Characterization of Dislocation Rearrangement in FCC Metals during Work Hardening Using X-ray Diffraction Line-Profile Analysis

Abstract

:1. Introduction

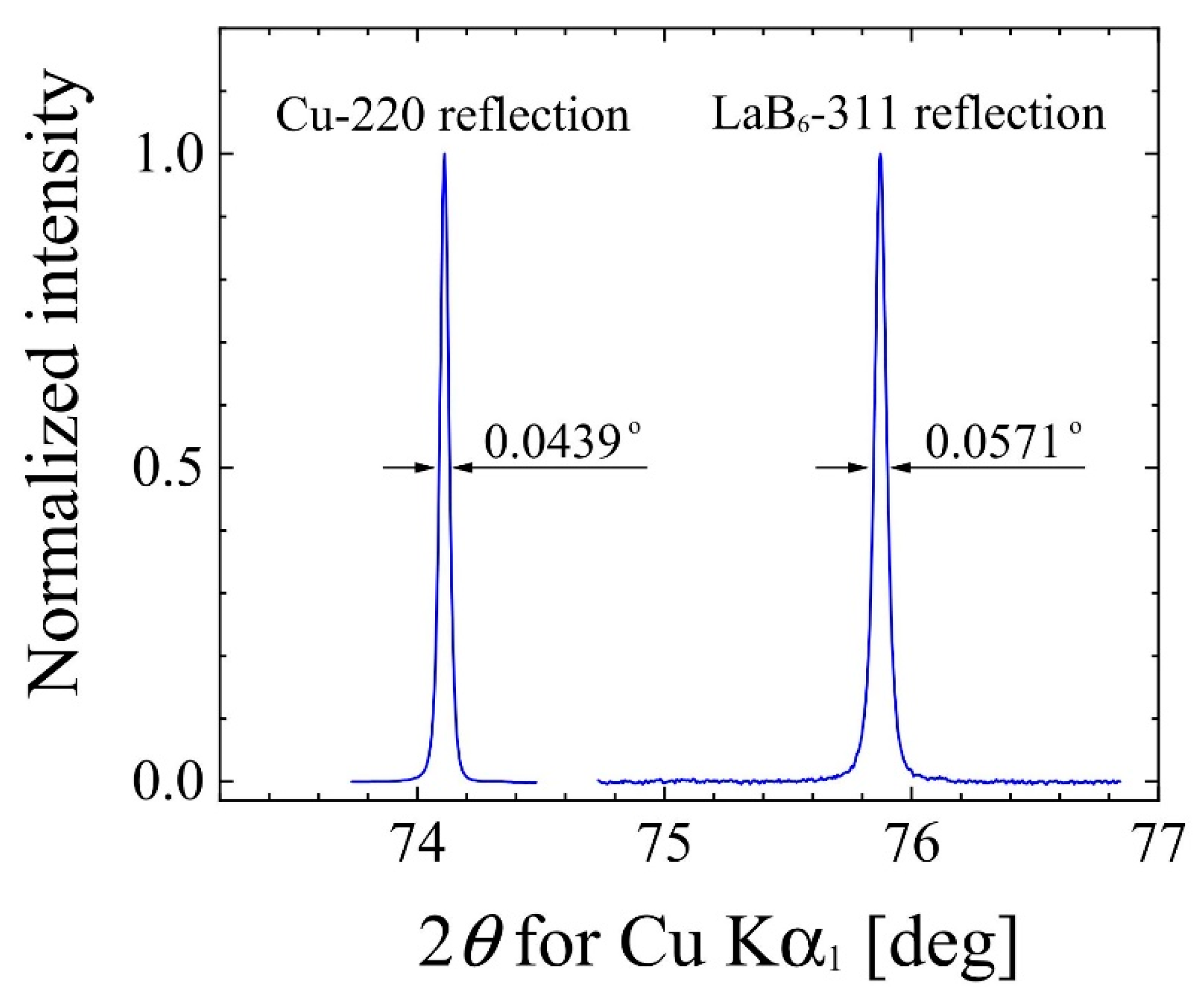

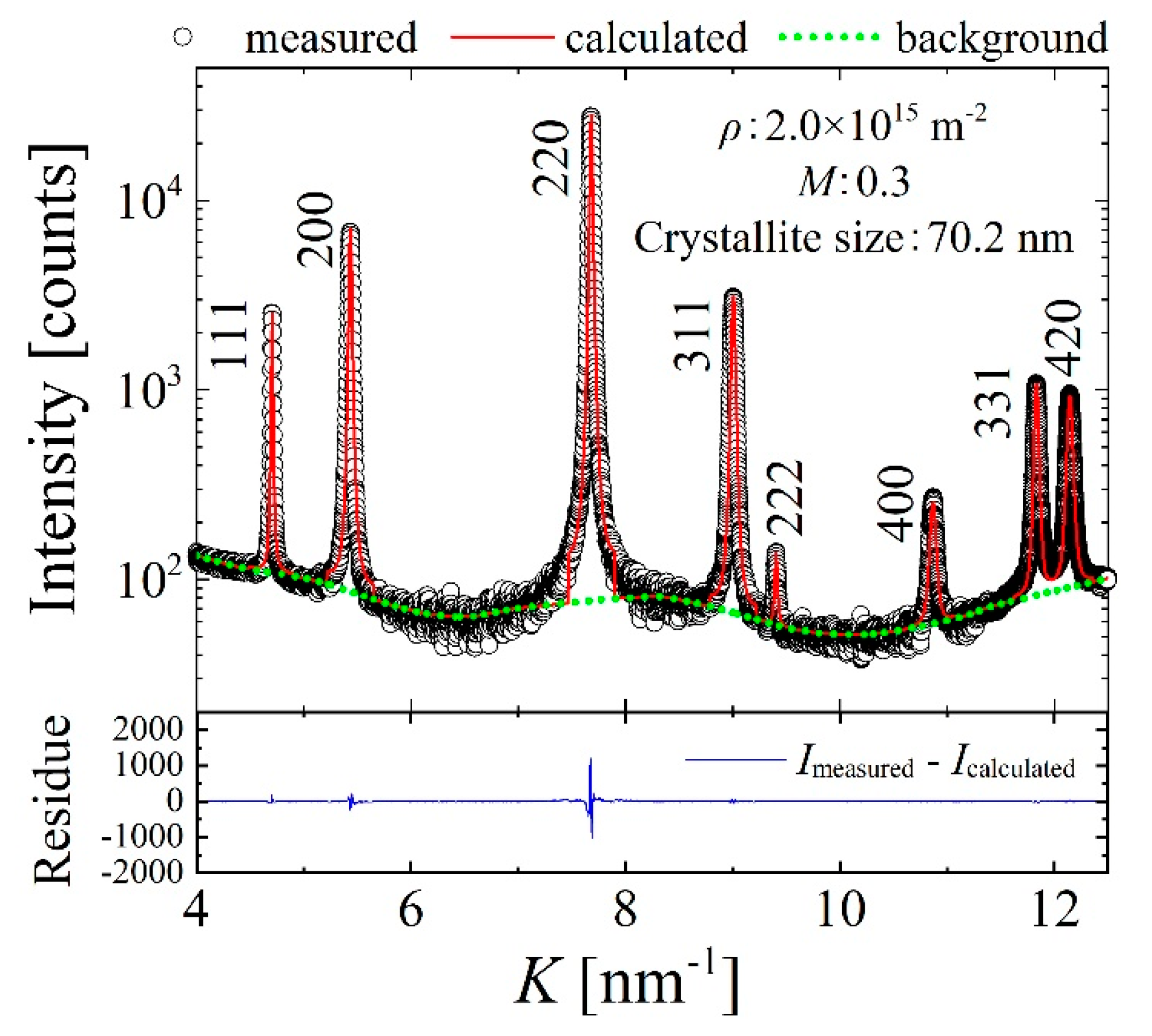

2. Materials and Methods

3. Results and Discussion

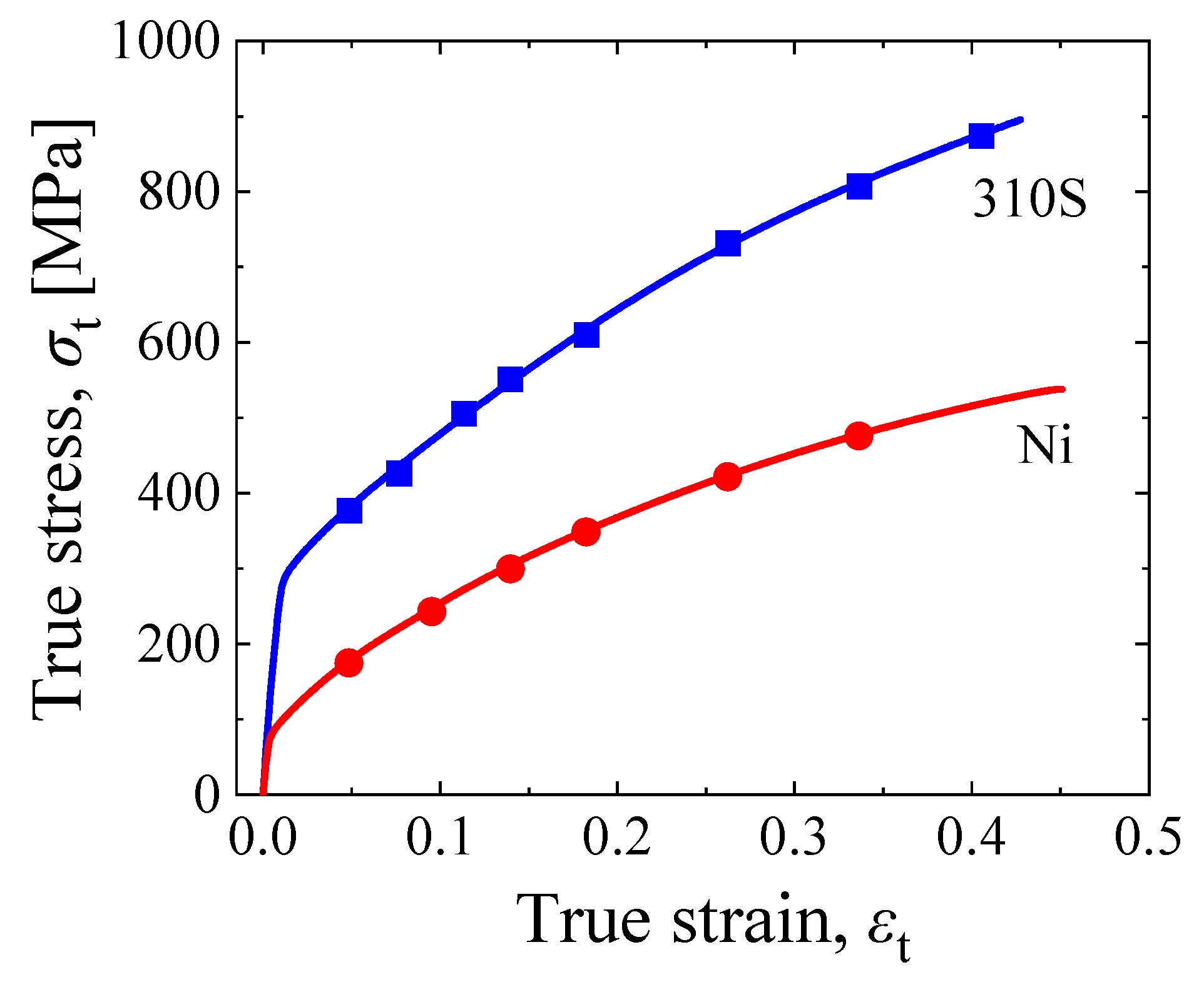

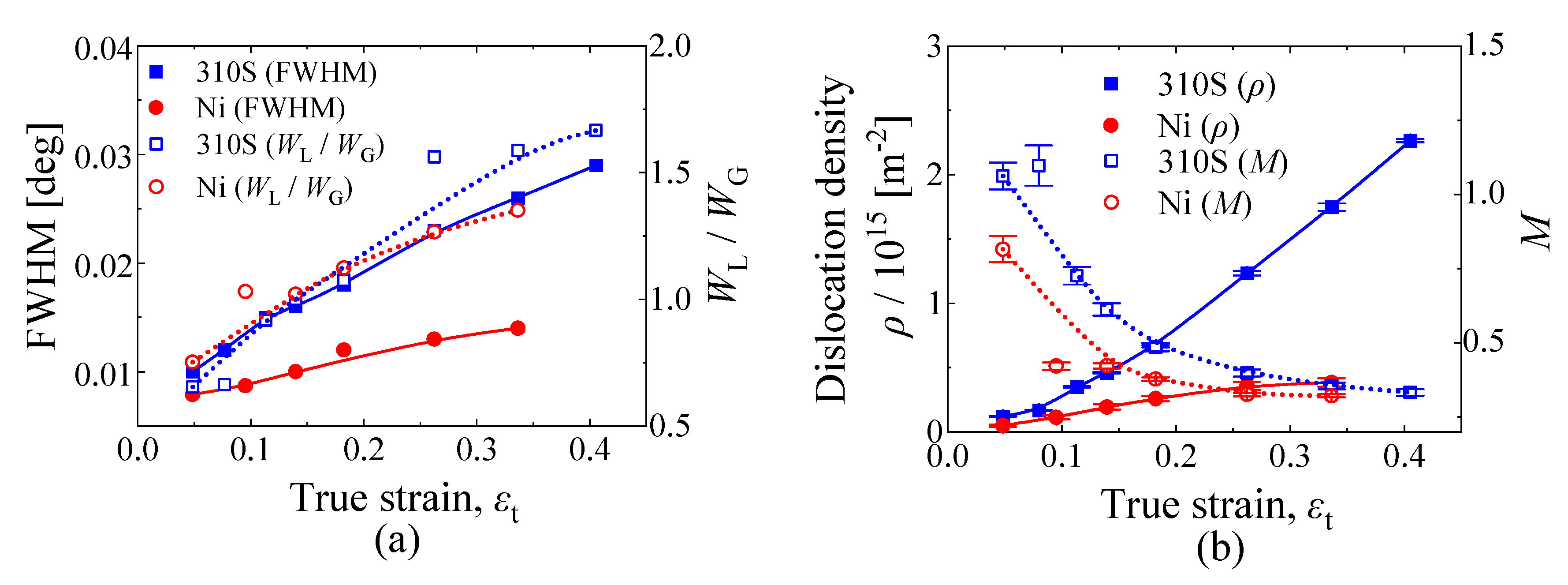

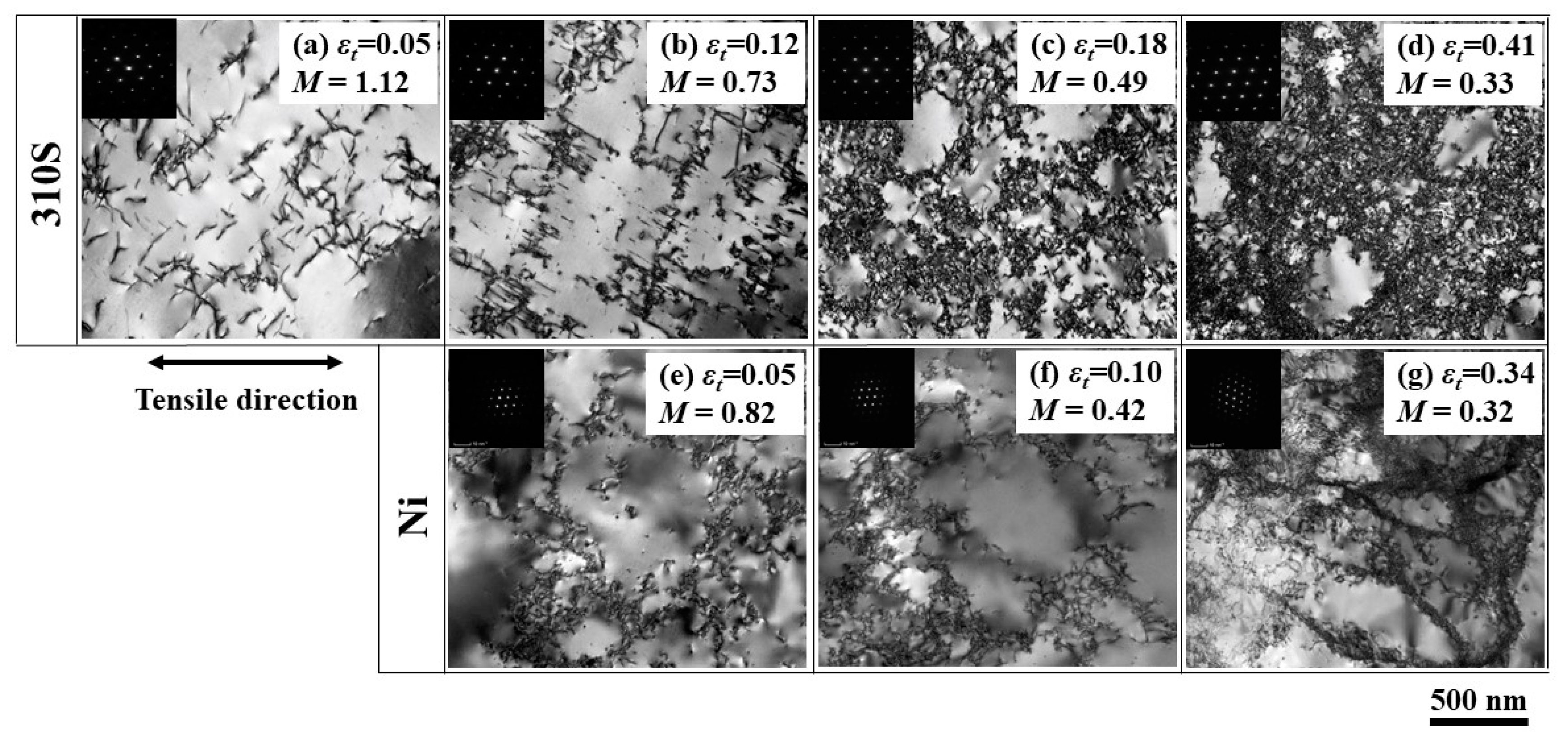

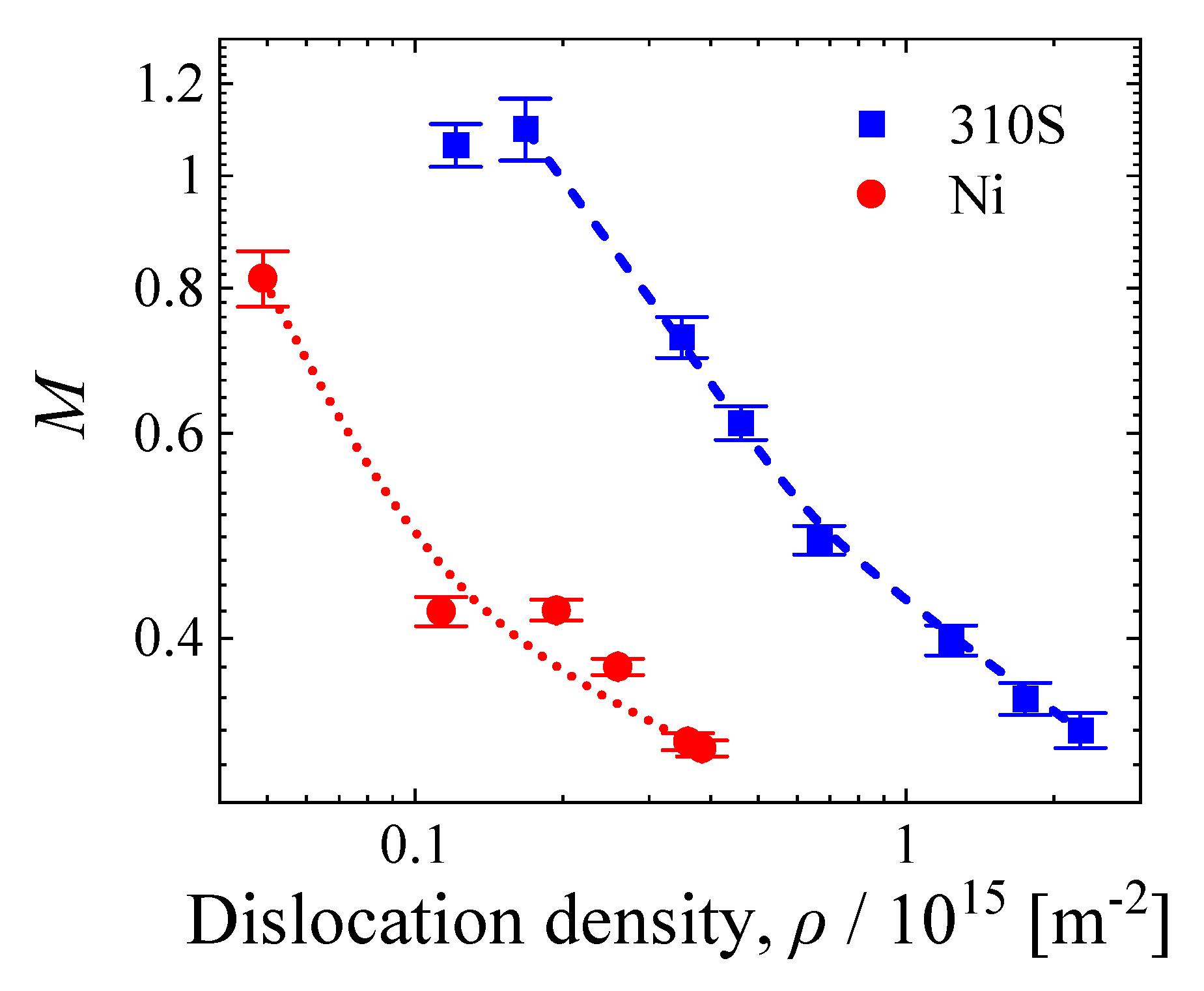

3.1. Variations in M Values during Tensile Deformation in Nickel and AISI 310S Stainless Steel

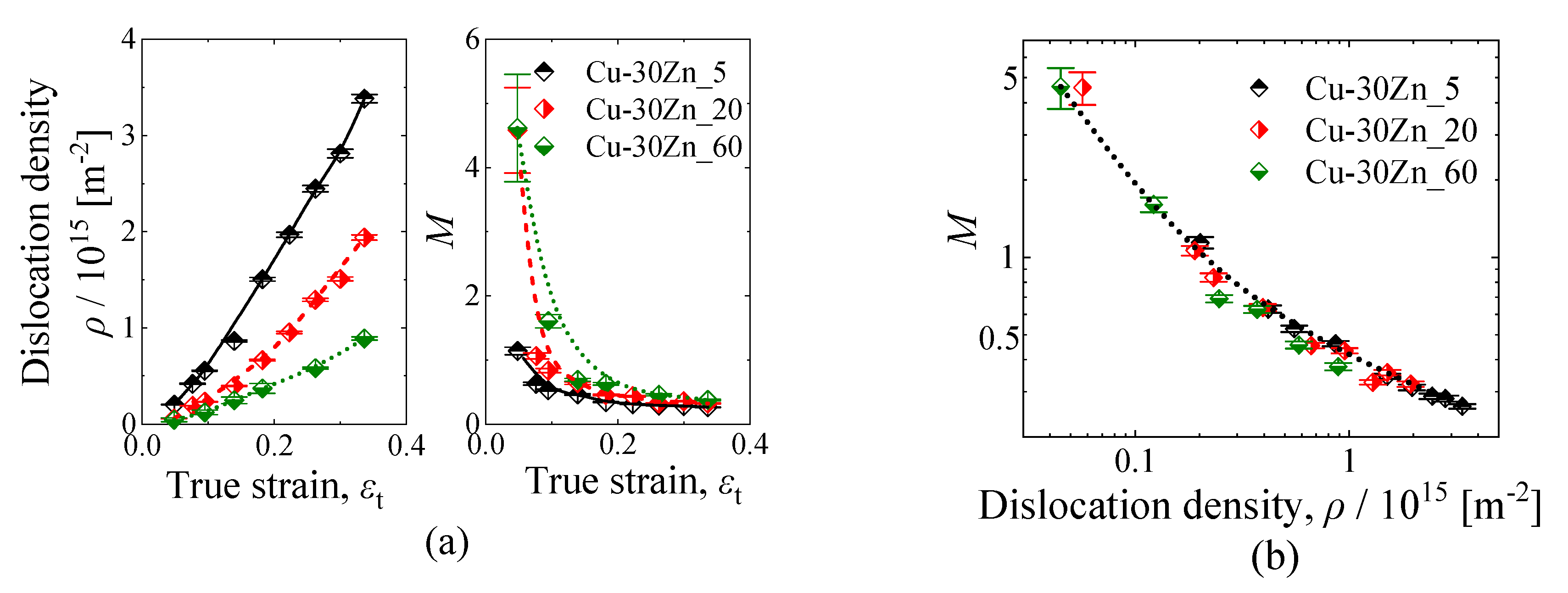

3.2. Effect of Grain Size on M Values

3.3. Effect of SFE on the Variation in M Value

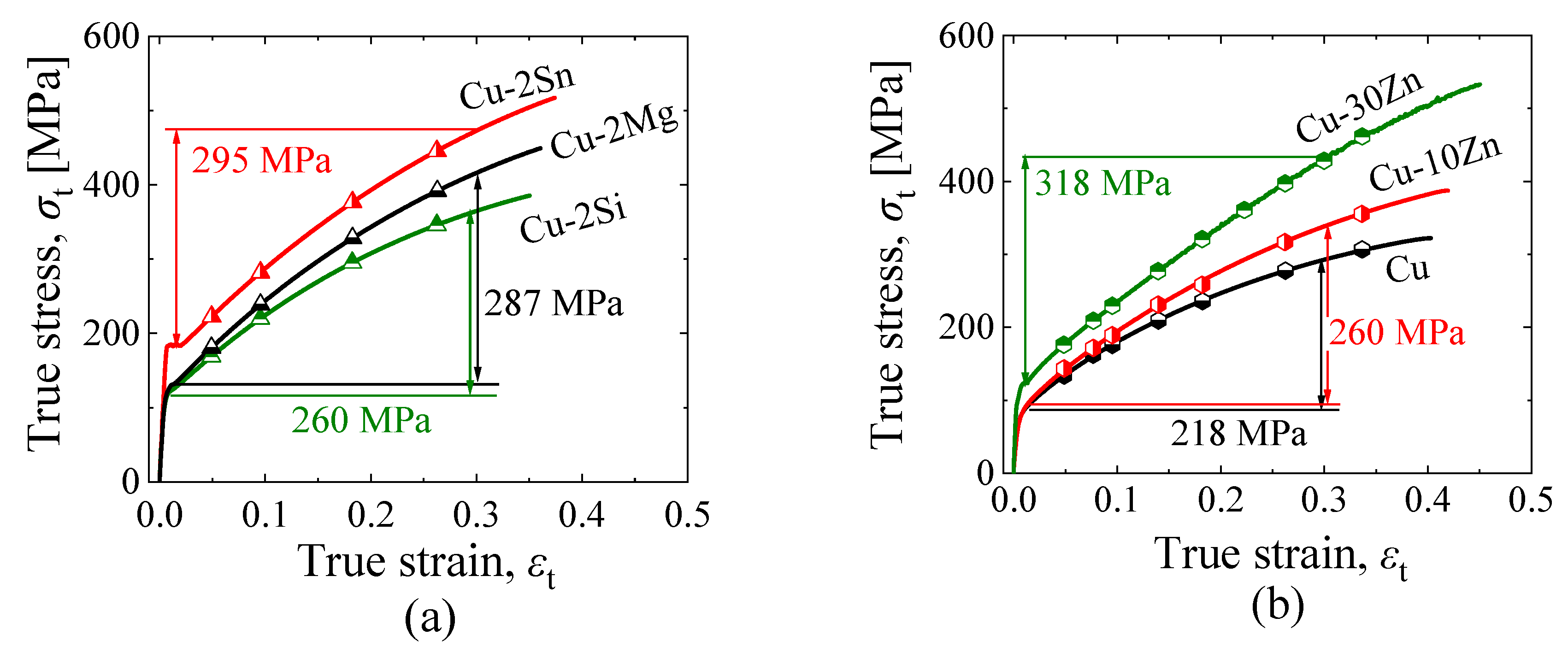

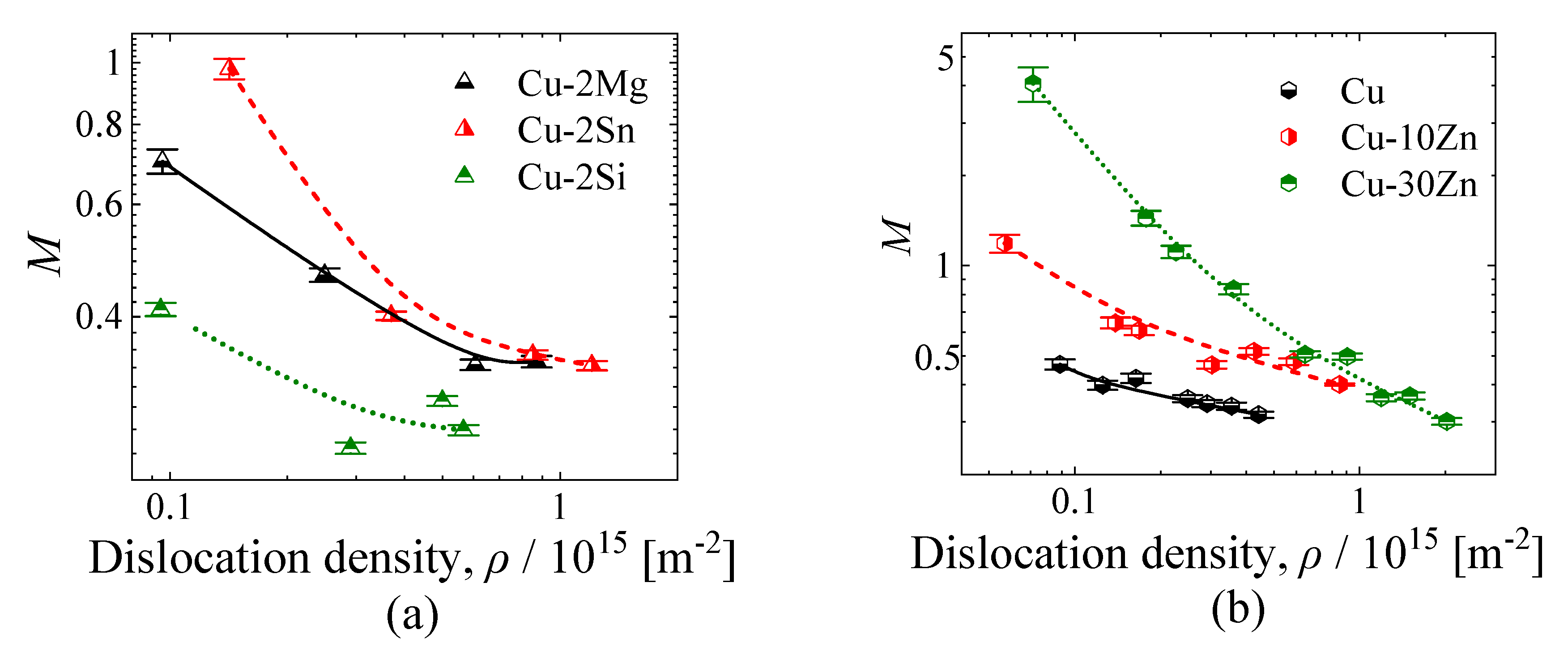

3.4. Effects of Solute Elements on the Variation in M Values

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hayashi, M.; Ito, Y.; Takano, K.; Mori, H.; Matsunaga, H.; Onuki, Y.; Suzuki, S.; Sato, S. Effect of kinds of alloying elements in solid-solution copper alloys on dislocation evolution. J. Jpn. Inst. Copper 2020, 59, 70–75. [Google Scholar]

- Nakagawa, K.; Takano, K.; Matsunaga, H.; Mori, H.; Kitahara, A.; Onuki, Y.; Suzuki, S.; Sato, S. Variation in dislocation-strengthening factors of Cu-Zn alloys with solid-solute zinc contents. J. Jpn. Inst. Copper 2020, 59, 59–63. [Google Scholar]

- Li, P.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed fcc single crystals. Prog. Mater. Sci. 2011, 56, 328–377. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, Y. An experimental study of the formation of typical dislocation patterns in polycrystalline copper under cyclic shear. Acta Mater. 2007, 55, 1831–1842. [Google Scholar] [CrossRef]

- Kashyap, B.P.; Tangri, K. On the Hall-Petch relationship and substructural evolution in type 316L stainless steel. Acta Metall. Mater. 1995, 43, 3971–3981. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir-Cernatescu, I.; Louër, D.; Audebrand, N. Dislocations and crystallite size distribution in nanocrystalline CeO2 obtained from an ammonium cerium (IV)-nitrate solution. J. Phys. Chem. Solids 2001, 62, 1935–1941. [Google Scholar] [CrossRef]

- Ito, M.; Sato, S.; Ito, Y.; Mori, H.; Matsunaga, H.; Maki, K.; Suzuki, S. Effects of microstructural characteristics on stress relaxation resistance of solid-solution hardened copper alloys. J. Jpn. Inst. Copper 2017, 56, 45–50. [Google Scholar]

- Sato, S.; Shobu, T.; Satoh, K.; Ogawa, H.; Wagatsuma, K.; Kumagai, M.; Imafuku, M.; Tashiro, H.; Suzuki, S. Distribution and anisotropy of dislocations in cold-drawn pearlitic steel wires analyzed using micro-beam X-ray diffraction. ISIJ Int. 2015, 55, 1432–1438. [Google Scholar] [CrossRef] [Green Version]

- Sato, S.; Wagatsuma, K.; Ishikuro, M.; Kwon, E.P.; Tashiro, H.; Suzuki, S. Precise characterization of dislocations and cementite in pearlitic steels at different drawing strains using X-ray diffraction. ISIJ Int. 2013, 53, 673–679. [Google Scholar] [CrossRef] [Green Version]

- Ungár, T.; Borbély, A. The effect of dislocation contrast on x-ray line broadening: A new approach to line profile analysis. Appl. Phys. Lett. 1996, 69, 3173–3175. [Google Scholar] [CrossRef]

- Ungár, T.; Ott, S.; Sanders, P.G.; Borbély, A.; Weertman, J.R. Dislocations, grain size and planar faults in nanostructured copper determined by high resolution X-ray diffraction and a new procedure of peak profile analysis. Acta Mater. 1998, 46, 3693–3699. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, Á.; Borbély, A. The contrast factors of dislocations in cubic crystals: The dislocation model of strain anisotropy in practice. J. Appl. Cryst. 1999, 32, 992–1002. [Google Scholar] [CrossRef] [Green Version]

- Ungár, T.; Tichy, G. The effect of dislocation contrast on x-ray line profiles in untextured polycrystals. Phys. Stat. Solidi A 1999, 171, 425–434. [Google Scholar] [CrossRef]

- Stokes, A.R. A numeridal Fourier-analysis method for the correction of widths and shapes of lines on X-ray powder photographs. Proc. Phys. Soc. 1948, 61, 382–391. [Google Scholar] [CrossRef]

- Dey, S.N.; Chatterjee, P.; Sen Gupta, S.P. Study of deformation stacking faults and dislocation microstructures in Cu–1Sn–Zn alloys. Acta Mater. 2005, 53, 4635–4642. [Google Scholar] [CrossRef]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al–Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 387, 343–347. [Google Scholar] [CrossRef]

- Balogh, L.; Ribárik, G.; Ungár, T. Stacking faults and twin boundaries in fcc crystals determined by x-ray diffraction profile analysis. J. Appl. Phys. 2006, 100, 023512. [Google Scholar] [CrossRef]

- Narita, N.; Hatano, A.; Takamura, J.; Yoshida, M.; Sakamoto, H. Stacking Fault Energy of Pure Nickel Evaluated from the Twinning Stress of Nickel-Based Alloys. J. Jpn. Inst. Met. Mater. 1978, 42, 533–541. [Google Scholar] [CrossRef] [Green Version]

- Schramm, R.E.; Reed, R.P. Stacking fault energies of seven commercial austenitic stainless steels. Metall. Trans. A 1975, 6, 1345–1351. [Google Scholar] [CrossRef]

- Narutani, T.; Takamura, J. Grain-size strengthening in terms of dislocation density measured by resistivity. Acta Metall. Mater. 1991, 39, 2037–2049. [Google Scholar] [CrossRef]

- Umezaki, S.; Murata, Y.; Nomura, K.; Kubushiro, K. Quantitative analysis of dislocation density in an austenitic steel after plastic deformation. J. Jpn. Inst. Met. Mater. 2014, 78, 218–224. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, K.; Hayashi, M.; Takano-Satoh, K.; Matsunaga, H.; Mori, H.; Kitahara, A.; Onuki, Y.; Suzuki, S.; Sato, S. Effect of grain size of Cu-Zn alloys on dislocation-strengthening factors. J. Jpn. Inst. Met. Mater. To be published.

- Hall, E.O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. Sec. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Horita, Z.; Langdon, T.G.; Zhu, Y.T. Evolution of defect structures during cold rolling of ultrafine-grained Cu and Cu-Zn alloys: Influence of stacking fault energy. Mater. Sci. Eng. A 2008, 474, 342–347. [Google Scholar] [CrossRef]

- Taylor, G. The mechanism of plastic deformation of crystals. Patr I-Theoretical. Proc. R. Soc. 1934, 145, 362–387. [Google Scholar]

- Simm, T.H. Peak broadening anisotropy and the contrast factor in metal alloys. Crystals 2018, 8, 212. [Google Scholar] [CrossRef] [Green Version]

- Simm, T.H.; Withers, P.J.; Quinta da Fonseca, J. Peak broadening anisotropy in deformed face-centered and hexagonal closed-packed alloys. J. Appl. Cryst. 2014, 47, 1535–1551. [Google Scholar] [CrossRef]

- Simm, T.H.; Withers, P.J.; Quinta da Fonseca, J. An evaluation of diffraction peak profile analysis (DPPA) methods to study plastically deformed metals. Mater. Design 2016, 111, 331–341. [Google Scholar] [CrossRef] [Green Version]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakagawa, K.; Hayashi, M.; Takano-Satoh, K.; Matsunaga, H.; Mori, H.; Maki, K.; Onuki, Y.; Suzuki, S.; Sato, S. Characterization of Dislocation Rearrangement in FCC Metals during Work Hardening Using X-ray Diffraction Line-Profile Analysis. Quantum Beam Sci. 2020, 4, 36. https://doi.org/10.3390/qubs4040036

Nakagawa K, Hayashi M, Takano-Satoh K, Matsunaga H, Mori H, Maki K, Onuki Y, Suzuki S, Sato S. Characterization of Dislocation Rearrangement in FCC Metals during Work Hardening Using X-ray Diffraction Line-Profile Analysis. Quantum Beam Science. 2020; 4(4):36. https://doi.org/10.3390/qubs4040036

Chicago/Turabian StyleNakagawa, Koutarou, Momoki Hayashi, Kozue Takano-Satoh, Hirotaka Matsunaga, Hiroyuki Mori, Kazunari Maki, Yusuke Onuki, Shigeru Suzuki, and Shigeo Sato. 2020. "Characterization of Dislocation Rearrangement in FCC Metals during Work Hardening Using X-ray Diffraction Line-Profile Analysis" Quantum Beam Science 4, no. 4: 36. https://doi.org/10.3390/qubs4040036

APA StyleNakagawa, K., Hayashi, M., Takano-Satoh, K., Matsunaga, H., Mori, H., Maki, K., Onuki, Y., Suzuki, S., & Sato, S. (2020). Characterization of Dislocation Rearrangement in FCC Metals during Work Hardening Using X-ray Diffraction Line-Profile Analysis. Quantum Beam Science, 4(4), 36. https://doi.org/10.3390/qubs4040036