Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil

Abstract

1. Introduction

2. Materials and Testing Methods

2.1. Materials

2.1.1. Asphalt Cement and Rejuvenator

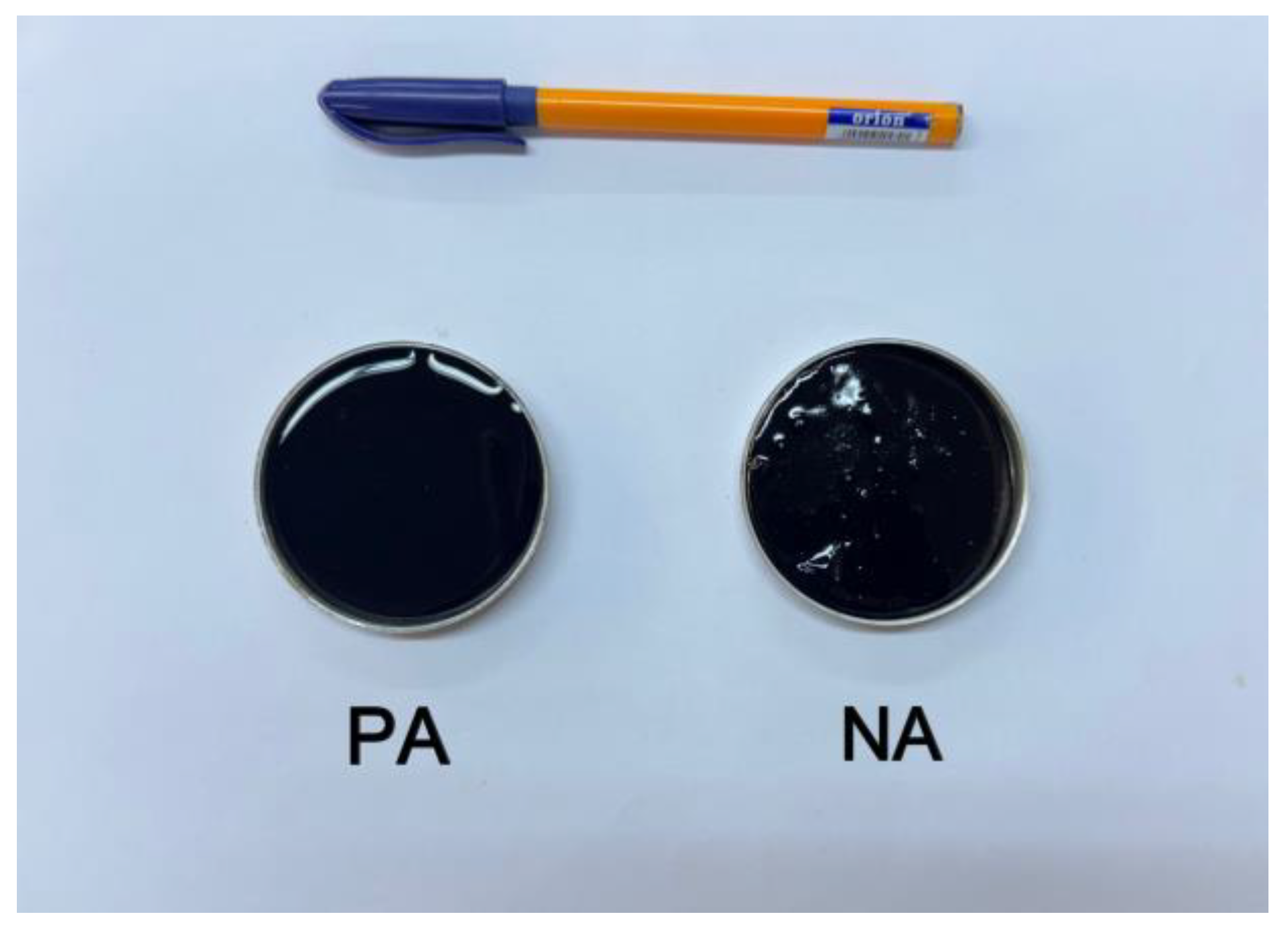

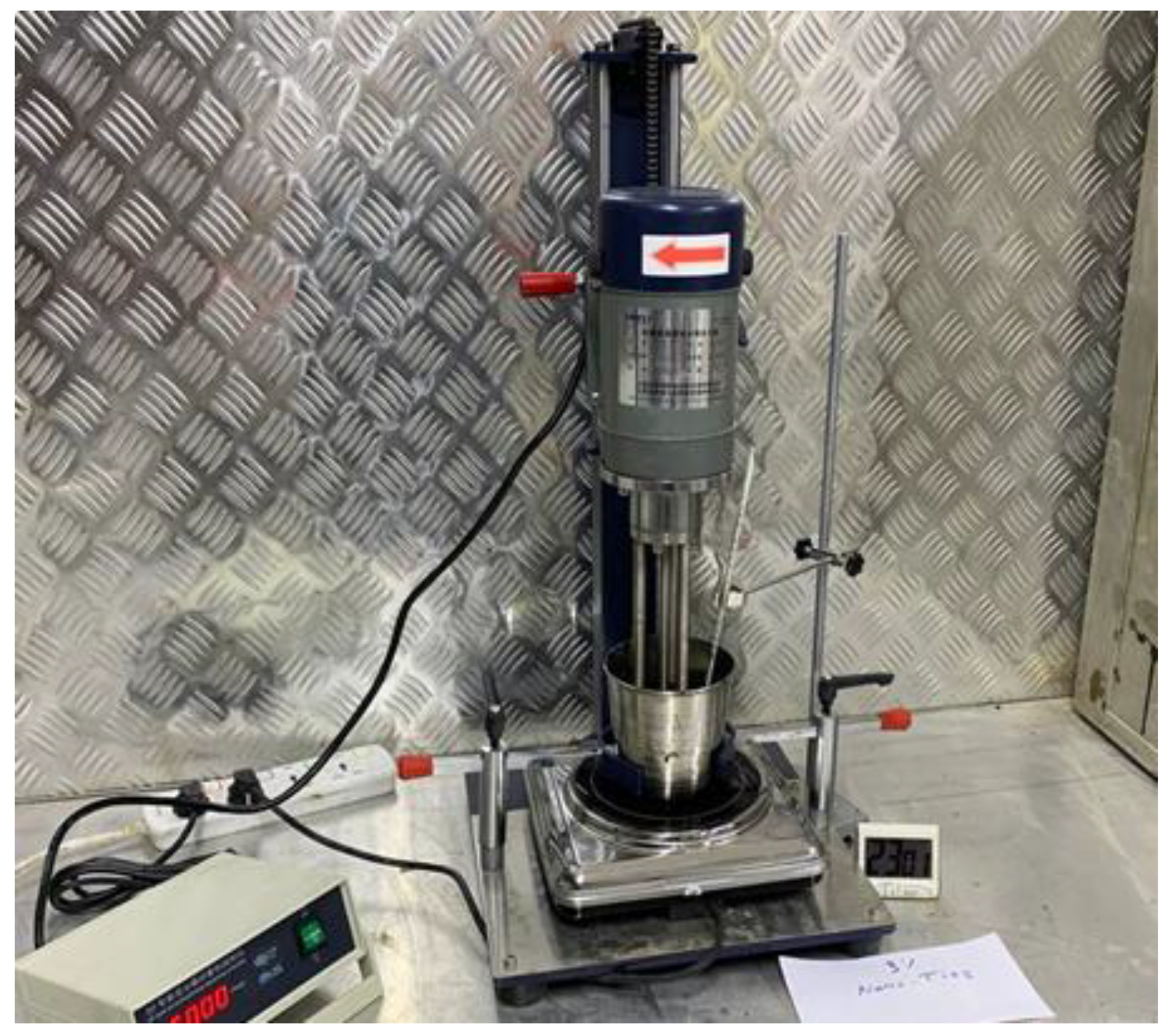

2.1.2. NA Modification Process

2.2. Experimental Test Methods

2.2.1. Physical Properties

2.2.2. Rheological Properties

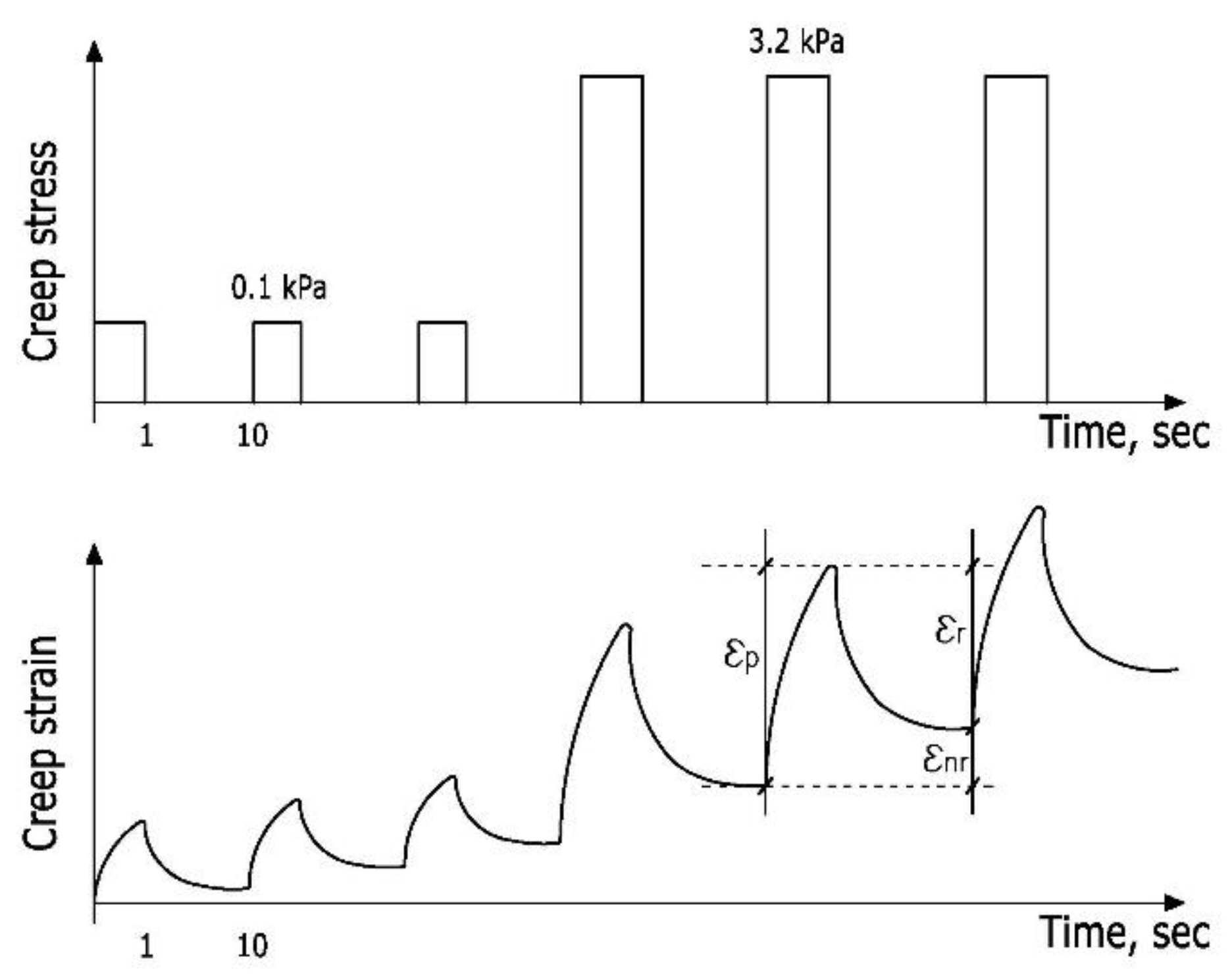

2.2.3. MSCR Test

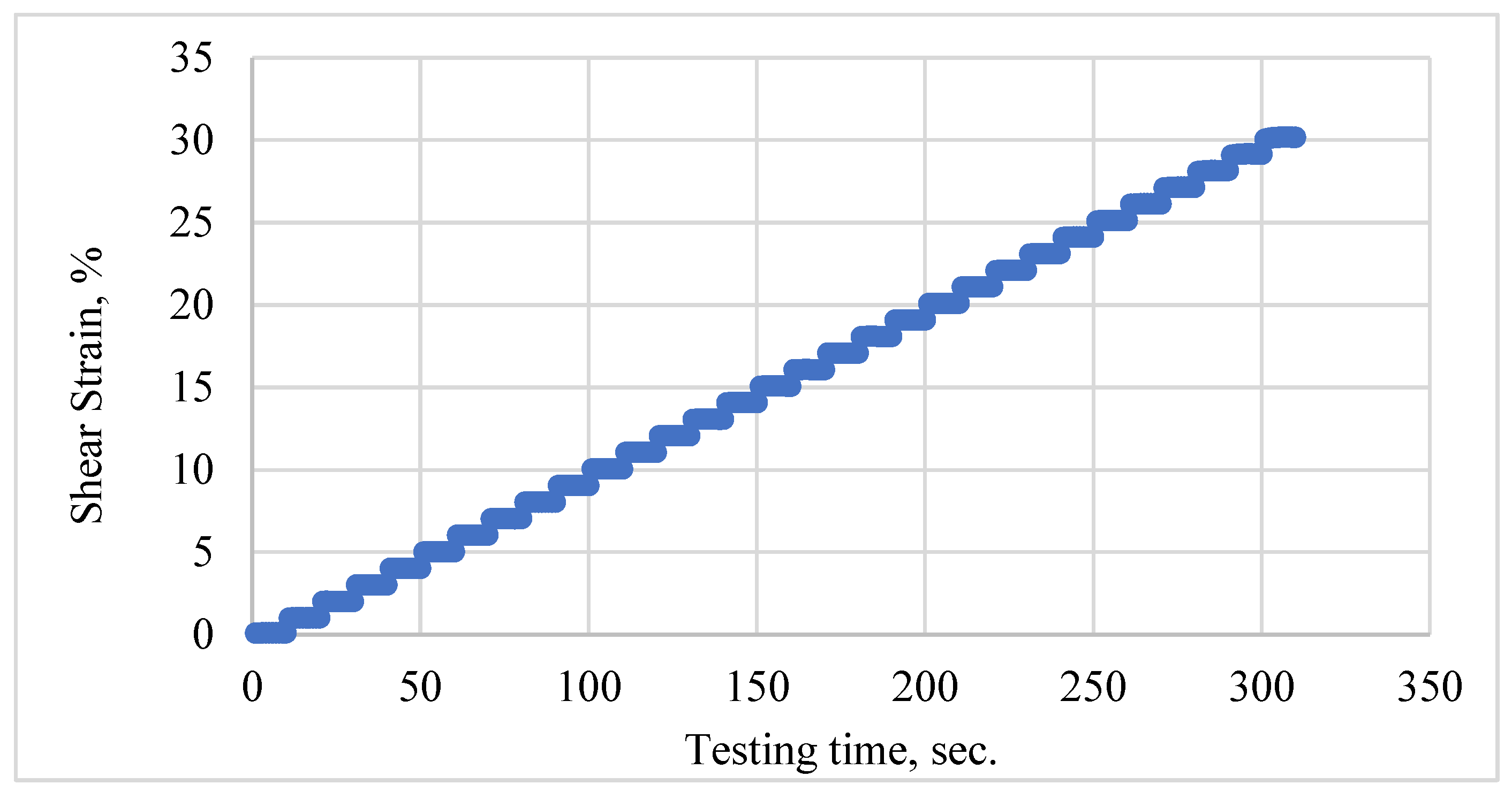

2.2.4. LAS Test

2.2.5. Chemical Composition and Morphology Analyses

3. Results and Discussion

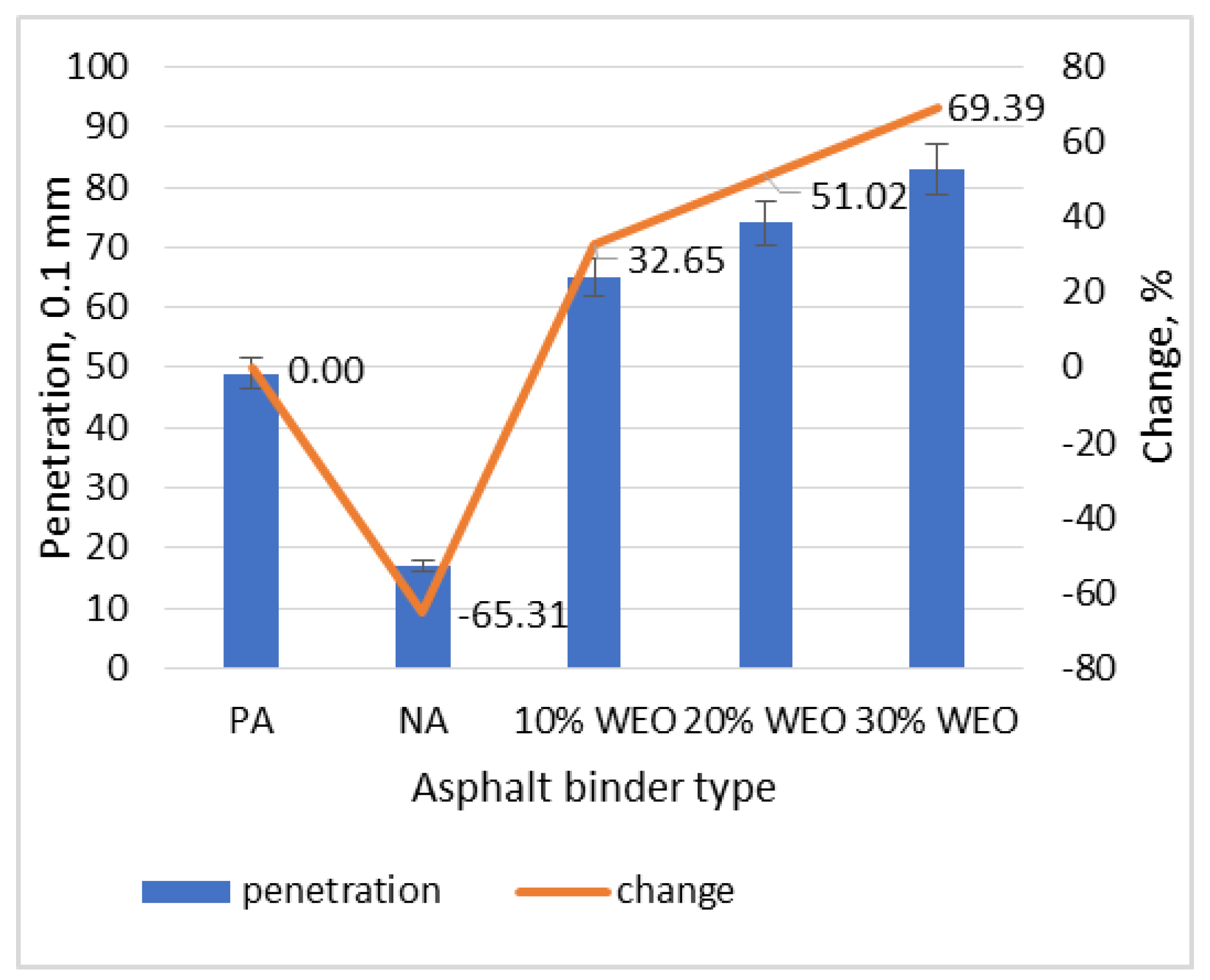

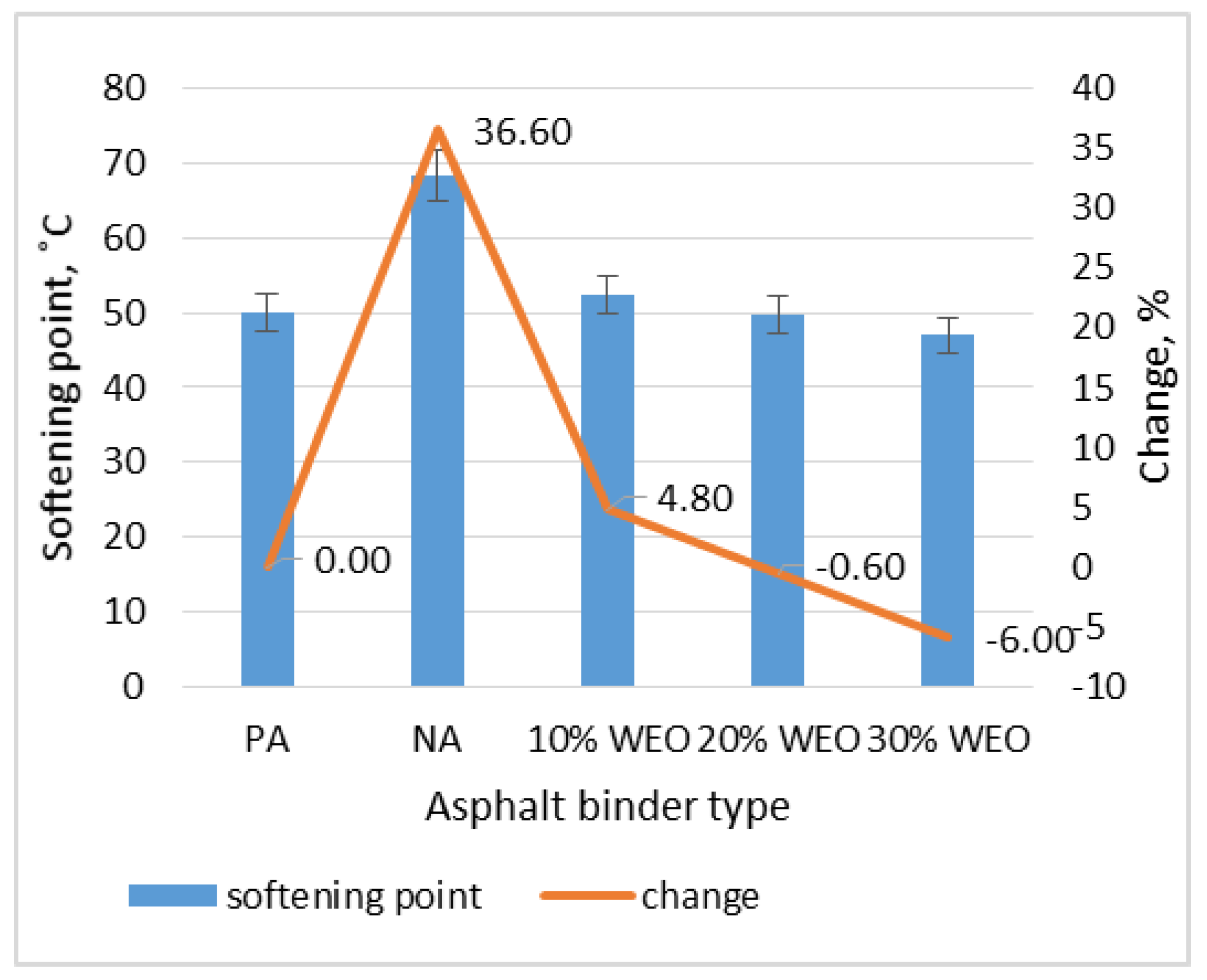

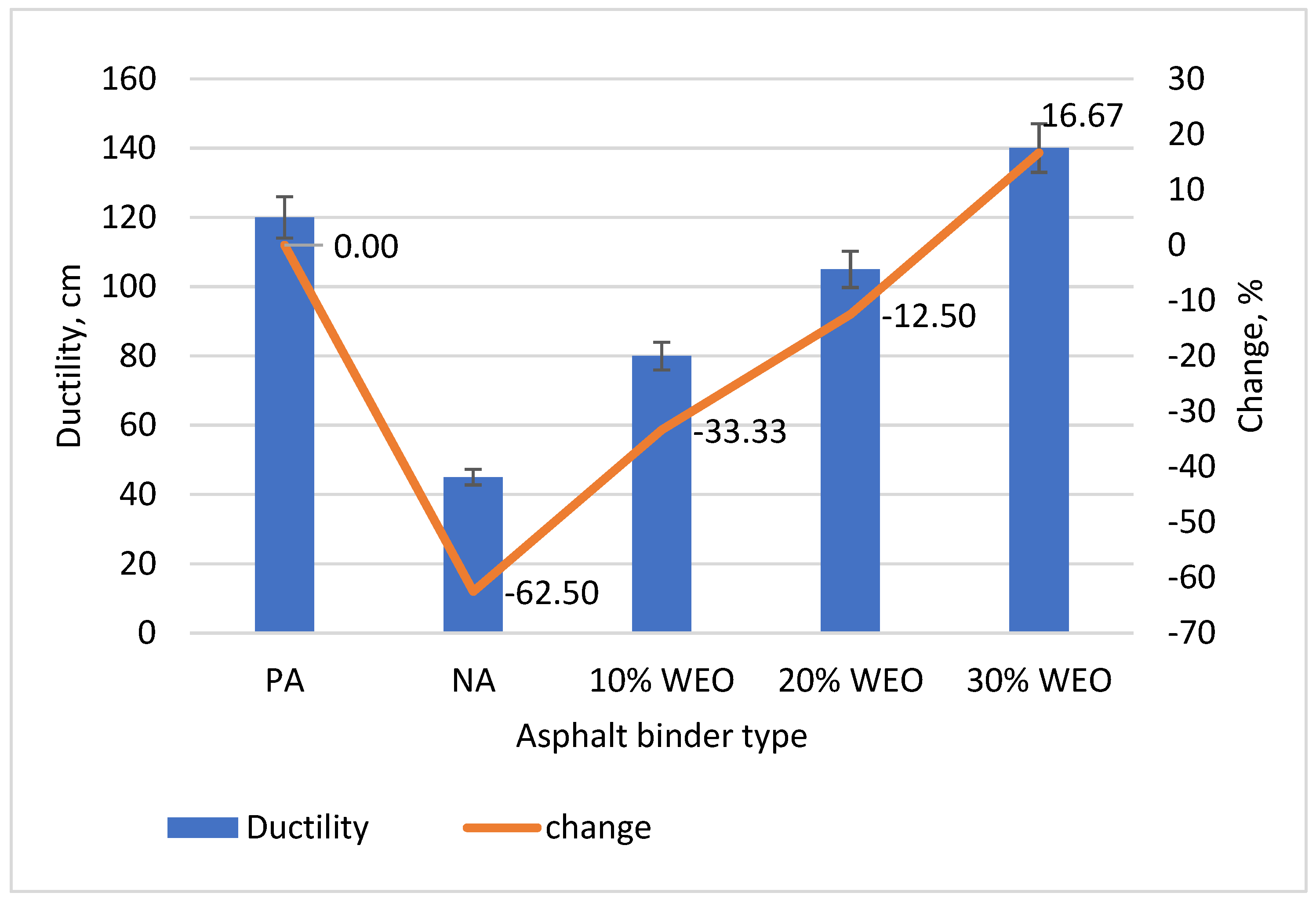

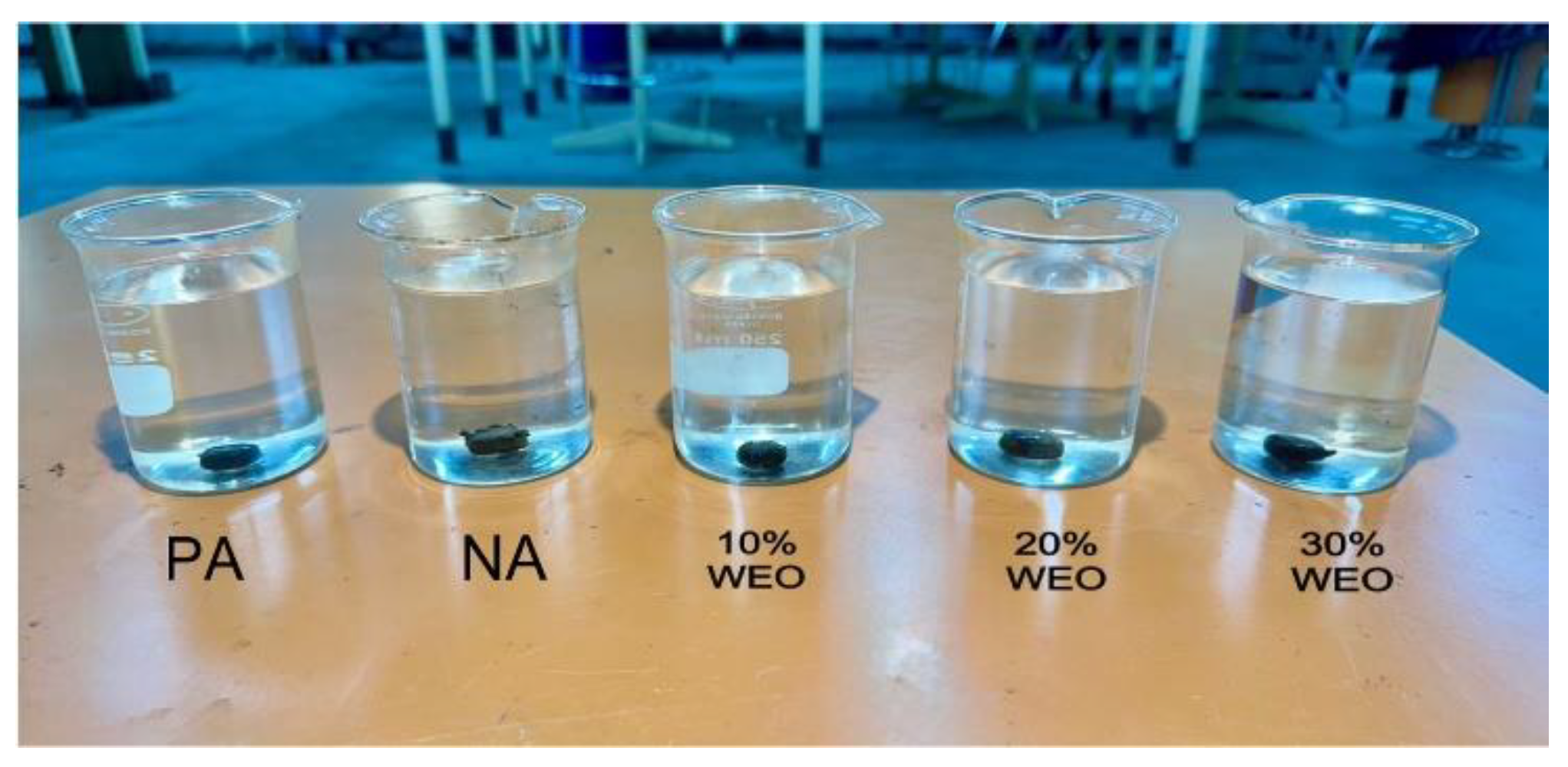

3.1. Physical Properties

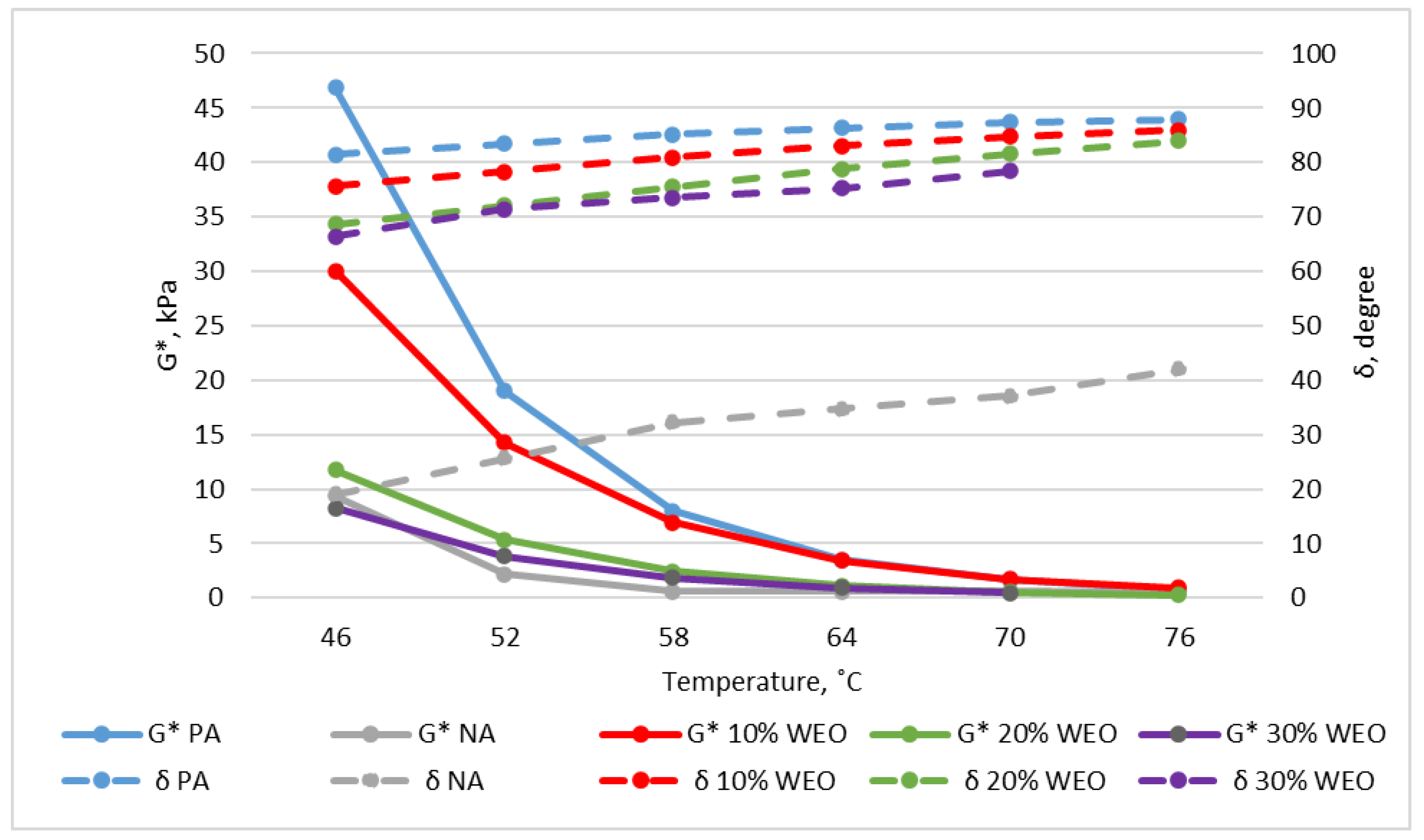

3.2. Rheological Properties

3.3. MSCR Results

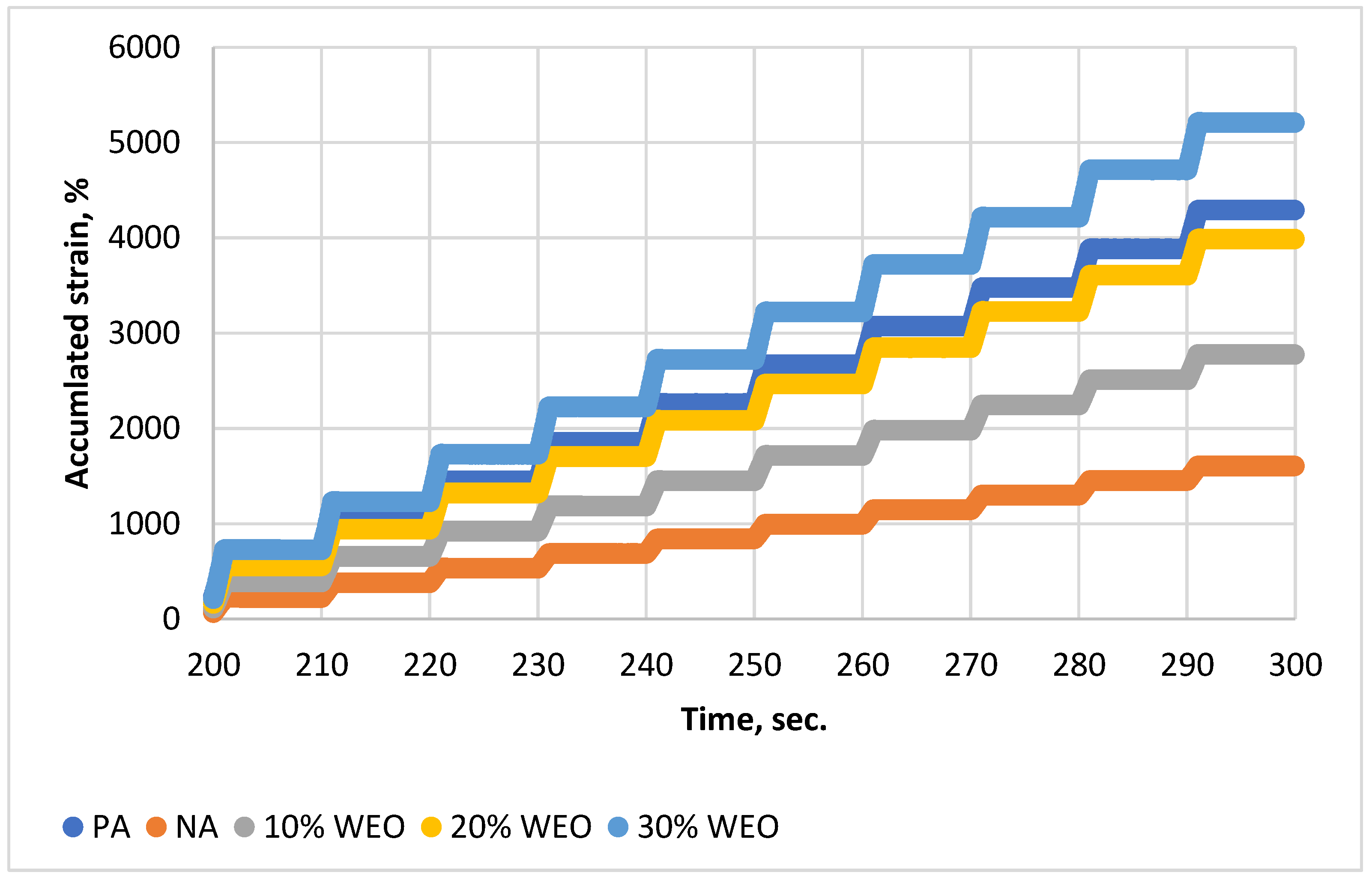

3.4. LAS Results

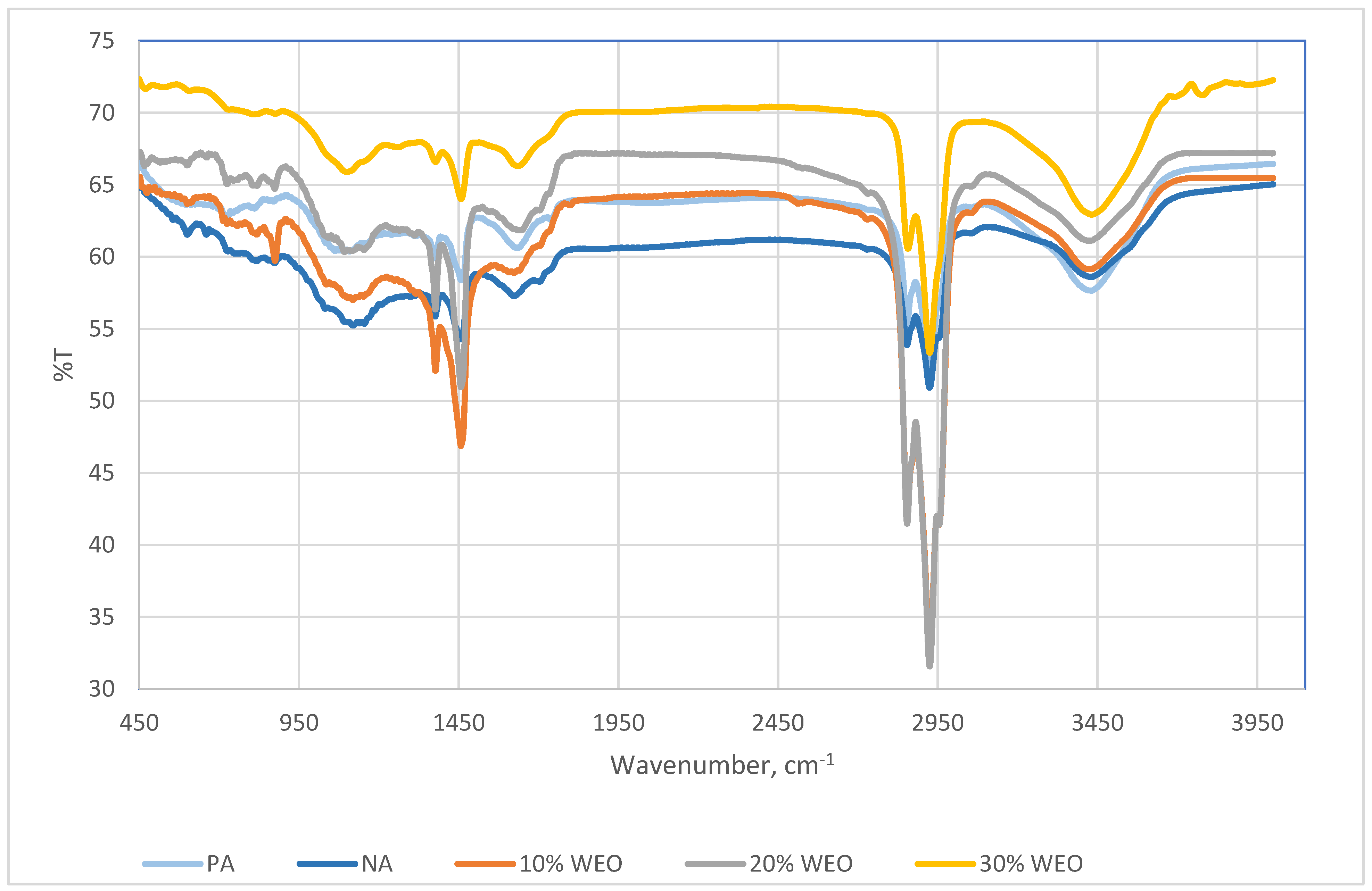

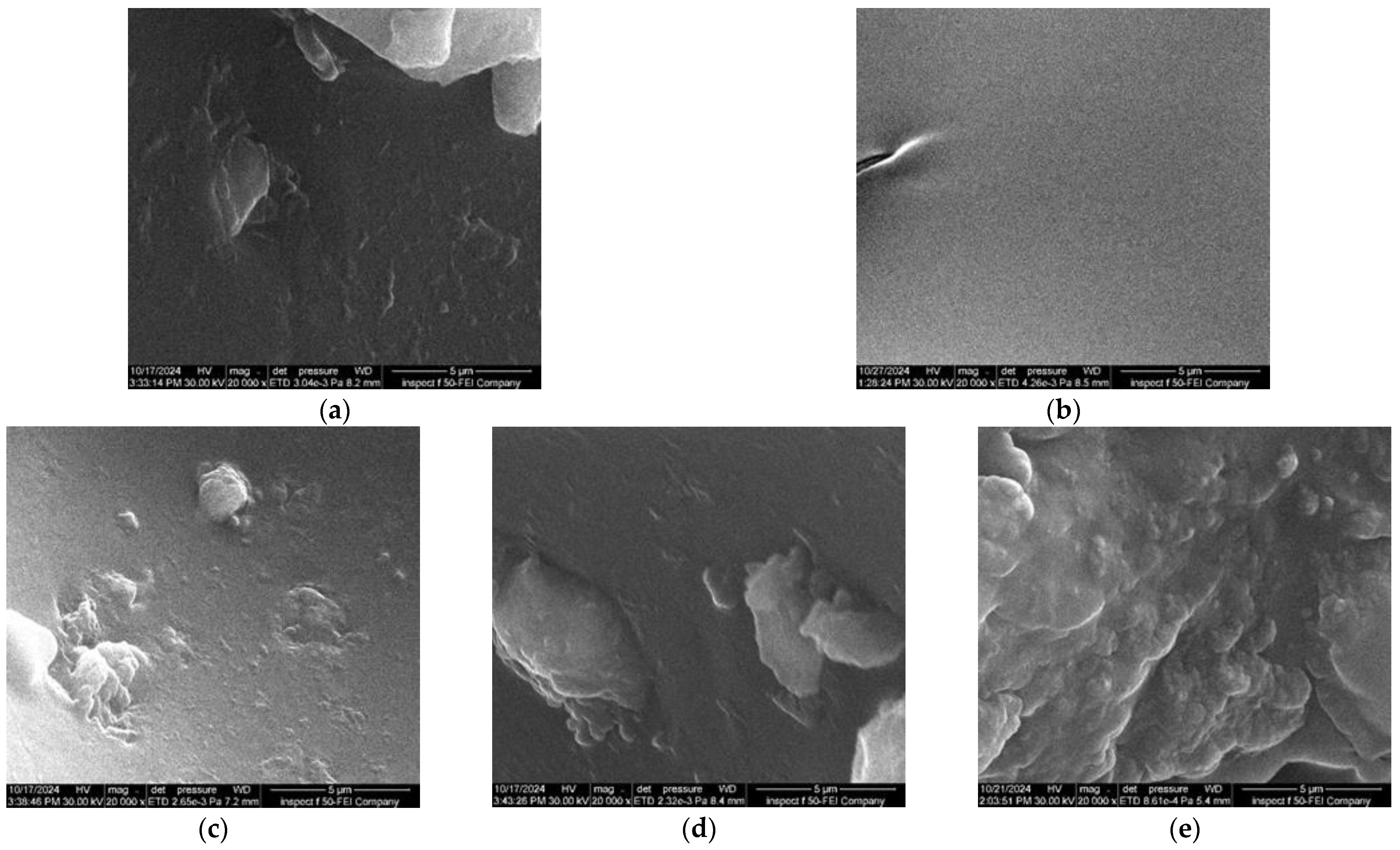

3.5. Interaction Mechanism and Morphology Results

3.5.1. EDX Analysis

3.5.2. FTIR Results Analysis

3.5.3. SEM Analysis

3.6. Economic Benefits of Eco-Friendly Asphalt

4. Conclusions

- WEO significantly improved the physical properties of NA by increasing penetration and ductility while reducing the softening point and viscosity. At 20% WEO, the physical properties closely matched those of PA. EDX and SEM analyses demonstrated improved chemical composition and surface homogeneity with 20% WEO, while 30% WEO showed phase separation and potential performance issues;

- Rotational viscosity test results at 135 °C revealed that unmodified NA had high viscosity, making it difficult to handle. WEO addition progressively reduced viscosity, with 10% WEO achieving an 83.31% reduction and 20% WEO nearing PA’s viscosity, enhancing workability. At 30% WEO, viscosity matched that of PA, indicating improved flow properties;

- Rheological analysis confirmed that PA, NA, 10% WEO, and 20% WEO binders maintained a high-temperature PG grade of 70 °C, suitable for rutting resistance. The 30% WEO binder had a lower PG grade of 64 °C, indicating reduced thermal stability at high WEO content;

- MSCR and LAS tests indicated that the 20% WEO binder achieved the best balance of deformation resistance and fatigue performance, meeting Superpave criteria and surpassing PA’s fatigue life. The 10% WEO binder also improved performance, while 30% WEO exhibited reduced effectiveness under stress;

- The comprehensive analysis suggests that 20% WEO is the optimal content for producing eco-friendly asphalt using NA, balancing flexibility, thermal stability, and resistance to deformation and fatigue. Higher WEO levels (30%) should be avoided as they compromise performance. However, these results are based on controlled laboratory conditions, and further field studies are necessary to verify the practical performance and long-term sustainability of these findings.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mehta, D.; Saboo, N. Use of sugarcane molasses for preparation of bio-asphalt: Effect of source. Constr. Build. Mater. 2024, 421, 135691. [Google Scholar] [CrossRef]

- Arnold, R.; Manocha, N.; Hubert, C. Infrastructure Decarbonisation and Resilience Strategies. Available at SSRN 4881353. 2024. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=4881353 (accessed on 4 December 2024).

- Hammond, G.P. Towards Net-Zero ‘Greenhouse Gas’ Emissions by 2050; Emerald Publishing Limited: Bingley, UK, 2024; pp. 95–97. [Google Scholar]

- Ahmed, F.; Latief, R.; Albayati, A. Effect of Natural Bitumen on the Performance of Hot Asphalt Mixture. Gazi Univ. J. Sci. 2024, 37, 1154–1170. [Google Scholar] [CrossRef]

- Soleiman-Beigi, M.; Kohzadi, H.; Toolabi, S. Natural Asphalt: A Novel Bitumen Modifier and Asphalt Filler. 2024. Available online: https://www.intechopen.com/online-first/1165464 (accessed on 4 December 2024).

- Mohammed, F.A.; Latief, R.H.; Albayati, A.H. Assessment of traditional asphalt mixture performance using natural asphalt from sulfur springs. J. Eng. 2024, 30, 54–73. [Google Scholar] [CrossRef]

- Liu, C.; Lv, S.; Jin, D.; Qu, F. Laboratory investigation for the road performance of asphalt mixtures modified by rock asphalt–styrene butadiene rubber. J. Mater. Civ. Eng. 2021, 33, 04020504. [Google Scholar] [CrossRef]

- Din, I.M.U.; Bhat, F.S.; Mir, M.S. A study investigating the impact of waste cooking oil and waste engine oil on the performance properties of RAP binders. Road Mater. Pavement Des. 2023, 24, 295–309. [Google Scholar] [CrossRef]

- Raouf, M.A.; Williams, R.C. Temperature and shear susceptibility of a nonpetroleum binder as a pavement material. Transp. Res. Rec. J. Transp. Res. Board 2010, 2180, 9–18. [Google Scholar] [CrossRef]

- Fini, E.H.; Al-Qadi, I.L.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Cai, X.; Zhang, J.; Xu, G.; Gong, M.; Chen, X.; Yang, J. Internal aging indexes to characterize the aging behavior of two bio-rejuvenated asphalts. J. Clean. Prod. 2019, 220, 1231–1238. [Google Scholar] [CrossRef]

- Li, H.; Zhang, F.; Feng, Z.; Li, W.; Zou, X. Study on waste engine oil and waste cooking oil on performance improvement of aged asphalt and application in reclaimed asphalt mixture. Constr. Build. Mater. 2021, 276, 122138. [Google Scholar] [CrossRef]

- Albayati, A.; Mosawe, H.A.; Sukhija, M.; Naidu, A.N.P. Appraising the synergistic use of recycled asphalt pavement and recycled concrete aggregate for the production of sustainable asphalt concrete. Case Stud. Constr. Mater. 2023, 19, e02237. [Google Scholar] [CrossRef]

- Meng, Y.; Wang, Z.; Lei, J.; Liao, Y.; Zhao, X.; Qin, Y.; Fang, G.; Zhang, C. Study on aging resistance and micro characteristics of bio-asphalt/TLA composite modified asphalt binder. Constr. Build. Mater. 2022, 359, 129566. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, Y.; Yang, J.; Li, X. A comprehensive review of bio-oil, bio-binder and bio-asphalt materials: Their source, composition, preparation and performance. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 151–166. [Google Scholar] [CrossRef]

- Cao, W.; Wang, Y.; Wang, C. Fatigue characterization of bio-modified asphalt binders under various laboratory aging conditions. Constr. Build. Mater. 2019, 208, 686–696. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Du, Y.; Zhu, X.; Lu, T.; Pang, Q.; Shi, S.; Dai, Z. Evaluation of optimized bio-asphalt containing high content waste cooking oil residues. Fuel 2017, 202, 529–540. [Google Scholar] [CrossRef]

- Liu, L.; Xiao, F.; Zhang, H.; Amirkhanian, S. Rheological characteristics of alternative modified binders. Constr. Build. Mater. 2017, 144, 442–450. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, H.; Bahia, H.U. Extended aging performance of high RAP mixtures and the role of softening oils. Int. J. Pavement Eng. 2022, 23, 2773–2784. [Google Scholar] [CrossRef]

- Gaudenzi, E.; Cardone, F.; Lu, X.; Canestrari, F. The use of lignin for sustainable asphalt pavements: A literature review. Constr. Build. Mater. 2023, 362, 129773. [Google Scholar] [CrossRef]

- Aljbouri, H.J.; Albayati, A.H. Effect of nanomaterials on the durability of hot mix asphalt. Transp. Eng. 2023, 11, 100165. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, M.; Han, X.; Wang, R.; Yu, J.; Xu, X.; Xue, L. Influence of characteristics of recycling agent on the early and long-term performance of regenerated SBS modified bitumen. Constr. Build. Mater. 2020, 237, 117631. [Google Scholar] [CrossRef]

- Cong, P.; Wang, J.; Zhou, Z.; Zhang, H. Preparation of rejuvenating agent and property evaluation of rejuvenated SBS modified asphalt binders. Constr. Build. Mater. 2020, 233, 117911. [Google Scholar] [CrossRef]

- Albayati, A.H. A review of rutting in asphalt concrete pavement. Open Eng. 2023, 13, 20220463. [Google Scholar] [CrossRef]

- Shen, J.; Amirkhanian, S.; Miller, J.A. Effects of rejuvenating agents on superpave mixtures containing reclaimed asphalt pavement. J. Mater. Civ. Eng. 2007, 19, 376–384. [Google Scholar] [CrossRef]

- Raouf, M.A.; Williams, C.R. General rheological properties of fractionated switchgrass bio-oil as a pavement material. Road Mater. Pavement Des. 2010, 11, 325–353. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical characterization of biobinder from swine manure: Sustainable modifier for asphalt binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Xinxin, C.; Xuejuan, C.; Boming, T.; Yuanyuan, W.; Xiaolong, L. Investigation on possibility of waste vegetable oil rejuvenating aged asphalt. Appl. Sci. 2018, 8, 765. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; You, Z.; Hasan, M.R.M.; Lei, Y.; Irfan, M. Rheological behavior and sensitivity of wood-derived bio-oil modified asphalt binders. Appl. Sci. 2018, 8, 919. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Zhou, S.; Wu, J.; Xuan, W.; Liu, W. Evaluation of the ageing behaviour of waste engine oil-modified asphalt binders. Constr. Build. Mater. 2019, 223, 394–408. [Google Scholar] [CrossRef]

- Al-Mutlaq, S.; Mahal, E.; Yahya, R.; Mahal, A. Effect of chlorination on the assessment of waste engine oil modified asphalt binders. Pet. Sci. Technol. 2019, 37, 617–628. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Apostolidis, P.; Gard, W.; van de Ven, M.; Erkens, S.; Jing, R. Chemical and rheological evaluation of aged lignin-modified bitumen. Materials 2019, 12, 4176. [Google Scholar] [CrossRef] [PubMed]

- Pérez, I.; Pasandín, A.R.; Pais, J.C.; Pereira, P.A.A. Feasibility of using a lignin-containing waste in asphalt binders. Waste Biomass Valorization 2020, 11, 3021–3034. [Google Scholar] [CrossRef]

- Yan, K.; Peng, Y.; You, L. Use of tung oil as a rejuvenating agent in aged asphalt: Laboratory evaluations. Constr. Build. Mater. 2020, 239, 117783. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z.; Chen, X.; Hasan, M.R. Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: A comprehensive review. J. Traffic Transp. Eng. (Engl. Ed.) 2020, 7, 137–151. [Google Scholar] [CrossRef]

- Fatemi, S.; Bazaz, J.B.; Ziaee, S.A. Evaluation of rutting and fatigue behaviors of asphalt binders modified with calcium lignosulfonate. Adv. Civ. Eng. 2021, 2021, 6894514. [Google Scholar] [CrossRef]

- Niu, D.; Xie, X.; Zhang, Z.; Niu, Y.; Yang, Z. Influence of binary waste mixtures on road performance of asphalt and asphalt mixture. J. Clean. Prod. 2021, 298, 126842. [Google Scholar] [CrossRef]

- Daryaee, D.; Habibpour, M.; Gulzar, S.; Underwood, B.S. Combined effect of waste polymer and rejuvenator on performance properties of reclaimed asphalt binder. Constr. Build. Mater. 2021, 268, 121059. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of aged asphalt binders by waste engine oil and SBS blend: Physical, chemical, and rheological properties of binders and mechanical evaluations of mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Harvey, J.T.; Butt, A.A.; Jia, M.; Liu, J. A review of converting woody biomass waste into useful and eco-friendly road materials. Transp. Saf. Environ. 2022, 4, tdab031. [Google Scholar] [CrossRef]

- Shi, K.; Fu, Z.; Liu, J.; Song, R.; Ma, F.; Dai, J.; Li, C.; Wen, Y. Multiscale investigation of waste soybean oil rejuvenated asphalt binder utilising experimental methodologies and molecular dynamics simulations. Int. J. Pavement Eng. 2023, 24, 2181961. [Google Scholar] [CrossRef]

- Hameed, M.A.; Al-Hdabi, A. Impact of Engine Oil as a Rejuvenator on the Properties of RAP Containing Asphalt Mixtures. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2023. [Google Scholar]

- SCRB/R9; Hot-Mix Asphalt Concrete Pavement, State Corporation of Roads and Bridges. General Specifications for Road and Bridge Construction, Ministry of Housing and Construction: Baghdad, Iraq, 2003.

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef]

- Mehmood, R.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Daud, N.N.N.; Ansari, A.H. Waste engine oil as a sustainable approach for asphalt rejuvenation and modification: A review. Heliyon 2024, 10, e40737. [Google Scholar] [CrossRef]

- Shams, M. Influence of Using Different Rejuvenators on Recycled Hot Mix Asphalt Properties. Master’s Thesis, Department of Civil Engineering, University of Technology, 2020. [Google Scholar]

| Reference, Year | Materials Used | Main Conclusions |

|---|---|---|

| [26], 2007 | Reclaimed asphalt pavement (RAP), WEO | WEO can rejuvenate RAP, but excessive amounts reduce high-temperature stability. |

| [27], 2010 | Waste engine oil (WEO), aged asphalt | WEO effectively rejuvenates aged asphalt, restoring flexibility and reducing brittleness. |

| [28], 2011 | Bio-oil, recycled materials | Bio-oil improves binder properties and reduces environmental impact in asphalt production. |

| [29], 2016 | Reclaimed asphalt pavement (RAP), WEO | WEO enhances RAP’s flexibility and cracking resistance, contributing to sustainable construction. |

| [30], 2018 | Waste vegetable oil (WVO), modified asphalt, HMA | Rejuvenators act to gain better performance and workability for aged asphalt, endurance fatigue cracking, susceptible to rutting resistance |

| [31], 2018 | Bio-oil (sawdust oil) | Bio-binders’ rheological properties are more susceptible to the RTFO aging condition than the reference binder. Also, there has been a significant increase in the complex shear modulus of modified asphalt binders. |

| [32], 2019 | WEO, modified asphalt | Promising to the anti-aging phenomena, suppress fatigue cracking, mitigate oxidative-aging polymerization |

| [33], 2019 | WEO, modified asphalt | Chlorination with WEO improves asphalt viscosity and durability, promoting sustainability. |

| [34], 2019 | Lignin, bio-binder, RAP | Lignin can partially replace bitumen, improving stiffness and temperature susceptibility. |

| [35], 2020 | Vegetable oil, RAP | Vegetable oil-based rejuvenators restore elasticity to aged asphalt and improve environmental sustainability. |

| [36], 2020 | Tung oil, modified asphalts blended | Upgrade flexibility of aged asphalt, sustain high-temperature resistance, induce low-temperature mechanisms |

| [37], 2020 | Bio-oil (mainly derived from wood waste) | Improves the workability, reduces the cracking sensitivity and stiffness of the mixture, and reduces its compaction temperature at the same time |

| [38], 2021 | Calcium lignosulfonate (CLS), bitumen | CLS reduces aging effects in bitumen, improving durability and high-temperature performance. |

| [39], 2021 | Waste cooking oil, aged asphalt | Waste cooking oil rejuvenates aged asphalt, improving flexibility and reducing the need for virgin binders. |

| [40], 2021 | PBR (waste polybutadiene rubber), reclaimed asphalt binder | Promote LAS fatigue performance and endure extremely heavy traffic against rutting at 64 °C within MSCR |

| [41], 2022 | Compound rejuvenator WS-rejuvenator (70% WEO + 30% SBS copolymer), 30% and 50% RAP | WS-rejuvenator has altered physical, chemical, and rheological properties, enhanced fatigue and rutting tolerance, and revived the aged binder. |

| [42], 2022 | Bio-mass oil (bio-crude oil, pyrolysis oil/liquid, wood acetic acid, and wood liquid) | Better low-temperature crack resistance and water stability than petroleum asphalt mixture and better anti-aging properties |

| [43], 2023 | WEO, aged asphalt, molecular dynamics simulations | WEO restores the physical properties of aged asphalt and reduces molecular aggregation. |

| [44], 2023 | Pure engine oil (PEO), RAP | Boost Marshall stability, indirect tensile strength value, and lower susceptibility to moisture damage |

| Test | Result | Specification Limit [45] | |

|---|---|---|---|

| Petroleum Asphalt | Natural Asphalt | ||

| Unaged (original) bitumen | |||

| Penetration at 25 °C, 100 gm, and 5 s (ASTM D5), dmm | 49 | 17 | 40–50 |

| Softening point, R&B (ASTM D36), °C | 50 | 68 | ---- |

| Specific gravity at 25 °C (ASTM D70) | 1.018 | 1.066 | ---- |

| Flashpoint (ASTM D92), °C | 296 | 334 | Min. 232 |

| Ductility (ASTM D113), cm | 120 | 45 | Min. 100 |

| Aged residue from thin film oven test (ASTM D1754) | |||

| Retained penetration, % of original (ASTM D5) | 59 | 70 | Min. 55 |

| Ductility at 25 °C, 5 cm/min, (ASTM D113), cm | 60 | 16 | Min. 25 |

| Binder Type | Jnr 0.1 | Jnr 3.2 | Jnr diff. | %R (0.1 kPa) | %R (3.2 kPa) |

|---|---|---|---|---|---|

| PA | 1.1635 | 1.2677 | 8.96 | 3.90 | 0.41 |

| NA | 0.4231 | 0.4747 | 12.19 | 18.24 | 3.45 |

| 10% WEO | 0.6539 | 0.8255 | 26.24 | 6.40 | 1.13 |

| 20% WEO | 0.9516 | 1.2387 | 30.17 | 5.61 | 0.75 |

| 30% WEO | 1.1333 | 1.5564 | 37.33 | 3.59 | 0.36 |

| Paving Grade | Test Temperature | Requirements |

|---|---|---|

| S | PG high temperature | Jnr3.2 ≤ 4.5 kPa, % R ≤ 75% |

| H | PG high temperature | Jnr3.2 ≤ 2.0 kPa, % R ≤ 75% |

| V | PG high temperature | Jnr3.2 ≤ 1.0 kPa, % R ≤ 75% |

| E | PG high temperature | Jnr3.2 ≤ 0.5 kPa, % R ≤ 75% |

| Binder Type | Strain Level (%) | Nf |

|---|---|---|

| PA | 2.5 | 141,006 |

| 5.0 | 1189 | |

| NA | 2.5 | 36,512 |

| 5.0 | 527 | |

| 10% WEO | 2.5 | 247,816 |

| 5.0 | 8070 | |

| 20% WEO | 2.5 | 812,048 |

| 5.0 | 48,431 | |

| 30% WEO | 2.5 | 502,011 |

| 5.0 | 20,572 |

| Sample | Element | Atomic % | Atomic % Error | Weight % | Weight % Error |

|---|---|---|---|---|---|

| PA | C | 94.6 | 0.6 | 86.9 | 0.6 |

| S | 5.4 | 0.1 | 13.1 | 0.1 | |

| NA | C | 91.0 | 0.6 | 79.3 | 0.5 |

| Al | 1.1 | 0.0 | 2.2 | 0.1 | |

| S | 7.3 | 0.1 | 17.1 | 0.1 | |

| Ca | 0.5 | 0.0 | 1.5 | 0.1 | |

| 10% WEO | C | 92.7 | 0.4 | 82.6 | 0.4 |

| Al | 0.2 | 0.0 | 0.3 | 0.0 | |

| Si | 0.3 | 0.0 | 0.7 | 0.0 | |

| S | 6.5 | 0.0 | 15.5 | 0.1 | |

| Ca | 0.3 | 0.0 | 0.9 | 0.0 | |

| 20% WEO | C | 93.7 | 0.5 | 84.7 | 0.5 |

| Si | 0.3 | 0.0 | 0.6 | 0.0 | |

| S | 5.7 | 0.0 | 13.7 | 0.1 | |

| Ca | 0.4 | 0.0 | 1.1 | 0.0 | |

| 30% WEO | C | 97.6 | 0.6 | 93.9 | 0.6 |

| S | 2.4 | 0.0 | 6.1 | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albayati, A.H.; Al-Kheetan, M.J.; Mohammed, A.M.; Al-ani, A.F.; Moudhafar, M.M. Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil. Infrastructures 2024, 9, 224. https://doi.org/10.3390/infrastructures9120224

Albayati AH, Al-Kheetan MJ, Mohammed AM, Al-ani AF, Moudhafar MM. Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil. Infrastructures. 2024; 9(12):224. https://doi.org/10.3390/infrastructures9120224

Chicago/Turabian StyleAlbayati, Amjad H., Mazen J. Al-Kheetan, Ahmed M. Mohammed, Aliaa F. Al-ani, and Mustafa M. Moudhafar. 2024. "Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil" Infrastructures 9, no. 12: 224. https://doi.org/10.3390/infrastructures9120224

APA StyleAlbayati, A. H., Al-Kheetan, M. J., Mohammed, A. M., Al-ani, A. F., & Moudhafar, M. M. (2024). Performance Assessment of Eco-Friendly Asphalt Binders Using Natural Asphalt and Waste Engine Oil. Infrastructures, 9(12), 224. https://doi.org/10.3390/infrastructures9120224