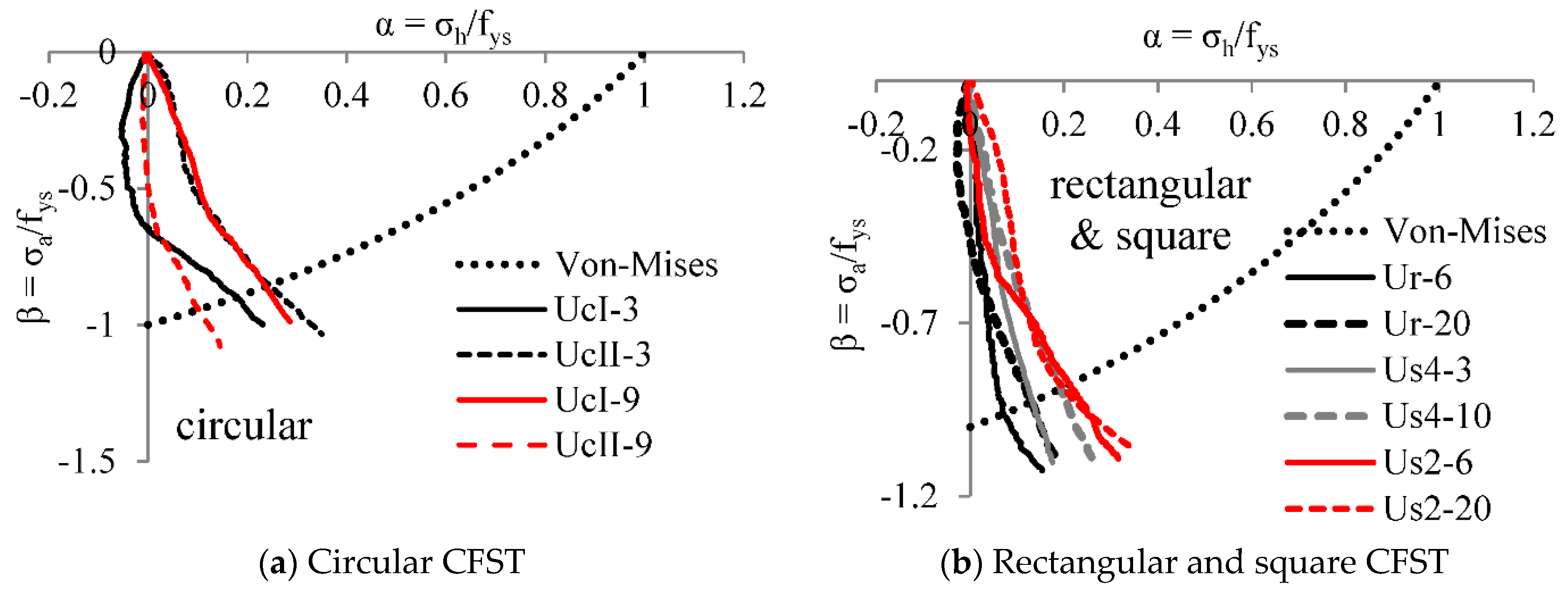

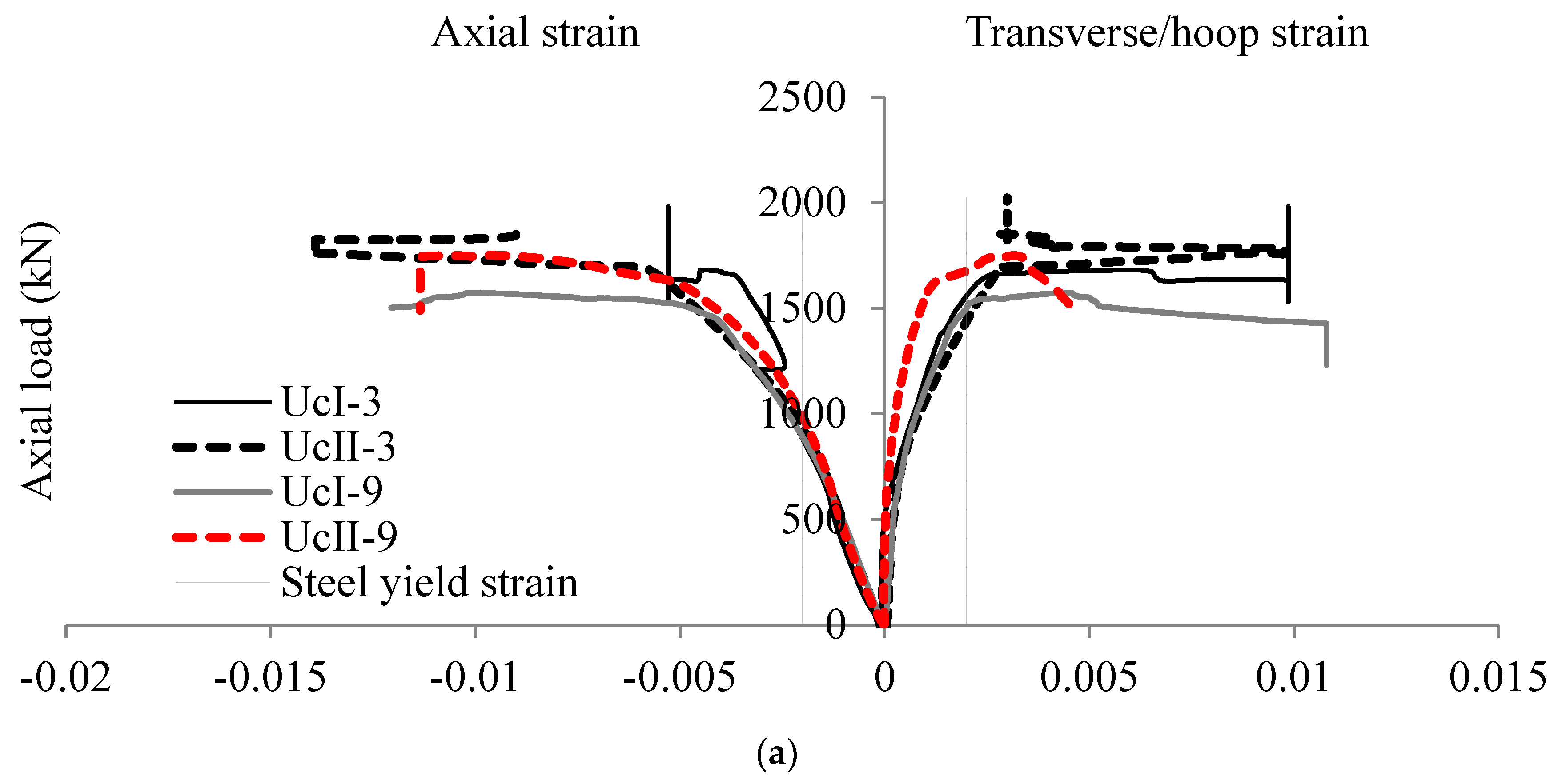

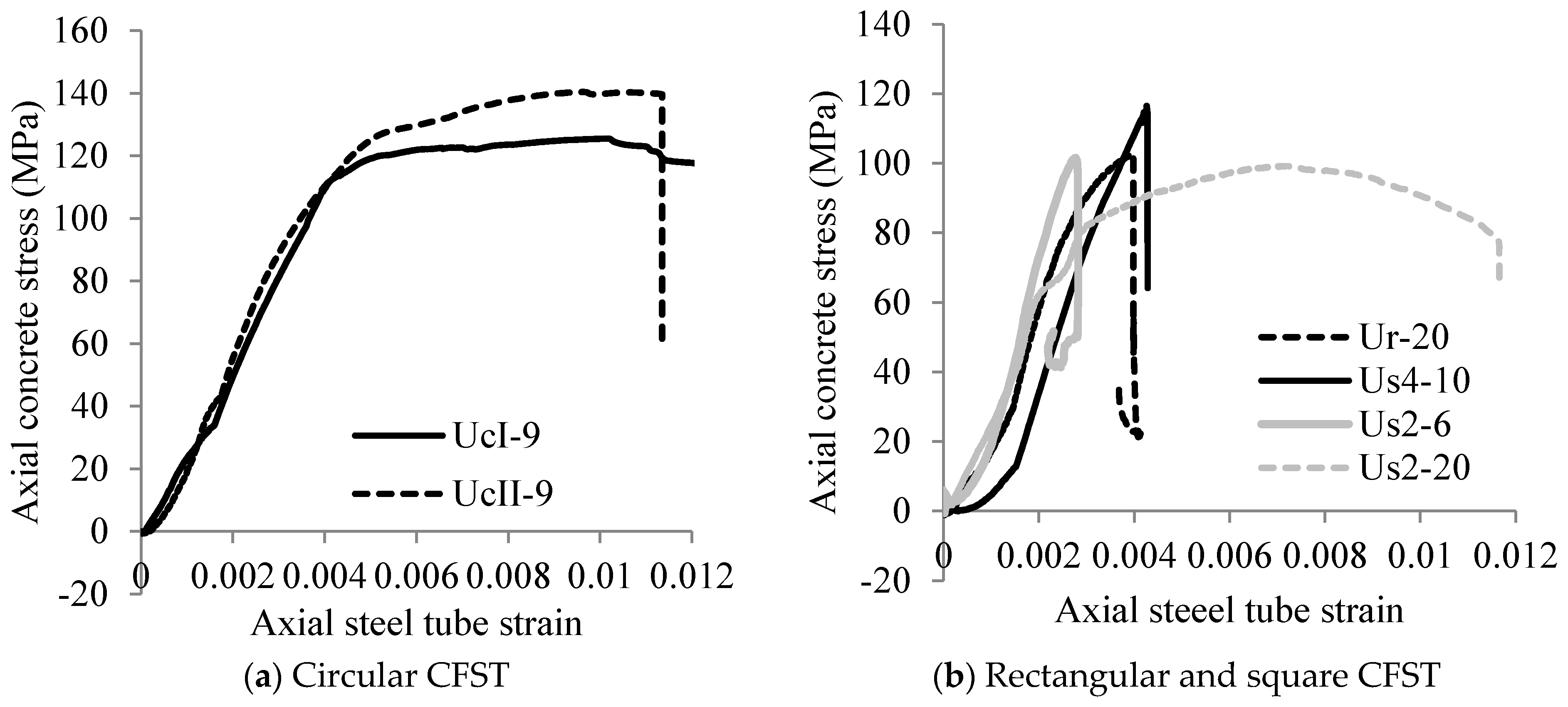

3.2. Analysis of Stress-Strain Behavior in CFST Columns

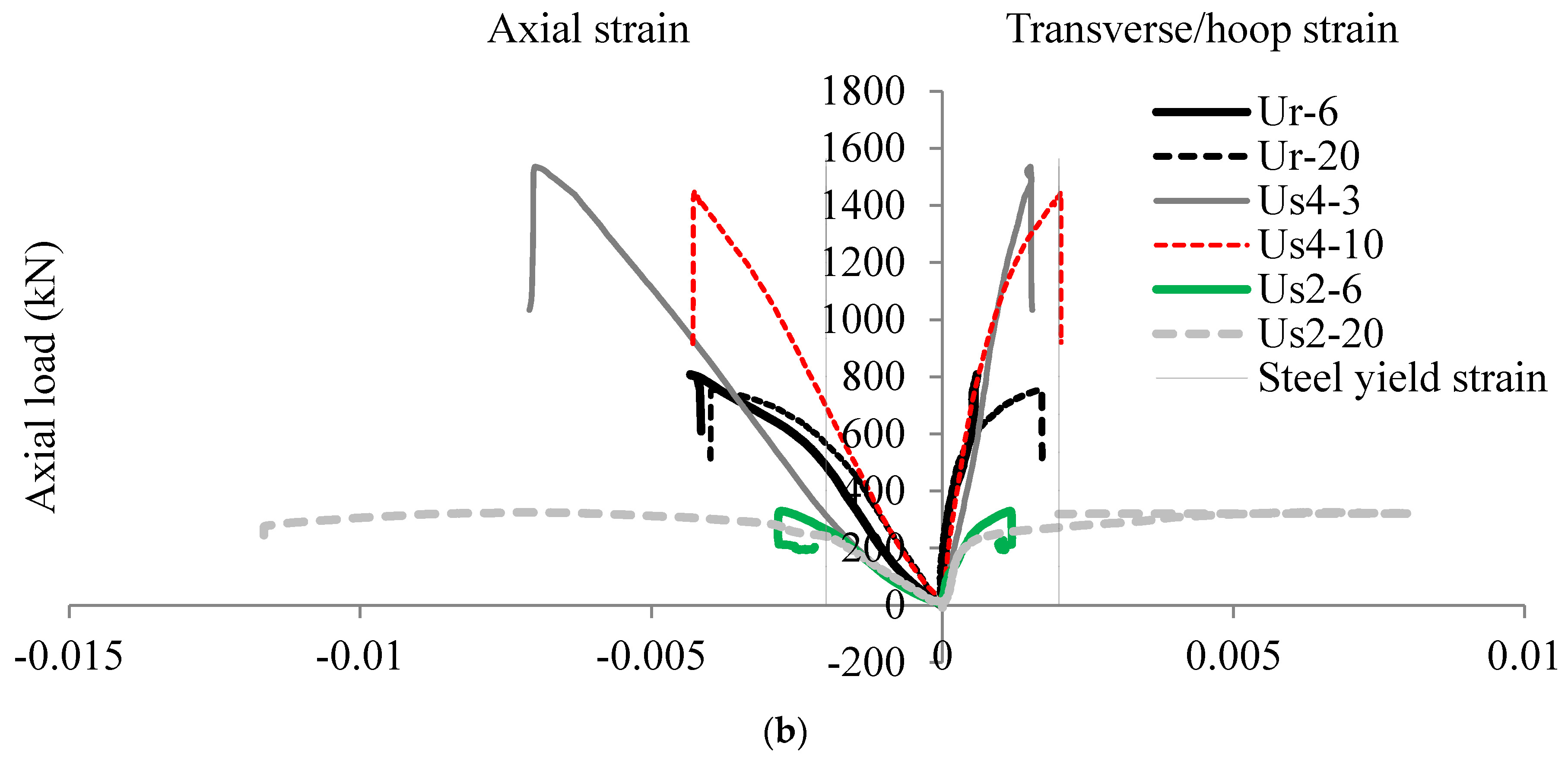

3.2.1. Biaxial Stress Development and Confinement in CFST Columns

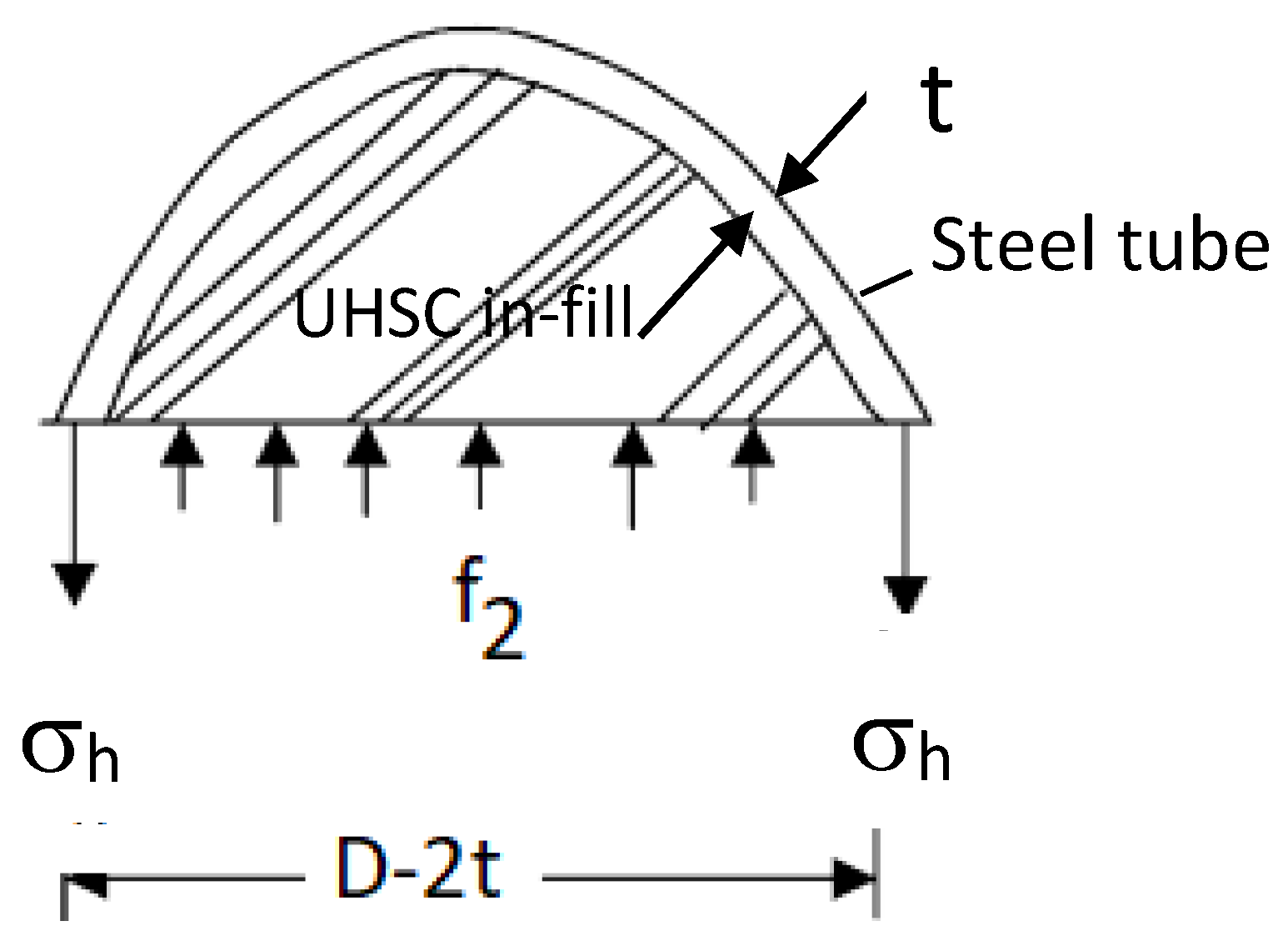

3.2.2. Quantification of Lateral Stresses and Concrete Confinement

4. Analytical Models for Confined Concrete Strength

Performance of Confined Concrete Strength Models

5. Development of Strength Models for CFST Columns

5.1. Code-Based Design Procedures for CFST Columns

5.2. Suggested Analytical Models for the Strength of CFST Columns

5.3. Performance of Strength Prediction Models and Identification of the Most Suitable Model

6. Conclusions

- UHSC-filled CFST columns failed to exhibit different types of failure based on slenderness (L/D or L/d ratios). Failure modes included global buckling for slenderness ranging between 16 and 20, shear yielding associated with successive formation of local buckling for slenderness varying from 4 to 12, and radial expansion with tube tearing for slenderness of 3.

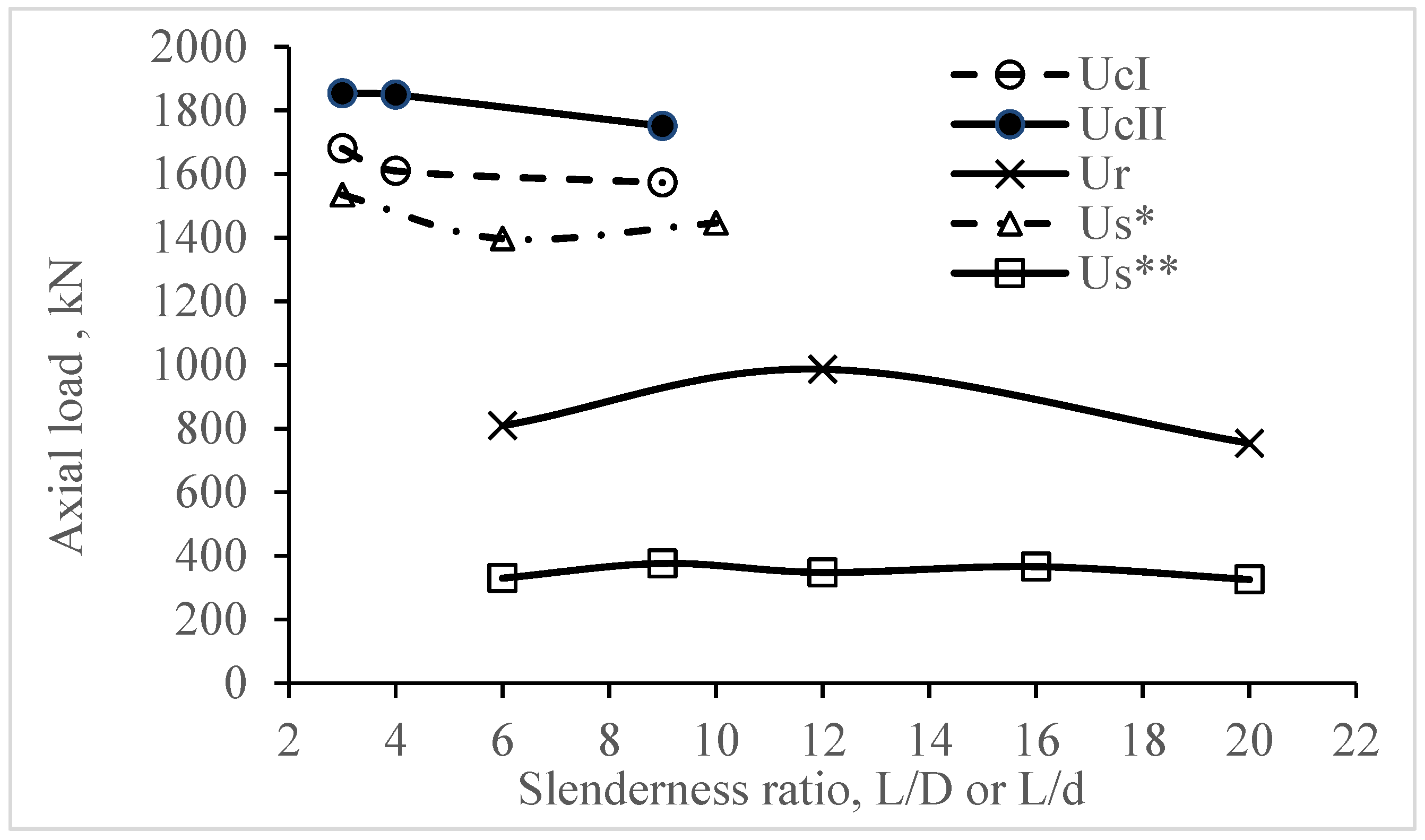

- Axial load-displacement responses of circular CFST columns generally showed multiple peaks and drops showing increase in load after each drop producing large post-peak deformation (ductility) before failure but the first peak always governed the load capacity. Square and rectangular columns displayed similar load-displacement responses exhibiting decrease in load after the first peak and lower ductility.

- Axial load capacity/strength generally decreased with the increase of slenderness and increased with the presence of longitudinal and hoop reinforcement. Circular columns showed higher axial load strength and ductility compared to their rectangular/square counterparts. The combined effect of D/t, L/D or L/d, steel tube geometry and failure modes governed the axial strength of CFST columns.

- Experimental UHSC confined strength increased with the increase of tube thickness, decreased for columns of higher slenderness and increased (by 11 to 27%) with the presence of longitudinal and hoop reinforcements. Existing analytical models overestimated the confined concrete strength resulting from tube and hoop confinement in CFST columns compared to those of experiments. This is attributed to overestimating the ability of UHSC to soften and dilate with progressive loading.

- Predicted axial strength from the three suggested analytical models were often greater than those obtained from experiments. This overestimation is attributed to the overprediction of confined UHSC strength and reduction factors are suggested for incorporation in analytical models for strength prediction.

- Eurocode 4 overpredicted the strength of CFST columns. Canadian CAN/CSA S16-09 and American AISC code provisions performed well, especially in estimating the strength of circular columns with or without bar/hoop reinforcements. The AISC code was especially good for square and rectangular UHSC-filled tube columns as it took into account cross-sectional shape.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dai, X.H.; Lam, D.; Jamaluddin, N.; Ye, J. Numerical analysis of slender elliptical concrete filled columns under axial compression. Thin-Walled Struct. 2014, 77, 26–35. [Google Scholar] [CrossRef]

- Inai, E.; Mukai, A.; Kai, M.; Tokinoya, H.; Fukumoto, T.; Mori, K. Behavior of concrete-filled steel tube beam columns. J. Struct. Eng. ASCE 2004, 130, 189–202. [Google Scholar] [CrossRef]

- Lachemi, M.; Hossain, K.M.A.; Lambros, V. Axial load behavior of self-consolidating concrete filled steel tube columns in construction and service stages. ACI Struct. J. 2006, 103, 38–47. [Google Scholar]

- Nie, J.-G.; Wang, Y.-H.; Fan, J.-S. Experimental study on seismic behavior of concrete filled steel tube columns under pure torsion and compression–torsion cyclic load. J. Constr. Steel Res. 2012, 79, 115–126. [Google Scholar] [CrossRef]

- Shakir-Khalil, H.; Zeghiche, J. Experimental behavior of concrete filled rolled rectangular hollow section columns. J. Struct. Eng. ASCE 1989, 67, 346–353. [Google Scholar]

- Gupta, P.; Sarda, S.; Kumar, M. Experimental and computational study of concrete filled steel tubular columns under axial loads. J. Constr. Steel Res. 2007, 63, 182–193. [Google Scholar] [CrossRef]

- Vrcelj, Z.; Uy, B. Strength of slender concrete-filled steel box columns incorporating local buckling. J. Constr. Steel Res. 2002, 58, 275–300. [Google Scholar] [CrossRef]

- Yu, Q.; Tao, Z.; Wu, Y.-X. Experimental behaviour of high performance concrete-filled steel tubular columns. Thin Walled Struct. 2008, 46, 362–370. [Google Scholar] [CrossRef]

- Lachemi, M.; Hossain, K.; Lambros, V. Self-consolidating concrete filled steel tube columns—Design equations for confinement and axial strength. Struct. Eng. Mech. 2006, 22, 541–562. [Google Scholar] [CrossRef]

- Hossain, K.M.A.; Mak, C.; Ametrano, D. GFRP reinforced UHPC composites for sustainable bridge construction. Can. Civ. Eng. 2012, 29, 12–15. [Google Scholar]

- Graybeal, B.A. Compressive behavior of ultra-high performance fibre-reinforced concrete. ACI Mat. J. 2007, 104, 146–152. [Google Scholar]

- Tafraoui, A.; Escadeillas, G.; Lebaili, S.; Vidal, T. Metakaolin in the formulation of UHPC. Constr. Build. Mater. 2009, 23, 669–674. [Google Scholar] [CrossRef]

- Song, T.-Y.; Xiang, K. Performance of axially-loaded concrete-filled steel tubular circular columns using ultra-high strength concrete. Structures 2020, 24, 163–176. [Google Scholar] [CrossRef]

- Xiong, M.-X.; Liew, J.Y.R. Buckling behavior of circular steel tubes infilled with C170/185 ultra-high-strength concrete under fire. Eng. Struct. 2020, 212, 10523. [Google Scholar] [CrossRef]

- Liew, J.R.; Xiong, D. Ultra-High Strength Concrete Filled Composite Columns for Multi-Storey Building Construction. Adv. Struct. Eng. 2012, 15, 1487–1503. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, R.; Jia, L.-J.; Wang, J.-Y.; Gu, P.; Xiong, M.-X.; Xiong, D.-X.; Liew, J.Y.R. Behaviour of steel tubular members infilled with ultra-high strength concrete. J. Constr. Steel Res. 2017, 138, 168–183. [Google Scholar]

- Chen, S.; Zhang, R.; Jia, L.-J.; Wang, J.-Y.; Gu, P. Structural behavior of UHPC filled steel tube columns under axial loading. Thin-Walled Struct. 2018, 130, 550–563. [Google Scholar] [CrossRef]

- Xiong, M.-X.; Xiong, D.-X.; Liew, J.R. Axial performance of short concrete filled steel tubes with high- and ultra-high-strength materials. Eng. Struct. 2017, 136, 494–510. [Google Scholar] [CrossRef]

- Liu, S.; Ding, X.; Li, X.; Liu, Y.; Zhao, S. Behavior of Rectangular-Sectional Steel Tubular Columns Filled with High-Strength Steel Fiber Reinforced Concrete Under Axial Compression. Materials 2019, 12, 2716. [Google Scholar] [CrossRef] [Green Version]

- Eurocode 4. Design of Composite Steel and Concrete Structures, Part 1.1: General Rules and Rules for Buildings; British Standards Institution: London, UK, 2004. [Google Scholar]

- CAN/CSA S16-09. Limit States Design of Steel Structures, Rexdale; Canadian Standards Association: Toronto, ON, Canada, 2009. [Google Scholar]

- American Institute of Steel Construction (AISC). Manual of Steel Construction, Load and Resistance Factor Design, 3rd ed.; AISC: Chicago, IL, USA, 2005. [Google Scholar]

- Hossain, K.M.A. Behaviour of thin walled composite columns under axial loading. Compos. Part B Eng. 2003, 34, 715–725. [Google Scholar] [CrossRef]

- Sakino, K.; Nakahara, H.; Morino, S.; Nishiyama, I. Behavior of Centrally Loaded Concrete-Filled Steel-Tube Short Columns. J. Struct. Eng. 2004, 130, 180–188. [Google Scholar] [CrossRef]

- Fujimoto, T.; Mukai, A.; Nishiyama, I.; Sakino, K. Behavior of Eccentrically Loaded Concrete-Filled Steel Tubular Columns. J. Struct. Eng. 2004, 130, 203–212. [Google Scholar] [CrossRef]

- Richart, F.E.; Brandtzaeg, A.; Brown, R.L. A Study of the Failure of Concrete under Combined Compressive Stresses; Bulleting #185; University of Illinois, Engineering Experimental Station: Urbana, IL, USA, 1928. [Google Scholar]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- O’Shea, M.D.; Bridge, R.Q. Design of circular thin-walled concrete filled steel tubes. J. Struct. Eng. ASCE 2000, 126, 1295–1303. [Google Scholar] [CrossRef]

- Schneider, S.P. Axially loaded concrete-filled steel tubes. J. Struct. Eng. ASCE 1998, 124, 1125–1138. [Google Scholar] [CrossRef]

| Column Desig. | L, mm | t, mm | D, mm | b, mm | d, mm | D/t or b/t | L/D or L/d | Pexp, kN | Failure Mode |

|---|---|---|---|---|---|---|---|---|---|

| UcI-3 | 342 | 4.8 | 114 | - | - | 24 | 3 | 1681 | Radial expansion |

| UcI-4 | 456 | 4.8 | 114 | - | - | 24 | 4 | 1610 | Shear |

| UcI-9 | 1026 | 4.8 | 114 | - | - | 24 | 9 | 1573 | Shear |

| UcII-3 | 342 | 4.8 | 114 | - | - | 24 | 3 | 1853 | Radial expansion |

| UcII-4 | 456 | 4.8 | 114 | - | - | 24 | 4 | 1849 | Shear |

| UcII-9 | 1026 | 4.8 | 114 | - | - | 24 | 9 | 1751 | Global buckling |

| Ur-6 | 306 | 3.2 | - | 102 | 51 | 32 | 6 | 809 | Shear |

| Ur-12 | 612 | 3.2 | - | 102 | 51 | 32 | 12 | 987 | Shear |

| Ur-20 | 1020 | 3.2 | - | 102 | 51 | 32 | 20 | 754 | Global buckling |

| Us4-3 | 306 | 3.2 | - | 102 | 102 | 32 | 3 | 1535 | Radial expansion |

| Us4-6 | 612 | 3.2 | - | 102 | 102 | 32 | 6 | 1397 | Local buckling |

| Us4-10 | 1020 | 3.2 | - | 102 | 102 | 32 | 10 | 1446 | Local buckling |

| Us2-6 | 306 | 1.6 | - | 51 | 51 | 32 | 6 | 330 | Shear |

| Us2-9 | 459 | 1.6 | - | 51 | 51 | 32 | 9 | 376 | Shear |

| Us2-12 | 612 | 1.6 | - | 51 | 51 | 32 | 12 | 348 | Shear |

| Us2-16 | 816 | 1.6 | - | 51 | 51 | 32 | 16 | 366 | Global buckling |

| Us2-20 | 1020 | 1.6 | - | 51 | 51 | 32 | 20 | 326 | Global buckling |

| Column Type | L/D or L/d | α | β | |||

|---|---|---|---|---|---|---|

| UcI | 3 | 9 | 0.17 | 0.23 | 0.89 | 0.85 |

| UcII | 3 | 9 | 0.24 | 0.10 | 0.84 | 0.93 |

| Ur | 6 | 20 | 0.07 | 0.13 | 0.96 | 0.93 |

| Us4 | 3 | 10 | 0.13 | 0.19 | 0.93 | 0.89 |

| Us2 | 6 | 20 | 0.21 | 0.20 | 0.88 | 0.89 |

| Column | Pu, kN | εu | Pys, kN | εys | Pu/Pys | εu/εys |

|---|---|---|---|---|---|---|

| UcI-3 | 1681 | −0.004486 | 761 | −0.001682 | 2.21 | 2.67 |

| UcI-9 | 1573 | −0.010181 | 750 | −0.001600 | 2.10 | 6.36 |

| UcII-3 | 1853 | −0.009041 | 778 | −0.001594 | 2.38 | 5.67 |

| UcII-9 | 1751 | −0.009562 | 880 | −0.001757 | 1.99 | 5.44 |

| Ur-6 | 809 | −0.004329 | 343 | −0.001514 | 2.36 | 2.86 |

| Ur-20 | 754 | −0.003912 | 446 | −0.001464 | 1.69 | 2.67 |

| Us4-3 | 1535 | −0.006991 | 224 | −0.001589 | 6.85 | 4.40 |

| Us4-10 | 1446 | −0.004261 | 505 | −0.001521 | 2.86 | 2.80 |

| Us2-6 | 330 | −0.002772 | 204 | −0.001551 | 1.62 | 1.79 |

| Us2-20 | 326 | −0.007134 | 195 | −0.001567 | 1.67 | 4.55 |

| Column | f′cc, MPa | f′cc/f′c | f2 or f2max, MPa |

|---|---|---|---|

| UcI-3 | 139 | 1.09 | 5.2 |

| UcI-9 | 125 | 0.99 | 7.0 |

| UcII-3 | 161 | 1.27 | 108.0 |

| UcII-9 | 140 | 1.11 | 97.3 |

| Ur-6 | 113 | 0.89 | 2.2 |

| Ur-20 | 102 | 0.81 | 4.1 |

| Us4-3 | 124 | 0.98 | 2.7 |

| Us4-10 | 117 | 0.92 | 4.0 |

| Us2-6 | 102 | 0.80 | 4.5 |

| Us2-20 | 99 | 0.78 | 4.3 |

| Column | Confined Concrete Strength (f′cct), MPa | Ratio of Confined Concrete Strength Theoretical/Test | |||||

|---|---|---|---|---|---|---|---|

| Test | Theoretical Models | ||||||

Equation (8) | Equation (9) | Equation (10) | Equation (8) | Equation (9) | Equation (10) | ||

| UcI-3 | 139 | 148 | 160 | 149 | 1.07 | 1.15 | 1.07 |

| UcI-9 | 125 | 156 | 170 | 158 | 1.24 | 1.36 | 1.26 |

| UcII-3 | 161 | 158 | 246 | 231 | 0.98 | 1.52 | 1.43 |

| UcII-9 | 140 | 140 | 220 | 208 | 1.00 | 1.57 | 1.48 |

| Ur-6 | 113 | 136 | 142 | 133 | 1.21 | 1.26 | 1.18 |

| Ur-20 | 102 | 144 | 153 | 143 | 1.41 | 1.50 | 1.40 |

| Us4-3 | 124 | 138 | 145 | 136 | 1.11 | 1.16 | 1.09 |

| Us4-10 | 117 | 143 | 153 | 142 | 1.23 | 1.31 | 1.22 |

| Us2-6 | 102 | 145 | 156 | 145 | 1.43 | 1.53 | 1.43 |

| Us2-20 | 99 | 144 | 154 | 144 | 1.45 | 1.55 | 1.45 |

| Column Desig. | Axial Strength (kN) | Ratio of Strength (Test/Predicted) Pexp/Pp | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Test | Predicted (Equation (14)) | Predicted by Codes Equations (11)–(13) | |||||||||||

| Pexp | CSA [18] | AISC-LRFD [19] | EC4 [20] | CSA | AISC | EC4 | |||||||

| UcI-3 | 1681 | 1764 | 1864 | 1768 | 1624 | 1569 | 2029 | 0.95 | 0.90 | 0.95 | 1.04 | 1.07 | 0.83 |

| UcI-4 | 1610 | 1776 | 1883 | 1785 | 1564 | 1541 | 1913 | 0.91 | 0.86 | 0.90 | 1.03 | 1.04 | 0.84 |

| UcI-9 | 1573 | 1805 | 1929 | 1823 | 1382 | 1417 | 1858 | 0.87 | 0.82 | 0.86 | 1.14 | 1.11 | 0.85 |

| UcII-3 | 1853 | 1950 | 2705 | 2576 | 1624 | 1692 | 2155 | 0.95 | 0.69 | 0.72 | 1.14 | 1.10 | 0.86 |

| UcII-4 | 1849 | 1916 | 2655 | 2533 | 1564 | 1660 | 2039 | 0.97 | 0.70 | 0.73 | 1.18 | 1.11 | 0.91 |

| UcII-9 | 1751 | 1840 | 2530 | 2427 | 1382 | 1516 | 1984 | 0.95 | 0.69 | 0.72 | 1.27 | 1.16 | 0.88 |

| Ur-6 | 809 | 874 | 899 | 860 | 825 | 743 | 991 | 0.93 | 0.90 | 0.94 | 0.98 | 1.09 | 0.82 |

| Ur-12 | 987 | 885 | 917 | 876 | 739 | 690 | 956 | 1.12 | 1.08 | 1.13 | 1.34 | 1.43 | 1.03 |

| Ur-20 | 754 | 899 | 941 | 896 | 577 | 578 | 1115 | 0.84 | 0.80 | 0.84 | 1.31 | 1.30 | 0.68 |

| Us4-3 | 1535 | 1633 | 1695 | 1610 | 1434 | 1370 | 1925 | 0.94 | 0.91 | 0.95 | 1.07 | 1.12 | 0.80 |

| Us4-6 | 1397 | 1646 | 1720 | 1630 | 1366 | 1334 | 1809 | 0.85 | 0.81 | 0.86 | 1.02 | 1.05 | 0.77 |

| Us4-10 | 1446 | 1665 | 1751 | 1657 | 1252 | 1251 | 1791 | 0.87 | 0.83 | 0.87 | 1.15 | 1.16 | 0.81 |

| Us2-6 | 330 | 424 | 448 | 423 | 347 | 337 | 456 | 0.78 | 0.74 | 0.78 | 0.95 | 0.98 | 0.72 |

| Us2-9 | 376 | 423 | 447 | 423 | 326 | 322 | 452 | 0.89 | 0.84 | 0.89 | 1.15 | 1.17 | 0.83 |

| Us2-12 | 348 | 423 | 446 | 422 | 300 | 303 | 458 | 0.82 | 0.78 | 0.82 | 1.16 | 1.15 | 0.76 |

| Us2-16 | 366 | 423 | 446 | 422 | 249 | 218 | 282 | 0.87 | 0.82 | 0.87 | 1.47 | 1.68 | 1.30 |

| Us2-20 | 326 | 422 | 445 | 421 | 231 | 209 | 283 | 0.77 | 0.73 | 0.77 | 1.41 | 1.56 | 1.15 |

| R: Richart et al.; M: Mander et al.; O: O’Shea and Bridge | Mean ratio | 0.90 | 0.82 | 0.86 | 1.17 | 1.19 | 0.87 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, K.M.A.; Chu, K.; Anwar, M.S. Axial Load Behavior of Ultrahigh Strength Concrete-Filled Steel Tube Columns of Various Geometric and Reinforcement Configurations. Infrastructures 2021, 6, 66. https://doi.org/10.3390/infrastructures6050066

Hossain KMA, Chu K, Anwar MS. Axial Load Behavior of Ultrahigh Strength Concrete-Filled Steel Tube Columns of Various Geometric and Reinforcement Configurations. Infrastructures. 2021; 6(5):66. https://doi.org/10.3390/infrastructures6050066

Chicago/Turabian StyleHossain, Khandaker M. A., Katie Chu, and Muhammed S. Anwar. 2021. "Axial Load Behavior of Ultrahigh Strength Concrete-Filled Steel Tube Columns of Various Geometric and Reinforcement Configurations" Infrastructures 6, no. 5: 66. https://doi.org/10.3390/infrastructures6050066

APA StyleHossain, K. M. A., Chu, K., & Anwar, M. S. (2021). Axial Load Behavior of Ultrahigh Strength Concrete-Filled Steel Tube Columns of Various Geometric and Reinforcement Configurations. Infrastructures, 6(5), 66. https://doi.org/10.3390/infrastructures6050066