Rheological and Aging Characteristics of Polymer-Modified Asphalt with the Addition of Sulfur †

Abstract

:1. Introduction

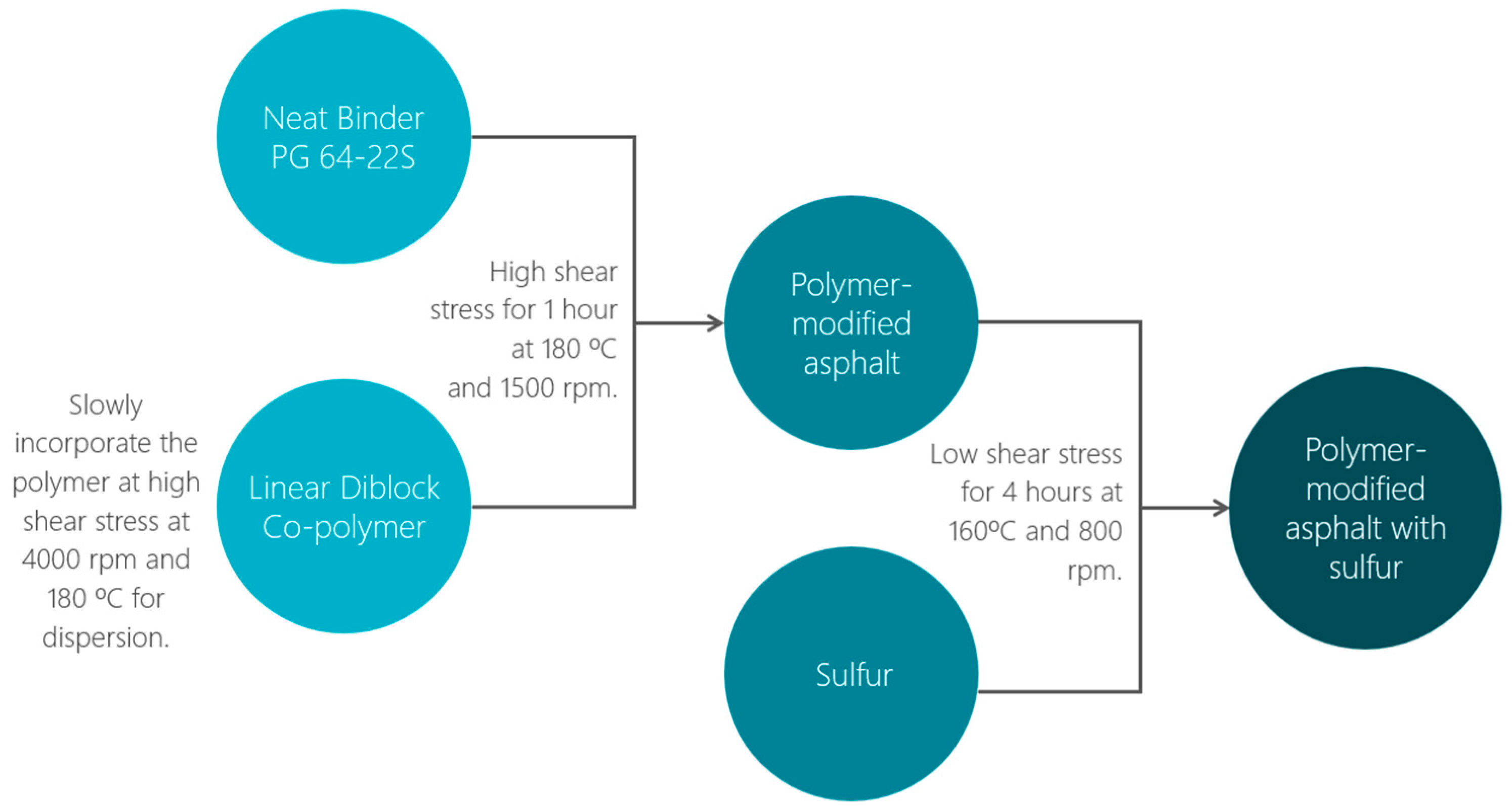

2. Materials and Methods

2.1. Materials

2.2. Methods

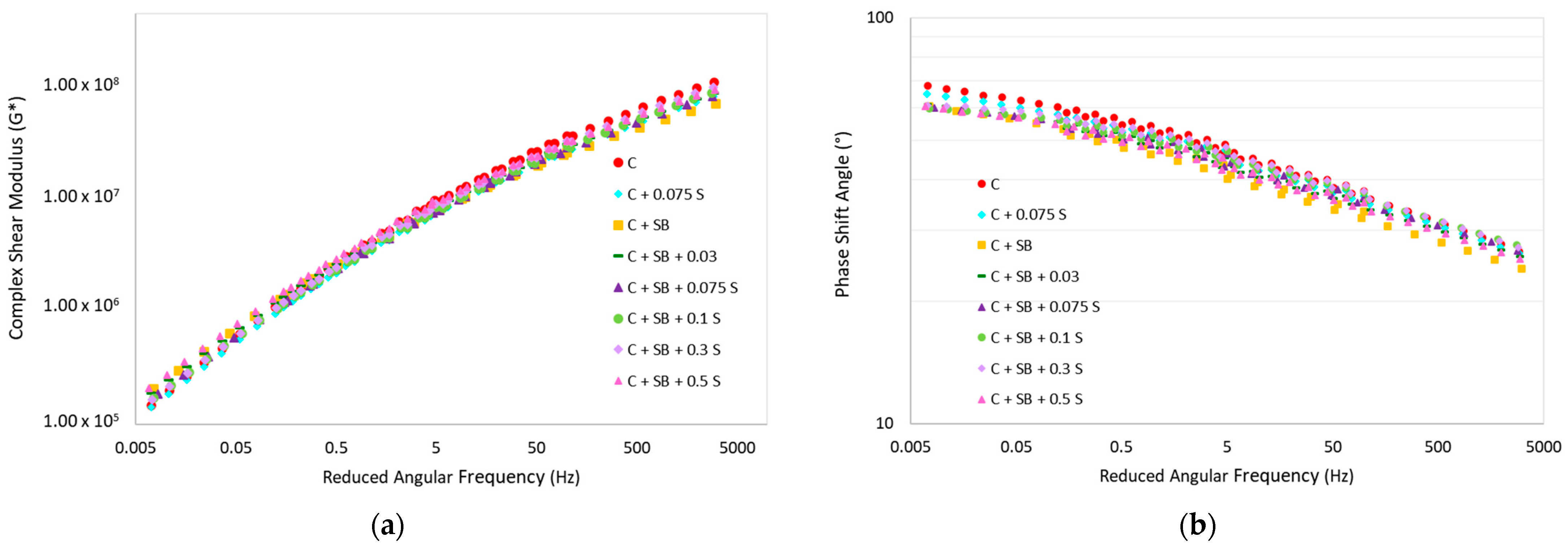

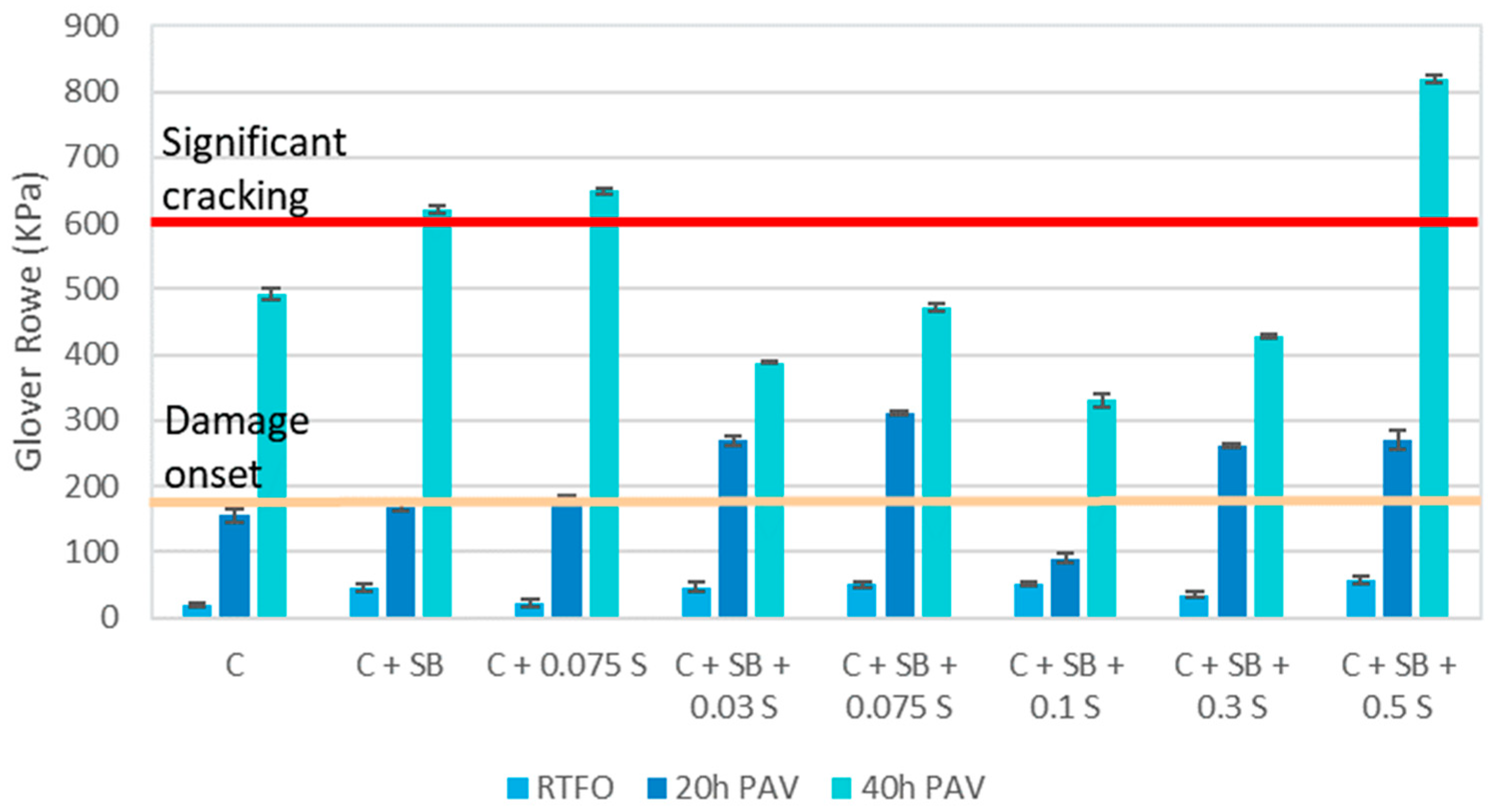

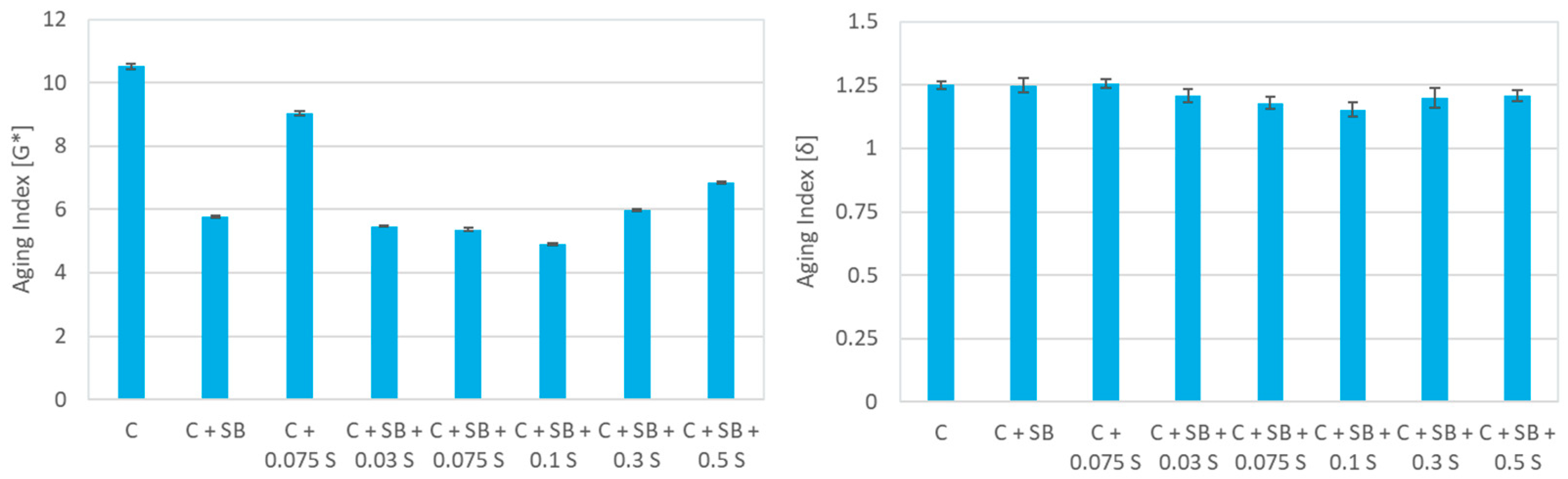

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Airey, G.D. Rheological properties of styrene butadiene styrene polymer modified road bitumens. Fuel 2003, 82, 1709–1719. [Google Scholar] [CrossRef]

- Vlachovicova, Z.; Wekumbura, C.; Stastna, J.; Zanzotto, L. Creep characteristics of asphalt modified by radial styrene–butadiene–styrene copolymer. Constr. Build. Mater. 2007, 21, 567–577. [Google Scholar] [CrossRef]

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112. [Google Scholar] [CrossRef] [PubMed]

- Sun, D.; Lu, W. Investigation and improvement of storage stability of SBS modified asphalt. Pet. Sci. Technol. 2003, 21, 901–910. [Google Scholar] [CrossRef]

- Imanbayev, Y.; Akkenzheyeva, A.; Bussurmanova, A.; Serikbayeva, A.; Boranbayeva, A. Preparation of polymer bitumen binder in the presence of a stabilizer. Processes 2021, 9, 182. [Google Scholar] [CrossRef]

- Abed, A.H. Effects of functionalized polyethylene and styrene butadiene styrene polymers on performance grade of local asphalt binder. J. Eng. 2012, 18, 735–742. [Google Scholar]

- King, G.N.; King, H.W.; Charerot, P.; Planche, J.P.; Harders, O. Using European wheel cracking and restrained tensile teste to validate SHRP performance graded binder specification for polymer modified asphalt. In Proceedings of the Fifth Eurobitume Congress 1993, Stockholm, Sweden, 16–18 June 1993; Volume 1, pp. 51–55. [Google Scholar]

- Sun, D.; Ye, F.; Shi, F.; Lu, W. Storage stability of SBS-modified road asphalt: Preparation, morphology, and rheological properties. Pet. Sci. Technol. 2006, 24, 1067–1077. [Google Scholar] [CrossRef]

- Gawel, I.; Stepkowski, R.; Czechowski, F. Molecular Interactions between Rubber and Asphalt. Ind. Eng. Chem. Res. 2006, 45, 3044–3049. [Google Scholar] [CrossRef]

- Tang, N.; Huang, W.; Hao, G. Effect of aging on morphology, rheology, and chemical properties of highly polymer modified asphalt binders. Constr. Build. Mater. 2021, 281, 107–116. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Rheological characterization of storage-stable SBS-modified asphalts. Polym. Test. 2002, 21, 295–302. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS- and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Bahia, H.; Golalipour, A.; Coenen, A. Comparing Effects of Crumb Rubber and Synthetic Polymers on Hot Mix As-phalt Performance. In Proceedings of the Asphalt Rubber Conference, Munich, Germany, 26 October 2012; pp. 1–26. [Google Scholar]

- Oae, S.; Kim, Y.H.; Fukushima, D.; Takata, T. Oxidation of some biologially active and related sulfur containing compounds. Pure Appl. Chem. 1977, 49, 153–162. [Google Scholar] [CrossRef]

- Chough, S.H.; Chang, D.H. Kinetics of sulfur vulcanization of NR, BR, SBR, and their blends using a rheometer and DSC. J. Appl. Polym. Sci. 1996, 61, 449–454. [Google Scholar] [CrossRef]

- Liang, M.; Xin, X.; Fan, W.; Wang, H.; Ren, S.; Shi, J. Effects of polymerized sulfur on rheological properties, morphology, and stability of SBS modified asphalt. Constr. Build. Mater. 2017, 150, 860–871. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). An Alternative Asphalt Binder, Sulfur-Extended Asphalt (SEA); Report FHWA-HIF-12-037; Federal Highway Administration (FHWA): Washington, DC, USA, 2012.

- Priyadarsini, K.; Ojha, J. Experimental Studies on Properties of Sulfur Modified Binder with Aging. Int. J. Civ. Eng. Technol. 2020, 11, 140–155. [Google Scholar] [CrossRef]

- Behnood, A.; Gharehveran, M.M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2019, 112, 766–791. [Google Scholar]

- Aditya, K.; Khosla, S.K.; Jain, S.K. Sulfur as an adequate extender for virgin bitumen. Constr. Build. Mater. 2017, 156, 1056–1064. [Google Scholar]

- Zeng, J.; Zhao, J. Mechanism and Performance Investigation of SBS/Sulfur Composite Modified Asphalt. Pet. Chem. 2022, 62, 732–739. [Google Scholar] [CrossRef]

- Welborn, J.Y.; Babashak, J.F. Sulfur in asphaltic materials. Ind. Eng. Chem. 1958, 50, 1507–1511. [Google Scholar]

- Maldonado, P.; Mas, J.; Phung, K.T. Precede de Preparation de Compositions de Bitumes Polymers. FR Patent No. 2376188, 15 September 1981. [Google Scholar]

- Polacco, G.; Filippi, S. Vulcanization accelerators as an alternative to elemental sulfur to produce storage stable SBS modified asphalts. Constr. Build. Mater. 2014, 58, 94–100. [Google Scholar] [CrossRef]

- Huang, W.; Tang, N. Characterizing SBS modified asphalt with sulfur using multiple stress creep recovery test. Constr. Build. Mater. 2015, 93, 514–521. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Wu, S. Influence of aging on rheology of SBR/sulfur-modified asphalts. Polym. Eng. Sci. 2012, 52, 71–79. [Google Scholar]

- Wen, H.; Zhang, J.; Zhang, Z.; Yu, J. Preparation and performance of a new type of sulfur-extended asphalt binder with SBS modifier. Constr. Build. Mater. 2010, 24, 1629–1635. [Google Scholar]

- Jin, H.; Gao, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Fan, Y. Improved properties of polystyrene-modified asphalt through dynamic vulcanization. Polym. Test. 2002, 21, 633–640. [Google Scholar] [CrossRef]

- Martínez-Estrada, A.; Chávez-Castellanos, A.E.; Herrera-Alonso, M.; Herrera-Nájera, R. Comparative study of the effect of sulfur on the morphology and rheological properties of SB- and SBS-modified asphalt. J. Appl. Polym. Sci. 2010, 115, 3409–3422. [Google Scholar] [CrossRef]

- Partl, M.N.; Bahia, H.U.; Canestrari, F.; de la Roche, C.; Di Benedetto, H.; Piber, H.; Sybilski, D. Advances in Interlaboratory Testing and Evaluation of Bituminous Materials; International Union of Laboratories and Experts in Construction Materials, Systems and Structures, RILEM; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Petersen, J.C. A brief review of the chemistry of asphalt oxidation: Implications of oxidation on asphalt durability. Road Mater. Pavement Des. 2009, 10 (Suppl. S1), 7–37. [Google Scholar]

- Pei, Z.; Xu, M.; Cao, J.; Feng, D.; Ren, J.; Yi, J. Analysis of the microcharacteristics of different kinds of asphalt based on different aging conditions. Mater. Struct. 2022, 55, 250. [Google Scholar]

- Abouelsaad, A.; White, G. Comparing the Effect of Thermal-Oxidation and Photooxidation of Asphalt Mixtures on the Rheological and Chemical Properties of Extracted Bituminous Binder. Materials 2022, 15, 6793. [Google Scholar]

- Rostler, F.; White, R. Influence of Chemical Composition of Asphalts on Performance, Particularly Durability; Symposium on Road and Paving Materials—1959 By American Society for Testing and Materials (ASTM); ASTM International: West Conshohocken, PA, USA, 1960; pp. 64–88. [Google Scholar]

- Hu, D.; Gu, X.; Cui, B.; Pei, J.; Zhang, Q. Modeling the Oxidative Aging Kinetics and Pathways of Asphalt: A ReaxFF Molecular Dynamics Study. Energy Fuels 2020, 34, 3601–3613. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Lin, P.; Jing, R.; Erkens, S. Toward the long-term aging influence and novel reaction kinetics models of bitumen. Int. J. Pavement Eng. 2022, 1–16. [Google Scholar] [CrossRef]

- Zaghdoudi, M.; Kömmling, A.; Jaunich, M.; Wolff, D. Scission, crosslinking, and physical relaxation during thermal degradation of elastomers. Polymers 2019, 11, 1280. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Wang, Y.; Zhang, Y. Aging mechanism and effective recycling ratio of SBS modified asphalt. Constr. Build. Mater. 2014, 70, 26–35. [Google Scholar] [CrossRef]

- Cuciniello, G.; Leandri, P.; lo Presti, D.; Losa, M.; Airey, G. Investigating the Effect of Artificial Ageing on the Creep and Recovery of SBS-Modified Bitumen. MATEC Web Conf. 2019, 271, 03009. [Google Scholar] [CrossRef]

- Wang, S.; Huang, W.; Liu, X.; Lin, P. Aging Characteristics of Rubber Modified Bitumen Mixed with Sulfur after Terminal Blend Process. Sustainability 2022, 14, 2612. [Google Scholar] [CrossRef]

- Wręczycki, J.; Demchuk, Y.; Bieliński, D.M.; Bratychak, M.; Gunka, V.; Anyszka, R.; Gozdek, T. Bitumen Binders Mod-ified with Sulfur/Organic Copolymers. Materials 2022, 15, 1774. [Google Scholar] [CrossRef]

- Wen, G.; Zhang, Y.; Zhang, Y.; Sun, K.; Chen, Z. Vulcanization characteristics of asphalt/SBS blends in the presence of sulfur. J. Appl. Polym. Sci. 2001, 82, 989–996. [Google Scholar] [CrossRef]

- Wang, Y.; Yi, H.; Liang, P.; Chai, C.; Yan, C.; Zhou, S. Investigation on Preparation Method of SBS-Modified Asphalt Based on MSCR, LAS, and Fluorescence Microscopy. Appl. Sci. 2022, 12, 7304. [Google Scholar] [CrossRef]

- AASHTO M 320; Standard Specification for Performance-Graded Asphalt Binder. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO R 28; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2022.

- AASHTO TP 70; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2013.

- Booshehrian, A.; Mogawer, W.S.; Bonaquist, R. How to Construct an Asphalt Binder Master Curve and Assess the Degree of Blending between RAP and Virgin Binders. J. Mater. Civ. Eng. 2013, 25, 1813–1821. [Google Scholar] [CrossRef]

- Hainin, M.R.; Aziz, A.M.; Adnan, A.M.; Abdul Hassan, N.; Putra Jaya, R.; Liu, H.Y. Performance of Modified Asphalt Binder with Tire Rubber Powder. J. Teknol. 2015, 73, 55–60. [Google Scholar] [CrossRef]

- Glover, C.; Davison, R.; Domke, C.; Ruan, Y.; Juristyarini, P.; Knorr, D.; Jung, S. Development of a New Method for Assessing Asphalt Binder Durability with Field Evaluation; Publication FHWA-TX05-1872-2; National Research Council: Washington, DC, USA, 2005.

- Rowe, G.M. Prepared discussion for the AAPT paper by Anderson et al.: Evaluation of the relationship between asphalt binder properties and non-load related cracking. J. Assoc. Asph. Paving Technol. 2011, 80, 649–662. [Google Scholar]

- Herrington, P. Thermal decomposition of asphalt sulfoxides. Fuel 1995, 74, 1232–1235. [Google Scholar] [CrossRef]

- Le Guern, M.; Chailleux, E.; Farcas, F.; Dreessen, S.; Mabille, I. Physico-chemical analysis of five hard bitumens: Identification of chemical species and molecular organization before and after artificial aging. Fuel 2010, 89, 3330–3339. [Google Scholar] [CrossRef]

- Karlsson, R.; Isacsson, U. Application of FTIR-ATR to Characterization of Bitumen Rejuvenator Diffusion. J. Mater. Civ. Eng. 2003, 15, 157–165. [Google Scholar] [CrossRef]

- Baqersad, M.; Ali, H. Rheological and chemical characteristics of asphalt binders recycled using different recycling agents. Constr. Build. Mater. 2019, 228, 116738. [Google Scholar] [CrossRef]

- Van den Bergh, W. The Effect of Ageing on the Fatigue and Healing Properties of Bituminous Mortars; Wohrmann Print Service: Zutphen, The Netherlands, 2011; ISBN 978-90-8570-784-4. [Google Scholar]

| Sample | PG | MSCR @ 64 °C | ||

|---|---|---|---|---|

| Jnr [1/kPa] | %Recovery | Grade | ||

| C | 64–22 | 1.99 | 0.88 | S |

| C + SB | 70–22 | 0.68 | 22.05 | V |

| C + 0.075 S | 64–22 | 1.57 | 2.010 | H |

| C + SB + 0.03 S | 76–22 | 0.39 | 45.62 | E |

| C + SB + 0.075 S | 76–22 | 0.49 | 37.59 | E |

| C + SB + 0.1 S | 76–22 | 0.48 | 37.69 | E |

| C + SB + 0.3 S | 76–22 | 0.21 | 65.63 | E |

| C + SB + 0.5 S | 76–18 | 0.67 | 21.11 | Fail |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, A.L.; Falcão, C.; Williams, R.C. Rheological and Aging Characteristics of Polymer-Modified Asphalt with the Addition of Sulfur. Infrastructures 2023, 8, 160. https://doi.org/10.3390/infrastructures8110160

Rodrigues AL, Falcão C, Williams RC. Rheological and Aging Characteristics of Polymer-Modified Asphalt with the Addition of Sulfur. Infrastructures. 2023; 8(11):160. https://doi.org/10.3390/infrastructures8110160

Chicago/Turabian StyleRodrigues, Ana Luiza, Caio Falcão, and R. Christopher Williams. 2023. "Rheological and Aging Characteristics of Polymer-Modified Asphalt with the Addition of Sulfur" Infrastructures 8, no. 11: 160. https://doi.org/10.3390/infrastructures8110160

APA StyleRodrigues, A. L., Falcão, C., & Williams, R. C. (2023). Rheological and Aging Characteristics of Polymer-Modified Asphalt with the Addition of Sulfur. Infrastructures, 8(11), 160. https://doi.org/10.3390/infrastructures8110160