Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives

Abstract

:1. Introduction

2. Lasers in Metal Additive Manufacturing

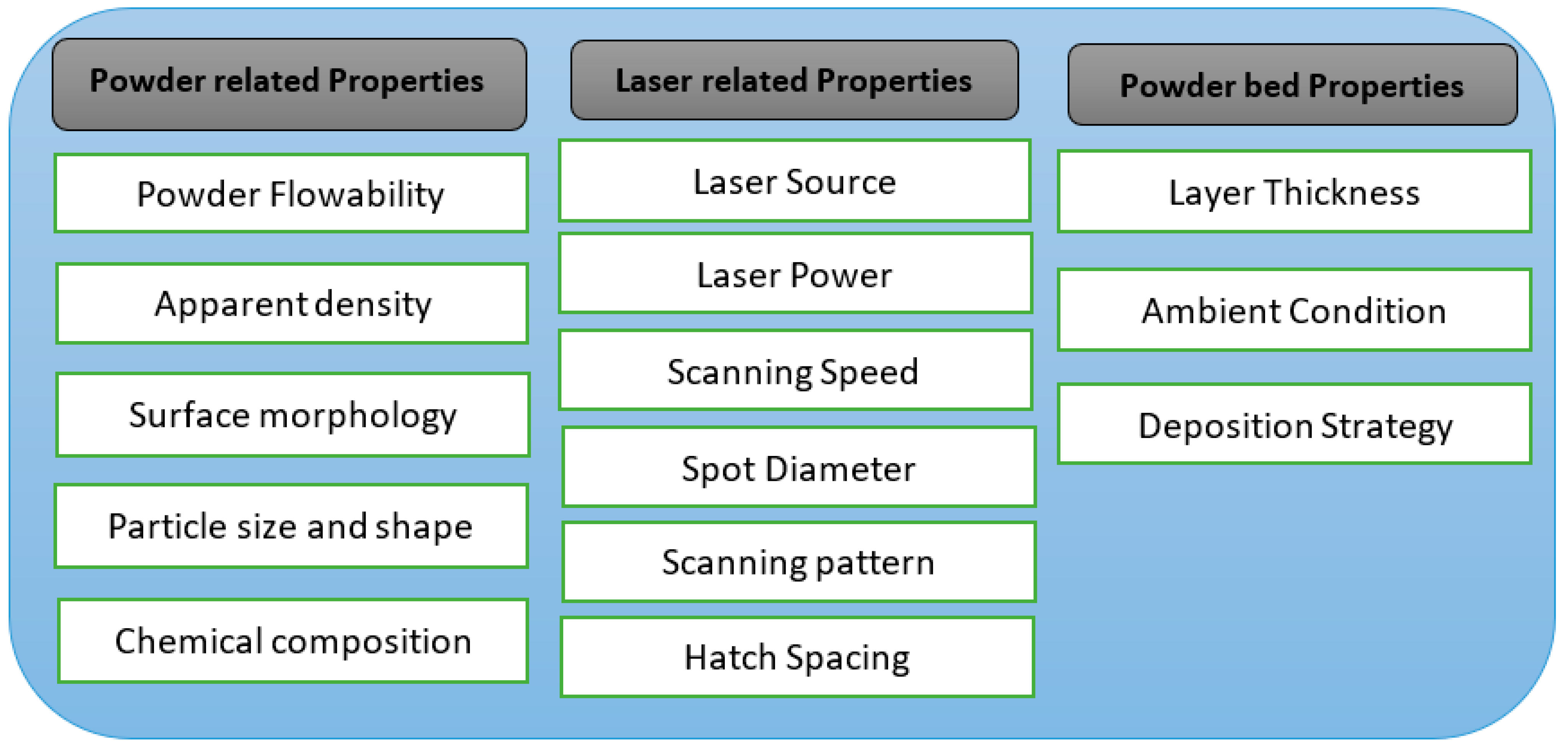

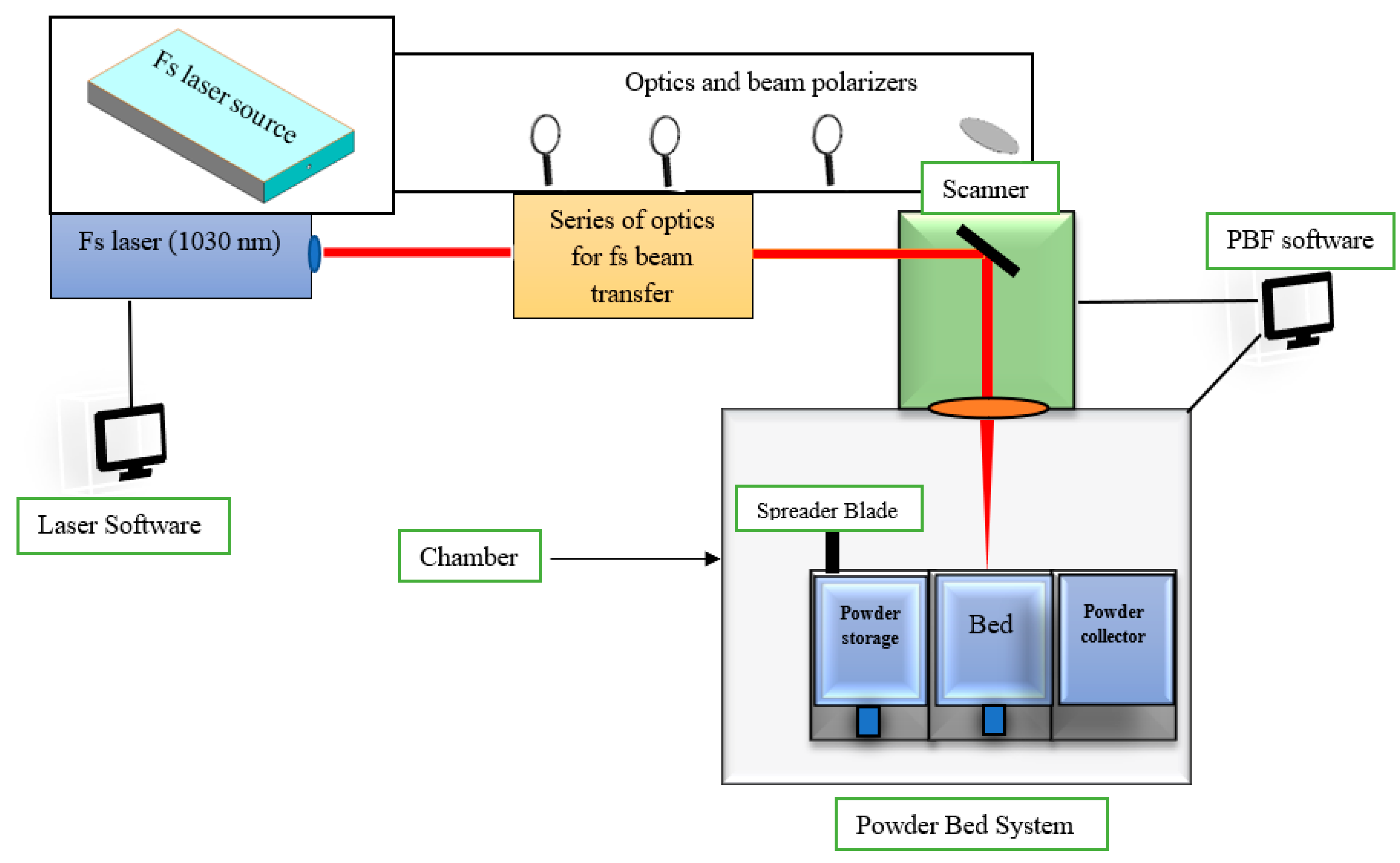

Laser Parameters Used in AM

3. Femtosecond Lasers and Laser–Material Interaction

3.1. A Brief History of Ultrafast Laser Development

3.2. Mechanisms of Ultrafast Laser–Matter Interaction

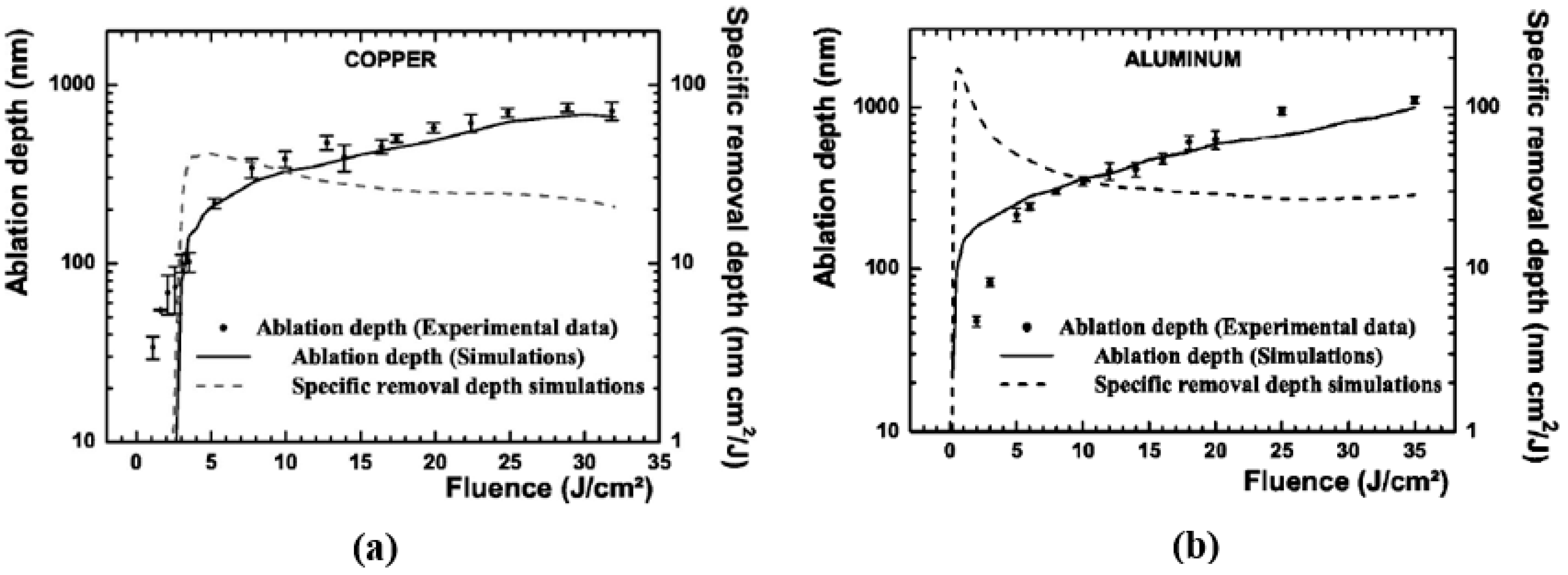

3.3. Modelling and Numerical Analysis of Laser-Based AM

4. Femtosecond Laser-Based Additive Manufacturing—Powder Bed Fusion

5. Femtosecond Laser Additive Manufactured Powder Materials, Print Qualities and Characterisation

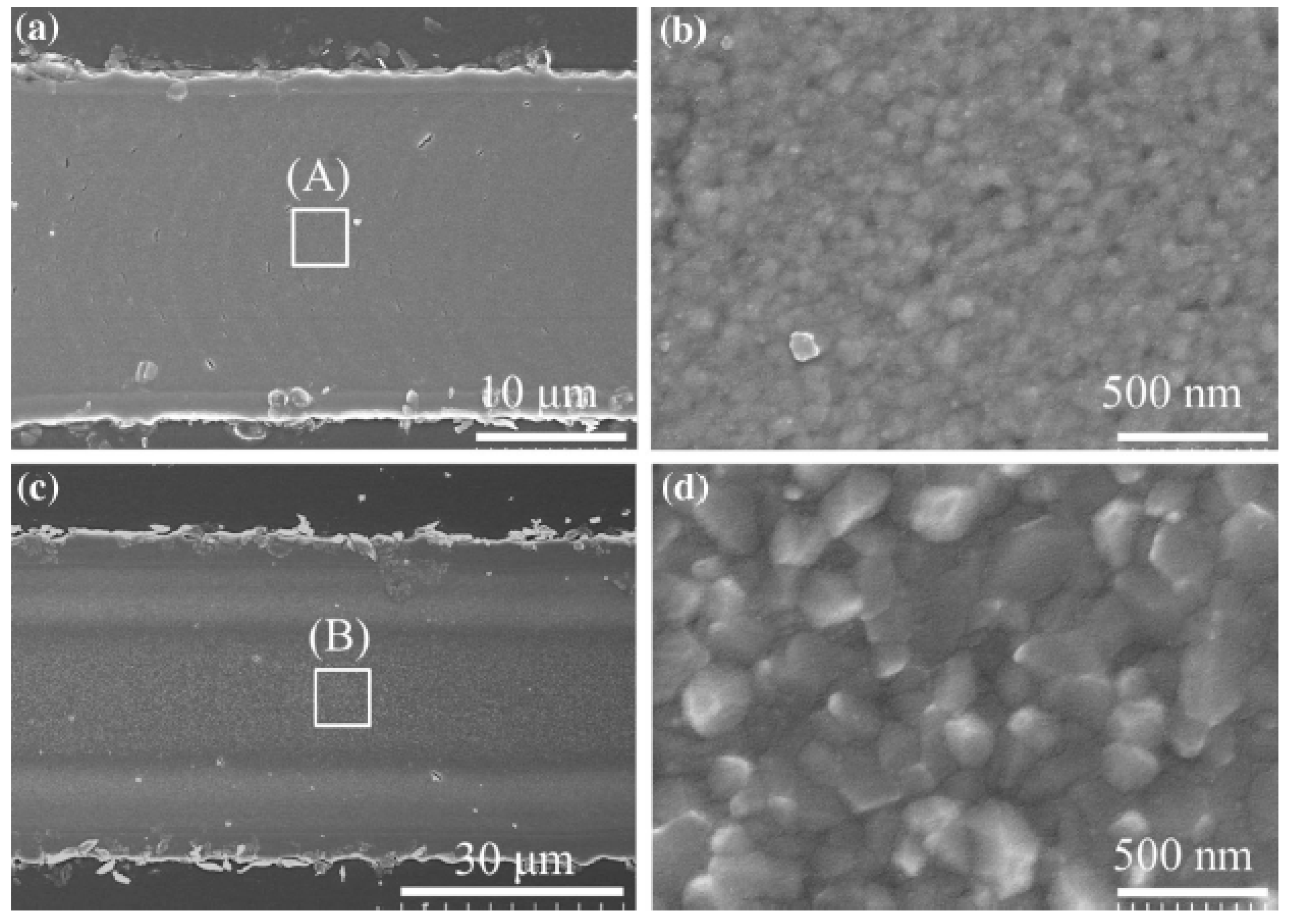

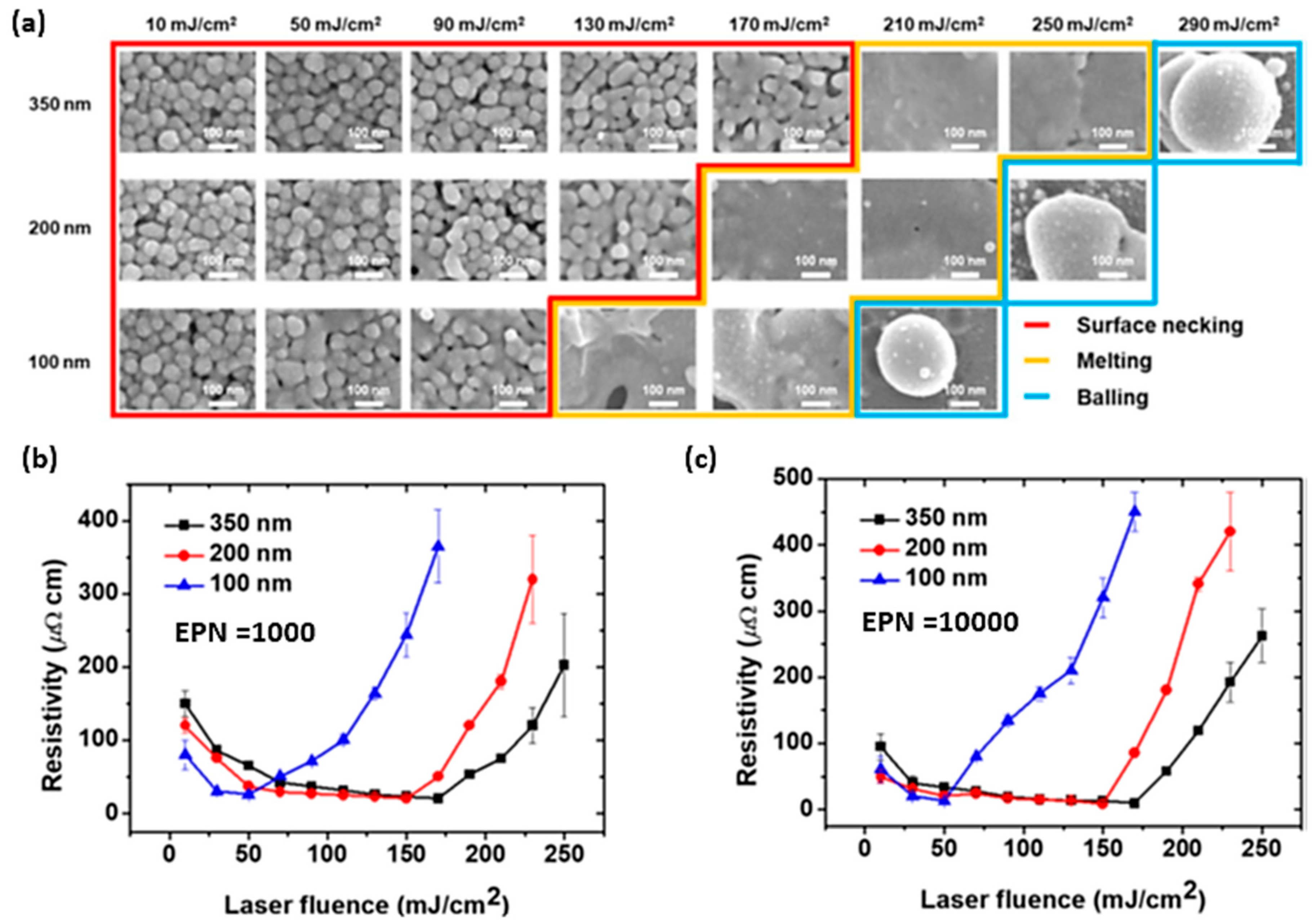

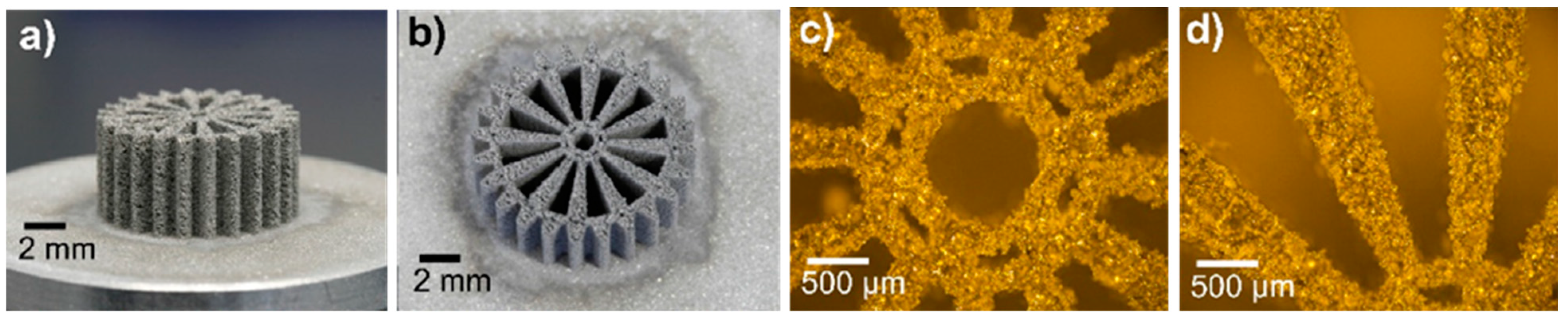

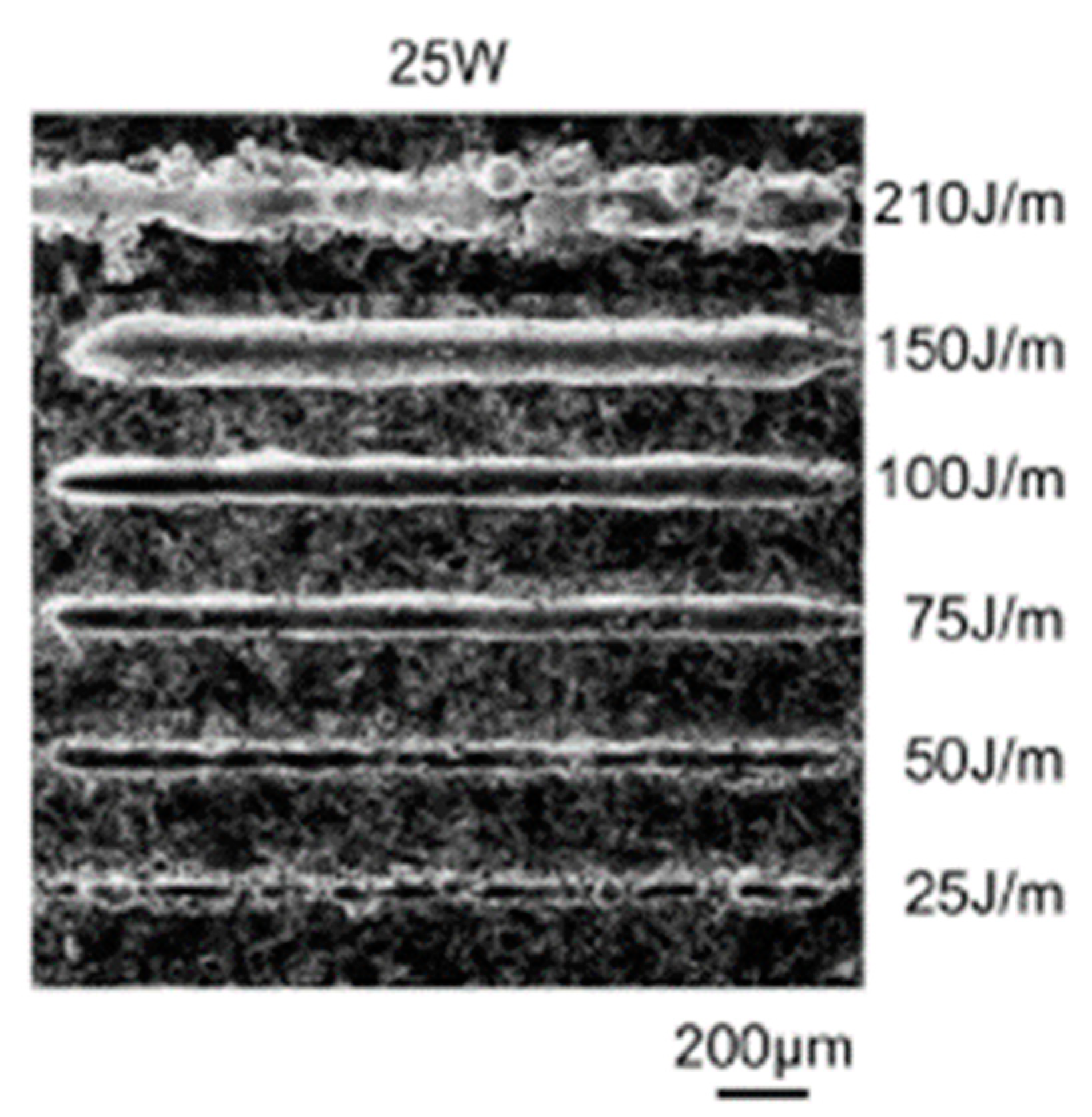

5.1. Femtosecond Laser Sintering of Copper

5.2. Femtosecond Laser Sintering of Iron and Tungsten

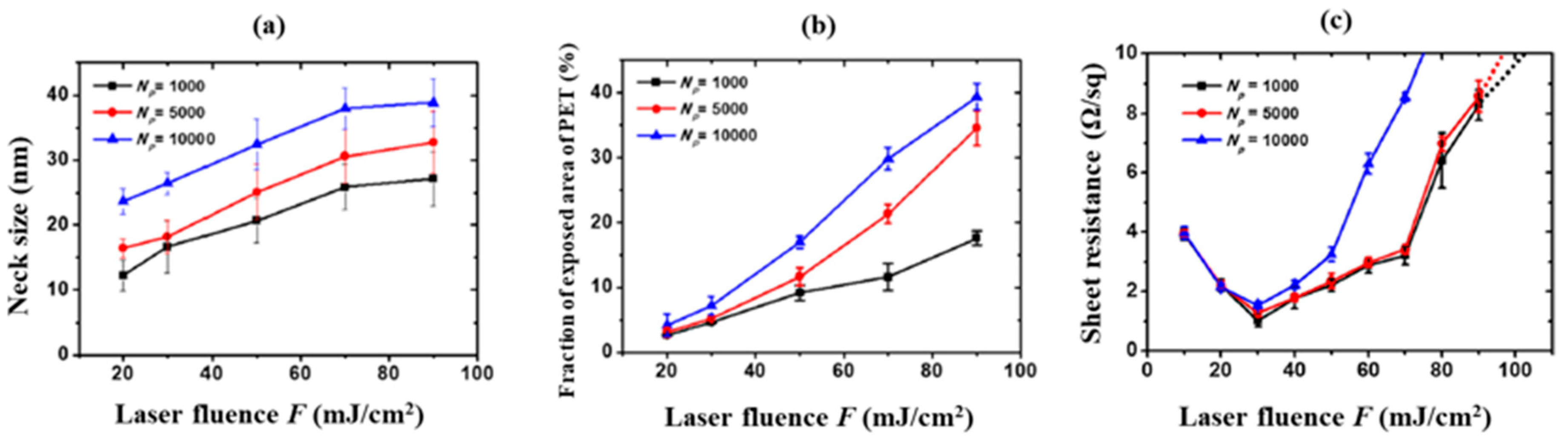

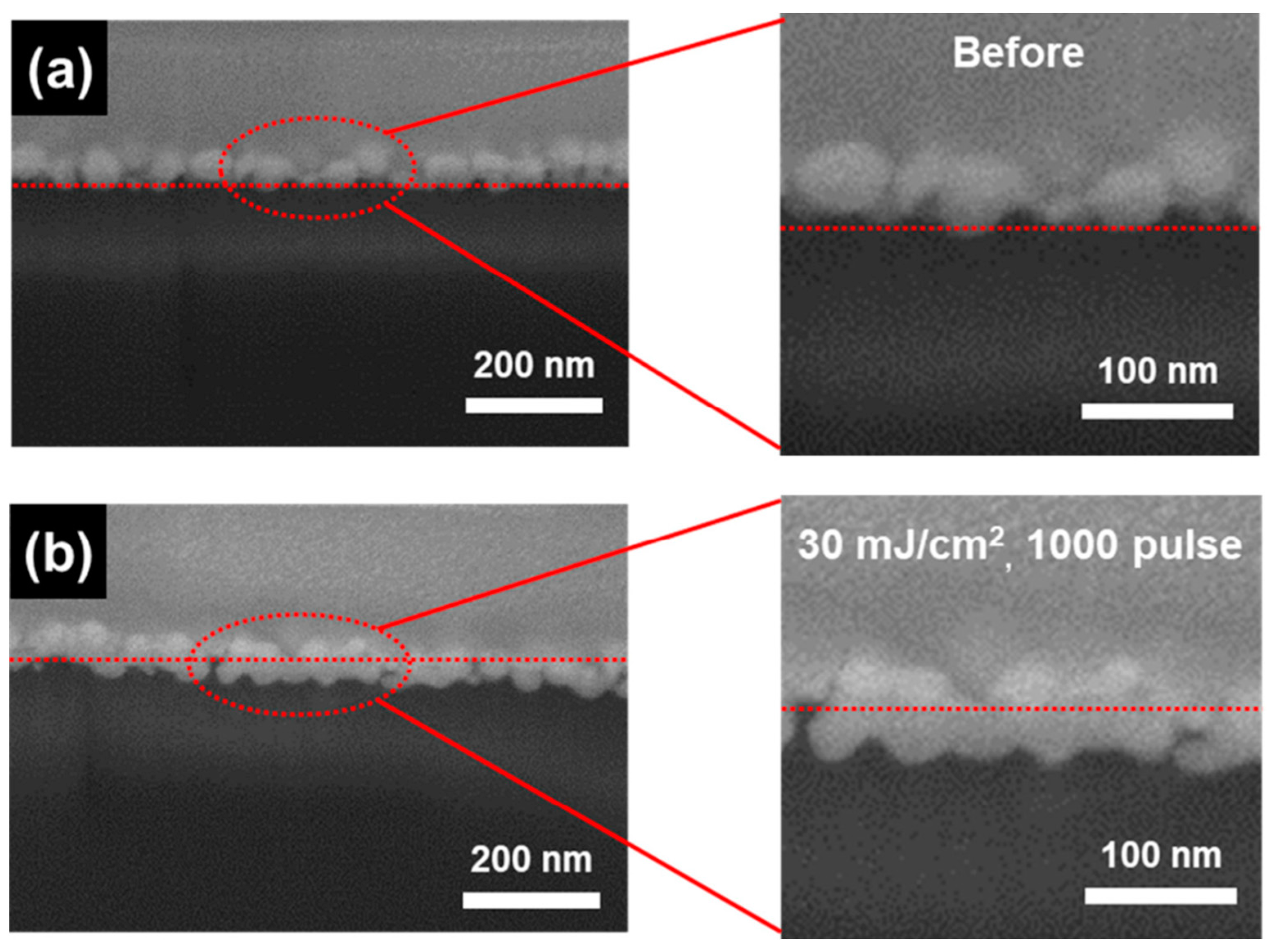

5.3. Femtosecond Laser Sintering of Silver

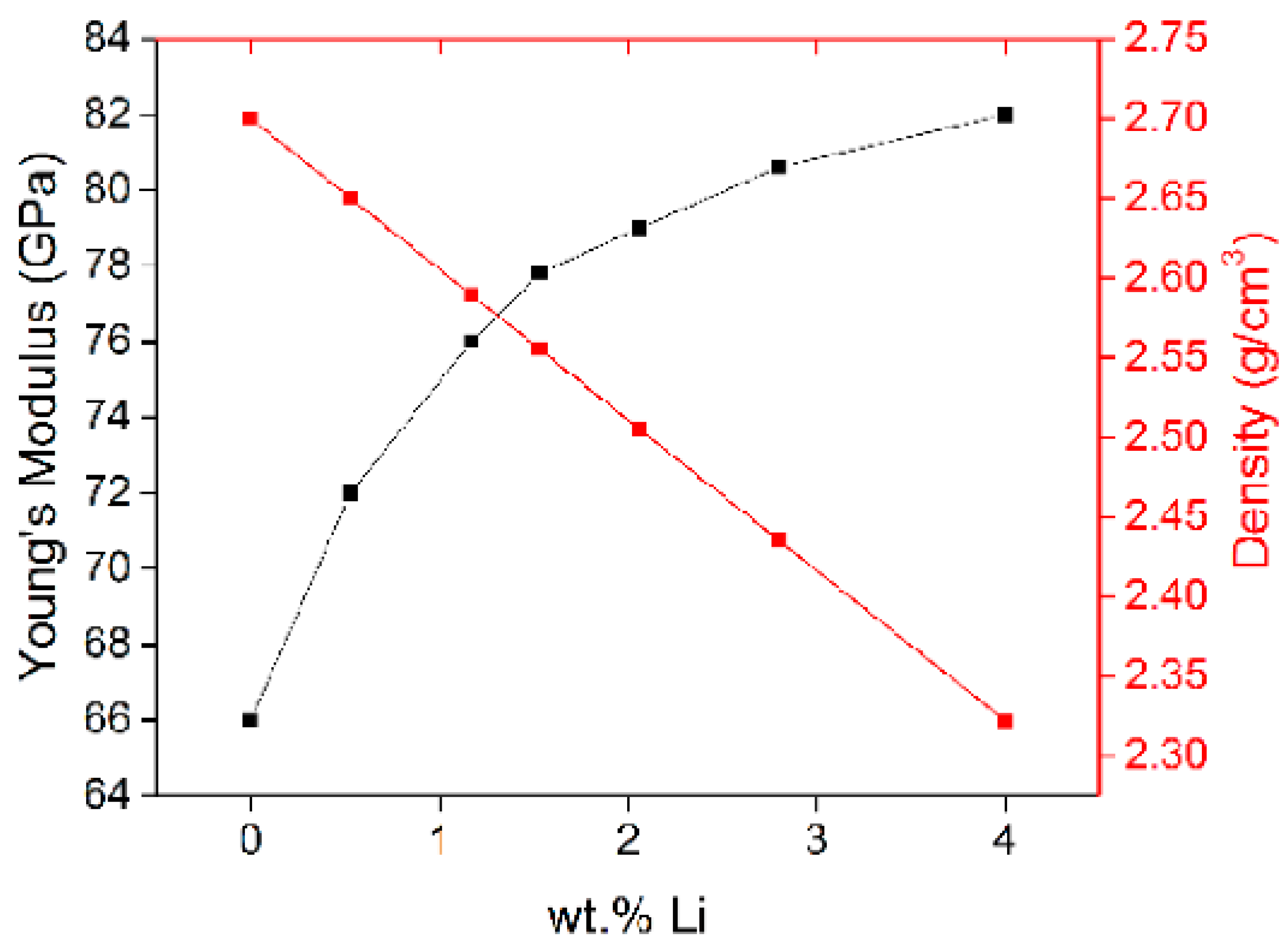

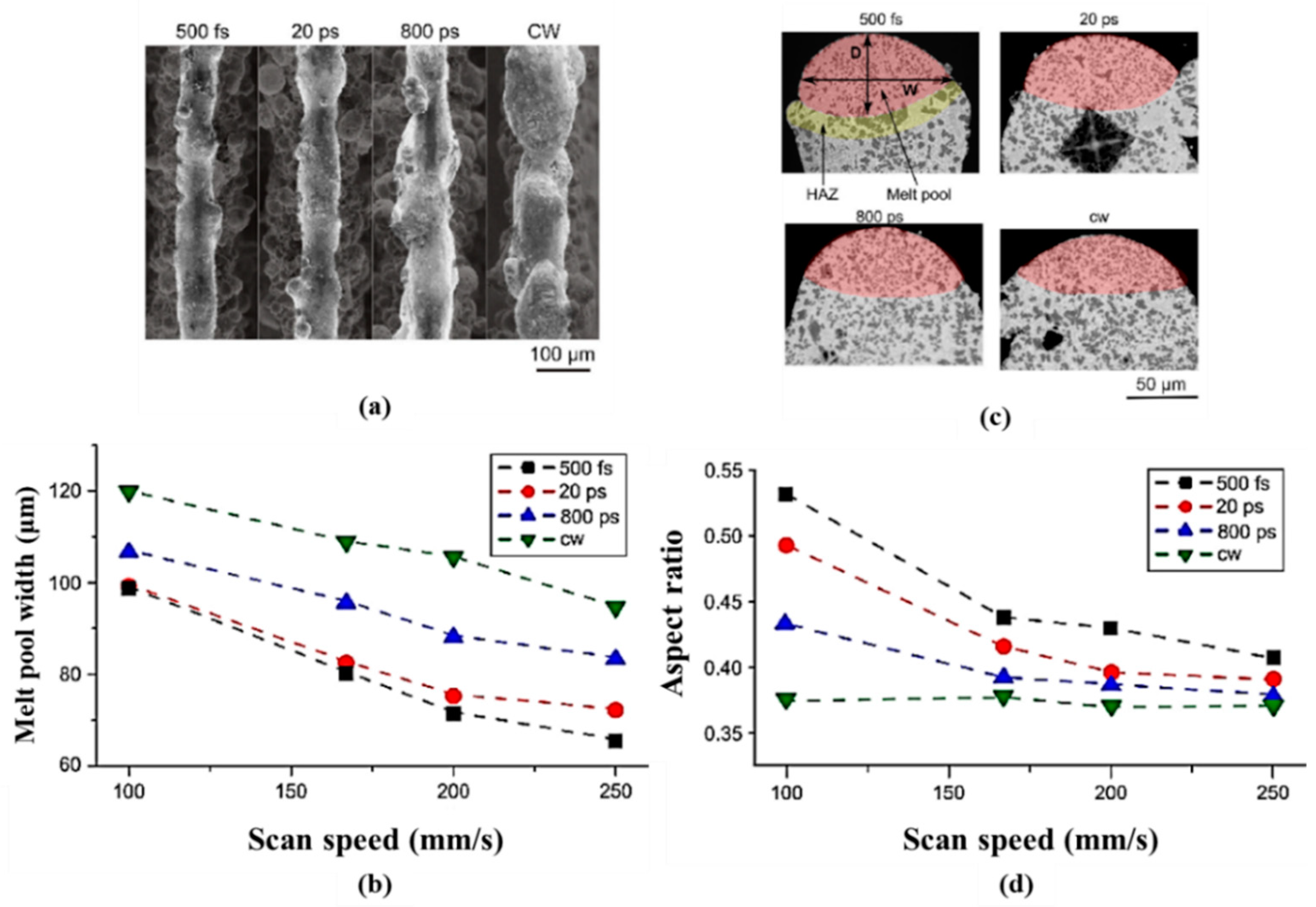

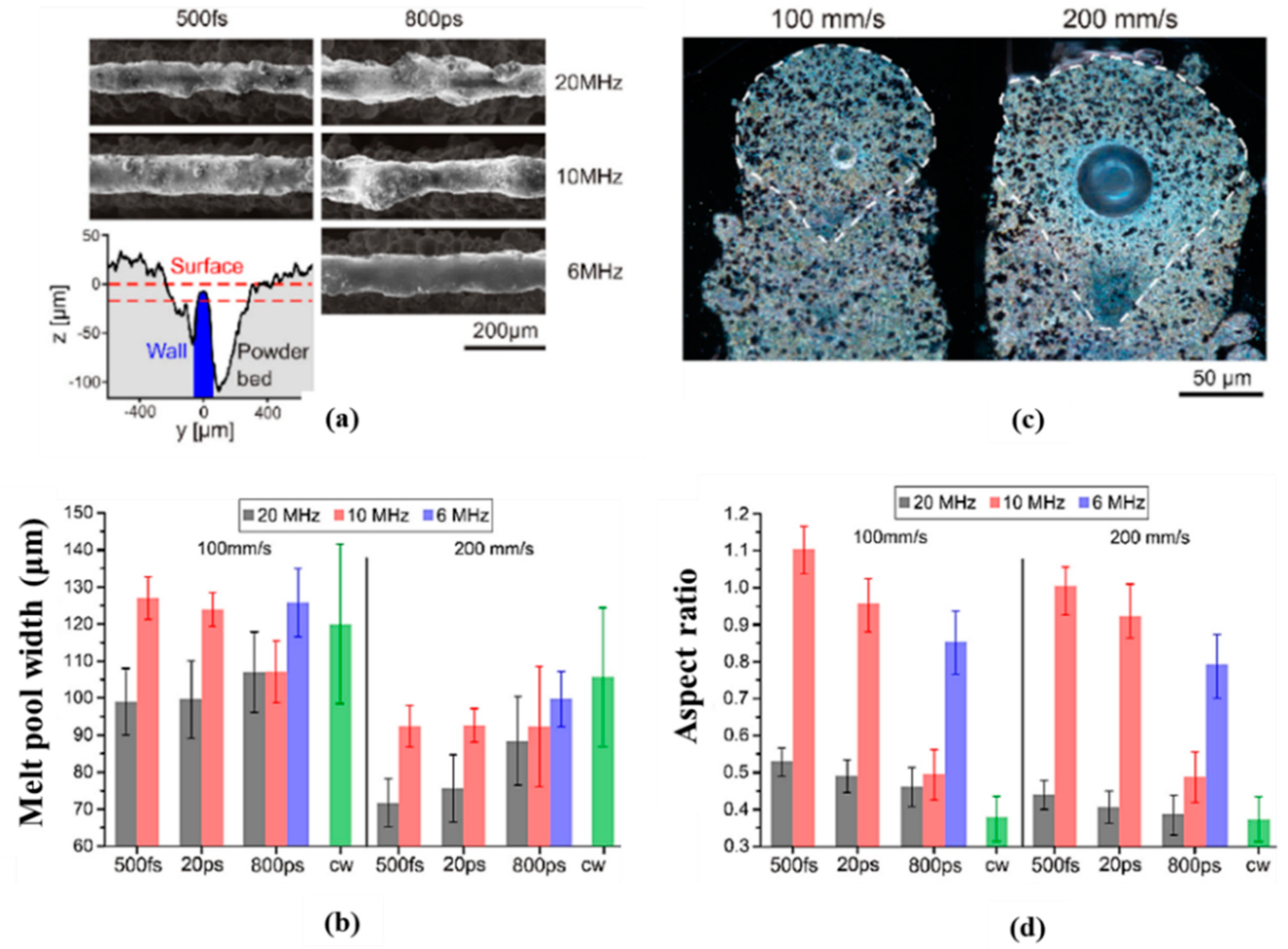

5.4. Femtosecond Laser Sintering of Aluminium Alloy

5.5. Femtosecond-Pulsed-Laser Sintering in Hard Tissue Engineering

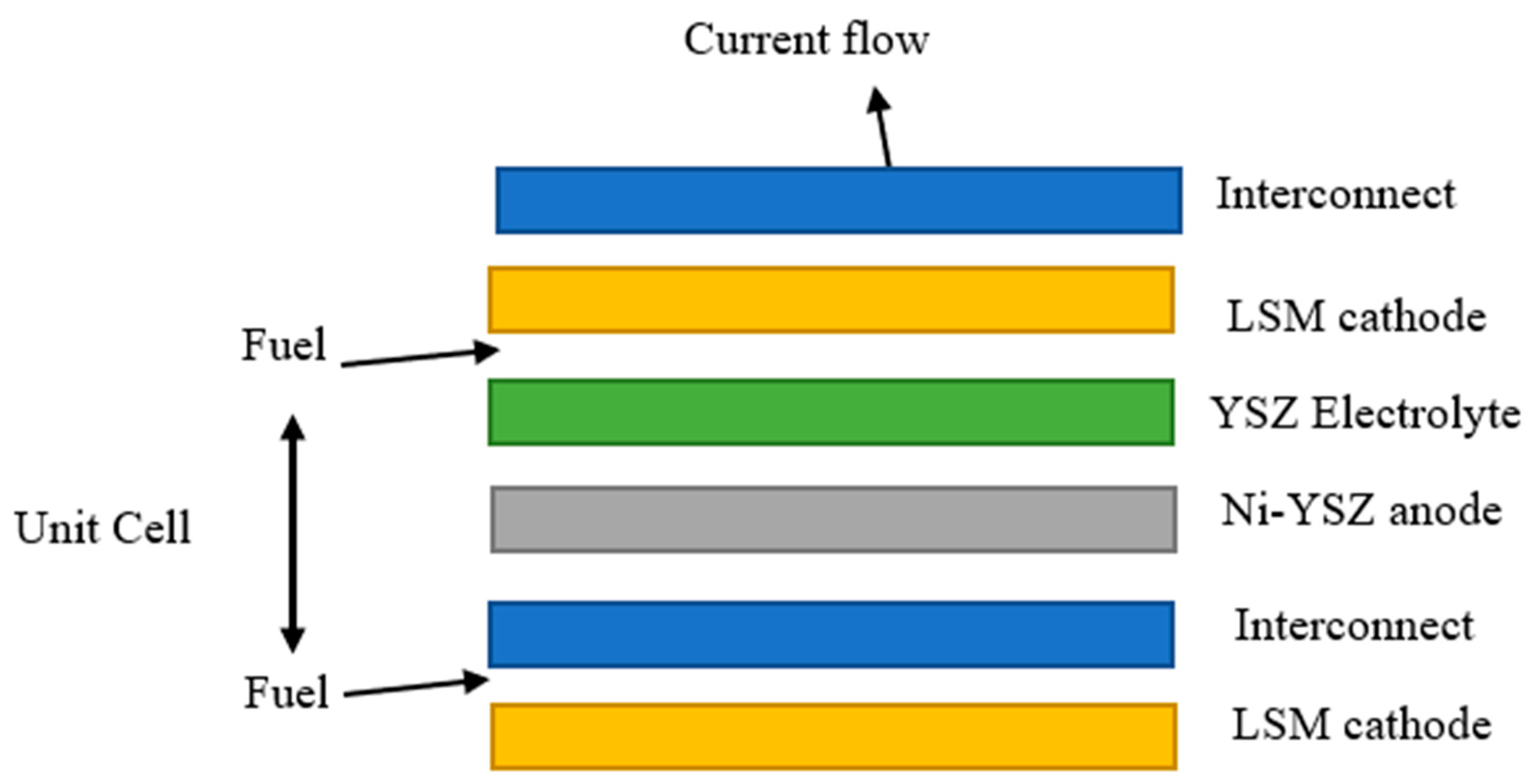

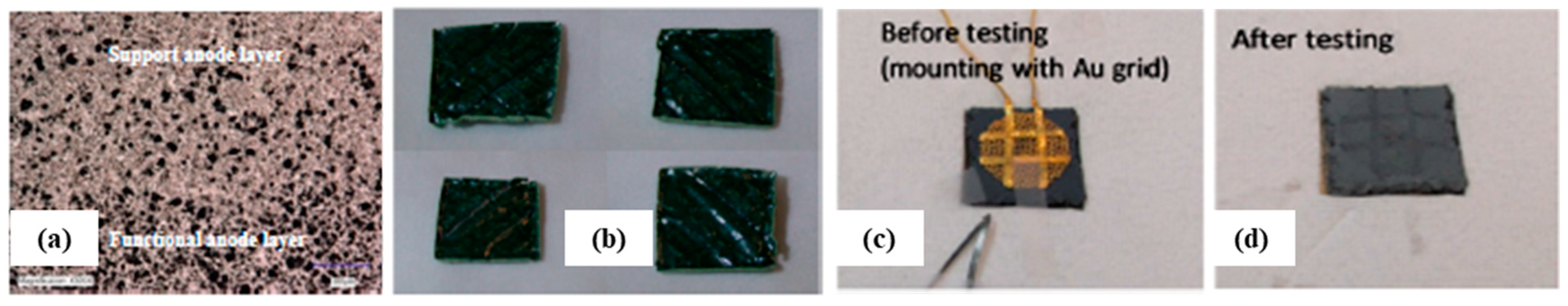

5.6. Femtosecond Laser-Based Additive Manufacturing Multi-Material Layered Structure

5.7. Femtosecond Laser Processing of Titanium and Titanium Alloys

5.8. Femtosecond Laser Processing of Graphene

5.9. A summary of the fs Laser AM Parameter Sets for Various Materials

6. Summary

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D. Additive Manufacturing Technologies, 17th ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Barroqueiro, B.; Andrade-Campos, A.; Valente, R.; Neto, V. Metal Additive Manufacturing Cycle in Aerospace Industry: A Comprehensive Review. J. Manuf. Mater. Process. 2019, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Katz-Demyanetz, A.; Popov, V.V.; Kovalevsky, A.; Safranchik, D.; Koptyug, A. Powder-bed additive manufacturing for aerospace application: Techniques, metallic and metal/ceramic composite materials and trends. Manuf. Rev. 2019, 6, 5. [Google Scholar] [CrossRef] [Green Version]

- Mohanavel, V.; Ali, K.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Huang, H.; Nie, B.; Wan, P.; Yang, L.-M.; Bai, S.; Liu, J. Femtosecond fiber laser additive manufacturing and welding for 3D manufacturing. In Laser 3D Manufacturing II; Proc. SPIE: San Francisco, CA, USA, 2015; Volume 9353, p. 93530A. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The Evolution of Al-Li Base Products for Aerospace and Space Applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Byskov-Nielsen, J.; Savolainen, J.-M.; Christensen, M.S.; Balling, P. Ultra-short pulse laser ablation of metals: Threshold fluence, incubation coefficient and ablation rates. Appl. Phys. A 2010, 101, 97–101. [Google Scholar] [CrossRef]

- Chua, C.K.; Matham, M.V.; Kim, Y.-J. Lasers in 3D Printing and Manufacturing; World Scientific Publishing Company: Singapore, 2017. [Google Scholar] [CrossRef] [Green Version]

- Dordlofva, C. A Design for Qualification Framework for the Development of Additive Manufacturing Components—A Case Study from the Space Industry. Aerospace 2020, 7, 25. [Google Scholar] [CrossRef] [Green Version]

- Pinkerton, A.J. [INVITED] Lasers in additive manufacturing. Opt. Laser Technol. 2016, 78, 25–32. [Google Scholar] [CrossRef] [Green Version]

- Paolini, A.; Kollmannsberger, S.; Rank, E. Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit. Manuf. 2019, 30, 100894. [Google Scholar] [CrossRef]

- Saengchairat, N.; Tran, T.; Chua, C.-K. A review: Additive manufacturing for active electronic components. Virtual Phys. Prototyp. 2017, 12, 31–46. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Sibbett, W.; Lagatsky, A.A.; Brown, C.T.A. The development and application of femtosecond laser systems. Opt. Express 2012, 20, 6989–7001. [Google Scholar] [CrossRef]

- Application Spotlight: 3D Printing for Footwear, AMFG. 2019. Available online: https://amfg.ai/2019/09/18/application-spotlight-3d-printing-for-footwear/ (accessed on 30 October 2021).

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Meier, M.; Tan, K.H.; Lim, M.K.; Chung, L. Unlocking innovation in the sport industry through additive manufacturing. Bus. Process. Manag. J. 2019, 25, 456–475. [Google Scholar] [CrossRef]

- Wimpenny, D.I.; Pandey, P.M.; Kumar, L.J. (Eds.) Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; pp. 9–28. [Google Scholar] [CrossRef]

- Das, S.; Bourell, D.L.; Babu, S. Metallic materials for 3D printing. MRS Bull. 2016, 41, 729–741. [Google Scholar] [CrossRef] [Green Version]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Herderick, E. Additive manufacturing of metals: A review. Mater. Sci. Technol. Conf. Exhib. 2011, 2, 1413–1425. Available online: http://www.scopus.com/inward/record.url?eid=2-s2.0-84856301323&partnerID=40&md5=e02018d10b2ca37a7e2ae1773e4fcaec (accessed on 30 November 2021).

- Liu, R.; Wang, Z.; Sparks, T.; Liou, F.; Newkirk, J. Aerospace applications of laser additive manufacturing. In Laser Additive Manufacturing: Materials, Design, Technologies, and Applications; Woodhead Publishing: Sawston, UK, 2017; ISBN 9780081004340. [Google Scholar]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Saracyakupoglu, T. The Qualification of the Additively Manufactured Parts in the Aviation Industry. Am. J. Aerosp. Eng. 2019, 6, 1. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y.J. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Deckers, J.; Meyers, S.; Kruth, J.; Vleugels, J. Direct Selective Laser Sintering/Melting of High Density Alumina Powder Layers at Elevated Temperatures. Phys. Procedia 2014, 56, 117–124. [Google Scholar] [CrossRef] [Green Version]

- Kruth, J.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Biffi, C.; Fiocchi, J.; Bassani, P.; Tuissi, A. Continuous wave vs. pulsed wave laser emission in selective laser melting of AlSi10Mg parts with industrial optimized process parameters: Microstructure and mechanical behaviour. Addit. Manuf. 2018, 24, 639–646. [Google Scholar] [CrossRef]

- Kumar, H.; Kumaraguru, S. Distortion in Metal Additive Manufactured Parts. In 3D Printing and Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2019; pp. 281–295. [Google Scholar]

- Oliveira, J.P.; LaLonde, A.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Yeong, W.; Yap, C.; Mapar, M.; Chua, C. State-of-the-art review on selective laser melting of ceramics. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping; CRC Press: Boca Raton, FL, USA, 2013; pp. 65–70. [Google Scholar]

- Lonergan, J.M.; Fahrenholtz, W.; Hilmas, G. Zirconium Diboride with High Thermal Conductivity. J. Am. Ceram. Soc. 2014, 97, 1689–1691. [Google Scholar] [CrossRef]

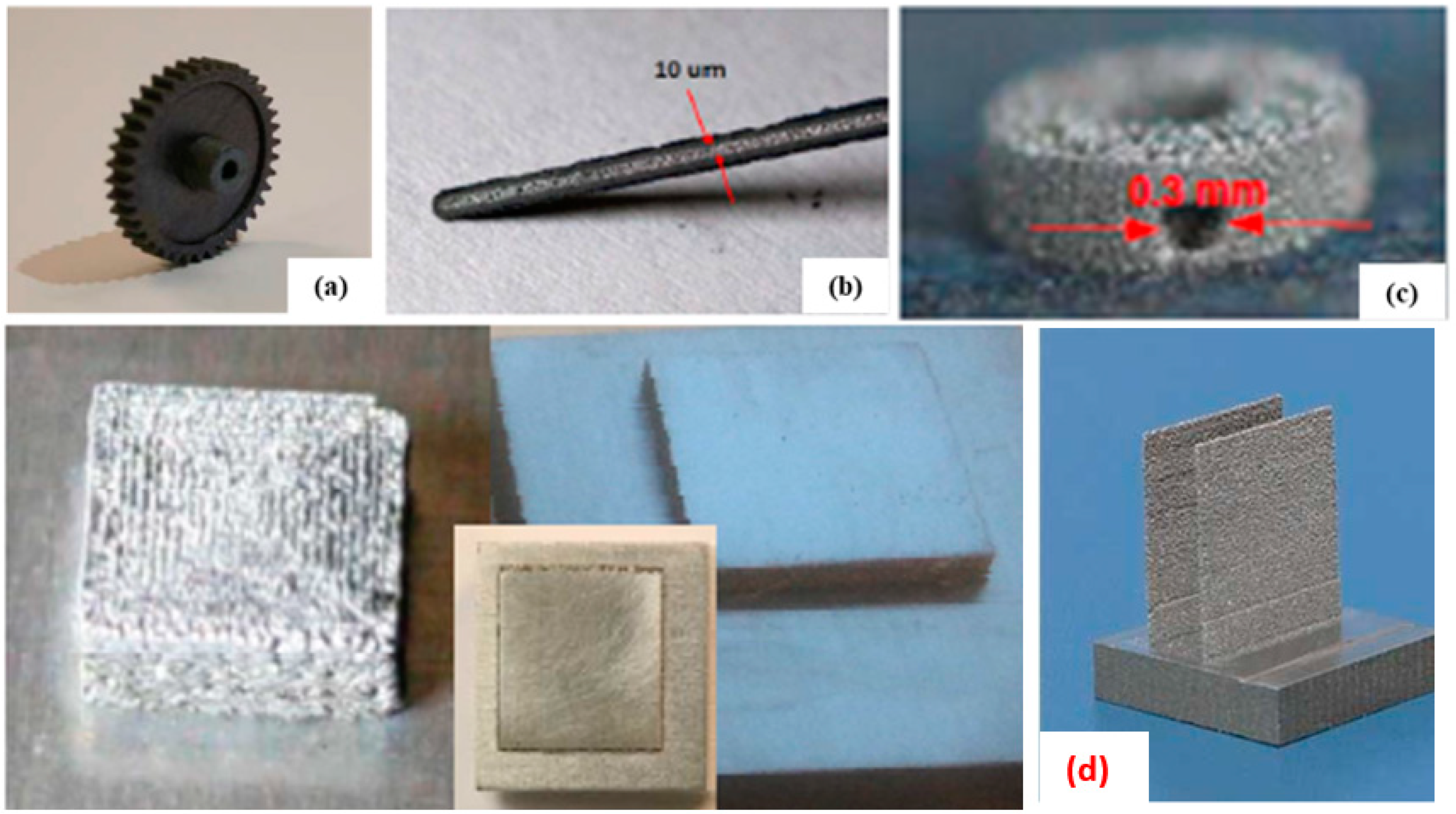

- In’t Veld, B.H.; Overmeyer, L.; Schmidt, M.; Wegener, K.; Malshe, A.; Bartolo, P. Micro additive manufacturing using ultra short laser pulses. CIRP Ann. 2015, 64, 701–724. [Google Scholar] [CrossRef]

- Ullsperger, T.; Matthäus, G.; Kaden, L.; Rettenmayr, M.; Risse, S.; Tünnermann, A.; Nolte, S. Selective laser melting of AlSi40 using ultrashort laser pulses for additive manufacturing applications. In Proceedings of the Lasers in Manufacturing Conference 2017, Munich, Germany, 26–29 June 2017. [Google Scholar]

- Neuenschwander, B.; Jaeggi, B.; Schmid, M.; Dommann, A.; Neels, A.; Bandi, T.; Hennig, G. Factors controlling the incubation in the application of ps laser pulses on copper and iron surfaces. In Laser Applications in Microelectronic and Optoelectronic Manufacturing (LAMOM) XVIII; Proc. of SPIE: San Francisco, CA, USA, 2013; Volume 8607, p. 86070D. [Google Scholar] [CrossRef] [Green Version]

- Nedialkov, N.; Atanasov, P. Molecular dynamics simulation study of deep hole drilling in iron by ultrashort laser pulses. Appl. Surf. Sci. 2006, 252, 4411–4415. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Ultrafast Lasers Market-Growth, Trends, COVID-19 Impact, and Forecasts (2021–2026), Mordor Intell. 2020. Available online: https://www.mordorintelligence.com/industry-reports/ultrafast-lasers-market (accessed on 25 November 2021).

- Eaton, S.M.; Zhang, H.; Herman, P.R.; Yoshino, F.; Shah, L.; Bovatsek, J.; Arai, A.Y. Heat accumulation effects in femtosecond laser-written waveguides with variable repetition rate. Opt. Express 2005, 13, 4708–4716. [Google Scholar] [CrossRef]

- Bai, S.; Liu, J.; Yang, P.; Huang, H.; Yang, L.-M. Femtosecond fiber laser additive manufacturing of tungsten. In Laser 3D Manufacturing III; Proc. of SPIE: San Francisco, CA, USA, 2016; Volume 9738, p. 97380. [Google Scholar] [CrossRef]

- Hodgson, N.O.R.M.A.N.; Laha, M.I.C.H.A.E.L.; Lee, T.S.; Steinkopff, A.L.B.R.E.C.H.T.; Heming, S.E.B.A.S.T.I.A.N. Industrial femtosecond lasers and material processing. In Industrial Laser Solutions; PennWell Publishing: Nashville, TN, USA, 2019. [Google Scholar]

- Gieseke, M.; Senz, V.; Vehse, M.; Fiedler, S.; Irsig, R.; Hustedt, M.; Sternberg, K.; Nölke, C.; Kaierle, S.; Wesling, V.; et al. Additive Manufacturing of Drug Delivery Systems. Biomed. Tech. Eng. 2012, 57, 398–401. [Google Scholar] [CrossRef]

- Birnbaum, M. Semiconductor Surface Damage Produced by Ruby Lasers. J. Appl. Phys. 1965, 36, 3688–3689. [Google Scholar] [CrossRef]

- Hodgson, N.; Laha, M.; Lee, T.S.; Haloui, H.; Heming, S.; Steinkopff, A. Industrial Ultrafast Lasers–Systems, Processing Fundamentals, and Applications. In CLEO: QELS_Fundamental Science; Optical Society of America: San Jose, CA, USA, 2019. [Google Scholar] [CrossRef]

- Mingareev, I.; Bonhoff, T.; El-Sherif, A.; Meiners, W.; Kelbassa, I.; Biermann, T.; Richardson, M. Femtosecond laser post-processing of metal parts produced by laser additive manufacturing. J. Laser Appl. 2013, 25, 052009. [Google Scholar] [CrossRef] [Green Version]

- Mingareev, I.; Bonhoff, T.; El-Sherif, A.; Biermann, T.; Meiners, W.; Kelbassa, I.; Richardson, M. Ultrafast laser-based post-processing of parts produced by additive manufacturing. Int. Congr. Appl. Lasers Electro-Opt. 2013, 2013, 787. [Google Scholar] [CrossRef]

- Liang, S.; Ye, H.; Yuan, F. Changes in Crystal Phase, Morphology, and Flexural Strength of As-Sintered Translucent Monolithic Zirconia Ceramic Modified by Femtosecond Laser. Appl. Sci. 2021, 11, 6925. [Google Scholar] [CrossRef]

- Cheng, C.W.; Chen, J.K. Femtosecond laser sintering of copper nanoparticles. Appl. Phys. A 2016, 122, 1–8. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Hata, S. Direct Writing of Cu-based Micro-temperature Sensors onto Glass and Poly(dimethylsiloxane) Substrates Using Femtosecond Laser Reductive Patterning of CuO Nanoparticles. Res. Rev. J. Mater. Sci. 2016, 4, 47–54. [Google Scholar] [CrossRef] [Green Version]

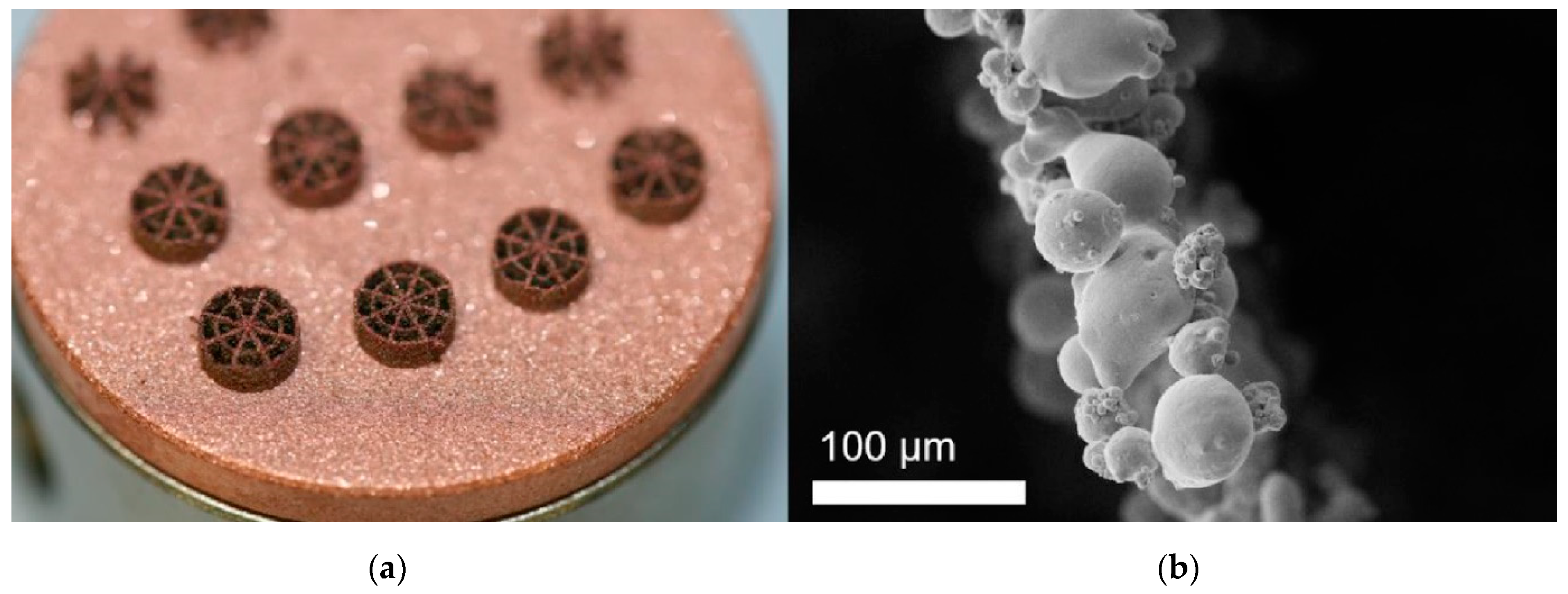

- Kaden, L.; Matthäus, G.; Ullsperger, T.; Engelhardt, H.; Rettenmayr, M.; Tünnermann, A.; Nolte, S. Selective laser melting of copper using ultrashort laser pulses. Appl. Phys. A 2017, 123, 596. [Google Scholar] [CrossRef]

- Son, Y.; Yeo, J.; Ha, C.W.; Hong, S.; Ko, S.H.; Yang, D.Y. Fabrication of submicron-sized metal patterns on a flexible polymer substrate by femtosecond laser sintering of metal nanoparticles. Int. J. Nanomanuf. 2013, 9, 468. [Google Scholar] [CrossRef]

- Kurnoothala, R.; Sai, M.V.; Vishnubhatla, K.C. Facile fabrication of integrated microfluidic SERS substrate by femtosecond laser sintering of silver nano particles. Opt. Mater. 2021, 111, 110518. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Deng, S.; Liao, H.; Coddet, C. Microstructure and tensile properties of iron parts fabricated by selective laser melting. Opt. Laser Technol. 2014, 56, 451–460. [Google Scholar] [CrossRef]

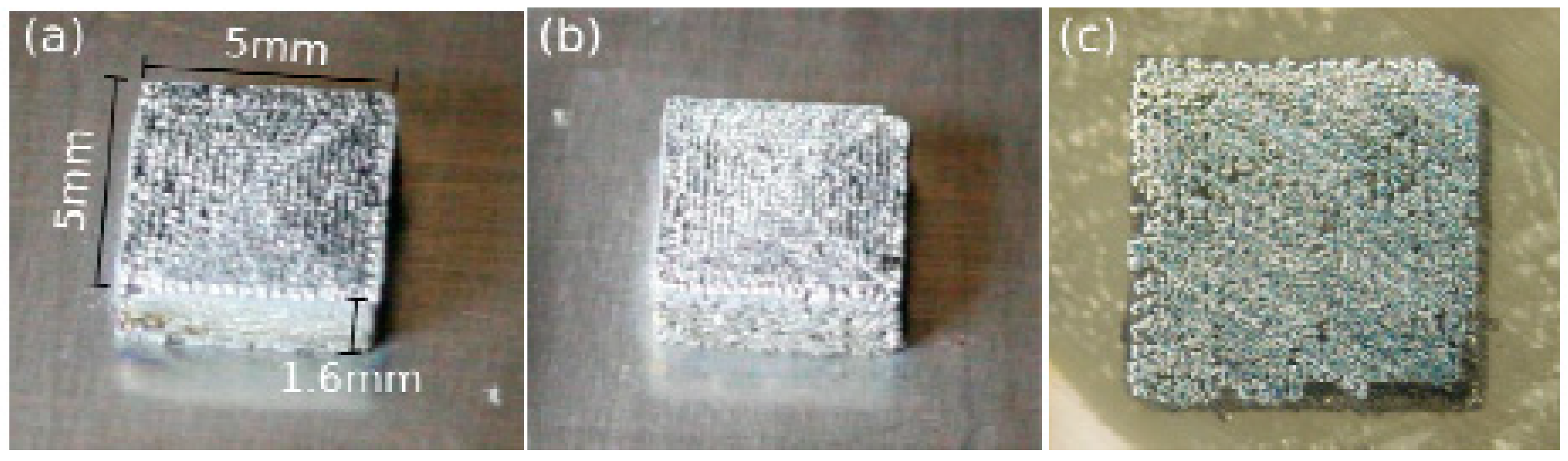

- Nie, B.; Huang, H.; Bai, S.; Liu, J. Femtosecond laser melting and resolidifying of high-temperature powder materials. Appl. Phys. A 2014, 118, 37–41. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.; Dalgarno, K. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

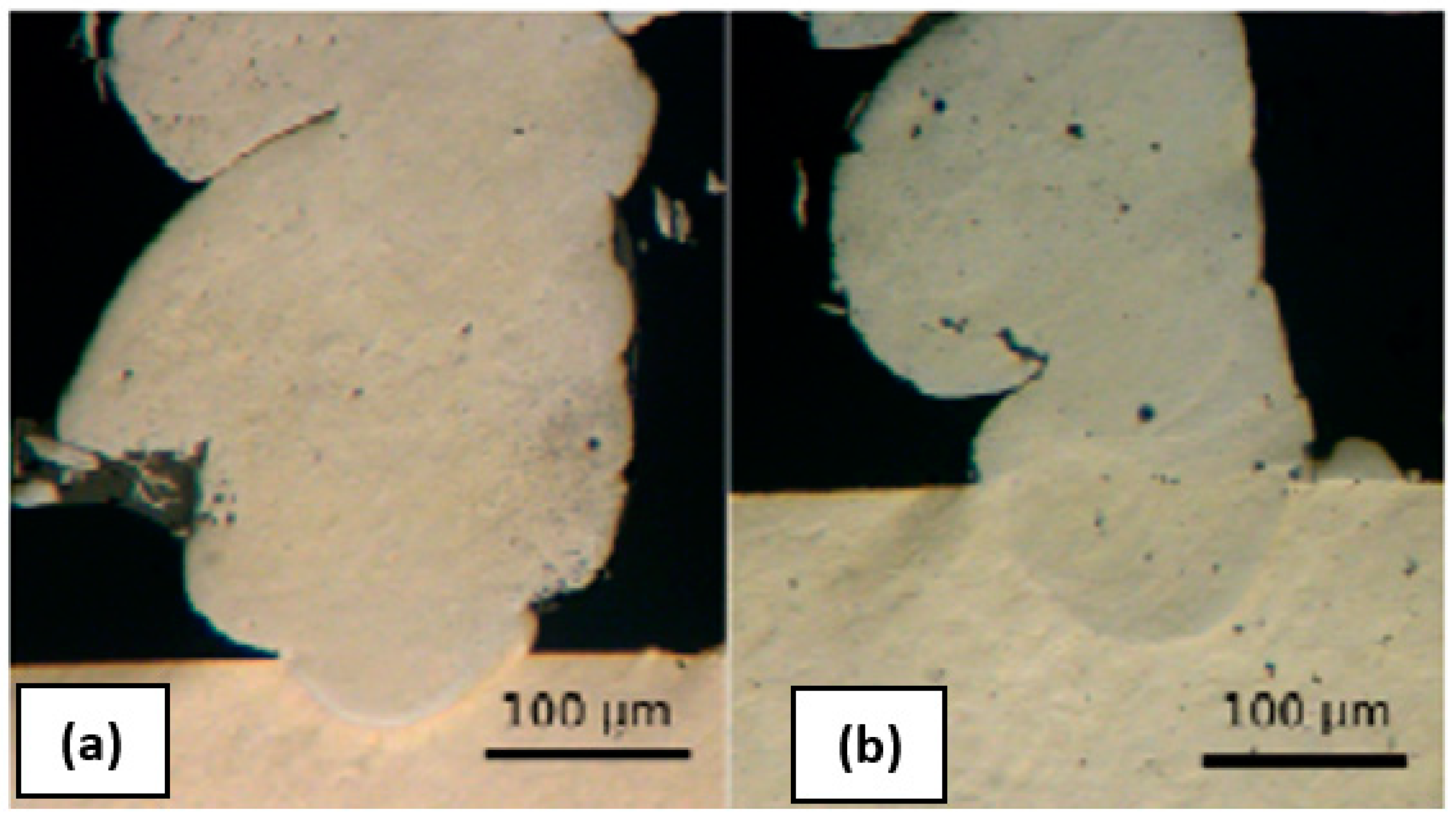

- Yürekli, B.; Schade, L.; Ullsperger, T.; Seyfarth, B.; Kohl, H.; Matthäus, G.; Liu, D.; Rettenmayr, M.; Nolte, S. Additive manufacturing of binary Al-Li alloys. Procedia CIRP 2020, 94, 69–73. [Google Scholar] [CrossRef]

- Ferrage, L.; Bertrand, G.; Lenormand, P. Dense yttria-stabilized zirconia obtained by direct selective laser sintering. Addit. Manuf. 2018, 21, 472–478. [Google Scholar] [CrossRef] [Green Version]

- Anastasiou, A.; Thomson, C.; Hussain, S.; Edwards, T.; Strafford, S.; Malinowski, M.; Mathieson, R.; Brown, C.; Brown, A.; Duggal, M.; et al. Sintering of calcium phosphates with a femtosecond pulsed laser for hard tissue engineering. Mater. Des. 2016, 101, 346–354. [Google Scholar] [CrossRef] [Green Version]

- Bai, S.; Liu, J. Additive manufacturing of bimetallic structures. SN Appl. Sci. 2020, 2, 1152. [Google Scholar] [CrossRef]

- Lei, S.; Zhao, X.; Yu, X.; Hu, A.; Vukelic, S.; Jun, M.B.G.; Joe, H.-E.; Yao, Y.L.; Shin, Y.C. Ultrafast Laser Applications in Manufacturing Processes: A State-of-the-Art Review. J. Manuf. Sci. Eng. 2020, 142, 031005. [Google Scholar] [CrossRef]

- Mottay, E.; Liu, X.; Zhang, H.; Mazur, E.; Sanatinia, R.; Pfleging, W. Industrial applications of ultrafast laser processing. MRS Bull. 2016, 41, 984–992. [Google Scholar] [CrossRef]

- Strickland, D.; Mourou, G. Compression of amplified chirped optical pulses. Opt. Commun. 1985, 56, 219–221. [Google Scholar] [CrossRef]

- Bakshi, K. A Review on Selective Laser Sintering: A Rapid Prototyping Technology. IOSR J. Mech. Civ. Eng. 2016, 4, 53–57. [Google Scholar] [CrossRef]

- Hong, S. Selective Laser Sintering of Nanoparticles. Sinter. Funct. Mater. 2018, 147–164. [Google Scholar] [CrossRef] [Green Version]

- Ruszaj, A. Additive methods in micro and nano manufacturing technologies. Mechanik 2019, 92, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Engstrøm, D.; Porter, B.; Pacios, M.; Bhaskaran, H. Additive nanomanufacturing–A review. J. Mater. Res. 2014, 29, 1792–1816. [Google Scholar] [CrossRef] [Green Version]

- Milewski, J.O. Lasers, Electron Beams, Plasma Arcs; Springer: Singapore, 2017; pp. 85–97. [Google Scholar]

- Jamie, D. A Comprehensive List of all the Metal 3D Printer Manufacturers, 3D Nativ. 2021. Available online: https://www.3dnatives.com/en/metal-3d-printer-manufacturers/#! (accessed on 13 November 2021).

- Schmidt, M.; Merklein, M.; Bourell, D.; Dimitrov, D.; Hausotte, T.; Wegener, K.; Overmeyer, L.; Vollertsen, F.; Levy, G.N. Laser based additive manufacturing in industry and academia. CIRP Ann. 2017, 66, 561–583. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Mosadegh, B.; Xiong, G.; Dunham, S.; Min, J.K. Current progress in 3D printing for cardiovascular tissue engineering. Biomed. Mater. 2015, 10, 034002. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Majumdar, J.D.; Manna, I. Laser-Assisted Fabrication of Materials; Springer: Berlin, Germany, 2012. [Google Scholar]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zuback, J.S.; De, A.; Debroy, T. Printability of alloys for additive manufacturing. Sci. Rep. 2016, 6, 19717. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Karia, M.C.; Popat, M.A.; Sangani, K.B. Selective laser melting of Inconel super alloy-a review. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017. [Google Scholar]

- Garban-Labaune, C.; Fabre, E.; Max, C.E.; Fabbro, R.; Amiranoff, F.; Virmont, J.; Weinfeld, M.; Michard, A. Effect of Laser Wavelength and Pulse Duration on Laser-Light Absorption and Back Reflection. Phys. Rev. Lett. 1982, 48, 1018–1021. [Google Scholar] [CrossRef]

- Buchbinder, D.; Schleifenbaum, J.H.; Heidrich, S.; Meiners, W.; Bültmann, J. High Power Selective Laser Melting (HP SLM) of Aluminum Parts. Phys. Procedia 2011, 12, 271–278. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Ke, L.; Zhu, H.; Yin, J.; Wang, X. Effects of peak laser power on laser micro sintering of nickel powder by pulsed Nd:YAG laser. Rapid Prototyp. J. 2014, 20, 328–335. [Google Scholar] [CrossRef]

- Sufiiarov, V.; Popovich, A.; Borisov, E.; Polozov, I.; Masaylo, D.; Orlov, A. The Effect of Layer Thickness at Selective Laser Melting. Procedia Eng. 2017, 174, 126–134. [Google Scholar] [CrossRef]

- Aboulkhair, N.T. Additive Manufacture of an Aluminium Alloy: Processing, Microstructure, and Mechanical Properties. Ph.D. Dissertation, University of Nottingham, Nottingham, UK, 2015. [Google Scholar]

- Aboulkhair, N.T.; Everitt, N.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- DeMaria, A.J.; Stetser, D.A.; Heynau, H. Self mode-locking of lasers with saturable absorbers. Appl. Phys. Lett. 1966, 8, 174–176. [Google Scholar] [CrossRef]

- Shank, C.V. Subpicosecond kilowatt pulses from a mode-locked cw dye laser. Appl. Phys. Lett. 1974, 24, 373. [Google Scholar] [CrossRef]

- Haus, H.A. Theory of mode locking with a fast saturable absorber. J. Appl. Phys. 1975, 46, 3049–3058. [Google Scholar] [CrossRef] [Green Version]

- Fermann, M.E.; Hartl, I. Ultrafast fibre lasers. Nat. Photonics 2013, 7, 868–874. [Google Scholar] [CrossRef]

- Spence, D.E.; Kean, P.N.; Sibbett, W. 60-Femtosecond pulse generation from a self-mode-locked Ti:sapphire laser. Opt. Lett. 1991, 16, 42–44. [Google Scholar] [CrossRef] [PubMed]

- Sutter, D.; Jung, I.; Kartner, F.; Matuschek, N.; Morier-Genoud, F.; Scheuer, V.; Tilsch, M.; Tschudi, T.; Keller, U. Self-starting 6.5-fs pulses from a Ti:sapphire laser using a semiconductor saturable absorber and double chirped mirrors. IEEE J. Sel. Top. Quantum Electron. 1998, 4, 169–178. [Google Scholar] [CrossRef]

- Hamad, A.H. Effects of Different Laser Pulse Regimes (Nanosecond, Picosecond and Femtosecond) on the Ablation of Materials for Production of Nanoparticles in Liquid Solution; IntechOpen: London, UK, 2016. [Google Scholar]

- Byskov-Nielsen, J. Short-Pulse Laser Ablation of Metals: Fundamentals and Applications for Micro-Mechanical Interlocking. Ph.D. Dissertation, University of Aarhus, Aarhus, Denmark, 2010. [Google Scholar]

- Hu, A.; Li, R.; Bai, S.; Yu, Y.; Zhou, W.; Bridges, D.; Deng, Y.; Zhang, L. Introduction to Laser Micro-to-Nano Manufacturing; Springer: Singapore, 2020; pp. 1–74. [Google Scholar]

- Wellershoff, S.-S.; Hohlfeld, J.; Güdde, J.; Matthias, E. The role of electron-phonon coupling in femtosecond laser damage of metals. Appl. Phys. A 1999, 69, S99–S107. [Google Scholar] [CrossRef]

- Liu, J.; Deng, C.; Bai, S. Glass surface metal deposition with high-power femtosecond fiber laser. Appl. Phys. A 2016, 122, 1064. [Google Scholar] [CrossRef]

- Ebert, R. Laser Processing of Tungsten Powder with Femtosecond Laser Radiation. J. Laser Micro/Nanoeng. 2012, 7, 38–43. [Google Scholar] [CrossRef]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast laser processing of materials: A review. Adv. Opt. Photonics 2015, 7, 684–712. [Google Scholar] [CrossRef]

- Key Parameters of a Laser System, EDMUND Opt. (n.d.) Available online: https://www.edmundoptics.com/knowledge-center/application-notes/lasers/key-parameters-of-a-laser-system/ (accessed on 25 November 2021).

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Wei, Q.; He, W.; Shi, Y. Influence of powder characteristic and process parameters on SLM formability. J. HuaZhong Univ. Sci. Technol. (Nat. Sci. Ed.) 2012, 2. [Google Scholar] [CrossRef]

- Lindgren, L.-E.; Lundbäck, A. Approaches in computational welding mechanics applied to additive manufacturing: Review and outlook. Comptes Rendus Mécanique 2018, 346, 1033–1042. [Google Scholar] [CrossRef]

- Francois, M.; Sun, A.; King, W.; Henson, N.; Tourret, D.; Bronkhorst, C.; Carlson, N.; Newman, C.; Haut, T.; Bakosi, J.; et al. Modeling of additive manufacturing processes for metals: Challenges and opportunities. Curr. Opin. Solid State Mater. Sci. 2017, 21, 198–206. [Google Scholar] [CrossRef]

- Liu, J.; Jalalahmadi, B.; Guo, Y.; Sealy, M.P.; Bolander, N. A review of computational modeling in powder-based additive manufacturing for metallic part qualification. Rapid Prototyp. J. 2018, 24, 1245–1264. [Google Scholar] [CrossRef]

- Wang, G.-X.; Prasad, V. Microscale heat and mass transfer and non-equilibrium phase change in rapid solidification. Mater. Sci. Eng. A 2000, 292, 142–148. [Google Scholar] [CrossRef]

- Hopkins, J.-M.; Sibbett, W. Ultrashort-pulse lasers: Big payoffs in a flash. Sci. Am. 2000, 283, 72–79. [Google Scholar] [CrossRef]

- Momma, C.; Chichkov, B.; Nolte, S.; von Alvensleben, F.; Tünnermann, A.; Welling, H.; Wellegehausen, B. Short-pulse laser ablation of solid targets. Opt. Commun. 1996, 129, 134–142. [Google Scholar] [CrossRef]

- Zhang, Y.; Tzou, D.Y.; Chen, J.K. Micro-and nanoscale heat transfer in femtosecond laser processing of metals. arXiv 2015, arXiv:1511.03566. Available online: https://arxiv.org/abs/1511.03566 (accessed on 25 November 2021).

- Hirayama, Y.; Obara, M. Heat-affected zone of metals ablated with femtosecond laser pulses. In Photon Processing in Microelectronics and Photonics II; Proc. of SPIE: San Jose, CA, USA, 2003; pp. 417–425. [Google Scholar]

- Hohlfeld, J.; Wellershoff, S.-S.; Güdde, J.; Conrad, U.; Jähnke, V.; Matthias, E. Electron and lattice dynamics following optical excitation of metals. Chem. Phys. 2000, 251, 237–258. [Google Scholar] [CrossRef]

- Chowdhury, I.H.; Xu, X. Heat transfer in femtosecond laser processing of metal. Numer. Heat Transf. Part A Appl. 2003, 44, 219–232. [Google Scholar] [CrossRef]

- Ji, P.; Zhang, Y. Multiscale modeling of femtosecond laser irradiation on a copper film with electron thermal conductivity from ab initio calculation. Numer. Heat Transf. Part A Appl. 2017, 71, 128–136. [Google Scholar] [CrossRef] [Green Version]

- Povarnitsyn, M.; Fokin, V.B.; Levashov, P.R. Microscopic and macroscopic modeling of femtosecond laser ablation of metals. Appl. Surf. Sci. 2015, 357, 1150–1156. [Google Scholar] [CrossRef]

- Perez, D.; Lewis, L.J. Molecular-dynamics study of ablation of solids under femtosecond laser pulses. Phys. Rev. B 2003, 67, 184102. [Google Scholar] [CrossRef] [Green Version]

- Colombier, J.P.; Combis, P.; Bonneau, F.; Le Harzic, R.; Audouard, E. Hydrodynamic simulations of metal ablation by femtosecond laser irradiation. Phys. Rev. B 2005, 71, 165406. [Google Scholar] [CrossRef] [Green Version]

- Rethfeld, B.; Ivanov, D.S.; E Garcia, M.; I Anisimov, S. Modelling ultrafast laser ablation. J. Phys. D Appl. Phys. 2017, 50, 193001. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perel-man, T.L. Electron emission from metal surfaces exposed to ultrashort laser pulses. Zh. Eksp. Teor. Fiz 1974, 66, 375–377. [Google Scholar]

- Qiu, T.; Tien, C. Femtosecond laser heating of multi-layer metals—I. Analysis. Int. J. Heat Mass Transf. 1994, 37, 2789–2797. [Google Scholar] [CrossRef]

- Qiu, T.Q.; Tien, C.L. Heat Transfer Mechanisms During Short-Pulse Laser Heating of Metals. J. Heat Transf. 1993, 115, 835–841. [Google Scholar] [CrossRef]

- Abdelmalek, A.; Bedrane, Z.; Amara, E.-H.; Sotillo, B.; Bharadwaj, V.; Ramponi, R.; Eaton, S.M. Ablation of Copper Metal Films by Femtosecond Laser Multipulse Irradiation. Appl. Sci. 2018, 8, 1826. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Kannatey-Asibu, E. Numerical Analysis of Ultrashort Pulse Laser-Material Interaction Using ABAQUS. J. Manuf. Sci. Eng. 2009, 131, 021005. [Google Scholar] [CrossRef]

- Lee, D.; Kannatey-Asibu, E. Numerical Analysis on the Feasibility of Laser Microwelding of Metals by Femtosecond Laser Pulses Using ABAQUS. J. Manuf. Sci. Eng. 2008, 130, 061014. [Google Scholar] [CrossRef]

- Jiang, L.; Tsai, H.-L. An improved two-temperature model for metal thin film heating by femtosecond laser pulses. Int. Congr. Appl. Lasers Electro-Opt. 2004, 2004, M602. [Google Scholar] [CrossRef]

- Davydov, R.; Antonov, V.; Angelina, M. Computer Simulation of Metal Ablation by Single and Multiple Ultrashort Laser Pulses. In 2018 IEEE International Conference on Electrical Engineering and Photonics (EExPolytech); IEEE: Piscataway, NJ, USA, 2018; pp. 236–239. [Google Scholar]

- Dasallas, L.L.; Garcia, W.O. Numerical simulation of femtosecond pulsed laser ablation of copper for oblique angle of incidence through two-temperature model. Mater. Res. Express 2018, 5, 016518. [Google Scholar] [CrossRef]

- Kuo, L.S.; Qiu, T. Microscale Energy Transfer during Picosecond Laser Melting of Metal Films; American Society of Mechanical Engineers: New York, NY, USA, 1996. [Google Scholar]

- Fischer, P.; Karapatis, N.; Romano, V.; Glardon, R.; Weber, H. A model for the interaction of near-infrared laser pulses with metal powders in selective laser sintering. Appl. Phys. A 2002, 74, 467–474. [Google Scholar] [CrossRef]

- Konrad, C.; Zhang, Y.; Shi, Y. Melting and resolidification of a subcooled metal powder particle subjected to nanosecond laser heating. Int. J. Heat Mass Transf. 2007, 50, 2236–2245. [Google Scholar] [CrossRef]

- Cheng, C.-W.; Chang, C.-L.; Chen, J.-K.; Wang, B. Femtosecond laser melting of silver nanoparticles: Comparison of model simulations and experimental results. Appl. Phys. A 2018, 124, 371. [Google Scholar] [CrossRef]

- Jia, X.; Zhao, X. Numerical study of material decomposition in ultrafast laser interaction with metals. Appl. Surf. Sci. 2019, 463, 781–790. [Google Scholar] [CrossRef]

- Li, X.; Guan, Y. Theoretical fundamentals of short pulse laser–metal interaction: A review. Nanotechnol. Precis. Eng. 2020, 3, 105–125. [Google Scholar] [CrossRef]

- Ji, P.; Zhang, Y. Melting and thermal ablation of a silver film induced by femtosecond laser heating: A multiscale modeling approach. Appl. Phys. A 2017, 123, 671. [Google Scholar] [CrossRef]

- Wu, H.; Wu, C.; Zhang, N.; Zhu, X.; Ma, X.; Zhigilei, L.V. Experimental and computational study of the effect of 1 atm background gas on nanoparticle generation in femtosecond laser ablation of metals. Appl. Surf. Sci. 2018, 435, 1114–1119. [Google Scholar] [CrossRef]

- Kaden, L.; Seyfarth, B.; Ullsperger, T.; Matthäus, G.; Nolte, S. Selective laser melting of copper using ultrashort laser pulses at different wavelengths. In Laser 3D Manufacturing V; Proc. of SPIE: San Francisco, CA, USA, 2018; Volume 10523, p. 1052312. [Google Scholar]

- Paeng, D.; Lee, D.; Yeo, J.; Yoo, J.-H.; Allen, F.I.; Kim, E.; So, H.; Park, H.K.; Minor, A.M.; Grigoropoulos, C. Laser-Induced Reductive Sintering of Nickel Oxide Nanoparticles under Ambient Conditions. J. Phys. Chem. C 2015, 119, 6363–6372. [Google Scholar] [CrossRef]

- Kang, B.; Han, S.; Kim, J.; Ko, S.; Yang, M. One-Step Fabrication of Copper Electrode by Laser-Induced Direct Local Reduction and Agglomeration of Copper Oxide Nanoparticle. J. Phys. Chem. C 2011, 115, 23664–23670. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. [Google Scholar] [CrossRef]

- Roy, N.; Dibua, O.; Foong, C.S.; Cullinan, M. Preliminary Results on the Fabrication of Interconnect Structures Using Microscale Selective Laser Sintering. In ASME 2017 International Technical Conference and Exhibition on Packaging and Integration of Electronic and Photonic Microsystems; American Society of Mechanical Engineers: New York, NY, USA, 2017. [Google Scholar]

- Singer, F.; Deisenroth, D.C.; Hymas, D.M.; Ohadi, M.M. Additively manufactured copper components and composite structures for thermal management applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 174–183. [Google Scholar]

- Pogson, S.; Fox, P.; Sutcliffe, C.; O’Neill, W. The production of copper parts using DMLR. Rapid Prototyp. J. 2003, 9, 334–343. [Google Scholar] [CrossRef]

- Sciammarella, F.; Gonser, M.J.; Styrcula, M. Laser Additive Manufacturing of Pure Copper. In Proceedings of the SME RAPID Conference and Exposition, Dearborn, MI, USA, 10–13 June 2013; Volume 71, pp. 1241–1248. [Google Scholar]

- Gradl, P.R.; Protz, C.S.; Cooper, K.; Ellis, D.; Evans, L.J.; Garcia, C. GRCop-42 Development and Hot-fire Testing Using Additive Manufacturing Powder Bed Fusion for Channel-cooled Combustion Chambers. In Proceedings of the AIAA Propulsion and Energy 2019 Forum, Indianapolis, IN, USA, 19–22 August 2019. [Google Scholar] [CrossRef] [Green Version]

- Polozov, I.A.; Borisov, E.V.; Sufiiarov, V.S.; Popovich, A.A. Selective laser melting of copper alloy. Mater. Phys. Mech. 2020, 43, 65–71. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Roy, N.; Jou, W.; Feng, H.; Jeong, J.; Wang, Y.; Cullinan, M. Laser Sintering of Copper Nanoparticles: A Simplified Model for Fluence Estimation and Validation. In International Manufacturing Science and Engineering Conference; American Society of Mechanical Engineers: New York, NY, USA, 2017. [Google Scholar]

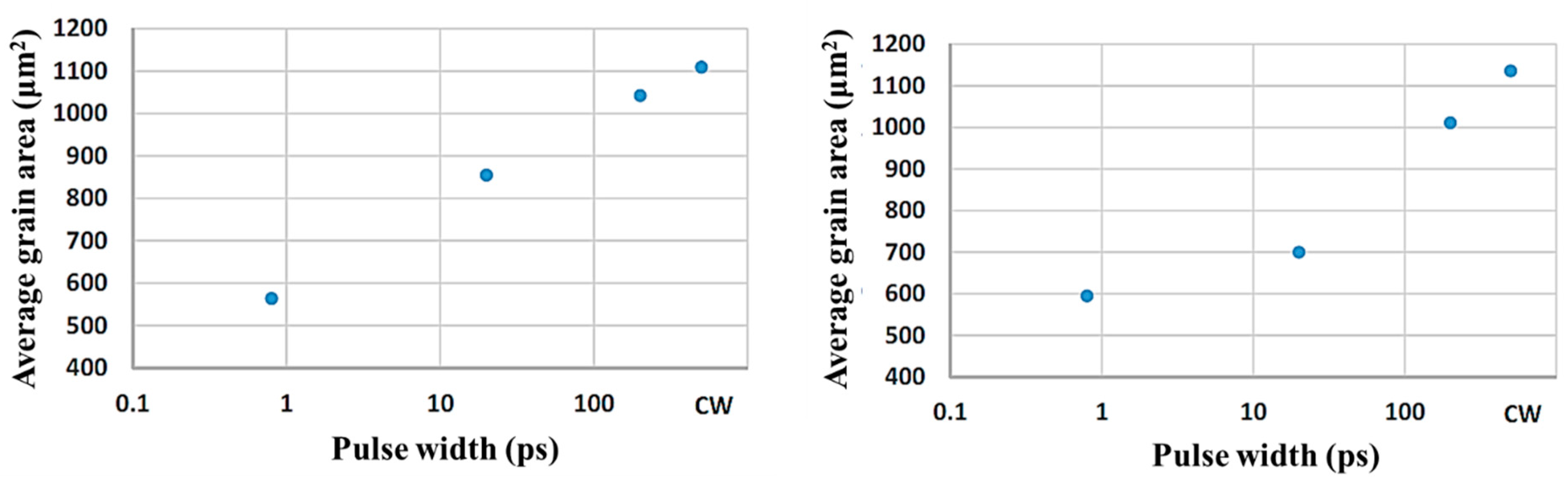

- Roy, N.K.; Dibua, O.G.; Jou, W.; He, F.; Jeong, J.; Wang, Y.; Cullinan, M.A. A Comprehensive Study of the Sintering of Copper Nanoparticles Using Femtosecond, Nanosecond, and Continuous Wave Lasers. J. Micro Nano-Manuf. 2017, 6, 010903. [Google Scholar] [CrossRef] [Green Version]

- Lim, J.; Kim, Y.; Shin, J.; Lee, Y.; Shin, W.; Qu, W.; Hwang, E.; Park, S.; Hong, S. Continuous-Wave Laser-Induced Transfer of Metal Nanoparticles to Arbitrary Polymer Substrates. Nanomaterials 2020, 10, 701. [Google Scholar] [CrossRef] [Green Version]

- Mizoshiri, M.; Yoshidomi, K. Cu Patterning Using Femtosecond Laser Reductive Sintering of CuO Nanoparticles under Inert Gas Injection. Materials 2021, 14, 3285. [Google Scholar] [CrossRef]

- Le Harzic, R.; Huot, N.; Audouard, E.; Jonin, C.; Laporte, P.; Valette, S.; Fraczkiewicz, A.; Fortunier, R. Comparison of heat-affected zones due to nanosecond and femtosecond laser pulses using transmission electronic microscopy. Appl. Phys. Lett. 2002, 80, 3886–3888. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Nishitani, K.; Hata, S. Effect of Heat Accumulation on Femtosecond Laser Reductive Sintering of Mixed CuO/NiO Nanoparticles. Micromachines 2018, 9, 264. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.F.; Lu, Y.F. Laser 3D printing of complex copper structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

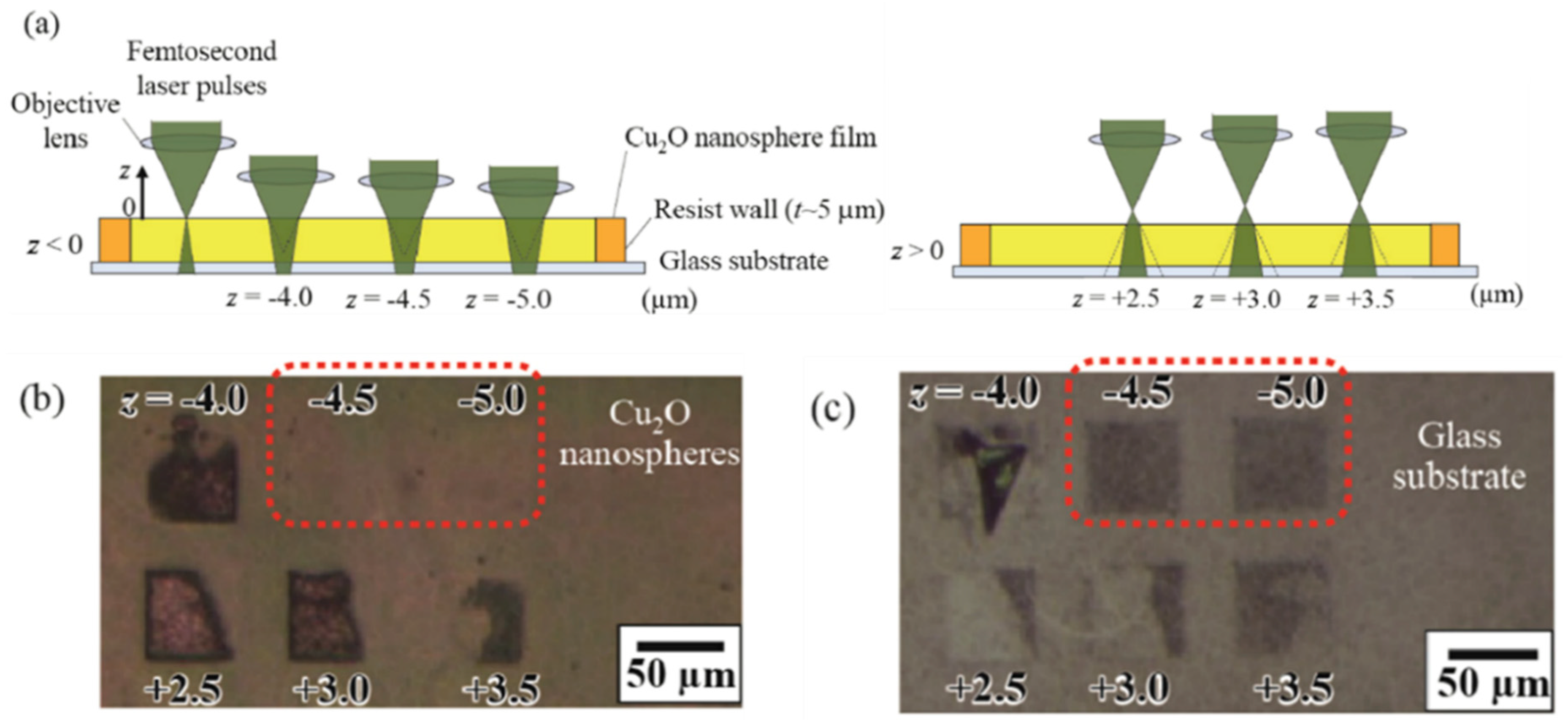

- Mizoshiri, M.; Kondo, Y. Direct writing of Cu-based fine micropatterns using femtosecond laser pulse-induced sintering of Cu2O nanospheres. Jpn. J. Appl. Phys. 2019, 58, SDDF05. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Kondo, Y. Direct writing of two- and three-dimensional Cu-based microstructures by femtosecond laser reductive sintering of the Cu2O nanospheres. Opt. Mater. Express 2019, 9, 2828–2837. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Tanokuchi, A. Direct writing of Cu-based micropatterns inside Cu2O nanosphere films using green femtosecond laser reductive sintering. Opt. Mater. Express 2020, 10, 2533–2541. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Attard, B.; Zhang, P.; Kuang, T. Selective laser melting of high-performance pure tungsten: Parameter design, densification behavior and mechanical properties. Sci. Technol. Adv. Mater. 2018, 19, 370–380. [Google Scholar] [CrossRef] [Green Version]

- Li, J.; Wu, Y.; Zhou, B.; Wei, Z. Laser Powder Bed Fusion of Pure Tungsten: Effects of Process Parameters on Morphology, Densification, Microstructure. Materials 2020, 14, 165. [Google Scholar] [CrossRef]

- Iveković, A.; Omidvari, N.; Vrancken, B.; Lietaert, K.; Thijs, L.; Vanmeensel, K.; Vleugels, J.; Kruth, J.-P. Selective laser melting of tungsten and tungsten alloys. Int. J. Refract. Met. Hard Mater. 2018, 72, 27–32. [Google Scholar] [CrossRef]

- Selective Laser Melting (AM), Wolfmet. (n.d.) Available online: https://www.wolfmet.com/applications/slm/selective-laser-melting-tungsten/ (accessed on 25 November 2021).

- Hirai, T.; Escourbiac, F.; Carpentier-Chouchana, S.; Fedosov, A.; Ferrand, L.; Jokinen, T.; Komarov, V.; Kukushkin, A.; Merola, M.; Mitteau, R.; et al. ITER tungsten divertor design development and qualification program. Fusion Eng. Des. 2013, 88, 1798–1801. [Google Scholar] [CrossRef]

- Müller, A.V.; Schlick, G.; Neu, R.; Anstätt, C.; Klimkait, T.; Lee, J.; Pascher, B.; Schmitt, M.; Seidel, C. Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 °C. Nucl. Mater. Energy 2019, 19, 184–188. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Das, A.K.; Saha, P. Selective Laser Sintering: A Case Study of Tungsten Carbide and Cobalt Powder Sintering by Pulsed Nd:YAG Laser. Funct. Graded Mater. 2015, 441–459. [Google Scholar] [CrossRef]

- Wang, D.; Yu, C.; Zhou, X.; Ma, J.; Liu, W.; Shen, Z. Dense Pure Tungsten Fabricated by Selective Laser Melting. Appl. Sci. 2017, 7, 430. [Google Scholar] [CrossRef]

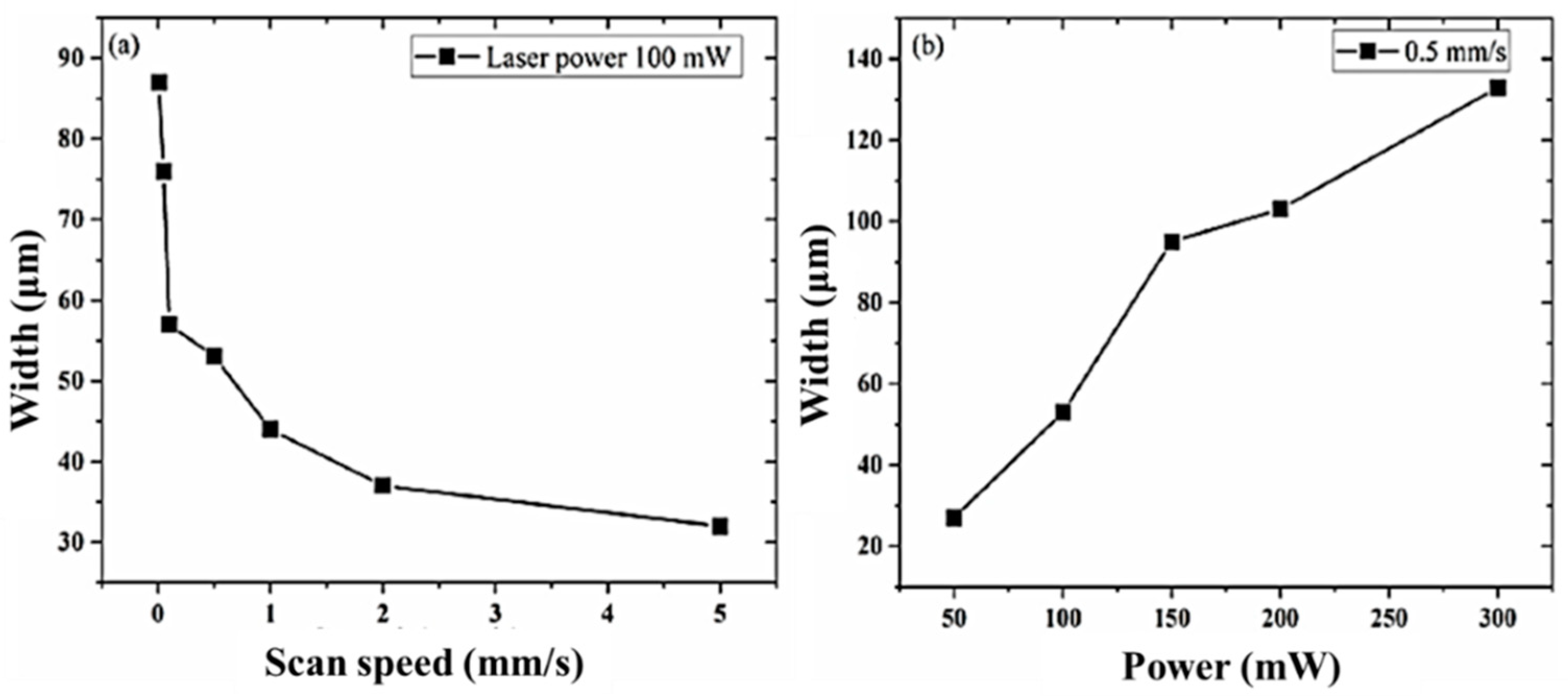

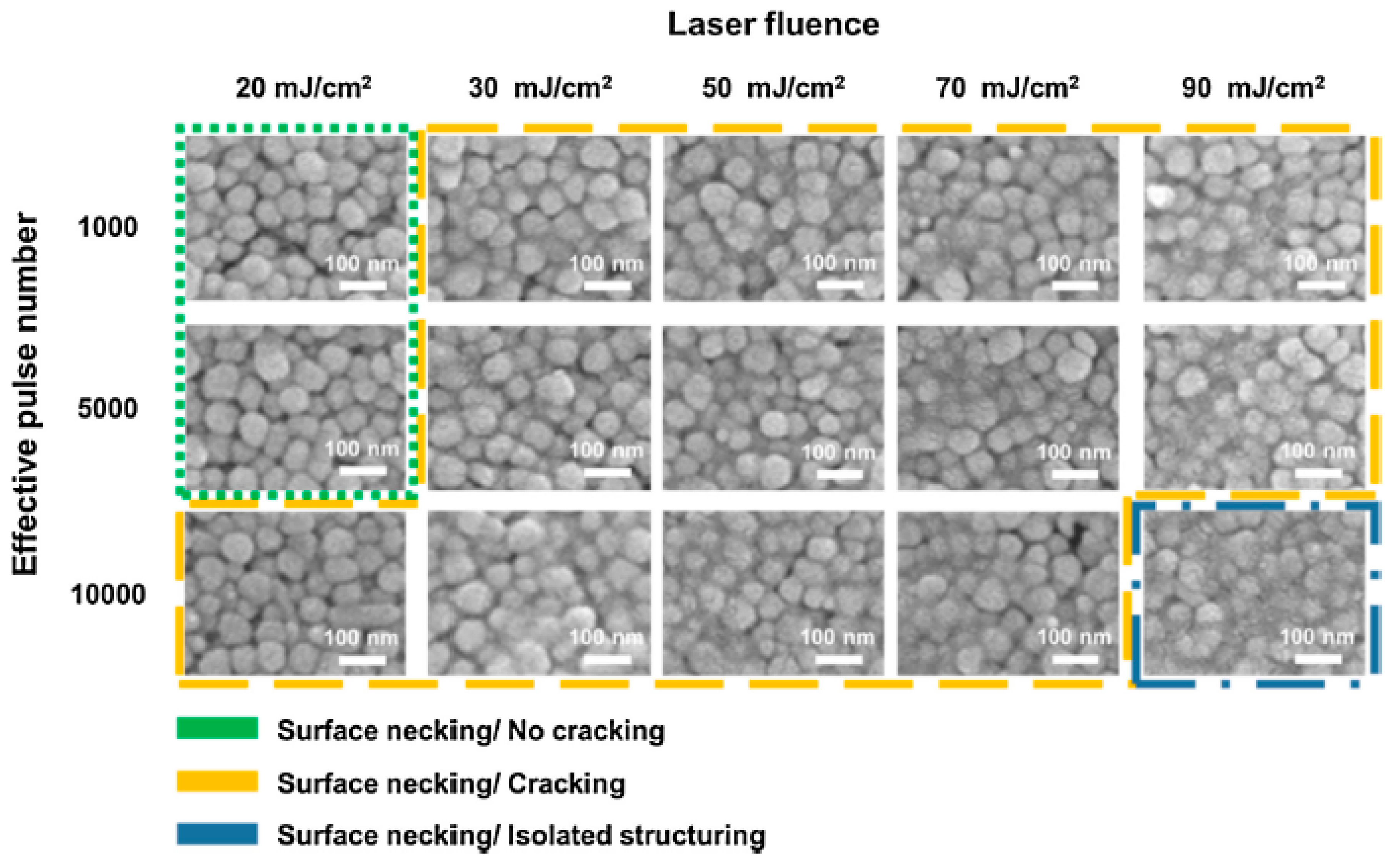

- Zacharatos, F.; Theodorakos, I.; Karvounis, P.; Tuohy, S.; Braz, N.; Melamed, S.; Kabla, A.; De La Vega, F.; Andritsos, K.; Hatziapostolou, A.; et al. Selective Laser Sintering of Laser Printed Ag Nanoparticle Micropatterns at High Repetition Rates. Materials 2018, 11, 2142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khosravani, M.R.; Reinicke, T. 3D-printed sensors: Current progress and future challenges. Sens. Actuators A Phys. 2020, 305, 111916. [Google Scholar] [CrossRef]

- Courbat, J.; Kim, Y.; Briand, D.; De Rooij, N. Inkjet printing on paper for the realization of humidity and temperature sensors. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 1356–1359. [Google Scholar] [CrossRef]

- Dankoco, M.; Tesfay, G.; Benevent, E.; Bendahan, M. Temperature sensor realized by inkjet printing process on flexible substrate. Mater. Sci. Eng. B 2016, 205, 1–5. [Google Scholar] [CrossRef]

- Hong, S.; Yeo, J.; Kim, G.; Kim, D.; Lee, H.; Kwon, J.; Lee, H.; Lee, P.; Ko, S.H. Nonvacuum, Maskless Fabrication of a Flexible Metal Grid Transparent Conductor by Low-Temperature Selective Laser Sintering of Nanoparticle Ink. ACS Nano 2013, 7, 5024–5031. [Google Scholar] [CrossRef]

- Noh, J.; Kim, D. Femtosecond laser sintering of silver nanoparticles for conductive thin-film fabrication. Appl. Phys. A 2020, 126, 1–7. [Google Scholar] [CrossRef]

- Noh, J.; Ha, J.; Kim, D. Femtosecond and nanosecond laser sintering of silver nanoparticles on a flexible substrate. Appl. Surf. Sci. 2020, 511, 145574. [Google Scholar] [CrossRef]

- Son, Y.; Lim, T.W.; Yeo, J.; Ko, S.H.; Yang, D.-Y. Fabrication of Nano-scale Conductors by Selective Femtosecond Laser Sintering of Metal Nanoparticles. In Proceedings of the 10th IEEE International Conference on Nanotechnology, Ilsan, Korea, 17–20 August 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 390–393. [Google Scholar]

- Son, Y.; Yeo, J.; Moon, H.; Lim, T.W.; Hong, S.; Nam, K.H.; Yoo, S.; Grigoropoulos, C.P.; Yang, D.-Y.; Ko, S.H. Nanoscale Electronics: Digital Fabrication by Direct Femtosecond Laser Processing of Metal Nanoparticles. Adv. Mater. 2011, 23, 3176–3181. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Thermal and Mechanical Properties of Commercial-Purity Aluminum Fabricated Using Selective Laser Melting. Mater. Trans. 2017, 58, 799–805. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Paola, E.; Biamino, S.; Ugues, D.; Pavese, M.; Fino, P. Additive Manufacturing of Al Alloys and Aluminium Matrix Composites (AMCs). In Light Metal Alloys Applications; InTech: Rijeka, Croatia, 2014. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Kannan, C.S.; Chandra, S.S.S.; Krishnan, G.P.; Raj, S.P. A Review on Additive Manufacturing of AA2024 and AA6061 Alloys Using Powder Bed Fusion; IOP Publishing: Bristol, UK, 2020; Volume 988, p. 012002. [Google Scholar]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Lassance, D.; Fabregue, D.; Delannay, F.; Pardoen, T. Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog. Mater. Sci. 2007, 52, 62–129. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Tarasova, T.V.; Gvozdeva, G.O.; Nowotny, S. Structure Formation of Hypereutectic Al-Si-Alloys Produced by Laser Surface Treatment. Stroj. Vestn.-J. Mech. Eng. 2014, 60, 389–394. [Google Scholar] [CrossRef]

- Ullsperger, T.; Liu, D.; Yürekli, B.; Matthäus, G.; Schade, L.; Seyfarth, B.; Kohl, H.; Ramm, R.; Rettenmayr, M.; Nolte, S. Ultra-short pulsed laser powder bed fusion of Al-Si alloys: Impact of pulse duration and energy in comparison to continuous wave excitation. Addit. Manuf. 2021, 46, 102085. [Google Scholar] [CrossRef]

- Dinçel, Y.M. Bone Graft Types. In Bone Grafting-Recent Advances with Special References to Cranio-Maxillofacial Surgery; IntechOpen: London, UK, 2018; pp. 27–40. [Google Scholar]

- Shivalkar, S.; Singh, S. Solid Freeform Techniques Application in Bone Tissue Engineering for Scaffold Fabrication. Tissue Eng. Regen. Med. 2017, 14, 187–200. [Google Scholar] [CrossRef]

- Duan, B.; Wang, M. Selective laser sintering and its application in biomedical engineering. MRS Bull. 2011, 36, 998–1005. [Google Scholar] [CrossRef] [Green Version]

- Tan, K.; Chua, C.; Leong, K.; Cheah, C.; Cheang, P.; Abu Bakar, M.; Cha, S. Scaffold development using selective laser sintering of polyetheretherketone–hydroxyapatite biocomposite blends. Biomaterials 2003, 24, 3115–3123. [Google Scholar] [CrossRef]

- Masaud, Z.; Khan, M.Z.; Hussain, A.; Ishfaq, H.A.; Song, R.-H.; Lee, S.-B.; Joh, D.W.; Lim, T.-H. Recent Activities of Solid Oxide Fuel Cell Research in the 3D Printing Processes. Trans. Korean Hydrog. New Energy Soc. 2021, 32, 11–40. [Google Scholar] [CrossRef]

- Tai, X.Y.; Zhakeyev, A.; Wang, H.; Jiao, K.; Zhang, H.; Xuan, J. Accelerating Fuel Cell Development with Additive Manufacturing Technologies: State of the Art, Opportunities and Challenges. Fuel Cells 2019, 19, 636–650. [Google Scholar] [CrossRef]

- Pesce, A.; Hornés, A.; Núñez, M.; Morata, A.; Torrell, M.; Tarancón, A. 3D printing the next generation of enhanced solid oxide fuel and electrolysis cells. J. Mater. Chem. A 2020, 8, 16926–16932. [Google Scholar] [CrossRef]

- Bai, S.; Liu, J. Femtosecond Laser Additive Manufacturing of Multi-Material Layered Structures. Appl. Sci. 2020, 10, 979. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Bai, S. Femtosecond laser additive manufacturing of YSZ. Appl. Phys. A 2017, 123, 293. [Google Scholar] [CrossRef]

- Furuta, T. Automobile applications of titanium. In Titanium for Consumer Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 77–90. [Google Scholar] [CrossRef]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.; Eckert, J. Selective laser manufacturing of Ti-based alloys and composites: Impact of process parameters, application trends, and future prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Agius, D.J.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef] [Green Version]

- Vorobyev, A.Y.; Guo, C. Femtosecond laser structuring of titanium implants. Appl. Surf. Sci. 2007, 253, 7272–7280. [Google Scholar] [CrossRef]

- Löw, K.; Leong, K.F.; Sun, C. Review of Selective Laser Melting process parameters for Commercially Pure Titanium and Ti6Al4V. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping; CRC Press: Boca Raton, FL, USA, 2013; pp. 71–76. [Google Scholar]

- Kumbhar, N.N.; Mulay, A.V. Post Processing Methods used to Improve Surface Finish of Products which are Manufactured by Additive Manufacturing Technologies: A Review. J. Inst. Eng. India Ser. C 2018, 99, 481–487. [Google Scholar] [CrossRef]

- Jiao, L.; Chua, Z.Y.; Moon, S.K.; Song, J.; Bi, G.; Zheng, H. Femtosecond Laser Produced Hydrophobic Hierarchical Structures on Additive Manufacturing Parts. Nanomaterials 2018, 8, 601. [Google Scholar] [CrossRef] [Green Version]

- Worts, N.; Jones, J.; Squier, J. Surface structure modification of additively manufactured titanium components via femtosecond laser micromachining. Opt. Commun. 2019, 430, 352–357. [Google Scholar] [CrossRef]

- Cheng, C.W.; Huang, C.J.; Cheng, H.T.; Kuo, C.N. Fabrication of porous Ti structures with nanostructures from Ti powders by femtosecond laser pulses. J. Laser Micro Nanoeng. 2015, 10, 310. [Google Scholar] [CrossRef]

- Hammouti, S.; Holybee, B.; Zhu, W.; Allain, J.P.; Jurczyk, B.; Ruzic, D.N. Titanium nitride formation by a dual-stage femtosecond laser process. Appl. Phys. A 2018, 124, 411. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Femtosecond laser three-dimensional micro- and nanofabrication. Appl. Phys. Rev. 2014, 1, 041303. [Google Scholar] [CrossRef] [Green Version]

- Han, T.-H.; Kim, H.; Kwon, S.-J.; Lee, T.-W. Graphene-based flexible electronic devices. Mater. Sci. Eng. R Rep. 2017, 118, 1–43. [Google Scholar] [CrossRef]

- You, R.; Liu, Y.; Hao, Y.; Han, D.; Zhang, Y.; You, Z. Laser Fabrication of Graphene-Based Flexible Electronics. Adv. Mater. 2020, 32, e1901981. [Google Scholar] [CrossRef]

- Liu, Y.-Q.; Chen, Z.-D.; Mao, J.-W.; Han, D.-D.; Sun, X. Laser Fabrication of Graphene-Based Electronic Skin. Front. Chem. 2019, 7, 461. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Feng, Z.; Huang, L.; Essa, K.; Bilotti, E.; Zhang, H.; Peijs, T.; Hao, L. Additive manufacturing high performance graphene-based composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105483. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(lactic acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef] [PubMed]

- Fu, X.-Y.; Chen, Z.-D.; Han, D.-D.; Zhang, Y.-L.; Xia, H.; Sun, H.-B. Laser fabrication of graphene-based supercapacitors. Photonics Res. 2020, 8, 577. [Google Scholar] [CrossRef]

- Bi, Y.-G.; Feng, J.; Li, Y.-F.; Zhang, Y.-L.; Liu, Y.-S.; Chen, L.; Liu, Y.-F.; Guo, L.; Wei, S.; Sun, H.-B. Arbitrary Shape Designable Microscale Organic Light-Emitting Devices by Using Femtosecond Laser Reduced Graphene Oxide as a Patterned Electrode. ACS Photonics 2014, 1, 690–695. [Google Scholar] [CrossRef]

- An, J.; Le, T.-S.D.; Huang, Y.; Zhan, Z.; Li, Y.; Zheng, L.; Huang, W.; Sun, G.; Kim, Y.-J. All-Graphene-Based Highly Flexible Noncontact Electronic Skin. ACS Appl. Mater. Interfaces 2017, 9, 44593–44601. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Tao, L.-Q.; Liu, Y.; Zhang, T.-Y.; Pang, Y.; Wang, Q.; Jiang, S.; Yang, Y.; Ren, T.-L. High performance flexible strain sensor based on self-locked overlapping graphene sheets. Nanoscale 2016, 8, 20090–20095. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Y.; Wang, Y.; Tian, H.; Li, M.; Jian, J.; Wei, Y.; Tian, Y.; Wang, D.-Y.; Pang, Y.; Geng, X.; et al. Multilayer Graphene Epidermal Electronic Skin. ACS Nano 2018, 12, 8839–8846. [Google Scholar] [CrossRef]

| Category | Manufacturing Systems | Laser |

|---|---|---|

| Direct energy deposition (DED) | Trumpf GmbH: TruLaser series | TruDiode diode laser, up to 6 kW (600 nm) |

| Meltio | 1200 W diode laser | |

| BeAM: Modulo series | 500–2000 W fibre laser | |

| Oerlikon Metco Group: MetcoClad systems | 1–6 kW diode laser | |

| InssTek: Fab series | Maximum 2000 W fibre laser | |

| Optomec Inc.: LENS series | 400–1000 W fibre laser | |

| Powder bed fusion (PBF) | Renishaw: AM250 | 200 or 400 W fibre laser |

| SLM Solutions GmbH: SLM systems | 400–1000 W fibre laser (for metals) | |

| EOS GmbH: EOSINT, EOS M and PRECIOUS M machines | 30, 70 or 2 × 50 W CO2 lasers (for thermoplastics) 200 W–1 kW fibre laser (for metals) | |

| 3D Systems Inc.: ProX, sPro and ProX SLM systems | 30–200 W CO2 laser (for thermoplastics) 50–500 W fibre laser (for metals) | |

| Concept Laser | 400–1000 W fibre laser (for metals) | |

| Aconity ONE | 400–1000 W fibre laser | |

| Trumpf: Truprint 5000 | 500 W fibre laser |

| Industry | Trend/Goal | Laser-Based AM Process |

|---|---|---|

| Aerospace [12,29] | Demand for lightweight structures | DMD, SLS and SLM |

| Rapid tooling, fixturing | DMD and SLS | |

| Fuel reduction | DMD, SLS and SLM | |

| Organic features | SLM, SLS and DMD | |

| Automotive [10] | Demand for lightweight structures | SLS, SLM and DMD |

| Medical (dental, implants) [75] | Minimally invasive surgery | SMS and SLM |

| Replication of anatomic structures | SLA and SLS | |

| Biomaterial manufacturing | SLS and SLA | |

| Electronics [76] | Smart microsystems | SLA and Micro-SLS |

| Miniaturisation | SLA and Micro-SLS | |

| Accelerated product development | SLA and Micro-SLS |

| Laser Type | CO2 Laser | Yb-Fibre Laser | Nd:YAG Laser | Excimer Laser |

|---|---|---|---|---|

| Type of laser | Pulsed and CW | Pulsed and CW | Pulsed and CW | Pulsed |

| AM process | SLA, SLM, SLS and LENS | SLS, SLM and LENS | SLS, SLM and LENS | SLA |

| Wavelength | 9.4 and 10.6 µm | 1.07 µm | 1.06 µm | 193, 248 and 308 nm |

| Output power (CW) | Up to 20 kW | Up to 10 kW | Up to 16 kW | 300 W (average) |

| Pulse duration | 100–10 s ns | 10 s ns to 10 s ms | Few ns to 10 s ms | 10 s ns |

| Efficiency | 5–20% | 10–30% | 10–20% | 1–4% |

| Beam quality (mm.mrad) | 3–5 | 0–4 | 0.4–20 | 0.5–2 |

| Material | Optimum Avgerage Fluence at 400 fs and 1035 nm (J/cm2) | Maximum Ablation Rate at 400 fs and 1035 nm (mm3/W min) |

|---|---|---|

| Steel | 0.35 | 0.22 |

| Nitinol | 0.6 | 0.21 |

| Aluminium | 1 | 0.3 |

| Copper | 1.7 | 0.16 |

| Si | 1.3 | 0.16 |

| SiC | 0.7 | 0.13 |

| PET | 0.7 | 8 |

| Fused silica | 3 | 0.4 |

| Sapphire | 4 | 0.3 |

| Various Factors | Description |

|---|---|

| Pulse energy | Depends on the average output power and pulse repetition rate |

| Pulse width | Called pulse duration also and, in general, varies a few hundred femtoseconds in the case of fs laser material processing |

| Average power | Total average output power utilised in material processing |

| Pulse repetition rate | Number of pulses per second, in general, between kHz and a few MHz will be utilised during material processing |

| Peak power | Maximum peak power attained by a single pulse |

| Focus spot area/volume | The laser spot area or volume is the exposed area/volume, which is important to consider during precise processing |

| Hatch spacing | The spacing between each line exposed during area-wise material processing |

| Scanning velocity | The scan velocity is the speed of the laser travelling during processing; it is the most critical parameter to control because the exposure time depends on this parameter |

| Operation mode | The environment during processing |

| Wavelength | The laser operating wavelength |

| Powder particle size | The powder size is important to consider, depending on the application |

| Shape of the powder particle | In general, for SLS/M spherical powder particles are considered |

| Powder morphology | The uniformity of powder size distribution |

| Hardness (HRC) | Fs Sample | CW Sample | 20 ps Sample | 200 ps Sample | Tungsten Sample |

|---|---|---|---|---|---|

| Cross-section | 47.7 | 44.7 | 41.8 | 45.1 | 45.8 |

| Top | 45.4 | 44.9 | 44.1 | 42.4 | 44.9 |

| Sample Number | Material | Wavelength (nm) | Pulse Duration (fs) | Pulse Repetition Rate (MHz) | Power (W) | Scan Speed (mm/s) | Spot Diameter (microns) | Layer Thickness (microns) | Line Spacing (μm) | Pulse Energy (J) (or) Fluence (J/cm2) (or) Energy Density (W/cm2) | Reference |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Al–40Si | 1030 | 500 | 6–20 MHz | 25 | 200 | 50 | 15 to 30 | - | <0.4 J/cm2 | [183] |

| 2 | Al–Li Alloy | 1030 | 500 | 10–20 MHz | 30 | 100–700 | 35 | 20 to 40 | - | 1.5–3 μJ | [60] |

| 3 | AlSi4O (40 microns) | 1030 | 500 | 20 MHz | 12 to 25 | 200 | 50 | 35 to 50 | - | 40–170 J/m | [38] |

| 4 | Calcium Phosphate | 1045 | 130–190 | 1000 | 0.4 | 0.1 | 30 | - | - | 0.4 nJ | [62] |

| 5 | Copper (10 nm) | 800 | 100 | 80 MHz | 0.195–0.210 | 0.1 | 6.97 | - | - | 12.8–13.8 mJ/cm2 | [52] |

| 6 | Copper (35 microns) | 1030 | 200–20 MHz | - | 833 and 666 | 35 | 30 | 15 | 1, 1.25 μJ, 100 J/m | [54,138] | |

| 7 | Copper (CuO) | 780 | 120 | 81 MHz | - | 0.5–20 | - | 1000 | - | 0.54 nJ | [53] |

| 8 | Cu2O | 780 | 120 | 83 MHz | - | 100 | 0.7 | - | 163 GW/cm2 | [158] | |

| 9 | CuO and NiO | 780 | 120 | 82 MHz | - | 0.1–5 | 1.3 | 10 | - | 0.059 J/cm2 | [154] |

| 10 | CuO/Cu2O | 780 | 120 | 84 MHz | - | 10 | - | - | 0.74 nJ | [152] | |

| 11 | Iron (1–5 microns) | 1030 | 350 | 80 MHz | 50 | 50 | - | - | - | [7] | |

| 12 | Iron on glass | 1060 | 800 | 80 MHz | 37 and 53 | 300 and 400 | - | 40 | - | - | [100] |

| 13 | Monolithic zirconia | 1030 | 400 | 200 kHz | 5 | - | - | - | 25 μJ | [51] | |

| 14 | Silver (Ag) NP | 1030 | 370 | 1 MHz | 0.05–0.3 | 0.01–5 | - | - | - | - | [56] |

| 15 | Silver (Ag) NP | 780 | 100 | 80 MHz | 0.1–0.4 | 0.1–0.6 | - | - | - | - | [174] |

| 16 | Silver (Ag) NP | 800 | 50 | 1 kHz | - | 0.02–4 | - | - | - | 10–300 m J/cm2 | [172] |

| 17 | Silver (Ag) NP | 800 | 50 | 1 kHz | - | 0.02–0.2 | - | - | 200 | 10–120 m J/cm2 | [173] |

| 18 | Silver (Ag) NP | 780 | 100 | 1 kHz | 0.5, 0.6 | 0.1–0.6 | - | - | - | - | [55] |

| 19 | SS 316 L | 793 | 150–200 | 1 kHz | 0.15 | - | - | - | - | - | [46] |

| 20 | Tungsten | 1030 | 180 | 0.125–1 MHz | 0.4 to 0.875 | 100–5000 | 36 | - | 10 | 0.4–7.5 μJ, 0.07–1.3 J/cm2 | [101] |

| 21 | Tungsten | 1030 | 400 | 1 MHz | 35 | 20 | 20 | 25–50 | - | 22.5 μJ | [58] |

| 22 | Tungsten | 1030 | 750 | 100 kHz to 100 MHz | Maximum 1 kW | - | - | - | - | maximum 500 J | [44] |

| 23 | Tungsten | 1030 | 400 | 1 MHz | 45 | 25 | - | - | - | - | [7] |

| 24 | YSZ, Ni-YSZ | 1030 | 800 | 80 MHz | 130 | 300 | 25 | 5–600 | - | - | [191] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaligar, A.B.; Kumar, H.A.; Ali, A.; Abuzaid, W.; Egilmez, M.; Alkhader, M.; Abed, F.; Alnaser, A.S. Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Sci. 2022, 6, 5. https://doi.org/10.3390/qubs6010005

Kaligar AB, Kumar HA, Ali A, Abuzaid W, Egilmez M, Alkhader M, Abed F, Alnaser AS. Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Science. 2022; 6(1):5. https://doi.org/10.3390/qubs6010005

Chicago/Turabian StyleKaligar, Atiq Basha, Hemnath Anandan Kumar, Asghar Ali, Wael Abuzaid, Mehmet Egilmez, Maen Alkhader, Farid Abed, and Ali Sami Alnaser. 2022. "Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives" Quantum Beam Science 6, no. 1: 5. https://doi.org/10.3390/qubs6010005

APA StyleKaligar, A. B., Kumar, H. A., Ali, A., Abuzaid, W., Egilmez, M., Alkhader, M., Abed, F., & Alnaser, A. S. (2022). Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Science, 6(1), 5. https://doi.org/10.3390/qubs6010005