Using Construction and Demolition Waste Materials to Develop Chip Seals for Pavements

Abstract

1. Introduction

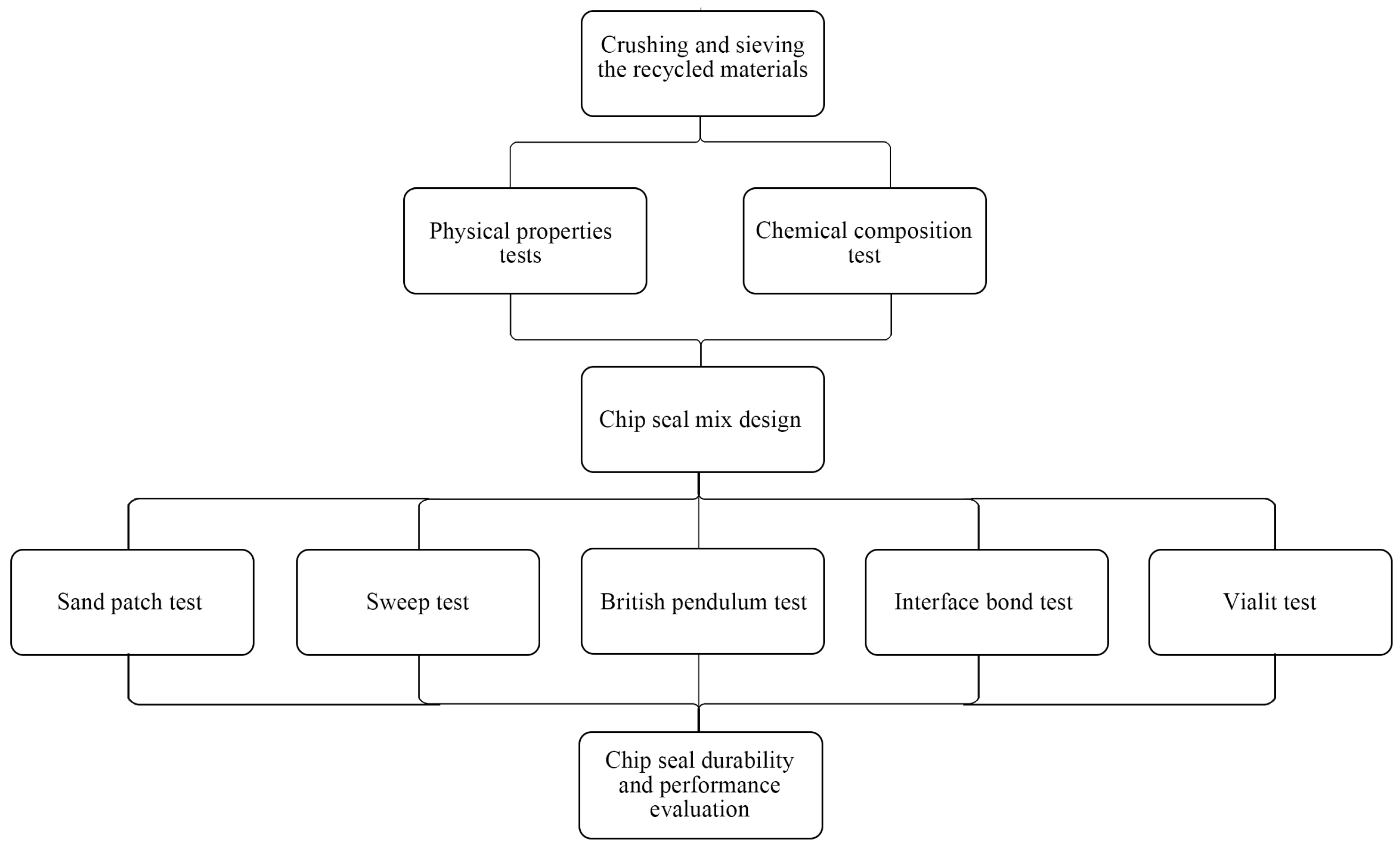

2. Materials and Methods

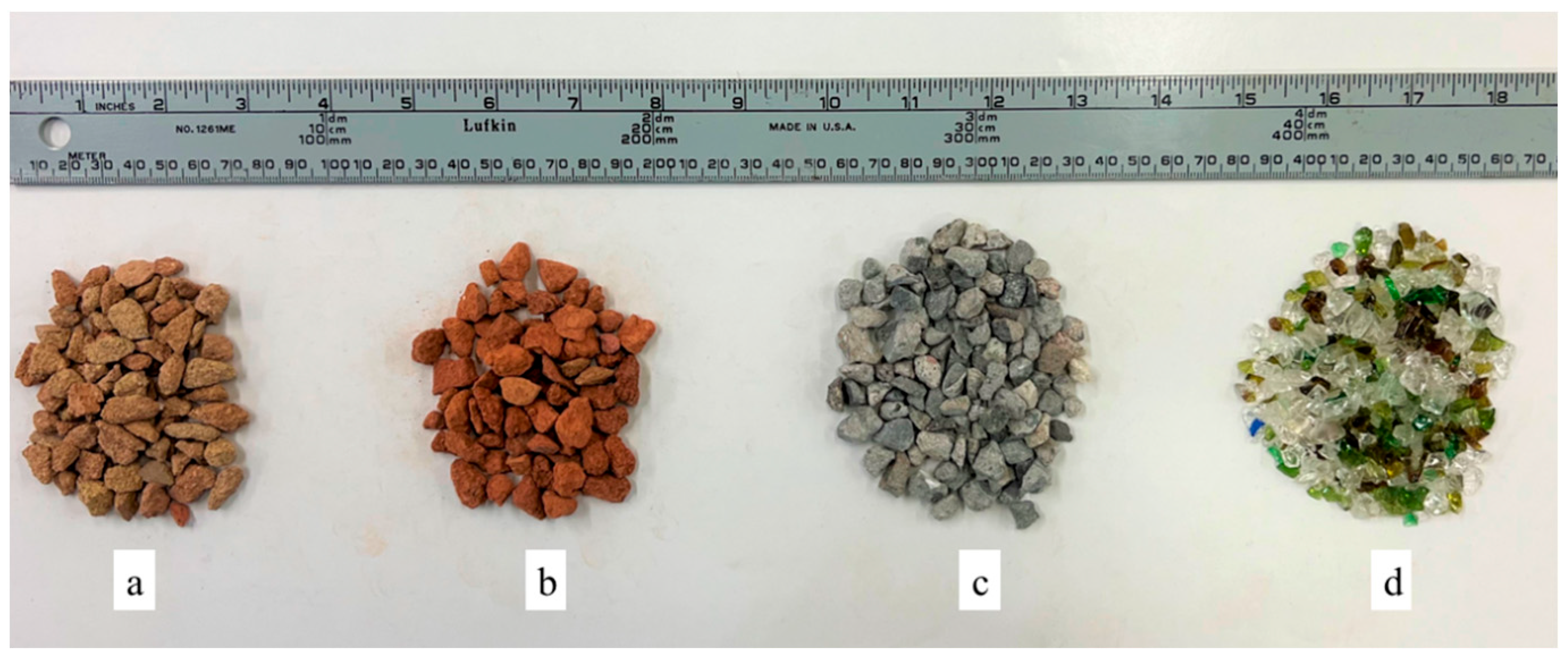

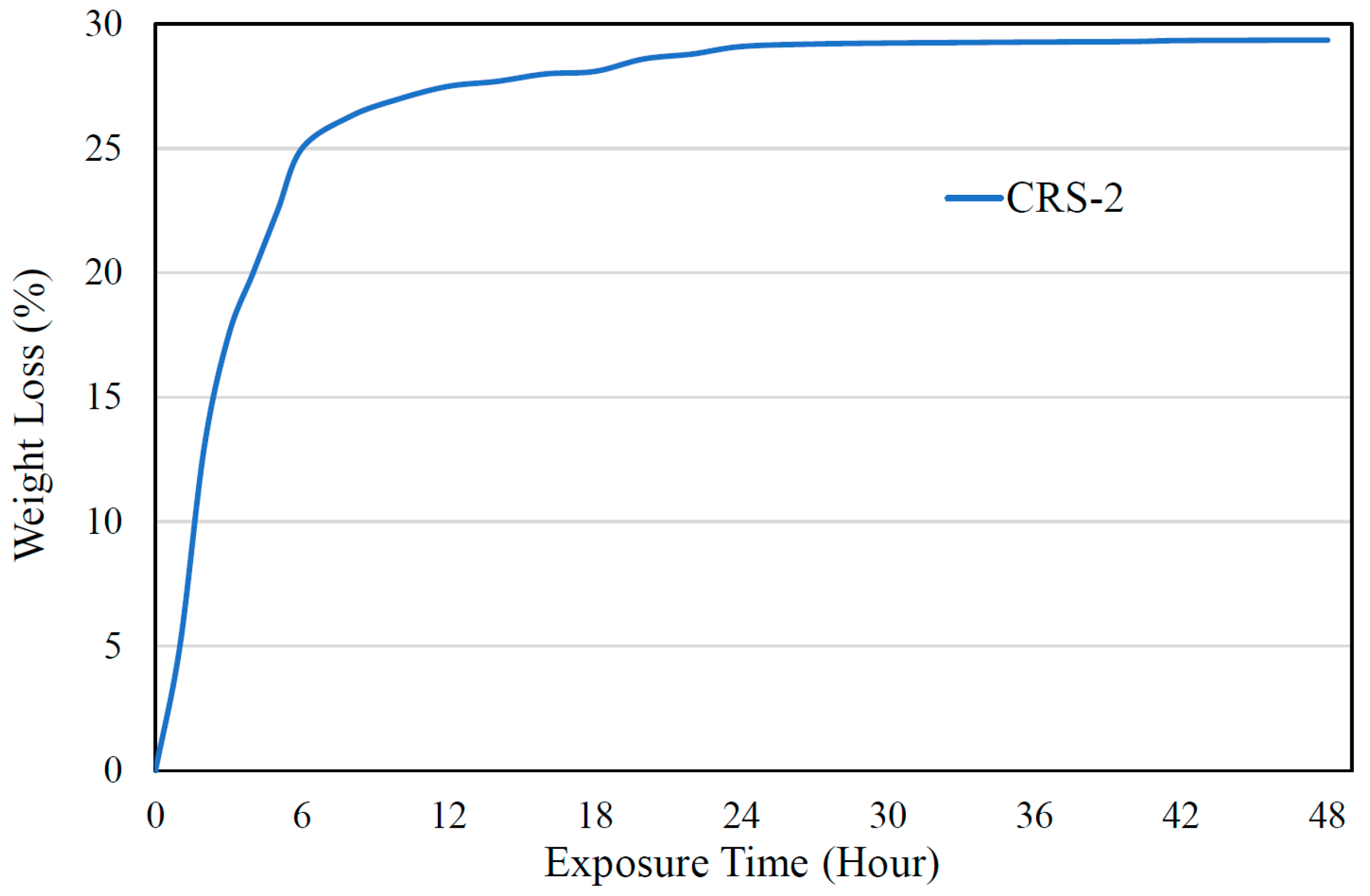

2.1. Materials

2.2. Chip Seal Design

2.3. Description of Tests

2.3.1. The Sand Patch Test

2.3.2. The Sweep Test

2.3.3. The British Pendulum Tester

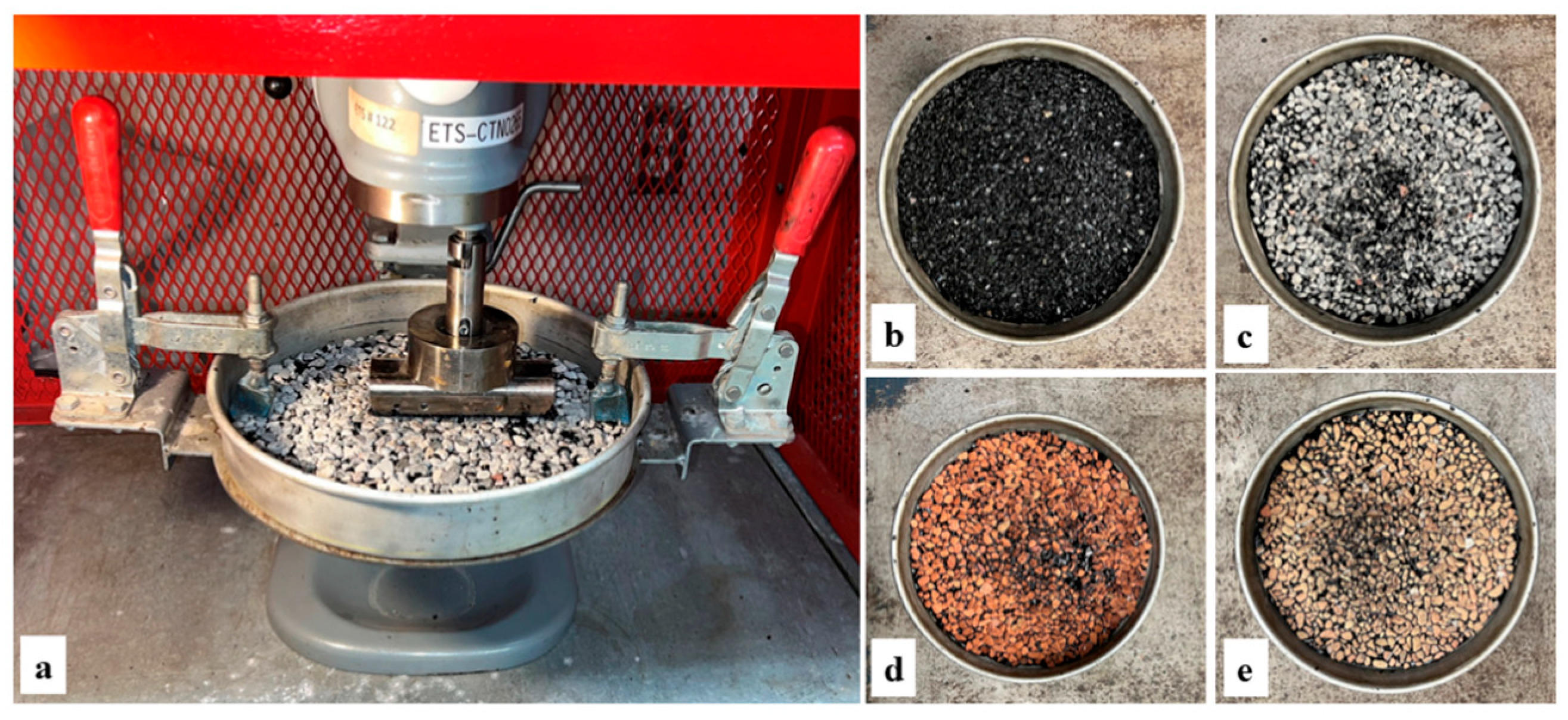

2.3.4. The Interface Bond Test

2.3.5. The Vialit Test

3. Result and Discussion

3.1. The Macrotexture of Chip Seal

3.2. The Sweep Test

3.3. The Skid Resistance

3.4. The Interface Bond between the Asphalt Mixture and Chip Seals

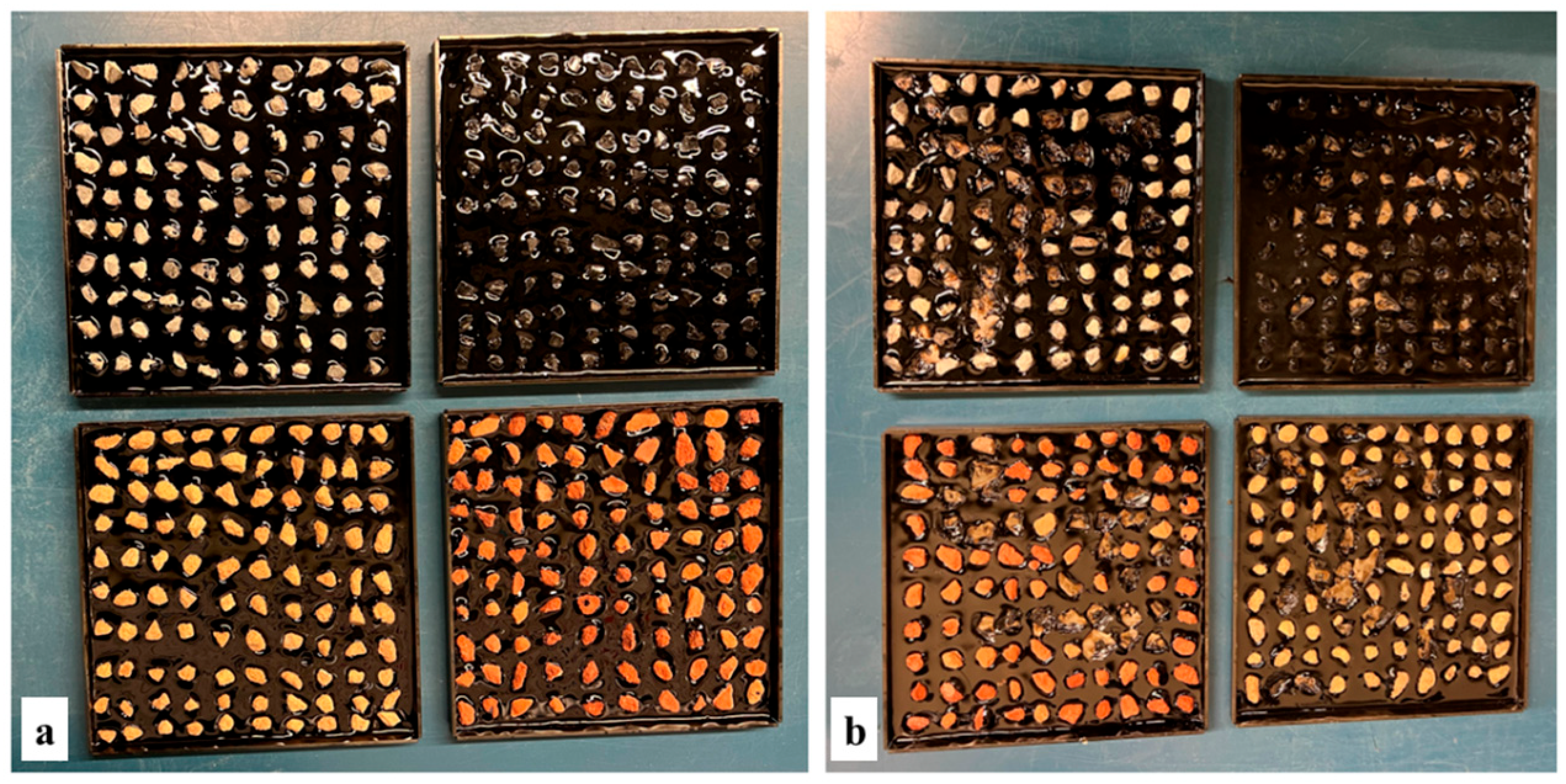

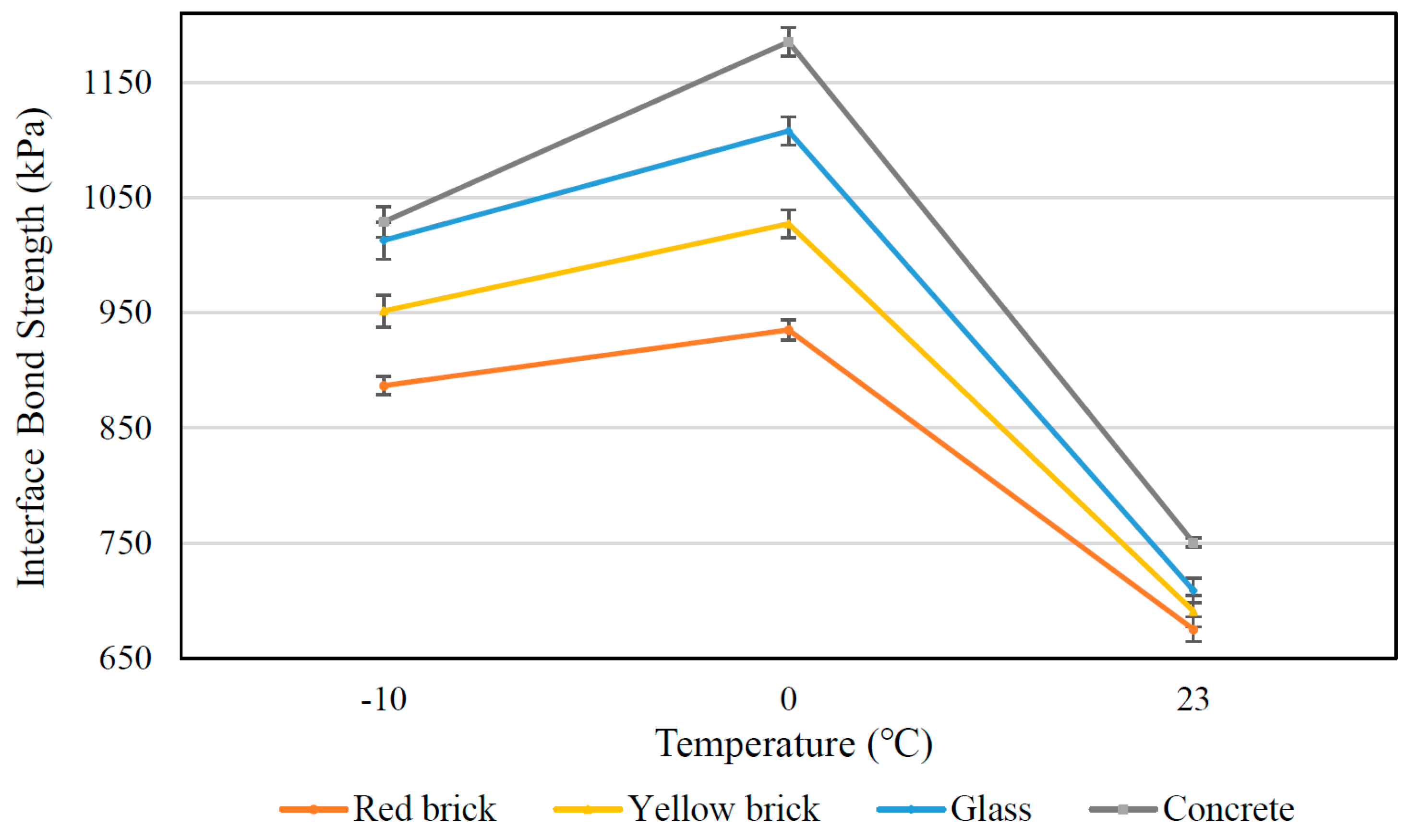

3.5. Aggregate and Bitumen Emulsion Adhesion in Low Temperatures

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Duan, H.; Miller, T.R.; Liu, G.; Tam, V.W.Y. Construction Debris Becomes Growing Concern of Growing Cities. Waste Manag. 2019, 83, 1–5. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.; Tam, V.W.Y. Construction and Demolition Waste Management Contributing Factors Coupled with Reduce, Reuse, and Recycle Strategies for Effective Waste Management: A Review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Menegaki, M.; Damigos, D. A Review on Current Situation and Challenges of Construction and Demolition Waste Management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An Overview of the Waste Hierarchy Framework for Analyzing the Circularity in Construction and Demolition Waste Management in Europe. Sci. Total Environ. 2022, 803, 149892. [Google Scholar] [CrossRef]

- Yeheyis, M.; Hewage, K.; Alam, M.S.; Eskicioglu, C.; Sadiq, R. An Overview of Construction and Demolition Waste Management in Canada: A Lifecycle Analysis Approach to Sustainability. Clean Technol. Environ. Policy 2013, 15, 81–91. [Google Scholar] [CrossRef]

- Molla, A.S.; Tang, P.; Sher, W.; Bekele, D.N. Chemicals of Concern in Construction and Demolition Waste Fine Residues: A Systematic Literature Review. J. Environ. Manag. 2021, 299, 113654. [Google Scholar] [CrossRef]

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and Demolition Waste Management in China through the 3R Principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- Umar, U.A.; Shafiq, N.; Malakahmad, A.; Nuruddin, M.F.; Khamidi, M.F. A Review on Adoption of Novel Techniques in Construction Waste Management and Policy. J. Mater. Cycles Waste Manag. 2017, 19, 1361–1373. [Google Scholar] [CrossRef]

- Ulubeyli, S.; Kazaz, A.; Arslan, V. Construction and Demolition Waste Recycling Plants Revisited: Management Issues. Procedia Eng. 2017, 172, 1190–1197. [Google Scholar] [CrossRef]

- Yang, H.; Huang, X.; Thompson, J.R.; Flower, R.J. Chinese Landfill Collapse: Urban Waste and Human Health. Lancet Glob. Health 2016, 4, e452. [Google Scholar] [CrossRef]

- Narasimhan, B.; Bhallamudi, S.M.; Mondal, A.; Ghosh, S.; Mujumdar, P. Chennai Floods 2015: A Rapid Assessment; Interdisciplinary Centre for Water Research, Indian Institute of Science: Bangalore, India, 2016. [Google Scholar]

- Duan, H.; Li, J.; Liu, G. Growing Threat of Urban Waste Dumps. Nature 2017, 546, 599. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid Life Cycle Assessment of Greenhouse Gas Emissions from Cement, Concrete and Geopolymer Concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Fatemi, S.; Imaninasab, R. Performance Evaluation of Recycled Asphalt Mixtures by Construction and Demolition Waste Materials. Constr. Build. Mater. 2016, 120, 450–456. [Google Scholar] [CrossRef]

- Shamsaei, M.; Khafajeh, R.; Ghasemzadeh Tehrani, H.; Aghayan, I. Experimental Evaluation of Ceramic Waste as Filler in Hot Mix Asphalt. Clean Technol. Environ. Policy 2020, 22, 535–543. [Google Scholar] [CrossRef]

- Shamsaei, M.; Aghayan, I.; Kazemi, K.A. Experimental Investigation of Using Cross-Linked Polyethylene Waste as Aggregate in Roller Compacted Concrete Pavement. J. Clean. Prod. 2017, 165, 290–297. [Google Scholar] [CrossRef]

- Aghayan, I.; Khafajeh, R.; Shamsaei, M. Life Cycle Assessment, Mechanical Properties, and Durability of Roller Compacted Concrete Pavement Containing Recycled Waste Materials. Int. J. Pavement Res. Technol. 2021, 14, 595–606. [Google Scholar] [CrossRef]

- Serigos, P.A.; Smit, A.d.F.; Prozzi, J.A. Performance of Preventive Maintenance Treatments for Flexible Pavements in Texas; Center for Transportation Research, University of Texas at Austin: Austin, TX, USA, 2017. [Google Scholar]

- Khafajeh, R.; Shamsaei, M.; Latifi, A.; Amin Javaheri, B.; Vaillancourt, M. Comprehensive Investigation of Influential Mix-Design Factors on the Microsurfacing Mixture Performance. J. Mater. Civ. Eng. 2023, 35, 4023214. [Google Scholar] [CrossRef]

- Montoya, M.A.; Jason Weiss, W.; Haddock, J.E. Using Electrical Resistance to Evaluate the Chip Seal Curing Process. Road Mater. Pavement Des. 2017, 18, 98–111. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Dai, Q.; Xie, X.; Washko, S.; Gao, J. Investigation of Adhesion and Interface Bond Strength for Pavements Underlying Chip-Seal: Effect of Asphalt-Aggregate Combinations and Freeze-Thaw Cycles on Chip-Seal. Constr. Build. Mater. 2019, 203, 322–330. [Google Scholar] [CrossRef]

- Contreras Llanes, M.; Romero Pérez, M.; Gázquez González, M.J.; Bolívar Raya, J.P. Construction and Demolition Waste as Recycled Aggregate for Environmentally Friendly Concrete Paving. Environ. Sci. Pollut. Res. 2022, 29, 9826–9840. [Google Scholar] [CrossRef]

- Strieder, H.L.; Dutra, V.F.P.; Graeff, Â.G.; Núñez, W.P.; Merten, F.R.M. Performance Evaluation of Pervious Concrete Pavements with Recycled Concrete Aggregate. Constr. Build. Mater. 2022, 315, 125384. [Google Scholar] [CrossRef]

- Mohsenian Hadad Amlashi, S.; Vaillancourt, M.; Carter, A.; Bilodeau, J.-P. Resilient Modulus of Pavement Unbound Granular Materials Containing Recycled Glass Aggregate. Mater. Struct. 2018, 51, 89. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C. Skid Resistance Performance of Asphalt Mixtures Containing Recycled Pavement Materials under Simulated Weather Conditions. Recycling 2022, 7, 47. [Google Scholar] [CrossRef]

- Pomoni, M.; Plati, C.; Loizos, A. How Can Sustainable Materials in Road Construction Contribute to Vehicles’ Braking? Vehicles 2020, 2, 4. [Google Scholar] [CrossRef]

- Lachance-Tremblay, É.; Vaillancourt, M.; Perraton, D. Evaluation of the Impact of Recycled Glass on Asphalt Mixture Performances. Road Mater. Pavement Des. 2016, 17, 600–618. [Google Scholar] [CrossRef]

- Mammeri, A.; Vaillancourt, M.; Shamsaei, M. Experimental and Numerical Investigation of Using Waste Glass Aggregates in Asphalt Pavement to Mitigate Urban Heat Islands. Clean Technol. Environ. Policy 2023. [Google Scholar] [CrossRef]

- Gheni, A.A.; Abdelkarim, O.I.; Abdulazeez, M.M.; ElGawady, M.A. Texture and Design of Green Chip Seal Using Recycled Crumb Rubber Aggregate. J. Clean. Prod. 2017, 166, 1084–1101. [Google Scholar] [CrossRef]

- Durrani, A. Analysis of Reclaimed Asphalt Pavement (RAP) Proposed for Use as Aggregate in Microsurfacing and Chip Seal Mixes for Local Roadways Applications in Ohio. Master’s Thesis, Ohio University, Athens, GA, USA, 2021. [Google Scholar]

- Shamsaei, M.; Carter, A.; Vaillancourt, M. A Review on the Heat Transfer in Asphalt Pavements and Urban Heat Island Mitigation Methods. Constr. Build. Mater. 2022, 359, 129350. [Google Scholar] [CrossRef]

- Alducin-Ochoa, J.M.; Martín-del-Río, J.J.; Torres-González, M.; Flores-Alés, V.; Hernández-Cruz, D. Performance of Mortars Based on Recycled Glass as Aggregate by Accelerated Decay Tests (ADT). Constr. Build. Mater. 2021, 300, 124057. [Google Scholar] [CrossRef]

- Tareq Noaman, A.; Subhi Jameel, G.; Ahmed, S.K. Producing of Workable Structural Lightweight Concrete by Partial Replacement of Aggregate with Yellow and/or Red Crushed Clay Brick (CCB) Aggregate. J. King Saud Univ.-Eng. Sci. 2021, 33, 240–247. [Google Scholar] [CrossRef]

- Ye, T.; Xiao, J.; Zhao, W.; Duan, Z.; Xu, Y. Combined Use of Recycled Concrete Aggregate and Glass Cullet in Mortar: Strength, Alkali Expansion and Chemical Compositions. J. Build. Eng. 2022, 55, 104721. [Google Scholar] [CrossRef]

- ASTM C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- ASTM C29/C29M; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM C131/C131M; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM D4791; Standard Test Method for Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregate. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM C136/C136M; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM D6997; Standard Test Method for Distillation of Emulsified Asphalt. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- ASTM D6936; Standard Test Method for Determining Demulsibility of Emulsified Asphalt. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D7496; Standard Test Method for Viscosity of Emulsified Asphalt by Saybolt Furol Viscometer. Annual Book of ASTM Standards. American Society for Testing and Materials: West Conshohocken, PA, USA, 2018.

- ASTM D6930; Standard Test Method for Settlement and Storage Stability of Emulsified Asphalts. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM D5Standard Test Method for Penetration of Bituminous Materials, American Society for Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM D7402; Standard Practice for Identifying Cationic Emulsified Asphalts. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D113; Standard Test Method for Ductility of Asphalt Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- ASTM D2042; Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene. American Society for Testing and Materials: West Conshohocken, PA, USA, 2015.

- McLeod, N.W.; Chaffin, C.W.; Holberg, A.E.; Parker, C.F.; Obrcian, V.; Edwards, J.M.; Campen, W.H.; Kari, W.J. A General Method of Design for Seal Coats and Surface Treatments. Proceedings of the Association of Asphalt Paving Technologists;Chicago, USA, 1969; Volume 38, pp. 537–630. Available online: https://mcasphalt.com/wp-content/uploads/download-manager-files/1969-A%20General%20Method%20of%20Design%20for%20Seal%20Coats%20and%20Surface%20Treatments-Norman%20McLeod.pdf (accessed on 21 March 2023).

- Kearby, J.P. Tests and Theories on Penetration Surfaces. Proceedings of the Highway Research Board Proceedings; Oklahoma City, USA, 1953; Volume 32. Available online: https://onlinepubs.trb.org/Onlinepubs/hrbproceedings/32/32-014.pdf (accessed on 21 March 2023).

- Stockton, W.R.; Epps, J.A. Engineering Economy and Energy Considerations. Seal Coat Economics and Design; Texas A&M University: College Station, TX, USA, 1975. [Google Scholar]

- Wood, T.J.; Janisch, D.W.; Gaillard, F.S. Minnesota Seal Coat Handbook 2006; Minnesota Local Road Research Board (LRRB): MN, USA, 2006. Available online: https://trid.trb.org/view/803470 (accessed on 21 March 2023).

- ASTM D7000; Standard Test Method for Sweep Test of Emulsified Asphalt Surface Treatment Samples. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- ASTM E965; Standard Test Method for Measuring Pavement Macrotexture Depth Using a Volumetric Technique. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Mills, B.N.; Tighe, S.L.; Andrey, J.; Smith, J.T.; Huen, K. Climate Change Implications for Flexible Pavement Design and Performance in Southern Canada. J. Transp. Eng. 2009, 135, 773–782. [Google Scholar] [CrossRef]

- BS EN 12272-3; Determination of Binder Aggregate Adhesivity by the Vialit Plate Shock Test Method. British Standards Institution: London, UK, 2003.

- Pierce, L.M.; Kebede, N. Chip Seal Performance Measures: Best Practices; Applied Pavement Technology, Inc.: Olympia, WA, USA, 2015. [Google Scholar]

- Buss, A.F.; Guriguis, M.; Claypool, B.; Gransberg, D.D.; Williams, R.C. Chip Seal Design and Specifications: Final Report; Oregon Departmet of Transportation: Washington, DC, USA, 2016. [Google Scholar]

- Shuler, S.; Epps-Martin, A.; Lord, A.; Hoyt, D. Manual for Emulsion-Based Chip Seals for Pavement Preservation; National Academies Press: Washington, DC, USA, 2011; ISBN 978-0-309-28084-6. [Google Scholar]

- You, L.; Jin, D.; You, Z.; Dai, Q.; Xie, X.; Washko, S.; Cepeda, S. Laboratory Shear Bond Test for Chip-Seal under Varying Environmental and Material Conditions. Int. J. Pavement Eng. 2021, 22, 1107–1115. [Google Scholar] [CrossRef]

- Ahammed, M.A.; Tighe, S.L. Asphalt Pavements Surface Texture and Skid Resistance—Exploring the Reality. Can. J. Civ. Eng. 2012, 39, 1–9. [Google Scholar] [CrossRef]

- Lee, J.; Lee, J.; Kim, Y.; Mun, S. A Comparison Study of Friction Measurements for Chip Seal. J. Test. Eval. 2012, 40, 603–611. [Google Scholar] [CrossRef]

- Henry, J.J. Evaluation of Pavement Friction Characteristics; Transportation Research Board: Washington, DC, USA, 2000; ISBN 978-0-309-06874-1. [Google Scholar]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal Conductivity of Concrete—A Review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Dondi, M.; Mazzanti, F.; Principi, P.; Raimondo, M.; Zanarini, G. Thermal Conductivity of Clay Bricks. J. Mater. Civ. Eng. 2004, 16, 8–14. [Google Scholar] [CrossRef]

- Peng, B.; Li, J.; Ling, T.; Li, X.; Diao, H.; Huang, X. Semi-Flexible Pavement with Glass for Alleviating the Heat Island Effect. Constr. Build. Mater. 2023, 367, 130275. [Google Scholar] [CrossRef]

- Park, S.; Jo, M.-C.; Park, J.-B. Adsorption and Thermal Desorption Behavior of Asphalt-like Functionalities on Silica. Adsorpt. Sci. Technol. 2000, 18, 675–684. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Study of Cohesion and Adhesion Properties of Asphalt Concrete with Molecular Dynamics Simulation. Comput. Mater. Sci. 2016, 112, 161–169. [Google Scholar] [CrossRef]

- Khafajeh, R.; Shamsaei, M.; Tehrani, H.G.; Easa, S.M. Proposing Load Transfer Efficiency as Criterion for Repairing Longitudinal and Transverse Cracks of Asphalt Pavements. J. Transp. Eng. Part B Pavements 2021, 147, 6021002. [Google Scholar] [CrossRef]

| Properties | Standard | Concrete | Yellow Brick | Red Brick | Glass |

|---|---|---|---|---|---|

| Density (kg/m3) | ASTM C127 [35] | 2369 | 1932 | 1906 | 2490 |

| Loose unit weight (kg/m3) | ASTM C29 [36] | 1513 | 1116 | 1121 | 1485 |

| Voids in loose aggregates (%) | ASTM C29 [36] | 35 | 58 | 59 | 36 |

| Water absorption (%) | ASTM C127 [35] | 4.7 | 13.55 | 14.12 | 0.15 |

| Los Angeles (%) | ASTM C131 [37] | 23 | 39 | 41 | 44 |

| Flakiness index (%) | ASTM D4791 [38] | 15 | 20 | 22 | 31 |

| Median particle size (mm) | ASTM C136 [39] | 6.5 | 6.7 | 6.8 | 4.7 |

| Chemical Composition (%) | Concrete | Yellow Brick | Red Brick | Glass |

|---|---|---|---|---|

| Silicon dioxide (SiO2) | 34.97 | 59.03 | 62.07 | 73.30 |

| Aluminum oxide (Al2O3) | 7.34 | 14.53 | 16.14 | 1.68 |

| Iron (III) oxide (Fe2O3) | 3.31 | 6.44 | 5.07 | 0.38 |

| Calcium oxide (CaO) | 47.19 | 11.90 | 5.45 | 11.41 |

| Magnesium oxide (MgO) | 1.90 | 2.44 | 3.38 | 1.11 |

| Sulfur trioxide (SO3) | 1.17 | 0.61 | 0.68 | 0.14 |

| Potassium oxide (K2O) | 1.47 | 2.80 | 3.69 | 0.50 |

| Sodium oxide (Na2O) | 1.34 | 1.10 | 2.34 | 10.70 |

| Titanium dioxide (TiO2) | 0.40 | 0.72 | 0.75 | 0.04 |

| Phosphorus pentoxide (P2O5) | 0.13 | 0.12 | 0.16 | 0.02 |

| Loss on ignition (LOI) | 0.78 | 0.31 | 0.27 | 0.72 |

| Tests | Unit | Test Method | Result For CRS-2 | Specifications | |

|---|---|---|---|---|---|

| Min. | Max. | ||||

| Residue by distillation (by weight) | % | ASTM D6997 [40] | 69 | 65 | - |

| Oil distillate (by volume) | % | ASTM D6997 [40] | 0.3 | - | 3 |

| Demulsibility | % | ASTM D6936 [41] | 85 | 40 | - |

| Saybolt Furol viscosity at 50 °C | s | ASTM D7496 [42] | 223 | 100 | 400 |

| Settlement and storage stability, 1 day | % | ASTMD6930 [43] | 0.31 | Max. 1 | |

| Penetration, 25 °C, 100 g, 5 s. | 0/1 mm | ASTM D5 [44] | 153 | 100 | 250 |

| Particle charge | ASTM D7402 [45] | Positive | |||

| Ductility, 4 °C, 5 cm/min | cms | ASTM D113 [46] | 75 | 40 | - |

| Solubility in TCE | % | ASTM D2042 [47] | 99.5 | 98.5 | - |

| Material | Avg. MTD (mm) | Variance | Standard Deviation (SD) | Coefficient of Variation (CV) (%) |

|---|---|---|---|---|

| Yellow brick | 2.70 | 0.0274 | 0.17 | 6.12% |

| Red brick | 2.68 | 0.0076 | 0.09 | 3.26% |

| Glass | 1.91 | 0.0107 | 0.10 | 5.42% |

| Concrete | 2.79 | 0.0336 | 0.18 | 6.58% |

| Temperature (°C) | Materials | BPN (Avg.) | Variance | Standard Deviation (SD) | Coefficient of Variation (CV) (%) |

|---|---|---|---|---|---|

| 23 | Yellow brick | 102 | 6.64 | 2.58 | 2.52 |

| Red brick | 94 | 6.56 | 2.56 | 2.72 | |

| Glass | 74 | 5.36 | 2.32 | 3.14 | |

| Concrete | 108 | 6.64 | 2.58 | 2.39 | |

| 60 | Yellow brick | 76 | 4.96 | 2.23 | 2.94 |

| Red brick | 72 | 7.76 | 2.79 | 3.86 | |

| Glass | 53 | 6.80 | 2.61 | 4.92 | |

| Concrete | 84 | 3.44 | 1.85 | 2.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shamsaei, M.; Carter, A.; Vaillancourt, M. Using Construction and Demolition Waste Materials to Develop Chip Seals for Pavements. Infrastructures 2023, 8, 95. https://doi.org/10.3390/infrastructures8050095

Shamsaei M, Carter A, Vaillancourt M. Using Construction and Demolition Waste Materials to Develop Chip Seals for Pavements. Infrastructures. 2023; 8(5):95. https://doi.org/10.3390/infrastructures8050095

Chicago/Turabian StyleShamsaei, Mohsen, Alan Carter, and Michel Vaillancourt. 2023. "Using Construction and Demolition Waste Materials to Develop Chip Seals for Pavements" Infrastructures 8, no. 5: 95. https://doi.org/10.3390/infrastructures8050095

APA StyleShamsaei, M., Carter, A., & Vaillancourt, M. (2023). Using Construction and Demolition Waste Materials to Develop Chip Seals for Pavements. Infrastructures, 8(5), 95. https://doi.org/10.3390/infrastructures8050095